ISO 21498-2:2024

(Main)Electrically propelled road vehicles — Electrical specifications and tests for voltage class B systems and components — Part 2: Electrical tests for components

Electrically propelled road vehicles — Electrical specifications and tests for voltage class B systems and components — Part 2: Electrical tests for components

This document applies to voltage class B electric propulsion systems and connected auxiliary electric systems of electrically propelled road vehicles. It applies to electric circuits and components in these systems. This document focuses on the characteristics at the DC voltage class B terminals of these components as specified in ISO 21498-1. It describes testing methods, test conditions and test requirements for components exposed to electrical behaviour caused by the operation of electric loads and power sources. This document does not cover electrical safety (see ISO 6469-3 and the ISO 5474 series).

Véhicules à propulsion electrique — Spécifications et essais electriques pour les systèmes et composants de classe B — Partie 2: Composants et essais electriques

General Information

- Status

- Published

- Publication Date

- 21-Nov-2024

- Technical Committee

- ISO/TC 22/SC 37 - Electrically propelled vehicles

- Drafting Committee

- ISO/TC 22/SC 37 - Electrically propelled vehicles

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 31-Oct-2025

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 06-Jun-2022

Overview

ISO 21498-2:2024 - "Electrically propelled road vehicles - Electrical specifications and tests for voltage class B systems and components - Part 2: Electrical tests for components" defines electrical test methods, test conditions and pass/fail requirements for components connected to voltage class B DC systems in electrically propelled road vehicles. The document focuses on the characteristics at the DC voltage class B terminals (as specified in ISO 21498‑1) and addresses component behaviour caused by operation of electric loads and power sources. It explicitly excludes electrical safety testing (see related standards).

Key topics and technical requirements

This standard provides structured, repeatable electrical tests and related requirements, including:

- General test parameters - test setup, voltages, powers, temperatures, timing, wiring, sampling rates, data acquisition and documentation.

- DC supply variation - component performance across the operational DC voltage range.

- Generated voltage slope & immunity - behaviour when voltage changes with specific slopes and the component’s immunity to such transients.

- Voltage ripple & immunity - generated ripple characteristics and component robustness to ripple.

- Overvoltage and undervoltage - test procedures and requirements for excursions above and below nominal DC bus voltage.

- Voltage offset - effects of DC offsets on component function.

- Load dump and immunity to load dump - generated load-dump events and component tolerance.

- Short circuit - procedures to verify component response to short-circuit conditions.

- Supporting annexes - example EV electrical system diagrams, example values, artificial network specification and measurement setup guidance.

The standard defines test applicability, setups and measurement practices but does not provide electrical safety methods.

Applications and practical value

ISO 21498-2 is used to:

- Validate electrical performance and robustness of EV components (inverters, converters, sensors, controllers).

- Define repeatable laboratory test procedures for R&D and production validation.

- Support supplier and OEM contractual test requirements.

- Guide test-house and compliance lab test plans for voltage-class B DC equipment. Practical outcomes include improved system reliability, harmonized test evidence for procurement and reduced field failures related to DC electrical phenomena.

Who should use this standard

- EV OEMs and Tier‑1 suppliers designing voltage class B systems.

- Component manufacturers (power electronics, sensors, auxiliary units).

- Test laboratories and certification bodies developing electrical test protocols.

- Systems integrators and validation engineers responsible for DC bus behaviour.

Related standards

- ISO 21498‑1 - terminal characteristics and system-level specifications for voltage class B.

- ISO 6469‑3 and ISO 5474 series - electrical safety standards for electrically propelled road vehicles.

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

ISO 21498-2:2024 is a standard published by the International Organization for Standardization (ISO). Its full title is "Electrically propelled road vehicles — Electrical specifications and tests for voltage class B systems and components — Part 2: Electrical tests for components". This standard covers: This document applies to voltage class B electric propulsion systems and connected auxiliary electric systems of electrically propelled road vehicles. It applies to electric circuits and components in these systems. This document focuses on the characteristics at the DC voltage class B terminals of these components as specified in ISO 21498-1. It describes testing methods, test conditions and test requirements for components exposed to electrical behaviour caused by the operation of electric loads and power sources. This document does not cover electrical safety (see ISO 6469-3 and the ISO 5474 series).

