ISO 22013:2021

(Main)Marine environment sensor performance — Specifications, testing and reporting — General requirements

Marine environment sensor performance — Specifications, testing and reporting — General requirements

This document defines terms, specifies test methods and provides reporting requirements for marine sensor specifications to ensure a consistent reporting by manufacturers. It is applicable to those devices known as conductivity-temperature-depth (CTDs), sound velocity probes, multi-parameter sondes and dissolved gas sensors, that measure parameters such as conductivity, temperature, pressure, sound speed, dissolved oxygen, turbidity, pH, and chlorophyll in seawater. It is also generally applicable to all marine environment instruments. NOTE 1: A CTD directly measures conductivity, temperature, and pressure. Depth is derived from pressure using an equation. NOTE 2: The term sound velocity probe is widely used to describe instruments that measure sound speed. In this document the term ?sound velocity is used when describing the type of sensor, and the term sound speed is used when describing the parameter or measurand, but these terms can be used interchangeably.

Navires et technologie maritime — Performances des capteurs marins

General Information

- Status

- Published

- Publication Date

- 25-Jan-2021

- Technical Committee

- ISO/TC 8/SC 13 - Marine technology

- Drafting Committee

- ISO/TC 8/SC 13/WG 2 - Ocean hydrometeorological observation

- Current Stage

- 9020 - International Standard under periodical review

- Start Date

- 15-Jan-2026

- Completion Date

- 15-Jan-2026

Overview - ISO 22013:2021 (Marine environment sensor performance)

ISO 22013:2021 defines general requirements for specifications, testing and reporting of marine environment sensors. It standardizes terms and test methods and sets reporting requirements so manufacturers produce consistent, comparable specifications for instruments such as CTDs (conductivity‑temperature‑depth), sound velocity probes, multi‑parameter sondes and dissolved gas sensors. The standard covers sensors measuring conductivity, temperature, pressure (depth), sound speed, dissolved oxygen, turbidity, pH, chlorophyll and is generally applicable to all marine environment instruments. Note: a CTD directly measures conductivity, temperature and pressure (depth is derived from pressure); the document uses both “sound velocity” and “sound speed” terminology.

Key topics and technical requirements

ISO 22013:2021 specifies how to define and test the following critical sensor attributes:

- Terms and definitions to ensure consistent vocabulary across manufacturers and test labs.

- Specifications including calibration, calibrated/measuring ranges, accuracy, resolution, response time, sample rate, and stability.

- Depth and pressure ratings (maximum depth, crush depth and pressure case void considerations).

- Mechanical properties such as wetted materials, exterior dimensions, mass and weights in air/freshwater/seawater, operating temperature range.

- Electrical requirements including input voltage, operating and startup power consumption.

- Interface and communications (electrical connections, communications protocols, galvanic isolation).

- Test methods covering calibration design, statistical analysis for precision and trueness (accuracy), resolution/noise characterization, response‑time experiments, stability and shelf‑life testing. ISO 22013 references established statistical guidance (e.g., ISO 5725) and provides experimental layouts and reporting formats.

- Publication and reporting: required content for datasheets, test reports and calibration certificates to ensure transparent manufacturer claims.

Applications and practical value

ISO 22013:2021 is practical for:

- Sensor manufacturers producing CTDs, sondes, dissolved‑gas and other marine probes - to create standardized datasheets and validation reports.

- Independent test laboratories conducting calibration, accuracy and stability tests following accepted experimental designs.

- Oceanographers, survey companies and environmental monitoring agencies selecting and specifying instruments based on verified performance metrics.

- Procurement and regulatory bodies requiring consistent, auditable sensor specifications for contracts and compliance.

Adopting ISO 22013 improves comparability of sensor data, helps reduce procurement risk, and supports reproducible environmental monitoring.

Related standards

- ISO 5725 (statistical methods for measurement accuracy) is referenced for precision and trueness assessment.

