ISO/FDIS 22367

(Main)Medical laboratories — Application of risk management to medical laboratories

Medical laboratories — Application of risk management to medical laboratories

This document specifies a process for a medical laboratory to identify and manage the risks to patients, laboratory workers and service providers that are associated with medical laboratory examinations. The process includes identifying, estimating, evaluating, controlling and monitoring the risks. The requirements of this document are applicable to all aspects of the examinations and services of a medical laboratory, including the pre-examination and post-examination aspects, examinations, accurate transmission of test results into the electronic medical record and other technical and management processes described in ISO 15189. This document does not specify acceptable levels of risk. This document does not apply to risks from post-examination clinical decisions made by healthcare providers. This document does not apply to the management of risks affecting medical laboratory enterprises that are addressed by ISO 31000, such as business, economic, legal, and regulatory risks.

Laboratoires de biologie médicale — Application de la gestion des risques aux laboratoires de biologie médicale

Le présent document spécifie un processus permettant à un laboratoire de biologie médicale d'identifier et de gérer les risques pour les patients, le personnel de laboratoire et les prestataires de service qui sont associés aux examens de laboratoire de biologie médicale. Le processus inclut l'identification, l'estimation, l'évaluation, la maîtrise et la gestion des risques. Les exigences du présent document sont applicables à tous les aspects relatifs aux examens et aux services d'un laboratoire de biologie médicale, y compris les aspects préanalytiques et postanalytiques, les examens, la transmission rigoureuse des résultats d'examen dans un dossier médical électronique et les autres processus techniques et managériaux décrits dans l'ISO 15189. Le présent document ne spécifie pas les niveaux de risque acceptables. Le présent document ne s'applique pas aux risques liés aux décisions cliniques postanalytiques prises par des prestataires de soins de santé. Le présent document ne s'applique pas à la gestion des risques afférents aux entreprises de laboratoire de biologie médicale qui sont couverts par l'ISO 31000, tels que les risques commerciaux, économiques, juridiques et réglementaires.

General Information

- Status

- Not Published

- Drafting Committee

- ISO/TC 212/WG 1 - Quality and competence in the medical laboratory

- Current Stage

- 5020 - FDIS ballot initiated: 2 months. Proof sent to secretariat

- Start Date

- 06-Jan-2026

- Completion Date

- 06-Jan-2026

Relations

- Effective Date

- 12-Feb-2026

- Revises

ISO 22367:2020 - Medical laboratories — Application of risk management to medical laboratories - Effective Date

- 16-Sep-2023

Overview - ISO/FDIS 22367 (Medical laboratories, Risk Management)

ISO/FDIS 22367 specifies a structured process for applying risk management in medical laboratories. It guides laboratories to identify, estimate, evaluate, control and monitor risks to patients, laboratory personnel and service providers that arise from laboratory examinations and associated processes. The standard covers all phases of testing - pre‑examination, examination, and post‑examination (including accurate transmission of results into the electronic medical record). It does not set acceptable risk levels, nor does it cover clinical decisions made after results are reported or enterprise business risks managed under ISO 31000.

Key topics and technical requirements

The standard emphasizes practical, process‑oriented risk management with topics that include:

- Risk management process: structured steps to identify, estimate, evaluate, control and monitor risk.

- Proactive and reactive risk management: planning and analysis before implementation, and handling risks arising from incidents or nonconformities.

- Benefit‑risk analysis: assessing whether benefits justify residual risks where appropriate.

- Risk control and verification: selection of control options, evaluation of residual risk, and verification of control effectiveness.

- Risk monitoring and review: ongoing data sources, internal/external inputs and periodic management review.

- Qualification and responsibilities: management commitment and personnel competencies for risk activities.

- Scope of application: includes transmission of test results into electronic medical records and interfaces with ISO 15189 technical/management processes.

- Informative annexes with guidance on acceptability criteria, risk analysis tools, foreseeable hazards, nonconformities, and benefit‑risk methods.

Practical applications and benefits

ISO/FDIS 22367 helps medical laboratories to:

- Systematically reduce patient and staff harm from laboratory activities.

- Integrate risk management into quality systems and workflows required by ISO 15189.

- Improve incident investigation, corrective actions and continual improvement.

- Manage risks related to laboratory‑developed tests (LDTs) and interactions with IVD device manufacturers (concepts aligned with ISO 14971).

- Support safer result reporting and electronic health record integration.

Practical outcomes include clearer risk registers, prioritized mitigation actions, documented benefit‑risk decisions, and better alignment between technical processes and management oversight.

Who should use this standard

- Medical laboratory directors and quality managers

- Clinical laboratory scientists and safety officers

- Accreditation bodies and auditors

- Laboratories developing LDTs or integrating IVD devices

- Healthcare organizations coordinating laboratory services

Related standards

- ISO 15189 (Medical laboratories - Quality and competence)

- ISO 14971 (Medical device risk management concepts referenced for IVDs)

- ISO 31000 (Enterprise risk management - business/economic/legal risk guidance)

ISO/FDIS 22367 - Medical laboratories — Application of risk management to medical laboratories Released:23. 12. 2025

REDLINE ISO/FDIS 22367 - Medical laboratories — Application of risk management to medical laboratories Released:23. 12. 2025

ISO/FDIS 22367 - Laboratoires de biologie médicale — Application de la gestion des risques aux laboratoires de biologie médicale Released:27. 01. 2026

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

ISO/FDIS 22367 is a draft published by the International Organization for Standardization (ISO). Its full title is "Medical laboratories — Application of risk management to medical laboratories". This standard covers: This document specifies a process for a medical laboratory to identify and manage the risks to patients, laboratory workers and service providers that are associated with medical laboratory examinations. The process includes identifying, estimating, evaluating, controlling and monitoring the risks. The requirements of this document are applicable to all aspects of the examinations and services of a medical laboratory, including the pre-examination and post-examination aspects, examinations, accurate transmission of test results into the electronic medical record and other technical and management processes described in ISO 15189. This document does not specify acceptable levels of risk. This document does not apply to risks from post-examination clinical decisions made by healthcare providers. This document does not apply to the management of risks affecting medical laboratory enterprises that are addressed by ISO 31000, such as business, economic, legal, and regulatory risks.

This document specifies a process for a medical laboratory to identify and manage the risks to patients, laboratory workers and service providers that are associated with medical laboratory examinations. The process includes identifying, estimating, evaluating, controlling and monitoring the risks. The requirements of this document are applicable to all aspects of the examinations and services of a medical laboratory, including the pre-examination and post-examination aspects, examinations, accurate transmission of test results into the electronic medical record and other technical and management processes described in ISO 15189. This document does not specify acceptable levels of risk. This document does not apply to risks from post-examination clinical decisions made by healthcare providers. This document does not apply to the management of risks affecting medical laboratory enterprises that are addressed by ISO 31000, such as business, economic, legal, and regulatory risks.

ISO/FDIS 22367 is classified under the following ICS (International Classification for Standards) categories: 11.100.01 - Laboratory medicine in general. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/FDIS 22367 has the following relationships with other standards: It is inter standard links to FprEN ISO 22367, ISO 22367:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO/FDIS 22367 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

FINAL DRAFT

International

Standard

ISO/TC 212

Medical laboratories — Application

Secretariat: ANSI

of risk management to medical

Voting begins on:

laboratories

2026-01-06

Laboratoires de biologie médicale — Application de la gestion

Voting terminates on:

des risques aux laboratoires de biologie médicale

2026-03-03

RECIPIENTS OF THIS DRAFT ARE INVITED TO SUBMIT,

WITH THEIR COMMENTS, NOTIFICATION OF ANY

RELEVANT PATENT RIGHTS OF WHICH THEY ARE AWARE

AND TO PROVIDE SUPPOR TING DOCUMENTATION.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO

ISO/CEN PARALLEL PROCESSING LOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE

TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL

TO BECOME STAN DARDS TO WHICH REFERENCE MAY BE

MADE IN NATIONAL REGULATIONS.