This document applies to voltage class B electric propulsion systems and connected auxiliary electric systems of electrically propelled road vehicles. It applies to electric circuits and components in these systems. This document focuses on the characteristics at the DC voltage class B terminals of these components as specified in ISO 21498-1. It describes testing methods, test conditions and test requirements for components exposed to electrical behaviour caused by the operation of electric loads and power sources. This document does not cover electrical safety (see ISO 6469-3 and the ISO 5474 series).

ISO 21498-2:2024 is classified under the following ICS (International Classification for Standards) categories: 43.120 - Electric road vehicles. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 21498-2:2024 has the following relationships with other standards: It is inter standard links to ISO 21498-2:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 21498-2:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

International

Standard

ISO 21498-2

Second edition

Electrically propelled road

2024-11

vehicles — Electrical specifications

and tests for voltage class B systems

and components —

Part 2:

Electrical tests for components

Véhicules à propulsion electrique — Spécifications et essais

electriques pour les systèmes et composants de classe B —

Partie 2: Composants et essais electriques

Reference number

ISO 21498-2:2024(en)

© ISO 2024

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

ISO 21498-2:2024(en)

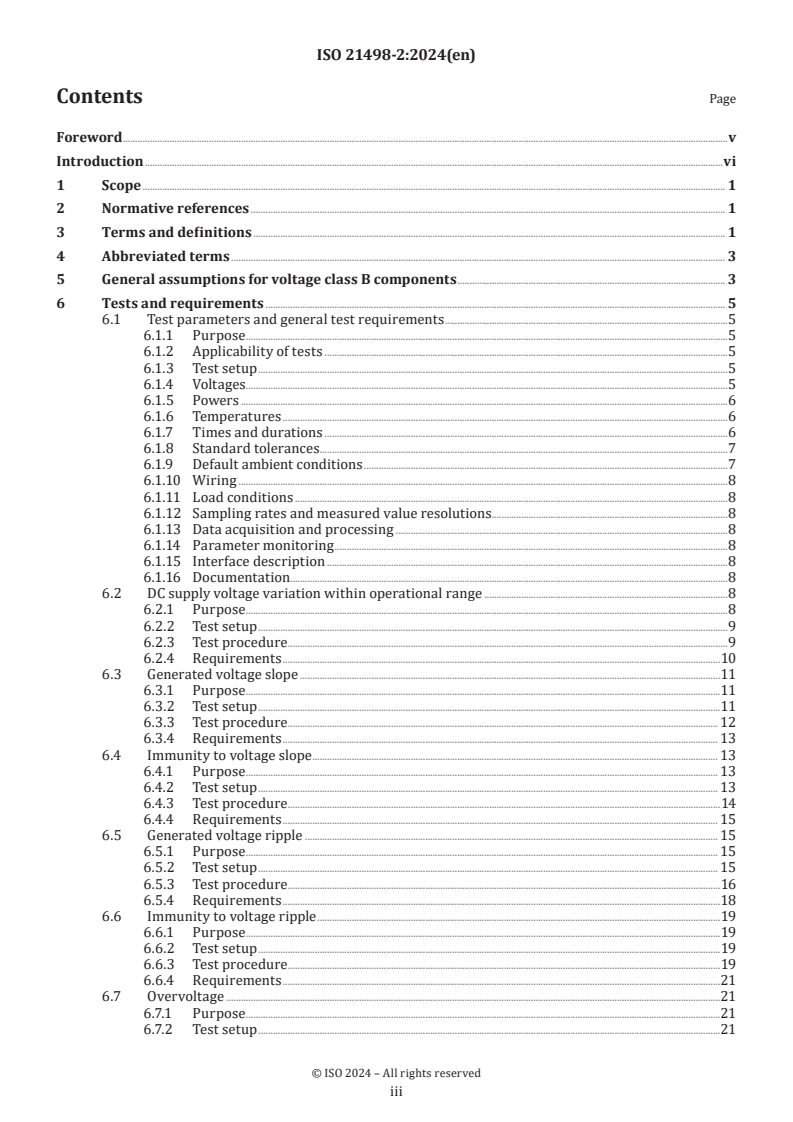

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Abbreviated terms . 3

5 General assumptions for voltage class B components . 3

6 Tests and requirements . 5

6.1 Test parameters and general test requirements .5

6.1.1 Purpose .5

6.1.2 Applicability of tests .5

6.1.3 Test setup .5

6.1.4 Voltages . .5

6.1.5 Powers .6

6.1.6 Temperatures .6

6.1.7 Times and durations .6

6.1.8 Standard tolerances . .7

6.1.9 Default ambient conditions .7

6.1.10 Wiring .8

6.1.11 Load conditions .8

6.1.12 Sampling rates and measured value resolutions.8

6.1.13 Data acquisition and processing .8

6.1.14 Parameter monitoring .8

6.1.15 Interface description .8

6.1.16 Documentation.8

6.2 DC supply voltage variation within operational range .8

6.2.1 Purpose .8

6.2.2 Test setup .9

6.2.3 Test procedure.9

6.2.4 Requirements .10

6.3 Generated voltage slope .11

6.3.1 Purpose .11

6.3.2 Test setup .11

6.3.3 Test procedure. 12

6.3.4 Requirements . 13

6.4 Immunity to voltage slope . 13

6.4.1 Purpose . 13

6.4.2 Test setup . 13

6.4.3 Test procedure.14

6.4.4 Requirements . 15

6.5 Generated voltage ripple . 15

6.5.1 Purpose . 15

6.5.2 Test setup . 15

6.5.3 Test procedure.16

6.5.4 Requirements .18

6.6 Immunity to voltage ripple .19

6.6.1 Purpose .19

6.6.2 Test setup .19

6.6.3 Test procedure.19

6.6.4 Requirements .21

6.7 Overvoltage .21

6.7.1 Purpose .21

6.7.2 Test setup .21

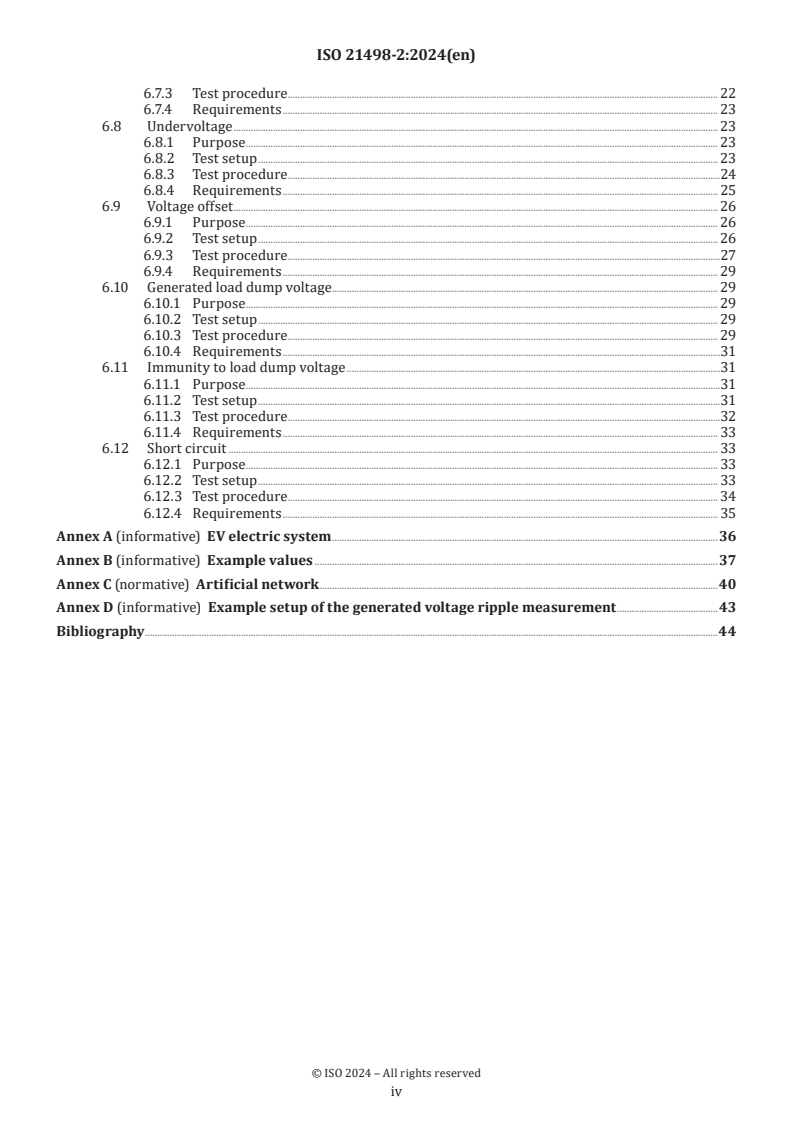

iii

ISO 21498-2:2024(en)