- Users should consult sector‑specific standards and calibration laboratory accreditation guidance when implementing ISO 22013 requirements.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Sponsored listings

Frequently Asked Questions

ISO 22013:2021 is a standard published by the International Organization for Standardization (ISO). Its full title is "Marine environment sensor performance — Specifications, testing and reporting — General requirements". This standard covers: This document defines terms, specifies test methods and provides reporting requirements for marine sensor specifications to ensure a consistent reporting by manufacturers. It is applicable to those devices known as conductivity-temperature-depth (CTDs), sound velocity probes, multi-parameter sondes and dissolved gas sensors, that measure parameters such as conductivity, temperature, pressure, sound speed, dissolved oxygen, turbidity, pH, and chlorophyll in seawater. It is also generally applicable to all marine environment instruments. NOTE 1: A CTD directly measures conductivity, temperature, and pressure. Depth is derived from pressure using an equation. NOTE 2: The term sound velocity probe is widely used to describe instruments that measure sound speed. In this document the term ?sound velocity is used when describing the type of sensor, and the term sound speed is used when describing the parameter or measurand, but these terms can be used interchangeably.

This document defines terms, specifies test methods and provides reporting requirements for marine sensor specifications to ensure a consistent reporting by manufacturers. It is applicable to those devices known as conductivity-temperature-depth (CTDs), sound velocity probes, multi-parameter sondes and dissolved gas sensors, that measure parameters such as conductivity, temperature, pressure, sound speed, dissolved oxygen, turbidity, pH, and chlorophyll in seawater. It is also generally applicable to all marine environment instruments. NOTE 1: A CTD directly measures conductivity, temperature, and pressure. Depth is derived from pressure using an equation. NOTE 2: The term sound velocity probe is widely used to describe instruments that measure sound speed. In this document the term ?sound velocity is used when describing the type of sensor, and the term sound speed is used when describing the parameter or measurand, but these terms can be used interchangeably.

ISO 22013:2021 is classified under the following ICS (International Classification for Standards) categories: 47.020.99 - Other standards related to shipbuilding and marine structures. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 22013:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 22013

