ISO/FDIS 21220

(Main)Particulate air filters for general ventilation — Determination of the filtration performance

Particulate air filters for general ventilation — Determination of the filtration performance

ISO 21220:2008 refers to particulate air filters for general ventilation. It describes testing methods and the test rig for measuring filter performance. The test rig is designed for an air flow rate between 0,25 m3/s (900 m3/h, 530 ft3/min) and 1,5 m3/s (5 400 m3/h, 3 178 ft3/min). ISO 21220:2008 applies to air filters having an initial efficiency of less than 99 % with respect to 0,4 µm particles. Filters in the higher end and above 99 % initial efficiency are tested and classified according to other standards. Two test methods are combined in ISO 21220:2008: a “fine method” for air filters in the higher efficiency range and a “coarse method” for lower efficiency filters. In either case, a flat sheet media sample or media pack sample from an identical filter shall be conditioned (discharged) to provide information about the intensity of the electrostatic removal mechanism. After determination of its initial efficiency, the untreated filter is loaded with synthetic dust in one step until its final test-pressure drop is reached. Information on the loaded performance of the filter is then obtained. The performance results obtained in accordance with ISO 21220:2008 cannot, by themselves, be quantitatively applied to predict performance in service with regard to efficiency and lifetime. It is necessary to take into account other factors influencing performance.

Filtres à air de ventilation générale pour l'élimination des particules — Détermination des performances de filtration

General Information

- Status

- Withdrawn

- Technical Committee

- ISO/TC 142 - Cleaning equipment for air and other gases

- Drafting Committee

- ISO/TC 142 - Cleaning equipment for air and other gases

- Current Stage

- 5098 - Project deleted

- Start Date

- 12-Mar-2009

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 17-Mar-2009

ISO/FDIS 21220 - Particulate air filters for general ventilation -- Determination of the filtration performance

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

NSF International

Global independent organization facilitating standards development and certification.

QAI Laboratories

Building and construction product testing and certification.

Sponsored listings

Frequently Asked Questions

ISO/FDIS 21220 is a draft published by the International Organization for Standardization (ISO). Its full title is "Particulate air filters for general ventilation — Determination of the filtration performance". This standard covers: ISO 21220:2008 refers to particulate air filters for general ventilation. It describes testing methods and the test rig for measuring filter performance. The test rig is designed for an air flow rate between 0,25 m3/s (900 m3/h, 530 ft3/min) and 1,5 m3/s (5 400 m3/h, 3 178 ft3/min). ISO 21220:2008 applies to air filters having an initial efficiency of less than 99 % with respect to 0,4 µm particles. Filters in the higher end and above 99 % initial efficiency are tested and classified according to other standards. Two test methods are combined in ISO 21220:2008: a “fine method” for air filters in the higher efficiency range and a “coarse method” for lower efficiency filters. In either case, a flat sheet media sample or media pack sample from an identical filter shall be conditioned (discharged) to provide information about the intensity of the electrostatic removal mechanism. After determination of its initial efficiency, the untreated filter is loaded with synthetic dust in one step until its final test-pressure drop is reached. Information on the loaded performance of the filter is then obtained. The performance results obtained in accordance with ISO 21220:2008 cannot, by themselves, be quantitatively applied to predict performance in service with regard to efficiency and lifetime. It is necessary to take into account other factors influencing performance.

ISO 21220:2008 refers to particulate air filters for general ventilation. It describes testing methods and the test rig for measuring filter performance. The test rig is designed for an air flow rate between 0,25 m3/s (900 m3/h, 530 ft3/min) and 1,5 m3/s (5 400 m3/h, 3 178 ft3/min). ISO 21220:2008 applies to air filters having an initial efficiency of less than 99 % with respect to 0,4 µm particles. Filters in the higher end and above 99 % initial efficiency are tested and classified according to other standards. Two test methods are combined in ISO 21220:2008: a “fine method” for air filters in the higher efficiency range and a “coarse method” for lower efficiency filters. In either case, a flat sheet media sample or media pack sample from an identical filter shall be conditioned (discharged) to provide information about the intensity of the electrostatic removal mechanism. After determination of its initial efficiency, the untreated filter is loaded with synthetic dust in one step until its final test-pressure drop is reached. Information on the loaded performance of the filter is then obtained. The performance results obtained in accordance with ISO 21220:2008 cannot, by themselves, be quantitatively applied to predict performance in service with regard to efficiency and lifetime. It is necessary to take into account other factors influencing performance.

