ISO 16792:2015

(Main)Technical product documentation — Digital product definition data practices

Technical product documentation — Digital product definition data practices

ISO 16792:2015 specifies requirements for the preparation, revision, and presentation of digital product definition data, hereafter referred to as data sets. It supports two methods of application: model-only and model and drawing in digital format. Its structure presents requirements common to both methods followed by clauses providing for any essential, differing requirements for each method. Additionally, its use in conjunction with computer-aided design (CAD) systems could assist in the progression towards improved modelling and annotation practices for CAD and engineering disciplines, as well as serving as a guideline for IT engineers. The aspects specified in this International Standard refer mainly, but not exclusively, to requirements that differ or are additional to those provided in existing, related standards. Where no such requirements are identified, it is safe to assume that the appropriate existing ISO standards are instead applicable.

Documentation technique de produits — Données de définition d'un produit

General Information

- Status

- Withdrawn

- Publication Date

- 18-Nov-2015

- Withdrawal Date

- 18-Nov-2015

- Technical Committee

- ISO/TC 10 - Technical product documentation

- Drafting Committee

- ISO/TC 10/WG 16 - 3D models: Presentation of product definition data

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 07-Apr-2021

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 03-Jun-2017

- Effective Date

- 03-Jul-2010

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

NYCE

Mexican standards and certification body.

Sponsored listings

Frequently Asked Questions

ISO 16792:2015 is a standard published by the International Organization for Standardization (ISO). Its full title is "Technical product documentation — Digital product definition data practices". This standard covers: ISO 16792:2015 specifies requirements for the preparation, revision, and presentation of digital product definition data, hereafter referred to as data sets. It supports two methods of application: model-only and model and drawing in digital format. Its structure presents requirements common to both methods followed by clauses providing for any essential, differing requirements for each method. Additionally, its use in conjunction with computer-aided design (CAD) systems could assist in the progression towards improved modelling and annotation practices for CAD and engineering disciplines, as well as serving as a guideline for IT engineers. The aspects specified in this International Standard refer mainly, but not exclusively, to requirements that differ or are additional to those provided in existing, related standards. Where no such requirements are identified, it is safe to assume that the appropriate existing ISO standards are instead applicable.

ISO 16792:2015 specifies requirements for the preparation, revision, and presentation of digital product definition data, hereafter referred to as data sets. It supports two methods of application: model-only and model and drawing in digital format. Its structure presents requirements common to both methods followed by clauses providing for any essential, differing requirements for each method. Additionally, its use in conjunction with computer-aided design (CAD) systems could assist in the progression towards improved modelling and annotation practices for CAD and engineering disciplines, as well as serving as a guideline for IT engineers. The aspects specified in this International Standard refer mainly, but not exclusively, to requirements that differ or are additional to those provided in existing, related standards. Where no such requirements are identified, it is safe to assume that the appropriate existing ISO standards are instead applicable.

ISO 16792:2015 is classified under the following ICS (International Classification for Standards) categories: 01.110 - Technical product documentation; 35.240.10 - Computer-aided design (CAD). The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 16792:2015 has the following relationships with other standards: It is inter standard links to ISO 16792:2021, ISO 16792:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 16792:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 16792