First edition

2021-01

Marine environment sensor

performance — Specifications,

testing and reporting — General

requirements

Navires et technologie maritime — Performances des capteurs marins

Reference number

©

ISO 2021

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

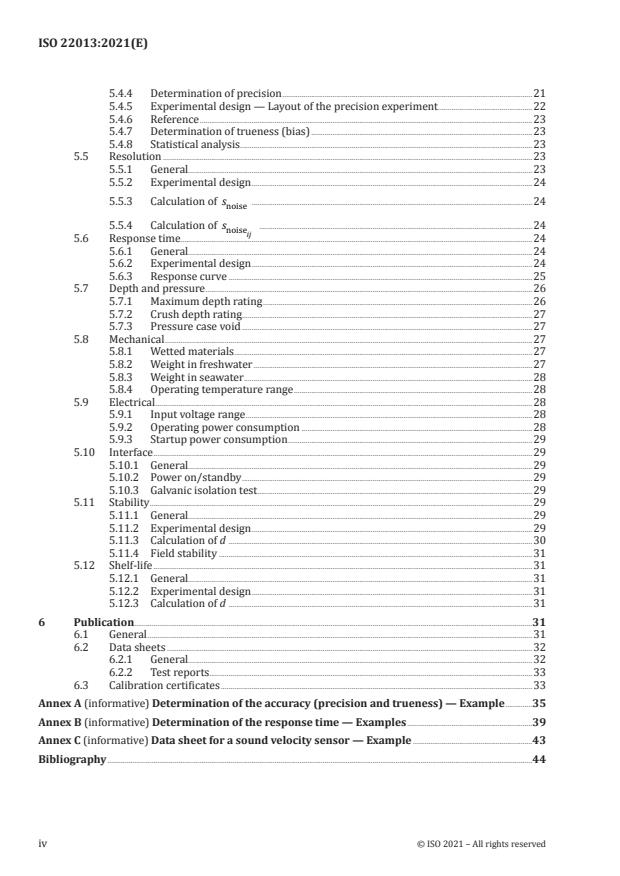

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Specifications .14

4.1 General .14

4.2 Calibration .14

4.3 Range .15

4.3.1 Calibrated range .15

4.3.2 Measuring range.15

4.3.3 Maximum range .15

4.4 Accuracy .15

4.5 Resolution .15

4.6 Response time.15

4.7 Depth and pressure .15

4.7.1 Maximum depth rating .15

4.7.2 Crush depth rating . . .15

4.8 Sample rate .15

4.9 Mechanical .15

4.9.1 Wetted materials .15

4.9.2 Exterior dimensions.16

4.9.3 Mass or weight in air .16

4.9.4 Weight in freshwater .16

4.9.5 Weight in seawater . .16

4.9.6 Operating temperature range .16

4.10 Electrical .16

4.10.1 Input voltage range .16

4.10.2 Operating power consumption .17

4.10.3 Startup power consumption .17

4.11 Interface .17

4.11.1 Electrical connections .17

4.11.2 Communications protocol.17

4.12 Stability .17

4.13 Shelf-life .18

5 Test methods .18

5.1 Overview .18

5.2 General experimental design .18

5.2.1 General.18

5.2.2 Sensor settings.18

5.2.3 Reference .18

5.2.4 Re-calibration .18

5.3 Calibration .18

5.3.1 General.18

5.3.2 Calibration method .19

5.3.3 Experimental design — Layout of the calibration .19

5.3.4 Calibration curve .19

5.3.5 Post-calibration operations .20

5.4 Accuracy .20

5.4.1 General.20

5.4.2 Modifications to ISO 5725 .20

5.4.3 Statistical model .21

5.4.4 Determination of precision .21

5.4.5 Experimental design — Layout of the precision experiment .22

5.4.6 Reference .23

5.4.7 Determination of trueness (bias) .23

5.4.8 Statistical analysis . .23

5.5 Resolution .23

5.5.1 General.23

5.5.2 Experimental design .24

5.5.3 Calculation of s . .24

noise

5.5.4 Calculation of s .24

noise

ij

5.6 Response time.24

5.6.1 General.24

5.6.2 Experimental design .24

5.6.3 Response curve .25

5.7 Depth and pressure .26

5.7.1 Maximum depth rating .26

5.7.2 Crush depth rating . . .27

5.7.3 Pressure case void .27

5.8 Mechanical .27

5.8.1 Wetted materials .27

5.8.2 Weight in freshwater .27

5.8.3 Weight in seawater . .28

5.8.4 Operating temperature range .28

5.9 Electrical .28

5.9.1 Input voltage range .28

5.9.2 Operating power consumption .28

5.9.3 Startup power consumption .29

5.10 Interface .29

5.10.1 General.29

5.10.2 Power on/standby .29

5.10.3 Galvanic isolation test . .29

5.11 Stability .29

5.11.1 General.29

5.11.2 Experimental design .29

5.11.3 Calculation of d .30

5.11.4 Field stability .31

5.12 Shelf-life .31

5.12.1 General.31

5.12.2 Experimental design .31

5.12.3 Calculation of d .31

6 Publication .31

6.1 General .31

6.2 Data sheets .32

6.2.1 General.32

6.2.2 Test reports.33

6.3 Calibration certificates .33

Annex A (informative) Determination of the accuracy (precision and trueness) — Example .35

Annex B (informative) Determination of the response time — Examples .39

Annex C (informative) Data sheet for a sound velocity sensor — Example .43

Bibliography .44

iv © ISO 2021 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2. www .iso .org/ directives

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received. www .iso .org/ patents

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 8, Ships and marine technology,

Subcommittee SC 13, Marine technology.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

Introduction

Oceans are intertwined with many of humanity’s priorities, including trade, food, energy, climate

and security. Understanding what’s going on below the sea surface is important for making decisions

around maritime boundaries, exploiting energy and mineral resources, expanding waterways, and

monitoring aquaculture. All depend on the availability of data produced by marine environment sensors

that measure physical, ecological and chemical parameters of seawater, such as salinity, temperature,

oxygen, carbon dioxide and acidity.

As an example of the growing importance of these data, marine business is increasingly mandated

by law to record them to meet environmental regulations. But common definitions for even basic

performance specifications of these sensors, such as accuracy or stability, don't exist. This weakens

the utility of the laws and diminishes confidence in sensor performance. It also acts to dampen the

market forces driving sensor innovation, as it is difficult for end-users to compare and reward true

breakthroughs from existing manufacturers, or to trust new entrants. This document aims to address

this by establishing a set of performance specifications common to all marine environment sensors,

including terms, definitions and test methods.

vi © ISO 2021 – All rights reserved

INTERNATIONAL STANDARD ISO 22013:2021(E)

Marine environment sensor performance — Specifications,

testing and reporting — General requirements

1 Scope

This document defines terms, specifies test methods and provides reporting requirements for marine

sensor specifications to ensure a consistent reporting by manufacturers.

