IEC 60951-2:2009

(Main)Nuclear power plants - Instrumentation important to safety - Radiation monitoring for accident and post-accident conditions - Part 2: Equipment for continuous off-line monitoring of radioactivity in gaseous effluents and ventilation air

Nuclear power plants - Instrumentation important to safety - Radiation monitoring for accident and post-accident conditions - Part 2: Equipment for continuous off-line monitoring of radioactivity in gaseous effluents and ventilation air

IEC 60951-2:2009 provides general guidance on the design principles and performance criteria for equipment for continuous off-line monitoring of radioactivity in gaseous effluents and ventilation air used in nuclear power plants for accident and post-accident conditions. General requirements for technical characteristics, test procedures, radiation characteristics, electrical, mechanical, and environmental characteristics are given in IEC 60951-1. These requirements are applicable in this part unless otherwise stated. The main technical changes with regard to the previous edition are as follows:

- clarify the definitions;

- up-date the references to new standards published since the first edition;

- update the units of radiation.

This publication is to be read in conjunction with IEC 60951-1:2009.

Centrales nucléaires de puissance - Instrumentation importante pour la sûreté - Surveillance des rayonnements pour les conditions accidentelles et post-accidentelles - Partie 2: Matériels pour la surveillance des rayonnements en continu avec prélèvements dans les effluents gazeux et l'air de ventilation

La CEI 60951-2:2009 fournit des recommandations générales sur les principes de conception et les critères de performance des matériels de surveillance des rayonnements en continu avec prélèvements dans les effluents gazeux et l'air de ventilation, utilisés dans les centrales nucléaires en conditions accidentelles et post-accidentelles. Les exigences générales relatives aux caractéristiques techniques, aux procédures d'essai, aux caractéristiques des rayonnements, aux caractéristiques électriques, mécaniques et environnementales sont fournies dans la CEI 60951-1. Ces exigences sont applicables dans cette partie sauf indication explicite contraire. Les principaux changements techniques par rapport à l'édition précédente sont les suivants:

- clarifier les définitions;

mettre à jour les références aux nouvelles normes publiées depuis la première édition;

- mettre à jour les unités relatives aux rayonnements.

Cette publication doit être lue conjointement avec la CEI 60951-1:2009.

General Information

- Status

- Published

- Publication Date

- 28-Jun-2009

- Technical Committee

- SC 45A - Instrumentation, control and electrical power systems of nuclear facilities

- Drafting Committee

- WG 5 - TC 45/SC 45A/WG 5

- Current Stage

- PPUB - Publication issued

- Start Date

- 29-Jun-2009

- Completion Date

- 15-Jul-2009

Relations

- Effective Date

- 10-Feb-2026

Overview

IEC 60951-2:2009 is an international standard published by the International Electrotechnical Commission (IEC) that specifies requirements for equipment used in nuclear power plants to continuously monitor radioactivity in gaseous effluents and ventilation air under accident and post-accident conditions. This standard is part of a broader framework focusing on radiation monitoring instrumentation vital for safety in nuclear facilities.

Key highlights include:

- Design principles and performance criteria for off-line radiation monitoring equipment

- Technical requirements covering radiation, electrical, mechanical, and environmental characteristics

- Updated definitions, references, and radiation units to align with current industry practices

- Intended for use alongside IEC 60951-1, which details general requirements applicable to this part

IEC 60951-2 targets manufacturers developing radiation monitoring systems as well as purchasers defining technical specifications for plant-specific safety instrumentation.

Key Topics

1. Design and Functional Requirements

- Detailed guidance on design principles ensuring reliable, robust operation for continuous off-line monitoring

- Specifications on sampling assembly including filters, collecting devices, and air circuit materials to guarantee accurate detection of radioactive gases and particulates

- Requirements for measurement techniques specific to gaseous effluents and ventilation air during accident scenarios

2. Performance Testing

- Methods to assess response to various radioactive gases and particles to ensure accuracy and safety compliance

- Procedures to test the efficiency of the sampling circuit, flow rate stability, and susceptibility to interference from gas or particulate retention

- Evaluation of the effects of power supply variations on equipment operation

3. Integration with Related Standards

- Alignment with IEC 60951-1 covering general technical characteristics

- Inclusion in the IEC 60951 series alongside standards for gamma area monitoring (IEC 60951-3) and in-line monitoring of process streams (IEC 60951-4)

- Recommendations for referencing ISO 2889 for guidance on gas and particulate sampling techniques

4. Scope and Application Limits

- Focused on equipment critical for accident and post-accident radiation monitoring rather than routine operational monitoring

- Does not impose additional functional safety requirements beyond those established in overarching safety systems standards

- Emphasizes design and test methods rather than prescribing specific instrument performance parameters, which depend on application context

Applications

IEC 60951-2:2009 is integral to nuclear power plant safety instrumentation, providing assurance that radiation monitoring equipment for hazardous gaseous effluents and ventilation air meets stringent international standards during emergencies. Typical applications include:

- Accident Condition Monitoring: Continuous off-line systems detecting radioactivity release via gaseous effluents help operators identify and manage radiological hazards promptly.