Second edition

2015-12-01

Technical product documentation —

Digital product definition data

practices

Documentation technique de produits — Données de définition d’un

produit

Reference number

©

ISO 2015

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

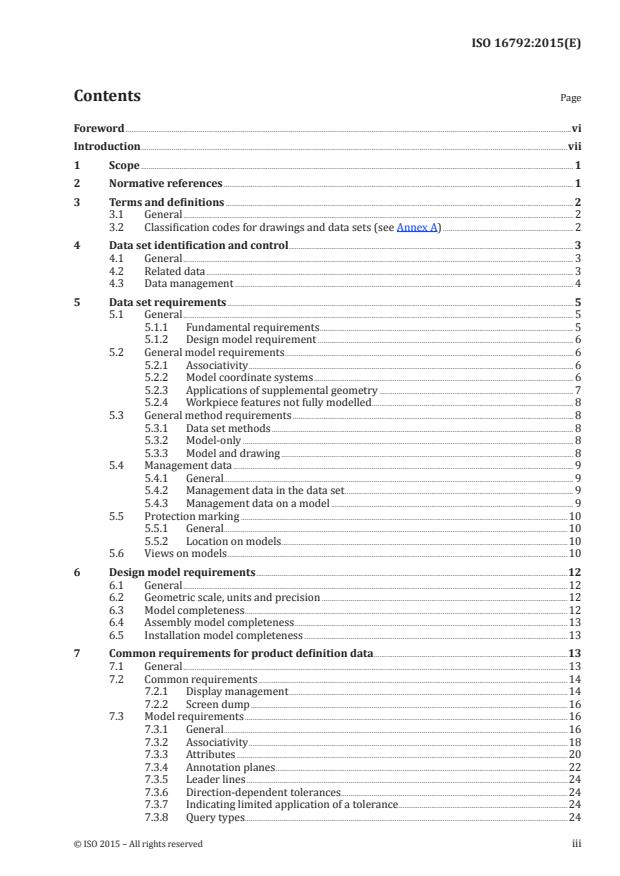

Contents Page

Foreword .vi

Introduction .vii

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

3.1 General . 2

3.2 Classification codes for drawings and data sets (see Annex A) . 2

4 Data set identification and control . 3

4.1 General . 3

4.2 Related data . 3

4.3 Data management . 4

5 Data set requirements . 5

5.1 General . 5

5.1.1 Fundamental requirements . 5

5.1.2 Design model requirement . 6

5.2 General model requirements . 6

5.2.1 Associativity . 6

5.2.2 Model coordinate systems . 6

5.2.3 Applications of supplemental geometry . 7

5.2.4 Workpiece features not fully modelled. 8

5.3 General method requirements . 8

5.3.1 Data set methods . 8

5.3.2 Model-only . 8

5.3.3 Model and drawing . 8

5.4 Management data . 9

5.4.1 General. 9

5.4.2 Management data in the data set . 9

5.4.3 Management data on a model . 9

5.5 Protection marking .10

5.5.1 General.10

5.5.2 Location on models.10

5.6 Views on models .10

6 Design model requirements .12

6.1 General .12

6.2 Geometric scale, units and precision .12

6.3 Model completeness .12

6.4 Assembly model completeness .13

6.5 Installation model completeness .13

7 Common requirements for product definition data .13

7.1 General .13

7.2 Common requirements .14

7.2.1 Display management .14

7.2.2 Screen dump .16

7.3 Model requirements .16

7.3.1 General.16

7.3.2 Associativity .18

7.3.3 Attributes .20

7.3.4 Annotation planes .22

7.3.5 Leader lines .24

7.3.6 Direction-dependent tolerances . .24

7.3.7 Indicating limited application of a tolerance .24

7.3.8 Query types.24

7.4 Drawing requirements .29

7.4.1 General.29

7.4.2 Orthographic views .32

7.4.3 Axonometric views .32

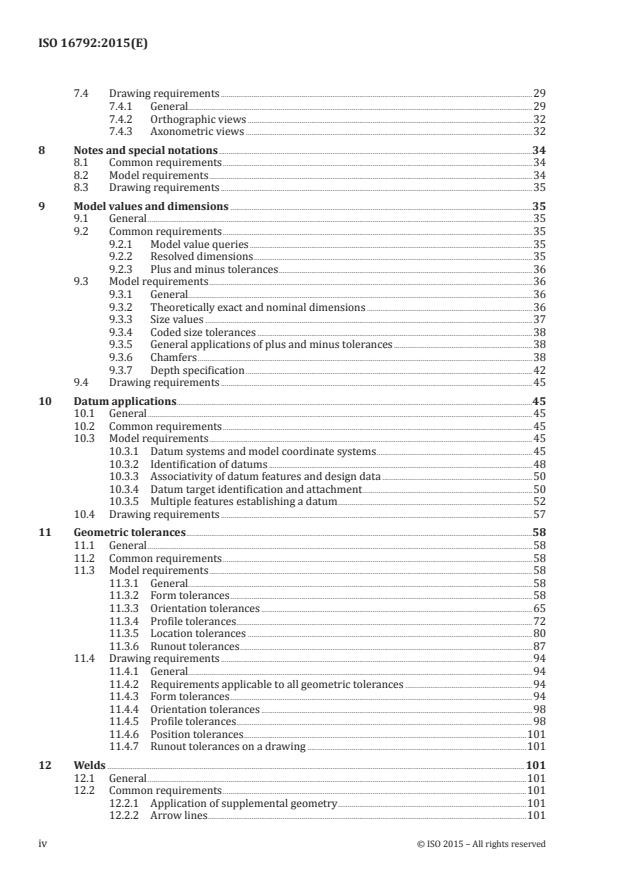

8 Notes and special notations .34

8.1 Common requirements .34

8.2 Model requirements .34

8.3 Drawing requirements .35

9 Model values and dimensions .35

9.1 General .35

9.2 Common requirements .35

9.2.1 Model value queries .35

9.2.2 Resolved dimensions . .35

9.2.3 Plus and minus tolerances .36

9.3 Model requirements .36

9.3.1 General.36

9.3.2 Theoretically exact and nominal dimensions .36

9.3.3 Size values .37

9.3.4 Coded size tolerances .38

9.3.5 General applications of plus and minus tolerances .38

9.3.6 Chamfers .38

9.3.7 Depth specification .42

9.4 Drawing requirements .45

10 Datum applications .45

10.1 General .45

10.2 Common requirements .45

10.3 Model requirements .45

10.3.1 Datum systems and model coordinate systems .45

10.3.2 Identification of datums .48

10.3.3 Associativity of datum features and design data .50

10.3.4 Datum target identification and attachment .50

10.3.5 Multiple features establishing a datum .52

