ISO 27831-1:2008

(Main)Metallic and other inorganic coatings — Cleaning and preparation of metal surfaces — Part 1: Ferrous metals and alloys

Metallic and other inorganic coatings — Cleaning and preparation of metal surfaces — Part 1: Ferrous metals and alloys

ISO 27831-1:2008 specifies processes for the cleaning of the surfaces of ferrous metals and their alloys to remove any irrelevant or unwanted deposits or other material at any stage of manufacture, storage or service and for the preparation of these surfaces for further treatment. It does not cover cleaning operations associated with the preliminary removal of heavy deposits of oil, grease or dirt accumulated during operational service, preparations for welding or the cleaning of electrical contacts. However, many of the processes included in this part of ISO 27831 may be used for these operations at the discretion of the users of this part of ISO 27831. It covers processes which are needed for the preparation of metal surfaces prior to the application of the following surface coatings: electrodeposited metal coatings; autocatalytic metal coatings (autocatalytic and displacement types); conversion coatings; hot-dipped coatings; sprayed metal coatings; diffusion coatings; coatings produced by vitreous enamelling; coatings produced by physical vapour deposition of aluminium and cadmium; powder coatings. It describes processes for carrying out the following treatments: degreasing; descaling; pickling; de-rusting; chemical smoothing; electropolishing. It relates the processes described above to the following metals: non-corrosion-resisting steels, cast irons and pure irons; corrosion-resisting and heat-resisting steels.

Revêtements métalliques et autres revêtements inorganiques — Nettoyage et préparation des surfaces métalliques — Partie 1: Métaux ferreux et alliages

General Information

- Status

- Published

- Publication Date

- 01-Oct-2008

- Technical Committee

- ISO/TC 107/SC 3 - Electrodeposited coatings and related finishes

- Drafting Committee

- ISO/TC 107/SC 3 - Electrodeposited coatings and related finishes

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 21-Oct-2024

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 09-Feb-2026

Overview

ISO 27831-1:2008 - Metallic and other inorganic coatings: Cleaning and preparation of metal surfaces (Part 1: Ferrous metals and alloys) defines standardized processes for cleaning and preparing the surfaces of ferrous metals and alloys prior to further surface treatment. The standard covers removal of unwanted deposits and describes pretreatment methods intended to ensure consistent adhesion, corrosion resistance and quality of subsequent coatings. It applies to non‑corrosion‑resisting steels, cast irons and pure irons, as well as corrosion‑resisting and heat‑resisting steels.

Key topics and technical requirements

- Scope limits: Does not cover heavy removal of oil/grease accumulated during service, welding preparation, or electrical contact cleaning, although methods in the standard may be used at users’ discretion.

- Surface coatings supported: Electrodeposited metals, autocatalytic (chemical) coatings, conversion coatings, hot‑dipped coatings, sprayed metal coatings, diffusion coatings, vitreous enamelling, PVD (Al and Cd), and powder coatings.

- Primary pretreatment processes described:

- Degreasing (organic‑solvent and alkaline methods)

- Descaling and descaling by caustic or permanganate

- Acid pickling and acid dipping (including anodic pickling)

- De‑rusting (acidic and alkaline de‑rusting)

- Abrasive cleaning (blasting, tumbling, wire brushing)

- Chemical smoothing and electropolishing

- Passivation and contamination tests for stainless and heat‑resisting steels

- Process-to-metal guidance: The standard links cleaning methods and specific preparation sequences to types of ferrous metals and intended coatings (e.g., pretreatment before galvanizing, electroplating, phosphating, metal spraying, enamelling or powder coating).

- Quality and information requirements: Specifies essential information purchasers should supply to processors and includes normative tests and informative annexes on bath maintenance and acidity control.

Applications and who uses it

ISO 27831-1 is used by:

- Coating specifiers and process engineers planning pretreatment workflows

- Electroplaters, galvanizers, metal sprayers and powder coating shops

- Quality managers and inspectors enforcing surface preparation requirements

- OEMs in automotive, aerospace, heavy engineering and construction defining procurement and acceptance criteria

Practical benefits include improved coating adhesion, predictable corrosion performance, reproducible surface cleanliness and clearer supplier/processor communication.

Related standards

- Complements other ISO and industry standards on surface treatment, coating performance and testing. Use ISO 27831‑1 alongside coating‑specific standards and industry best practices when defining pretreatment and inspection requirements.

Keywords: ISO 27831-1:2008, cleaning and preparation of metal surfaces, ferrous metals, degreasing, pickling, descaling, electropolishing, metal surface preparation standard, pretreatment for coatings.

