ISO/IEC TR 24720:2008

(Main)Information technology — Automatic identification and data capture techniques — Guidelines for direct part marking (DPM)

Information technology — Automatic identification and data capture techniques — Guidelines for direct part marking (DPM)

ISO/IEC TR 24720:2008 describes several methods for applying permanent machine-readable symbols to items - including components, parts and products - using the direct part marking (DPM) methods outlined herein. ISO/IEC TR 24720:2008 describes marking methods, marking surface preparation, marking location, protective coatings and other parameters that contribute to the production of quality symbols, but does not specify the information to be encoded.

Technologies de l'information — Techniques automatiques d'identification et de capture des données — Lignes directrices pour DPM ("direct part marking")

General Information

- Status

- Published

- Publication Date

- 21-May-2008

- Technical Committee

- ISO/IEC JTC 1/SC 31 - Automatic identification and data capture techniques

- Drafting Committee

- ISO/IEC JTC 1/SC 31/WG 1 - Data carrier

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 11-Jun-2021

- Completion Date

- 12-Feb-2026

Overview

ISO/IEC TR 24720:2008 - "Information technology - Automatic identification and data capture techniques - Guidelines for direct part marking (DPM)" is a Technical Report that documents methods and practical guidance for applying permanent machine‑readable symbols directly to parts. Published in 2008 as a type‑3 Technical Report, it surveys both intrusive (subtractive) and non‑intrusive (additive) DPM techniques, explains preparation and inspection considerations, and addresses equipment and imaging approaches. It does not prescribe what data to encode in marks.

Key topics and requirements

The report covers the following technical topics and practical requirements:

DPM methods

- Intrusive: e.g., direct laser marking, dot peen, chemical etch, engraving (marks alter the part surface).

- Non‑intrusive: e.g., ink jet, laser bonding, screen printing, cast/forge (marks add material or are produced in manufacture).

Marking method selection - guidance on choosing techniques based on material, geometry, and lifecycle needs.

Surface preparation and cleaning - assessing marking surfaces and recommended preparation steps to achieve consistent symbol quality.

Protective coatings - considerations for coatings that affect durability and readability of marks.

Marking location and human‑readable elements - placing marks for reliable scanning and for complementary human interpretation.

Symbol quality, reading, grading and verification - approaches for measuring symbol quality, recommended verifier/imager setup, and equipment configurations (fixed‑mount, presentation, handheld imagers).

Imager types and system considerations - factors in selecting and deploying imagers for DPM applications.

Informative annexes - deeper discussion of specific technologies such as laser marking, dot peen, ink jet, and manufacturing‑integrated approaches (e.g., casting, weaving).

Practical applications

ISO/IEC TR 24720 is intended to support reliable part identification across manufacturing and product lifecycles, including:

- Traceability and serialization of components and assemblies

- Error‑proofing and process control on production lines

- Durable identification for harsh environments where labels are unsuitable

- marking of PCBs and hard materials where specific methods are preferred

Keywords: direct part marking, DPM, laser marking, dot peen, ink jet, machine‑readable symbols, part traceability, AIDC.

Who should use this standard

- Manufacturing and design engineers specifying part identification

- Quality and inspection engineers defining symbol verification and grading procedures

- AIDC integrators and systems architects deploying scanner/imager solutions

- Suppliers of marking equipment (laser, dot‑peen, ink‑jet) and protective coatings

- Supply chain and traceability managers seeking durable, automated identification methods

Related standards

- ISO/IEC 19762‑1 and ISO/IEC 19762‑2 (harmonized vocabulary for AIDC and optically readable media) - normative references cited by the report.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

NYCE

Mexican standards and certification body.

Sponsored listings

Frequently Asked Questions

ISO/IEC TR 24720:2008 is a technical report published by the International Organization for Standardization (ISO). Its full title is "Information technology — Automatic identification and data capture techniques — Guidelines for direct part marking (DPM)". This standard covers: ISO/IEC TR 24720:2008 describes several methods for applying permanent machine-readable symbols to items - including components, parts and products - using the direct part marking (DPM) methods outlined herein. ISO/IEC TR 24720:2008 describes marking methods, marking surface preparation, marking location, protective coatings and other parameters that contribute to the production of quality symbols, but does not specify the information to be encoded.

ISO/IEC TR 24720:2008 describes several methods for applying permanent machine-readable symbols to items - including components, parts and products - using the direct part marking (DPM) methods outlined herein. ISO/IEC TR 24720:2008 describes marking methods, marking surface preparation, marking location, protective coatings and other parameters that contribute to the production of quality symbols, but does not specify the information to be encoded.