- Post-Accident Ventilation Control: Monitoring ventilation air to assess contamination levels and guide filtration or containment strategies after nuclear incidents.

- Plant Safety Systems: Supporting overall radiation safety infrastructure by ensuring instrumentation reliability under extreme conditions.

- Regulatory Compliance: Assisting manufacturers and operators in meeting international nuclear safety regulations and performance benchmarks.

By adhering to IEC 60951-2, operators enhance nuclear safety culture through dependable radiological surveillance critical to protecting plant personnel, the public, and the environment.

Related Standards

IEC 60951-2 is part of a comprehensive series addressing radiation monitoring at nuclear facilities:

- IEC 60951-1: General requirements for instrumentation important to safety in nuclear power plants

- IEC 60951-3: Equipment for continuous high-range gamma area radiation monitoring

- IEC 60951-4: Equipment for continuous in-line or on-line monitoring of radioactivity in process streams

- IEC 60761 & IEC 60861: Standards covering radiation monitoring equipment used under normal operating conditions for gaseous and liquid effluents respectively

- ISO 2889: Provides guidance on gas and particulate sampling techniques relevant to radiation monitoring systems

- IEC 61513: Top-level standard for instrumentation and control (I&C) systems important to safety in nuclear power plants, providing the structural framework for IEC 60951 series

Together, these linked standards provide a robust technical foundation for the design, testing, and operation of nuclear safety instrumentation, ensuring comprehensive radiation monitoring under both normal and emergency scenarios.

Keywords: IEC 60951-2, radiation monitoring, nuclear power plants, gaseous effluents, ventilation air, accident conditions, post-accident monitoring, nuclear safety instrumentation, continuous off-line monitoring, IEC standards, nuclear instrumentation, radiological surveillance

IEC 60951-2:2009 - Nuclear power plants - Instrumentation important to safety - Radiation monitoring for accident and post-accident conditions - Part 2: Equipment for continuous off-line monitoring of radioactivity in gaseous effluents and ventilation air

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC 60951-2:2009 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Nuclear power plants - Instrumentation important to safety - Radiation monitoring for accident and post-accident conditions - Part 2: Equipment for continuous off-line monitoring of radioactivity in gaseous effluents and ventilation air". This standard covers: IEC 60951-2:2009 provides general guidance on the design principles and performance criteria for equipment for continuous off-line monitoring of radioactivity in gaseous effluents and ventilation air used in nuclear power plants for accident and post-accident conditions. General requirements for technical characteristics, test procedures, radiation characteristics, electrical, mechanical, and environmental characteristics are given in IEC 60951-1. These requirements are applicable in this part unless otherwise stated. The main technical changes with regard to the previous edition are as follows: - clarify the definitions; - up-date the references to new standards published since the first edition; - update the units of radiation. This publication is to be read in conjunction with IEC 60951-1:2009.

IEC 60951-2:2009 provides general guidance on the design principles and performance criteria for equipment for continuous off-line monitoring of radioactivity in gaseous effluents and ventilation air used in nuclear power plants for accident and post-accident conditions. General requirements for technical characteristics, test procedures, radiation characteristics, electrical, mechanical, and environmental characteristics are given in IEC 60951-1. These requirements are applicable in this part unless otherwise stated. The main technical changes with regard to the previous edition are as follows: - clarify the definitions; - up-date the references to new standards published since the first edition; - update the units of radiation. This publication is to be read in conjunction with IEC 60951-1:2009.

IEC 60951-2:2009 is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 27.120.20 - Nuclear power plants. Safety. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60951-2:2009 has the following relationships with other standards: It is inter standard links to prEN IEC 62705:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60951-2:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60951-2 ®

Edition 2.0 2009-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Nuclear power plants – Instrumentation important to safety – Radiation

monitoring for accident and post-accident conditions –

Part 2: Equipment for continuous off-line monitoring of radioactivity in gaseous

effluents and ventilation air

Centrales nucléaires de puissance – Instrumentation importante pour la sûreté –

Surveillance des rayonnements pour les conditions accidentelles et post-

accidentelles –

Partie 2: Matériels pour la surveillance des rayonnements en continu avec

prélèvements dans les effluents gazeux et l’air de ventilation

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60951-2 ®

Edition 2.0 2009-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Nuclear power plants – Instrumentation important to safety – Radiation