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

ISO 27831-1:2008 is a standard published by the International Organization for Standardization (ISO). Its full title is "Metallic and other inorganic coatings — Cleaning and preparation of metal surfaces — Part 1: Ferrous metals and alloys". This standard covers: ISO 27831-1:2008 specifies processes for the cleaning of the surfaces of ferrous metals and their alloys to remove any irrelevant or unwanted deposits or other material at any stage of manufacture, storage or service and for the preparation of these surfaces for further treatment. It does not cover cleaning operations associated with the preliminary removal of heavy deposits of oil, grease or dirt accumulated during operational service, preparations for welding or the cleaning of electrical contacts. However, many of the processes included in this part of ISO 27831 may be used for these operations at the discretion of the users of this part of ISO 27831. It covers processes which are needed for the preparation of metal surfaces prior to the application of the following surface coatings: electrodeposited metal coatings; autocatalytic metal coatings (autocatalytic and displacement types); conversion coatings; hot-dipped coatings; sprayed metal coatings; diffusion coatings; coatings produced by vitreous enamelling; coatings produced by physical vapour deposition of aluminium and cadmium; powder coatings. It describes processes for carrying out the following treatments: degreasing; descaling; pickling; de-rusting; chemical smoothing; electropolishing. It relates the processes described above to the following metals: non-corrosion-resisting steels, cast irons and pure irons; corrosion-resisting and heat-resisting steels.

ISO 27831-1:2008 specifies processes for the cleaning of the surfaces of ferrous metals and their alloys to remove any irrelevant or unwanted deposits or other material at any stage of manufacture, storage or service and for the preparation of these surfaces for further treatment. It does not cover cleaning operations associated with the preliminary removal of heavy deposits of oil, grease or dirt accumulated during operational service, preparations for welding or the cleaning of electrical contacts. However, many of the processes included in this part of ISO 27831 may be used for these operations at the discretion of the users of this part of ISO 27831. It covers processes which are needed for the preparation of metal surfaces prior to the application of the following surface coatings: electrodeposited metal coatings; autocatalytic metal coatings (autocatalytic and displacement types); conversion coatings; hot-dipped coatings; sprayed metal coatings; diffusion coatings; coatings produced by vitreous enamelling; coatings produced by physical vapour deposition of aluminium and cadmium; powder coatings. It describes processes for carrying out the following treatments: degreasing; descaling; pickling; de-rusting; chemical smoothing; electropolishing. It relates the processes described above to the following metals: non-corrosion-resisting steels, cast irons and pure irons; corrosion-resisting and heat-resisting steels.

ISO 27831-1:2008 is classified under the following ICS (International Classification for Standards) categories: 25.220.20 - Surface treatment; 25.220.40 - Metallic coatings. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 27831-1:2008 has the following relationships with other standards: It is inter standard links to EN ISO 9717:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 27831-1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 27831-1

First edition

2008-10-15

Metallic and other inorganic coatings —

Cleaning and preparation of metal

surfaces —

Part 1:

Ferrous metals and alloys

Revêtements métalliques et autres revêtements inorganiques —

Nettoyage et préparation des surfaces métalliques —

Partie 1: Métaux ferreux et alliages

Reference number

©

ISO 2008

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2008

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2008 – All rights reserved

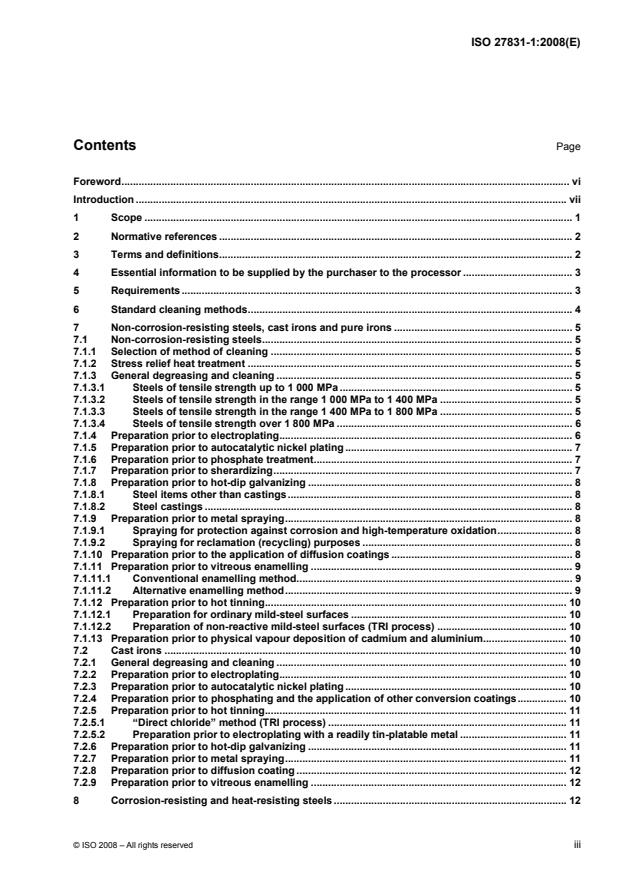

Contents Page

Foreword. vi

Introduction . vii

1 Scope . 1

2 Normative references . 2

3 Terms and definitions. 2

4 Essential information to be supplied by the purchaser to the processor . 3

5 Requirements . 3

6 Standard cleaning methods. 4

7 Non-corrosion-resisting steels, cast irons and pure irons . 5

7.1 Non-corrosion-resisting steels. 5

7.1.1 Selection of method of cleaning . 5

7.1.2 Stress relief heat treatment . 5

7.1.3 General degreasing and cleaning . 5

7.1.3.1 Steels of tensile strength up to 1 000 MPa . 5

7.1.3.2 Steels of tensile strength in the range 1 000 MPa to 1 400 MPa . 5

7.1.3.3 Steels of tensile strength in the range 1 400 MPa to 1 800 MPa . 5

7.1.3.4 Steels of tensile strength over 1 800 MPa . 6

7.1.4 Preparation prior to electroplating. 6

7.1.5 Preparation prior to autocatalytic nickel plating .7

7.1.6 Preparation prior to phosphate treatment. 7

7.1.7 Preparation prior to sherardizing. 7

7.1.8 Preparation prior to hot-dip galvanizing . 8

7.1.8.1 Steel items other than castings . 8

7.1.8.2 Steel castings . 8

7.1.9 Preparation prior to metal spraying. 8

7.1.9.1 Spraying for protection against corrosion and high-temperature oxidation. 8

7.1.9.2 Spraying for reclamation (recycling) purposes . 8

7.1.10 Preparation prior to the application of diffusion coatings . 8

7.1.11 Preparation prior to vitreous enamelling . 9

7.1.11.1 Conventional enamelling method. 9

7.1.11.2 Alternative enamelling method. 9

7.1.12 Preparation prior to hot tinning. 10

7.1.12.1 Preparation for ordinary mild-steel surfaces . 10

7.1.12.2 Preparation of non-reactive mild-steel surfaces (TRI process) . 10

7.1.13 Preparation prior to physical vapour deposition of cadmium and aluminium. 10

7.2 Cast irons . 10

7.2.1 General degreasing and cleaning . 10

7.2.2 Preparation prior to electroplating. 10

7.2.3 Preparation prior to autocatalytic nickel plating . 10

7.2.4 Preparation prior to phosphating and the application of other conversion coatings. 10

7.2.5 Preparation prior to hot tinning. 11

7.2.5.1 “Direct chloride” method (TRI process) . 11

7.2.5.2 Preparation prior to electroplating with a readily tin-platable metal . 11

7.2.6 Preparation prior to hot-dip galvanizing . 11

7.2.7 Preparation prior to metal spraying. 11

7.2.8 Preparation prior to diffusion coating . 12

7.2.9 Preparation prior to vitreous enamelling . 12

8 Corrosion-resisting and heat-resisting steels . 12

8.1 Corrosion-resisting steels. 12

8.1.1 Stress-relieving heat treatment . 12

8.1.2 General degreasing and cleaning . 12

8.1.3 Preparation prior to electroplating. 12

8.1.4 Preparation prior to autocatalytic nickel plating . 12

8.1.5 Preparation prior to metal spraying . 12

8.1.5.1 Preparation for metal spraying .12

8.1.5.2 Spraying for reclamation (recycling) purposes. 13

8.1.6 Preparation prior to vitreous enamelling — Austenitic steels . 13

8.2 Heat-resisting steels . 13

9 Pretreatment of metals prior to powder coating. 14

9.1 General degreasing and cleaning . 14

9.2 Preparation of non-corrosion-resisting steels. 14

9.3 Preparation of corrosion-resisting steels. 14

10 Cleaning and preparation processes. 14

10.1 Process A — Organic-solvent degreasing and cleaning . 14

