ISO 7635:2003

(Main)Road vehicles — Air or air-over hydraulic braking systems for motor vehicles (including those with electronic control functions) — Test procedures

Road vehicles — Air or air-over hydraulic braking systems for motor vehicles (including those with electronic control functions) — Test procedures

ISO 7635:2003 specifies procedures for testing the air or air-over hydraulic braking systems of vehicles of categories M and N (excluding M1 and N1) as defined in UNECE R.E.3.

Véhicules routiers — Dispositifs de freinage à air comprimé ou hydropneumatiques pour automobiles (y compris ceux à fonctions de commande électronique) — Mode opératoire d'essai

General Information

- Status

- Withdrawn

- Publication Date

- 06-Nov-2003

- Withdrawal Date

- 06-Nov-2003

- Technical Committee

- ISO/TC 22 - Road vehicles

- Drafting Committee

- ISO/TC 22 - Road vehicles

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 12-Jun-2006

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 15-Apr-2008

- Effective Date

- 15-Apr-2008

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

ISO 7635:2003 is a standard published by the International Organization for Standardization (ISO). Its full title is "Road vehicles — Air or air-over hydraulic braking systems for motor vehicles (including those with electronic control functions) — Test procedures". This standard covers: ISO 7635:2003 specifies procedures for testing the air or air-over hydraulic braking systems of vehicles of categories M and N (excluding M1 and N1) as defined in UNECE R.E.3.

ISO 7635:2003 specifies procedures for testing the air or air-over hydraulic braking systems of vehicles of categories M and N (excluding M1 and N1) as defined in UNECE R.E.3.

ISO 7635:2003 is classified under the following ICS (International Classification for Standards) categories: 43.040.40 - Braking systems. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 7635:2003 has the following relationships with other standards: It is inter standard links to ISO 7635:1991, ISO 7635:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 7635:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 7635