monitoring for accident and post-accident conditions –

Part 2: Equipment for continuous off-line monitoring of radioactivity in gaseous

effluents and ventilation air

Centrales nucléaires de puissance – Instrumentation importante pour la sûreté –

Surveillance des rayonnements pour les conditions accidentelles et post-

accidentelles –

Partie 2: Matériels pour la surveillance des rayonnements en continu avec

prélèvements dans les effluents gazeux et l’air de ventilation

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

Q

CODE PRIX

ICS 27.120.20 ISBN 978-2-88910-347-8

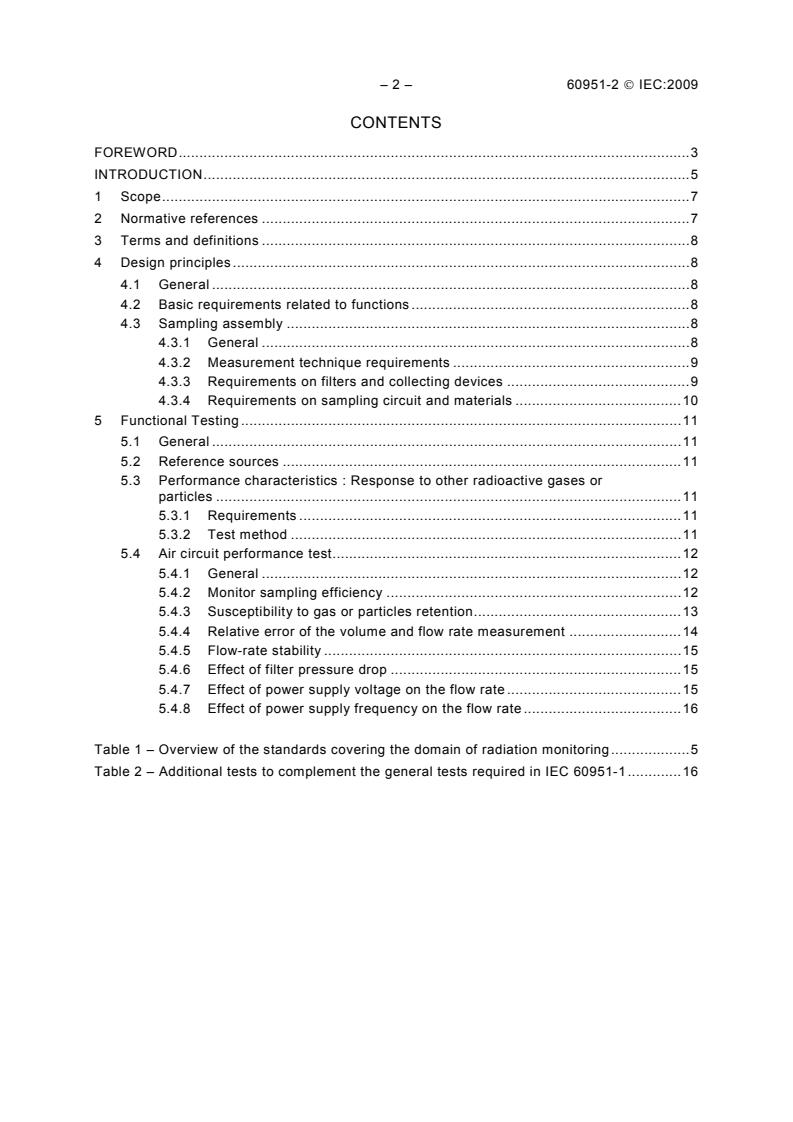

– 2 – 60951-2 © IEC:2009

CONTENTS

FOREWORD.3

INTRODUCTION.5

1 Scope.7

2 Normative references .7

3 Terms and definitions .8

4 Design principles.8

4.1 General .8

4.2 Basic requirements related to functions .8

4.3 Sampling assembly .8

4.3.1 General .8

4.3.2 Measurement technique requirements .9

4.3.3 Requirements on filters and collecting devices .9

4.3.4 Requirements on sampling circuit and materials .10

5 Functional Testing .11

5.1 General .11

5.2 Reference sources .11

5.3 Performance characteristics : Response to other radioactive gases or

particles .11

5.3.1 Requirements .11

5.3.2 Test method .11

5.4 Air circuit performance test.12

5.4.1 General .12

5.4.2 Monitor sampling efficiency .12

5.4.3 Susceptibility to gas or particles retention.13

5.4.4 Relative error of the volume and flow rate measurement .14

5.4.5 Flow-rate stability .15

5.4.6 Effect of filter pressure drop .15

5.4.7 Effect of power supply voltage on the flow rate .15

5.4.8 Effect of power supply frequency on the flow rate .16

Table 1 – Overview of the standards covering the domain of radiation monitoring.5

Table 2 – Additional tests to complement the general tests required in IEC 60951-1.16

60951-2 © IEC:2009 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

NUCLEAR POWER PLANTS –

INSTRUMENTATION IMPORTANT TO SAFETY –

RADIATION MONITORING FOR ACCIDENT

AND POST-ACCIDENT CONDITIONS –

Part 2: Equipment for continuous off-line monitoring of

radioactivity in gaseous effluents and ventilation air

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60951-2 has been prepared by subcommittee 45A: Instrumentation

and control of nuclear facilities, of IEC technical committee 45: Nuclear instrumentation.