ISO/FDIS 21220 is classified under the following ICS (International Classification for Standards) categories: 13.040.20 - Ambient atmospheres; 91.140.30 - Ventilation and air-conditioning systems. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/FDIS 21220 has the following relationships with other standards: It is inter standard links to ISO/TS 21220:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO/FDIS 21220 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

FINAL

INTERNATIONAL ISO/FDIS

DRAFT

STANDARD 21220

ISO/TC 142

Particulate air filters for general

Secretariat: UNI

ventilation — Determination of the

Voting begins on:

filtration performance

2008-07-15

Voting terminates on:

Filtres à air de ventilation générale pour l'élimination des particules —

2008-09-15

Détermination des performances de filtration

Please see the administrative notes on page iii

RECIPIENTS OF THIS DRAFT ARE INVITED TO

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPORT-

ING DOCUMENTATION.

IN ADDITION TO THEIR EVALUATION AS

Reference number

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO-

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN-

DARDS TO WHICH REFERENCE MAY BE MADE IN

©

NATIONAL REGULATIONS. ISO 2008

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

Copyright notice

This ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user's country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic,

photocopying, recording or otherwise, without prior written permission being secured.

Requests for permission to reproduce should be addressed to either ISO at the address below or ISO's

member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii © ISO 2008 – All rights reserved

In accordance with the provisions of Council Resolution 15/1993, this document is circulated in the

English language only.

