ISO 23828:2008

(Main)Fuel cell road vehicles - Energy consumption measurement — Vehicles fuelled with compressed hydrogen

Fuel cell road vehicles - Energy consumption measurement — Vehicles fuelled with compressed hydrogen

ISO 23828:2008 specifies the procedures for measuring the energy consumption of fuel cell passenger cars and light duty trucks which use compressed hydrogen and which are not externally chargeable.

Véhicules routiers avec pile à combustible — Mesurage de la consommation d'énergie — Véhicules alimentés par hydrogène comprimé

General Information

- Status

- Withdrawn

- Publication Date

- 21-Apr-2008

- Withdrawal Date

- 21-Apr-2008

- Technical Committee

- ISO/TC 22 - Road vehicles

- Drafting Committee

- ISO/TC 22 - Road vehicles

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 15-Nov-2013

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 26-Nov-2011

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

ISO 23828:2008 is a standard published by the International Organization for Standardization (ISO). Its full title is "Fuel cell road vehicles - Energy consumption measurement — Vehicles fuelled with compressed hydrogen". This standard covers: ISO 23828:2008 specifies the procedures for measuring the energy consumption of fuel cell passenger cars and light duty trucks which use compressed hydrogen and which are not externally chargeable.

ISO 23828:2008 specifies the procedures for measuring the energy consumption of fuel cell passenger cars and light duty trucks which use compressed hydrogen and which are not externally chargeable.

ISO 23828:2008 is classified under the following ICS (International Classification for Standards) categories: 43.120 - Electric road vehicles. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 23828:2008 has the following relationships with other standards: It is inter standard links to ISO 23828:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 23828:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 23828

First edition

2008-05-01

Fuel cell road vehicles — Energy

consumption measurement — Vehicles

fuelled with compressed hydrogen

Véhicules routiers avec pile à combustible — Mesurage de la

consommation d'énergie — Véhicules alimentés par hydrogène

comprimé

Reference number

©

ISO 2008

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2008

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2008 – All rights reserved

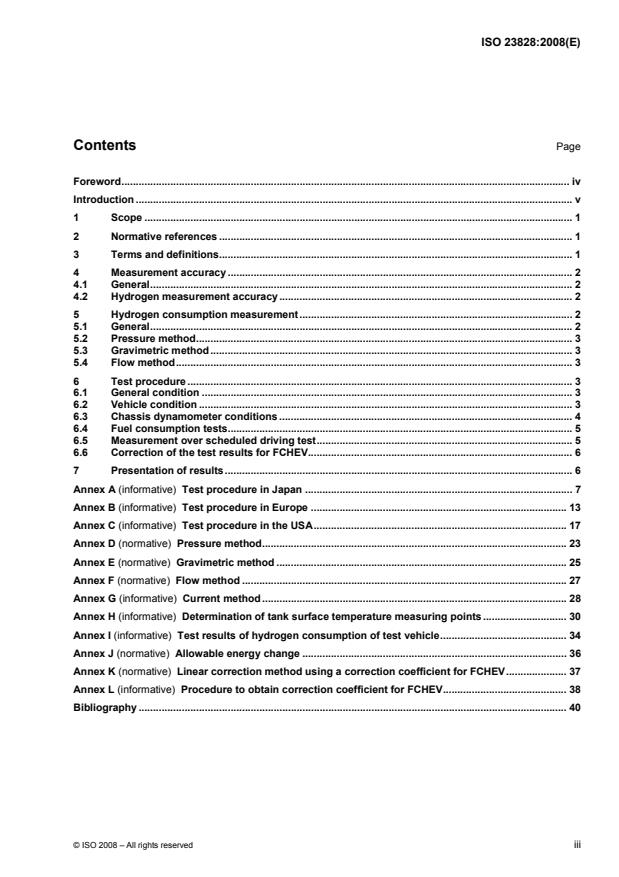

Contents Page

Foreword. iv

Introduction . v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions. 1

4 Measurement accuracy . 2

4.1 General. 2

4.2 Hydrogen measurement accuracy. 2

5 Hydrogen consumption measurement. 2

5.1 General. 2

5.2 Pressure method. 3

5.3 Gravimetric method. 3

5.4 Flow method. 3

6 Test procedure . 3

6.1 General condition . 3

6.2 Vehicle condition . 3

6.3 Chassis dynamometer conditions . 4

6.4 Fuel consumption tests. 5

6.5 Measurement over scheduled driving test.5

6.6 Correction of the test results for FCHEV. 6

7 Presentation of results. 6

Annex A (informative) Test procedure in Japan . 7

Annex B (informative) Test procedure in Europe . 13

Annex C (informative) Test procedure in the USA. 17

Annex D (normative) Pressure method. 23

Annex E (normative) Gravimetric method . 25

Annex F (normative) Flow method . 27

Annex G (informative) Current method. 28

Annex H (informative) Determination of tank surface temperature measuring points . 30