ISO/IEC TR 24720:2008 is classified under the following ICS (International Classification for Standards) categories: 35.040 - Information coding; 35.040.50 - Automatic identification and data capture techniques. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/IEC TR 24720:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

TECHNICAL ISO/IEC

REPORT TR

First edition

2008-06-01

Information technology — Automatic

identification and data capture

techniques — Guidelines for direct part

marking (DPM)

Technologies de l'information — Techniques automatiques

d'identification et de capture des données — Lignes directrices pour

DPM («direct part marking»)

Reference number

©

ISO/IEC 2008

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO/IEC 2008

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO/IEC 2008 – All rights reserved

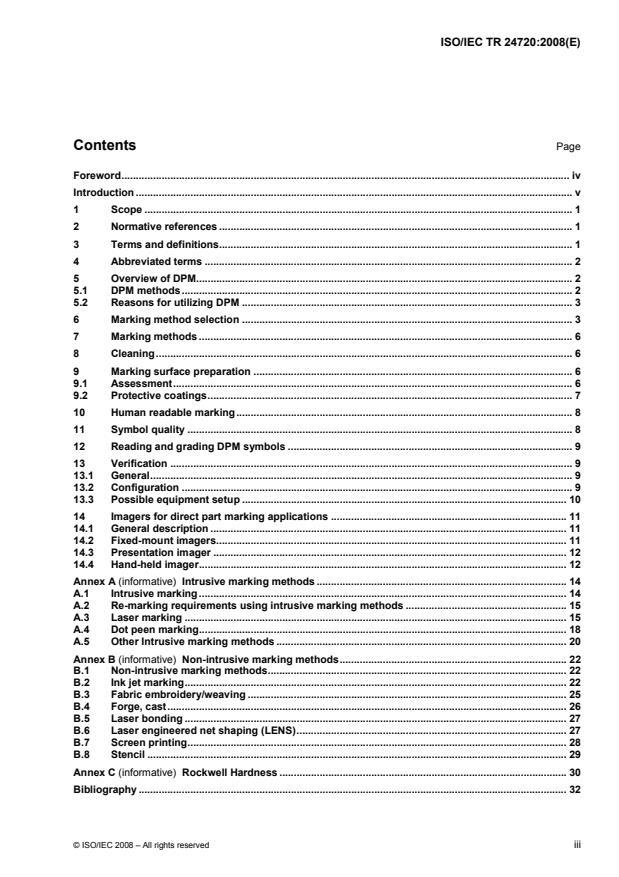

Contents Page

Foreword. iv

Introduction . v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions. 1

4 Abbreviated terms . 2

5 Overview of DPM. 2

5.1 DPM methods. 2

5.2 Reasons for utilizing DPM . 3

6 Marking method selection . 3

7 Marking methods . 6

8 Cleaning. 6

9 Marking surface preparation . 6

9.1 Assessment. 6

9.2 Protective coatings. 7

10 Human readable marking. 8

11 Symbol quality . 8

12 Reading and grading DPM symbols . 9

13 Verification . 9

13.1 General. 9

13.2 Configuration . 9

13.3 Possible equipment setup . 10

14 Imagers for direct part marking applications . 11

14.1 General description . 11

14.2 Fixed-mount imagers. 11

14.3 Presentation imager . 12

14.4 Hand-held imager. 12

Annex A (informative) Intrusive marking methods . 14

A.1 Intrusive marking. 14

A.2 Re-marking requirements using intrusive marking methods . 15

A.3 Laser marking . 15

A.4 Dot peen marking. 18

A.5 Other Intrusive marking methods . 20

Annex B (informative) Non-intrusive marking methods. 22

B.1 Non-intrusive marking methods. 22

B.2 Ink jet marking. 22

B.3 Fabric embroidery/weaving . 25

B.4 Forge, cast. 26

B.5 Laser bonding . 27

B.6 Laser engineered net shaping (LENS). 27

B.7 Screen printing. 28

B.8 Stencil . 29

Annex C (informative) Rockwell Hardness . 30

Bibliography . 32

© ISO/IEC 2008 – All rights reserved iii

Foreword

ISO (the International Organization for Standardization) and IEC (the International Electrotechnical

Commission) form the specialized system for worldwide standardization. National bodies that are members of

ISO or IEC participate in the development of International Standards through technical committees

established by the respective organization to deal with particular fields of technical activity. ISO and IEC

technical committees collaborate in fields of mutual interest. Other international organizations, governmental

and non-governmental, in liaison with ISO and IEC, also take part in the work. In the field of information

technology, ISO and IEC have established a joint technical committee, ISO/IEC JTC 1.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of the joint technical committee is to prepare International Standards. Draft International

Standards adopted by the joint technical committee are circulated to national bodies for voting. Publication as

an International Standard requires approval by at least 75 % of the national bodies casting a vote.