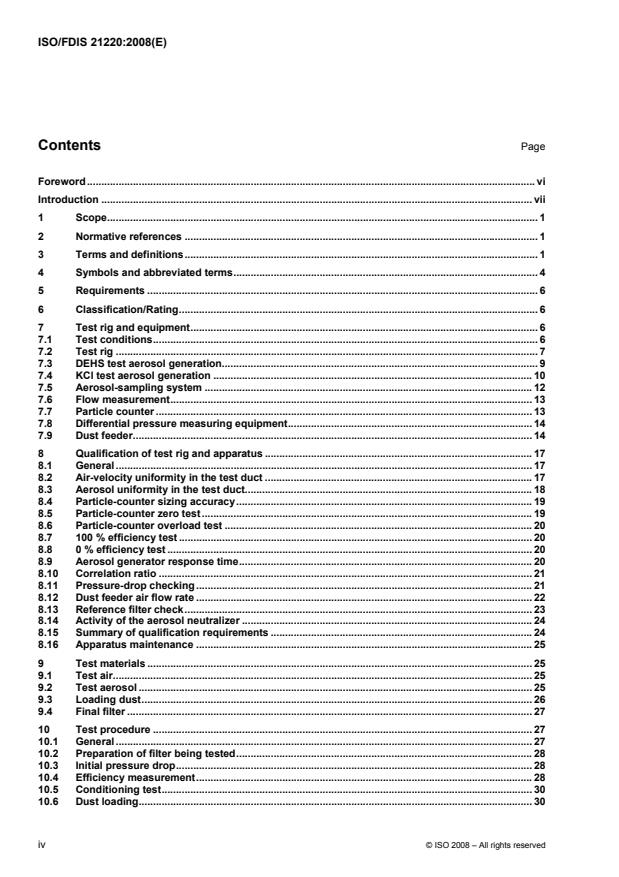

Contents Page

Foreword. vi

Introduction . vii

1 Scope. 1

2 Normative references . 1

3 Terms and definitions. 1

4 Symbols and abbreviated terms. 4

5 Requirements . 6

6 Classification/Rating. 6

7 Test rig and equipment. 6

7.1 Test conditions. 6

7.2 Test rig . 7

7.3 DEHS test aerosol generation. 9

7.4 KCl test aerosol generation . 10

7.5 Aerosol-sampling system . 12

7.6 Flow measurement. 13

7.7 Particle counter . 13

7.8 Differential pressure measuring equipment. 14

7.9 Dust feeder. 14

8 Qualification of test rig and apparatus . 17

8.1 General . 17

8.2 Air-velocity uniformity in the test duct . 17

8.3 Aerosol uniformity in the test duct. 18

8.4 Particle-counter sizing accuracy. 19

8.5 Particle-counter zero test. 19

8.6 Particle-counter overload test . 20

8.7 100 % efficiency test . 20

8.8 0 % efficiency test . 20

8.9 Aerosol generator response time. 20

8.10 Correlation ratio . 21

8.11 Pressure-drop checking . 21

8.12 Dust feeder air flow rate . 22

8.13 Reference filter check. 23

8.14 Activity of the aerosol neutralizer . 24

8.15 Summary of qualification requirements .24

8.16 Apparatus maintenance . 25

9 Test materials . 25

9.1 Test air. 25

9.2 Test aerosol . 25

9.3 Loading dust. 26

9.4 Final filter . 27

10 Test procedure . 27

10.1 General . 27

10.2 Preparation of filter being tested. 28

10.3 Initial pressure drop. 28

10.4 Efficiency measurement. 28

10.5 Conditioning test. 30

10.6 Dust loading. 30

iv © ISO 2008 – All rights reserved

11 Uncertainty calculation of the test results . 32

12 Reporting . 33

12.1 General. 33

12.2 Interpretation of test reports . 33

12.3 Summary. 34

12.4 Efficiency . 36

12.5 Pressure drop and air flow rate. 36

12.6 Marking . 36

Annex A (normative) Conditioning test procedure . 43

Annex B (informative) Shedding from filters . 47

Annex C (informative) Commentary . 49

Annex D (normative) Pressure-drop calculation . 54

Bibliography . 56

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 21220 was prepared by Technical Committee ISO/TC 142, Cleaning equipment for air and other gases.

vi © ISO 2008 – All rights reserved

Introduction

The procedures described in this International Standard have been developed from those given in EN 779 and

ANSI/ASHRAE 52.2 and includes testing of performance of air filters mainly used in general ventilation

applications.

Representative samples of particles upstream and downstream the filters are analysed by an optical particle

counter (OPC) to provide filter particle size efficiency data.

Classification or rating of air filters is determined by national bodies or other associations and is not a part of

this International Standard.

A brief principle description of the method is given in Annex C.

Initiatives to address certain filtration characteristics, such as the potential problems of particle re-entrainment,

shedding and the in-service charge neutralization characteristics of certain types of media, have been

included in Annexes A and B.

Certain types of filter media rely on electrostatic effects to achieve high efficiencies at low resistance to air

flow. Exposure to some types of challenge, such as combustion particles or other fine particles, can inhibit

such charges with the result that filter performance suffers. The normative test procedure, described in

Annex A, provides techniques for identifying this type of behaviour. This procedure is used to determine

whether the filter efficiency is dependent on the electrostatic removal mechanism and to provide quantitative

information about the importance of the electrostatic removal. The procedure is selected because it is well

established, reproducible, simple to perform, relatively quick and because an acceptable alternative procedure

is not available.

In an ideal filtration process, each particle would be permanently arrested at the first contact with a filter fibre,

but incoming particles can impact a captured particle and dislodge it into the air stream. Fibres or particles

from the filter itself can also be released, due to mechanical forces. From the user’s point of view, it can be

important to know this; see Annex B.

Annexes A and D form a normative part of this International Standard.

Annexes B and C are for information only.

FINAL DRAFT INTERNATIONAL STANDARD ISO/FDIS 21220:2008(E)

Particulate air filters for general ventilation — Determination

of the filtration performance

1 Scope

This International Standard refers to particulate air filters for general ventilation. It describes testing methods

and the test rig for measuring filter performance. The test rig is designed for an air flow rate between

3 3 3 3 3 3

0,25 m /s (900 m /h, 530 ft /min) and 1,5 m /s (5 400 m /h, 3 178 ft /min).

This International Standard applies to air filters having an initial efficiency of less than 99 % with respect to

0,4 µm particles. Filters in the higher end and above 99 % initial efficiency are tested and classified according

to other standards.

Two test methods are combined in this International Standard: a “fine method” for air filters in the higher

efficiency range and a “coarse method” for lower efficiency filters. In either case, a flat sheet media sample or

media pack sample from an identical filter shall be conditioned (discharged) to provide information about the

intensity of the electrostatic removal mechanism.

After determination of its initial efficiency, the untreated filter is loaded with synthetic dust in one step until its

final test-pressure drop is reached. Information on the loaded performance of the filter is then obtained.

The performance results obtained in accordance with this International Standard cannot, by themselves, be

quantitatively applied to predict performance in service with regard to efficiency and lifetime. It is necessary to

take into account other factors influencing performance, as described in Annexes A and B.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 2854, Statistical interpretation of data — Techniques of estimation and tests relating to means and

variances

ISO 5167-1, Measurement of fluid flow by means of pressure differential devices inserted in circular

cross-section conduits running full — Part 1: General principles and requirements

3 Terms and definitions

3.1

arrestance

weighted (mass) removal of loading dust

3.2

average arrestance

ratio of the total amount of loading dust retained by the filter to the total amount of dust fed up to final test

pressure drop

3.3

charged filter

filter in which the filter media is electrostatically charged or polarized

3.4

conditioned efficiency

efficiency of the conditioned filter media operating at an average media velocity corresponding to the test air

flow rate in the filter

3.5

counting rate

number of counting events per unit of time

3.6

correlation ratio

ratio of downstream to upstream particle counts without the test filter in the test duct

3.7

DEHS

DES

liquid di(2-ethylhexyl)sebacate or bis(2-ethylhexyl)sebacate used for generating the DEHS test aerosol

See 9.2.1.

