ISO 13856-2:2005

(Main)Safety of machinery - Pressure-sensitive protective devices - Part 2: General principles for the design and testing of pressure-sensitive edges and pressure-sensitive bars

Safety of machinery - Pressure-sensitive protective devices - Part 2: General principles for the design and testing of pressure-sensitive edges and pressure-sensitive bars

ISO 13856-2:2005 specifies the general principles and requirements for the design and testing of pressure-sensitive edges and pressure-sensitive bars for use as safety devices and not as actuating devices for normal operation. It is applicable to pressure-sensitive edges and pressure-sensitive bars, with or without an external reset facility, used to detect persons or parts of persons who may be exposed to danger such as hazardous moving parts. Its purpose relates primarily to safety and reliability rather than suitability. It is restricted to the functioning of pressure-sensitive edges and pressure-sensitive bars and does not specify the requirements for their application, but does contain requirements for the information for use to be provided by the manufacturer. It does not specify the dimensions of the pressure-sensitive edges or bars in relation to a particular application. It is not applicable to stopping devices according to IEC 60204-1 used only for normal operational, including emergency stopping, of machinery. Additional requirements could be necessary where pressure-sensitive edges and pressure-sensitive bars are used in locations accessible to elderly or disabled people or children.

Sécurité des machines — Dispositifs de protection sensibles à la pression — Partie 2: Principes généraux de conception et d'essai des bords et barres sensibles à la pression

General Information

Relations

Frequently Asked Questions

ISO 13856-2:2005 is a standard published by the International Organization for Standardization (ISO). Its full title is "Safety of machinery - Pressure-sensitive protective devices - Part 2: General principles for the design and testing of pressure-sensitive edges and pressure-sensitive bars". This standard covers: ISO 13856-2:2005 specifies the general principles and requirements for the design and testing of pressure-sensitive edges and pressure-sensitive bars for use as safety devices and not as actuating devices for normal operation. It is applicable to pressure-sensitive edges and pressure-sensitive bars, with or without an external reset facility, used to detect persons or parts of persons who may be exposed to danger such as hazardous moving parts. Its purpose relates primarily to safety and reliability rather than suitability. It is restricted to the functioning of pressure-sensitive edges and pressure-sensitive bars and does not specify the requirements for their application, but does contain requirements for the information for use to be provided by the manufacturer. It does not specify the dimensions of the pressure-sensitive edges or bars in relation to a particular application. It is not applicable to stopping devices according to IEC 60204-1 used only for normal operational, including emergency stopping, of machinery. Additional requirements could be necessary where pressure-sensitive edges and pressure-sensitive bars are used in locations accessible to elderly or disabled people or children.

ISO 13856-2:2005 specifies the general principles and requirements for the design and testing of pressure-sensitive edges and pressure-sensitive bars for use as safety devices and not as actuating devices for normal operation. It is applicable to pressure-sensitive edges and pressure-sensitive bars, with or without an external reset facility, used to detect persons or parts of persons who may be exposed to danger such as hazardous moving parts. Its purpose relates primarily to safety and reliability rather than suitability. It is restricted to the functioning of pressure-sensitive edges and pressure-sensitive bars and does not specify the requirements for their application, but does contain requirements for the information for use to be provided by the manufacturer. It does not specify the dimensions of the pressure-sensitive edges or bars in relation to a particular application. It is not applicable to stopping devices according to IEC 60204-1 used only for normal operational, including emergency stopping, of machinery. Additional requirements could be necessary where pressure-sensitive edges and pressure-sensitive bars are used in locations accessible to elderly or disabled people or children.

ISO 13856-2:2005 is classified under the following ICS (International Classification for Standards) categories: 13.110 - Safety of machinery. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 13856-2:2005 has the following relationships with other standards: It is inter standard links to ISO 13856-2:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 13856-2:2005 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 13856-2

First edition

2005-02-15

Safety of machinery — Pressure-

sensitive protective devices —

Part 2:

General principles for the design and

testing of pressure-sensitive edges and

pressure-sensitive bars

Sécurité des machines — Dispositifs de protection sensibles à la

pression —

Partie 2: Principes généraux de conception et d'essai des bords et

barres sensibles à la pression

Reference number

©

ISO 2005

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2005

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2005 – All rights reserved

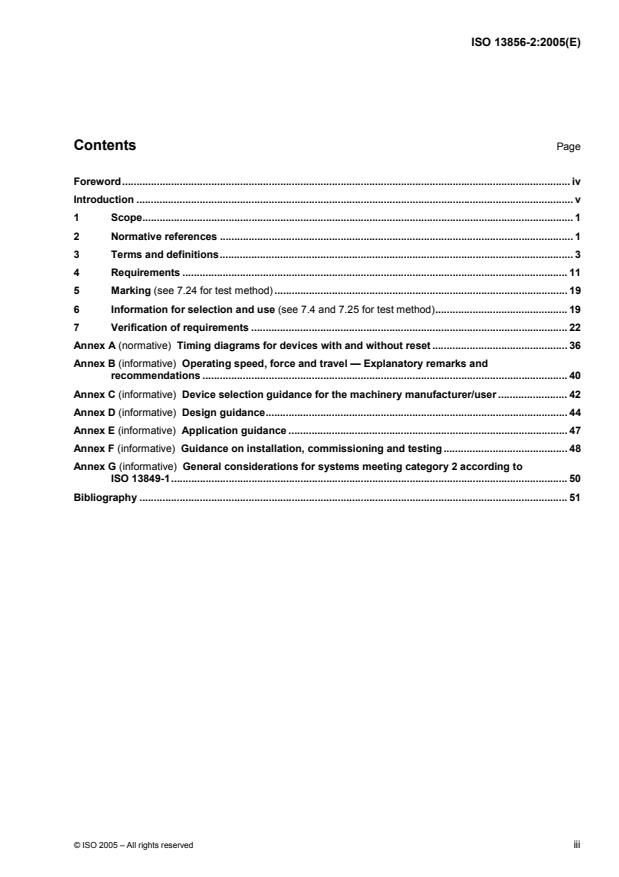

Contents Page

Foreword. iv

Introduction . v

1 Scope. 1

2 Normative references . 1

3 Terms and definitions. 3

4 Requirements . 11

5 Marking (see 7.24 for test method) . 19

6 Information for selection and use (see 7.4 and 7.25 for test method). 19

7 Verification of requirements . 22

Annex A (normative) Timing diagrams for devices with and without reset . 36

Annex B (informative) Operating speed, force and travel — Explanatory remarks and

recommendations . 40

Annex C (informative) Device selection guidance for the machinery manufacturer/user . 42

Annex D (informative) Design guidance. 44

Annex E (informative) Application guidance . 47

Annex F (informative) Guidance on installation, commissioning and testing . 48

Annex G (informative) General considerations for systems meeting category 2 according to

ISO 13849-1. 50

Bibliography . 51

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 199 was prepared by Technical Committee ISO/TC 199, Safety of machinery.

ISO 13856 consists of the following parts, under the general title Safety of machinery — Pressure-sensitive

protective devices:

Part 1: General principles for design and testing of pressure-sensitive mats and pressure-sensitive floors

Part 2: General principles for the design and testing of pressure-sensitive edges and pressure-sensitive

bars

iv © ISO 2005 – All rights reserved

Introduction

ISO 13856 covers safety devices that detect the presence of a person through the application of a pressure or

force by a part of the person's body. After actuation, the safety devices give a stop command which is used by

the control system of the machine to provide protection for the person who caused the device to be actuated.

Annex A of this part of ISO 13856 presents timing diagrams for devices with and without reset. Annex B

explains the relationship between operating speed, the force exerted on the body and the distance travelled

by the device following actuation. Annex C provides guidance to users on the selection of a suitable device. It

is advisable that the supplier and customer liaise to examine carefully the constraints presented by the

application before placing an order for the equipment.

The safeguarding of machinery (see ISO 12100-1:2003, 3.20) can be achieved by many different means.

These means include guards which prevent access to the hazard zone by means of a physical barrier (e.g.

fixed guards according to ISO 14120, or interlocking guards according to ISO 14119), protective devices (e.g.

electro-sensitive protective equipment according to IEC 61496) and pressure-sensitive protective devices

according to this document.

Type-C standards makers and designers of machinery/installations (see page vi for an explanation of the

different types of machinery safety standards) need to consider the best way to achieve the required level of

safety taking into account the intended application and the results of the risk assessment (see ISO 14121).

The best solution may combine several of these different means. It is advisable, too, that the

machinery/installation supplier and the user examine together carefully the existing constraints before making

their decision on the choice of safeguarding means.

Annex D gives guidance regarding the design of pressure-sensitive edges and pressure-sensitive bars.

Annex E gives guidance on the application of pressure-sensitive edges and pressure-sensitive bars. Annex F

gives guidance on installation, commissioning and testing. Annex G covers general considerations for meeting

category 2 according to ISO 13849-1.

This part of ISO 13856 does not specify the dimensions or the configuration of the effective sensing surface of

pressure-sensitive edges or pressure-sensitive bars in relation to any particular application. However, there is

a requirement for the manufacturer of any safety device to provide sufficient information to enable the user (i.e.

the machinery manufacturer and/or user of the machinery) to specify an adequate arrangement.

Pressure-sensitive edges and pressure-sensitive bars are safety devices of the “mechanically actuated trip

device” type. General requirements for these devices (as well as other safety devices) are given in

ISO 12100-2:2003, 5.1 and 5.2.