Annex I (informative) Test results of hydrogen consumption of test vehicle. 34

Annex J (normative) Allowable energy change . 36

Annex K (normative) Linear correction method using a correction coefficient for FCHEV. 37

Annex L (informative) Procedure to obtain correction coefficient for FCHEV. 38

Bibliography . 40

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 23828 was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 21,

Electrically propelled road vehicles.

iv © ISO 2008 – All rights reserved

Introduction

Fuel cell vehicles (FCV) include the following types:

⎯ pure fuel cell vehicle (PFCV), in which the fuel cell system is the only on-board energy source for

propulsion and auxiliary systems;

⎯ fuel cell hybrid electric vehicle (FCHEV), in which the fuel cell system is integrated with an on-board

rechargeable energy storage system (RESS) for electric energy supply to propulsion and auxiliary

systems.

FCHEV design options include:

a) externally chargeable or non-externally chargeable;

b) rechargeable energy storage system (RESS): battery or capacitor;

c) driver-selected operating modes: if the FCHEV has no driver-selected operating mode, it has only an

FCHEV mode.

Table 1 shows the classification of FCHEV.

Table 1 — Classification of FCHEV

Chargeability Operating mode

FCHEV mode

externally chargeable

EV mode

FCHEV

FCHEV mode

non-externally chargeable

EV mode

This International Standard is applicable to PFCV and to non-externally chargeable FCHEV with FCHEV

mode only (see shaded boxes in Table 1).

INTERNATIONAL STANDARD ISO 23828:2008(E)

Fuel cell road vehicles — Energy consumption measurement —

Vehicles fuelled with compressed hydrogen

1 Scope

This International Standard specifies the procedures for measuring the energy consumption of fuel cell

passenger cars and light duty trucks which use compressed hydrogen and which are not externally

chargeable.

Annexes A, B and C describe procedures specific to particular regions.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 1176, Road vehicle — Masses — Vocabulary and codes

ISO 3833, Road vehicles — Types — Terms and definitions

ISO 10521-1, Road vehicles — Road load — Part 1: Determination under reference atmospheric conditions

ISO 10521-2, Road vehicles — Road load — Part 2: Reproduction on chassis dynamometer

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 3833 and ISO 1176 and the

following apply.

3.1

battery state of charge

battery SOC

residual capacity of battery available to be discharged

NOTE Battery state of charge is normally expressed as a percentage of full charge.

3.2

charge balance of battery

change of charge in battery during test period

NOTE Charge balance of battery is normally expressed in A·h.

3.3

electric vehicle operation mode

EV operation mode

mode of a FCHEV in which only the RESS is used for the vehicle propulsion and possibly auxiliary systems

3.4

fuel cell hybrid electric vehicle operation mode

FCHEV operation mode

mode of a FCHEV in which both RESS and fuel cell system are used sequentially or simultaneously for

vehicle propulsion

NOTE The fuel cell system can also charge the RESS during propulsion or standstill.

3.5

fuel cell vehicle

FCV

electric vehicle using a fuel cell power system for vehicle propulsion

NOTE A FCV can have additionally a RESS or other power sources for vehicle propulsion.

3.6

fuel cell hybrid electric vehicle

FCHEV

electric vehicle using a RESS and a fuel cell power system for vehicle propulsion

3.7

pure fuel cell vehicle

pure FCV

FCV using only a fuel cell power system for vehicle propulsion

3.8

rechargeable energy storage system

RESS

system that stores energy for delivery of electric energy and that is rechargeable

EXAMPLE Batteries, capacitors.

4 Measurement accuracy

4.1 General

Measurement accuracy shall be in accordance with national standards.

4.2 Hydrogen measurement accuracy

Test apparatus shall assure the accuracy of measurement of ± 1 % for the total mass of hydrogen

consumption during the test cycle, unless otherwise specified in the relevant annexes.

5 Hydrogen consumption measurement

5.1 General

Various methods for the measurement of hydrogen consumption have been developed which reflect the

current state of studies in the field. Hydrogen consumption shall be measured using one of the following:

⎯ pressure method;

⎯ gravimetric method;

⎯ flow method.

2 © ISO 2008 – All rights reserved

These three methods, which are described in detail in Annexes D, E and F, have been shown to give

sufficiently equivalent results. Other methods may also become applicable if they show comparable

equivalence and reliability.

5.2 Pressure method

Hydrogen consumption is determined by measuring the pressure and temperature of gas in the high-pressure

hydrogen tank, before and after the test. A tank with known internal volume that allows measurement of gas

pressure and temperature shall be used for the test.

5.3 Gravimetric method

Hydrogen consumption is calculated by measuring the weight of the high-pressure hydrogen tank before and

after the test. The tank used for the test shall be suitable for measuring weight.

5.4 Flow method

The amount of hydrogen supplied to and consumed by a vehicle is measured by a flow meter.

6 Test procedure

6.1 General condition

The test shall be conducted after preparation of the vehicle and test apparatus as described in this clause.