In exceptional circumstances, the joint technical committee may propose the publication of a Technical Report

of one of the following types:

— type 1, when the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts;

— type 2, when the subject is still under technical development or where for any other reason there is the

future but not immediate possibility of an agreement on an International Standard;

— type 3, when the joint technical committee has collected data of a different kind from that which is

normally published as an International Standard (“state of the art”, for example).

Technical Reports of types 1 and 2 are subject to review within three years of publication, to decide whether

they can be transformed into International Standards. Technical Reports of type 3 do not necessarily have to

be reviewed until the data they provide are considered to be no longer valid or useful.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO and IEC shall not be held responsible for identifying any or all such patent rights.

ISO/IEC TR 24720, which is a Technical Report of type 3, was prepared by Joint Technical Committee

ISO/IEC JTC 1, Information technology, Subcommittee SC 31, Automatic identification and data capture

techniques.

iv © ISO/IEC 2008 – All rights reserved

Introduction

Identification technologies have become an essential part of managing the life cycle of manufactured goods,

from their "birth" to the scrap recovery process. The need to identify parts easily and correctly is critical for

controlling and error proofing the assembly process, tracking work in process and building traceability. Fast

and accurate identification methods are also important after the product leaves the plant.

Industries worldwide rely heavily on the use of various marking methods. Because many of these methods

were originally designed to apply human-readable marks, they frequently are not appropriate for applying

high-density machine-readable symbols.

With the widespread implementation of machine-readable marking, the parts identification industry began to

refine existing marking methods. Dot peen machines replaced manual metal stamping and embossing

techniques. Desktop publishing systems were developed for the production of stencils. Ink jet machines were

built to replace rubber stamps. Laser marking systems were designed to replace electric-arc etching and hot

stamping processes.

One of the most popular methods of identifying a part is with a two-dimensional (2D) symbol applied directly

onto the surface of parts. Compared with printing and applying labels, marking directly on parts is more secure,

more cost-effective and easier to automate. When direct marked, two-dimensional symbols are able to

withstand harsh manufacturing processes and abuse in the field.

Several direct part marking (DPM) technologies are addressed in this Technical Report, such as ink jet

printing, laser etch, chemical etch and dot peen marking. Ink jet printing is one of the least expensive of the

marking methods. Laser etch is popular because of its ability to produce small, precise marks, and the ability

of lasers to mark symbols on many materials, from hardened steel to soft plastic. Lasers can also access

small, tight locations. Dot peen marking is usually reserved for marking metal. This marking method uses a

stylus to indent the surface of the part to create the desired mark. Chemical etch marking is often used to

mark printed circuit boards (PCBs), since it is already part of the normal manufacturing process.

For the purposes of this Technical Report, direct part marking (DPM) is considered a generic term referring to

methods of applying a permanent mark directly onto a surface of an item. There are two generic direct

marking techniques described in this Technical Report: intrusive and non-intrusive.

Intrusive (or subtractive) marking methods alter the surface of a part and are considered controlled defects. Of

the intrusive marking methods, this Technical Report addresses dot peen and direct laser marking, and briefly

describes other technologies.

Non-intrusive marking methods, also known as additive markings, are produced as part of the manufacturing

process or by adding a layer of media to the surface of a part. Of the non-intrusive methods, this Technical

Report addresses ink jet marking and other technologies.

© ISO/IEC 2008 – All rights reserved v

TECHNICAL REPORT ISO/IEC TR 24720:2008(E)

Information technology — Automatic identification and data

capture techniques — Guidelines for direct part marking (DPM)

1 Scope

This Technical Report describes several methods for applying permanent machine-readable symbols to

items – including components, parts and products – using the direct part marking (DPM) methods outlined

herein. This Technical Report describes marking methods, marking surface preparation, marking location,

protective coatings and other parameters that contribute to the production of quality symbols, but does not

specify the information to be encoded.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO/IEC 19762-1, Information technology — Automatic identification and data capture (AIDC) techniques —

Harmonized vocabulary — Part 1: General terms relating to AIDC

ISO/IEC 19762-2, Information technology — Automatic identification and data capture (AIDC) techniques —

Harmonized vocabulary — Part 2: Optically readable media (ORM)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO/IEC 19762-1, ISO/IEC 19762-2 and

the following apply.

3.1

intrusive marking

marking method designed to alter a surface to form a human- or machine-readable symbol

NOTE This marking category includes, but is not limited to, methods that abrade, burn, corrode, cut, deform, dissolve,

etch, melt, oxidize or vaporize a surface. Intrusive marking methods include stamping, laser etching, chemical etching, dot

peen and micro-sandblast.

3.2

non-intrusive marking

marking method designed to add material to a surface to form a human- or machine-readable symbol

NOTE Non-intrusive marking methods include ink jet, some forms of laser bonding, liquid metal jet, screen process,

stencil and thin film deposition.