Reference number

FINAL DRAFT

International

Standard

ISO/TC 212

Medical laboratories — Application

Secretariat: ANSI

of risk management to medical

Voting begins on:

laboratories

2026-01-02

Laboratoires de biologie médicale — Application de la gestion

Voting terminates on:

des risques aux laboratoires de biologie médicale

RECIPIENTS OF THIS DRAFT ARE INVITED TO SUBMIT,

WITH THEIR COMMENTS, NOTIFICATION OF ANY

RELEVANT PATENT RIGHTS OF WHICH THEY ARE AWARE

AND TO PROVIDE SUPPOR TING DOCUMENTATION.

© ISO 2026

IN ADDITION TO THEIR EVALUATION AS

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO

ISO/CEN PARALLEL PROCESSING

LOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL

or ISO’s member body in the country of the requester.

TO BECOME STAN DARDS TO WHICH REFERENCE MAY BE

MADE IN NATIONAL REGULATIONS.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland Reference number

ii

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Risk management . 9

4.1 Risk management process .9

4.2 Management responsibilities .9

4.3 Qualification of personnel .10

4.4 Risk management activities .10

4.4.1 General .10

4.4.2 Foreseeable risk . 12

4.4.3 Opportunity . 13

4.4.4 Information provided to users . 13

5 Proactive risk management .13

5.1 Proactive risk management plan. 13

5.2 Scope of the plan .14

5.3 Contents of the plan .14

5.4 Revisions to the plan .14

5.5 Documentation of the risk management plan. 15

6 Proactive risk analysis .15

6.1 General . 15

6.2 Risk analysis process . 15

6.3 Documentation of the risk analysis process .16

6.3.1 General .16

6.3.2 Intended medical laboratory use and reasonably foreseeable misuses .16

6.3.3 Identification of characteristics related to safety .16

6.3.4 Identification of hazards .16

7 Risk evaluation . 17

7.1 Overview .17

7.1.1 General .17

7.1.2 Reactive evaluation of risks .17

7.1.3 Proactive evaluation of risks .17

7.2 Benefit-risk analysis .18

7.3 Proactive risk evaluation .18

7.3.1 Risk acceptability criteria .18

7.3.2 Risk reduction . . .19

8 Risk control . 19

8.1 General .19

8.2 Risk control options . 20

8.2.1 General . 20

8.2.2 Role of standards in risk control . 20

8.2.3 Role of IVD medical devices in risk control . 20

8.3 Risks external to the laboratory .21

8.4 Risks arising from risk control measures .21

8.5 Residual risk evaluation .21

8.6 Risk control verification . 22

9 Risk management review .22

9.1 General . 22

9.2 Completeness of risk control . 22

9.3 Evaluation of overall residual risk . 22

iii

9.4 Risk management report . 23

10 Risk monitoring, analysis and control activities .23

10.1 Risk monitoring procedure . 23

10.2 Internal sources of risk information .24

10.3 External sources of risk information.24

11 Immediate actions to reduce risk .24

Annex A (informative) Implementation of risk management within the management system .25

Annex B (informative) Guidance on establishing risk acceptability criteria .35

Annex C (informative) Guidance on risk acceptability considerations .37

Annex D (informative) Identification of characteristics related to safety .40

Annex E (informative) Examples of foreseeable risks, hazards, foreseeable sequences of events

and hazardous situations . 47

Annex F (informative) Nonconformities potentially leading to significant risks .55

Annex G (informative) Risk analysis tools and techniques.63

Annex H (informative) Risk analysis of foreseeable user actions .68

Annex I (informative) Methods of risk assessment, including estimation of probability and

severity of harm .72

Annex J (informative) Overall residual risk evaluation and risk management review .77

Annex K (informative) Conducting a benefit-risk analysis .79

Annex L (informative) Residual risks.81

Bibliography .82

iv

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee

has been established has the right to be represented on that committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely

with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types

of ISO documents should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent

rights in respect thereof. As of the date of publication of this document, ISO had not received notice of (a)

patent(s) which may be required to implement this document. However, implementers are cautioned that

this may not represent the latest information, which may be obtained from the patent database available at

www.iso.org/patents. ISO shall not be held responsible for identifying any or all such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO’s adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 212, Medical laboratories and in vitro diagnostic

systems, in collaboration with the European Committee for Standardization (CEN) Technical Committee

CEN/TC 140, in vitro diagnostic medical devices, in accordance with the Agreement on technical cooperation

between ISO and CEN (Vienna Agreement).

This second edition cancels and replaces the first edition (ISO 22367:2020), which has been technically

revised.

The main changes are as follows:

— the application of risk management to processes has been emphasized;

— reactive and proactive risk management has been discussed, differentiated, and illustrated;

— the content is as far as possible in agreement the requirements for risk management in ISO 15189:2022;

— the relation with ISO 15189:2022 is indicated in Annex A in which Figure A.1 provides a flow chart for

the underlying management system to underpin this document;

— Clause I.5 has been slightly modified to emphasize that risks most often require benefit-risk assessment

to determine risk acceptability.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

v

Introduction

Medical laboratories deal with risks as part of their usual activities; these risks affect patients, personnel,

caregivers, and the organization as a whole. Risks span the range of services: pre-examination, examination

and post-examination processes, including the design and development of laboratory examinations. The

intent of this document is not to introduce risk as a concern for the laboratory but to provide a structure

for addressing, managing, and documenting risks that are part of the day-to-day and long-term (strategic)

activities of the laboratory.

ISO 15189 requires that medical laboratories review all work processes to identify potential failures for

risk of harm to patients and opportunities for improvement, modify the processes to reduce or eliminate

the identified risks, and document the decisions and actions taken. This document describes a process

for managing these risks to the patient, the operator, other persons, equipment and other property, the

healthcare enterprise as a whole, and the environment. It does not address business enterprise risks, which

are the subject of ISO 31000; however, ISO 31000 is consistent with and can provide further understanding

for the concepts in this document.

Medical laboratories span a broad range of activities, some of which rely on the use of in vitro medical

devices to achieve their quality objectives. When such devices are involved, risk management is a shared

responsibility between the in vitro diagnostic (IVD) manufacturer and the medical laboratory. Since most

IVD manufacturers have already implemented ISO 14971, this document has adopted similar concepts,

principles and framework to manage the risks associated with the medical laboratory when appropriate.

This is especially meaningful for laboratories that implement their own examinations on devices (laboratory

developed tests or LDTs); concepts integral to ISO 14971 can be directly applicable. ISO 5649 is a useful

reference for identifying and addressing risks in the development, implementation and retirement phases of

LDTs.

Activities in a medical laboratory can expose patients, workers or other stakeholders to a variety of hazards,

which can lead directly or indirectly to varying degrees of harm. The concept of risk has two components:

a) the probability of occurrence of harm;

b) the consequence of that harm, that is, how severe the harm might be.

Risk management is complex because each stakeholder can place a different value on the risk of harm.

Risk management interfaces with quality management at many points in the medical laboratory. In

ISO 15189, as an example, risk management is a component of complaint management, internal audit,

corrective action, quality control, management review and external assessment (for both accreditation

and proficiency testing). Management of risk also coincides with the management of safety in the medical

laboratories, as exemplified by the safety audit checklists in ISO 15190. This document is intended to assist

medical laboratories with the integration of risk management into their routine organization, operation and

management.

While this document is intended for use throughout the currently recognized medical laboratory disciplines,

it can effectively be applied to other healthcare services, such as diagnostic imaging, respiratory therapy,

physiological sciences, blood banks and transfusion services.