6.2 Vehicle condition

6.2.1 General

The vehicle shall be clean, and the windows and air entries that are not needed for the correct operation of the

vehicle and the drive system shall be closed by the normal operating controls.

The lighting, signalling and auxiliary devices shall be turned off, except those required for testing and for usual

day-time operation of the vehicle.

6.2.2 Vehicle stabilization

Prior to testing, the test vehicle shall be stabilized; this includes vehicle mileage accumulation in accordance

with a manufacturer-determined distance, unless otherwise specified in Annex A, B or C (as appropriate).

6.2.3 Vehicle appendages

Vehicles shall be tested with normal appendages (mirrors, bumpers, etc.). Where necessary, certain items

(e.g. hub caps) may be removed for safety on the dynamometer.

6.2.4 Vehicle test mass

The vehicle test mass shall be selected in accordance with Annex A, B, or C.

6.2.5 Tyres

6.2.5.1 General

Tyres recommended by the vehicle manufacturer shall be used.

6.2.5.2 Tyre pressure

When the vehicle tyres are at ambient temperature, they shall be inflated to the pressure specified by the

vehicle manufacturer for the chosen test (track or chassis dynamometer).

6.2.5.3 Tyre conditioning

Tyres shall be conditioned as recommended by the vehicle manufacturer. See Annex A, B, or C for additional

requirements.

6.2.6 Lubricants

The vehicle lubricants specified by the manufacturer shall be used.

6.2.7 Gear shifting

If the vehicle is fitted with a manually shifted gear box, gear shifting positions shall correspond to the test

procedures described in Annexes A, B and C. However, the shift positions may be selected and determined

previously in accordance with the vehicle characteristics.

6.2.8 Regenerative braking

If the vehicle has regenerative braking, the regenerative braking system shall be enabled for all dynamometer

testing. If a vehicle is equipped with an antilock braking system (ABS) or a traction control system (TCS) and

is tested on a single-roll dynamometer, these systems may inadvertently interpret the non-movement of the

set of wheels that are off the dynamometer as a malfunctioning system. If so, modifications to these systems

shall be made to achieve normal operation of the remaining vehicle systems, including the regenerative

braking system.

6.2.9 RESS stabilization

The RESS shall have been stabilized with the vehicle, as defined in 6.2.2, or by equivalent conditioning.

6.3 Chassis dynamometer conditions

6.3.1 General

The vehicle generally should be tested on a single-roll chassis dynamometer. A four-wheel-drive vehicle shall

be tested by modifying the drive train of the vehicle. When the vehicle is modified, the details shall be

explained in the test report.

A four-wheel-drive dynamometer test may be performed when a modification for a single-roll dynamometer

test is not possible for a specific four-wheel-drive vehicle.

6.3.2 Dynamometer calibration

The dynamometer shall be calibrated as specified by the vehicle manufacturer, or in accordance with the

specifications indicated in the service manual provided by the dynamometer manufacturer.

6.3.3 Dynamometer warm-up

The dynamometer shall be warmed up sufficiently prior to the testing.

4 © ISO 2008 – All rights reserved

6.3.4 Determining the dynamometer load coefficient

The determination of vehicle road load under reference atmospheric conditions shall conform to ISO 10521-1,

and the reproduction on a chassis dynamometer shall conform to ISO 10521-2 or national standards. Vehicles

equipped with regenerative braking systems that are activated at least in part when the brake pedal is not

depressed shall have regenerative braking disabled during the deceleration portion of coast-down testing on

both the test track and dynamometer.

6.4 Fuel consumption tests

6.4.1 General

Depending on the region concerned, the appropriate procedure shall be followed from Annex A, B, or C.

Details and common procedures for each test mode are described below.

6.4.2 Vehicle preconditioning

Vehicle preconditioning shall be carried out in accordance with the annex appropriate for the region. In the

case of FCHEV, the RESS state of charge may be pre-adjusted by charging or discharging, to obtain a

suitable energy difference in RESS between the start and the end of test.

6.4.3 Vehicle soak

The vehicle shall be soaked in accordance with the appropriate regional procedure prescribed in Annex A, B,

or C.

6.5 Measurement over scheduled driving test

For the measurement of hydrogen consumption, the test vehicle shall be driven on the chassis dynamometer

in accordance with the running mode prescribed for the region (see Annex A, B, or C, as appropriate). The

hydrogen consumption can be measured by one of the methods described in Annex D, E, or F, or by an

alternative method that provides equivalent accuracy.