This second edition cancels and replaces the first edition published in 1988, as well as

IEC 60951-5, published in 1994. This edition constitutes a technical revision.

The main technical changes with regard to the previous edition are as follows:

• To clarify the definitions.

• To update the references to new standards published since the first issue.

• To update the units of radiation.

– 4 – 60951-2 © IEC:2009

This standard is to be read in conjunction with IEC 60951-1.

The text of this standard is based on the following documents:

FDIS Report on voting

45A/735/FDIS 45A/757/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of IEC 60951 series, under the general title Nuclear power plants –

Instrumentation important to safety – Radiation monitoring for accident and post-accident

conditions, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

60951-2 © IEC:2009 – 5 –

INTRODUCTION

a) Technical background, main issues and organisation of the standard

This IEC standard specifically focuses on radiation monitoring systems used for accident and

post-accident operations.

This standard is intended for use by purchasers in developing specifications for their plant-

specific radiation monitoring systems and by manufacturers to identify needed product

characteristics when developing systems for accident monitoring conditions. Some specific

instrument characteristics such as measurement range, required energy response, and

ambient environment requirements will depend upon the specific application. In such cases.

guidance is provided on determining the specific requirements, but specific requirements

themselves are not stated.

This standard is one in a series of standards covering post-accident radiation monitors

important to safety. The full series is comprised of the following standards.

• IEC 60951-1 – General requirements

• IEC 60951-2 – Equipment for continuous off-line monitoring of radioactivity in gaseous

effluents and ventilation air

• IEC 60951-3 – Equipment for continuous high range area gamma monitoring

• IEC 60951-4 – Equipment for continuous in-line or on-line monitoring of radioactivity in

process streams

b) Situation of the current standard in the structure of the IEC SC 45A standard series

The IEC 60951 series of standards are at the third level in the hierarchy of SC 45A standards.

They provide guidance on the design and testing of radiation monitoring equipment used for

accident and post-accident conditions. Other standards developed by SC 45A and SC 45B

provide guidance on instruments used for monitoring radiation as part of normal operations.

The IEC 60761 series provide requirements for equipment for continuous off-line monitoring

of radioactivity in gaseous effluents in normal conditions. IEC 60861 provides requirements

for equipment for continuous off-line monitoring of radioactivity in liquid effluents in normal

conditions. IEC 60768 provides requirements for equipment for continuous in-line and on-line

monitoring of radioactivity in process streams in normal and incident conditions. Finally,

ISO 2889 gives guidance on gas and particulate sampling. The relationship between these

various radiation monitoring standards is given in Table 1 below.

Table 1 – Overview of the standards covering the domain of radiation monitoring

Developer ISO SC 45A – Process and safety monitoring SC 45B – Radiation

protection and

Scope Sampling circuits Accident and post- Normal and incident

effluents monitoring

and methods accident conditions conditions

Gas, particulate and ISO 2889 IEC 60951-1 and IEC 60761 series and IEC 62302 (noble

iodine with sampling IEC 60951-2 gases only)

(OFF LINE)

Liquid with sampling N/A N/A IEC 60861

(OFF LINE)

Process streams N/A IEC 60951-1 and IEC 60768 N/A

(gaseous effluents, IEC 60951-4

steam or liquid)

without sampling

(ON or IN-LINE)

Area monitoring N/A IEC 60951-1 and IEC 60532

IEC 60951-3

– 6 – 60951-2 © IEC:2009

Developer ISO SC 45A – Process and safety monitoring SC 45B – Radiation

protection and

Scope Sampling circuits Accident and post- Normal and incident

effluents monitoring

and methods accident conditions conditions

Central system N/A IEC 61504 IEC 61559 series

For more details on the structure of the IEC SC 45A standard series, see item d) of this

introduction.

c) Recommendations and limitations regarding the application of this standard

It is important to note that this Standard establishes no additional functional requirements for

safety systems.

d) Description of the structure of the IEC SC 45A standard series and relationships

with other IEC documents and other bodies documents (IAEA, ISO)

The top-level document of the IEC SC 45A standard series is IEC 61513. It provides general

requirements for I&C systems and equipment that are used to perform functions important to

safety in NPPs. IEC 61513 structures the IEC SC 45A standard series.

IEC 61513 refers directly to other IEC SC 45A standards for general topics related to

categorization of functions and classification of systems, qualification, separation of systems,

defence against common cause failure, software aspects of computer-based systems,

hardware aspects of computer-based systems, and control room design. The standards

referenced directly at this second level should be considered together with IEC 61513 as a

consistent document set.

At a third level, IEC SC 45A standards not directly referenced by IEC 61513 are standards

related to specific equipment, technical methods, or specific activities. Usually these

documents, which make reference to second-level documents for general topics, can be used

on their own.

A fourth level extending the IEC SC 45A standard series, corresponds to the Technical

Reports which are not normative.

