IEC 60282-1/AMD1/FRAG5

(Amendment)Amendment to IEC 282-1 - Deletion of note 5 to table 4

Amendment to IEC 282-1 - Deletion of note 5 to table 4

Applicable to non-dispersive infra-red analyzers specified for installation either indoors or outdoors and used for the continuous determination of certain aspects of air quality by measuring the gaseous constituents. Special definitions. Functional characteristics. Test methods for determining the performance and for verifying compliance with specifications.

Amendement à la CEI 282-1 - Suppression de la note 5 du tableau 4

S'applique aux analyseurs infrarouges non dispersifs, prévus pour installation à l'intérieur ou à l'extérieur et utilisés pour déterminer en continu certains aspects de la qualité de l'air par mesure des constituants gazeux. Fixe la terminologie relative aux qualités de fonctionnement des analyseurs, unifie les méthodes utilisées pour exprimer et vérifier ces qualités et spécifie les essais nécessaires pour les déterminer.

Expression of performance of air quality infra red analyzers

General Information

- Status

- Published

- Publication Date

- 29-Feb-1996

- Technical Committee

- SC 32A - High-voltage fuses

- Current Stage

- MERGED - Merged project

- Start Date

- 01-Mar-1996

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview

This IEC standard defines how to express and verify the functional performance of non-dispersive infra‑red (NDIR) air‑quality analyzers used for continuous measurement of gaseous constituents in ambient and confined atmospheres. The extract covers scope, definitions, required statements by manufacturers, performance characteristics, influence quantities (environmental and supply conditions), and recommended test methods for calibration and verification. The referenced amendment (IEC 60282-1/AMD1/FRAG5) indicates a corrective change: the deletion of note 5 to Table 4, affecting the published tables/clarifications.

Key topics and requirements

- Scope and applicability

- Applies to complete NDIR analyzers (optical, mechanical, electrical, electronic) specified for indoor or outdoor installation.

- Excludes sample handling systems and external data acquisition accessories.

- Primary definitions

- Clear definitions for terms such as non-dispersive infra‑red analyzer, calibration gas, influence quantity, rated value/range, effective range, intrinsic/operating error, linearity error, interference error, drift, warm‑up time, delay/rise time.

- Manufacturer statements

- Manufacturers must publish rated values/ranges, limits of error, drift limits, repeatability and other performance characteristics.

- Environmental and supply conditions must be declared using one of the defined usage Groups and any exceptions explicitly stated.

- Performance characteristics and error reporting

- Requirements for stating operating error, intrinsic error (reference conditions), linearity, interference errors (for specified interfering gases and at agreed concentrations), repeatability (2 standard deviations), minimum detectable concentration, and output characteristics.

- Drift and timing

- Zero/span drift limits to be stated over specified intervals (examples range from 15 min to 1 year) and warm‑up time requirements.

- Test and verification

- Use of traceable calibration gases and specified procedures for determining and verifying performance; uncertainties of conventionally true values must be stated.

Applications and who uses it

- Who uses this standard

- NDIR analyzer manufacturers, instrument designers, calibration and test laboratories, environmental monitoring agencies, procurement/specification teams, and regulatory bodies.

- Practical uses

- Producing compliance data sheets and performance declarations for ambient air monitors, emissions analyzers, and stationary/indoor monitoring systems.

- Designing test plans for factory acceptance, field calibration, verification, and routine maintenance.

- Ensuring traceability of calibration gases and consistency in reporting limits of error and uncertainty.

Related standards

- IEC 348 - Safety requirements for electronic measuring apparatus (safety aspects).

- IEC 359 - Expression of the functional performance of electronic measuring equipment (general principles).

- IEC 381 - Analogue D.C. current signals for process control (output signal conventions).

Keywords: NDIR, non‑dispersive infra‑red analyzer, air quality monitoring, performance specification, calibration gas, limits of error, drift, interference error, IEC standard.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

BSMI (Bureau of Standards, Metrology and Inspection)

Taiwan's standards and inspection authority.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Sponsored listings

Frequently Asked Questions

IEC 60282-1/AMD1/FRAG5 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Amendment to IEC 282-1 - Deletion of note 5 to table 4". This standard covers: Applicable to non-dispersive infra-red analyzers specified for installation either indoors or outdoors and used for the continuous determination of certain aspects of air quality by measuring the gaseous constituents. Special definitions. Functional characteristics. Test methods for determining the performance and for verifying compliance with specifications.