It is applicable to those devices known as conductivity-temperature-depth (CTDs), sound velocity

probes, multi-parameter sondes and dissolved gas sensors, that measure parameters such as

conductivity, temperature, pressure, sound speed, dissolved oxygen, turbidity, pH, and chlorophyll in

seawater.

It is also generally applicable to all marine environment instruments.

NOTE 1 A ‘CTD’ directly measures conductivity, temperature, and pressure. Depth is derived from pressure

using an equation.

NOTE 2 The term ‘sound velocity probe’ is widely used to describe instruments that measure sound speed. In

this document the term ‘sound velocity’ is used when describing the type of sensor, and the term ‘sound speed’ is

used when describing the parameter or measurand, but these terms can be used interchangeably.

2 Normative references

The following documents are referred to in the text in such a way that some or all their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 5725-2:2019, Accuracy (trueness and precision) of measurement methods and results — Part 2: Basic

method for the determination of repeatability and reproducibility of a standard measurement method

ISO/IEC 17025:2017, General requirements for the competence of testing and calibration laboratories

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

quantity

parameter

property of a phenomenon, body, or substance, where the property has a magnitude that can be

expressed as a number and a reference

Note 1 to entry: A reference can be a measurement unit, a measurement procedure, a reference material, or a

combination of such.

EXAMPLE Pressure, P

[SOURCE: ISO/IEC Guide 99:2007, 1.1, modified — The admitted term “parameter” has been added.

All Notes have been removed except Note 2 to entry, renumbered as Note 1 to entry. The Example has

been added.]

3.2

derived quantity

quantity (3.1) that has been calculated from one or more measurements of other quantities

[8]

EXAMPLE Absolute salinity, S , is calculated from conductivity, temperature and pressure (IOC 56:2010) .

A

3.3

quantity value

value

number and reference together, expressing magnitude of a quantity (3.1)

EXAMPLE 1 Conductivity of a volume of seawater: 35 mS/cm or 3, 5 S/m

EXAMPLE 2 Sound speed of a volume of seawater: 1 500 m/s

[SOURCE: ISO/IEC Guide 99:2007, 1.19, modified — All Examples and Notes have been removed. New

Examples 1 and 2 have been added.]

3.4

measurand

quantity (3.1) intended to be measured

Note 1 to entry: The specification of a measurand requires knowledge of the kind of quantity, description of the

state of the phenomenon, body, or substance carrying the quantity, including any relevant component, and the

chemical entities involved.

Note 2 to entry: In the second edition of the VIM and in IEC 60050-300:2001, the measurand is defined as the

'particular quantity subject to measurement'.

Note 3 to entry: The measurement, including the measuring system and the conditions under which the

measurement is carried out, might change the phenomenon, body, or substance such that the quantity being

measured may differ from the measurand as defined. In this case, adequate correction is necessary.

EXAMPLE 1 The conductivity of a volume of seawater with the ambient Celsius temperature of 23 °C will be

different from the conductivity at the specified temperature of 20 °C, which is the measurand. In this case, a

correction is necessary.

EXAMPLE 2 The length of a steel rod in equilibrium with the ambient Celsius temperature of 23 °C will be

different from the length at the specified temperature of 20 °C, which is the measurand. In this case, a correction

is necessary.

[SOURCE: ISO/IEC Guide 99:2007, 2.3, modified — Note 4 has been removed. Example 2 has been

changed.]

3.5

measurement

process of experimentally obtaining one or more quantity values (3.3) that can reasonably be attributed

to a quantity (3.1)

[SOURCE: ISO/IEC Guide 99:2007, 2.1, modified — All Notes have been removed.]

3.6

measurement unit

unit

real scalar quantity (3.1), defined and adopted by convention, with which any other quantity of the same

kind can be compared to express the ratio of the two quantities as a number

Note 1 to entry: Measurement units are designated by conventionally assigned names and symbols.