10.4 Drawing requirements .57

11 Geometric tolerances .58

11.1 General .58

11.2 Common requirements .58

11.3 Model requirements .58

11.3.1 General.58

11.3.2 Form tolerances .58

11.3.3 Orientation tolerances .65

11.3.4 Profile tolerances .72

11.3.5 Location tolerances .80

11.3.6 Runout tolerances .87

11.4 Drawing requirements .94

11.4.1 General.94

11.4.2 Requirements applicable to all geometric tolerances .94

11.4.3 Form tolerances .94

11.4.4 Orientation tolerances .98

11.4.5 Profile tolerances .98

11.4.6 Position tolerances .101

11.4.7 Runout tolerances on a drawing .101

12 Welds .101

12.1 General .101

12.2 Common requirements .101

12.2.1 Application of supplemental geometry .101

12.2.2 Arrow lines.101

iv © ISO 2015 – All rights reserved

12.3 Model requirements .102

12.3.1 Annotation plane .102

12.3.2 Associativity .102

12.3.3 Indicating extents of the weld .102

12.3.4 Query of weld path .104

12.4 Drawing requirements .105

13 Surface texture .105

13.1 General .105

13.2 Common requirements .105

13.3 Model requirements .105

13.3.1 Display techniques .105

13.3.2 Annotation plane .106

13.3.3 Associativity .106

13.3.4 Indication of direction of lay .106

13.3.5 Use of all around indication .107

13.4 Drawing requirements .108

Annex A (informative) Classification codes for drawings and data sets .109

Bibliography .111

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 10, Technical product documentation.

This second edition cancels and replaces the first edition (ISO 16792:2006), which has been technically

revised mainly to incorporate the technical changes in ISO 1101:2012 and ISO 5459:2011. Clause

12 on indication for welds and Clause 13 on indications for surface texture have been added. A new

informative annex on classification codes has also been added.

vi © ISO 2015 – All rights reserved

Introduction

Every effort was made during the preparation of the first edition of this International Standard,

adapted from ASME Y14.41:2012, to apply existing requirements developed for two-dimensional (2D)

presentation equally to the output from three-dimensional (3D) models. Where new geometrical

product specification (GPS) rules have proved essential, these have been drafted with a view to their

being equally applicable to both 2D and 3D. Therefore, in order to maintain the integrity of a single

system, these new rules are being incorporated in the relevant existing ISO standards for cross-

reference. Application examples have been included where, due to the specific requirements of 3D

modelling, additional guidance was deemed beneficial.

It is recognized that there is a need to support drawings in conjunction with 3D models now and for the

foreseeable future. This need has been addressed in this International Standard through the definition

of the two methods for documenting digital models and specification of requirements to ensure that

the information in a data set is consistent between the model and the drawing.