The use of this document facilitates cooperation between medical laboratories and other healthcare services,

assists in the exchange of information, and in the harmonization of methods and procedures.

vi

FINAL DRAFT International Standard ISO/FDIS 22367:2026(en)

Medical laboratories — Application of risk management to

medical laboratories

1 Scope

This document specifies a process for a medical laboratory to identify and manage the risks to patients,

laboratory workers and service providers that are associated with medical laboratory examinations. The

process includes identifying, estimating, evaluating, controlling and monitoring the risks.

The requirements of this document are applicable to all aspects of the examinations and services of a

medical laboratory, including the pre-examination, examination, and post-examination aspects including

accurate transmission of examination results into the electronic medical record, as well as other technical

and management processes described in ISO 15189.

This document does not specify acceptable levels of risk.

This document does not apply to risks from post-examination clinical decisions made by healthcare

providers.

This document complements the management of risks affecting medical laboratory enterprises that are

addressed by ISO 31000, such as business, economic, legal, and regulatory risks.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

benefit

impact or desirable outcome of a process (3.21), procedure (3.19) or the use of a medical device on the health

of an individual or a positive impact on patient management or public health

Note 1 to entry: Benefits include prolongation of life, reduction of pain, relief of symptoms, improvement in function,

or an increased sense of well-being.

3.2

event

occurrence or change of a particular set of circumstances

Note 1 to entry: An event can be one or more occurrences, and can have several causes.

Note 2 to entry: An event can consist of something not happening.

Note 3 to entry: An event can sometimes be referred to as an “incident” or “accident”.

Note 4 to entry: An event without consequences can also be referred to as a “near miss”, “incident”, “near hit” or “close

call”.

[SOURCE: ISO 31073:2022, 3.3.11. modified — Note to entry 2 was changed; the original Note 3 to entry was

removed, and a new Note 3 to entry and a Note 4 were added.]

3.3

examination

set of operations having the objective of determining the numerical value, text value or characteristics of a

property

Note 1 to entry: An examination may be the total of a number of activities, observations or measurements required to

determine a value or characteristics.

Note 2 to entry: Laboratory examinations that determine a numerical value of a property are called “quantitative

examinations”; those that determine the characteristics of a property are called “qualitative examinations”.

Note 3 to entry: Laboratory examinations are also called “assays” or “tests”.

[SOURCE: ISO 15189:2022, 3.8]

3.4

foreseeable risk

risk (3.25) that is predictable prior to its occurrence

Note 1 to entry: Risk can be known from prior experience, assessment of current circumstances, prior occurrence of

an event (3.2), or other sources.

Note 2 to entry: Addressing foreseeable risk results in preventive action.

Note 3 to entry: A risk that is foreseeable does not imply that it has been anticipated or addressed.

3.5

frequency

number of events (3.2) or outcomes per defined unit of time

Note 1 to entry: Frequency can be applied to past events or to potential future events, where it can be used as a

measure of likelihood or probability (3.20)

[SOURCE: ISO 31073:2022, 3.3.20]

3.6

harm

injury or damage to the health of people, or damage to property or the environment

[SOURCE: ISO/IEC Guide 51:2014, 3.1]

3.7

hazard

source of potential harm (3.6)

[SOURCE: ISO 31073:2022, 3.3.12, modified — Note 1 to entry has been deleted.]

3.8

hazardous situation

circumstance in which people, property, or the environment are exposed to one or more hazard(s) (3.7)

[SOURCE: ISO/IEC Guide 51:2014, 3.4]

3.9

healthcare provider

individual authorized to deliver health services to a patient

EXAMPLE Physician, nurse, ambulance attendant, dentist, diabetes educator, laboratory technician, laboratory

technologist, biomedical laboratory scientist, medical assistant, medical specialist, respiratory care practitioner.

[SOURCE: ISO 18113-1:2022, 3.1.28, modified — “laboratory technologist” and “biomedical laboratory

scientist” were added to the example.]

3.10

in vitro diagnostic manufacturer

IVD manufacturer

natural or legal person with responsibility for the design and/or manufacture of an IVD medical device (3.11)

with the intention of making the IVD medical device available for use, under his name, whether or not such

an IVD medical device is designed and/or manufactured by that person himself or on that person’s behalf by

another person(s)

[SOURCE: ISO 14971:2019, 3.9, modified — The term “manufacturer” was changed to “in vitro diagnostic

manufacturer”; in the definition, “medical device” was changed to “IVD medical device”; Notes to entry were

removed.]

3.11

in vitro diagnostic medical device

IVD medical device

medical device, whether used alone or in combination, intended by the manufacturer for the in vitro

examination (3.3) of specimens derived from the human body solely or principally to provide information for

diagnostic, monitoring or compatibility purposes

Note 1 to entry: The device includes reagents, calibrators, control materials, specimen receptacles, software, and

related instruments or apparatus or other articles.

Note 2 to entry: Adapted from ISO 18113-1:2022, 3.1.53.

3.12

in vitro diagnostic instrument

IVD instrument

equipment or apparatus intended by a manufacturer to be used as an IVD medical device (3.11)

[SOURCE: ISO 18113-1:2022, 3.1.32]

3.13

information supplied by the manufacturer

information that is related to identification, technical description, intended use (3.15) and proper use of the

IVD medical device (3.11), but excluding shipping documents

EXAMPLE Labels, instructions for use, manual, written, printed, electronic, or graphic matter.

Note 1 to entry: In IEC standards, documents provided with a medical device and containing important information

for the responsible organization or operator, particularly regarding safety, are called “accompanying documents”.

Note 2 to entry: Catalogues and material safety data sheets are not considered information supplied by the

manufacturer of IVD medical devices.

Note 3 to entry: Adapted from ISO 18113-1:2022, 3.1.35.

3.14

instructions for use

information supplied by the manufacturer (3.13) to enable the safe and proper use of an IVD medical device

(3.11)

Note 1 to entry: It includes the directions supplied by the manufacturer for the use, maintenance, troubleshooting and

disposal of an IVD medical device, as well as warnings and precautions.

Note 2 to entry: Instructions for use can also be referred to as “package insert” or manual for instruments.

Note 3 to entry: Adapted from ISO 18113-1:2022, 3.1.36.

3.15

intended use

intended purpose

objective intent of an IVD manufacturer (3.10) regarding the use of a product, process (3.21) or service (3.38)

as reflected in the specifications, instructions and information supplied by the IVD manufacturer

Note 1 to entry: Intended use statements for IVD information supplied by the manufacturer (3.13) can include two

components: a description of the functionality of the IVD medical device (3.11) (e.g. an immunochemical measurement

procedure (3.19) for the detection of analyte “x” in serum or plasma), and a statement of the intended medical use of

the examination (3.3) results.

[SOURCE: ISO 18113-1:2022, 3.1.37, modified — In Note 1 to entry, “labelling” was changed to “information

supplied by the manufacturer”; Note 2 was removed.]

3.16

laboratory management

person(s) with responsibility for, and authority over, a laboratory

Note 1 to entry: Laboratory management has the power to delegate authority and provide resources within the

laboratory.

Note 2 to entry: The laboratory management includes the laboratory director(s) and delegates together with

individuals specifically assigned to ensure the quality of the activities of the laboratory.

[SOURCE: ISO 15189:2022, 3.15]

3.17

likelihood

chance of something happening

Note 1 to entry: In risk management terminology, the word “likelihood” is used to refer to the chance of something

happening, whether defined, measured or determined objectively or subjectively, qualitatively or quantitatively, and

described using general terms or mathematically (such as a probability (3.20) or a frequency (3.5) over a given time

period).

Note 2 to entry: The English language term “likelihood” does not have a direct equivalent in some languages; instead,

the equivalent of the term “probability” is often used. However, in English, “probability” is often narrowly interpreted

as a mathematical term. Therefore, in risk management terminology, “likelihood” is used with the intent that it should

have the same broad interpretation as the term “probability” has in many languages other than English.