IEC 61513 has adopted a presentation format similar to the basic safety publication

IEC 61508 with an overall safety life-cycle framework and a system life-cycle framework and

provides an interpretation of the general requirements of IEC 61508-1, IEC 61508-2 and

IEC 61508-4, for the nuclear application sector. Compliance with IEC 61513 will facilitate

consistency with the requirements of IEC 61508 as they have been interpreted for the nuclear

industry. In this framework, IEC 60880 and IEC 62138 correspond to IEC 61508-3 for the

nuclear application sector.

IEC 61513 refers to ISO standards as well as to IAEA 50-C-QA (now replaced by IAEA GS-R-

3) for topics related to quality assurance (QA).

The IEC SC 45A standards series consistently implements and details the principles and

basic safety aspects provided in the IAEA code on the safety of NPPs and in the IAEA safety

series, in particular the Requirements NS-R-1, establishing safety requirements related to the

design of Nuclear Power Plants, and the Safety Guide NS-G-1.3 dealing with instrumentation

and control systems important to safety in Nuclear Power Plants. The terminology and

definitions used by SC 45A standards are consistent with those used by the IAEA.

60951-2 © IEC:2009 – 7 –

NUCLEAR POWER PLANTS –

INSTRUMENTATION IMPORTANT TO SAFETY –

RADIATION MONITORING FOR ACCIDENT

AND POST-ACCIDENT CONDITIONS –

Part 2: Equipment for continuous off-line monitoring of

radioactivity in gaseous effluents and ventilation air

1 Scope

This part of IEC 60951 provides general guidance on the design principles and performance

criteria for equipment for continuous off-line monitoring of radioactivity in gaseous effluents

and ventilation air used in nuclear power plants for accident and post-accident conditions.

General requirements for technical characteristics, test procedures, radiation characteristics,

electrical, mechanical, and environmental characteristics are given in IEC 60951-1. These

requirements are applicable in this part unless otherwise stated.

This standard is applicable to:

• noble gas activity monitors intended to measure the volumetric activity of radioactive noble

gases in gaseous effluents at the discharge point and the variation of volumetric activity

with time during accident and post-accident conditions. The monitor may also be used for

the determination of the total discharge of noble gas activity over a given period;

• noble gas, aerosol and specific nuclide (commonly iodine, in its different forms: inorganic

iodine, organic iodine and iodine sticking on dust) monitors intended to measure the

volumetric activity in air or gas systems (control room ventilation, reactor leakage

collection, drywell ventilation exhaust, fuel handling building ventilation exhaust, reactor

building ventilation purge exhaust) and detect any significant increase of radioactivity

during or after an accident.

This standard is only applicable to continuous off-line measurement, i.e. monitors whose

detector measures a representative proportion of the main effluent or ventilation stream at

some remote location (sampling assembly). It does not apply to monitors with the detector

positioned in or adjacent to the effluent or ventilation stream, which are within the scope of

IEC 60951-4.

Sample extraction and laboratory analysis, which are essential to a complete programme of

effluent monitoring, are not within the scope of this standard.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60951-1:2009, Nuclear power plants – Instrumentation important to safety – Radiation

monitoring for accident and post-accident conditions – Part 1: General requirements

IEC 61226, Nuclear power plants – Instrumentation and control systems important to safety –

Classification of instrumentation and control functions

– 8 – 60951-2 © IEC:2009

ISO 2889:2009, Sampling airborne radioactive materials from the stacks and ducts of nuclear

facilities

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60951-1 apply.

4 Design principles

4.1 General

The general requirements of IEC 60951-1 are applicable to all types of monitors within the

scope of the present standard, unless otherwise stated.

4.2 Basic requirements related to functions

The equipment will typically measure levels of activity in engineered gaseous discharge

routes, such as reactor or fuel handling buildings, and ventilation ducts and stacks. It is

intended to provide, depending on the required function, a measure of activity discharged to

the environment or detection and quantification of leakage in containment barriers, and any

useful information on the behaviour of the plant, which causes or allows the activity release.

The measurement of activity discharge to the environment should ideally be comprehensive,

but since measurement of halogen and particulate activity released in effluents during an

accident is more complex, it is often judged that monitoring only noble gases will be sufficient.

Therefore, monitors should be capable of detecting and measuring gaseous effluent

radioactivity with compositions ranging from fresh equilibrium noble gas fission product

mixtures to 10 days old mixtures. Multiple instruments may be needed to cover the effective

range of measurements required.

Since the measurement is continuously carried out on a sample of effluent or ventilation

transferred to a remote location, the detection and measurement assembly shall be installed

in an accessible location and in an environment which is compatible with the equipment

design limits specified in this standard. This shall be also applicable to the active parts of the

sampling assembly (pumps, flow control instruments) requiring maintenance.

The other part of the sampling assembly (sampling probe, pipework) may be designed for and

located in a harsh environment. In this case, if the monitor is classified according to the

guidance of IEC 61226, it should be classified at the same level as the monitor. If qualification

is needed, the part of the sampling assembly located in the harsh environment should be

environmentally qualified to these specific ambient conditions.