6.7.3 Test procedure. 22

6.7.4 Requirements . 23

6.8 Undervoltage . 23

6.8.1 Purpose . 23

6.8.2 Test setup . 23

6.8.3 Test procedure.24

6.8.4 Requirements . 25

6.9 Voltage offset . 26

6.9.1 Purpose . 26

6.9.2 Test setup . 26

6.9.3 Test procedure.27

6.9.4 Requirements . 29

6.10 Generated load dump voltage . . 29

6.10.1 Purpose . 29

6.10.2 Test setup . 29

6.10.3 Test procedure. 29

6.10.4 Requirements .31

6.11 Immunity to load dump voltage .31

6.11.1 Purpose .31

6.11.2 Test setup .31

6.11.3 Test procedure.32

6.11.4 Requirements . 33

6.12 Short circuit . 33

6.12.1 Purpose . 33

6.12.2 Test setup . 33

6.12.3 Test procedure. 34

6.12.4 Requirements . 35

Annex A (informative) EV electric system .36

Annex B (informative) Example values .37

Annex C (normative) Artificial network .40

Annex D (informative) Example setup of the generated voltage ripple measurement .43

Bibliography .44

iv

ISO 21498-2:2024(en)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee

has been established has the right to be represented on that committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely

with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types

of ISO document should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent

rights in respect thereof. As of the date of publication of this document, ISO had not received notice of (a)

patent(s) which may be required to implement this document. However, implementers are cautioned that

this may not represent the latest information, which may be obtained from the patent database available at

www.iso.org/patents. ISO shall not be held responsible for identifying any or all such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 37,

Electrically propelled vehicles.

This second edition cancels and replaces the first edition (ISO 21498-2:2021), which has been technically

revised.

The main changes are as follows:

— testcase “Short circuit” has been added;

— Annex B “Testing at different temperatures” has been deleted;

— additional values have been added in Tables B.2 and B.3;

— example current limit values have been added to Table B.4;

— Annex C has been revised;

— methods for conversion from time domain to frequency domain for generated ripple have been revised

and moved from main body to informative Annex D.

A list of all parts in the ISO 21498 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

v

ISO 21498-2:2024(en)

Introduction

The requirements for voltage class B electric circuits used for electric power transfer for the propulsion of

electric road vehicles and their characteristics are significantly different to those of voltage class A electric

circuits. Moreover, the range of voltage class B is too wide to be used for a component design relating to

voltage.

The ISO 21498 series divides voltage class B in a set of voltage sub-classes to enable a component design

for each voltage sub-class relating to voltage. It provides appropriate descriptions and definitions for

requirements and characteristics of voltage class B systems for electrically propelled vehicles.

The voltage sub-class itself and the component characteristics have a large cost impact on the component

design and on the overall design of the electric system. Additionally, a high variety of different voltage sub-

classes and operating conditions impedes the use of an existing component in different vehicle models.

Standardising voltage sub-classes and characteristics and reducing varieties cuts component and system

costs. This allows the decoupling of the system or component designs of a voltage class B electric circuit

from the design of the electric energy source. Finally, the exchange of components from different suppliers

for different customers is facilitated.

ISO 21498-1 provides definitions of and for voltage sub-classes and characteristics for rechargeable energy

storage systems (RESS) and electric propulsion systems. It defines specific values for these sub-classes

based on maximum working voltage. Voltage sub-classes listed in ISO 21498-1 are used for voltage class B

systems of all kinds of current or future electrically propelled road vehicles.

This document provides electrical tests for electric and electronic components at voltage class B used for

electrically propelled road vehicles. All relevant characteristics are covered considering usual driving

scenarios as well as deviations from normal operation. The descriptions are generalized and include

purpose, setup, procedure and requirements for the tests.

The specifications in this document are not intended to restrict the development of component performance

or technology. The given definition of sub-classes does not exclude the use of other maximum operating

voltages for an individual system design.

vi

International Standard ISO 21498-2:2024(en)

Electrically propelled road vehicles — Electrical

specifications and tests for voltage class B systems and

components —

Part 2:

Electrical tests for components

1 Scope

This document applies to voltage class B electric propulsion systems and connected auxiliary electric

systems of electrically propelled road vehicles. It applies to electric circuits and components in these

systems.