Applicable to non-dispersive infra-red analyzers specified for installation either indoors or outdoors and used for the continuous determination of certain aspects of air quality by measuring the gaseous constituents. Special definitions. Functional characteristics. Test methods for determining the performance and for verifying compliance with specifications.

IEC 60282-1/AMD1/FRAG5 is classified under the following ICS (International Classification for Standards) categories: 13.040 - Air quality; 17.020 - Metrology and measurement in general; 31.260 - Optoelectronics. Laser equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60282-1/AMD1/FRAG5 has the following relationships with other standards: It is inter standard links to IEC 60282-1:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60282-1/AMD1/FRAG5 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Expression of performance of air quality infra red analyzersExpression des qualités de fonctionnement des analyseurs infrarouges de contrôle de la qualité de l'airExpression of performance of air quality infra-red analyzers07.060Geologija. Meteorologija. HidrologijaGeology. Meteorology. HydrologyICS:Ta slovenski standard je istoveten z:IEC 60528SIST IEC 60528:1995en01-avgust-1995SIST IEC 60528:1995SLOVENSKI

STANDARD

IEC•NORMECEIINTERNATIONALEIECINTERNATIONAL60528STAN DARDPremière éditionFirst edition1975-01Expression des qualités de fonctionnementdes analyseurs infrarouges de contrôlede la qualité de l'airExpression of performanceof air quality infra-red analyzers© IEC 1975 Droits de reproduction réservés — Copyright - all rights reservedAucune partie de cette publication ne peut être reproduite niNo part of this publication may be reproduced or utilized inutilisée sous quelque forme que ce soit et par aucunany form or by any means, electronic or mechanical,procédé, électronique ou mécanique, y compris la photo-including photocopying and microfilm, without permission incopie et les microfilms, sans l'accord écrit de l'éditeur.writing from the publisher.International Electrotechnical Commission3, rue de Varembé Geneva, SwitzerlandTelefax: +41 22 919 0300e-mail: inmail@iec.chIEC web site http: //www.iec.chCODE PRIXPRICE CODE^(Pour prix, voir catalogue en vigueur•For price, see current catalogueCommission Electrotechnique InternationaleInternational Electrotechnical CommissionMen gyHaporaHai 3neKTpoTexHN4ecnaç HOMHCCHASIST IEC 60528:1995