3.8

dust-holding capacity (deprecated)

See test dust capacity (3.35).

3.9

dust-loaded efficiency

efficiency of the filter operating at test flow rate and after dust loadings up to final test pressure drop

3.10

effective filtering area

area of filter medium in the filter that collects dust

3.11

efficiency

See initial efficiency (3.17), conditioned efficiency (3.4) or dust-loaded efficiency (3.9).

3.12

filter-face area

frontal face area of the filter including the header frame

NOTE The nominal values are 0,61 m × 0,61 m (24 in × 24 in).

3.13

filter-face velocity

air flow rate divided by the filter-face area

3.14

final filter

air filter used to collect the loading dust passing through or shedding from the filter under test

3.15

final pressure drop, recommended

maximum operating pressure drop of the filter as recommended by the manufacturer at rated air flow

2 © ISO 2008 – All rights reserved

3.16

final test pressure drop

pressure drop of the filter up to which the filtration performance is measured

3.17

initial efficiency

efficiency of the clean, untreated filter operating at the test air flow rate

3.18

initial pressure drop

pressure drop of the clean filter operating at the test air flow rate

3.19

isokinetic sampling

sampling of the air within a duct under conditions such that the probe inlet air velocity is the same as the

velocity in the duct at the sampling point

3.20

KCl

solid KCl (potassium chloride) particles generated from an aqueous solution and used as test aerosol

3.21

loading dust

test dust specifically formulated for loading of the filter

NOTE Two types of loading dusts are used: ISO fine test dust is used for the loading of filters in accordance with the

fine-dust method and ASHRAE dust is used for the filters tested in accordance with the coarse method.

3.22

mean diameter

geometric mean of the upper- and lower-limit diameters in a size range

3.23

medium velocity

air flow rate divided by the effective filtering area

NOTE The medium velocity is expressed to an accuracy of three significant figures.

3.24

minimum efficiency

lowest efficiency among the initial, conditioned or dust-loaded efficiencies

3.25

neutralization

bringing the aerosol to a Boltzmann charge equilibrium distribution with bipolar ions

3.26

particle bounce

behaviour of particles that impinge on the filter without being retained

3.27

particle size

equivalent optical diameter of a particle

3.28

particle-number concentration

number of particles per unit volume of the test air

3.29

penetration

ratio of the particle concentration downstream to that upstream of the filter

3.30

re-entrainment

releasing of particles previously collected on the filter into the air flow

3.31

shedding

releasing of particles into the air flow due to particle bounce and re-entrainment as well as the release of fibres

or particulate matter from the filter or filtering material

3.32

synthetic test dust

See loading dust (3.21).

3.33

test air flow rate

volumetric rate of air flow through the filter under test

3.34

test aerosol

aerosol used for determining the efficiency of the filter

3.35

test dust capacity

TDC

amount of loading dust kept by the filter at final test pressure drop

4 Symbols and abbreviated terms

For the application of this International Standard, the following symbols and abbreviated terms apply.

A Arrestance, expressed in percent

A Average arrestance during test to final test pressure drop, expressed in percent

m

ANSI American National Standards Institute

ASHRAE American Society of Heating, Refrigerating and Air Conditioning Engineers

ASTM American Society for Testing and Materials

CL Concentration limits of particle counter

C Coefficient of variation

V

C Coefficient of variation in size range, i

V,i

c Subscript indicating that the sample is conditioned

c Mean of measuring points value for size range, i

mean,i

CAS Chemical Abstracts Service

CEN European Committee for Standardization

d Geometric mean of a size range, expressed in micrometres

i

d Lower-limit diameter in a size range, expressed in micrometres

l

d Upper-limit diameter in a size range, expressed in micrometres

u

DHC Dust holding capacity, replaced by test dust capacity, TDC

4 © ISO 2008 – All rights reserved

Average efficiency in a size range, i

E

i

Average efficiency of conditioned samples in size range, i

E

i,c

Efficiency of conditioned sample “s” in size range, i

E

is,c,

Average initial efficiency of untreated samples in size range, i

E

i,u

Initial efficiency of untreated sample “s” in size range, i

E

is,u,

EN European Standard

EUROVENT European Committee of Air Handling and Refrigeration Equipment Manufacturers