This document focuses on the characteristics at the DC voltage class B terminals of these components as

specified in ISO 21498-1. It describes testing methods, test conditions and test requirements for components

exposed to electrical behaviour caused by the operation of electric loads and power sources.

This document does not cover electrical safety (see ISO 6469-3 and the ISO 5474 series).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the cited edition applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

ISO/TR 8713, Electrically propelled road vehicles — Vocabulary

ISO 21498-1, Electrically propelled road vehicles — Electrical specifications and tests for voltage class B systems

and components — Part 1: Voltage sub-classes and characteristics

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO/TR 8713 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

customer

party that is interested in using voltage class B (3.13) components or systems

[SOURCE: ISO 21498-1:2021, 3.2]

3.2

electric circuit

entire set of interconnected electric/electronic parts through which electrical current is designed to flow

under normal operating conditions

[SOURCE: ISO 21498-1:2021, 3.3]

ISO 21498-2:2024(en)

3.3

lower voltage limit

minimum voltage of a voltage class B (3.13) sub-class disregarding transients (3.10) and ripple (3.8)

[SOURCE: ISO 21498-1:2021, 3.4]

3.4

maximum working voltage

highest value of AC voltage (rms) or of DC voltage that can occur under any normal operating conditions

according to the customer's (3.1) specifications, disregarding transients (3.10) and ripple (3.8)

[SOURCE: ISO 21498-1:2021, 3.5]

3.5

operating status

General functional behaviour of components which depend directly on the voltage in voltage class B (3.13)

electric circuits (3.2)

[SOURCE: ISO 21498-1:2021, 3.1, modified — The term was originally "component operating status".]

3.6

power network

all components within voltage class B (3.13) DC network including their connections

[SOURCE: ISO 21498-1:2021, 3.6]

3.7

rechargeable energy storage system

RESS

rechargeable system that stores energy for delivery of electric energy for the electric drive

EXAMPLE Batteries, capacitors, flywheel.

[SOURCE: ISO 21498-1:2021, 3.7]

3.8

ripple

set of unwanted periodic deviations with respect to the average value of the measured or supplied quantity,

occurring at frequencies which can be related to that of components within a system

[SOURCE: ISO 21498-1:2021, 3.8]

3.9

supplier

party that provides voltage class B (3.13) components or systems

[SOURCE: ISO 21498-1:2021, 3.9]

3.10

transient

phenomenon or quantity which varies between two consecutive steady states during a short time interval

compared to the timescale of interest

[SOURCE: ISO 21498-1:2021, 3.10]

3.11

upper voltage limit

maximum voltage of a voltage class B (3.13) sub-class disregarding transients (3.10) and ripple (3.8)

Note 1 to entry: Maximum working voltages (3.4) within a voltage sub-class (3.15) are less than or equal to the upper

voltage limit.

[SOURCE: ISO 21498-1:2021, 3.11]

ISO 21498-2:2024(en)

3.12

voltage class A

classification of an electric component or circuit with a maximum working voltage (3.4) of ≤30 V AC (rms) or

≤60 V DC respectively

[SOURCE: ISO 21498-1:2021, 3.12]

3.13

voltage class B

classification of an electric component or circuit with a maximum working voltage (3.4) of (> 30 and ≤ 1 000) V

AC (rms) or (> 60 and ≤ 1 500) V DC respectively

[SOURCE: ISO 21498-1:2021, 3.13]

3.14

voltage range

general term covering voltage sub-class (3.15), working voltages (3.16) and deviations from working voltages

[SOURCE: ISO 21498-1:2021, 3.14]

3.15

voltage sub-class

classification of an electric component or circuit with a DC voltage within the voltage class B (3.13)

[SOURCE: ISO 21498-1:2021, 3.15]

3.16

working voltage

AC voltage (rms) or DC voltage that can occur in an electric system under normal operating conditions

according to the customer's (3.1) specifications, disregarding transients (3.10) and ripple (3.8)

[SOURCE: ISO 21498-1:2021, 3.16]

4 Abbreviated terms

DUT device under test

EV electrically propelled road vehicle

OS operating status

VCB voltage class B

VCA voltage class A

5 General assumptions for voltage class B components

General assumptions and definitions for voltage class B systems shall be in accordance with ISO 21498-1.

Figure 1 shows a generalized view on a voltage class B component. Some of the connections shown may not

be available for all voltage class B components. All voltage profiles or voltage values in this document refer to

the voltage between the “U +” and “U -” terminals of a voltage class B component, if not otherwise stated.