2 © ISO 2021 – All rights reserved

Note 2 to entry: Measurement units of quantities of the same quantity dimension may be designated by the

same name and symbol even when the quantities are not of the same kind. For example, joule per kelvin and

J/K are respectively the name and symbol of both a measurement unit of heat capacity and a measurement

unit of entropy, which are generally not considered to be quantities of the same kind. However, in some cases

special measurement unit names are restricted to be used with quantities of a specific kind only. For example,

the measurement unit ‘second to the power minus one’ (1/s) is called hertz (Hz) when used for frequencies and

becquerel (Bq) when used for activities of radionuclides.

EXAMPLE 1 meters per second (m/s)

EXAMPLE 2 millisiemens percentimetre (mS/cm).

EXAMPLE 3 degrees Celsius (°C).

[SOURCE: ISO/IEC Guide 99:2007, 1.9, modified — Notes 3 and 4 have been removed. The Examples

have been added.]

3.7

measurement principle

principle of measurement

phenomenon serving as a basis of a measurement (3.5)

EXAMPLE 1 Thermoelectric effect applied to the measurement of temperature.

EXAMPLE 2 Photoluminescence effect applied to the measurement of dissolved oxygen.

[SOURCE: ISO/IEC Guide 99:2007, 2.4, modified — All original Examples and Notes have been removed.

New Examples 1 and 2 have been added.]

3.8

measurement result

set of quantity values (3.3) being attributed to a measurand (3.4) together with any other available

relevant information

Note 1 to entry: A measurement result generally contains “relevant information” about the set of quantity values,

such that some may be more representative of the measurand than others. This may be expressed in the form of

a probability density function (PDF).

Note 2 to entry: A measurement result is generally expressed as a single measured quantity value and a

measurement uncertainty. If the measurement uncertainty is considered negligible for some purpose, the

measurement result may be expressed as a single measured quantity value. In many fields, this is the common

way of expressing a measurement result.

[SOURCE: ISO/IEC Guide 99:2007, 2.9, modified — Note 3 has been removed.]

3.9

measurement accuracy

closeness of agreement between a measured quantity value and a true quantity value of a measurand (3.4)

Note 1 to entry: The concept "measurement accuracy" is not a quantity and is not given a numerical quantity

value. A measurement is said to be more accurate when it offers a smaller measurement error.

Note 2 to entry: The term "measurement accuracy" should not be used for measurement trueness and the term

"measurement precision" should not be used for 'measurement accuracy', which, however, is related to both

these concepts.

Note 3 to entry: "Measurement accuracy" is sometimes understood as closeness of agreement between measured

quantity values that are being attributed to the measurand.

Note 4 to entry: The admitted term “accuracy” has been removed to reduce ambiguation between the concept of

‘measurement accuracy’ described in ISO/IEC Guide 99, and the method for calculating a marine environment

sensor’s datasheet accuracy as described in 5.4.

[SOURCE: ISO/IEC Guide 99:2007, 2.13, modified — The admitted term “accuracy” has been removed.

Note 4 has been added.]

3.10

measurement trueness

trueness

closeness of agreement between the average of an infinite number of replicate measured quantity

values and a reference quantity value

Note 1 to entry: Measurement trueness is not a quantity and thus cannot be expressed numerically, but measures

for closeness of agreement are given in ISO 5725.

Note 2 to entry: Measurement trueness is inversely related to systematic measurement error, but is not related to

random measurement error.

Note 3 to entry: “Measurement accuracy” should not be used for 'measurement trueness'.

[SOURCE: ISO/IEC Guide 99:2007, 2.14]

3.11

measurement precision

precision

closeness of agreement between indications (3.27) or measured quantity values obtained by replicate

measurements (3.5) on the same or similar objects under specified conditions

Note 1 to entry: Measurement precision is usually expressed numerically by measures of imprecision, such as

standard deviation, variance, or coefficient of variation under the specified conditions of measurement.

Note 2 to entry: The 'specified conditions' can be, for example, repeatability conditions of measurement,

intermediate precision conditions of measurement, or reproducibility conditions of measurement (see

ISO 5725-1:1994).

Note 3 to entry: Measurement precision is used to define measurement repeatability, intermediate measurement

precision, and measurement reproducibility.

Note 4 to entry: Sometimes “measurement precision” is erroneously used to mean measurement accuracy.