ISO International Organization for Standardization

IPA Isopropanol

i Subscript indicating the size range

m Mass passing filter, expressed in grams

m Mass of dust downstream of the test filter, expressed in grams

d

m Cumulative mass of dust fed to filter, expressed in grams

tot

m Mass of final filter before dust increment, expressed in grams

m Mass of final filter after dust increment, expressed in grams

N Number of particles upstream of the filter

u

N Number of particles in size range, i, upstream of the filter

u,i

N Number of points

N Number of particles downstream of the filter

d

N Number of particles in size range, i, downstream of the filter

d,i

N Average number of particles downstream of the filter

d

N Number of particles upstream of the filter

u

N Number of particles in size range, i, upstream of the filter

u,i

N Average number of particles upstream of the filter

u

n Exponent; see Annex D

OPC Optical particle counter

p Pressure, expressed in pascals [inches water, gauge (inWG)]

p Absolute air pressure upstream of filter, expressed in kilopascals [inches water, gauge (inWG)]

a

p Average pressure drop of conditioned samples

c

p Pressure drop of conditioned sample “s”

c,s

p Air flow meter static pressure, expressed in kilopascals (pounds per square inch)

sf

p Average initial pressure drop of untreated samples

u

p Pressure drop of untreated sample “s”

u,s

PAO Polyalphaolefins

q Mass flow rate at air flow meter, expressed in kilograms per second (pounds per second)

m

q Air flow rate at filter, expressed in cubic metres per second (cubic feet per minute)

V

q Air flow rate at air flow meter, expressed in cubic metres per second (cubic feet per minute)

Vf

R Correlation ratio

R Correlation ratio for size range, i

i

s Subscript indicating sample number (1, 2, 3, .)

T Temperature upstream of filter, expressed in degrees Celsius (degrees Fahrenheit)

T Temperature at air flow meter, expressed in degrees Celsius (degrees Fahrenheit)

f

Distribution variable

t

α

1−

()

TDC Test dust capacity, expressed in grams

U Uncertainty, expressed in percent

v Mean value of velocity, expressed in metres per second (feet per minute)

mean

δ Standard deviation

ν Number of degrees of freedom

ρ Air density, expressed in kilograms per cubic metre (pounds per cubic foot)

ϕ Relative humidity upstream of filter, expressed in percent

∆m Dust increment, expressed in grams

∆m Mass gain of final filter, expressed in grams

ff

∆p Filter pressure drop, expressed in pascals [inches water, gauge (inWG)]

∆p Air flow meter differential pressure, expressed in pascals [inches water, gauge (inWG)]

f

∆p Filter pressure drop at air density 1,20 kg/m , expressed in pascals [inches water, gauge (inWG)]

1,20

5 Requirements

The filter shall be designed or marked so as to prevent incorrect mounting. The filter shall be designed so that,

when correctly mounted in the ventilation duct, no air/dust leaks occur around the exterior filter frame and the

duct sealing surfaces.

The complete filter (filter and frame) shall be made of material suitable to withstand normal usage and

exposure to the range of temperature, humidity and corrosive environments likely to be encountered in service.

The complete filter shall be designed so that it can withstand mechanical constraints that are likely to be

encountered during normal use. Dust or fibre released from the filter media by air flow through the filter shall

not constitute a hazard or nuisance for the people (or devices) exposed to filtered air.

6 Classification/Rating

Filters are not classified or rated in this International Standard.

3 3 3

Many national and association bodies use 0,944 m /s (2 000 ft /min or 3 400 m /h) as nominal air flow for

classification or rating of air filters that have a nominal face area of 0,61 m × 0,61 m (24 in × 24 in). It is,

therefore, recommended to test filters at 0,944 m /s (if the manufacturer does not specify any other flow for

another application). The air flow velocity associated with the volumetric flow is 2,54 m/s (500 ft/min).

7 Test rig and equipment

7.1 Test conditions

Room air or outdoor air may be used as the test air source. Relative humidity shall be less than 65 % for the

KCl efficiency measurement and less than 75 % in other tests. The exhaust flow may be discharged outdoors,

indoors or recirculated. Requirements of certain measuring equipment can impose limits on the temperature of

the test air.

6 © ISO 2008 – All rights reserved

Filtration of the exhaust flow is recommended when test aerosol, loading dust or smell from the filter can be

present.

7.2 Test rig

The test rig (see Figure 1) consists of several square duct sections with 610 mm × 610 mm (24 in × 24 in)

nominal inner dimensions except for the section where the filter is installed. This section has nominal inner

dimensions between 616 mm (24,25 in) and 622 mm (24,50 in). The length of this duct section shall be at

least 1,1 times the length of the filter, with a minimum length of 1 m (39,4 in).

