IEC 61058-2-4:2018

(Main)Switches for appliances - Part 2-4: Particular requirements for independently mounted switches

Switches for appliances - Part 2-4: Particular requirements for independently mounted switches

IEC 61058-2-4:2018 applies to independently mounted switches for appliances (mechanical or electronic) actuated by hand, by foot or by other human activity, to operate or control electrical appliances and other equipment for household or similar purposes with a rated voltage not exceeding 480 V and a rated current not exceeding 63 A. This second edition cancels and replaces the first edition published in 1995 and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

- overall format modified to support the revised structure of the series;

- Annexes K and M have been included as an integral part of this document;

- Annex L has been included for information purposes only.

This document is to be used in conjunction with IEC 61058-1:2016.

Interrupteurs pour appareils - Partie 2-4: Exigences particulières pour les interrupteurs à montage indépendant

L'IEC 61058-2-4:2018 s'applique aux interrupteurs à montage indépendant (mécaniques ou électriques) pour appareils manœuvrés à la main, au pied ou par d'autres activités humaines, pour actionner ou commander des appareils électriques et autres matériels pour usage domestique et analogue, de tension assignée ne dépassant pas 480 V et de courant assigné ne dépassant pas 63 A. Cette deuxième édition annule et remplace la première édition parue en 1995, dont elle constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- format global a été modifié pour être compatible avec la structure révisée de la série;

- les Annexes K et M ont été ajoutés pour faire partie intégrante du présent document;

- l'Annexe L est donnée à titre d'information uniquement.

Ce document doit être utilisé conjointement avec l'IEC 61058-1:2016.

General Information

- Status

- Published

- Publication Date

- 11-Oct-2018

- Technical Committee

- SC 23J - Switches for appliances

- Drafting Committee

- MT 1 - TC 23/SC 23J/MT 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 12-Oct-2018

- Completion Date

- 11-Oct-2018

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61058-2-4:2018 - “Switches for appliances - Part 2‑4: Particular requirements for independently mounted switches” specifies safety and performance requirements for independently mounted mechanical or electronic switches used to operate or control household and similar appliances. It covers switches actuated by hand, foot or other human activity, with a rated voltage not exceeding 480 V and a rated current not exceeding 63 A. This 2nd edition (2018) replaces the 1995 edition, aligns the format with the IEC 61058 series structure, and incorporates Annexes K and M as normative (Annex L informative). It is intended to be used together with IEC 61058‑1:2016.

Key topics and technical requirements

The standard supplements and modifies the general requirements in IEC 61058‑1 and focuses on aspects specific to independently mounted switches:

- Scope & definitions: clarifies “independently mounted switch” and design types (Design A and B).

- Ratings and classification: rated voltage/current limits and classification by degree of protection and intended use.

- Marking and documentation: required product information, identification and instructions.

- Safety protections: requirements for protection against electric shock, earthing provisions and terminals/terminations.

- Construction & mechanism: mechanical design, actuator arrangements, and internal construction for safe operation.

- Environmental protection: ingress protection, resistance to humidity, dust and water where applicable.

- Electrical tests: insulation resistance, dielectric strength, clearances and creepage distances.

- Reliability tests: heating, endurance, mechanical strength, resistance to rusting and abnormal/fault condition tests.

- Fire and tracking resistance: requirements for materials and coatings to limit fire hazard and tracking.

- EMC and components: electromagnetic compatibility requirements and rules for substituted components.

- Annexes: routine tests (K), sampling tests (L - informative), and switch family provisions (M).

Applications

IEC 61058‑2‑4 is directly applicable to:

- Manufacturers of independently mounted switches for household and similar appliances.

- Design engineers specifying switch components or actuator interfaces.

- Test laboratories and certification bodies performing conformity assessment and type testing.

- OEMs integrating switches into appliances or remote-actuated controls.

- Regulatory and compliance teams ensuring product safety for markets using IEC standards.

Who should use this standard

- Switch designers and component manufacturers

- Appliance manufacturers and product development teams

- Compliance engineers, safety assessors and test houses

- Certification bodies that assess electrical safety of appliance controls

Related standards

- IEC 61058‑1:2016 - Switches for appliances (general requirements) - mandatory companion document.