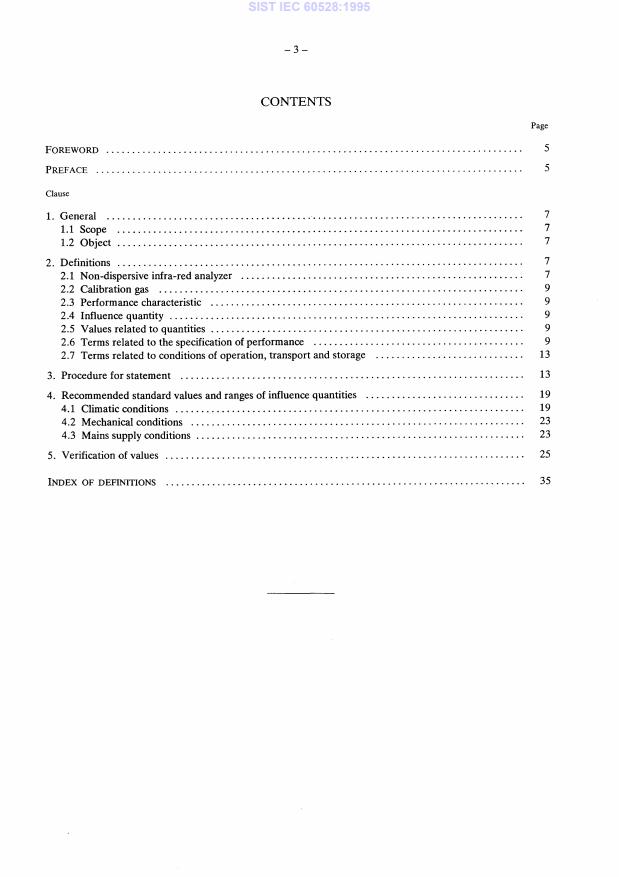

— 3 —CONTENTSPageFOREWORD

5PREFACE 5Clause1.General 71.1 Scope 71.2 Object 72.Definitions 72.1 Non-dispersive infra-red analyzer 72.2 Calibration gas 92.3 Performance characteristic 92.4 Influence quantity 92.5 Values related to quantities 92.6 Terms related to the specification of performance 92.7 Terms related to conditions of operation, transport and storage 133.Procedure for statement 134.Recommended standard values and ranges of influence quantities

194.1 Climatic conditions 194.2 Mechanical conditions

234.3 Mains supply conditions

235.Verification of values 25INDEX OF DEFINITIONS35SIST IEC 60528:1995

— 5 —INTERNATIONAL ELECTROTECHNICAL COMMISSIONEXPRESSION OF PERFORMANCEOF AIR QUALITY INFRA-RED ANALYZERSFOREWORD1)The formal decisions or agreements of the IEC on technical matters, prepared by Technical Committees on which all the NationalCommittees having a special interest therein are represented, express, as nearly as possible, an international consensus of opinion onthe subjects dealt with.2)They have the form of recommendations for international use and they are accepted by the National Committees in that sense.3)In order to promote international unification, the IEC expresses the wish that all National Committees should adopt the text ofthe IEC recommendation for their national rules in so far as national conditions will permit. Any divergence between the IECrecommendation and the corresponding national rules should, as far as possible, be clearly indicated in the latter.PREFACEThis publication has been prepared by IEC Technical Committee No. 66, Electronic Measuring Equipment.A first draft was discussed at the meeting held in The Hague in 1973. The draft, Document 66(CentralOffice)17, was submitted to the National Committees for approval under the Six Months' Rule in May 1974.The following countries voted explicitly in favour of publication:AustraliaJapanBelgiumNetherlandsBrazilPolandDenmarkPortugalGermanySwitzerlandHungaryTurkeyIsraelUnited KingdomItalyUnited States of AmericaOther IEC publications quoted in this publication:Publications Nos. 348: Safety Requirements for Electronic Measuring Apparatus.359: Expression of the Functional Performance of Electronic Measuring Equipment.381: Analogue D.C. Current Signals for Process Control Systems.SIST IEC 60528:1995

– 7 –EXPRESSION OF PERFORMANCEOF AIR QUALITY INFRA-RED ANALYZERS1. General1.1 Scope1.1.1 This standard applies to non-dispersive infra-red analyzers used for the continuous determination ofcertain aspects of air quality by measuring gaseous constituents either in ambient or confined atmospheres or ingaseous streams entering the ambient air.1.1.2 It applies to infra-red analyzers specified for installation either indoors or outdoors.1.1.3 It applies to the complete analyzer as an integral analytical unit, including all optical, mechanical,electrical and electronic portions.For the purpose of this standard, any regulated power supply, provided with the analyzer or specified by themanufacturer, is considered part of the analyzer whether it is integral with the analyzer or housed separately.1.1.4 It does not apply to the required sample handling systems or other accessories such as recorders,analogue-to-digital converters or data acquisition systems, used in conjunction with the analyzer.1.1.5 Safety requirements are dealt with in IEC Publication 348, Safety Requirements for ElectronicMeasuring Apparatus.1.1.6 This standard is in accordance with the general principles set out in IEC Publication 359, Expression ofthe Functional Performance of Electronic Measuring Equipment.1.2 ObjectThis standard is intended:–to specify the terminology and definitions related to the functional performance of non-dispersive infra-redanalyzers used for the continuous determination of certain aspects of air quality by measuring gaseousconstituents either in ambient or confined atmospheres or in gaseous streams entering the ambient air;–to unify methods used in making and verifying statements on the functional performance of such analyzers;–to specify what tests should be performed to determine the functional performance and how such testsshould be carried out.2. DefinitionsThe following definitions apply for the purpose of this standard:2.1 Non-dispersive infra-red analyzerAn electro-optical spectrophotometric instrument with no spectral dispersion component, consisting of asingle or double source of infra-red radiation and one or more infra-red detectors separated by an optical cellor cells through one or more of which the sample flows, whereby the specific spectral absorption of thecomponent of interest is determined.Notes 1. — For the purpose of this standard, the analyzer is adjusted by the manufacturer to select only the spectral band(s) at which thecomponent to be determined has its characteristic absorption, and the sample cell length is appropriate for the rated range ofconcentration.2. — Specific spectral sensitivity is obtained by a selective component such as a selective source, selective detector or selective filter,or any combination of these components.SIST IEC 60528:1995