The hydrogen consumption is determined by means of one of the following equations:

22,414

−3

−3 w××10

b ×10

m

t0

C== (1)

F1

L L

m

−3

b××10

−3 t0

w ×10

22,414

C== (2)

F2

L L

22,414

−3

−3wQ××10×

H

bQ××10

m

t0H

C== (3)

F3

L L

where

C is the hydrogen consumption per unit distance, in m /km, referred to volume at normal conditions

F1

(273 K; 101,3 kPa);

C is the hydrogen consumption per unit distance, in kg/km, referred to weight;

F2

C is the hydrogen consumption per unit distance, in MJ/km, referred to caloric value;

F3

L is the distance, in km;

b is the hydrogen consumption at normal conditions (273 K, 101,3 kPa);

t0

w is the hydrogen consumption, in g;

m is the molecular weight of hydrogen (2,016);

Q is the lower calorific value of hydrogen (10,8 MJ/Nm ).

H

6.6 Correction of the test results for FCHEV

6.6.1 General

After the FCHEV has been tested, the hydrogen consumption shall be corrected if the energy difference in the

RESS between the start and the end of test is above the limit described in 6.6.2.

6.6.2 Allowable limit for RESS energy change for FCHEV

The allowable limit for RESS energy change is

||∆ E u0,01× E (4)

RESS CF

where

∆E is the energy change in RESS over the test cycle;

RESS

E is the energy of consumed fuel over the test cycle.

CF

Further details are described in Annex J.

6.6.3 Correction procedure using a correction coefficient

The hydrogen consumption at ∆E = 0 shall be calculated by using a correction coefficient to be provided

RESS

by the vehicle manufacturer. Details on the acquisition and the application of the correction coefficient are

given in Annex K.

NOTE Annex L gives recommendations on the data collecting procedure to obtain the correction coefficient.

7 Presentation of results

Test results should be recorded in accordance with Annex I. The fourth significant digit should be rounded off

to provide the hydrogen consumption rate to three significant digits.

Other data should be recorded as required by the regional regulations.

6 © ISO 2008 – All rights reserved

Annex A

(informative)

Test procedure in Japan

A.1 General

This annex describes the typical procedures and related conditions in Japan for measuring the fuel

consumption of passenger cars and light duty trucks, as defined in Japanese regulations.

A.2 Accuracy for determining vehicle road load and others

When determining road load, the accuracy shall conform to ISO 10521-1 and ISO 10521-2.

A.3 Driving procedure

A.3.1 General

The gear manipulation in each operational condition specified in Tables A.1 and A.2 shall be performed

smoothly and quickly in accordance with the instructions in this clause.

A.3.2 Vehicles with manual transmission

A.3.2.1 The idling operation refers to a condition in which the accelerator pedal is not depressed, with the

transmission gear in neutral.

A.3.2.2 The transmission gear shall be shifted to the low gear position (or such a gear in instances where

the “low” gear position should read otherwise in Tables A.1 and A.2) 5 s before the idling operation mode is

switched to the acceleration mode.

A.3.2.3 For deceleration, the clutch shall be disengaged at a speed of 10 km/h during the deceleration

operation from 20 km/h to 0 km/h, and at a speed of 20 km/h during the deceleration operation from 40 km/h

to 0 km/h, as specified in Tables A.1 and A.2. In the same way, the clutch shall be disengaged at a speed of

30 km/h during the deceleration operation from 70 km/h to 0 km/h, as specified in Table A.2.

A.3.2.4 On vehicles with a 6-speed transmission in which it is not possible to drive by operating the shift

lever in respective gear positions as specified in Table A.2 because of the running performance of the vehicle,

driving may be carried out in accordance with the example of the 5-speed transmission specified in Table A.2.

A.3.2.5 If the revolutions of the motor of the test vehicle exceed the revolution speed at which the motor

delivers its maximum output during the operation of the test vehicle, the gear position that is one step higher

than the original gear may be used. In this case, the vehicle speed at which the gearshift takes place shall be

the vehicle speed corresponding to the revolution speed at which the motor delivers its maximum output.

A.3.3 Vehicle with automatic transmission

The selector position shall remain in drive position. No further manipulation shall be made.

A.3.4 Vehicles with other transmissions

Gear changes shall be made taking into consideration the running characteristics of the tested vehicle with

transmissions other than those described in A.3.2 and A.3.3.

A.4 Vehicle test mass

The test vehicle mass shall be obtained when two persons (each of an assumed mass of 55 kg) or a mass of

110 kg are loaded on the test vehicle, under the “unloaded state” prescribed in the Safety Regulations for

Road Vehicles, Ministry of Transportation Ordinance No. 67, 1951, Article 1, paragraph 1, item (3).

A.5 Tyre conditioning

Tyres shall be conditioned as recommended by the vehicle manufacturer, shall have accumulated a minimum

of 100 km (62 miles) and shall have at least 50 % of the original usable tread depth remaining.

A.6 Dynamometer inertia setting

The equivalent inertia mass set for the chassis dynamometer shall be the standard value of equivalent inertia

mass specified in the right column of Table A.3, corresponding to the vehicle test mass specified in the left

column of Table A.3.

However, if the specified equivalent inertia mass is not available on the chassis dynamometer being used, the

equivalent inertia mass of within +10 % of the specified standard value may be used.