- IEC 60669‑1:2017 - Switches for household and similar fixed installations.

- Relevant cable standards: IEC 60227, IEC 60245 series.

Keywords: IEC 61058-2-4, independently mounted switches, switch standards, appliance switches, switch testing, rated voltage 480 V, rated current 63 A, IEC 61058 series.

Buy Documents

IEC 61058-2-4:2018 RLV - Switches for appliances - Part 2-4: Particular requirements for independently mounted switches Released:10/12/2018 Isbn:9782832261231

IEC 61058-2-4:2018 - Switches for appliances - Part 2-4: Particular requirements for independently mounted switches Released:10/12/2018 Isbn:9782832260906

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 61058-2-4:2018 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Switches for appliances - Part 2-4: Particular requirements for independently mounted switches". This standard covers: IEC 61058-2-4:2018 applies to independently mounted switches for appliances (mechanical or electronic) actuated by hand, by foot or by other human activity, to operate or control electrical appliances and other equipment for household or similar purposes with a rated voltage not exceeding 480 V and a rated current not exceeding 63 A. This second edition cancels and replaces the first edition published in 1995 and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - overall format modified to support the revised structure of the series; - Annexes K and M have been included as an integral part of this document; - Annex L has been included for information purposes only. This document is to be used in conjunction with IEC 61058-1:2016.

IEC 61058-2-4:2018 applies to independently mounted switches for appliances (mechanical or electronic) actuated by hand, by foot or by other human activity, to operate or control electrical appliances and other equipment for household or similar purposes with a rated voltage not exceeding 480 V and a rated current not exceeding 63 A. This second edition cancels and replaces the first edition published in 1995 and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - overall format modified to support the revised structure of the series; - Annexes K and M have been included as an integral part of this document; - Annex L has been included for information purposes only. This document is to be used in conjunction with IEC 61058-1:2016.

IEC 61058-2-4:2018 is classified under the following ICS (International Classification for Standards) categories: 29.120.40 - Switches. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61058-2-4:2018 has the following relationships with other standards: It is inter standard links to IEC 61058-2-4:1995/AMD1:2003, IEC 61058-2-4:1995. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61058-2-4:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61058-2-4 ®

Edition 2.0 2018-10

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Switches for appliances –

Part 2-4: Particular requirements for independently mounted switches

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61058-2-4 ®

Edition 2.0 2018-10

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Switches for appliances –

Part 2-4: Particular requirements for independently mounted switches

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.120.40 ISBN 978-2-8322-6123-1

– 2 – IEC 61058-2-4:2018 RLV © IEC 2018

CONTENTS

FOREWORD . 4

1 Scope . 7

2 Normative references. 8

3 Terms and definitions . 8

4 General requirements . 8

5 General notes information on tests . 9

6 Rating . 9

7 Classification . 9

8 Marking and documentation . 10

9 Protection against electric shock . 10

10 Provision for earthing . 11

11 Terminals and terminations . 11

12 Construction . 12

13 Mechanism . 19

14 Protection against ingress of solid foreign objects, dust, ingress of water, and

protection against humid conditions . 19

15 Insulation resistance and dielectric strength . 20

16 Heating . 20

17 Endurance . 20

18 Mechanical strength . 20

19 Screws, current-carrying parts and connections . 20

20 Clearances, creepage distances and distances through insulation, solid insulation

and coatings of rigid printed board assemblies . 21

21 Resistance to heat, fire and tracking Fire hazard . 21

22 Resistance to rusting . 22

23 Abnormal operation and fault conditions for switches . 22

24 Components for switches . 22

25 EMC requirements . 22

Annexes . 26

Annex K (normative) Routine tests . 26

Annex L (informative) Sampling tests . 26

Annex M (normative) Switch families . 26

Figure 101 – Example of pull apparatus for testing the cord anchorage . 23

Figure 102 – Example of torque apparatus for testing the cord anchorage . 23

Figure 103 – Example of apparatus for flexing test . 24

Figure 104 – Example of terminal inlet openings .

Table 101 – Switch information .