– 9 –2.2 Calibration gasA mixture of known concentration of the component to be determined or a suitable simulant for thecomponent to be determined in air or another suitable carrier gas, used for periodic calibration of the infra-redanalyzer, and for various performance tests.Notes 1. – For the purpose of this standard, concentration means the mass or the volume of the component to be determined in a givenvolume of calibration gas. Different units may be used, but the manufacturer shall state exactly what is meant.2. – For the purpose of this standard, the concentrations of these gases represent the conventionally true values* (see Sub-clause2.6.2.1) against which indicated values are compared. Therefore, the values of the calibration gases should be traceable tostandards agreed upon by the manufacturer and the user or to national standards, and the uncertainty of the conventionally truevalues shall be stated.2.3 Performance characteristicOne of the quantities assigned to an apparatus in order to define by values, tolerances, ranges, etc., theperformance of the apparatus.2.4 Influence quantityAny quantity, generally external to an apparatus, which may affect the performance of the apparatus.2.5 Values related to quantities2.5.1 Rated valueThe value (or one of the values) of a quantity to be measured, observed, supplied or set, which themanufacturer has assigned to the apparatus.2.5.2 Rated rangeThe range of a quantity to be measured, observed, supplied or set, which the manufacturer has assigned tothe apparatus.2.5.3 Effective rangeThat part of the rated range where measurements can be made within the stated limits of error.2.6 Terms related to the specification of performance2.6.1 PerformanceThe degree to which the intended functions of an apparatus are accomplished.2.6.2 Error2.6.2.1 Absolute errorThe error expressed algebraically, in the unit of the measured quantity.For measuring apparatus, the error is the indicated value of the measured quantity minus its true value.Note. – The true value of a quantity is the value that would be measured by a measuring process having no error.In practice, since this true value cannot be determined by measurement, a conventionally true value, approaching the true value asclosely as necessary (having regard to the error to be determined), is used in place of the true value. This value should be traced tostandards agreed upon by the manufacturer and the user, or to national standards. In both cases, the uncertainty of the conven-tionally true value shall be stated.2.6.2.2 Relative errorThe ratio of the absolute error to a stated value.* This definition and related terms are given in IEC Publication 359.SIST IEC 60528:1995

– 11 –2.6.2.3 Percentage errorThe relative error expressed as a percentage, such as percent of full scale (the maximum value of theeffective range), percent of the indicated or preset value or of the rated value.2.6.2.4 Fiducial valueA value to which reference is made in order to specify the percentage error, e.g. the upper limit of theeffective range, or another clearly stated value.2.6.3 Intrinsic errorThe error determined under reference conditions.2.6.4 Operating errorThe error determined under rated operating conditions.2.6.5 Influence errorThe error determined when one influence quantity assumes any value within its rated range of use (or aninfluencing characteristic assumes any value within its effective range), all others being at reference conditions.2.6.6 Linearity errorThe maximum deviation between actual analyzer readings and the readings predicted by a linear function ofthe measured quantity which includes the indicated values at the upper and lower limits of_ the effective range.2.6.7 Interference errorThe error caused by interfering gases and vapours being present in the sample.Note. — This is an influence error and other influence errors are dealt with below.2.6.8 Limits of errorThe maximum values of error assigned by the manufacturer to a measured quantity of an apparatusoperating under specified conditions.2.6.9 RepeatabilityThe deviation between repeated measurements made in rapid succession at the same concentration of thecomponent to be determined, under constant environmental conditions and rated sample conditions.2.6.10 Zero driftThe shift in reading for zero calibration gas (see Sub-clause 5.2) over a stated period of time.2.6.11 Span drift (drift of the limits of the effective range)The shift in span over a stated period of time.2.6.12 Operating periodThe maximum time interval within which the limits of operating error are not exceeded, without adjustmentby external means.2.6.13 Output fluctuationDeviations from a mean output not caused by variation in the concentration of the component to bedetermined or by a change in any influence quantity.SIST IEC 60528:1995