10.1.1 General . 14

10.1.2 Method A1 — Hot solvent, not water-rinsable . 15

10.1.3 Method A2 — Cold solvent, not water-rinsable . 15

10.1.4 Method A3 — Hot solvent, water-rinsable . 15

10.1.5 Method A4 — Cold solvent, water-rinsable . 15

10.1.6 Method A5 — Petroleum fuel based mixtures containing emulsifying agents . 15

10.1.7 Method A6 — Ultrasonic cleaning. 16

10.2 Process B — Alkaline degreasing. 16

10.2.1 General . 16

10.2.2 Method B1 — General-purpose alkaline degreasing. 16

10.2.3 Method B2 — Mild alkaline degreasing .16

10.2.4 Method B3 — Cathodic alkaline degreasing . 16

10.3 Process C — Acid emulsion cleaning. 16

10.4 Process D — Abrasive cleaning . 17

10.4.1 General . 17

10.4.2 Method D1 — Coarse-abrasive blasting . 17

10.4.3 Method D2 — Fine-abrasive blasting . 17

10.4.4 Method D3 — Scouring. 17

10.4.5 Method D4 — Tumbling. 17

10.4.6 Method D5 — Wire brushing. 17

10.5 Process E — Caustic-alkali descaling . 18

10.5.1 Method E1 — Sodium hydride descaling . 18

10.5.2 Method E2 — Alkali permanganate descaling . 18

10.6 Process F — Acid pickling without electrolysis . 18

10.6.1 General . 18

10.6.2 Method F1 . 18

10.6.3 Method F2 . 18

10.6.4 Method F3 . 18

10.6.5 Method F4 . 19

10.6.6 Method F5 . 19

10.7 Process G — Acid dipping. 19

10.7.1 General . 19

10.7.2 Method G1. 19

10.7.3 Method G2. 19

10.8 Process H — Anodic pickling . 20

10.8.1 General . 20

10.8.2 Method H1. 20

10.8.3 Method H2. 20

10.8.4 Method H3. 20

10.9 Process J — Acid de-rusting . 20

10.10 Process K — Alkaline de-rusting. 21

10.10.1 General . 21

10.10.2 Method K1 (for light rust) . 21

iv © ISO 2008 – All rights reserved

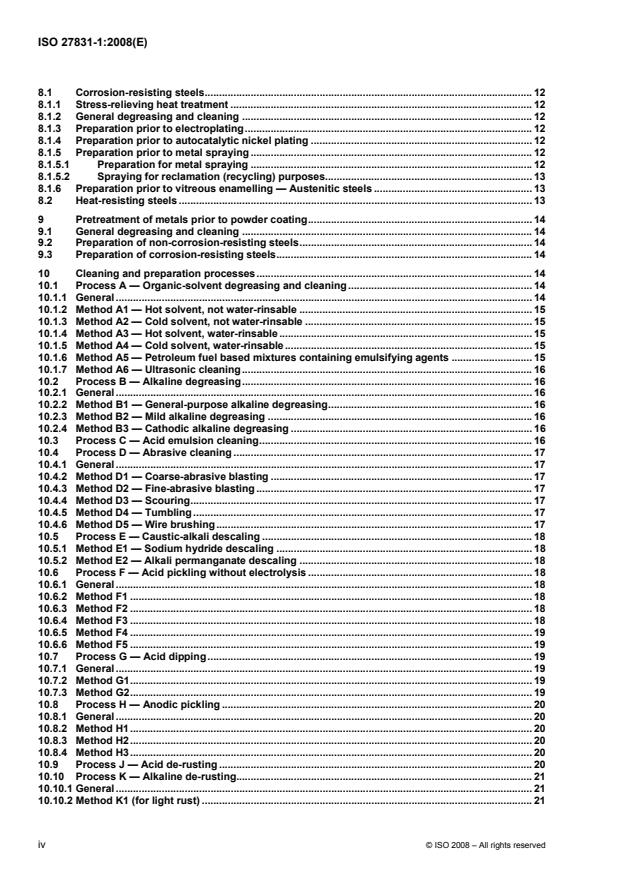

10.10.3 Method K2 (for heavy rust) . 21

10.10.4 Method K3 (for heavy rust) . 22

10.11 Process L — Chemical smoothing and electropolishing of steels . 22

10.11.1 Method L1 — Chemical smoothing process (for non-corrosion-resisting steels) . 22

10.11.2 Method L2 — Electropolishing of corrosion-resisting steels . 22

10.12 Process M — Passivation and removal of surface contamination from corrosion-resisting

steels and surface preparation prior to electroplating . 23

10.12.1 Method M1 — Passivation . 23

10.12.2 Method M2 — Test for surface contamination. 23

10.12.3 Method M3 — Alternative test for surface contamination. 23

10.12.4 Method M4 — Preparation of corrosion-resisting steels prior to electroplating . 24

Annex A (informative) Maintenance of organic and vapour degreasing baths . 25

Annex B (informative) The control of acidity in vapour cleaning baths . 26

Annex C (normative) Method for the determination of oxidizable material in sulfuric acid. 27

Bibliography . 28

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 27831-1 was prepared by Technical Committee ISO/TC 107, Metallic and other inorganic coatings,

Subcommittee SC 3, Electrodeposited coatings and related finishes.

ISO 27831 consists of the following parts, under the general title Metallic and other inorganic coatings —

Cleaning and preparation of metal surfaces:

⎯ Part 1: Ferrous metals and alloys

⎯ Part 2: Non-ferrous metals and alloys

vi © ISO 2008 – All rights reserved

Introduction

The adhesion of deposited coatings depends upon the efficiency of degreasing and cleaning processes used

on the substrate surface. The removal of grease, oil and dirt and all other forms of contamination left from

fabrication processes or due to corrosion/erosion of surfaces in storage or in service is essential for successful

production of a pristine, chemically clean active surface for deposition of coatings.