[SOURCE: ISO 31073:2022, 3.3.16]

3.18

medical laboratory

laboratory

entity for the examination (3.8) of materials derived from the human body for the purpose of providing

information for the diagnosis, monitoring, management, prevention and treatment of disease, or assessment

of health

Note 1 to entry: The laboratory can also provide advice covering all aspects of examinations including appropriate

selection, the interpretation of results and advice on further examinations.

Note 2 to entry: Laboratory activities include pre-examination, examination and post-examination processes (3.21).

Note 3 to entry: Materials for examination include but are not limited to, microbiological, immunological, biochemical,

immunohaematological, haematological, biophysical, cytological, tissue and cells, and genetic material.

[SOURCE: ISO 15189:2022, 3.20]

3.19

procedure

specified way to carry out an activity or a process (3.21)

Note 1 to entry: Procedures can be documented or not.

[SOURCE: ISO 9000:2015, 3.4.5]

3.20

probability

measure of the chance of occurrence expressed as a number between 0 and 1, where 0 is impossibility and 1

is absolute certainty

Note 1 to entry: See definition of likelihood (3.17), Note 2 to entry.

[SOURCE: ISO 31073:2022, 3.3.19]

3.21

process

set of interrelated or interacting activities that use inputs to deliver an intended result

Note 1 to entry: Whether the “intended result” of a process is called output, product or service (3.38) depends on the

context of the reference.

[SOURCE: ISO 9000:2015, 3.4.1, modified — Notes 2 to 6 have been removed.]

3.22

reasonably foreseeable misuse

use of a product, process (3.21) or service (3.38) in a way not intended by the supplier, but which can result

from readily predictable human behaviour

Note 1 to entry: Readily predictable human behaviour includes the behaviour of all types of intended users (3.43).

Note 2 to entry: In the context of consumer safety, the term “reasonably foreseeable use” is increasingly used as a

synonym for both “intended use” (3.15) and “reasonably foreseeable misuse”.

Note 3 to entry: Applies to use of examination (3.3) results by a healthcare provider (3.9) contrary to the intended use,

as well as use of IVD medical devices (3.11) by the laboratory contrary to the instructions for use (3.14).

Note 4 to entry: Misuse includes abnormal use, i.e. intentional use of the device in a way not intended by the

manufacturer.

Note 5 to entry: Misuse is intended to mean incorrect or improper performance of an examination procedure (3.19) or

any procedure critical for patient safety.

[SOURCE: ISO/IEC Guide 51:2014, 3.7 modified — In the definition, “system” was changed to “process or

service”; examples were removed from Note 1; Notes 3 to 5 were added.]

3.23

record

document stating results achieved or providing evidence of activities performed

Note 1 to entry: Records can be used, for example, to formalize traceability and to provide evidence of verification

(3.45), preventive action and corrective action.

Note 2 to entry: Generally, records need not be under revision control.

[SOURCE: ISO 9000:2015, 3.8.10]

3.24

residual risk

risk (3.25) remaining after risk control (3.28) measures have been taken

[SOURCE: ISO/IEC Guide 63:2019, 3.9]

3.25

risk

combination of the probability (3.19) of occurrence of harm (3.6) and the severity (3.39) of that harm

Note 1 to entry: This definition focuses on risks to the safety of patients and other persons. Other documents that

emphasize risk to a business enterprise will have alternative definitions

[SOURCE: ISO/IEC Guide 51:2014, 3.9, modified — The original Note 1 to entry was removed and a new note

was added.]

3.26

risk analysis

systematic use of available information to identify hazards (3.7) and to estimate the risk (3.25)

Note 1 to entry: Risk analysis includes examination of different sequences of events (3.2) that can produce hazardous

situations (3.8) and harm (3.6).

[SOURCE: ISO/IEC Guide 51:2014, 3.10, modified — Note 1 to entry was added.]

3.27

risk assessment

overall process (3.21) comprising a risk analysis (3.26) and a risk evaluation (3.30)

[SOURCE: ISO/IEC Guide 51:2014, 3.11]

3.28

risk control

process (3.21) in which decisions are made and measures implemented by which risks (3.25) are reduced to,

or maintained within, specified levels

[SOURCE: ISO/IEC Guide 63:2019, 3.12]

3.29

risk estimation

process (3.21) used to assign values to the probability (3.19) of occurrence of harm (3.6) and the severity

(3.39) of that harm

[SOURCE: ISO/IEC Guide 63:2019, 3.13]

3.30

risk evaluation

process (3.21) of comparing the estimated risk (3.25) against given risk criteria to determine the acceptability

of the risk

[SOURCE: ISO/IEC Guide 63:2019, 3.14]

3.31

risk management

systematic application of management policies, procedures (3.19) and practices to the tasks of analysing,

evaluating, controlling and monitoring risk (3.25)

[SOURCE: ISO/IEC Guide 63:2019, 3.15]

3.32

risk management documentation

set of records (3.23) and other documents that are produced by risk management (3.31)

[SOURCE: ISO 14971:2019, 3.25, modified — The term “risk management file” was changed to “risk

management documentation”.]

3.33

risk management plan

scheme specifying the approach, the management components and resources to be applied to the

management of risk (3.25)

[SOURCE: ISO 31073:2022, 3.2.3, modified — “scheme within the risk management framework” was changed

to “scheme”; the Notes to entry were removed.]

3.34

risk management policy

statement of the overall intentions and direction of an organization related to risk management (3.31)

[SOURCE: ISO 31073:2022, 3.2.2]

3.35

risk monitoring

surveillance

continual checking, critically observing or determining the status in order to identify change from the risk

(3.25) level required or expected

[SOURCE: ISO 31073:2022, 3.3.40, modified — The term “monitoring” has been changed to “risk monitoring”,

and surveillance was added as a preferred term; in the definition, “supervising” was deleted, and

“performance level” was changed to “risk level”; Note 1 to entry was deleted.]

3.36

risk reduction

actions taken to lessen the probability (3.19) or negative consequences, or both, associated with a risk (3.25)

[SOURCE: ISO 22300:2025, 3.2.20]

3.37

safety

freedom from unacceptable risk (3.25)

[SOURCE: ISO/IEC Guide 63:2019, 3.16]

3.38

service

laboratory medicine activity performed by a medical laboratory for the benefit (3.1) of patients, the

healthcare providers (3.9) responsible for the care of those patients, or screened populations

Note 1 to entry: Medical laboratory services include arrangements for examination (3.3) requests, patient preparation,

patient identification, collection, transportation, storage, processing and examination of clinical samples, together

with subsequent interpretation, reporting and advice, in addition to the considerations of safety (3.36) and ethics in

medical laboratory work.

3.39

severity

measure of the possible consequences of a hazard (3.7)

[SOURCE: ISO/IEC Guide 63:2019, 3.17]

3.40

stakeholder

person or organization that can affect, be affected by, or perceive themselves to be affected by a decision or

activity

[SOURCE: ISO 31073:2022, 3.3.2, modified — The preferred term “interested party” was removed.]

3.41

state of the art

developed stage of technical capability at a given time as regards products, processes (3.21) and services

(3.38), based on the relevant consolidated findings of science, technology and experience

Note 1 to entry: The state of the art embodies what is currently and generally accepted as good practice. The state of

the art does not necessarily imply the most technologically advanced solution. The state of the art described here is

sometimes referred to as the “generally acknowledged state of the art”.

[SOURCE: ISO/IEC Guide 63:2019, 3.18]

3.42

use error

laboratory medicine user (3.43) action or lack of user action while performing a laboratory examination (3.3)

or using an IVD medical device (3.11) or performing any task in any procedure (3.19) that leads to a different

result than that intended by the laboratory or manufacturer or expected by the user

Note 1 to entry: Use error includes the inability of the user to complete a task.

Note 2 to entry: Use errors can result from a mismatch between the characteristics of the user, user interface, task, or

use environment.