The figures in this International Standard are intended only as illustrations to aid the user in

understanding the practices elaborated in the text. In some cases, figures show a level of detail as

needed for emphasis; in others, they are only complete enough to illustrate a concept or facet thereof.

The absence of figures has no bearing on the applicability of the specified requirement or practice.

In order to comply with the requirements of this International Standard, actual data sets shall meet the

content requirements set forth in its text.

Most figures are illustrations of models in a 3D environment. Figures illustrating drawings in digital

format include a border.

Text in uppercase letters used in the figures are intended to appear in digital product definition data, or

data sets, while that in lowercase letters is for information only and is not intended to appear in data sets.

INTERNATIONAL STANDARD ISO 16792:2015(E)

Technical product documentation — Digital product

definition data practices

1 Scope

This International Standard specifies requirements for the preparation, revision, and presentation of

digital product definition data, hereafter referred to as data sets. It supports two methods of application:

model-only and model and drawing in digital format. Its structure presents requirements common to

both methods followed by clauses providing for any essential, differing requirements for each method.

Additionally, its use in conjunction with computer-aided design (CAD) systems could assist in the

progression towards improved modelling and annotation practices for CAD and engineering disciplines,

as well as serving as a guideline for IT engineers.

The aspects specified in this International Standard refer mainly, but not exclusively, to requirements

that differ or are additional to those provided in existing, related standards. Where no such requirements

are identified, it is safe to assume that the appropriate existing ISO standards are instead applicable.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 128 (all parts), Technical drawings — General principles of presentation

ISO 129-1:2004, Technical drawings — Indication of dimensions and tolerances — Part 1: General principles

ISO 286 (all parts), Geometrical product specifications (GPS) — ISO code system for tolerances on linear sizes

ISO 1101:2012, Geometrical product specifications (GPS) — Geometrical tolerancing — Tolerances of form,

orientation, location and run-out

ISO 1302, Geometrical Product Specifications (GPS) — Indication of surface texture in technical product

documentation

ISO 2553, Welding and allied processes — Symbolic representation on drawings — Welded joints

ISO 3098-1:2015, Technical product documentation — Lettering — Part 1: General requirements

ISO 3098-5:1997, Technical product documentation — Lettering — Part 5: CAD lettering of the Latin

alphabet, numerals and marks

ISO 5456 (all parts), Technical drawings — Projection methods

ISO 5457:1999, Technical product documentation — Sizes and layout of drawing sheets

ISO 5459:2011, Geometrical product specifications (GPS) — Geometrical tolerancing — Datums and

datum systems

ISO 7200:2004, Technical product documentation — Data fields in title blocks and document headers

ISO 10209:2012, Technical product documentation — Vocabulary — Terms relating to technical drawings,

product definition and related documentation

ISO 11442:2006, Technical product documentation — Document management

ISO 14405-1, Geometrical product specifications (GPS) – Dimensional tolerancing – Part 1: Linear sizes

ISO 14405-2, Geometrical product specifications (GPS) — Dimensional tolerancing — Part 2: Dimensions

other than linear sizes

ISO 16016, Technical product documentation — Protection notices for restricting the use of documents and

products

ISO 17450-1:2011, Geometrical product specifications (GPS) — General concepts — Part 1: Model for

geometrical specification and verification

ISO 80000-1, Quantities and units — Part 1: General

IEC 82045-2:2004, Document management — Part 2: Metadata elements and information reference model

3 Terms and definitions

For the purposes of this document, the terms and definitions in ISO 10209:2012 and the following apply.

3.1 General

3.1.1

absolute coordinate system

primary model coordinate system in the CAD model used to define the location of digital elements in

the CAD model

3.1.2

datum system

set of two or more situation features established in a specific order from two or more datum features

Note 1 to entry: To define a datum system, it is necessary to consider the collection surface created by the

considered datum features. The invariance class of a collection surface can be complex, prismatic, helical,

cylindrical, revolute, planar, or spherical (see ISO 5459:2011, Table B.1).