Second edition

2003-11-15

Road vehicles — Air or air-over hydraulic

braking systems for motor vehicles

(including those with electronic control

functions) — Test procedures

Véhicules routiers — Dispositifs de freinage à air comprimé ou

hydropneumatiques pour automobiles (y compris ceux à fonctions de

commande électronique) — Mode opératoire d'essai

Reference number

©

ISO 2003

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2003

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2003 — All rights reserved

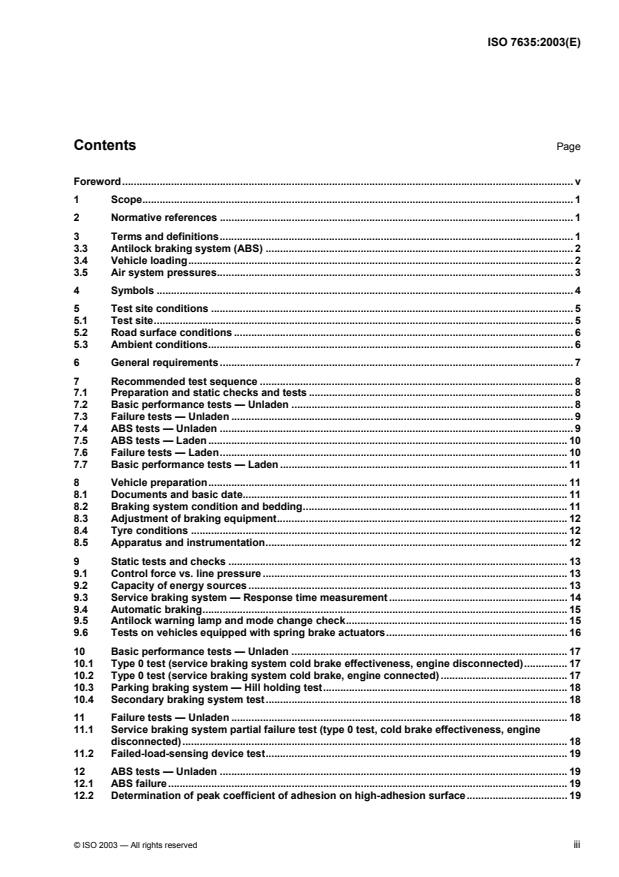

Contents Page

Foreword. v

1 Scope. 1

2 Normative references. 1

3 Terms and definitions. 1

3.3 Antilock braking system (ABS) . 2

3.4 Vehicle loading. 2

3.5 Air system pressures. 3

4 Symbols. 4

5 Test site conditions . 5

5.1 Test site. 5

5.2 Road surface conditions . 6

5.3 Ambient conditions. 6

6 General requirements. 7

7 Recommended test sequence . 8

7.1 Preparation and static checks and tests . 8

7.2 Basic performance tests — Unladen . 8

7.3 Failure tests — Unladen . 9

7.4 ABS tests — Unladen . 9

7.5 ABS tests — Laden . 10

7.6 Failure tests — Laden. 10

7.7 Basic performance tests — Laden . 11

8 Vehicle preparation. 11

8.1 Documents and basic date. 11

8.2 Braking system condition and bedding. 11

8.3 Adjustment of braking equipment. 12

8.4 Tyre conditions. 12

8.5 Apparatus and instrumentation. 12

9 Static tests and checks . 13

9.1 Control force vs. line pressure . 13

9.2 Capacity of energy sources . 13

9.3 Service braking system — Response time measurement. 14

9.4 Automatic braking. 15

9.5 Antilock warning lamp and mode change check. 15

9.6 Tests on vehicles equipped with spring brake actuators. 16

10 Basic performance tests — Unladen . 17

10.1 Type 0 test (service braking system cold brake effectiveness, engine disconnected). 17

10.2 Type 0 test (service braking system cold brake, engine connected) . 17

10.3 Parking braking system — Hill holding test. 18

10.4 Secondary braking system test. 18

11 Failure tests — Unladen . 18

11.1 Service braking system partial failure test (type 0 test, cold brake effectiveness, engine

disconnected). 18

11.2 Failed-load-sensing device test. 19

12 ABS tests — Unladen . 19

12.1 ABS failure. 19

12.2 Determination of peak coefficient of adhesion on high-adhesion surface. 19

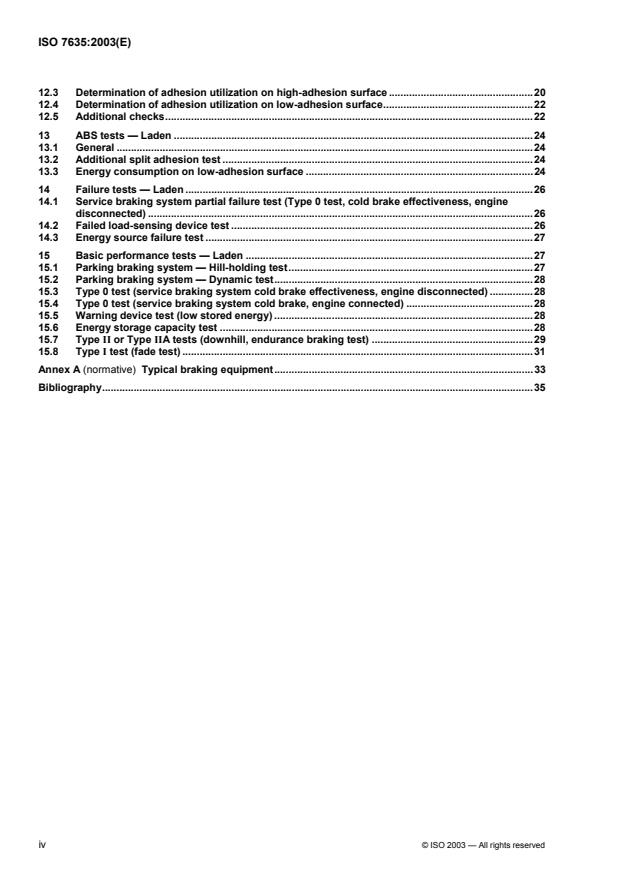

12.3 Determination of adhesion utilization on high-adhesion surface .20

12.4 Determination of adhesion utilization on low-adhesion surface.22

12.5 Additional checks.22

13 ABS tests — Laden .24

13.1 General.24

13.2 Additional split adhesion test .24

13.3 Energy consumption on low-adhesion surface .24

14 Failure tests — Laden .26

14.1 Service braking system partial failure test (Type 0 test, cold brake effectiveness, engine

disconnected) .26

14.2 Failed load-sensing device test .26

14.3 Energy source failure test .27

15 Basic performance tests — Laden .27

15.1 Parking braking system — Hill-holding test.27

15.2 Parking braking system — Dynamic test.28

15.3 Type 0 test (service braking system cold brake effectiveness, engine disconnected) .28

15.4 Type 0 test (service braking system cold brake, engine connected) .28

15.5 Warning device test (low stored energy) .28

15.6 Energy storage capacity test .28

15.7 Type II or Type IIA tests (downhill, endurance braking test) .29

15.8 Type I test (fade test) .31

Annex A (normative) Typical braking equipment.33

Bibliography.35

iv © ISO 2003 — All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 7635 was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 2, Braking

systems and equipment.

This second edition cancels and replaces the first edition (ISO 7635:1991), which has been technically revised.