The duct material shall be electrically conductive and electrically grounded, shall have a smooth interior finish

and shall be sufficiently rigid to maintain its shape at the operating pressure. Smaller parts of the test duct

may be made in glass or plastic to see the filter and equipment. Provision of windows to allow monitoring of

test progress is desirable.

High-efficiency filters (Figure 1, key item 7) shall be placed upstream of the duct section 1 (Figure 1, key

item 1), where the aerosol for efficiency testing is dispersed and mixed to create a uniform concentration

upstream the filter.

The mixing orifice (Figure 1, key item 10) is located in the upstream part of duct section 2 (Figure 1, key

item 2), in the centre of which is located the dust feeder discharge nozzle. Downstream of the dust feeder is a

perforated plate (Figure 1, key item 11) intended to achieve a uniform dust distribution. In the last third of this

duct section is the upstream aerosol sample head. For dust-loading tests, this sampling head shall be blanked

off or removed.

Key

1 duct section 1 of the test rig (entry plenum) 8 inlet point for DEHS particles

2 duct section 2 of the test rig 9 dust injection nozzle

3 filter being tested 10 mixing orifice

4 duct section 3 including the filter to be tested 11 perforated plate

5 duct section 4 of the test rig 12 upstream sampling head

6 duct section 5 of the test rig 13 downstream sampling head

7 high-efficiency filter (at least 99,97 % on 0,3 µm particles)

Figure 1 — Schematic diagram of the test rig

To avoid turbulence, the mixing orifice and the perforated plate should be removed during the efficiency test.

To avoid systematic error, removal of these items during pressure-drop measurements is recommended.

Duct section 4 (Figure 1, key item 5), which may be used for both efficiency and dust-loading measurements,

is fitted with a final filter for the loading test and with the downstream sampling head for the efficiency test.

This duct section can also be duplicated, allowing one part to be used for the loading test and the other for the

efficiency test.

The test rig can be operated in either a negative or a positive pressure air flow arrangement. In the case of

positive pressure, operation (i.e. with the fan upstream the test rig), the test aerosol and loading dust can leak

into the laboratory, while at negative pressure, particles can leak into the test system and affect the number of

measured particles. These possible air leaks shall be located and sealed prior to filter tests.

The dimensions of the test rig and the position of the pressure taps are shown in Figure 2. Additional duct

details are shown in Figure 3.

The pressure drop of the tested filter shall be measured using static pressure taps that shall be provided at

four points over the periphery of the duct and connected together by a ring line.

The entry plenum and the relative location of high efficiency filters and aerosol injections are discretionary and

a bend in the duct is optional, thereby allowing both a straight duct and a U-shaped duct configuration. Except

for the bend itself, all dimensions and components are the same for the straight and U-shaped configurations.

A downstream mixing baffle shall be included in the duct after the bend.

NOTE The purpose of the mixing baffle is to straighten out the flow and mix any aerosol that is downstream of the

bend.

Dimensions in millimetres

Figure 2 — Dimensions of the test rig

8 © ISO 2008 – All rights reserved

Dimensions in millimetres unless otherwise specified

Key

1 mixing orifice

2 perforated plate with Ø 152 mm ± 2 mm and 40 % open area

3 pressure tap

4 transition duct for a test filter smaller than the duct

5 transition duct for a test filter larger than the duct

Figure 3 — Details of test duct components

7.3 DEHS test aerosol generation

The test aerosol shall consist of untreated and undiluted DEHS, or other aerosols in accordance with 9.2. The

test aerosol of diethylhexylsebacate (DEHS) produced by a Laskin nozzle aerosol generator is widely used in

performance testing of high-efficiency filters.

Figure 4 gives an example of a system for generating the aerosol. It consists of a small container with DEHS

liquid and a Laskin nozzle. The aerosol is generated by feeding compressed, particle-free air through the

Laskin nozzle. The atomized droplets are then directly introduced into the test rig. The pressure and air flow to

the nozzle are varied according to the test flow and the required aerosol concentration. For a test flow of

3 3 2

0,944 m /s (2 000 ft /min) the pressure is about 17 kPa (2,5 lb/in ), corresponding to an air flow of about

3 3 3

0,39 dm /s (1,4 m /h, 0,82 ft /min) through the nozzle.