8 © ISO 2008 – All rights reserved

Table A.1 — Operation conditions, vehicle speed, acceleration/deceleration of 10 mode

Duration Acceleration

Mode Operation Vehicle Cumulative

of Standard gear positions or

no. conditions speed time

operation deceleration

(3+OD)-

3-speed 4-speed 5-speed

km/h s s speed m/s

transmission transmission transmission

transmission

1 idling — 20 20 — — — — —

a a

(0-15) Low (0-15) Low

a a

2 acceleration 0-20 7 27 (0-20) Low (0-20) Low 0,78

a a

(15-20) 2nd (15-20) 2nd

constant

3 20 15 42 2nd 2nd 2nd 2nd —

speed

4 deceleration 20-0 7 49 2nd 2nd 2nd 2nd 0,78

5 idling — 16 65 — — — — —

a a

(0-15) Low (0-15) Low

a a

(0-20) Low (0-20) Low

a a

6 acceleration 0-40 14 79 (15-30) 2nd (15-30) 2nd 0,78

a a

(20-40) 2nd (20-40) 2nd

a a

(30-40) 3rd (30-40) 3rd

constant

7 40 15 94 Top 3rd Top 4th —

speed

8 deceleration 40-20 10 104 Top 3rd Top 4th 0,59

constant

9 20 2 106 Top-2nd 3rd-2nd Top-3rd 4th-3rd —

speed

10 acceleration 20-40 12 118 2nd 2nd 3rd 3rd 0,49

40-20 10 128 Top 3rd Top 4th 0,59

11 deceleration

20-0 7 135 Top 3rd Top 4th 0,78

a

Figures in brackets represent vehicle speeds for respective gear positions.

Key

Y vehicle speed (km/h)

X time (s)

Figure A.1 — 10 Mode, vehicle speed versus time

Table A.2 — Operation conditions, vehicle speed, acceleration/deceleration of 15 mode

Duration Acceleration

Mode Operation Vehicle Cumulative

of Standard gear positions or

no. conditions speed time

operation deceleration

3-speed (3+OD)-speed 4-speed 5-speed 6-speed

km/h s s (m/s )

transmission transmission transmission transmission transmission

1 idling — 65 65 — — — — — —

a a a a a

(0-20) Low (0-20) Low (0-15) Low (0-15) Low (0-15) Low

a a a a a

2 acceleration 0-50 18 83 0,78

(20-40) 2nd (20-40) 2nd (15-35) 2nd (15-35) 2nd (15-35) 2nd

a a a a a

(40-50) Top (40-50) 3rd (35-50) 3rd (35-50) 3rd (35-50) 3rd

constant

3 50 12 95 Top 3rd Top 4th 4th —

speed

4 deceleration 50-40 4 99 Top 3rd Top 4th 4th 0,69

constant

5 40 4 103 Top 3rd 3rd 3rd 3rd —

speed

a

(40-50) 3rd

6 acceleration 40-60 16 119 Top 3rd 3rd 3rd 0,39

a

(50-60) 4th

constant

7 60 10 129 Top 3rd Top 4th 5th —

speed

8 acceleration 60-70 11 140 Top 3rd Top 4th 5th 0,29

constant

9 70 10 150 Top OD Top Top Top —

speed

10 deceleration 70-50 10 160 Top OD Top Top Top 0,59

constant

11 50 4 164 Top 3rd Top 4th 5th —

speed

12 acceleration 50-70 22 186 Top 3rd Top 4th 5th 0,29

constant

13 70 5 191 Top OD Top Top Top —

speed

70-30 20 211 Top OD Top Top Top 0,59

14 deceleration

30-0 10 221 — — — — — 0,88

15 idling — 10 231 — — — — — —

a

Figures in brackets represent vehicle speeds for respective gear positions.

Key

X time, s

Y vehicle speed, km/h

Figure A.2 — 15 Mode, vehicle speed versus time

10 © ISO 2008 – All rights reserved

Table A.3 — Standard value of equivalent inertia mass versus test vehicle mass

Test vehicle mass Standard value of equivalent inertia mass

m I

V

kg kg

m u 562 500

V

562 < m u 687 625

V

687 < m u 812 750

V

812 < m u 937 875

V

937 < m u 1 125 1 000

V

1 125 < m u 1 375 1 250

V

1 375 < m u 1 625 1 500

V

1 625 < m u 1 875 1 750

V

1 875 < m u 2 125 2 000

V

2 125 < m u 2 375 2 250

V

2 375 < m u 2 625 2 500

V

2 625 < m u 2 875 2 750

V

2 875 < m u 3 250 3 000

V

continues in increments of 500 kg continues in increments of 500 kg

A.7 Test procedure

A.7.1 Preconditioning for vehicle

The test vehicle shall be placed on the chassis dynamometer and warmed up continuously for about 20 min at

a constant speed of 60 ± 2 km/h. The vehicle shall then be further warmed up with 15 mode operation (as

shown in Table A.2) performed once.