The surface contaminants can be

⎯ corrosion products, mould sand or mould release agents on ferrous and non-ferrous castings;

⎯ corrosion products and mill scales on hot-rolled steel sheet, girders, etc. (broken mill scale is cathodic to

the underlying substrate);

⎯ oil and rolling lubricant on cold-rolled steel sheet;

⎯ rolling lubricant on e.g. cold-rolled aluminium sheet;

⎯ corrosion products on delivery or during storage on hot-dip-galvanized steel sheet or angle bars/brackets;

⎯ other undesirable materials from storage and handling.

The difficulty of coating these surfaces is well known.

Cleaning processes for removing surface contaminants are varied, depending, among other things, on the

identification and classification of the soil as well as the size and shape of the substrate, the degree of

cleanliness required, the availability of the facilities needed, the cost of the processes used and their impact

on the environment, and the nature of subsequent processes to which the substrate is going to be subjected.

ISO 27831 includes cleaning processes ranging from mechanical methods (which give the least degree of

cleanliness) to chemical and ultrasonic methods (which give a higher degree of surface preparation) and

substrate conditioning by glow discharge plasma (sputter cleaning) for vapour deposition.

ISO 27831 describes practices for cleaning a variety of metals and metal alloys prior to the application of a

range of coatings or without any coating requirements.

The cleaning processes described in ISO 27831-1 and ISO 27831-2 are indicative only of those most

commonly used in practice. However, there are numerous formulations of solutions and numerous proprietary

processes available which are not included in ISO 27831-1 or ISO 27831-2. Wherever possible, references to

particular processes have been made. For references concerning all other processes included in either part of

ISO 27831, the publications given in the Bibliography in the respective part should be consulted.

ISO 27831-1 covers ferrous metals and their alloys, whilst ISO 27831-2 covers non-ferrous metals and their

alloys. For ISO 27831-2 to be usable, as far as possible, as a “stand-alone” document, Clauses 1 to 6 of

ISO 27831-1 have been included in it as Clauses 1 to 6 and the numbering of the other clauses follows the

same sequence as in ISO 27831-1. Additionally, since some of the cleaning and preparation processes

specified for ferrous materials in ISO 27831-1 can also be used for non-ferrous metals, the cleaning and

preparation processes follow the same sequence, using the same designations, as in ISO 27831-1.

INTERNATIONAL STANDARD ISO 27831-1:2008(E)

Metallic and other inorganic coatings — Cleaning and

preparation of metal surfaces —

Part 1:

Ferrous metals and alloys

WARNING — This part of ISO 27831 may not be compliant with some countries’ health, safety and

environmental legislation. It calls for the use of substances and/or procedures that may be injurious to

health if adequate safety measures are not taken. This part of ISO 27831 does not address any health

hazards, safety or environmental matters, or legislation associated with its use. It is the responsibility

of the user of this part of ISO 27831 to establish appropriate health, safety and environmentally

acceptable practices and take appropriate action to comply with any national, regional and/or

international regulations. Compliance with this part of ISO 27831 does not, of itself, confer immunity

from legal obligations.

1 Scope

This part of ISO 27831 specifies processes for the cleaning of the surfaces of ferrous metals and their alloys

to remove any irrelevant or unwanted deposits or other material at any stage of manufacture, storage or

service and for the preparation of these surfaces for further treatment. It does not cover cleaning operations

associated with the preliminary removal of heavy deposits of oil, grease or dirt accumulated during operational

service, preparations for welding or the cleaning of electrical contacts. However, many of the processes

included in this part of ISO 27831 may be used for these operations at the discretion of the users of this part

of ISO 27831.

This part of ISO 27831 covers processes which are needed for the preparation of metal surfaces prior to the

application of the following surface coatings:

⎯ electrodeposited metal coatings;

⎯ autocatalytic metal coatings (autocatalytic and displacement types);

⎯ conversion coatings;

⎯ hot-dipped coatings;

⎯ sprayed metal coatings;

⎯ diffusion coatings;

⎯ coatings produced by vitreous enamelling;

⎯ coatings produced by physical vapour deposition of aluminium and cadmium;

⎯ powder coatings.

This part of ISO 27831 describes processes for carrying out the following treatments:

⎯ degreasing;

⎯ descaling;

⎯ pickling;

⎯ de-rusting;

⎯ chemical smoothing;

⎯ electropolishing.