INTERNATIONAL STANDARD ISO 7635:2003(E)

Road vehicles — Air or air-over hydraulic braking systems for

motor vehicles (including those with electronic control

functions) — Test procedures

1 Scope

This International Standard specifies procedures for testing the air or air-over hydraulic braking systems, with

and without antilock braking system (ABS), of vehicles of categories M and N (excluding M and N ) as

1 1

defined in UNECE R.E.3. The values given in square brackets and the values in the tables are taken from

ECE Regulation No. 13 for information.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 611, Road vehicles — Braking of automotive vehicles and their trailers — Vocabulary

ISO 1176:1990, Road vehicles — Masses — Vocabulary and codes

ISO 3833, Road vehicles — Types — Terms and definitions

ISO 6786, Road vehicles — Air braking systems — Identification of connections on units

ISO 7634:2003, Road vehicles — Compressed-air braking systems — Test procedures

ECE Regulation N° 10, Uniform Provisions Concerning the Approval of Vehicles of Categories M, N and O

with Regard to Electromagnetic Stability

ECE Regulation N° 13:1996, Uniform Provisions Concerning the Approval of Vehicles of Categories M, N and

O with regard to braking, incorporating the 09 series of amendments without supplements

1)

UNECE R.E.3:1997, Consolidated Resolution on the Construction of Vehicles

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 611, ISO 1176 and ISO 3833 and

the following apply.

3.1

air-over hydraulic braking system

braking system having stored pneumatic energy, hydraulically actuated brakes and transmission means

incorporating a pneumatic-to-hydraulic converter

1) United Nations Economic Commission for Europe

See Figure A.1.

[ISO 611:2003, definition 4.2.2]

3.2

pneumatic braking system

full-air braking system

braking system in which the control and energy are transmitted from the point of application to the brakes by

pneumatic transmission devices

[ISO 611:2003, definition 4.2.3]

See Figure A.2.

3.3 Antilock braking system (ABS)

3.3.1 Categories of ABS

3.3.1.1

Category 1

ABS which meets all the requirements of ECE Regulation No. 13:1996, Annex 13

3.3.1.2

Category 2

ABS which meets the requirements of ECE Regulation No. 13:1996, Annex 13, excepting paragraph 5.3.5 (no

braking rate on split-adhesion surfaces is prescribed)

3.3.1.3

Category 3

ABS which meets the requirements of ECE Regulation No. 13:1996, Annex 13, excepting paragraphs 5.3.4

and 5.3.5 (all split-adhesion tests are omitted)

3.3.2 Wheel control

3.3.2.1

directly controlled wheel

wheel whose braking force is modulated according to data provided at least by its own sensor

3.3.2.2

indirectly controlled wheel

wheel whose braking force is modulated according to data provided by sensor(s) of other wheel(s)

NOTE ABS with select-high control are deemed to include both directly and indirectly controlled wheels. In systems

with select-low control, all sensed wheels are deemed to be directly controlled wheels.

3.4 Vehicle loading

3.4.1

laden vehicle

vehicle laden so as to reach its maximum design total mass (Code: ISO-M07)

NOTE See ISO 1176:1990, 4.7.

3.4.1.1

laden motor vehicle other than semi-trailer tractor

motor vehicle laden to the maximum design total mass (Code: ISO-M07) specified by the vehicle

manufacturer and acknowledged by the technical services

2 © ISO 2003 — All rights reserved

NOTE 1 See ISO 1176:1990, 4.7.

NOTE 2 This mass may exceed the maximum authorized total mass (Code: ISO-M08) permitted by national

regulations. See ISO 1176:1990, 4.8.

NOTE 3 Mass distribution on the axles is to be stated by the vehicle manufacturer. In the event of several load

distribution patterns being planned, the distribution of the maximum design total mass among the axles is such that the

load on each axle is proportional to the maximum load for each axle defined by the manufacturer.

3.4.1.2

laden semi-trailer tractor

semi-trailor tractor laden to the maximum design total mass (Code: ISO-M07) that is technically feasible, as

specified by the vehicle manufacturer and acknowledged by the technical services, except that the load

defined by the manufacturer may be repositioned halfway between the kingpin position and the centre-line of

the rear axle(s), so as to compensate for the dynamic load transfer from the semi-trailer

NOTE See ISO 1176:1990, 4.7.

3.4.2

unladen vehicle

vehicle at its complete vehicle kerb mass (Code: ISO-M06) plus the mass of the required instrumentation

NOTE See ISO 1176:1990, 4.6.

3.4.2.1

unladen motor vehicle other than semi-trailer tractor

motor vehicle laden to complete vehicle kerb mass (Code: ISO-M06)

NOTE 1 See ISO 1176:1990, 4.6.

NOTE 2 During the tests, the fuel quantity in the fuel tank is to be maintained at least to 50 % of its capacity.

NOTE 3 An increase up to 200 kg mass over this mass is allowed. This corresponds, for instance, to the driver, one

observer and instrumentation. If necessary, the appropriate vehicle mass may be removed.