VCB VCB

Annex A gives an overview of typical components within an electrically propelled road vehicle.

A voltage class B component may have multiple interfaces for each type of voltage (see Figure 1: DC voltage

class B, AC voltage class B, voltage class A). For example, a DC/DC converter may interface to two voltage

class B electric circuits.

A voltage class B component may have multiple DC voltage class B terminals, which can be galvanically

separated. The tests described in this document shall be fulfilled for each of the DC voltage class B terminals.

ISO 21498-2:2024(en)

Key

1 VCB positive connection: U + 8 connection to further VCB component (e.g. AC or DC

VCB

power network)

a

2 VCB negative connection: U - DUT.

VCB

b

3 VCA power VCB circuit.

c

4 I/O and bus signals VCA circuit.

d

5 VCA terminal with direct connection to the Galvanic separation between VCA and VCB.

reference potential

e

6 reference potential VCB terminals under test.

7 connection to further VCB component (e.g. electric

motor)

Figure 1 — Generalized VCB component diagram

Figure 2 summarizes the voltage operating ranges and OS of a voltage class B component at its DC voltage

class B terminals. The overvoltage limit, the upper voltage limit and the lower voltage limit are properties of

the component.

Each voltage class B component shall have a voltage range in which it can be operated with its specified

performance (unlimited operating capability). All designated functions, including short-time overload

operations, shall be available. Within this voltage range, the component operates in OS1.

Above a maximum voltage, a component may reduce its performance as specified. This specified voltage is

called the maximum unlimited operating voltage (U ). The component shall provide its upper

max_unlimited_op

limited operating capability until the upper voltage limit (U ) is reached. In this case, the component

upper_limit

operates in OS2.

Above the upper voltage limit (U ), the component may derate or cut-off its performance for self-

upper_limit

protection. The component shall withstand this overvoltage until the overvoltage limit (U ) is

over_limit

reached. In this case, the component operates in OS3 or OS4.

A component shall perform in OS1 until the supply voltage drops to the minimum unlimited operating

voltage (U ). Between the minimum unlimited operating voltage (U ) and the

min_unlimited_op min_unlimited_op

lower voltage limit (U ), the component may reduce its performance as specified. In this case, the

lower_limit

component operates in OS2.

If the supply voltage is below U , the component may derate or cut-off its performance. In this case,

lower_limit

the component operates in OS3 or OS4.

ISO 21498-2:2024(en)

Figure 2 — Component voltage range and limits of corresponding OS

6 Tests and requirements

6.1 Test parameters and general test requirements

6.1.1 Purpose

In 6.1, the specification of test parameters are described, including tolerances and general test requirements.

Frequency, time and voltage levels used for the tests are also introduced.

6.1.2 Applicability of tests

Not all tests described in this document are applicable for all voltage class B components. The customer and

the supplier shall agree on the applicability of the individual tests for each component.

6.1.3 Test setup

The test setup shall provide appropriate interfaces, connections and loads to achieve representative

DUT operation and characteristics. Measurement of voltages shall be performed at the DC voltage class B

terminals of the DUT.

6.1.4 Voltages

Table 1 contains voltage definitions and their abbreviations.

ISO 21498-2:2024(en)

Table 1 — Voltage definitions and abbreviations

Test parameter Meaning

a

U Overvoltage limit

over_limit

a

U Upper voltage limit

upper_limit

a

U Lower voltage limit

lower_limit

b

U Maximum voltage for unlimited operating capability

max_unlimited_op

b

U Minimum voltage for unlimited operating capability

min_unlimited_op

U Initial voltage for all tests

init

U Voltage within voltage class B range

VCB

U DC part of the voltage U at the terminals of the DUT

VCB,DC VCB

U AC part of the voltage U at the terminals of the DUT (peak value)

VCB,AC VCB

U Peak-to-peak value of AC voltage

PP

U U at no load operation

VCB,Pidle VCB,DC

U U at peak power operation

VCB,Ppeak VCB,DC

U Voltage in the undervoltage range

m

a

Voltage defined in ISO 21498-1.

b

See Figure 2 for illustration. The unlimited operating capability is defined in ISO 21498-1.

6.1.5 Powers

Table 2 contains power definitions and their abbreviations.