If necessary, the system shall indicate a value related to the measured volumetric activity

under the conditions of temperature and pressure at the sampling location, agreed upon

between the manufacturer and purchaser. They shall also agree on how to correct the

expression of measurement if the conditions inside the measuring assembly are different from

the calibration conditions.

4.3 Sampling assembly

4.3.1 General

The design of the sampling assembly shall take into account the guidance of ISO 2889 and

shall comply with the general requirements of IEC 60951-1.

The sampling assembly typically includes one or more of the following assemblies and

functional units:

60951-2 © IEC:2009 – 9 –

• Sampling and exhaust pipes.

• Gas conditioning device (e.g. gas cooling device with condensate removing device or gas

reheating device to prevent condensation inside the measuring chamber, inlet and outlet

connection for an external purging system to remove the remaining gas in the collecting

device, etc).

• Measuring chamber.

• Airborne particles collecting devices:

• aerosol filter unit (filter tape or fixed filter) for aerosol monitors;

• inlet dust filter only for iodine and noble gas monitors;

• iodine molecular filter unit or charcoal filter or cartridge unit (filter changing device or

fixed filter) for iodine monitors.

• Ambient gamma radiation protection device and/or compensation device.

• Individual air pump or centralized pumping station.

• Air flow-rate measurement and/or control devices.

• When appropriate (depending on sampling conditions): pressure, temperature or humidity

measurement and/or control device.

4.3.2 Measurement technique requirements

Depending on the radionuclides to be monitored, the air or gas shall be filtered to remove

radioactive particulates and iodine or passed in a container of known constant volume; in the

latter case, the measuring cell shall be of the flow-through type, its volume and operating

pressure shall be specified, and the detector shall be easily removable for service or

replacement with a detector mounting ensuring a repeatable geometrical location.

Where the measurement technique is sensitive to pressure, a pressure measurement shall be

provided. The calibration shall take into account the actual conditions of service by

appropriate corrections; the acceptable pressure and variation of pressure in the sampling

assembly shall be specified by the manufacturer. Care shall be taken to ensure that the

pressure in the measuring volume is only slightly affected by the variation of pressure drop

across the inlet filter.

Where the measurement technique is sensitive to flow rate, a flow-rate measuring device shall

be provided. The calibration shall take into account the actual pressure and temperature of

service by appropriate corrections. The influence of gas stream conditioning devices upon the

volume measurement shall be considered. A flow-rate control device should also be provided

which has a flow-rate adjustment range sufficient to allow for variation in the intrinsic

characteristics of the air pump and any filters used. A correction of the measurement for the

effects of different flow-rates should also be provided.

If necessary, a humidity measurement of the atmosphere to be monitored may be provided to

control the conditioning device in order to avoid any condensation in the pipes and the

monitors; alarms should be provided to signal when the relative humidity exceeds a value

specified by the manufacturer.

If necessary, a temperature measurement of the sample in front of and close to the measuring

device may be provided. In this case, alarms should be provided to signal when the

temperature is close to the maximum allowed temperature for the detector.

4.3.3 Requirements on filters and collecting devices

If required, filters or other trapping devices shall be placed in holders at the sampling

assembly inlet to remove any dust, aerosols or volatiles from the air or gas. They shall

therefore be designed not to trap or retain noble gases or iodine (except iodine sticking onto

– 10 – 60951-2 © IEC:2009

dust); if this is not possible, they shall be monitored separately. The manufacturer of such

filters shall specify their retention characteristics for several chemical forms of iodine.

Collecting filters (e.g. glass fibre filter plate, glass fibre filter tape, charcoal filter cartridges)

shall be designed to ensure an as uniform as possible deposition of particles. The

manufacturer of such filters shall state the retention characteristics of the filters for several

chemical forms of radioactive particles, their lifetime, and the collection efficiency of the

collecting filter for particles over a range of at least 0,1 μm to 10,0 μm aerodynamic

equivalent diameter or to values agreed upon by the manufacturer and the purchaser. The

efficiency of the filters should be more than 98 % for dust apart from iodine and more than

99 % for iodine.

41 85 133 222

The presence of radioactive gases (for example Ar, Kr, Xe or Rn) in the air being

monitored has an effect on the monitoring of particles; this is especially true for non-selective

detectors; to reduce the effects of these radionuclides, the air space in the vicinity of the

detector and inside the filters shall be kept to the minimum. If necessary, and if practicable, a

purging capability could be provided, to reduce unwanted and disturbing influence of

radioactive noble gasses on the measurement of the particle activity.

Collecting filters or trapping devices shall be accessible during normal and post-accident

conditions; the pressure drop in the filter as well as its contamination should be controlled,

and it should be possible to replace it by an easy and quick disconnection of the filter unit

from the pipes.

For the collecting filters introducing an important pressure drop, a differential pressure

measurement should be provided to indicate a clogged or pierced collector. In this case,

alarms shall be provided for warning of any excessive variation of this differential pressure.