NOTE 4 For a vehicle without body, the manufacturer is to declare the minimum axle loads for a bodied vehicle.

3.4.2.2

unladen semi-trailer tractor

vehicle laden to complete vehicle kerb mass (Code: ISO-M06) and including the fifth wheel or a load

equivalent in value and position

NOTE See ISO 1176:1990, 4.6.

3.5 Air system pressures

3.5.1

pressure indicated by the manufacturer (of the vehicle)

reservoir pressure specified by the manufacturer from which it is possible to achieve the required efficiency for

service braking

NOTE It is the basis for the energy storage capacity test (see 15.6).

3.5.2

maximum pressure

pressure available for normal operation, i.e.

the cut-out pressure, in the case of an installation with a pressure regulating device

[90] % of the asymptotic pressure, in the case of an installation with a pressure-limited compressor

3.5.3

minimum pressure

pressure available for normal operation, i.e.

the cut-in pressure, in the case of an installation with a pressure regulating device

[90] % of the pressure indicated by the manufacturer, in the case of an installation with a pressure-limited

compressor

4 Symbols

Table 1 — Symbols used in this International Standard

Symbol Description Unit

a Mean deceleration m/s

m

d Mean fully developed deceleration m/s

m

E Wheelbase m

The adhesion utilized by the vehicle: quotient of the maximum braking rate with the ABS

ε

operative (z ) and the coefficient of adhesion (k)

AL

ε The ε value measured on axle i (in case of a power-driven vehicle with a Category 3 ABS)

i

ε The ε value on the high-adhesion surface

H

ε The ε value on the low-adhesion surface

L

F Actuating force daN

F Normal reaction of road surface under dynamic conditions with the ABS operative N

dyn

F F on axle i N

idyn dyn

F Normal reaction of road surface on axle i under static conditions N

i

F Total normal static reaction of road surface on all wheels of power-driven (towing) vehicles N

M

Total normal static reaction of road surface on the unbraked and non-driven axles of the

a

F N

Mnd

power-driven vehicle

Total normal static reaction of road surface on the unbraked and driven axles of the power-

a

F N

Md

driven vehicle

F 0,01 F + 0,015 F (rolling resistance) N

Wm Mnd Md

2 2

g Acceleration due to gravity (9,81 m/s) m/s

Height of centre of gravity specified by the manufacturer and agreed by the Technical

h m

Service conducting the approval test

h Height of fifth wheel coupling (kingpin) m

k

k Coefficient of adhesion between tyre and road

k k-factor of one front axle

f

k k-value determined on the high adhesion surface

H

k k-value determined on axle i for a vehicle with a Category 3 ABS

i

k k-value determined on the low adhesion surface

L

k value of adhesion for 100 % slip

lock

k k-factor of the power driven vehicle

M

k Maximum value of the curve “adhesion versus slip”

peak

4 © ISO 2003 — All rights reserved

Table 1 (continued)

Symbol Meaning Unit

k

k-factor of one rear axle

r

p Maximum pressure supplied by the towing vehicle in the supply circuit for the trailer kPa (bar)

max

p 65 % of p kPa (bar)

1 2

p Pressure level specified by the manufacturer enabling the prescribed performance of the kPa (bar)

service braking system to be achieved

P Mass of motor vehicle kg

M

P Maximum permissible mass of the trailer allowed to be towed by the power-driven vehicle t

T

R Ratio of k to k

peak lock

s Stopping distance m

t, t , ∆t Time interval s

i

t , t , t Pump-up times (ref. 9.2.1) min

1 2 3

t Mean value of t s

m

t Minimum value of t s

min

v Vehicle speed km/h

v Maximum speed of the vehicle km/h

max

v Lower speed limit for the antilock energy consumption test km/h

u

V Reservoir volume l

z Braking rate

z Braking rate of the vehicle with the ABS operative

AL

z Mean braking rate

m

z Maximum value of z

max

z Mean braking rate of front axle

mf

z Mean braking rate of rear axle

mr

z z of the power-driven vehicle on a “split-surface”

MALS AL

a

F and F : in case of two-axle power-driven vehicles these symbols may be simplified to corresponding F symbol.

Mnd Md i

5 Test site conditions

5.1 Test site

The test site shall be of sufficient size, without obstacles, to provide a safe testing environment.

The test site shall have a road of sufficient length prior to the test area to enable the test speeds to be attained.

The test area should be

a) of sufficient length to allow for poor braking performance, and

b) of sufficient width to allow for poor directional stability under braking.

5.2 Road surface conditions

5.2.1 Surface

5.2.1.1 The test area shall be a dry, smooth, hard surface, free of loose material and providing a peak

coefficient of adhesion of about [0,8].