Dimensions in millimetres

Key

1 particle-free air (pressure about 17 kPa) (2,5 lb/in )

2 aerosol to test rig

3 Laskin nozzle

4 test aerosol (for instance DEHS)

5 four ∅ 1,0 mm holes 90° apart at the top edge of the holes and just touching the bottom of the collar

6 four ∅ 2,0 mm holes next to tube in line with radial holes

Figure 4 — DEHS particle-generation system

Any other generator capable of producing droplets in sufficient concentrations in the size range of 0,3 µm to

1,0 µm can be used.

Before testing, regulate the upstream concentration to reach a steady state and to have a concentration below

the coincidence level of the particle counter.

7.4 KCl test aerosol generation

The test aerosol is solid-phase, dry potassium chloride (KCl) in particulate form generated from an aqueous

solution.

The aerosol is generated by nebulizing an aqueous KCl solution with an external-mixing-air atomizing nozzle

illustrated in Figure 5. The spray nozzle is operated at a relatively low air pressure to keep the particle

concentrations in the duct below the coincidence error concentration limit of the particle counter.

The nozzle is positioned at the top of a 305 mm (12 in) diameter, 1 300 mm (51 in) high transparent acrylic

spray tower. The tall tower serves two purposes: it allows the salt droplets to dry by providing an

approximately 40 s mean residence time, and it allows larger-sized particles to fall out of the aerosol.

10 © ISO 2008 – All rights reserved

An aerosol neutralizer reduces the charge level on the aerosol until the level is equivalent to a Boltzmann

charge distribution.

A Boltzmann charge distribution is the average charge found in the ambient air. Electrostatic charging is an

unavoidable consequence of most aerosol generation methods.

Key

1 clean, dry, compressed-air source

2 air control panel (rotometers with needle valve and outlet pressure gauge)

3 99,97 % efficiency filters (0,3 µm)

3 3

4 atomizing air 0,000 5 m /s (1 ft /min) nominal (adjusted speed)

5 air atomizing nozzle

6 spray tower 305 mm (12 in.) diam., 1 300 mm (51 in) high

7 metering pump 1,2 ml/min, 30 % mass fraction solution KCl in water

8 aerosol charger neutralizer

9 disk 152 mm (6 in) OD to create turbulence in the air stream and mix the aerosol

3 3

10 drying air 0,0019 m /s (4 ft /min)

11 tube 38 mm (1,5 in) ID with outlet towards the air stream

Figure 5 — Schematic diagram of the KCl particle generator system

The aerosol is injected in the entry plenum and counter to the airflow to improve the mixing of the aerosol with

the air stream.

The KCl solution is prepared by combining 300 g of KCl with 1 kg of distilled water. The solution is fed to the

atomizing nozzle at 1,2 ml/min by a metering pump. Varying the operating air pressure of the generator allows

control of the challenge aerosol concentration.

7.5 Aerosol-sampling system

Figure 6 gives an example of a aerosol-sampling system. Two sample lines of equal length and equivalent

geometry (bends and straight lengths) shall connect the upstream and downstream sampling heads to the

particle counter. The sample tubes shall be electrically conducting or have a high dielectric constant. The

tubing shall have a smooth inside surface (steel, tygon, etc.).

Key

1 filter

2 high-efficiency filter (clean air)

3 valve, upstream

4 valve, clean air

5 valve, downstream

6 computer

7 particle counter

8 pump

Figure 6 — Schematic diagram of the aerosol-sampling system

Tapered sampling probes are placed in the centre of the upstream and downstream measuring sections. The

sampling heads shall be centrally located with the inlet tip facing the inlet of the rig parallel to the air flow. The

3 3

sampling shall be isokinetic within 10 % at a test flow rate of 0,944 m /s (2 000 ft /min).

Three, one-way valves make it possible to sample the aerosol upstream or downstream of the filter under test,

or to have a “blank” suction through a high-efficiency filter. These valves shall be of a straight-through design.

Due to possible particle losses from the sampling system, the first measurement after a valve is switched

should be ignored.

The flow rate can be maintained by the pump in the counter in the case of a particle counter with a high flow

−3 3 3

rate (e.g. 0,47 × 10 m /s) (1 ft /min) or by an auxiliary pump in the case of a counter with smaller sample

flow rates. The exhaust line (to the pump) shall then be fitted with an isokinetic sampling nozzle directly

connected to the particle counter to achieve isokinetic conditions within a tolerance of ± 10 %.

Particle losses occur in the test duct, aerosol transport lines and particle counter. Minimization of particle

losses is desirable because a smaller number of counted particles means larger statistical errors and, thus,

less accurate results. The influence of particle losses on the result is minimized if the upstream and

downstream sampling losses are made as nearly equal as possible.