Note 3 to entry: Users might be aware or unaware that the use error has occurred.

Note 4 to entry: An unexpected physiological response of the patient is not by itself considered use error.

Note 5 to entry: A malfunction of an IVD medical device that causes an unexpected result is not considered a use error.

Note 6 to entry: Use error includes the use of an examination result for an unintended target group or for an unintended

diagnostic or patient management purpose.

Note 7 to entry: The term was chosen over “user error”, “human error” or “laboratory error” because not all causes

of error are partially or solely due to the user. Use errors are often the result of poorly designed user interface or

processes (3.21), or, inadequate instructions for use (3.14).

[SOURCE: IEC 62366-1:2015, 3.21 modified — In the definition, “user” was changed to “laboratory medicine

user”, and “performing a laboratory examination” and “performing any task in any procedure” were added;

the original Note 6 to entry was removed and a new Note 6 to entry and a Note 7 were added.]

3.43

user

individual responsible for an action that is intended to lead to a desired outcome

Note 1 to entry: Although such individuals are often laboratory personnel that are expected to be trained and

competent to perform the action, this term is not limited to such personnel and can include the patient.

Note 2 to entry: The use of this term is not intended to imply that a device is utilized for the action; it is used as a

general term to include any individual that has a role in producing the desired outcome.

3.44

validation

confirmation, through the provision of objective evidence, that the requirements for a specific intended use

(3.15) or application have been fulfilled

Note 1 to entry: The objective evidence needed for a validation is the result of a test or other form of determination

such as performing alternative calculations or reviewing documents.

Note 2 to entry: The word “validated” is used to designate the corresponding status.

Note 3 to entry: The use conditions for validation can be real or simulated.

[SOURCE: ISO 9000:2015, 3.8.13]

3.45

verification

confirmation, through the provision of objective evidence

...

ISO/DISFDIS 22367:2025(en)

ISO/TC 212

Secretariat: ANSI

Date: 2025-06-2312-22

Medical laboratories — Application of risk management to medical

laboratories

Laboratoires de biologie médicale — Application de la gestion des risques aux laboratoires de biologie médicale

FDIS stage

TThhiis drs draafftt i is s susubbmmiitttteed d ttoo aa ppaarraallellel l vvoottee i inn IISSOO,, CCEEN.N.

VVoottiing bng beegiginsns o on:n: 20220266--0101--0202

VoVotintingg t tererminminatateses o onn::

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication

may be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying,

or posting on the internet or an intranet, without prior written permission. Permission can be requested from either ISO

at the address below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: + 41 22 749 01 11

EmailE-mail: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

ISO/DISFDIS 22367:20252026(en)

Contents

Foreword . v

Introduction . vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Risk management . 10

4.1 Risk management process . 10

4.2 Management responsibilities . 10

4.3 Qualification of personnel . 11

4.4 Risk management activities . 11

5 Proactive risk management . 15

5.1 Proactive risk management plan . 15

5.2 Scope of the plan . 16

5.3 Contents of the plan . 16

5.4 Revisions to the plan . 17

5.5 Documentation of the risk management plan . 17

6 Proactive risk analysis . 17

6.1 General . 17

6.2 Risk analysis process . 18

6.3 Documentation of the risk analysis process . 18

7 Risk evaluation . 19

7.1 Overview . 19

7.2 Benefit-risk analysis . 20

7.3 Proactive risk evaluation . 21

8 Risk control . 22

8.1 General . 22

8.2 Risk control options . 22

8.3 Risks external to the laboratory . 24

8.4 Risks arising from risk control measures . 24

8.5 Residual risk evaluation . 24

8.6 Risk control verification . 25

9 Risk management review . 25

9.1 General . 25

9.2 Completeness of risk control . 25

9.3 Evaluation of overall residual risk . 25

9.4 Risk management report . 26

10 Risk monitoring, analysis and control activities . 26

10.1 Risk monitoring procedure . 26

10.2 Internal sources of risk information . 27

10.3 External sources of risk information . 27

11 Immediate actions to reduce risk . 27

Annex A (informative) Implementation of risk management within the management system . 29

Annex B (informative) Guidance on establishing risk acceptability criteria . 41

Annex C (informative) Guidance on risk acceptability considerations . 43

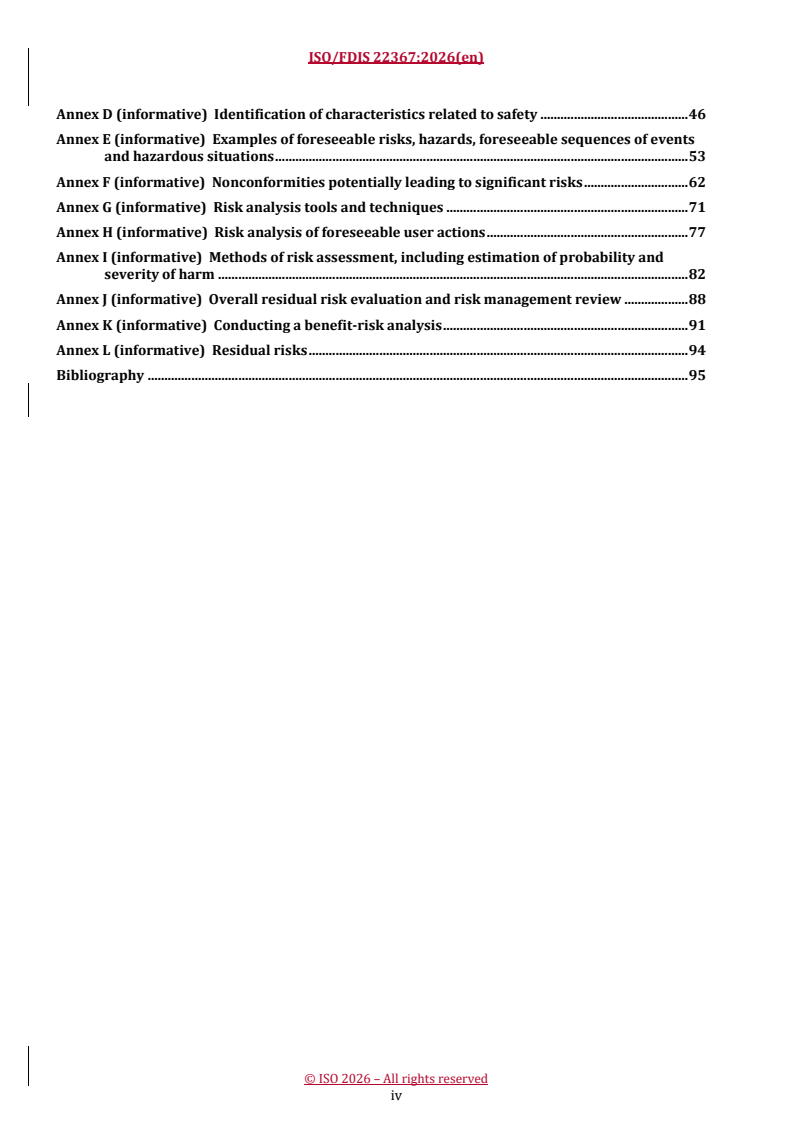

iii

Annex D (informative) Identification of characteristics related to safety . 46

Annex E (informative) Examples of foreseeable risks, hazards, foreseeable sequences of events

and hazardous situations . 53

Annex F (informative) Nonconformities potentially leading to significant risks . 62

Annex G (informative) Risk analysis tools and techniques . 71

Annex H (informative) Risk analysis of foreseeable user actions . 77

Annex I (informative) Methods of risk assessment, including estimation of probability and

severity of harm . 82

Annex J (informative) Overall residual risk evaluation and risk management review . 88

Annex K (informative) Conducting a benefit-risk analysis . 91

Annex L (informative) Residual risks . 94

Bibliography . 95

iv

ISO/DISFDIS 22367:20252026(en)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types of

ISO documents should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent rights

in respect thereof. As of the date of publication of this document, ISO had not received notice of (a) patent(s)

which may be required to implement this document. However, implementers are cautioned that this may not

represent the latest information, which may be obtained from the patent database available at

www.iso.org/patents. ISO shall not be held responsible for identifying any or all such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO'sISO’s adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 212, Medical laboratories and in vitro diagnostic

systems, in collaboration with the European Committee for Standardization (CEN) Technical Committee

CEN/TC 140, Inin vitro diagnostic medical devices, in accordance with the Agreement on technical cooperation

between ISO and CEN (Vienna Agreement).).