5.2.1.2 Additionally, for the testing of vehicles equipped with ABS, a surface providing a peak coefficient

of adhesion k of [0,3] or less is required. It shall be preceded and followed by a surface in accordance with

peak

5.2.1.1 of sufficient length on the approach side to enable the test speeds to be attained.

Until such test surfaces become generally available, tyres at the limit of wear, and higher values of k up to

peak

[0,4] may be used. The actual value obtained and the type of tyres and surface shall be recorded.

For testing of vehicles fitted with ABS of Category 1 or 2, it is also necessary for a low-adhesion surface (k ) to

L

have a high-adhesion surface (k ) on at least one side so that the split-adhesion tests can be performed. Both

H

surfaces shall be sufficiently wide to allow, using the vehicle under test, the peak coefficients of adhesion to

be determined separately.

The above-described surfaces shall be such that k is W [0,5] and k /k is W [2]. If any doubt arises as to

H H L

whether this requirement has been met, it is necessary to ascertain the peak coefficients of adhesion using

the procedure detailed in 12.2 and 12.4. It is always necessary to measure the peak coefficients of adhesion

when testing a vehicle fitted with antilock brakes of Category 1.

5.2.2 Gradient

5.2.2.1 The road surface shall be substantially level; a tolerance of ± 1 % average gradient, measured

over a minimum distance of 50 m, is allowed.

5.2.2.2 Type II and Type IIA test site conditions

See Table 2.

Table 2 — Type II and Type IIA test site conditions

Gradient Length of

gradient

% km

Type II 6 6

Type IIA 7 6

5.2.2.3 The parking braking system hill-holding test may be conducted on either an appropriate gradient

or on a level road as specified in 10.3.

5.2.3 Camber

The camber or transverse gradient across the road surface shall not exceed 2 %.

5.3 Ambient conditions

5.3.1 Wind speed

The tests shall be performed when there is no wind liable to affect the results. The wind speed shall not

exceed an average of 5 m/s.

6 © ISO 2003 — All rights reserved

5.3.2 Air temperature

The air temperature shall be recorded in the test report.

6 General requirements

6.1 General test conditions to be followed during determination of braking performance:

a) vehicle speed (see 6.11);

b) without exceeding the maximum permissible control force;

c) engine disconnected or connected (as prescribed);

d) without wheel-locking, except immediately before stopping, unless specifically allowed;

e) without deviation of the vehicle from its course (steering corrections of less than 90° allowed, if not

otherwise specified);

f) loading condition — unless otherwise specified, all tests shall be carried out with the vehicle laden and

unladen.

6.2 During all phases of the following test procedures, any unusual braking performance characteristics or

vehicle behaviour on both (e.g. course deviation or abnormal vibration) shall be observed and reported.

6.3 During the tests with the engine connected on vehicles with a manual gearbox, the clutch may be

disengaged just before the vehicle stops, to avoid the engine stalling.

6.4 Deceleration measurements used in the following test procedures, unless otherwise stated, refer to the

“mean fully developed deceleration” as defined in ECE Regulation 13:1996, Annex 4, paragraph 1.1.2.

6.5 Tests may be carried out under adverse conditions to avoid delays, but with due consideration for

safety. Such adverse conditions shall be reported. Any failed tests under such conditions shall be repeated

under the correct conditions, but not all tests need necessarily be repeated.

6.6 The recommended sequence of the tests is in accordance with Clause 7.

6.7 Full or partial re-tests, after a failed test or to test alternative braking system components, shall again

follow the recommended sequence (see Clause 7), with particular emphasis on the vehicle preparation and

bedding-in procedures.

6.8 Control forces shall be applied rapidly, but without significant overshoot, and shall then be maintained

constant during the stop (if not otherwise specified). An adjustable pressure regulating device should be used.

6.9 Skilled test drivers shall determine the optimum vehicle braking performance without wheel-locking

except immediately before stopping and without course deviation [see 6.1 e) for allowable steering correction]

after appropriately familiarizing themselves with the vehicle braking, steering and suspension systems.

6.10 The brakes are deemed to be cold when the initial temperature of the hottest brake measured on the

disc, on the outside of the drum or on the brake linings is lower than [100] °C before each test stop.

6.11 The speed of the vehicle before actuating the braking system control shall be stabilized at a level not

less than [98] % of the prescribed speed for the test in question unless there is any other overriding

requirement.

6.12 Where a vehicle is so constructed that its maximum speed is lower than that prescribed for any test, the

test shall be performed at the maximum speed of the vehicle.

6.13 Tests with the engine connected shall be carried out in the appropriate gear, defined as the highest

gear normally used at the specified speed without exceeding the manufacturer's recommended maximum

engine speed.

7 Recommended test sequence

7.1 Preparation and static checks and tests

See Table 3.