4.3.4 Requirements on sampling circuit and materials

Where a pump is an integral part of any assembly, its nominal flow rate shall be stated by the

manufacturer. The sampling assembly design shall provide simple access to the pump and its

replaceable parts. Care shall be taken to prevent radioactive gases from leaking into the

breathing zone of workers. The acceptable leakage rate depends on the emergency

conditions and shall be agreed upon between the manufacturer and the purchaser.

Prevention against condensation in the pipe by variation of temperature or pressure shall be

taken. If a gas stream cooling device is used, the condensate flow of the cooling device shall

be removed automatically.

Leakage of air or gas in the sampling system (between inlet and outlet of the monitor) shall be

less than 5 %.

Losses of particulates and iodine shall be maintained as low as possible by taking into

account piping circuit and constructional material in order to estimate and minimize

electrostatic effects, adsorption, condensation and plate-out; the level of such losses, and the

ways to reduce it, shall be agreed upon between the manufacturer and the purchaser. In any

case, the roughness of the surfaces in contact with the gas stream should be less than

0,4 μm.

Delay time to detector shall be maintained as low as possible by optimising the pipe length

and diameter, flow rate, etc.

Where the measured sample may contain an explosive mixture of gases (e.g. H ), the

assembly shall be designed to prevent the possibility of ignition of the sample by the

instrumentation.

60951-2 © IEC:2009 – 11 –

Where the measured sample may contain noxious or corrosive chemical vapour, the assembly

shall be designed to protect the measuring system.

5 Functional testing

5.1 General

Except where otherwise specified, all the tests specified in Clause 5 of IEC 60951-1 shall be

carried out.

The tests described hereinafter are only additional tests dedicated to the type of monitors

within the scope of the present standard. As for tests stated in IEC 60951-1, these tests shall

be considered as type tests, although any or all may be considered as acceptance tests by

agreement between manufacturer and purchaser.

These tests shall be carried out under standard conditions or with variation of the influence

quantities. They are listed in Table 2.

5.2 Reference sources

In addition to 5.2.5 of IEC 60951-1, the following requirements shall apply:

A range of test gases may need to be used depending on the function and design of the

monitor. These gases shall be agreed upon between the purchaser and the manufacturer.

Depending on the design of the monitor, the test shall be to:

• either circulate air or gas filled with known activity through the assembly under test during

a sufficient time interval to reach measurement equilibrium and note the readings;

• or to immerse the detector in a sufficiently large volume of gas so as to be equivalent to

the volume in the actual operating position of the detector and note the readings under

equilibrium conditions for the monitor under test.

NOTE Circulation may not be required if the measurement is properly corrected for temperature and pressure.

If it is intended to use a reference instrument for tests, then it should be inserted in the gas

flow (or in a sufficiently large volume of gas) in the same way as the instrument under test

and, for both of them, the readings should be noted. In this case, to estimate the accuracy of

the instrument under test, the readings and the absolute measurement error of the reference

instrument should be used instead of the conventionally true value and its absolute

uncertainty of the reference source.

5.3 Performance characteristics : response to other radioactive gases or particles

5.3.1 Requirements

The designated radioactive gases and particles to which this requirement applies shall be the

subject of an agreement between the manufacturer and the purchaser. The manufacturer shall

specify the response to the radioactive gases or particles of interest present in the sample of

air or carrier-gas.

5.3.2 Test method

The test method is similar to the method used for determining the reference response, but

using the appropriate radioactive gas or gases.

Two methods may be used:

– 12 – 60951-2 © IEC:2009

133 85

– Continuously inject a known volume activity of noble gas for example Xe or Kr into

the monitor for the time necessary to reach equilibrium. Note the reading corresponding to

the equilibrium value. Express the result as the ratio of the indication to the volume

activity of the test gas.

– Connect the inlet air duct to the outlet air duct and measure the total air duct volume (for

example connecting the inlet air duct to a known volume under pressure and noting the

pressure change at equilibrium). Inject into the system a small volume (1 % of the air duct

133 85

volume) of gas, for example Xe or Kr, of known total activity. Operate the monitor in

the normal way. Note the reading corresponding to the equilibrium and to the highest

value attained. Express the result as the ratio of the indication to the volume activity of the

test gas.

5.4 Air circuit performance test

5.4.1 General

These tests shall be applied to all monitors for which the response is dependent upon a

known flow-rate through a sampling and detection assembly.

Where the equipment is insensitive to flow-rate, but nevertheless requires a sampling flow-

rate in order to function, a simple test of the flow-rate circuit and any flow-rate alarms shall be

agreed upon between the manufacturer and the purchaser.

When the equipment is sensitive to flow-rate, and the flow-rate varies in conjunction with the

effluent flow-rate, appropriate tests shall be agreed upon between the manufacturer and the

purchaser.