This second edition cancels and replaces the first edition (ISO 22367:2020), which has been technically

revised.

The main changes are as follows:

— — the application of risk management to processes has been emphasized;

— — reactive and proactive risk management has been discussed, differentiated, and illustrated;

— — the content is as far as possible in agreement the requirements for risk management in

ISO 15189:2022;

— — the relation with ISO 15189:2022 is indicated in Annex AAnnex A in which Figure A.1Figure A.1

provides a flow chart for the underlying management system to underpin this standarddocument;

— Clause I.5— Clause I.5 has been slightly modified to emphasize that risks most often require

benefit-risk assessment to determine risk acceptability.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

v

Introduction

Medical laboratories deal with risks as part of their usual activities; these risks affect patients, personnel,

caregivers, and the organization as a whole. Risks span the range of services: pre-examination, examination

and post-examination processes, including the design and development of laboratory examinations. The

intent of this document is not to introduce risk as a concern for the laboratory but to provide a structure for

addressing, managing, and documenting risks that are part of the day-to-day and long-term (strategic)

activities of the laboratory.

ISO 15189 requires that medical laboratories review all work processes to identify potential failures for risk

of harm to patients and opportunities for improvement, modify the processes to reduce or eliminate the

identified risks, and document the decisions and actions taken. This document describes a process for

managing these risks to the patient, the operator, other persons, equipment and other property, the healthcare

enterprise as a whole, and the environment. It does not address business enterprise risks, which are the

subject of ISO 31000; however, ISO 31000 is consistent with and can provide further understanding for the

concepts in this document.

Medical laboratories span a broad range of activities, some of which rely on the use of in vitro medical devices

to achieve their quality objectives. When such devices are involved, risk management is a shared responsibility

between the in -vitro diagnostic (IVD) manufacturer and the medical laboratory. Since most IVD

manufacturers have already implemented ISO 14971, this document has adopted similar concepts, principles

and framework to manage the risks associated with the medical laboratory when appropriate. This is

especially meaningful for laboratories that implement their own examinations on devices (laboratory

developed tests or LDTs); concepts integral to ISO 14971:2019 can be directly applicable. ISO 5649 is a useful

reference for identifying and addressing risks in the development, implementation and retirement phases of

LDTs.

Activities in a medical laboratory can expose patients, workers or other stakeholders to a variety of hazards,

which can lead directly or indirectly to varying degrees of harm. The concept of risk has two components:

a) a) the probability of occurrence of harm;

b) b) the consequence of that harm, that is, how severe the harm might be.

Risk management is complex because each stakeholder can place a different value on the risk of harm.

Risk management interfaces with quality management at many points in the medical laboratory. In ISO 15189,

as an example, risk management is a component of complaint management, internal audit, corrective action,

quality control, management review and external assessment (for both accreditation and proficiency testing).

Management of risk also coincides with the management of safety in the medical laboratories, as exemplified

by the safety audit checklists in ISO 15190. This standarddocument is intended to assist medical laboratories

with the integration of risk management into their routine organization, operation and management.

While this document is intended for use throughout the currently recognized medical laboratory disciplines,

it can effectively be applied to other healthcare services, such as diagnostic imaging, respiratory therapy,

physiological sciences, blood banks and transfusion services.

The use of this document facilitates cooperation between medical laboratories and other healthcare services,

assists in the exchange of information, and in the harmonization of methods and procedures.

vi

DRAFT International Standard ISO/DIS 22367:2025(en)

Medical laboratories — Application of risk management to medical

laboratories

1 Scope

This document specifies a process for a medical laboratory to identify and manage the risks to patients,

laboratory workers and service providers that are associated with medical laboratory examinations. The

process includes identifying, estimating, evaluating, controlling and monitoring the risks.

The requirements of this document are applicable to all aspects of the examinations and services of a medical

laboratory, including the pre-examination, examination, and post-examination aspects including accurate

transmission of examination results into the electronic medical record, as well as other technical and

management processes described in ISO 15189.

This document does not specify acceptable levels of risk.

This document does not apply to risks from post-examination clinical decisions made by healthcare providers.

This document complements the management of risks affecting medical laboratory enterprises that are

addressed by ISO 31000, such as business, economic, legal, and regulatory risks.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— — ISO Online browsing platform: available at https://www.iso.org/obp

— — IEC Electropedia: available at https://www.electropedia.org/

3.1 3.1

benefit

impact or desirable outcome of a process (3.21(3.21),), procedure (3.19(3.19)) or the use of a medical device

on the health of an individual or a positive impact on patient management or public health

Note 1 to entry: Benefits include prolongation of life, reduction of pain, relief of symptoms, improvement in function, or

an increased sense of well-being.

3.2 3.2

event

occurrence or change of a particular set of circumstances

Note 1 to entry: An event can be one or more occurrences, and can have several causes.

Note 2 to entry: An event can consist of something not happening.

Note 3 to entry: An event can sometimes be referred to as an “incident” or “accident”.

Note 4 to entry: An event without consequences can also be referred to as a “near miss”, “incident”, “near hit” or “close

call”.

[SOURCE: ISO 31073:2022, 3.3.11. modified –— Note to entry 2 is simplified, Notes was changed; the original

Note 3 to entry 3was removed, and a new Note 3 to entry and a Note 4 were added].]

3.3 3.3

examination

set of operations having the objective of determining the numerical value, text value or characteristics of a

property

Note 1 to entry: An examination may be the total of a number of activities, observations or measurements required to

determine a value or characteristics.

Note 2 to entry: Laboratory examinations that determine a numerical value of a property are called “quantitative

examinations”; those that determine the characteristics of a property are called “qualitative examinations”.

Note 3 to entry: Laboratory examinations are also called “assays” or “tests”.

[SOURCE: ISO 15189:2022, 3.8]

3.4 3.4

foreseeable risk

risk (3.25(3.25)) that is predictable prior to its occurrence

Note 1 to entry: Risk (3.25) can be known from prior experience, assessment of current circumstances, prior occurrence

of an event (3.2(3.2),), or other sources.

Note 2 to entry: Addressing foreseeable risk results in preventive action.

Note 3 to entry: A risk (3.25) that is foreseeable does not imply that it has been anticipated or addressed.

3.5 3.5

frequency

number of events (3.2(3.2)) or outcomes per defined unit of time

Note 1 to entry: Frequency can be applied to past events (3.2) or to potential future events (3.2),, where it can be used as

a measure of likelihood or probability (3.20(3.20))

[SOURCE: ISO 31073:2022, 3.3.20]

3.6 3.6

harm

injury or damage to the health of people, or damage to property or the environment

[SOURCE: ISO/IEC Guide 51:2014, 3.1]

3.7 3.7

hazard

source of potential harm (3.6(3.6))

[SOURCE: ISO 31073:2022, 3.3.12, modified — Note 1 to entry has been deleted.]

ISO/DISFDIS 22367:20252026(en)

3.8 3.8

hazardous situation

circumstance in which people, property, or the environment are exposed to one or more hazard(s) (3.7(3.7))

[SOURCE: ISO/IEC Guide 51:2014, 3.4]

3.9 3.9

healthcare provider

individual authorized to deliver health services to a patient

EXAMPLE Physician, nurse, ambulance attendant, dentist, diabetes educator, laboratory technician, laboratory

technologist, biomedical laboratory scientist, medical assistant, medical specialist, respiratory care practitioner.