Table 3 — Preparation and static checks and tests

Relevant Relevant annex

Clause/Subclause and/or paragraph of

No. Test Engine status

of this International ECE Regulation

Standard 13:1996

Preparation (documents, instrumentation,

1 8 § 1 to 2

bedding etc.)

2 Control force vs line pressure 9.1 A4 § 2.1.1

3 Capacity of energy sources Running 9.2 A7 § 2

4 Response time 9.3 A4 § 4

5 Automatic braking 9.4 5.2.1.18.4

6 ABS warning lamp and mode change check 9.5 A13 § 4.1, 4.1.1, 4.1.2

7 Spring braking system 9.6 A8

7.2 Basic performance tests — Unladen

See Table 4.

Table 4 — Basic performance tests — Unladen

Relevant Relevant annex

Clause/Subclause and/or paragraph of

No. Test Engine status

of this International ECE Regulation

Standard 13:1996

1 Type 0 test Disconnected 10.1 A4 § 1.4.2, 2.1.1

2 Type 0 test Connected 10.2 A4 § 1.4.3

Dynamic test of the parking braking system

3 Disconnected 10.4 A4 § 2.2

(if applicable)

4 Parking braking system (hill-holding) Disconnected 10.3 Not prescribed

8 © ISO 2003 — All rights reserved

7.3 Failure tests — Unladen

See Table 5.

Table 5 — Failure tests — Unladen

Relevant Relevant annex

Clause/Subclause and/or paragraph of

No. Test Engine status

of this International ECE Regulation

Standard 13:1996

1 Service braking system failure, type 0 test Disconnected 11.1 A4 § 2.2 or 2.4

2 Failed load-sensing device Disconnected 11.2 A10 § 6

7.4 ABS tests — Unladen

See Table 6.

Table 6 — ABS tests — Unladen

Relevant Relevant annex

Clause/Subclause and/or paragraph of

No. Test Engine status

of this International ECE Regulation

Standard 13:1996

A13 § 4.5,

1 ABS failure Disconnected 12.1

A4 § 2.4.1

2 Determination of k Disconnected 12.2 A13 § app. 2

Hpeak

3 Adhesion utilization on high adhesion Disconnected 12.3 A13 § 5.2

4 Determination of k Disconnected 12.4 A13 § app. 2

Lpeak

5 Adhesion utilization on low adhesion Disconnected 12.4 A13 § 5.2

6 Wheel behaviour tests Disconnected 12.5.2.1 A13 § 5.3.1

7 Transition from high to low adhesion Disconnected 12.5.2.2 A13 § 5.3.2

8 Transition from low to high adhesion Disconnected 12.5.2.3 A13 § 5.3.3

a

9 Split-adhesion test Disconnected 12.5.3 A13 § 5.3.4

a

ABS Category 1 or 2.

7.5 ABS tests — Laden

See Table 7.

Table 7 — ABS tests — Laden

Relevant Relevant annex

Clause/Subclause and/or paragraph of

No. Test Engine status

of this International ECE Regulation

Standard 13:1996

A13 § 4.5,

1 ABS failure Disconnected 13

A4 § 2.4.1

Determination of k

2 Disconnected 13 A13 § app. 2

Hpeak

3 Adhesion utilization on high adhesion Disconnected 13 A13 § 5.2

Determination of k

4 Disconnected 13 A13 § app. 2

Lpeak

5 Adhesion utilization on low adhesion Disconnected 13 A13 § 5.2

6 Wheel behaviour tests Disconnected 13 A13 § 5.3.1

7 Transition from high to low adhesion Disconnected 13 A13 § 5.3.2

8 Transition from low to high adhesion Disconnected 13 A13 § 5.3.3

a

A13 § 5.3.4

9 Split-adhesion test Disconnected 13, 13.1

b

A13 § 5.3.5

10 Energy consumption Disconnected 13.2 A13 § 5.1

a

ABS Category 1 or 2.

b

ABS Category 1.

7.6 Failure tests — Laden

See Table 8.

Table 8 — Failure tests — Laden

Relevant Relevant annex

Clause/Subclause and/or paragraph of

No. Test Engine status

of this International ECE Regulation

Standard 13:1996

1 Service braking system failure, type 0 test Disconnected 14.1 A4 § 2.2 or 2.4

2 Failed load-sensing device Disconnected 14.2 A10 § 6

3 Energy source failure Disconnected 14.3 5.2.1.14

10 © ISO 2003 — All rights reserved

7.7 Basic performance tests — Laden

See Table 9.