Table 2 — Power definitions and abbreviations

Test parameter Meaning

P Continuous power of the DUT

cont

P Generated maximum power by the DUT

max_gen

P Maximum short-term power of the DUT

peak

P Power of the DUT during no load operation

idle

a

P Power request to the DUT

request

a

This value is related to the desired output power of the DUT. The actual set value may have another physical quantity (e.g.

current, speed, torque) depending on the DUT.

6.1.6 Temperatures

The tests in this document focus on the electrical behaviour of the component at the voltage class B terminals.

Thermal derating is not considered. All tests shall therefore be performed at ambient temperature.

If a component needs additional liquid cooling, the cooling system shall be chosen as such that the DUT’s

performance is not affected by thermal derating. Flow rate and coolant temperature shall be documented.

When performing the electric tests at different temperature levels, the customer and the supplier shall agree

on how these tests are to be performed, e.g. using a climate chamber or using a heat exchanger for the liquid

coolant.

6.1.7 Times and durations

Table 3 contains definitions of times and durations and their abbreviations.

ISO 21498-2:2024(en)

Table 3 — Times/duration definitions and abbreviations

Test parameter Meaning

t Fall time (e.g. of a voltage profile or a transient event)

f

t Hold time (e.g. of a voltage profile)

h

t Duration of P

idle idle

t Duration of P

peak peak

t Rise time (e.g. of a voltage profile or a transient event)

r

t Test duration

test

6.1.8 Standard tolerances

Unless otherwise specified, the tolerances outlined in Table 4 apply with accuracy as shown in Table 5.

The tolerances of the test equipment shall not lead to an OS change.

Tolerances shall only be applied in a way that requirements are not weakened.

Table 4 — Standard tolerances for test equipment

Test parameter Value

b

Amplitude of AC voltage 0 % to +5 % relating to the specified value

a

Capacitance ±10 % of specified component value

DC voltage ±0,2 % of U

upper_limit

a

Frequency of AC voltage ±1 % relating to the specified value

a

Inductance ±10 % of specified component value

a

Resistance ±10 % of specified component value

b

Time/duration 0 % to +5 % relating to the specified value

a

The specified value is given in the test description or in Annex B and Annex C.

b

The specified value is given in the test description. The value may not be below the given value.

Table 5 — Accuracy of measurement

Test parameter Value

DC voltage measurement ±0,5 % of U

upper_limit

a

AC voltage measurement ±1 % of U

VCB,AC

DC current measurement ±1 % of measured DC current or 100 mA, whichever is higher

AC current measurement ±3 % of measured AC current or 100 mA, whichever is

higher

a

For the U level, see Annex B.

VCB,AC

6.1.9 Default ambient conditions

Unless otherwise specified, the parameter values of ambient conditions outlined in Table 6 shall be used.

Table 6 — Default ambient conditions

Test parameter Value Remark

RT (23 ± 5) °C Room temperature

RH 25 % to 75 % Relative humidity

T RT Ambient temperature

amb

T According to specification or as agreed by the Coolant temperature

cool

customer and the supplier

ISO 21498-2:2024(en)

6.1.10 Wiring

The DUT shall be connected to the test setup using the following conditions. If there is an attached cable tail

at the DUT or a designated wiring, the test setup shall be connected at the end of the existing wiring. If not,

a cable with a maximum length of 2 m (straight and parallel if possible) shall be used to connect the DUT to

the test setup. The shielding of the wiring depends on DUT target configuration.

6.1.11 Load conditions

The DUT shall be connected to an appropriate load or source. For all tests, the DUT shall be operated at

continuous power, if not otherwise stated. If this condition can be reached at several operating points (e.g.

speed, torque), the customer and the supplier shall agree on an appropriate operating point.

If a component can consume and deliver electrical energy (e.g. a motor or generator), the component shall be

tested in both energy flow directions.

6.1.12 Sampling rates and measured value resolutions

The sampling rate, bandwidth and resolution of the measuring system shall be adapted for the respective

test. This document contains tests concerning DC operation only and tests concerning AC characteristics

within a frequency range from 10 Hz to 150 kHz.

6.1.13 Data acquisition and processing

Data acquisition is the measurement of electrical signals (e.g. voltage or current) and the conversion into

digital signals (acquired data).

Data processing is the processing of the acquired data, e.g. filtering. The processing can be done by the

measurement device or by post processing.

6.1.14 Parameter monitoring

All additional parameters to be monitored shall be defined for the relevant tests with their value ranges.