3.3

permanent marking

intrusive or non-intrusive markings designed to remain legible for at least the normal service life of an item,

subject to operating or usage conditions

© ISO/IEC 2008 – All rights reserved 1

4 Abbreviated terms

EDM Electrical Discharge Machine or Machining

LISI Laser Induced Surface Improvement

5 Overview of DPM

5.1 DPM methods

For the purposes of this Technical Report, direct part marking (DPM) is considered a generic term referring to

methods of applying a mark directly onto the surface of an item. There are two techniques for applying a mark,

intrusive and non-intrusive.

5.1.1 Intrusive

Intrusive (also known as “subtractive”) marking methods physically alter the surface or structure of a part

(abrade, cut, burn, vaporize, bond etc.) and the marks are considered controlled defects. It is highly

recommended that all item identification manufacturing methods should be controlled by appropriate

manufacturing instructions, approved by Engineering Design and that testing of materials should be

conducted before an intrusive mark is applied to an item. Typical intrusive marking methods include:

• Abrasive blast

• Direct laser marking

• Dot peen

• Electro-chemical marking

• Engraving/milling

• Fabric embroidery/weaving

• Stamping

Of these intrusive methods, this report addresses some forms of direct laser and dot peen marking, and briefly

refers to other marking technologies.

5.1.2 Non-intrusive

Non-intrusive (also known as “additive”) markings are produced as part of the manufacturing process or by

adding a layer of marking media to the surface using methods that have no adverse effect on material

properties. These methods include:

• Automated adhesive dispensing

• Cast, forge, and mold

• Ink jet

• Laser bonding (limited forms)

• Laser engineered net shaping (LENS)

• Liquid metal jet

• Screen printing

• Stencil (not when used by Electro Chemical Etch marking methods)

Of the non-intrusive marking methods, this report addresses ink jet marking in depth and other technologies

only briefly.

2 © ISO/IEC 2008 – All rights reserved

5.2 Reasons for utilizing DPM

• If traceability is required after the product is separated from its temporary identification.

• When the part cannot be marked with labels or tags.

• If the part will be subjected to environmental conditions that preclude the use of add-on identification

methods.

• When the use of DPM methods is more cost efficient than applying individual item labels.

• When identification is required for the anticipated life cycle of the part, as defined by the manufacturer.

6 Marking method selection

The overall quality of any form of part identification depends on several characteristics. These characteristics

can include the material being marked, the shape or geometry of the marking surface and any surface

coatings or discoloration that affects decode or readability of the mark.

It is, therefore, important to review all of these factors before selecting a marking method. If a component

definition instructs a specific marking method for that component, that method should always be selected.

Table 1 below provides a cross-reference of marking methods and commonly marked materials and provides

guidance for selecting marking methods appropriate for the listed materials.

© ISO/IEC 2008 – All rights reserved 3

Table 1 — Marking Method Selection

METALLICS NON-METALLICS

MATERIAL TO BE

MARKED

MARKING

PROCESS

Abrasive Blast • • • • • • • • • • •

Adhesive Dispensing • • • • • • • • • • 1 • • • •

Cast, Forge Or Mold • • • • • • • • • • •

Dot Peen • 1 • • • 1 1

Electro-Chemical Coloring • • • • • • • •

Electro-Chemical Etching

• • • • • • • •

Embroidery

•

Engraving/Milling

• • • • • 1 • •

Ink Jet 1

• • • • • • • • • • • • • •

Laser Bonding • • • • • • • • •

Laser - Short Wave Lengths • 1 • • • • • • • 1 • • • • •

Laser Visible Wave Lengths 1 1 • 1 • 1 • •

Laser – Long Wave Lengths 1 • • 1 • •

LENS • 1 • • • • • •

LISI

2 2 2

• • •

Silk Screen • • • • • • • • • • • • • • •

Stencil • • • • • • • • • • • • • •

Thin Film Deposition • • • • • • • • • • • •

• = Acceptable marking process for this material if marking location and marking parameters are agreed

1 = Additional technical input required from design authority and equipment / material suppliers

2 = Marking method under development for this material

Blank space = Marking method not recommended for this material0

The physical size of the item to be marked is also a factor in DPM. When available marking space falls below

an accepted size, it may be necessary to review the data string and/or select a different marking method that

is acceptable to the component definition and/or operating condition. Table 2 below provides additional

guidance in the selection of an appropriate marking process.