Table 9 — Basic performance tests — Laden

Reference to this Reference to ECE R

No. Test Engine status

standard 13:1996

1 Parking braking system (hill-holding) Disconnected 15.1 A4 § 2.3.1-5

2 Dynamic test of the parking braking system Disconnected 15.2 A4 § 2.3.6 or 2.2

3 Type 0 test (plot deceleration vs pressure) Disconnected 15.3 A4 § 1.4.2, 2.1.1

4 Type 0 test Connected 15.4 A4 § 1.4.3

5 Warning device (low pressure warning) Disconnected 15.5 5.2.1.13, 5.2.1.29

6 Capacity of energy storage devices Disconnected 15.6 A7

7 Type II or IIA test Connected 15.7 A4 § 1.6, 1.8 or A5

Type 0 hot performance test (if the service

8 Disconnected 15.7.2.2.3 A4 § 1.6.3

braking system was used for type II test)

9 Type I test Connected 15.8 A4 § 1.5.1

10 Type 0 hot performance (fade) test Disconnected 15.8.4 A4 § 1.5.3.1

8 Vehicle preparation

8.1 Documents and basic date

NOTE The control of the data related to pneumatic braking systems and to ABS (3.2 and 3.3) is also an integral part

of the vehicle preparation.

The vehicle shall be verified based upon the documentation as follows:

a) main technical data according to Annex 2 of ECE Regulation No. 13:1996;

b) piping diagram, layout and list of the elements of the braking system;

c) braking system performance calculation;

d) report/approval of EMC (if vehicle is equipped with an ABS) in accordance with ECE Regulation No. 10 or

Annex B of this International Standard.

8.2 Braking system condition and bedding

8.2.1 The braking system components shall be new, or capable of functioning as new, and within the

vehicle manufacturer's specifications. Individual brake forces should be measured on a roller test bench prior

to the braking performance tests.

8.2.2 The brake linings shall be bedded. Until a uniform procedure is established, the bedding of the service

and parking brake linings should be carried out according to the manufacturer's recommendations.

The brake linings may be regarded as bedded if at least 80 % of their surface is in contact with the brake

drums or discs. Glazed, burned or damaged surfaces are not acceptable.

8.3 Adjustment of braking equipment

Adjustable brake components shall be set according to the vehicle manufacturer's recommendations. Re-

adjustment of the brakes, including automatically adjusted brakes according to the vehicle manufacturer's

recommendations, may be made prior to each specific test.

8.4 Tyre conditions

8.4.1 The tyres shall be inflated to the vehicle manufacturer's recommended pressure levels.

8.4.2 Tyre tread wear should not exceed 50 % of the new condition; totally new tyres should not be used.

8.5 Apparatus and instrumentation

Care should be taken to ensure that instruments and devices needed for testing added to the vehicle braking

equipment do not significantly affect braking system performance.

8.5.1 Additional devices for carrying out the testing of the braking systems

8.5.1.1 Pressure regulating/shut off devices

8.5.1.2 Air reservoir of 0,5 l for trailer control line

8.5.1.3 Air reservoir for simulation of trailer pipe capacity (see 9.2.2)

8.5.1.4 Signalling device (e.g. control lamp) to show functioning of the retarder and, in the case of

integrated retarder control, means of disabling the retarder

8.5.1.5 Towing vehicle for optional drag test(s)

8.5.2 Instrumentation

The test vehicle (and the towing vehicle if appropriate) shall be prepared for testing by the installation of

additional instruments or calibration of the existing standard vehicle instruments, or both, as required.

All the instruments shall be checked to ensure correct functioning, and, with the vehicle stationary on the test

surface, all shall be set.

The instrumentation may include the following.

8.5.2.1 Control force gauge for the service braking system, parking braking system and secondary

braking system (if this system is not combined with either the service or the parking braking system)

8.5.2.2 Decelerometer

8.5.2.3 Speed measuring system or calibrated speedometer

8.5.2.4 Stopping distance measuring means

8.5.2.5 Time measuring means

8.5.2.6 Brake temperature indicating system

8.5.2.7 Application and response time measuring equipment

8.5.2.8 Line pressure gauges/transducers

8.5.2.9 Towing force measuring system

12 © ISO 2003 — All rights reserved

8.5.2.10 Optional instruments, which may include

a) control travel gauges

b) wheel lock indicators

c) steering wheel angle indicator

d) low- to high-adhesion surface transition indicator

8.5.3 Provision for failure simulation

The vehicle shall be equipped with the necessary added devices and piping as agreed with the vehicle

manufacturer, to provide the required failure simulations.

In the pneumatic part of the braking system, a failure shall correspond to an uncoupled pipe.

In the hydraulic part of the braking system, a leakage shall be simulated with the brake fluid being

returned to its reservoir.

9 Static tests and checks

9.1 Control force vs line pressure

Produce a graph of increasing line pressure against control force for the service, secondary and parking

braking functions. The graphs should be produced with the vehicle stationary and the system pressure

between the zero and the maximum specified pressure. If the graphs are to be constructed from a series of

individual readings, then at least five readings should be taken, including the threshold value. Care should

also be taken to accurately depict any changes in the force–pressure relationship, taking additional readings if

necessary.