[SOURCE: ISO 5459:2011, 3.10]

3.1.3

user defined coordinate system

model coordinate system which is created in the CAD model in addition to the absolute coordinate system

3.2 Classification codes for drawings and data sets (see Annex A)

3.2.1

classification code

designation assigned to product definition data that defines what data are included within the drawing,

data set, or both

Note 1 to entry: A drawing can either be in physical or electronic format.

3.2.2

classification code 1

drawing with optional data set

Note 1 to entry: Classification code 1 identifies that the data elements are located on the drawing and the drawing

is the original.

3.2.3

classification code 2

data set with model and drawing

Note 1 to entry: Classification code 2 identifies that data elements are located on a drawing and the drawing is

the original. A computer is used as a tool to prepare the drawing and the model. Data elements are located in the

digital data and the drawing.

2 © ISO 2015 – All rights reserved

3.2.4

classification code 3

data set with model and simplified drawing

Note 1 to entry: Classification code 3 identifies a model with a simplified drawing used to expedite communication

of common part features and to define non-geometric part definitions.

3.2.5

classification code 4

data set with model and drawing

Note 1 to entry: Classification code 4 identifies that all data elements are located in both the digital data and the

drawing. The data set is the original.

3.2.6

classification code 5

data set with model

Note 1 to entry: Classification code 5 identifies that all data elements are located in the data set with model. No

drawing exists.

4 Data set identification and control

4.1 General

Data sets for which compliance with this International Standard is claimed shall include a reference to this

International Standard, ISO 16792, either in the data set itself or in a document referenced by the data set.

The current revision of the data and the computer application(s) and version(s) used to develop the data

set shall be specified with other management data (see 5.4).

The data set identifier shall be unique and shall consist of numeric, alphabetic, or special characters in

any combination. Spaces are not permitted between any of the characters of the data set identifier.

The length of the data set identifier may be a direct function of the computer system and the operating

system. When the part or identifying number is used as the data set identifier, the length shall be

compatible with recognized limitations on number length in accordance with ISO 7200 and IEC 82045-2.

Special characters, such as hyphen (-), slash (/), or asterisk (*), shall be selected in a manner that does

not hinder data set identification or have an adverse effect on the computer system operation.

A recognizable prefix or suffix may be included as part of the identifier to associate files and sets of

related data.

See ISO 7200 and IEC 82045-2 for the description and use of drawings, drawing numbers, and

identifying numbers.

An optional system for classification codes established to define what data are included within the

drawing, data set, or both is presented in Annex A.

4.2 Related data

Related data shall be integral to, or referenced in, the data set. Related data consists of, but is not

limited to, analytical data, parts lists, test requirements, material specifications, process, and finish

requirements in accordance with Figure 1.

4.3 Data management

The following specifies the structure and control requirements for data management:

a) The data management system shall meet the requirements of ISO 11442, providing information to

enable the control and tracking of data sets, throughout the life cycle of the product to which each

relates. The system may include work in process, data review status, model checked status, release

status, design tool and version, libraries, etc.

b) Revision history information per ISO 11442 shall be contained in the data set.

Key

a

Related data (as applicable) required for complete definition may be integral to or referenced in the product

definition data set. Data not integral to the product definition data set may be revised independently.

b

A drawing is not required for Model Only data sets.

c

Related data may be manually or computer generated.

Figure 1 — Content of a product definition data set

4 © ISO 2015 – All rights reserved

Figure 2 — Content of a model

5 Data set requirements

5.1 General

The data set shall provide complete product definition, for example, a design model, its annotation, and

related documentation.

5.1.1 Fundamental requirements

The following are the fundamental requirements and other provisions applicable to both annotated

models and drawings, specific to annotated models and specific to drawings.

a) Common to annotated models and drawings

— All model values and resolved dimensions shall be obtained from the model.

— Rounding requirements for resolved dimensions shall comply with 9.2.2.

— The ability to query the model shall be available (see 7.3.8).

— All angular values shall be queried from the model (see 9.3). Exceptions to this are model

coordinate system(s), planes and axes in a datum system, and orthographic views.

— When query is required, a notation stating the requirement for query of the model or associated

data shall be added to the drawing or in the general notes.

— When applying tolerances to features, alignment of the annotation plane to the nominal or

theoretically exact profile is not required.