4 © ISO/IEC 2008 – All rights reserved

Aluminum

Anodized

Beryllium

Carbon Steel

Copper

Brass

Magnesium

Titanium

Ceramics

Glass

Cloth

Painted

Plastics

Rubber

Teflon

Wood

Epoxy-glass

© ISO/IEC 2008 – All rights reserved 5

Table 2 — Symbol sizes by marking process

Data Format

P/N, EI and EI and S/N -

S/N Only -

S/N - Typically 13 Characters

Marking Process

Typical Data Cell Size Typically 7 Characters

Symbol Size Categories

Typically 29 Characters (18x18 Matrix)

(12x12 Matrix)

(Assenting Order)

(24x24 matrix)

Micro - <0.008-inch Laser Marking – Short 0.004 inch (0,102 mm)

0.0002 inch (0,005 mm) 0.003 inch (0,076 mm) 0.002 inch (0,051 mm)

Wave Length (Excimer)

(0,203 mm) data cells

Typical - 0.08 inch LaserShot Peening 0.009 inch (0,238 mm) 0.216 inch (5,486 mm) 0.162 inch (4,115 mm) 0.108 inch (2,743 mm)

(2,032 mm) to 0.034 Stencil(Photo-Process)

0.010 inch (0,254 mm) 0.240 inch (6,096 mm) 0.180 inch (4,572 mm) 0.120 inch (3,048 mm)

(0,864 mm) data cells

Laser Bonding

0.010 inch (0,254 mm) 0.240 inch (6,096 mm) 0.180 inch (4,572 mm) 0.120 inch (3,048 mm)

Laser Marking 0.010 inch (0,254 mm) 0.240 inch (6,096 mm) 0.180 inch (4,572 mm) 0.120 inch (3,048 mm)

Stencil(Mechanical Cut)

*0.020 inch (0,508 mm) 0.480 inch (12,192 mm) 0.360 inch (9,144 mm) 0.240 inch (6,096 mm)

Adhesive Dispensing 0.020 inch (0,508 mm) 0.480 inch (12,192 mm) 0.360 inch (9,144 mm) 0.240 inch (6,096 mm)

Dot Peen*

*0.022 inch (0,558 mm) 0.528 Inch (13,411 mm) 0.396 inch (10,058 mm) 0.264 inch (6,706 mm)

LISI

0.024 inch (0,610 mm) 0.576 inch (14,630 mm) 0.432 inch (10,973 mm) 0.288 inch (7,315 mm)

Stencil (Laser Cut) *0.024 inch (0,610 mm) 0.580 inch (14,732 mm) 0.440 inch (11,176 mm) 0.288 inch (7,315 mm)

Abrasive Blast

0.025 inch (0,635 mm) 0.600 inch (15,240 mm) 0.450 inch (11,430 mm) 0.300 inch (7,620 mm)

Ink Jet 0.030 inch (0,762 mm) 0.720 inch (18,288 mm) 0.540 inch (13,716 mm) 0.360 inch (9,144 mm)

Engraving/Milling

Macro – ≥0.035 inch *0.040 inch (1,016 mm) 0.960 inch (24,384 mm) 0.720 inch (18,288 mm) 0.480 inch (12,192 mm)

(0,889 mm)

Fabric Weaving

0.040 inch (1,016 mm) 0.960 inch (24,384 mm) 0.720 inch (18,288 mm) 0.480 inch (12,192 mm)

LENS 0.040 inch (1,016 mm) 0.960 inch (24,384 mm) 0.720 inch (18,288 mm) 0.480 inch (12,192 mm)

Fabric Embroidery

0.045 inch (1,143 mm) 1.080 inch (27,432 mm) 0.810 inch (20,574 mm) 0.540 inch (13,716 mm)

Cast, Mold & Forge 0.060 inch (1,524 mm) 1.440 inch (36,576 mm) 1.080 inch (27,432 mm) 0.720 inch (18,288 mm)

Note: Table courtesy NASA-STD-6002B and is reproduced here verbatim.

* Includes spacing between data cells

Note: See Annex A and Annex B for descriptions of marking methods.

Note: Technology developments in the marking processes are continuously improving the resolution that is achievable using that process. It should be noted, however, that some equipment might

achieve better or worse results than those indicated in Table 2.

7 Marking methods

For most two-dimensional symbols to be read successfully, the decoding software requires a quiet zone (a

clear space of a specified minimum width) around the entire periphery of the symbol. In addition to this

requirement, manufacturers often impose additional marking location restrictions within their drawings and/or

specifications. This report recommends that care be exercised when marking in the following locations:

• Highly polished curved surfaces

• In direct air streams (e.g., leading edge of wings, helicopter rotors, exposed portions of turbine blades,

etc.)

• Near high heat sources

• Sealing surfaces

• Wearing surfaces

In addition, the effects of adjacent structures on the imager’s illumination source must be considered. Fixed

station imagers with movable light sources can usually be configured to illuminate symbols placed in recesses

or adjacent to protruding structures. These structures, however, can pose a challenge for hand-held imagers

with fixed positioned light sources. It is therefore advisable to read marked parts in places that provide

maximum access to lighting.