[SOURCE: ISO 18113-1:2022, 3.1.28, modified — “laboratory technologist” and “biomedical laboratory

scientist” were added to the example.]

3.10 3.10

in vitro diagnostic manufacturer

IVD manufacturer

natural or legal person with responsibility for the designanddesign and/or manufactureofmanufacture of an

IVD medical device (3.11(3.11)) with the intention of making the IVD medical device (3.11) available for use,

under his name, whether or not such an IVD medical device (3.11) is designed and/or manufactured by that

person himself or on that person'sperson’s behalf by another person(s)

[SOURCE: ISO 14971:2019, 3.9, modified –— The term “manufacturer” has beenwas changed to “in vitro

diagnostic manufacturer”. “A ”; in the definition, “medical device” has beenwas changed to “an IVD medical

device” (3.11).]”; Notes to entry were removed.]

3.11 3.11

in vitro diagnostic medical device

IVD medical device

medical device, whether used alone or in combination, intended by the manufacturer for the in vitro

examination (3.3(3.3)) of specimens derived from the human body solely or principally to provide information

for diagnostic, monitoring or compatibility purposes.

Note 1 to entry: The device includes reagents, calibrators, control materials, specimen receptacles, software, and related

instruments or apparatus or other articles.

[SOURCE:Note 2 to entry: Adapted from ISO 18113-1:2022, 3.1.53, modified].

3.12 3.12

in vitro diagnostic instrument

IVD instrument

equipment or apparatus intended by a manufacturer to be used as an IVD medical device (3.11(3.11))

[SOURCE: ISO 18113-1:2022, 3.1.32]

3.13 3.13

information supplied by the manufacturer

labelling

information that is related to identification, technical description, intended use (3.15(3.15)) and proper use of

the IVD medical device (3.11(3.11),), but excluding shipping documents

EXAMPLE :

Labels;, instructions for use;, manual;, written, printed, electronic, or graphic matter.

Note 1 to entry: In IEC standards, documents provided with a medical device and containing important information for

the responsible organization or operator, particularly regarding safety, are called “accompanying documents”.

Note 2 to entry: Catalogues and material safety data sheets are not considered information supplied by the manufacturer

of IVD medical devices (3.11).

Note 3 to entry: Adapted from ISO 18113-1:2022, 3.1.35.

3.14 3.14

instructions for use

information supplied by the manufacturer (3.13(3.13)) to enable the safe and proper use of an IVD medical

device (3.11(3.11))

Note 1 to entry: Includes It includes the directions supplied by the manufacturer for the use, maintenance,

troubleshooting and disposal of an IVD medical device (3.11),, as well as warnings and precautions.

Note 2 to entry: Instructions for use can also be referred to as ‘“package insert’insert” or manual for instruments.

[SOURCE: adaptedNote 3 to entry: Adapted from ISO 18113-1:2022, 3.1.36 ].

3.15 3.15

intended use

intended purpose

objective intent of an IVD manufacturer (3.10(3.10)) regarding the use of a product, process (3.21(3.21)) or

service (3.38(3.38)) as reflected in the specifications, instructions and information supplied by the IVD

manufacturer (3.10)

Note 1 to entry: Intended use statements for IVD information supplied by the manufacturer (3.13(3.13)) can include two

components: a description of the functionality of the IVD medical device (3.11(3.11)) (e.g.,. an immunochemical

measurement procedure (3.19(3.19)) for the detection of analyte “x” in serum or plasma), and a statement of the intended

medical use of the examination (3.3(3.3)) results.

[SOURCE: ISO 18113-1:2022, 3.1.37, modified — In Note 1 to entry, “labelling” was changed andto

“information supplied by the manufacturer”; Note 2 deleted]was removed.]

3.16 3.16

laboratory management

person(s) with responsibility for, and authority over, a laboratory

Note 1 to entry: Laboratory management has the power to delegate authority and provide resources within the

laboratory.

Note 2 to entry: The laboratory management includes the laboratory director(s) and delegates together with individuals

specifically assigned to ensure the quality of the activities of the laboratory.

[SOURCE: ISO 15189:2022, 3.15]

3.17 3.17

likelihood

chance of something happening

Note 1 to entry: In risk management terminology, the word “likelihood” is used to refer to the chance of something

happening, whether defined, measured or determined objectively or subjectively, qualitatively or quantitatively, and

described using general terms or mathematically (such as a probability (3.20(3.20)) or a frequency (3.5(3.5)) over a given

time period).

Note 2 to entry: The English language term “likelihood” does not have a direct equivalent in some languages; instead, the

equivalent of the term “probability” (3.20) is often used. However, in English, “probability” (3.20) is often narrowly

ISO/DISFDIS 22367:20252026(en)

interpreted as a mathematical term. Therefore, in risk management terminology, “likelihood” is used with the intent that

it should have the same broad interpretation as the term “probability” (3.20) has in many languages other than English.

[SOURCE: ISO 31073:2022, 3.3.16.]

3.18 3.18

medical laboratory

laboratory

entity for the examination (3.8(3.8)) of materials derived from the human body for the purpose of providing

information for the diagnosis, monitoring, management, prevention and treatment of disease, or assessment

of health

Note 1 to entry: The laboratory can also provide advice covering all aspects of examinations including appropriate

selection, the interpretation of results and advice on further examinations.

Note 2 to entry: Laboratory activities include pre-examination (3.25),, examination (3.8) and post-examination processes

(3.21(3.24).).

Note 3 to entry: Materials for examination (3.8) include but are not limited to, microbiological, immunological,

biochemical, immunohaematological, haematological, biophysical, cytological, tissue and cells, and genetic material.

[SOURCE: ISO 15189:2022, 3.20]

3.19

3.19

procedure

specified way to carry out an activity or a process (3.21(3.21) )

Note 1 to entry: Procedures can be documented or not.

[SOURCE: ISO 9000:2015, 3.4.5]

3.20 3.20

probability

measure of the chance of occurrence expressed as a number between 0 and 1, where 0 is impossibility and 1

is absolute certainty

Note 1 to entry: See definition of likelihood (3.17(3.17),), Note 2 to entry.

[SOURCE: ISO 31073:2022, 3.3.19]

3.21 3.21

process

set of interrelated or interacting activities that use inputs to deliver an intended result

Note 1 to entry: Whether the “intended result” of a process is called output, product or service (3.38(3.38)) depends on

the context of the reference.

[SOURCE: ISO 9000:2015, 3.4.1, modified– Note — Notes 2 to entry to Note 6 to entry have been

deletedremoved.]

3.22 3.22

reasonably foreseeable misuse

use of a product, process (3.21(3.21)) or service (3.38(3.38)) in a way not intended by the supplier, but which

can result from readily predictable human behaviour

Note 1 to entry: Readily predictable human behaviour includes the behaviour of all types of intended users (3.43(3.43).).

Note 2 to entry: In the context of consumer safety, the term “reasonably foreseeable use” is increasingly used as a

synonym for both “intended use” (3.15(3.15)) and “reasonably foreseeable misuse.””.

Note 3 to entry: Applies to use of examination (3.3(3.3)) results by a healthcare provider (3.9(3.9)) contrary to the

intended use (3.15),, as well as use of IVD medical devices (3.11(3.11)) by the laboratory contrary to the instructions for

use (3.14(3.14).).

Note 4 to entry: Misuse includes abnormal use, i.e. intentional use of the device in a way not intended by the

manufacturer.

Note 5 to entry: Misuse is intended to mean incorrect or improper performance of an examination (3.3) procedure

(3.19(3.19)) or any procedure (3.19) critical for patient safety.