— Values obtained from the model for any feature(s) without any tolerance or datum target

specifications assigned shall be auxiliary dimensions.

— Legibility requirements of ISO 3098-1 and ISO 3098-5 shall apply when the annotation is viewed

perpendicular to the annotation plane.

— Annotation in any given annotation plane shall not overlap other annotation in the same

annotation plane when the model is viewed perpendicular to the annotation plane.

— Annotation text within any given annotation plane shall not be placed over the design model

when the model is viewed perpendicular to the annotation plane.

b) Applicable only to models

— All annotation shall be specified in one or more annotation planes. When CAD software does

not support maintenance of annotation plane orientation relative to the model, the model-only

method shall not be used (see 7.3.4).

— The associated entities, annotation, and attributes shall be in agreement (see 7.3.2).

— Resolved dimensions created from queried model values are considered the same as dimensions

displayed on a model (see 9.2.1).

— Display of centrelines or centre planes for features of size is optional.

— To ensure that the annotation is readable — the text, for example, could be upside down or

backwards following rotation of the model — one of the following techniques shall be used:

a) ensuring that the reading direction is updated after rotation of a model;

b) inclusion of means of determining the correct reading direction in each annotation plane

applied to a model;

c) when using saved views, ensuring that the model is orientated in the intended view

direction — for example, by including a means of determining the correct reading

direction in the view.

— Dimensions and tolerances to internal features can be shown without the use of a section [see

Figure 25 c)].

c) Applicable only to drawings

— Annotation may be applied to orthographic or axonometric views.

— For axonometric views, the orientation of the annotation shall be parallel to, normal to, or

coincident with the surface to which it applies. An annotation shall not overlap another or the

geometrical representation of the part.

5.1.2 Design model requirement

A design model is required and shall be in accordance with 5.2 and Clause 6.

5.2 General model requirements

5.2.1 Associativity

The ability to associate digital elements shall be available and maintained. Associativity information

shall be electronically accessible.

5.2.2 Model coordinate systems

A design model shall contain one or more model coordinate systems. A model coordinate system shall

be depicted by three mutually perpendicular line segments with its origin located at the intersection of

6 © ISO 2015 – All rights reserved

the three axes. Each axis shall be labelled and the positive direction shown. Model coordinate systems

shall be right-handed unless otherwise specified [see Figure 3 b)].

a) Mirror-image relationship

b) Recognizing the right-hand coordinate system

NOTE When observed in the Z direction, with positive Y ascending, positive X is directed to the right-hand

side of the observer.

Figure 3 — Left- and right-hand model coordinate systems

5.2.3 Applications of supplemental geometry

When supplemental geometry is used, there shall be a clear distinction between the supplemental

geometry and the model geometry.

a) Represented line element

When a represented line element is used to indicate the direction of a geometric tolerance

application, the leader line from the tolerance frame shall terminate on the represented line

element in an arrowhead (see Figure 41). The following geometric tolerances can use a represented

line element to clarify the directionality of a two-dimensional tolerance zone of parallel lines:

— straightness applied to the line elements of a planar surface (see 11.3.2 and Figure 41);

— orientation tolerance applied on each line element on a surface (see 11.3.3 and Figure 47).

— profile any line (see 11.3.4 and Figure 56).

NOTE It might be necessary to carefully define the placement and orientation of the represented line

element on the real workpiece.

b) Associativity

The represented line element, the tolerance frame, and the toleranced model feature should be

organized as an associated group (see Figures 41, 47, and 56).

5.2.4 Workpiece features not fully modelled

A conventional simplified representation of workpiece features such as threads, holes, fillets, rounds,

and drafts can be shown using partial geometry definition, annotations, attributes, or a combination

thereof (see Figure 10).

5.3 General method requirements

5.3.1 Data set methods

The following subclauses cover the product definition methods listed below. Each different method

for specifying product definition is used in support of different industry processes and requirements.

The data set is the original for all of the methods: any copy, no matter what the media of presentation,

is subordinate.

5.3.2 Model-only

The following is applicable when there is complete product definition within a model.

a) Product definition data, including but not limited to notes, parts lists, marking requirements,

dimensions, and tolerances, shall be contained or referenced in the data set.

b) The data elements of a draw

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...