8 Cleaning

Cleaning processes used for removing soil and contamination from parts to be marked are varied, and their

effectiveness depends on the requirements of the specific application. The appropriate cleaning method

should be selected according to the needs of the specific application. In selecting a cleaning process, many

factors must be considered, including:

• The nature of the soil to be removed

• Substrate to be cleaned (e.g. ferrous, non-ferrous, etc.)

• Importance of the condition of the surface to the end use of the part

• Degree of cleanliness required

• Capabilities of the available facilities

• Environmental impact of the cleaning process

• Cost

• Total surface area to be cleaned

• Effects of previous processes

• Rust inhibition requirements

• Material handling factors

• Surface requirements of subsequent operations, such as phosphate conversion coating, painting, or

plating

9 Marking surface preparation

9.1 Assessment

Prior to marking, operators are required to determine if additional surface preparation is required. This

assessment should address:

• Surface finishes that cause excessive amounts of shadow and/or specular reflection

• Surfaces that do not provide the necessary contrast for decoding

• Safety critical parts that cannot be marked using intrusive marking methods

• Materials that are not suitable for marking with the user’s preferred marking method

The most common methods utilized to prepare surfaces for marking are additives and coatings.

6 © ISO/IEC 2008 – All rights reserved

9.1.1 Additives

To assist readability of the mark, specialized additives can be mixed with metal alloys and thermoplastic

formulations to enhance and optimize marking contrast. These additives increase the ability of the material to

absorb or reflect specific wavelengths of light, but do not generally affect overall material performance.

9.1.2 Coatings

In a limited number of applications, it is possible for coatings to be used to modify the surface of a part to

improve readability and/or to provide corrosion protection. Coatings can be utilized to aid part marking by:

• Smoothing rough surfaces to reduce the effects of shadowing

• Providing increased contrast for surfaces of parts that inherently provide insufficient contrast

• Dulling highly polished surfaces to reduce specular reflection

• Providing a surface that can be removed with intrusive markings to expose a substrate of contrasting

color

• Serving as a medium for marking using a stencil as a mask

Following are the processes most commonly used to coat surfaces prior to marking:

9.1.3 Dip, Barrier and Conversion Coating

“Dip, barrier, and chemical conversion coating” is a term that encompasses an entire family of processes used

to prevent corrosion. The appropriate method should be selected according to the needs of the application.

9.1.4 Laser induced surface improvement (LISI)

LISI is a laser process utilized to impart stainless properties to carbon steel. The process can also be used to

improve the wear characteristics of aluminum surfaces. LISI treated surfaces can be discolored or removed to

create a symbol.

9.1.5 Plating and electroplating

Plating and electroplating processes are divided into two categories: Electro-deposition and Non-electrolytic

deposition processes. These techniques should be selected according to the needs of the application.

9.1.6 Vacuum controlled-atmosphere coating and surface modification processes

“Vacuum and controlled-atmosphere coatings” is a general term that encompasses thermal spray, chemical

vapor deposition, physical deposition, diffusion, and pulsed-laser deposition processes. This family of

processes is used to modify surfaces by depositing material onto a surface that is subsequently marked.

Vacuum controlled-atmosphere coatings and surface modification processes are frequently used in

conjunction with stencil marking.

9.1.7 Machining

Because extremely rough surfaces can produce shadows that adversely affect reader performance,

machining is often performed to smooth the surface roughness of parts to be marked. A number of machining

methods are commonly used for surface smoothing, and the appropriate method should be selected

according to the needs of the application.

9.2 Protective coatings

Metals are often unstable and susceptible to degradation by corrosion from hostile environments. Protective

coatings are often applied to marked surfaces to protect the marking and prevent corrosion. It should be noted,

however, that surface coatings might adversely affect the performance of some types of mark.

© ISO/IEC 2008 – All rights reserved 7

Intrusive markings applied to a surface that has been previously coated should be re-coated to prevent

corrosion in or around the area of the marking.

Note that a protective coating may alter the specular characteristics of the part and the optical quality should

be measured in its final configuration. Typical coatings include, but are not limited to, the following:

9.2.1 Clear anodize

Anodizing is an electrolytic oxidation process in which the surface of the metal is converted to a coating

having desirable protective, decorative, or functional properties.

9.2.2 Lacquer

Lacquer is a coating formulation based on thermoplastic film-forming material dissolved in an organic solvent.

The coating dries primarily by evaporation of the solvent.

9.2.3 Thin film deposition

Thin film deposition is a technique for depositing a thin film of material onto a substrate or onto previously

deposited layers of material. This process may be used to aid in adhesion or substrate cleaning or to smooth

surface roughness prior to marking.