A.7.2 Operating cycle

After the preconditioning, the operating cycle shall start with the idling operation for 24 s, then 10 mode

operation (as shown in Table A.1) shall be repeated 3 times consecutively, and 15 mode operation (as shown

in Table A.2) shall be performed once.

A.7.3 Tolerance of vehicle speed and time

The test vehicle shall be operated within a range of ±2 km/h of the specified speed, and within a range of ±1 s

of the specified time, during the operations specified in Tables A.1 and A.2. The tolerable range is shown in

the area marked in Figure A.3.

If the testing time deviates from the tolerance, but the deviation time is less than 1 s at the time of gear shift

and transition of operation mode, the test result is acceptable.

For those vehicles that cannot reach the acceleration specified in Tables A.1 and A.2 with full stroke of the

accelerator pedal, the aforesaid requirement shall not apply.

If the test vehicle cannot reach the level of acceleration specified in Tables A.1 and A.2, the acceleration

obtained from fully depressing the accelerator pedal shall be used.

Key

1 upper tolerable line

2 reference mode

3 lower tolerable line

4 reference point

Figure A.3 — Tolerance of vehicle speed and time in 10-15 driving mode

12 © ISO 2008 – All rights reserved

Annex B

(informative)

Test procedure in Europe

B.1 General

Based on the legal requirements in Europe, this annex specifies the specific preconditioning procedures and

relevant test equipment for the determination of hydrogen consumption of PFCV and FCHEV non-externally

chargeable, and with FCHEV mode only of categories M1 and N1 with a maximum permissible total mass (in

accordance with ISO 1176) of 3 500 kg.

NOTE The outline given in this annex contains only those elements essential to understanding the procedure. For

further details, reference is made to the relevant clauses and subclauses in the regulations UNECE R 101 and

1)

UNECE R 83.

B.2 Test equipment

B.2.1 Chassis dynamometer

Features, accuracy, load and inertia setting, calibration and other steps to prepare the chassis dynamometer

to be used are prescribed in UNECE R 83, Annex 4, 4.1, 5.1 and 5.2, and in Annex 4, Appendixes 2 and 3.

The adjustment of the inertia simulators to the vehicle's translatory inertias shall be in accordance with

Table B.1, given in UNECE R 83, Annex 4, 5.1.

B.2.2 Chassis dynamometer

Features, accuracy, load and inertia setting, calibration and other steps to prepare the chassis dynamometer

to be used are prescribed in UNECE R 83, Annex 4, 4.1, 5.1 and 5.2 and in Appendixes 2 and 3 of Annex 4.

The adjustment of the inertia simulators to the vehicle's translatory inertias shall be in accordance with

Table B.1 (as given in UNECE R 83, Annex 4, 5.1).

1) This annex is based on the following editions of the two regulations:

⎯ UNECE R 101: Trans/WP.29/GRPE/2004/2, 30 October 2003;

⎯ UNECE R 83: E/ECE/324 Rev.1/Add.82/Rev.2 E/ECE/Trans/505, 30 October 2001.

It does not necessarily reflect subsequent amendments to UNECE R 101 and UNECE R 83.

Table B.1 — Equivalent inertia of the dynamometer related to the reference mass of the vehicle

Reference mass of the vehicle Equivalent inertia

m I

V

kg kg

m u 480 455

V

480 < m u 540 510

V

540 < m u 595 570

V

595 < m u 650 625

V

650 < m u 710 680

V

710 < m u 765 740

V

765 < m u 850 800

V

850 < m u 965 910

V

965 < m u 1 080 1 020

V

1 080 < m u 1 190 1 130

V

1 190 < m u 1 305 1 250

V

1 305 < m u 1 420 1 360

V

1 420 < m u 1 530 1 470

V

1 530 < m u 1 640 1 590

V

1 640 < m u 1 760 1 700

V

1 760 < m u 1 870 1 810

V

1 870 < m u 1 980 1 930

V

1 980 < m u 2 100 2 040

V

2 100 < m u 2 210 2 150

V

2 210 < m u 2 380 2 270

V

2 380 < m u 2 610 2 270

V

2 610 < m 2 270

V

B.2.3 Test equipment for hydrogen measurement methods

For specific test equipment for the hydrogen measurement methods, see Clause 5 and Annexes D, E and F.

B.3 Test vehicle

B.3.1 General

The test vehicle shall be in running order, as determined by the manufacturer, with all the equipment provided

as standard.

B.3.2 Test mass

The mass of the vehicle under test (referred to as “reference mass” in UNECE R 83, 2.2) shall be the

“unloaded mass” plus a uniform figure of 100 kg. The “unloaded mass” (see UNECE R 83, 2.2.1) is the mass

of the vehicle in running order, without load and persons, but with the hydrogen tank 90 % full.

14 © ISO 2008 – All rights reserved

B.3.3 Tyres

The tests shall be performed with standard width tyres, as provided by the vehicle manufacturer. Alternatively,

the prescription of UNECE R 83, Annex 4, Appendix 3, 4.1.2, may be applied, i.e. only the widest of the

standard widths or the widest minus one (in case of more than three standard widths) shall be chosen.