[SOURCE: ISO/IEC Guide 51:2014, 3.7 modified — inIn the definition, “system” was changed to “process or

service”; examples were removed from Note 1; Notes 3 to 5 were added.]

3.23 3.23

record

document stating results achieved or providing evidence of activities performed

Note 1 to entry: Records can be used, for example, to formalize traceability and to provide evidence of verification

(3.45(3.45),), preventive action and corrective action.

Note 2 to entry: Generally, records need not be under revision control.

[SOURCE: ISO 9000:2015, 3.8.10]

3.24 3.24

residual risk

risk (3.25(3.25)) remaining after risk control (3.28(3.28)) measures have been taken

[SOURCE: ISO/IEC Guide 63:2019, 3.9]

3.25 3.25

risk

combination of the probability (3.19(3.19)) of occurrence of harm (3.6(3.6)) and the severity (3.39(3.39)) of

that harm (3.6)

Note 1 to entryThis entry: This definition focuses on risks to the safety of patients and other persons. Other documents

that emphasize risk to a business enterprise will have alternative definitions

[SOURCE: ISO/IEC Guide 51:2014, 3.9, modified — The original Note 1 to entry has been modifiedwas

removed and a new note was added.]

3.26 3.26

risk analysis

systematic use of available information to identify hazards (3.7(3.7)) and to estimate the risk (3.25(3.25))

Note 1 to entry: Risk analysis includes examination of different sequences of events (3.2(3.2)) that can produce hazardous

situations (3.8(3.8)) and harm (3.6(3.6).).

[SOURCE: ISO/IEC Guide 51:2014, 3.10, modified — Note 1 to entry has beenwas added.]

ISO/DISFDIS 22367:20252026(en)

3.27 3.27

risk assessment

overall process (3.21(3.21)) comprising a risk analysis (3.26(3.26)) and a risk evaluation (3.30(3.30))

[SOURCE: ISO/IEC Guide 51:2014, 3.11]

3.28 3.28

risk control

process (3.21(3.21)) in which decisions are made and measures implemented by which risks (3.25(3.25)) are

reduced to, or maintained within, specified levels

[SOURCE: ISO/IEC Guide 63:2019, 3.12]

3.29 3.29

risk estimation

process (3.21(3.21)) used to assign values to the probability (3.19(3.19)) of occurrence of harm (3.6(3.6)) and

the severity (3.39(3.39)) of that harm (3.6)

[SOURCE: ISO/IEC Guide 63:2019, 3.13]

3.30 3.30

risk evaluation

process (3.21(3.21)) of comparing the estimated risk (3.25(3.25)) against given risk criteria to determine the

acceptability of the risk

[SOURCE: ISO/IEC Guide 63:2019, 3.14]

3.31 3.31

risk management

systematic application of management policies, procedures (3.19(3.19)) and practices to the tasks of analysing,

evaluating, controlling and monitoring risk (3.25(3.25))

[SOURCE: ISO/IEC Guide 63:2019, 3.15]

3.32 3.32

risk management documentation

set of records (3.23(3.23)) and other documents that are produced by risk management (3.31(3.31))

[SOURCE: ISO 14971:2019, 3.25, modified — The term “risk management file” was changed to “risk

management documentation”.]

3.33 3.33

risk management plan

scheme specifying the approach, the management components and resources to be applied to the management

of risk (3.25(3.25))

Note 1 to entry: Adapted from ISO 31000:2009.

3.34[SOURCE: ISO 31073:2022, 3.2.3, modified — “scheme within the risk management framework” was

changed to “scheme”; the Notes to entry were removed.]

3.34

risk management policy

statement of the overall intentions and direction of an organization related to risk management (3.31(3.31))

[SOURCE: ISO 31073:2022, 3.2.2]

3.35 3.35

risk monitoring

surveillance

continual checking, critically observing or determining the status in order to identify change from the risk

(3.25(3.25)) level required or expected

[SOURCE: ISO 31073:2022, 3.3.40, modified — The term “Monitoringmonitoring” has been changed to “risk

monitoring”;”, and surveillance was added as a preferred term; in the definition, “supervising” has beenwas

deleted, and “performance level” has beenwas changed to “risk level”; Note 1 to entry has beenwas deleted.]

3.36 3.36

risk reduction

actions taken to lessen the probability (3.19(3.19)) or negative consequences, or both, associated with a risk

(3.25(3.25))

[SOURCE: ISO 22300:20182025, 3.2102.20]

3.37 3.37

safety

freedom from unacceptable risk (3.25(3.25))

[SOURCE: ISO/IEC Guide 63:2019, 3.16]

3.38 3.38

service

laboratory medicine activity performed by a medical laboratory for the benefit (3.1(3.1)) of patients, the

healthcare providers (3.9(3.9)) responsible for the care of those patients, or screened populations.

Note 1 to entry: Medical laboratory services include arrangements for examination (3.3(3.3)) requests, patient

preparation, patient identification, collection, transportation, storage, processing and examination (3.3) of clinical

samples, together with subsequent interpretation, reporting and advice, in addition to the considerations of safety

(3.36(3.36)) and ethics in medical laboratory work.

Note 2 to entry: Adapted from ISO 15189:2022.

3.39 3.39

severity

measure of the possible consequences of a hazard (3.7(3.7))

[SOURCE: ISO/IEC Guide 63:2019, 3.17]

3.40 3.40

stakeholder

person or organization that can affect, be affected by, or perceive themselves to be affected by a decision or

activity

[SOURCE: ISO 31073:2022, 3.3.2, modified from — The preferred term “interested party to stakeholder]” was

removed.]

3.41 3.41

state of the art

developed stage of technical capability at a given time as regards products, processes (3.21(3.21)) and services

(3.38(3.38),), based on the relevant consolidated findings of science, technology and experience

ISO/DISFDIS 22367:20252026(en)

Note 1 to entry: The state of the art embodies what is currently and generally accepted as good practice. The state of the

art does not necessarily imply the most technologically advanced solution. The state of the art described here is

sometimes referred to as the “generally acknowledged state of the art”.

[SOURCE: ISO/IEC Guide 63:2019, 23.18]

3.42 3.42

use error

laboratory medicine user (3.43(3.43)) action or lack of user (3.43) action while performing a laboratory

examination (3.3(3.3)) or using an IVD medical device (3.11(3.11)) or performing any task in any procedure

(3.19(3.19)) that leads to a different result than that intended by the laboratory or manufacturer or expected

by the user (3.43)

Note 1 to entry: Use error includes the inability of the user (3.43 to complete a task.

Note 2 to entry: Use errors can result from a mismatch between the characteristics of the user (3.43),, user interface, task,

or use environment.

Note 3 to entry: Users (3.43) might be aware or unaware that the use error has occurred.

Note 4 to entry: An unexpected physiological response of the patient is not by itself considered use error.

Note 5 to entry: A malfunction of an IVD medical device that causes an unexpected result is not considered a use error.

Note 6 to entry: Use error includes the use of an examination (3.3) result for an unintended target group or for an

unintended diagnostic or patient management purpose.

Note 7 to entry: The term was chosen over “user error”, “human error” or “laboratory error” because not all causes of

error are partially or solely due to the user (3.43). Use errors are often the result of poorly designed user (3.43) interface

or processes (3.21(3.21),), or, inadequate instructions for use (3.14(3.14).).

[SOURCE: IEC 62366-1:2015, 3.21 modified – — In the definition, “user” was changed to “laboratory

medicine” has been added; user”, and “performing a laboratory examination”,” and “performing any task in

any procedure” have beenwere added.; the original Note 6 to entry was deleted. A removed and a new Note 6

to entry and a Note 7 to entry were added.]

3.43 3.43

user

individual responsible for an action that is intended to lead to a desired outcome

Note 1 to entry: Although such individuals are often laboratory personnel that are expected to be trained and competent

to perform the action, this term is not limited to such personnel and can include the patient.