5.4.2 Monitor sampling efficiency

5.4.2.1 General

The collection efficiency, between the inlet of the monitor and the collecting filter, shall not

differ by more than 10 % from the value stated by the manufacturer for each given size of

particle.

If agreed upon between the manufacturer and the purchaser, a simulation could be also

performed, instead of real tests.

5.4.2.2 Particle size

The particle diameter and range of sizes used in the measurement of the collection efficiency

of the sampling system shall be agreed upon between the manufacturer and the purchaser,

for example depending upon the diameter of the aerosol to be monitored, collection efficiency

of the filter media versus particle size, etc.

5.4.2.3 Aerosol type

Various types of aerosols are suitable for use in the collection efficiency tests and include, for

example:

• non-radioactive aerosols with particles having a fluorescent tracer,

• non-radioactive aerosols composed of latex or polystyrene spheres,

• radioactive aerosols.

5.4.2.4 Test method

Collection efficiency shall be tested by introducing a sample of air containing particles of the

appropriate median aerodynamic diameter into the inlet sampling pipe. The distribution may

be polydispersed with a small geometric standard deviation. The sampling equipment shall be

operating under standard test conditions, e.g., flow-rate.

60951-2 © IEC:2009 – 13 –

After the shutdown of the sampling equipment, the amount of aerosol collected on the

sampling medium shall be determined. In addition, the total amount of aerosol available at the

monitor inlet shall be determined. This may be done by an independent measurement of the

sampled amount of aerosol, or by determining:

• the amount of aerosol collected on the internal surfaces of the inlet line and other surfaces

of the air circuit upstream from the collection medium,

• the amount of aerosol downstream from the collection medium.

5.4.2.5 Determination of collection efficiency

The collection efficiency (E ) of the monitor shall be calculated as:

m

C

M

E = ×100

m

C

T

where:

C is the amount deposited on the collection medium,

M

C is the total amount of aerosol.

T

It is recommended, if practical, that the total amount of aerosol (C ) be determined by an

T

alternative method as a means of verifying the values obtained. Such methods include the

measurement of the concentration of aerosols that enter into the instrument by various

instrumental techniques, for example spectrophotometer, particle analyzer, reference

sampling, etc.

If the total aerosol sampled is determined by the sum of the material collected within the

monitor, then the total amount of aerosol (C ) (activity, mass or number of particles) is given

T

by:

C = C + C + C

T M U D

where:

C is the amount recovered from the internal surfaces of the air circuit upstream of the

U

collection medium,

C is the amount collected downstream of the collection medium.

D

5.4.3 Susceptibility to gas or particles retention

5.4.3.1 General

The retention of noble gas or particles inside the air circuit may influence the measuring

results. Therefore the intention of the manufacturer’s air circuit design, selection of materials,

and construction shall be to prevent such a retention.

If agreed upon between the manufacturer and the purchaser, a simulation could be also

performed, instead of real tests.

5.4.3.2 Requirements

Noble gas with a volumetric activity greater than 10 times the decision threshold shall be

introduced into the monitor. The test for susceptibility to gaseous retention shall indicate less

than 1 % of the maximum resulting reading after clean air is introduced into the monitor.

– 14 – 60951-2 © IEC:2009

Particle concentration shall be introduced into the monitor. The test for susceptibility to

particle retention shall indicate less than 5 % of the maximum resulting reading after clean air

is introduced into the monitor.

5.4.3.3 Test method for noble gas

Introduce into the detection assembly, for a period of at least 10 times the response time of

the equipment, noble gas of the chemical form that the equipment is designed to measure

with a volumetric activity approximately equal to 10 times the decision threshold.

For assemblies not comprising a trapping system, make the gas system a closed loop and

introduce into this system sufficient noble gas for the volumetric activity to equal 1 000 times

the decision threshold. Operate until equilibrium of the gas concentration.

Verify that the indication of the measuring assembly stays at its maximum value for at least

10 times the response time of the equipment.

Then circulate fresh air at ambient temperature and pressure with the air circuit open at the

nominal flow-rate, for a time long enough to reach an equilibrium in indicated value. This

value shall be less than 1 % of the maximum indicated value during the test with noble gas

activity.

5.4.3.4 Test method for particles

Introduce into the detection assembly a well known quantity/mass of non-radioactive particles

by injecting the particles into the sampling pipe. The particles should be of the chemical form

that the equipment is designed to measure.

Then circulate fresh air at ambient temperature and pressure with the air circuit open at the

nominal flow-rate, for several minutes. Then measure the quantity/mass of the particles

collected on the filter unit of the monitor.

The total loss of particles shall be < 5 %.

5.4.4 Relative error of the volume and flow rate measurement

5.4.4.1 General

The relative error of the measured values of radioactive gas in air concentrations is directly

related to the relative error of the measured values of flow rate or volume for those samplers,

which concentrate or absorb the gas into the collection medium. An accurate volume and flow

rate measurement of counting gas mixed with the noble gas containing medium is also

important for an accura

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...