This part of ISO 27831 relates the processes described above to the following metals:

⎯ non-corrosion-resisting steels, cast irons and pure irons;

⎯ corrosion-resisting and heat-resisting steels.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 2064, Metallic and other inorganic coatings — Definitions and conventions concerning the measurement

of thickness

ISO 2080, Metallic and other inorganic coatings — Surface treatment, metallic and other inorganic coatings —

Vocabulary

ISO 4527, Metallic coatings — Autocatalytic (electroless) nickel-phosphorus alloy coatings — Specification

and test methods

ISO 9587, Metallic and other inorganic coatings — Pretreatment of iron or steel to reduce the risk of hydrogen

embrittlement

ISO 9588, Metallic and other inorganic coatings — Post-coating treatments of iron or steel to reduce the risk

of hydrogen embrittlement

ISO 22778, Metallic coatings — Physical vapour-deposited coatings of cadmium on iron and steel —

Specification and test methods

ISO 22779, Metallic coatings — Physical vapour-deposited coatings of aluminium — Specification and test

methods

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 2064, ISO 2080, ISO 9587,

ISO 9588, ISO 22778 and ISO 22779 apply.

2 © ISO 2008 – All rights reserved

4 Essential information to be supplied by the purchaser to the processor

When ordering articles to be processed in accordance with this part of ISO 27831, the purchaser shall provide

the following information in writing, e.g. in the contract, in the purchase order or on the engineering drawing:

a) the number of this part of ISO 27831 (ISO 27831-1);

b) the specification and metallurgical condition of the material of which the item is made;

c) the tensile strength of the steel components and the requirements for stress relief and post-cleaning

embrittlement relief heat treatments of the steel to reduce the risk of hydrogen embrittlement (see 7.1);

d) the cleaning method or methods given in this part of ISO 27831 which are to be used, and any deviation

from these methods (e.g. the use of a proprietary method for health or safety reasons);

e) details of any particular requirements for special surfaces;

f) details of any special procedures (e.g. process H, method H1);

g) details of any particularly difficult surface condition and any special information regarding coatings to be

removed or coatings or inserts to be protected;

h) where appropriate, details of the surface coating which is to be subsequently applied.

5 Requirements

−6

5.1 Any materials used for cleaning and preparation shall contain not more than a mass fraction of 5 × 10

of mercury (Hg). Where items can be regarded as susceptible to degradation by residual arsenic and/or

antimony, the following maximum limitations shall also apply:

−6

for arsenic (As): a mass fraction of 15 × 10 ;

−6

for antimony (Sb): a mass fraction of 15 × 10 .

NOTE 1 The presence of arsenic, reduced sulfur or reduced phosphorous compounds in an acid bath will promote

absorption of hydrogen by steel and may reduce the adhesion of subsequently applied coatings.

NOTE 2 Contamination of steel components can occur when antimony-inhibited solutions are used. The resultant

deposit of antimony on exposed surfaces can adversely affect the properties of the steel and subsequent processing of

the item. If processing solutions become contaminated, this can lead to further items being similarly affected.

5.2 When assembled items are being processed, the treatments chosen shall be suitable for each

constituent material and the combination of materials.

5.3 Items will often require a sequence of several degreasing and cleaning treatments. Solvent cleaning

may occasionally leave traces of soil after evaporation of the solvent and care shall be taken to remove such

contamination. Inorganic contamination may not always be removed by organic solvents. It may therefore be

necessary to use additional aqueous processes after final degreasing and cleaning.

5.3.1 The surfaces shall be free from grease, oil, oxide, scale and other foreign matter and shall be in a

chemically clean condition, i.e. fully receptive to any subsequent processing.

To test for surface cleanliness, the cleaned surface may be sprayed with, or immersed in, cool, clean water.

On clean surfaces, the water will form a uniform film whereas, in the presence of oily soils, the water film will

break away from contaminated areas. In cases of gross contamination, the entire film may break down into

discrete globules. If the surface to be tested has any residue of cleaning agent containing surface-active agent,

a continuous film may be obtained even in the presence of grease. This false effect can be overcome by

dipping the surface in dilute acid and rinsing before carrying out the test. Subsequent specified treatments

shall be applied without delay.

5.3.2 Abrasives used on any metal or alloy shall not also be used on any dissimilar metal or alloy. Separate

abrasive cleaning media shall be used for different alloy families, for example iron and its alloys, aluminium

and its alloys. Thus alumina, for example, used for abrasive cleaning of aluminium surfaces, shall not have

been used for any other type of material, such as steel or copper-rich alloys, or been otherwise externally

contaminated.

Shot peening of the basis metal or substrate, if required, shall be performed before final cleaning and the

application of the coating.

5.3.3 The mechanical properties shall not be impaired except where they may be recovered by subsequent

heat, or other, treatments forming part of the normal processing sequence.

5.3.4 The dimensions and surface finish shall be such as to enable the finished (e.g. electroplated) items to

be within the required drawing or specification limits.