Pressure-sensitive edges and bars are used in a wide range of applications with different conditions of use

relating, for example, to loading, electrical, physical and chemical environments. They are interfaced with

machine controls to ensure that the machine reverts to a safe condition if the device is actuated.

Pressure-sensitive edges and pressure-sensitive bars may be fitted to a moving part of a machine at the point

where a trapping, crushing or collision hazard may occur. They may also be fitted to a fixed part of a machine

or an obstacle to prevent trapping or crushing hazards with a moving part of a machine. Pressure-sensitive

edges and pressure-sensitive bars are designed, selected, installed and/or interfaced with the control system

of the machine so that the force/pressure applied to a person or parts of the body do not exceed certain limits.

Pressure-sensitive edges, bars, bumpers and barriers have many similarities. Table 1 summarises the

differences which generally apply between the two types of devices covered by this part of ISO 16856 and

gives guidance for their application.

Table 1 — Characteristic features of pressure-sensitive edges and bars

Feature Edge Bar

According to this part of ISO 13856-2

Cross section Regular Regular

Length/width ratio >1 Any ratio

Effective sensing surface Deflects locally Moves as a whole

Intended to detect… finger finger

hand hand

arm arm

leg leg

head head

torso torso

The structure of safety standards in the field of machinery is as follows:

type-A standards (basis safety standards) giving basic concepts, principle for design, and general aspects

that can be applied to machinery;

type-B standards (generic safety standards) dealing with one safety aspect or one type of safeguard that

can be used across a wide range of machinery:

type-B1 standards on particular safety aspects (e.g. safety distances, surface temperature, noise);

type-B2 standards on safeguards (e.g. two-hands controls, interlocking devices, pressure-sensitive

devices, guards);

type-C standards (machinery safety standards) dealing with detailed safety requirements for a particular

machine or group of machines.

This part of ISO 13856 is a type-B2 standard as stated in ISO 12100-1.

When provisions of a type-C standard are different from those which are stated in type-A or -B standards, the

provisions of the type-C standard take precedence over the provisions of the other standards, for machines

that have been designed and built according to the provisions of the type-C standard.

ISO/TC 199 has a mandate in this area to produce type-A and type-B standards, which will allow verification

of conformity with the essential safety requirements.

ISO 13856-2 is based on EN 1760-2:2001, published by the European Committee for Standardization (CEN).

vi © ISO 2005 – All rights reserved

INTERNATIONAL STANDARD ISO 13856-2:2005(E)

Safety of machinery — Pressure-sensitive protective devices —

Partie 2:

General principles for the design and testing of pressure-

sensitive edges and pressure-sensitive bars

1 Scope

This part of ISO 13856 specifies the general principles and requirements for the design and testing of

pressure-sensitive edges and pressure-sensitive bars for use as safety devices and not as actuating devices

for normal operation. It is applicable to pressure-sensitive edges and pressure-sensitive bars, with or without

an external reset facility, used to detect persons or parts of persons who may be exposed to danger such as

hazardous moving parts. Its purpose relates primarily to safety and reliability rather than suitability (for the

relationship between safety and reliability, see ISO 13849-1:1999, Annex D).

This part of ISO 13856 is restricted to the functioning of pressure-sensitive edges and pressure-sensitive bars

and does not specify the requirements for their application. However, Clause 6 does contain requirements for

the information for use to be provided by the manufacturer. This document does not specify the dimensions of

the pressure-sensitive edges or bars in relation to a particular application. It is not applicable to stopping

devices according to IEC 60204-1 used only for normal operational, including emergency stopping,

of machinery. Additional requirements could be necessary where pressure-sensitive edges and

pressure-sensitive bars are used in locations accessible to elderly or disabled people or children.

NOTE It may not be possible to carry out all the tests in this document for pressure-sensitive edges and

pressure-sensitive bars when they have been designed and built into the machinery by the manufacturer.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 4413, Hydraulic fluid power — General rules relating to systems

ISO 4414, Pneumatic fluid power — General rules relating to systems

ISO 12100-1:2003, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic

terminology, methodology

ISO 12100-2:2003, Safety of machinery — Basic concepts, general principles for design — Part 2: Technical

principles

ISO 13849-1:1999, Safety of machinery — Safety-related parts of control systems — Part 1: General

principles for design

ISO 13849-2:1999, Safety of machinery — Safety-related parts of control systems — Part 2: Validation

IEC 60068-2-6, Environmental testing — Part 2: Tests — Test Fc: Vibration (sinusoidal)

IEC 60068-2-14, Environmental testing — Part 2: Tests — Test N: Change of temperature

IEC 60068-2-29, Environmental testing — Part 2: tests. Test Eb and guidance: bump

IEC 60068-2-78, Environmental testing — Part 2-78: Tests — Test Cab: Damp heat, steady state

IEC 60204-1:1997, Safety of machinery — Electrical equipment of machines — Part 1: General requirements