[SOURCE: ISO/IEC Guide 99:2007, 2.15]

3.12

measurement error

error

measured quantity value minus a reference quantity value

Note 1 to entry: The concept of 'measurement error' can be used both a) when there is a single reference quantity

value to refer to, which occurs if a calibration is made by means of a measurement standard with a measured

quantity value having a negligible measurement uncertainty or if a conventional quantity value is given, in which

case the measurement error is known, and b) if a measurand is supposed to be represented by a unique true quantity

value or a set of true quantity values of negligible range, in which case the measurement error is not known.

Note 2 to entry: Measurement error should not be confused with production error or mistake.

[SOURCE: ISO/IEC Guide 99:2007, 2.16]

3.13

systematic measurement error

component of measurement error (3.12) that in replicate measurements (3.5) remains constant or varies

in a predictable manner

Note 1 to entry: A reference quantity value for a systematic measurement error is a true quantity value, or a

measured quantity value of a measurement standard of negligible measurement uncertainty, or a conventional

quantity value.

4 © ISO 2021 – All rights reserved

Note 2 to entry: Systematic measurement error, and its causes, can be known or unknown. A correction can be

applied to compensate for a known systematic measurement error.

Note 3 to entry: Systematic measurement error equals measurement error minus random measurement error.

[SOURCE: ISO/IEC Guide 99:2007, 2.17, modified — The admitted term “systematic error” has been

removed.]

3.14

measurement bias

bias

estimate of a systematic measurement error (3.13)

[SOURCE: ISO/IEC Guide 99:2007, 2.18]

3.15

repeatability condition of measurement

repeatability condition

condition of measurement, out of a set of conditions that includes the same measurement procedure,

same operators, same measuring system, same operating conditions and same location, and replicate

measurements (3.5) on the same or similar objects over a short period of time

[SOURCE: ISO/IEC Guide 99:2007, 2.20, modified — The Notes have been removed.]

3.16

intermediate precision condition of measurement

intermediate precision condition

condition of measurement, out of a set of conditions that includes the same measurement procedure,

same location, and replicate measurements (3.5) on the same or similar objects over an extended period

of time, but may include other conditions involving changes

Note 1 to entry: The changes can include new calibrations, calibrators, operators, and measuring systems.

[SOURCE: ISO/IEC Guide 99:2007, 2.22, modified — Notes 2 and 3 have been removed.]

3.17

reproducibility condition of measurement

reproducibility condition

condition of measurement, out of a set of conditions that includes different locations, operators,

measuring systems, and replicate measurements (3.5) on the same or similar objects

[SOURCE: ISO/IEC Guide 99:2007, 2.24, modified — The Notes have been removed.]

3.18

level of the test in a precision experiment

level

average of measurements (3.5) from all sensors (3.45) for one reference material or measurement

standard

[SOURCE: ISO 5725-1:1994, 3.3, modified — The admitted term "level" has been added. The definition

has been adapted.]

3.19

cell of a precision experiment

cell

measurement result (3.8) at a single level (3.18) obtained by one sensor (3.45)

[SOURCE: ISO 5725-1:1994, 3.4, modified — The admitted term "cell" has been added. The definition

has been adapted.]

3.20

measurement uncertainty

uncertainty

non-negative parameter characterizing the dispersion of the quantity values (3.3) being attributed to a

measurand (3.4), based on the information used

Note 1 to entry: Measurement uncertainty includes components arising from systematic effects, such as

components associated with corrections and the assigned quantity values of measurement standards, as well

as the definitional uncertainty. Sometimes estimated systematic effects are not corrected for but, instead,

associated measurement uncertainty components are incorporated.

Note 2 to entry: The parameter may be, for example, a standard deviation called standard measurement

uncertainty (or a specified multiple of it), or the half-width of an interval, having a stated coverage probability.

Note 3 to entry: Measurement uncertainty comprises, in general, many components. Some of these may be

evaluated by Type A evaluation of measurement uncertainty from the statistical distribution of the quantity

values from series of measurements and can be characterized by standard deviations. The other components,

which may be evaluated by Type B evaluation of measurement uncertainty, can also be characterized by standard

deviations, evaluated from probability density functions based on experience or other information.

Note 4 to entry: In general, for a given set of information, it is understood that the measurement uncertainty is

associated with a stated quantity value attributed to the measurand. A modification of this value results in a

modification of the associated uncertainty.