5.4 Where solvent cleaning is used, corrosion of items, particularly those made from light alloys, may occur

if they are subjected to heat before all the solvent has disappeared from the surfaces. Thus, solvents which

thermally degrade with the liberation of corrosive products shall not be used. Care shall also be taken to

ensure that all traces of liquid are removed from items of complex form or containing blind holes. Bundles of

items intended for immediate heat treatment shall be shaken to ensure that liquid is not retained by capillary

attraction between surfaces in contact. In any event, after removal from the degreaser, items shall not be

immersed in a molten salt bath until they are completely dry and have reached room temperature.

It is not good practice to allow an interval between treatments. It shall be borne in mind that degreasing and

cleaning procedures produce a surface whose resistance to corrosive attack is low. Consequently, readily

corrodible materials need to be protectively coated or further processed immediately.

5.5 Immediately after each treatment in an aqueous solution, the items shall be thoroughly rinsed in clean

hot and/or clean cold water, as appropriate, paying special attention to items containing crevices. Immediately

after the final rinsing, the metal surface shall not exhibit a water break. Water used for final rinsing after

processing shall be discarded or retreated when the conductivity exceeds 10 µS/cm.

5.6 After the final rinsing or other final preparatory treatment, items to be given a protective treatment in

aqueous solutions shall be transferred immediately, without drying, to the treatment bath.

5.7 Items to be given further treatment by dry processes and items which are not to be subjected to further

processing shall be thoroughly dried.

5.7.1 Where drying in a draught of warm air is recommended, the air shall be free from oil and other

contaminants.

5.7.2 The use of chlorinated solvents for drying purposes is not permitted.

5.8 All stages of the degreasing and cleaning procedures shall follow each other without delay.

5.9 The acid and alkaline solutions used in some of the cleaning and preparation processes can have a

deleterious effect on unstable materials. When an item is for use with unstable materials, particular care shall

to be taken to ensure that all such solutions are completely removed by thorough washing with clean water.

Special attention shall be paid to irregularly shaped items and to blind holes and crevices.

5.10 Where limits of composition of solutions are known, they are quoted in this part of ISO 27831. Where

limits are not quoted, other proportions may be used provided they are within a tolerance of ± 10 %.

6 Standard cleaning methods

6.1 The processes and methods described in this part of ISO 27831 are indicative only of those most

commonly used in practice. However, there are numerous formulations of solutions and proprietary processes

available which are not included in this part of ISO 27831. Throughout this part of ISO 27831, the process and

method designations in brackets which follow references to cleaning treatments refer to the processes and

methods in Clause 10.

4 © ISO 2008 – All rights reserved

6.2 All porous castings shall be degreased, cleaned and dried prior to their impregnation.

6.3 The efficiency of some of the methods may be increased by the use of ultrasonic agitation (process A,

method A6), but care shall be taken to avoid damage to delicate items and assemblies such as electrical or

electronic equipment and semi-conductor devices.

6.4 To avoid packing or nesting of large volumes of small items in soak cleaners, a barrel cleaning method

may be used. This method is not suitable for thin or delicate items.

6.5 Vibratory cleaning methods may be used for the deburring and polishing of fragile components in a

moving bed of abrasive medium (process D, method D3) containing a detergent compound.

7 Non-corrosion-resisting steels, cast irons and pure irons

7.1 Non-corrosion-resisting steels

7.1.1 Selection of method of cleaning

The choice of cleaning methods for steels of tensile strength 1 000 MPa and above is restricted by the

requirements of 7.1.2 and 7.1.3 in order to avoid embrittlement by hydrogen absorption during cathodic or acid

treatments. In general, the methods given are suitable for both steel and iron. Treatment of cast iron in acid

solutions is, however, liable to set up preferential etching around the graphite, especially around flake graphite,

which may become detached, leaving holes which may trap treatment solution and give rise to subsequent

staining or corrosion.

7.1.2 Stress relief heat treatment

Items made from steel of tensile strength 1 000 MPa and above which have been ground or subjected to

heavy machining after final tempering shall be stress relieved in accordance with ISO 9587 or as specified by

the purchaser. Any stress-relieving treatment shall be applied after degreasing (process A) and before any

treatment liable to cause embrittlement (see 7.1.1). Items which have been treated in order to introduce

beneficial compressive stresses into any part of the surface, e.g. by shot peening or cold working, shall not be

heated above 230 °C.

7.1.3 General degreasing and cleaning

7.1.3.1 Steels of tensile strength up to 1 000 MPa

Degrease in accordance with process A (method A1 or A2) and process B (method B1, B2 or B3) prior to the

commencement of a cleaning sequence selected from processes D to L, as appropriate.

7.1.3.2 Steels of tensile strength in the range 1 000 MPa to 1 400 MPa

Any form of cathodic cleaning treatment of these steels is incompatible. Degrease in accordance with

process A (method A1 or A2) and process B (method B1, B2 or B3) prior to the commencement of a cleaning

sequence selected from processes D, F, H and K, as appropriate.