IEC 60439-1:1999, Low-voltage switchgear and controlgear assemblies — Part 1: Type-tested and partially

type-tested assemblies

IEC 60529, Degrees of protection provided by enclosures (IP code)

IEC 60664-1:1992, Insulation co-ordination for equipment within low-voltage systems — Part 1: Principles,

requirements and tests

IEC 60947-5-1:1997, Low-voltage switchgear and controlgear — Part 5-1: Control circuit devices and

switching elements — Electromechanical control circuit devices

IEC 61000-4-2, Electromagnetic compatibility (EMC) — Part 4: Testing and measurement techniques —

Section 2: Electrostatic discharge immunity test — Basic EMC publication

IEC 61000-4-3, Electromagnetic compatibility (EMC) — Part 4-3: Testing and measurement techniques —

Radiated, radio-frequency, electromagnetic field immunity test

IEC 61000-4-4, Electromagnetic compatibility (EMC) — Part 4: Testing and measurement techniques —

Section 4: Electrical fast transient/burst immunity test — Basic EMV publication

IEC 61000-4-5, Electromagnetic compatibility (EMC) — Part 4: Testing and measurement techniques —

Section 5: Surge immunity test

IEC 61000-4-6, Electromagnetic compatibility (EMC —- Part 4: Testing and measurement techniques —

Section 6: Immunity to conducted disturbances, induced by radio-frequency fields

IEC 61000-6-2, Electromagnetic compatibility (EMC) — Part 6-2: Generic standards — Immunity for industrial

environments

IEC 61000-6-3, Electromagnetic compatibility (EMC) — Part 6-3: Generic standards — Emission standard for

residential, commercial and light-industrial environments

IEC 61496-1, Safety of machinery — Electro-sensitive protective equipment — Part 1: General requirements

and tests

IEC 61496-2, Safety of machinery — Electrosensitive protective equipment — Part 2: Particular requirements

for equipment using active optoelectronic protective devices

IEC 61496-3, Safety of machinery — Electro-sensitive protective equipment — Part 3: Particular requirements

for Active Opto-electronic Protective Devices responsive to Diffuse Reflection (AOPDDR)

2 © ISO 2005 – All rights reserved

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 12100-1 and the following apply.

3.1

pressure-sensitive edge

safety device of the “mechanically activated trip” type intended to detect the touch of a person or part of a

person and comprising

a) sensor(s) which generates a signal when pressure is applied to part of its surface, where

the length is greater than the width,

the cross section throughout the pressure-sensitive area is constant,

the width of the cross section is greater than 8 mm,

the effective sensing surface is deformed locally to actuate the sensor(s), and

b) control unit, which responds to the signal from the sensor and generates an output signal(s) to the control

system of a machine

See Figure 1.

NOTE The width of the sensor's cross section is usually u 80 mm.

3.2

pressure-sensitive bar

safety device comprising

a) sensor(s) which generates a signal when pressure is applied to part of its surface, where

the length is greater than the width,

the cross section throughout the pressure-sensitive area is constant,

the width of the cross section is greater than 8 mm,

the effective sensing surface moves as a whole to actuate the sensor(s), and

b) control unit, which responds to the signal from the sensor and generates an output signal(s) to the control

system of a machine

See Figure 1.

NOTE 1 The width of the sensor's cross section is usually u 80 mm.

NOTE 2 The surface of a pressure-sensitive bar can also deform locally but the deformation does not actuate the

sensor(s).

3.3

sensor

part of the pressure-sensitive edge or pressure-sensitive bar which generates a signal in response to sufficient

pressure applied to part of its surface

NOTE Definitions 3.3 to 3.5 define the functional components of a pressure-sensitive edge or bar. These functions

may be integrated into a single assembly or may be contained in any number of separate assemblies (see Figure 1). For

example, a simple pressure-sensitive edge or pressure-sensitive bar actuating a position detection switch may be

considered to be the sensor, the control unit, and the output signal switching device.

3.4

control unit

part of the pressure-sensitive edge or pressure-sensitive bar which responds to the condition of the sensor

and generates output signals to the machine control system

NOTE Definitions 3.3 to 3.5 define the functional components of a pressure-sensitive edge or bar. These functions

may be integrated into a single assembly or may be contained in any number of separate assemblies (see Figure 1). For

example, a simple pressure-sensitive edge or pressure-sensitive bar actuating a position detection switch may be

considered to be the sensor, the control unit, and the output signal switching device.

3.5

output signal switching device

part of the control unit of a pressure-sensitive edge or pressure-sensitive bar which is connected to the

machine control system and transmits output signals

NOTE Definitions 3.3 to 3.5 define the functional components of a pressure-sensitive edge or bar. These functions

may be integrated into a single assembly or may be contained in any number of separate assemblies (see Figure 1). For

example, a simple pressure-sensitive edge or pressure-sensitive bar actuating a position detection switch may be

considered to be the sensor, the control unit, and the output signal switching device.