Table 3 – Switch information and loads placed in groups . 10

Table 102 101 – Rated currents for resistor loads and related types of cables . 16

Table 103 102 – Torque values for torque test . 17

Table 104 103 – Torque values for screws of insulating material screws . 20

– 4 – IEC 61058-2-4:2018 RLV © IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SWITCHES FOR APPLIANCES –

Part 2-4: Particular requirements for

independently mounted switches

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 61058-2-4 has been prepared by subcommittee 23J: Switches for

appliances, of IEC technical committee 23: Electrical accessories.

This second edition cancels and replaces the first edition published in 1995 and constitutes a

technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) overall format modified to support the revised structure of the series;

b) Annexes K and M have been included as an integral part of this document;

c) Annex L has been included for information purposes only.

The text of this International Standard is based on the following documents:

CDV Report on voting

23J/433/CDV 23J/441/RVC

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

This document is to be used in conjunction with IEC 61058-1:2016.

This document supplements or modifies the corresponding clauses in IEC 61058-1, so as to

convert that publication into the IEC standard: Particular requirements for independently

mounted switches.

When a particular subclause of IEC 61058-1 is not mentioned in this document, that

subclause applies as far as reasonable. Where this document states "addition", "modification"

or "replacement", the relevant text of IEC 61058-1 is to be adapted accordingly.

In this document:

1) the following print types are used:

– requirements proper: in roman type;

– test specifications: in italic type;

– explanatory matter: in smaller roman type.

2) subclauses, figures or tables which are additional to those in IEC 61058-1 are numbered

starting from 101.

A list of all the parts in the IEC 61058 series, under the general title Switches for appliances,

can be found on the IEC website.

– 6 – IEC 61058-2-4:2018 RLV © IEC 2018

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

SWITCHES FOR APPLIANCES –

Part 2-4: Particular requirements for

independently mounted switches

1 Scope

Clause 1 of IEC 61058-1:2016 is applicable, except as follows.

1.1 Replacement:

Addition:

This document applies to independently mounted switches for appliances (mechanical or

electronic) actuated by hand, by foot or by other human activity for use with, to operate or

control electrical appliances and other equipment for household and or similar purposes with

a rated voltage not exceeding 440 480 V and a rated current not exceeding 63 A.

These switches are intended to be operated by a person, via an actuating member or by

actuating a sensing unit. The actuating member or sensing unit can be integral with or

arranged separately, either physically or electrically, from the switch and involve transmission

of a signal, for example, electrical, optical, acoustic or thermal, between the actuating

member or sensing unit and the switch.

Switches which incorporate additional control functions governed by the switch function are

within the scope of this document.

1.2 Replacement:

This standard applies to independently mounted switches intended to be used with an

appliance or equipment.

This document also covers the indirect actuation of the switch when the operation of the

actuating member or sensing unit is provided by a remote control or by a part of an appliance

or equipment, such as a door.

NOTE 1 Electronic switches can be combined with mechanical switches giving full disconnection or micro-

disconnection.

NOTE 2 Electronic switches without a mechanical switch in the supply circuit provide only electronic

disconnection. Therefore, the circuit on the load side is always considered to be live.

NOTE 3 For switches used in tropical climates, additional requirements may be necessary can apply.

NOTE 4 Attention is drawn to the fact that the standards for appliances and equipment may can contain additional

or alternative requirements for switches.

NOTE 4 Throughout this standard the word "switch" means "independently mounted switch" unless otherwise

stated.

NOTE 5 Throughout this document, the word "appliance" means "appliance or equipment".

1.3 Replacement:

This standard applies to switches intended to be mounted apart from the appliance

(independently mounted switches) other than those within the scope of IEC 669-1.

– 8 – IEC 61058-2-4:2018 RLV © IEC 2018

2 Normative references

Clause 2 of IEC 61058-1:2016 is applicable except as follows:.

2.1 IEC standards

Replacement of IEC 669-1:1981 by IEC 669-1:1993.

Addition:

IEC 60227-3:1993, Polyvinyl chloride insulated cables of rated voltages up to and including

450/750 V – Part 3: Non-sheathed cables for fixed wiring

IEC 60227-5, Polyvinyl chloride insulated cables of rated voltages up to and including

450/750 V – Part 5: Flexible cables (cords)

IEC 60245-4, Rubber insulated cables – Rated voltages up to and including 450/750 V –

Part 4: Cords and flexible cables

IEC 60669-1:2017, Switches for household and similar fixed-electrical installations – Part 1:

General requirements

IEC 61058-1:2016, Switches for appliances – Part 1: General requirements

3 Terms and definitions

Clause 3 of IEC 61058-1:2016 is applicable, except as follows.