7.1.3.3 Steels of tensile strength in the range 1 400 MPa to 1 800 MPa

Degrease in accordance with process A (method A1 or A2) and process B (method B1), with an applied

anodic current, if needed. Alkaline de-rusting (method K1) may also be used. Neither cathodic- nor

alternating-current treatment is applicable for these steels.

For cleaning, use abrasive cleaning (process D) and anodic pickling in a sulfuric acid solution (process H). If

electrolytic de-rusting is needed, an alkaline electrolyte and anodic current shall be used.

7.1.3.4 Steels of tensile strength over 1 800 MPa

Degrease in accordance with process A (method A1 or A2) and process B (method B1), and for cleaning use

abrasive cleaning process D (method D1) or anodic pickling in a sulfuric acid solution (process H).

Abrasive cleaning, especially grit blasting (method D1), leaves the surface readily corrodible. Therefore,

further processing shall be carried out without delay.

If sulfuric acid cleaning is used instead of process D, the items shall be connected up and the current switched

on before the items are immersed in the solution and, after treatment, the items shall be withdrawn rapidly

before the current is finally switched off, and rinsed immediately (see 5.5). The sulfuric acid used to make up

−6

the solution shall at no time contain a mass fraction of more than 11 × 10 of oxidizable material, calculated

as sulfur dioxide, determined by the method described in Annex C. This precaution is necessary because

reduced sulfur, phosphorous and arsenic compounds in the acid promote hydrogen absorption during rinsing.

Process H and electrolytic de-rusting shall not be used for steels of tensile strength 1 800 MPa or greater. For

these steels, abrasive cleaning (process D) shall only be used following process A and/or process B, in order

to avoid any risk of hydrogen embrittlement. For electrolytic de-rusting of steels of tensile strength over

1 000 MPa, cathodic current or alternating current shall not be used.

7.1.4 Preparation prior to electroplating

Degrease and clean in accordance with 7.1.3, taking into account the tensile strength of the steel, using:

a) process A (method A1 or A2);

b) process B (method B1, B2 or B3);

c) processes D to F, as appropriate (method F, treatment in HCl, shall be avoided for spring temper and

case-hardened items);

d) process J or K, de-rusting;

e) process G or, if inhibited solutions are used for acid pickling (process F), it may be necessary to remove

adsorbed inhibitor from the surface by acid dipping (process G) or by a suitable alkaline solution

(process B), before chemical smoothing (process L) and/or electroplating;

f) process H, anodic pickling;

g) process L, chemical smoothing.

For steels of tensile strength 1 800 MPa and above, see 7.1.3.4.

Tin, tin-zinc, lead and lead-tin electroplating is not recommended for steels of tensile strength over 1 000 MPa

because of the danger of inter-granular penetration of the tin into the steel occurring at temperatures below

the melting point of tin (232 °C) during embrittlement relief heat treatment at 190 °C to 220 °C as specified in

ISO 9588 or as otherwise specified by the purchaser.

For steels of tensile strength 1 400 MPa and above, zinc and cadmium electrolyte shall not contain

brightening agents, in order to avoid hydrogen embrittlement. Copper electrodeposition on steels of tensile

strength 1 400 MPa and above is not recommended as it can introduce irreversible embrittlement and may

adversely affect the fatigue properties.

6 © ISO 2008 – All rights reserved

7.1.5 Preparation prior to autocatalytic nickel plating

7.1.5.1 For steels having a tensile strength below 1 000 MPa, items may be treated as follows before

autocatalytic nickel plating:

a) degrease in accordance with process A (method A1) and process B (method B1) prior to the

commencement of a cleaning sequence selected from processes D to F and K, as appropriate;

b) clean by periodically reversed current (finishing anodically) in an alkaline solution;

c) acid dip in a solution containing a 10 % volume fraction of sulfuric acid (ρ = 1,84 g/cm ) or in a solution

containing a 10 % to 50 % volume fraction of hydrochloric acid (ρ = 1,16 g/cm ).

Some steels containing chromium and molybdenum may become passivated by anodic cleaning. For these

steels, cathodic cleaning in place of cleaning by periodically reversed current, taking into account 7.1.3, may

be employed.

A warm rinse may be found desirable to pre-heat large items immediately before autocatalytic nickel

deposition, but care shall be taken to ensure that the items do not dry off before being immersed in the

autocatalytic nickel solution.

The items are now ready for autocatalytic nickel plating in accordance with ISO 4527 or another appropriate

International Standard.

7.1.5.2 For steels having a tensile strength in the range 1 000 MPa to 1 400 MPa, the following

procedure shall be carried out:

a) Degrease in accordance with process A (method A1) and process B (method B1) prior to the

commencement of a cleaning sequence selected from processes D, F and K, as appropriate.

b) Anodic etch (process H) for between 1 min and 3 min.

This bath is liable to deteriorate from frequent use. Therefore, care shall be taken to monitor the bath and

maintain it in good condition

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...