4 © ISO 2005 – All rights reserved

Key

A Manual reset signal to machine control system (where appropriate alternative to 9).

B Machine control system(s)

1 pressure-sensitive edge or bar 7 sensor output signal

2 sensor(s) 8 on state/off state signal

a

3 control unit 9 manual reset signal

a (where appropriate alternative to A)

4 output signal switching device(s)

10 reset signal from machine control system

5 part of machine control system for pressure-sensitive

(where appropriate)

edge/pressure-sensitive bar output signal processing

11 monitoring signals (optional)

6 actuating force

a

May be located within the machine control system enclosure or be part of the machine control system.

Figure 1 — Pressure-sensitive edge or bar applied to machine

3.6

ON state

state in which the output circuit(s) of an output signal switching device is complete and permits the flow of

current or fluid

3.7

OFF state

state in which the output circuit(s) of an output signal switching device is broken and interrupts the flow of

current or fluid

3.8

actuating force

any force applied to the sensor which causes the output signal switching device(s) to go to the OFF state

3.9

effective sensing surface

part of the surface of the sensor or a combination of sensors within the effective sensing angle and the

effective sensing length where the application of an actuating force creates an OFF state in the output signal

switching device

NOTE See, for example, Figures 2 and 3.

3.10

effective sensing length

length of the effective sensing surface

3.11

reference axis

line in the direction of the length of the sensor, whose position in the cross-sectional view of the sensor is

used to define the effective sensing surface

See Figures 2 and 3.

3.12

effective sensing angle

angle around the reference axis, which limits the effective sensing surface along the effective sensing length

See Figures 2 and 3.

3.13

reference direction

direction of actuation, from a point on the effective sensing surface towards the reference axis, which bisects

the effective sensing angle and is normal to the reference axis

See Figures 2 and 3.

3.14

dead surface(s)

part of the surface area of the sensor outside the effective sensing surface

See Figures 2 and 3.

a) Symmetrical with dead surface at ends

6 © ISO 2005 – All rights reserved

b) Symmetrical without dead surface at ends

c) Asymmetrical with dead surface at ends

d) Asymmetrical without dead surface at ends

Key

effective sensing surface

dead surface

L effective sensing length 1 reference direction

α effective sensing angle 2 reference axis

β see 7.5.2

Figure 2 — Effective sensing surfaces of pressure-sensitive edges

Key

effective sensing surface

dead surface

L effective sensing length 1 reference direction

α effective sensing angle 2 reference axis

β see 7.5.2

Figure 3 — Effective sensing surface of pressure-sensitive bars

3.15

pre-travel

distance travelled by an object, moving in a direction normal to the reference axis and in the axis of the

applied actuating force measured from where this object touches the effective sensing surface to where the

output signal switching device(s) changes to an OFF state under specified conditions

See Figure 4.

3.16

working travel

distance travelled by an object, moving in a direction normal to the reference axis, from where this object

touches the effective sensing surface, under specified conditions, to where a stated limit force is exerted on

the object

See Figure 4.

8 © ISO 2005 – All rights reserved

3.17

overtravel

difference between the working travel and the pre-travel when both are measured with the same object

applied under the same conditions

See Figure 4.

3.18

force–travel relationship

relationship between force applied normal to the reference axis and the distance travelled by a specified

object normal to the reference axis under specified conditions

See Figure 4.

Test piece 1 according to Figure 6 is used to apply the forces.

Key

a

A pre-travel (actuating point and actuating maximum operating) Force (N).

b

B working travel (for example, occurs at 250 N or 400 N operating Travel (mm).

c

speed of less than or equal to 10 mm/s)

Pre-travel.

d

C total travel (for example, occurs at 600 N operating

Overtravel at 250 N.

speed of less than or equal to 10 mm/s)

e

Working travel at 250 N.

f

Overtravel at 400 N.

1 stated limit force

g

Working travel at 400 N.

2 lowest actuating force

h

Total travel.

Figure 4 — Diagram of force — Travel relationship

3.19

reset

function which permits an ON state in the output signal switching device(s) provided that certain conditions are

met

NOTE See Annex A.

3.20

mounting orientations

orientation in space of the sensor

See Figure 5.

Figure 5 — Sensor mounting orientations A to E

10 © ISO 2005 – All rights reserved

3.21

total travel

movement or deformation of the effective sensing surface of a pressure-sensitive edge or pressure-sensitive

bar which is measured in the direction of the actuating force, from the point of contact to the point where no

further significant deformation of the effective sensing surface occurs, e.g. at a force of 600 N

3.22

start interlock

means which prevents the start of an automatic machine when power (e.g. the electrical supply) is switched

on to the pressure-sensitive edge or pressure-sensitive bar, or is interrupted and restored

3.23

operating speed

any speed at which a force is applied to the sensor and which causes the output signal switching device to go

to the OFF state

4 Requirements

4.1 Effective sensing surface

As shown in Figures 2 and 3, the manufacturer shall state the effective sensing surface by giving the

dimensions x, y, z; the angles alpha and beta and the effective sensing length.