12 © ISO 2008 – All rights reserved

7.6 Flow measurement

Flow measurement shall be made by standardized flow measuring devices in accordance with ISO 5167-1.

Examples are orifice plates, nozzles, Venturi tubes, etc.

The uncertainty of measurement shall not exceed 5 % of the measured value at the 95 % confidence level.

7.7 Particle counter

This method requires the use of an optical particle counter (OPC) having a particle size range of at least

0,3 µm to 5,5 µm or two counters covering the size range 0,3 µm to 1,2 µm and 1 µm to 5,5 µm. The counting

efficiency shall be 50 % ± 20 % for calibration particles with a size close to the minimum detectable size, and it

shall be 100 % ± 10 % for calibration particles which are 1,5 to 2 times larger than the minimum detectable

particle size. Each size range shall be divided into at least five size classes, the boundaries of which should

be approximately equidistant on a logarithmic scale. If a single counter is used to cover the entire size range,

a minimum of eight size classes is required.

The number of particle size measurements enables the user to generate a curve of efficiency vs. particle size

data covering at least the 0,3 µm to 5,5 µm particle size range. The efficiency can then be calculated (by

interpolation) for any given geometric particle size, for example, 0,4 µm, 1 µm, 1,5 µm, 2,5 µm and 5 µm.

The efficiency measurements may be made with one particle counter sampling sequentially upstream and

downstream or may be performed with two particle counters sampling simultaneously. If two particle counters

are used, it is necessary that they be closely matched in design and sampling flow rate.

Clause 8 contains further information and details about the calibration and operation of the OPCs used for this

test.

An example of how a single or dual particle-counter system can be configured is shown below.

Dual counter example

Geometric mean diameter

Counter 1 Channel boundaries

of the range

Fine range

µm µm

Class 1 0,3 to 0,4 0,35

Class 2 0,4 to 0,52 0,46

Class 3 0,52 to 0,7 0,6

Class 4 0,7 to 0,9 0,8

Class 5 0,9 to 1,2 1,0

Geometric mean diameter

Counter 2 Channel boundaries

of the range

Coarse range

µm µm

Class 1 1,0 to 1,4 1,2

Class 2 1,4 to 2,0 1,7

Class 3 2,0 to 2,8 2,4

Class 4 2,8 to 4,0 3,4

Class 5 4,0 to 5,5 4,7

Single counter example

Geometric mean diameter

Channel boundaries

of the range

Complete range

µm µm

Class 1 0,3 to 0,45 0,4

Class 2 0,45 to 0,65 0,5

Class 3 0,65 to 1,0 0,8

Class 4 1,0 to 1,5 1,2

Class 5 1,5 to 2,2 1,8

Class 6 2,2 to 3,0 2,6

Class 7 3,0 to 4,0 3,5

Class 8 4,0 to 5,5 4,7

7.8 Differential pressure measuring equipment

Measurements of pressure drop shall be taken between measuring points located in the duct wall as shown in

Figure 2. Each measuring point shall be comprised of four interconnected static taps equally distributed

around the periphery of the duct cross section.

The pressure-measuring equipment used shall be capable of measuring pressure differences with an

accuracy of ± 2 Pa (± 0,01 inWG) in the range of 0 Pa to 70 Pa (0,28 inWG). Above 70 Pa (0,28 inWG), the

accuracy shall be ± 3 % of the measured value.

7.9 Dust feeder

The purpose of the dust feeder is to supply the synthetic dust to the filter under test at a constant rate over the

test period. The general design of the dust feeder and its critical dimensions are given in Figure 7 and

Figure 8. Any dust feeder can be chosen as long as it gives the same test result as the described dust feeder.

The angle between the dust pickup tube and dust feed trough is 90° in the figure but could be less in real

application. A certain mass of dust previously weighed is loaded into the mobile dust feeder tray. The tray

moves at a uniform speed and the dust is taken up by a paddle wheel and carried to the slot of the dust pickup

tube of the ejector.

The ejector disperses the dust with compressed air and directs it into the test rig through the dust feed tube.

The dust injection nozzle shall be positioned at the entrance of duct section 2 and be collinear with the duct

centre line.

Backflow of air through the pickup tube from the positive duct pressure shall be prevented when the feeder is

not in use.

The degree of dust dispersion by the feeder is dependent on the characteristics of the compressed air, the

geometry of the aspirator assembly and the rate of air flow through the aspirator. The aspirator Venturi is

subject to wear from the aspirated dust and will become enlarged with use. Its dimension shall be monitored

periodically to ensure that the tolerances shown in Figure 8 are met.

The gauge pressure on the air line t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...