10 Human readable marking

Whenever possible, the data encoded in the symbol should be marked in human readable form for use when

code-reading devices are not available or when a symbol is unreadable. Human readable characters can be

applied using the marking methods defined in this Technical Report, so whenever practical, the human

readable and symbol marking should be applied simultaneously and by the same method. Human readable

markings, when used, should be applied in close proximity to the two-dimensional symbols, as demonstrated

in Figure 1 below.

Figure 1 — Human readable marking in close proximity to two-dimensional symbol

11 Symbol quality

The quality of direct marking is affected several factors, including the material to be marked, the selected

marking method and component operating conditions.

See Table 1 of this report for guidance in matching the marking method and selected materials appropriately.

Methodologies for measuring the print quality of machine-readable marks using DPM procedures are not

available.

8 © ISO/IEC 2008 – All rights reserved

12 Reading and grading DPM symbols

The ultimate purpose of DPM that produces a machine-readable symbol is for a scanner to be able to read the

symbol. Historically, marks were either scanned in a fixtured environment custom-tailored for each mark or not

scanned at all. Application standards generally specified marks in terms of mechanical and dimensional

properties. "Marks,” meaning dimensionally accurate patterns which change a substrate using methods

described in this document, become "symbols", meaning the light reflecting from the combination of the mark

and the substrate, intended to be read by a scanner in an application. Depending on many factors, sometimes

a great "mark" is not a good "symbol".

As more actual scanning became the norm, many marks that were mechanically correct failed to scan in

application environments. Good marks may not scan if the background has either too much texture or not

enough, if inks are the wrong color or any number of other marking combinations occurs such that the lighting

and scanning configuration of the application do not match the optical properties of the symbol. On the other

hand, in some cases, marks that scanned easily were not deemed acceptable from a dimensional standpoint.

This lack of scanning predictability lead to considerable technological development in the area of camera

based symbol quality evaluation, sometimes called "verification" (see Verification Section 13).

As of the writing of this document, there is a mix of mechanical and optical-based quality measurement

methods that are specified by various industries. It is important for the engineer who specifies the symbol and

for the manufacturer who creates the symbol to make sure that they are designing and marking to the latest

version of the industry application specification that covers the eventual scanning environment of the symbol.

For this reason it is only possible to produce a machine-readable symbol to meet physical geometry

definitions and not to the requirements of any particular imaging device. It is important to stress, given the

correct imaging device, that mark quality is the consideration and readability is the output.

Reading considerations for the marking methods included in this report are outlined in the guidelines provided

in Annex A and Annex B.

13 Verification

13.1 General

In order to assure that the marking equipment applies a machine-readable symbol that will meet the

requirements for achieving the highest read rates, it is highly recommended that a form of acceptance be

carried out for mark quality acceptance. Not only is this an important factor for downstream reading

performance, but it reduces costs associated with rejected parts due to unreadable codes. If a part loses its

identity due to the poor quality of the mark, it cannot be used. A verification system will immediately detect a

problem, which could be due to poor fixing of the part, damage to the machine such as a broken stylus tip on

a dot peen machine or incorrect settings during part changeover.

13.2 Configuration

A symbol verifier is a system that includes lighting, optics, camera, symbol verification software, and

calibration. Due to the various types of materials, surface conditions and marks a verification system for DPM

symbols, based on the scanning requirements, needs to be defined for each application.

Lighting and optics should be configured to ensure an optimal image formation that delivers good contrast with

adequate resolution. In order to have meaningful verification results, it is recommended that the resolution at

the verification station be at least twice that of the reading station resolution. This can be accomplished with

either higher magnification optics or an imaging device in which the resolution is twice that of the reading

devices to be used. Another important step in generating consistent and meaningful results is consistent part

presentation.

© ISO/IEC 2008 – All rights reserved 9

13.3 Possible equipment setup

As an example, the arrangement described here and illustrated in Figure 2 and Figure 3 below may be found

suitable for many open applications. A standard monochrome video camera images the test symbol directly

on axis with its centre and normal to its plane. The lens used is appropriate to frame the entire symbol

(including any required quiet zones) in good focus, and with a sufficiently small field of view to minimize optical

distortions whilst also ensuring that the effective resolution obtained is appropriate to the X dimension of the

symbol. Light illumination uniformly floods the symbol area with a 45° angle of incidence. Test images are

captured with 8-bit grey-scale digitization using standard frame capture equipment, and the grey-scale is

calibrated using targets of known diffuse reflectance.