The effective sensing angle of pressure-sensitive devices with heights (see Figure 2) x + z W 40 mm shall

be W 90°.

The effective sensing angle of pressure-sensitive devices with a height x + z < 40 mm shall be at least 40°.

If the effective sensing angle is less than 90°, a clear warning shall be given in the information for use

(see Clause 6).

4.2 Actuating force (see 7.5 and 7.6 for test method)

CAUTION — The forces specified in this subclause are primarily intended for the purposes of

assessing the pressure-sensitive performance of the device. These forces should not be considered

as safe forces (see Annex C and ISO 14120:2002, 5.2.5.2 for guidance).

The lowest actuating force(s), normal to the reference axis, shall not exceed those specified in Table 2 when

applied at the test speeds (from minimum to maximum operating speed) over the effective sensing surface

and over the operating temperature range with the sensor in the mounting orientations (see Figure 5) which

the manufacturer has specified are suitable for use.

Table 2 — Relationship between test pieces and actuating forces

Test piece (see Figure 6) 1 2 3

Actuating force (N) 150 600 50

Test piece 3 shall be applied only to pressure-sensitive edges and pressure-sensitive bars that are designed

to detect fingers.

4.3 Pre-travel (see 7.7.2 for test method)

The pre-travel shall not be more than that stated by the manufacturer.

4.4 Overtravel (see 7.7.4 for test method)

The overtravel shall not be less than that stated by the manufacturer.

4.5 Working travel (see 7.7.3 for test method)

The working travel shall not be less than that stated by the manufacturer.

4.6 Force–travel relationship(s) (see 7.7 for test method)

The manufacturer of the pressure-sensitive edge or pressure-sensitive bar shall provide force–travel

relationship data for a representative sample in the form of a diagram as shown in Figure 4. This data shall be

determined with the force applied through test piece 1 (see Figure 6). The manufacturer shall state the

temperature, the operating speed(s), the mounting orientation and the direction of operation at which the data

was determined.

Each diagram shall show as a minimum:

the actuating force and pre-travel (point A on Figure 4);

the working travel for a reaction force of 250 N (see NOTE 2) or a force as stated in the type-C standard

(point B1 on Figure 4);

the working travel for a reaction force of 400 N (see NOTE 2) or a force as stated in the type-C standard

(point B2 on Figure 4);

the force–travel relationship above 400 N, for example up to 600 N (point C on Figure 4).

NOTE 1 The directions of operation to be considered depend upon the intended application of the pressure-sensitive

edge or pressure-sensitive bar.

NOTE 2 See Introduction and Annex C concerning acceptable forces.

4.7 Minimum operating speed (see 7.6 for test method)

The minimum operating speed shall not exceed 10 mm/s.

4.8 Number of operations (see 7.8 for test method)

4.8.1 General

The requirements for 4.8.2 and 4.8.3 apply to pressure-sensitive edges and/or pressure-sensitive bars in

order for them to be accepted as well-tried components. Where this requirement is not fulfilled, other means

shall be used to ensure the safety of the system, e.g. the use of a category 2 system according to

ISO 13849-1:1999.

4.8.2 Single sensors (see 7.8.1 for test method)

The pressure-sensitive edge or pressure-sensitive bar shall continue in normal operation and the sensor shall

have no visible signs of damage after 10 000 operations.

4.8.3 Combination of sensors (see 7.8.2 for test method)

Where the effective sensing surface comprises more than one sensor, the pressure-sensitive edge or

pressure-sensitive bar shall continue in normal operation and the sensors shall have no visible signs of

damage after a further 1 000 operations at each joint.

12 © ISO 2005 – All rights reserved

4.9 Sensor output (see 7.9 for test method)

The sensor output shall have a value which causes the output signal switching device to change to the OFF

state when the actuating force, normal to the reference axis, is applied to the effective sensing surface.

Dimensions in millimetres

Tolerance on radii ± 0,2

a) Test piece 1

b) Test piece 2

c) Test piece 3

a

Mounting proposal only.

Figure 6 — Test pieces (see 7.3)

4.10 Response of output signal switching device to actuating force

(see 7.9 and 7.10 for test method)

4.10.1 For systems where sensor output remains in OFF state for as long as actuating force is applied

When the minimum actuating force is applied normal to the reference axis, the output signal switching device

shall change from an ON state to an OFF state and shall remain in the OFF state for at least as long as the

actuating force is applied. The output signal switching device shall only revert to the ON state when

the actuating force is removed and a reset signal is applied, or

the actuating force is removed.

See Annex A.