9.2 Capacity of energy sources

9.2.1 Pump-up times

Measure t , the time required for the relative pressure to rise from zero to p , in the least favourably positioned

1 1

braking energy reservoir.

Measure t , the time required for the pressure to rise from zero to p , in the least favourably positioned braking

2 2

energy reservoir, where the vehicle is equipped with no pneumatic reservoir for auxiliary equipment or with

one or more pneumatic reservoirs for the same purpose with a total capacity not exceeding [20] % of the total

capacity of the braking system pneumatic reservoirs.

Measure t , the time required for the relative pressure to rise from zero to p , in the least favourably positioned

3 2

braking energy reservoir, where the vehicle is equipped with one or more pneumatic reservoirs for auxiliary

equipment with a total capacity exceeding [20] % of the total reservoir capacity of the braking system.

9.2.2 Measurement conditions

The speed of the compressor shall be that corresponding to the maximum power of the engine or to that

allowed by the engine governor. The auxiliary equipment reservoirs shall be isolated during the tests for

determination of t and t .

1 2

On motor vehicles capable of towing air-braked trailers, the trailer shall be simulated by a reservoir, attached

to the supply line whose volume V, expressed in litres, is given from the formula:

p ×=VP20

T

max

9.2.3 Basic test (all vehicles)

9.2.3.1 The pump-up time t shall not be greater than [3] min.

9.2.3.2 The pump-up time t shall not be greater than [6] min.

9.2.3.3 Test vehicles capable of towing air-braked trailers shall in this case be tested without the trailer

simulation reservoir.

9.2.4 Basic test (vehicles able to tow air-braked trailers)

9.2.4.1 The pump-up time t shall not be greater than [6] min.

9.2.4.2 The pump-up time t shall not be greater than [9] min.

9.2.5 Additional tests

9.2.5.1 Carry out these tests if the auxiliary equipment reservoir capacity is more than [20] % of the total

capacity of the braking system reservoirs. Independently of t , the pressure in the auxiliary equipment

reservoirs shall reach the pressure(s) specified by the vehicle manufacturer.

9.2.5.2 The pump-up time t for all vehicles shall not be greater than [8] min.

9.2.5.3 The pump-up time t for vehicles capable of towing air-braked trailers shall not be greater than

[11] min. Test vehicles capable of towing air-braked trailers shall in this case be tested without the trailer

simulation reservoir.

9.3 Service braking system — Response time measurement

9.3.1 Test conditions

9.3.1.1 The response time of the service braking system shall be measured at the input port to that

pneumatic actuator which is in the least favourable position.

9.3.1.2 In the case of towing vehicles, the response time shall also be measured at the end of a pipe

[2,5] m long with an internal diameter of [13] mm. This pipe shall be connected to the coupling head of the

control line of the service braking system. A volume of [(385 ± 5)] cm shall be connected to the coupling

head of the supply line.

9.3.1.3 At the beginning of each test, the pressure in all reservoirs shall be equal to the minimum

pressure.

9.3.1.4 The load-sensing device, if fitted, shall be set in the position corresponding to the laden vehicle.

9.3.2 Test procedure

9.3.2.1 Determine the response times to reach [10] % and/or [75] % of the asymptotic pressures, by a

succession of full brake actuations, beginning with the fastest possible control application time and slowing to

an application time of about [0,4] s.

9.3.2.2 Plot the measured response times on a graph. If the figure representing the 100th is five or more,

round the value up to the next higher tenth.

14 © ISO 2003 — All rights reserved

9.3.2.3 The response time to be taken into consideration for the purpose of the test is that corresponding

to an application time of [0,2] s. This response time can be obtained from the graph by linear interpolation

rounded to the nearest tenth of a second.

9.3.2.4 In the case of a semi-trailer tractor, record the length and internal diameter of the coiled flexible

pipes prior to the coupling heads.

9.3.2.5 The time elapsing from the initiation of brake pedal actuation to the moment when the pressure

measured at the pneumatic actuator in the least favourable position (Position A), and at the coupling head of

the pneumatic control line where a pneumatic control line is present (Position B), reaches “x” % of its

asymptotic and respectively final value, shall not exceed the times given in Table 10.

Table 10 — Elapsing time versus percentage of asymptotic pressure

Percentage (x) Time

Position

% s

A 75 0,6

B 10 0,2

B 75 0,4

9.4 Automatic braking

Carry out the following test to check the automatic braking function in the case of a trailer control line failure.

Simulate a break in the trailer control line at the coupling head. Apply the service braking system control

device fully and check that the pressure at the end of the [2,5] m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...