– 13 –2.6.14 Minimum detectable concentrationThe concentration which corresponds to twice the output fluctuation level when the concentration of thecomponent to be determined is zero.2.6.15 Delay timeThe time interval from the instant a step change occurs in the concentration of the component to bedetermined at the analyzer inlet, to the instant when the change in the indicated value passes 10% of itssteady-state amplitude, with the sample flow kept at its rated value.2.6.16 Rise (fall) timeThe time interval within which the indicated value passes from 10% to 90% (from 90% to 10%) of itssteady-state amplitude after a step increase (decrease) in the concentration of the component to be determinedat the analyzer inlet, with the sample flow kept at its rated value.2.6.17 Warm-up timeThe time interval after switching on the analyzer under specified conditions, until the zero and span driftsare within specifications.2.7 Terms related to conditions of operation, transport and storage2.7.1 Reference conditionsA set of values with tolerances, or of restricted ranges of influence quantities, specified for making compari-son and calibration tests.2.7.2 Rated range of use (of influence quantities)The range of values for an influence quantity within which the requirements concerning operating error aresatisfied.2.7.3 Rated operating conditionsThe whole of the effective ranges for performance characteristics, and rated ranges of use for influencequantities, within which the performance of the apparatus is specified.2.7.4 Limit conditions of operationThe whole of the ranges of values for influence quantities and performance characteristics (beyond the ratedranges of use and effective ranges respectively) within which an apparatus can function without resulting indamage or degradation of performance when it is afterwards operated under rated operating conditions (seeSub-clause 3.2.3).2.7.5 Conditions of storage and transportThe whole of the conditions of temperature, humidity, air pressure, vibration, shock, etc., within which theapparatus may be stored or transported in an inoperative condition, without resulting in damage or degra-dation of performance when it is afterwards operated under rated operating conditions.3. Procedure for statement3.1 The manufacturer shall provide statements on the following:3.1.1 The rated values for the performance characteristics listed in Sub-clause 3.3. The rated values for theseperformance characteristics shall be equal to their effective ranges.3.1.2 The limits of errors listed in Sub-clause 3.4.SIST IEC 60528:1995

– 15 –3.1.3 The limits of drifts listed in Sub-clause 3.5.3.1.4 The performance characteristics listed in Sub-clause 3.6.3.1.5 The reference values or ranges, the rated ranges of use and the limit ranges of operation, storage andtransport, for all influence quantities shall be stated and shall be selected from only one of the usage Groups I,II or III in Clause 4. Any exceptions to the values given there shall be explicitly and clearly stated by themanufacturer with an indication that they are exceptions.Note. – Analyzers may correspond to one group of the rated ranges of use for environmental conditions and to another group for mainssupply conditions, but this must be clearly stated by the manufacturer.3.2 Statements on rated operating conditions and limit conditions shall be made in such a way that thefollowing requirements are met unless otherwise specified.3.2.1 The analyzer, while functioning, shall show no damage or degradation of performance when anynumber of performance characteristics and/or influence quantities assume any value within the limit conditionsof operation during a specified time or, if no time is specified, for an unlimited time.3.2.2 The analyzer shall show no permanent damage or degradation of performance when, being inoperative,it has been subjected to conditions where any number of influence quantities assume any value within theirstorage or transport conditions during a specified time or, if no time is specified, for an unlimited time.3.2.3 Absence of damage or degradation of performance means that after re-establishing reference con-ditions or rated operating conditions the analyzer again meets the requirements concerning its performance.3.3 Performance characteristics requiring statements of rated values3.3.1 Minimum and maximum rated values for the concentration of the component to be determined (range orranges)The lower value is specified first, then the upper value (e.g. 0 to 1 cm3/m3 or 10 to 20 mg/m3).3.3.2 Minimum and maximum rated values for output signals corresponding to the concentrations as given inSub-clause 3.3.1These signals shall be stated in units of either voltage or current, and if multiple outputs are provided theyshall be stated. If stated in units of voltage, the minimum allowable load, in ohms, shall be stated also. If statedin units of current, the maximum allowable load, in ohms, shall be stated also.If capacitive or inductive load will influence the output signal, this shall be specified.Note. – If the analyzer output signal is electrical current and more than one output range is supplied, the minimum and maximum ratedvalues of one output range should be 4 mA and 20 mA (see IEC Publication 381, Analogue D.C. Current Signals for ProcessControl Systems).3.3.3 Rated ranges for sample conditions at the analyzer inlet, including flow rate, pressure and temperature '3.4 Error limits to be stated3.4.1 Operating error for the indicated concentration, expressed as concentration of the component to bedetermined (e.g. ±2 mg/m3 or ±1 cm3/m3), or as percent of full scale.Note. – For the purpose of this standard, the stated operating error will not include effects of interference errors or effects of variation inbarometric pressure. They are stated separately and must be considered as additive to the operating error as stated by themanufacturer (see Sub-clauses 3.4.3, 3.4.3.1, 3.4.3.2, 5.7.2, 5.7.2.1, 5.7.2.2 and 5.7.8.1 relative to interference errors; see Sub-clauses 3.6.8 and 5.7.8.1 relative to the effect of barometric pressure variation).SIST IEC 60528:1995