4.10.2 For systems where sensor output does not stay in OFF state when actuating force remains

When the minimum actuating force is applied normal to the reference axis, the output signal switching device

shall change from an ON state to an OFF state. The output signal switching device shall only revert to the ON

state when a reset signal is applied (see Annex A) or when additional safety measures are taken, e.g.

automatic reversal of hazardous movement. Such additional measures shall be stated in information for use,

see 6.3.

Since the output switching device can revert to an ON state when the actuating force remains, additional

safety measures are required to ensure that there is no hazard.

See Annexes A and G for systems which are relevant to particular applications.

4.11 Reset function (see 7.10 for test method)

The reset function of a pressure-sensitive edge or pressure-sensitive bar shall fulfil the general requirements

of ISO 13849-1:1999, 5.5 and the functional requirements of Annex A.

To reset a start interlock or a restart interlock of a pressure-sensitive edge or pressure-sensitive bar, the reset

signal shall be applied

either directly to the control unit of the pressure sensitive device, or

via the machine control system.

When manual reset is provided, it shall function according to Annex A and ISO 13849-1:1999, 5.4.

4.12 Environmental conditions (see 7.11 for test method)

4.12.1 General

The pressure-sensitive edge or pressure-sensitive bar shall continue in normal operation in the environmental

conditions stated by the manufacturer. The minimum requirements are stated in 4.12.2, 4.12.3, 4.12.4 and

4.12.5.

4.12.2 Climatic conditions (see 7.11.2 and 7.11.3 for test method)

The pressure-sensitive edge or pressure-sensitive bar shall continue in normal operation under the following

climatic conditions.

The minimum temperature range shall be +5 °C to +40 °C. If the manufacturer states that the

pressure-sensitive edge or bar is suitable for a wider temperature range, then it shall meet this

requirement over the stated temperature range (see 7.11.2).

After storage at a relative humidity of 93 % and at a temperature of 40 °C, for four days, the system shall

continue in normal operation (see 7.11) and the integrity of the electrical insulation shall be maintained

(see 7.11.3).

14 © ISO 2005 – All rights reserved

4.12.3 Electromagnetic compatibility (see 7.11.4 for test method)

The pressure-sensitive edge or pressure-sensitive bar shall continue in normal operation under the conditions

given in Table 13 (see 7.11.4). The manufacturer may state a higher level for which the pressure-sensitive

edge or pressure-sensitive bar shall continue in normal operation.

4.12.4 Vibration (see 7.11.5 for test method)

The pressure-sensitive edge or pressure-sensitive bar shall continue to operate without being actuated under

the following vibration conditions in accordance with IEC 60068-2-6:

frequency range 10 Hz to 55 Hz;

displacement 0,15 mm;

10 cycles per axis;

sweep rate 1 octave per minute.

After this vibration test, the pressure-sensitive edge or pressure-sensitive bar shall continue in normal

operation.

4.12.5 Bump (see 7.11.6 for test method)

The pressure-sensitive bar shall continue to operate without being actuated under the following conditions.

The requirements apply to the sensor of bars in the reference direction and opposite direction only and shall

be in accordance with IEC 60068-2-29.

Peak acceleration: 100 m/s

Duration of pulse: 16 ms

Form of pulse: half-sine

Number of pulses per direction: 1 000

Frequency approximately: 1 hz

The pressure-sensitive bar shall continue to operate without being actuated under the above conditions. After

this bump test, the pressure-sensitive bar shall continue in normal operation.

4.13 Power supply variation

4.13.1 General

The pressure-sensitive edge and pressure-sensitive bar shall continue in normal operation when subjected to

the power supply variations given in 4.13.2 and 4.13.3.

4.13.2 Electrical power supply variation (see 7.12.2 for test method)

The pressure-sensitive edge and pressure-sensitive bar shall meet the requirements of IEC 60204-1:1997, 4.3.

4.13.3 Non-electrical power supply variations (see 7.12.3 for test method)

The pressure-sensitive edge and pressure-sensitive bar shall continue in normal operation when subjected to

power supply variations as stated by the manufacturer and in accordance with the relevant requirements of

ISO 4413 for hydraulic systems and ISO 4414 for pneumatic systems.

Where overpressure protective devices are not incorporated, overpressure variations outside the stated range

shall not result in a failure to danger.

Variations outside the stated range shall not result in a failure to danger.

4.14 Electrical equipment (see 7.13.1 for test method)

4.14.1 General

The electrical equipment (components) of pressure-sensitive edges and pressure-sensitive bars shall

conform to EN standards where they exist,

be suitable for the intended use, and

be operated within their specified ratings.

4.14.2 Protection against electric shock

Protection against electric shock shall be provided in accordance with IEC 60204-1:1997 (EN 60204-1:1997),

6.1, 6.2 and 6.3.

4.14.3 Protection against overcurrent

Overcurrent protection shall be provided in accordance with IEC 60204-1:1997, 7.2.1, 7.2.2, 7.2.4, 7.2.8, 7.2.9

and 7.2.10.