The tyre pressure shall comply with the vehicle manufacturer specification, but may be increased by up to

50 % when the test is carried out on a two roller dynamometer (see UNECE R 83, Annex 4, 5.3.2).

B.4 Test cycle

The test cycle to be applied shall be the same as that prescribed for the Type I test. This test, including

allowable tolerances, is described in UNECE R 83, Annex 4, Appendix 1.

The test cycle is made up of one Part 1 (urban) cycle, consisting of four elementary urban cycles, and one

Part 2 (extra-urban) cycle, as illustrated roughly in Figure B.1 and described in Table B.2.

Key

X time, s

Y vehicle speed, km/h

1 Part 1 (urban) cycle

2 Part 2 (extra-urban) cycle

3 elementary urban cycle

Figure B.1 — Test cycle

Table B.2 — General information on the test cycle

Parameter Urban cycle Extra-urban cycle

Average speed 19 km/h 62,6 km/h

Maximum speed 50 km/h 120 km/h

Effective running time 4 × 195 s = 780 s (13 min) 400 s (6 min 40 s)

Theoretical distance 4 × 1 013 km = 4 052 km 6 955 km

B.5 Test procedure

B.5.1 Preconditioning of the vehicle

The vehicle shall be stabilized in accordance with the vehicle manufacturer’s specification, followed by two

consecutive full test cycles (see Clause B.4).

B.5.2 Conditioning of the vehicle

After preconditioning in accordance with B.5.1, the vehicle shall be kept in a room with a relative constant

temperature of between 20 °C and 30 °C for at least 6 h, until the lubricant and coolant temperatures are

within ±2 °C of the room temperature.

B.5.3 Performance of the test

B.5.3.1 General

After preconditioning and conditioning in accordance with B.5.1 and B.5.2, respectively, one complete test

cycle shall be run in accordance with Clause B.4. The test equipment shall comply with Clause B.2 and the

test vehicle shall comply with Clause B.3. The following requirements also shall be met during the test.

B.5.3.2 Additional conditions

The temperature shall be between 20 °C and 30 °C and the absolute humidity between 5,5 g and 12,2 g

H O/kg dry air.

B.5.3.3 Performing the different steps of the test cycle

The test shall be performed in accordance with the prescriptions of the vehicle manufacturer, starting with the

activation of the propulsion system and followed by applying the test cycle. To match the allowable tolerances

of the test cycle, the procedure recommended by the vehicle manufacturer should be applied.

The hydrogen consumption shall be measured using one of the methods described in Clause 5 and

Annexes D, E and F, respectively, and in the case of FCHEV it shall be corrected, if necessary.

16 © ISO 2008 – All rights reserved

Annex C

(informative)

Test procedure in the USA

C.1 Background

This annex describes the test procedure recommended for use in the USA and in other countries that use

SAE (Society of Automotive Engineers, Inc.) methods, for measuring fuel consumption and range of fuel cell

and hybrid fuel cell electric vehicles fuelled by compressed gaseous hydrogen. This annex makes reference to

SAE J2572:2006 as the specific governing document.

C.2 General

This annex prescribes the uniform chassis dynamometer test procedures for fuel cell and hybrid fuel cell

electric vehicles designed to be driven on public roads. Low speed vehicles are not covered in this annex.

Instructions are given for measuring and calculating the fuel consumption and range using two test types:

⎯ the “city” fuel consumption test using the Urban Dynamometer Driving Schedule (UDDS), and

⎯ the “highway” fuel consumption test using the Highway Fuel Economy Driving Schedule (HFEDS).

This annex covers only fuel cell vehicles fuelled with compressed gaseous hydrogen and hybrid fuel cell

electric vehicles, also fuelled with compressed gaseous hydrogen, and which have a rechargeable energy

storage system (RESS) (battery or capacitor).

C.3 General test information

C.3.1 Driving schedules

The driving schedules to be used for vehicle testing provided by the United States Environmental Protection

Agency (EPA) are the Urban Dynamometer Driving Schedule (UDDS) and the Highway Fuel Economy Driving

Schedule (HFEDS). The City Fuel Economy Test, which uses the UDDS, is detailed in SAE J2572:2006, 6.1.

The Highway Fuel Economy Test, which uses the HFEDS, is detailed in SAE J2572:2006, 6.2.

C.3.2 Battery state of charge

If the net energy of the battery/capacitor system increases or decreases by less than or equal to 1 % of the

total hydrogen energy consumed by the vehicle during the course of the test, the application of a correction

equation is not necessary, i.e. no correction calculation is necessary if

∆ stored electrical energy

u1%

total fuel energy consumed

where both the change in stored electrical energy (∆E ) and the total fuel (H ) energy consumed, reported

RESS 2

to one decimal point (e.g. 0,1 g), are expressed in units of energy (J). The lower net heating value for

hydrogen gas is used to convert the total hydrogen consumed into units of A·h, using a factor of 120 000 J/g.