3.3 Terms and definitions relating to the different types of switches

Additional terms and definitions:

3.3.101

independently mounted switch

switch intended to be mounted away from the controlled appliance or equipment and intended

to be connected to the fixed wiring on the supply side

3.3.102

design A switch

switch where the cover or coverplate can be removed without displacement of the

conductor(s)

NOTE Displacement means movement of the conductor, see IEC 60669-1, subclause 7.1.7.

3.3.103

design B switch

switch where the cover or coverplate cannot be removed without displacement of the

conductor(s)

NOTE Displacement means movement of the conductor, see IEC 60669-1, subclause 7.1.7.

4 General requirements

Clause 4 of IEC 61058-1:2016 is applicable.

5 General notes information on tests

Clause 5 of IEC 61058-1:2016 is applicable.

6 Rating

Clause 6 of IEC 61058-1:2016 is applicable.

7 Classification

Clause 7 of IEC 61058-1:2016 is applicable except as follows.

7.5 Degree of protection against solid foreign objects

Replacement:

7.1.5 According to the degree of protection provided by the switch, when mounted as

declared:

7.1.5.1.1, 7.1.5.1.2 and 7.1.9.1 are not applicable.

The degree of protection against solid foreign objects is declared.

With the exception of IP0X and IP1X, all IP ratings are allowed.

7.11 According to resistance to ignitability by the glow wire temperature

Subclause 7.11.1 of IEC 61058-1:2016 is not applicable.

7.22 According to the type of forced cooling

Subclause 7.22.2 of IEC 61058-1:2016 is not applicable.

Additional subclauses:

7.1.101 According to design

7.1.101.1 design A switch;

7.1.101.2 design B switch.

NOTE 1 See definitions 3.3.102 and 3.3.103.

NOTE 2 If a switch has a base which cannot be separated from the cover or cover plate, and requires an

intermediate plate which can be removed for redecorating the wall, it is considered to be of design A, provided the

intermediate plate meets the requirements specified for covers and cover plates.

7.1.102 According to outlet facilities

7.1.102.1 switch with inlet/outlet facilities for rigid cables;

7.1.102.2 switch with inlet facilities for rigid cables and outlet facilities for flexible cables.

– 10 – IEC 61058-2-4:2018 RLV © IEC 2018

8 Marking and documentation

Clause 8 of IEC 61058-1:2016 is applicable, except as follows with the following modifications

to Table 3:

Addition:

Table 101 – Switch information

No. Subclause

Switch with unique-type-reference ……………………………………. U.t.

Switch with common-type-reference ………………………….…………. C.T.

101 SWITCH DESIGN

101.1 Type of switch design 7.1.101 Do Do

102 OUTLET FACILITIES

102.1 Type of outlet facilities 7.1.102 Do Do

Table 3 – Switch information and loads placed in groups

Modification:

Means of information

Common Unique

Characteristic Subclause

No.

type type

reference reference

CT UT

2 SWITCH ENVIRONMENT/MOUNTING

2.1 Degree of protection provided for the switch when 7.5 and 7.6 Marking Marking

mounted according to documentation

(IP code of IEC 60529)

NOTE Additional letters listed in IEC 60529 are not

used.

4 ELECTRICAL LOAD/CONNECTION

4.1 Rated voltage or rated voltage range 6.1 Marking Marking

Additional rows:

101 SWITCH DESIGN

101.1 Type of switch design 7.101.1 and Document- Document-

7.101.2 ation ation

102 OUTLET FACILITIES

102.1 Type of outlet facilities 7.102 Document- Document-

ation ation

9 Protection against electric shock

Clause 9 of IEC 61058-1:2016 is applicable, except as follows.

9.1 Addition of the following sentence to a):

The switch shall be fitted with the cable conductor of the smallest or largest nominal cross-

sectional area according to Table 3 4 whichever is more unfavourable, or with a rigid conduit,

a pliable conduit or a flexible conduit.