— 17 —3.4.1.1 Intrinsic error (which applies under reference conditions) may be stated in addition, for comparisonand calibration purposes.3.4.2 Linearity error for each specified range, expressed as percentage values in terms of the rated range ofconcentration (e.g. +2% of full scale or —2% of full scale).Note.— Deviation from linearity is strictly considered as an error only if a linear output signal is claimed for the analyzer. However, as aperformance characteristic it should be included for comparison purposes and is referred to as an error in all cases for simplicity.3.4.3 Interference errors for each specified range:3.4.3.1 Interference errors shall be stated in terms of the equivalent concentration of the component to bedetermined for at least two concentration levels of the interfering component. Depending on the design andadjustment of the analyzer, the interference error may be either positive or negative; therefore, the sign shallbe included in the statement.3.4.3.2 The manufacturer should indicate which components are known to have interference in the particularapplication under consideration. The specification of all interfering components for which interference errorsare to be stated, and their concentration levels, shall be made by agreement between the manufacturer and theuser.3.4.4 Repeatability error for each specified range, in terms of two standard deviations in the concentration ofthe component to be determined.3.5 Zero drift and span drift, expressed as percentage values in terms of the rated range of concentration(e.g. 2% of full scale) over a specified time interval.The time interval for which the drift limits are stated should be chosen appropriately for the specific applica-tion (e.g. 1, 3 or 7 h for automobile exhaust analyzers; 24 h, 7 days or 30 days for ambient air monitors). Theyshould be chosen from the following:15 min7 days1h30 days3h3 months7h6 months24 h1 yearThese values are to be stated on the basis that no adjustments will be made on the analyzer by externalmeans during the stated time intervals. The warm-up time is always excluded from the time interval.3.6 Although no statements of error limits are required for the performance characteristics listed below, themanufacturer shall state their values or ranges.3.6.1 Output fluctuation expressed as a percentage value in terms of the rated range of concentration for thepeak-to-peak deviation (e.g. 0.25% of full scale).3.6.1.1 In the case of analyzers having variable time constants in the output circuit, the output fluctuationshall be stated for the same time constant as used for the statement of delay time, rise time and fall time.3.6.2 Minimum detectable concentration3.6.3 Delay time3.6.4 Rise time3.6.5 Fall timeSIST IEC 60528:1995

— 19 —3.6.6 Warm-up time3.6.7 Operating period3.6.7.1 The time interval for the operating period shall be chosen from the same list as used for zero drift.3.6.8 The quantitative effect on indicated concentration produced by variation in barometric pressureNote. – If the sample cell vents directly to the atmosphere, barometric pressure controls the pressure of the sample and thus the number ofinfra-red absorbing molecules in the sample cell. Therefore, in the absence of any provision either to control the sample pressureindependently of atmospheric pressure or to sense the barometric pressure and apply a correction, the output signal correspondingto a given concentration will vary with the barometric pressure.4. Recommended standard values and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...