Expressed in terms of the energy content of hydrogen per unit of weight, the calculation is as follows:

|∆ EM|u 0,01××120 000 (C.1)

RESS

where M is the total mass of hydrogen consumed over each phase of the test (MUDDS1, MUDDS2,

MHWFET), in g.

All mass values are reported to the nearest 0,1 g.

All distances are reported to the third decimal place (0,001 km).

All fuel consumption values are reported to the nearest 0,000 1 kg/km.

C.4 Test requirements

C.4.1 Vehicle condition

C.4.1.1 General

Prior to initiation of testing and during testing, the overall condition and configuration of the vehicle shall be as

delineated in SAE J2572:2006, 4.1 and subsequent subclauses, all of which are represented below.

C.4.1.2 Vehicle stabilization

Prior to testing, the test vehicle shall be stabilized as determined by the manufacturer to a minimum of

1 600 km (1 000 miles), but not more than 9 978 km (6 200 miles) using the durability driving schedule

specified in CFR Title 40, Part 86, Appendix IV, section (a), or an equivalent schedule. For all preparations

and testing, hydrogen complying with fuel specified by the SAE or the appropriate U.S. government agency

shall be used, and that fuel shall comply with the fuel quality guidance specified in SAE J2719.

C.4.1.3 Vehicle appendages

Vehicles shall be tested with normal appendages (mirrors, bumpers, etc.). Certain items (e.g. hub caps) may

be removed where necessary for safety on the dynamometer. If an off-board fuel source is used for the test,

the test vehicle may include a connector to receive the fuel from that source.

C.4.1.4 Accessories

All accessories shall be turned off.

C.4.1.5 Vehicle test mass

The vehicle shall be tested at loaded vehicle weight [curb weight plus 136 kg (300 lb)].

C.4.1.6 Tyres

Manufacturer's recommended tyres shall be used. For dynamometer testing, tyre pressures should be set at

the beginning of the test at the pressure used to establish the dynamometer road-load coefficients (see C.4.3)

and shall not exceed levels necessary for safe operation. Tyres shall be conditioned as recommended by the

vehicle manufacturer, have accumulated a minimum of 100 km (62 miles) and have at least 50 % of the

original usable tread depth remaining.

C.4.1.7 Lubricants

The vehicle lubricants normally specified by the manufacturer shall be used.

18 © ISO 2008 – All rights reserved

C.4.1.8 Regenerative braking

If the vehicle has regenerative braking, the regenerative braking system shall be enabled for all chassis

dynamometer testing, except for track coast down testing. If the regenerative braking level is adjustable, it

shall be set in accordance with the manufacturer’s specification prior to starting dynamometer testing.

Operation of the regenerative braking system shall not cause speed and time tolerances specified by the test

driving schedule to be exceeded.

C.4.1.9 Vehicle capability

The test vehicle shall be able to maintain the speed and distance tolerances required by the UDDS and

HFEDS schedules.

C.4.1.10 Fuel cell stack condition

The stack shall have been aged with the vehicle as detailed in C.4.1.2, or equivalent conditioning.

C.4.1.11 Propulsion battery/capacitor condition

The propulsion system battery/capacitor shall have been aged with the vehicle, as detailed in C.4.1.2, or

equivalent conditioning. The vehicle shall have an access point for measurement of current readings into and

out of the energy storage device. Reading from a vehicle onboard current measurement system may be used

provided that ±1 % NIST (National Institute of Standards and Technology) traceability can be demonstrated.

C.4.2 Environmental conditions

All test sequences shall be conducted with an ambient temperature within the range of 20 °C to 30 °C (68 °F

to 86 °F).

C.4.3 Dynamometer

Use of an electric 48-inch single roll chassis dynamometer, or equivalent, is required for fuel cell vehicle and

hybrid fuel cell electric vehicle testing. All factors concerning the dynamometer, specifically its capability

requirements, configuration, calibration, warm-up and settings, are presented in SAE J2572:2006, 4.5 and

subsequent subclauses, and these give further reference to other specific requirements as contained in

CFR Title 40, Part 86, section 135-90 (i). The determination of the dynamometer load coefficients shall be as

specified in SAE J2264.

C.4.4 Instrumentation

All instrumentation requirements for the test, including the list of instruments and instrument accuracy

requirements, are presented in SAE J2572:2006, 4.6 and subsequent subclauses. All instrumentation

calibration must be NIST traceable to within ±1,0% of the full scale of the appropriate range.

C.5 Required data collection

The data that must be collected regarding the vehicle, test conditions, instrumentation, fuel consumed and the

dynamometer type, settings and results, are detailed in SAE J2572:2006, 5.1, 5.2 and subsequent subclauses.

C.6 Testing the vehicle

C.6.1 General

The driving schedules provided by the U.S. Environmental Protection Agency (EPA) are u

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...