4.14.4 Electromechanical devices

Electromechanical control units and output signal switching devices shall meet the relevant requirements of

IEC 60947-5-1.

4.14.5 Pollution degree

The electrical equipment shall be suitable for pollution degree 2 in accordance with IEC 60439-1:1999, 6.1.2.3.

4.14.6 Clearance, creepage distances and isolating distances

The electrical equipment shall be designed and constructed in accordance with IEC 60439-1:1999

(EN 60439-1:1999), 7.1.2.

4.14.7 Wiring

The electrical equipment shall be wired in accordance with IEC 60439-1:1999, 7.8.3.

4.15 Pneumatic equipment (see 7.13.2 for test method)

Pneumatic equipment shall meet the relevant requirements of ISO 4414.

4.16 Hydraulic equipment (see 7.13.3 for test method)

Hydraulic equipment shall meet the relevant requirements of ISO 4413.

16 © ISO 2005 – All rights reserved

4.17 Enclosure (see 7.14 for test method)

4.17.1 Sensor

The manufacturer shall specify the suitability of the sensor for particular environment, e.g. wet or dusty

conditions. This specification shall be defined as an index of protection, e.g. IP 44 according to IEC 60529.

Those parts of the sensor which contain electrical components shall have an enclosure which meets the

requirements of IP 54 as a minimum. If the manufacturer specifies that the sensor may be immersed in water,

the sensor enclosure shall meet the requirements of IP 67 as a minimum. The manufacturer shall state the

time and depth of immersion.

4.17.2 Control unit and output signal switching device

The control unit and any external output signal switching device enclosure shall meet the requirements of

IP 54 as a minimum. Where the control unit and output signal switching device is designed for mounting in

another control equipment enclosure, this enclosure shall meet the requirements of the document of

protection relevant to that application. In these circumstances, the control unit and output signal switching

device shall meet the requirements of IP 2X as a minimum.

4.18 Additional coverings for sensors (see 7.15 for test method)

Where the manufacturer states that additional coverings can be used for the sensor, the overall requirements

of this document shall still be fulfilled (see Annex D).

4.19 Access (see 7.16 for test method)

Where access is required to the interior of any part of the pressure-sensitive edge or pressure-sensitive bar, it

shall only be possible by means of a key or tool.

4.20 Categories according to ISO 13849-1 (see 7.17 for test method)

Pressure-sensitive edges and pressure-sensitive bars shall meet the requirements of the categories which are

stated by the manufacturer. For pressure-sensitive edges and pressure-sensitive bars, the categories are as

follows:

the sensor shall meet the requirements of category 1 or in association with the other parts of the

pressure-sensitive edge or pressure-sensitive bar, categories 2, 3 or 4;

the control unit and the output signal switching device shall meet the requirements of category 1 or 2 or 3

or 4.

NOTE 1 Pressure-sensitive edges and pressure-sensitive bars are examples of a system made up of a combination of

safety-related parts. Consequently the categories of the parts of the device can differ one from another.

NOTE 2 At the time of preparing this document, the majority of known sensors were based on the requirements of

category 1. Air-pulse systems were not considered to fulfil the requirements of category 1. It may be possible for an air

pulse system to fulfil the requirements of category 2 when the safety function is checked (see Annexes A, D and G for

guidance on air pulse sensors).

NOTE 3 The sensor will be considered to meet the requirements of category 1 if it meets the requirements of this

document, and the requirements of ISO 13849-1.

NOTE 4 Type-C standards may set out other requirements relevant to their application to achieve a relevant level of

safety.

NOTE 5 It was not possible at the time of preparing this document for the majority of sensors to meet all the

requirements specified for the categories 3 or 4, in particular when considering mechanical damage and long-term

deterioration.

NOTE 6 At the time of preparing this document, control units and output signal switching devices built up with

electronic components were expected to fulfil the requirements of category 2 or 3 or 4.

4.21 Adjustments (see 7.18 for test method)

Pressure-sensitive edges and pressure-sensitive bars should have no means of adjustment.

If it is necessary to make adjustments during commissioning, the manufacturer shall supply instructions to

enable the adjustments to be made so that the requirements of the document can be met. There shall be

arrangements for checking that such adjustments have been made correctly. The adjustable elements shall

only be accessible by means of a key, security code or tool.

4.22 Sensor fixing and mechanical strength (see 7.19 for test method)

Means shall be provided for all parts of the sensor to be fixed securely in the specified mounting orientation.

The fixed sensor shall have sufficient mechanical strength to withstand the maximum forces in the specified

directions which are stated by the manufacturer.

4.23 Recovery after deformation (see 7.20 for test method)

After the effective sensing surface of the sensor has been deformed or moved by the working travel using

test piece 1 for 24 h, the effective sensing surface shall recover as shown in T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...