[SOURCE: ISO/IEC Guide 99:2007, 2.26]

3.21

standard measurement uncertainty

standard uncertainty

measurement uncertainty (3.20) expressed as a standard deviation

[SOURCE: ISO/IEC Guide 99:2007, 2.30]

3.22

combined standard uncertainty

combined uncertainty

standard uncertainty of the result of a measurement when that result is obtained from the values of a

number of other quantities (3.1), equal to the positive square root of a sum of terms, the terms being the

variances or covariances of these other quantities weighted according to how the measurement result

(3.8) varies with changes in these quantities

[SOURCE: ISO/IEC Guide 98-3:2008, 2.3.4, modified — The admitted term “combined uncertainty” has

been added.]

3.23

calibration

operation that establishes a relation between the quantity values (3.3) and corresponding indications

(3.27) of a sensor (3.45)

Note 1 to entry: A calibration may be expressed by a statement, calibration function, calibration diagram,

calibration curve, or calibration table. In some cases, it may consist of an additive or multiplicative correction of

the indication with associated measurement uncertainty.

Note 2 to entry: Calibration should not be confused with adjustment of a measurement system, often mistakenly

called “self-calibration”, nor with verification of the calibration.

Note 3 to entry: Often, the step of conducting the operation to establish a relation between quantity values and

corresponding sensor indications alone is already perceived as being calibration.

[SOURCE: ISO/IEC Guide 99:2007, 2.39, modified — The definition has been truncated for clarity.]

6 © ISO 2021 – All rights reserved

3.24

influence quantity

quantity (3.1) that, in a direct measurement, does not affect the quantity that is actually measured, but

affects the relation between the indication (3.27) and the measurement result (3.8)

EXAMPLE Temperature of the sound velocity sensor, but not the temperature of the surrounding seawater

which would enter into the definition of the measurand.

Note 1 to entry: An indirect measurement involves a combination of direct measurements, each of which may be

affected by influence quantities.

Note 2 to entry: In the GUM, the concept “influence quantity” is defined as in the second edition of the VIM,

covering not only the quantities affecting the measuring system, as in the definition above, but also those

quantities that affect the quantities actually measured. Also, in the GUM this concept is not restricted to direct

measurements.

[SOURCE: ISO/IEC Guide 99:2007, 2.52, modified — The original Examples have been removed, and a

new Example has been added.]

3.25

measuring system

set of one or more measuring instruments (3.47) and often other devices, including any reagent and

supply, assembled and adapted to give information used to generate measured quantity values within

specified intervals for quantities of specified kinds

Note 1 to entry: A measuring system may consist of only one measuring instrument.

[SOURCE: ISO/IEC Guide 99:2007, 3.2]

3.26

adjustment of a measuring system

adjustment

set of operations carried out on a measuring system so that it provides prescribed indications (3.27)

corresponding to given values (3.3) of a quantity (3.1) to be measured

Note 1 to entry: Types of adjustment of a measuring system include zero adjustment of a measuring system,

offset adjustment, and span adjustment (sometimes called gain adjustment)

Note 2 to entry: Adjustment of a measuring system should not be confused with calibration, which is a

prerequisite for adjustment.

Note 3 to entry: After an adjustment of a measuring system, the measuring system must usually be recalibrated.

[SOURCE: ISO/IEC Guide 99:2007, 3.11]

3.27

indication

signal

quantity value (3.3) provided by a sensor (3.45) or instrument (3.47)

Note 1 to entry: An indication may be presented in visual or acoustic form or may be transferred to another

device. An indication is often given by the position of a pointer on the display for analogue outputs, a displayed

or printed number for digital outputs, a code pattern for code outputs, or an assigned quantity value for material

measures.

Note 2 to entry: An indication and a corresponding value of the quantity being measured are not necessarily

values of quantities of the same kind.

[SOURCE: ISO/IEC Guide 99:2007, 4.1, modified — The admitted term “signal” has been added. In the

definition, the words “measuring instrument or a measuring system” have been replaced with “sensor

or instrument”.]

3.28

indication range

range

set of quantity values (3.3) bounded by extreme possible indications (3.27)

Note 1 to entry: An indication range is usually stated in terms of its smallest and greatest quantity values, for

example “0 mS/cm to 100 mS/cm”.

[SOURCE: ISO/IEC Guide 99:2007, 4.3, modified — The original term "indication interval" has been

replaced with "indication range" and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...