A

B

ϑ ϑ

1 – Light sensing element

2 – Lens providing 1:1 magnification (measurement A = measurement B)

3 – Inspection area

4 – Light sources

ϑ - Angle of incidence of light relative to plane of symbol (default = 45°, optionally 30° or 90° diffuse)

Figure 2 — Reference optical arrangement, side view

10 © ISO/IEC 2008 – All rights reserved

Figure 3 — Example of a quality testing setup. Marking quality verifiers are available

from multiple sources

14 Imagers for direct part marking applications

14.1 General description

There are three types of imager (decoder) products for DPM in general use today: fixed-mount imagers,

presentation imagers, and hand-held imagers. Imaging systems include:

• a means of illuminating the symbol

• optics for focusing an image of the symbol on a detector

• software for processing the image and decoding the symbol

• an output device, either a display or interface to a data processing system

14.2 Fixed-mount imagers

Fixed-mount imagers are used in reading symbols on parts that are handled and moved automatically by

conveyor, indexer, or robot. Typically, fully automated manufacturing lines such as those found in electronics

and automotive manufacturing use fixed-mount imagers.

In operation, this type of imager (Figure 4) is mounted in a fixed position where the symbol can be repeatedly

placed in front of the imager in either continuous or indexed motion. The imager is signaled that the part is

ready for reading by a “trigger”. This trigger event is performed by an external sensor that detects the

presence of the part or by an encoder that knows the position of the part at all times and can signal the imager

to decode.

© ISO/IEC 2008 – All rights reserved 11

Fixed-mount imagers are configured with either an integrated light source or with an external light source as

required by the application. Advantages of a fixed-mount imager without an integrated light source are that it

can be mounted at varied distances from the part and supplemental lighting can be selected to meet the

application needs.

Figure 4 — Example of a fixed-mount imager

14.3 Presentation imager

Similar to a fixed-mount imager, a presentation imager (Figure 5) is mounted in a fixed position; however, it

operates in a continuous reading cycle, automatically performing the decoding task once the operator places

the part bearing the symbol in front of the imager. Presentation imager can provide a very fast way of reading

symbols in areas where parts are handled manually. A presentation imager can be implemented with either a

fixed-mount or a hand-held imager. Using a hand-held imager in presentation mode provides the opportunity

for multi-use, as one can also remove the imager from its stand and bring it to the part.

Figure 5 — Example of a presentation imager

14.4 Hand-held imager

Hand-held imagers (Figure 6 below) are typically used in applications where the symbol size is fixed and the

part is too large or it is difficult to bring the part to the imagers. Variable or multiple lens imagers are used in

applications in which two-dimensional symbols of more than one size are to be read.

Hand-held imagers are preferred in those environments where part handling is not automated or parts vary

greatly in size. Handhelds are used in job shop manufacturing operations, QC test stations, and in logistics

areas. Hand-held imagers come in either tethered (with a cord), or cordless configurations. Tethered hand-

held imagers have the advantage of not being displaced from the application location. Cordless operation is

required in cases where part size or position is a practical limitation to cord length.

12 © ISO/IEC 2008 – All rights reserved

Figure 6 — Example of handheld imager

© ISO/IEC 2008 – All rights reserved 13

Annex A

(informative)

Intrusive marking methods

A.1 Intrusive marking

Intrusive Marking is designed to alter the surface of a material to form a human readable mark or a machine-

readable symbol. This marking category includes, but is not limited to, devices that abrade, burn, corrode, cut,

deform, dissolve, etch, melt, oxidize or vaporize the surface of a material.

Because intrusive markings alter the surface of a part (abrade, cut, burn, vaporize, etc.) they are considered

to be controlled defects. If not done properly, they can degrade material properties beyond a point of

acceptability. Consequently, some intrusive markings, especially direct laser, are generally not used in safety

critical applications without appropriate metallurgical testing. Typical intrusive marking methods include:

• Abrasive blast

• Dot peen

• Electro-chemical marking

• Engraving/milling

• Fabric embroidery/weaving

• Direct laser marking

Figure A.1 below provides cross section views of intrusive markings described in this section.

Discolored Markings –

Etched Markings – Electro-

Textured Marking – Micro-

Chemical Coloring, Electro-

Chemical Etch and Laser

Abrasive Blast and Laser Etch

Chemical Coloring (AC) and

Engraving

Laser Coloring

Recessed Markings – Deep Dot Peen Marking

Recessed Markings – Machine

Laser Engraving

Engraving and Milling

Recessed Marking Coated to

Recessed/Etched Marking

Prevent Accumulation of

Surface Coating Removed

Backfilled to Provide Contrast

Foreign material or Corrosion

to Form Symbol

Figure A.1 — Intrusive marking cross-sections

14 © ISO/IEC 2008 – All rights reserved

A.2 Re-marking requirements using intrusive marking methods

Because the application of a single mark using an intrusive marking method causes material degradation,

additional intrusive markings made to obliterate or change those original markings could reduce material

properties beyond a point of acceptability. Therefore, approval should be secured from the responsible quality

assurance or engineering organizations before additional markings are permitted.

A.3 Laser marking

A.3.1 General

Selecting a system for laser marking involves choosing the proper wavelength for the material to be marked.

Marking ap

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...