During the complete test, the parameters to be monitored shall be recorded. The data resulting from the

continuous parameter monitoring shall be examined for trends and drifting to detect abnormalities or

malfunctions of the component. For components with fault memory, the customer and the supplier shall

prior to the testing agree on which component behaviour to store during the test. The fault memory shall be

monitored and all entries shall be documented.

6.1.15 Interface description

A detailed description of the states and electrical properties of all interfaces (measuring setup and

component) shall be provided.

6.1.16 Documentation

For documentation, see individual requirements given during the test description.

6.2 DC supply voltage variation within operational range

6.2.1 Purpose

This test verifies that the voltage class B component can perform as specified when the DC voltage varies

in the range between the lower voltage limit and the upper voltage limit. The purpose is to emulate real

battery operation.

ISO 21498-2:2024(en)

6.2.2 Test setup

The test setup according to Figure 3 shall be used. The test setup consists of a variable voltage class B DC

power supply and the DUT. A profile for the voltage U is given in Figure 4.

VCB

Key

1 VCB positive connection: U + 8 current sensor (optional)

VCB

2 VCB negative connection: U - 9 voltage sensor (reference for U )

VCB VCB

a

3 VCA power DUT.

b

4 I/O and bus signals VCB circuit.

c

5 VCA terminal with direct connection to the VCA circuit.

reference potential

d

6 reference potential Wiring.

e

7 VCB DC power supply Measurement devices.

Figure 3 — Test setup for DC supply voltage variation within operational range

6.2.3 Test procedure

Install the DUT in a test setup according to Figure 3. Verify that all functions operate according to OS1 at a

voltage within the specification for unlimited operation (e.g. at U ).

init

Change the level of the voltage class B DC power supply so that U meets the voltage profile in Figure 4 and

VCB

Table 7.

If a DUT has no OS2 (i.e. U has the same value as U and/or U has the

max_unlimited_op upper_limit min_unlimited_op

same value as U ), the respective test procedures and test profiles shall be adapted accordingly. The

lower_limit

customer and the supplier shall agree on the adaptation.

The voltage U and relevant parameters to evaluate the OS shall be recorded during the test.

VCB

ISO 21498-2:2024(en)

Key

b

U voltage U

min_unlimited_op.

c

t time U

max_unlimited_op.

d

t fall time U

f upper_limit.

e

t hold time U

h over_limit.

f

t rise time U

r init.

a g

U One test cycle.

lower_limit.

Figure 4 — Voltage profile for DC supply voltage variation within operational range

Table 7 — Test parameters for DC supply voltage variation within operational range

Test parameter Value Remark

a

Voltage at start of test

U

UU+ / 2

()

init

maxu__nlimited op minu__nlimited op

t ≥30 s Hold time

h1

b

t |ΔU/Δt| ≤ 2 V/s Fall time, to be determined with |ΔU/Δt|

f

t ≥5 s Hold time

h2

b

t ΔU/Δt ≤ 2 V/s Rise time, to be determined with ΔU/Δt

r

t ≥10 s Hold time

h3

ΔU <1 V voltage increment of U

VCB,DC

n 1 Number of test cycles

a

Or as agreed by the customer and the supplier.

b

The voltage change rate may be faster if the DUT stays in stable operation.

6.2.4 Requirements

The DUT shall stay in OS1 for voltages equal to and in between U and U .

min_unlimited_op max_unlimited_op

ISO 21498-2:2024(en)

The DUT shall stay in OS2 for a voltage below U , but above or equal to U . After the

min_unlimited_op lower_limit

voltage returns to a level equal to or above U , the DUT shall enter OS1 and the specified

min_unlimited_op

performance shall be obtained again.

The DUT shall stay in OS2 for a voltage above U , but below or equal to U . After the

max_unlimited_op upper_limit

voltage returns to a level equal to or below U , the DUT shall enter OS1 and the specified

max_unlimited_op

performance shall be obtained again.

6.3 Generated voltage slope

6.3.1 Purpose

This test evaluates the generated voltage slope and confirms that it is within a specified maximum rate.

6.3.2 Test setup

For this test, a test setup according to Figure 5 shall be used. The test setup consists of the DUT, a variable

voltage class B DC power supply and an artificial network.

The artificial network emulates the dynamic behaviour of a vehicle power network including the internal

resistance of the battery/batteries. The

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...