Addition to b d):

This test finger, with an electrical indicator, is not applied to membranes in inlet openings and

is applied to thin-walled knock-outs with a force of only 10 N.

Additional subclause:

9.101 Switches operated by means of a removable key or by means of an intermediate part,

such as a cord, a chain or a rod, shall be so designed that the key or intermediate part can

only touch parts which are insulated from live parts.

The key or intermediate part shall be insulated from metal parts of the mechanism, unless the

clearances and creepage distances between live parts and metal parts of the mechanism

have at least twice the values specified in 20.2.5 and 20.4.5.

Compliance is checked by inspection, by the test of 15.3 and, if necessary, by measurement.

NOTE Lacquer or enamel is not considered to be insulating material for the purpose of 9.101.

10 Provision for earthing

Clause 10 of IEC 61058-1:2016 is applicable, except as follows.

Additional subclause:

10.101 Switches for class I appliances shall have provision for earthing continuity

connection.

11 Terminals and terminations

Clause 11 of IEC 61058-1:2016 is applicable, except as follows.

Table 3 Additional note:

NOTE Switches with a rated current of 10 A and less shall have terminals accepting 1,5 mm conductors.

11.1.1.2.2 Addition to a):

When testing with rigid conductors the tests are carried out first with rigid stranded conductors

and the tests are then repeated with rigid solid conductors if a solid conductor with the same

cross-sectional area is specified in IEC 60227-3.

Additional subclauses:

11.1.2.101 Terminals classified in 7.2.4 are in general not permitted. Such terminals may

however in particular cases be permitted for the load side of the switch (see 11.1.3).

– 12 – IEC 61058-2-4:2018 RLV © IEC 2018

11.1.3.101 The power supply cable shall be connected only by a method of attachment such

that the cable can be replaced without the aid of special purpose tools or by a cable not

requiring special preparation. Connection from the switch to the appliance shall normally be

performed in a similar way, but may in particular cases (e.g. a particular manufactured

connection between the switch and the appliance) be made by a method of attachment such

that the cable can only be replaced with the aid of special purpose tools normally available to

the manufacturer or his agent.

A method of attachment such that the cable cannot be replaced without destroying the

integrity of the switch shall not be used.

12 Construction

Clause 12 of IEC 61058-1:2016 is not applicable.

Replacement:

Additional subclauses:

12.101 Insulating linings, barriers and the like, shall have adequate mechanical strength and

shall be secured in a reliable manner.

Compliance is checked by inspection after the tests of Clause 18.

12.102 Switches shall be so constructed as to permit:

• easy introduction and connection of the conductors in the terminals;

• adequate space between the underside of the base and the surface on which the base is

mounted or between the sides of the base and the enclosure (cover or box) so that, after

installation of the switch, the insulation of the conductors does not come in contact with

live parts of different polarity or with moving parts of the mechanism, such as the spindle

of a rotary switch;

NOTE This requirement does not imply that the metal parts of the terminals are necessarily protected by

insulating barriers or insulating shoulders to avoid contacts, due to incorrect installation of the terminal metal

parts, with the insulation of the conductor.

• easy fixing of the base to a wall or in a box and correct positioning of the conductors.

NOTE For surface-type switches, mounted on a mounting plate, a wiring channel may be

needed to comply with this requirement.

In addition, switches classified according to 7.1.101.1 (design A switch) shall permit an easy

positioning and removal of the cover or cover plate, without displacing the conductors.

Compliance is checked by inspection and by an installation test with conductors of the largest

cross-sectional area for the relevant terminal size, in Table 3 4.

12.103 Covers and cover plates or parts thereof, which are intended to ensure protection

against electric shock, shall be held in place at two or more points by effective fixing.

Covers and cover plates or parts thereof may be fixed by means of a single fixing, for

example by a screw, provided that they are retained in position by another means (e.g. by a

shoulder).

NOTE 1 It is recommended that the fixings of covers and cover plates or parts thereof be

captive. The use of tight fixing washers of cardboard or the like is deemed to be an adequate

method for securing screws intended to be captive.

NOTE 2 Live parts and non-earthed metal parts separated from live parts in such a way that creepage distances

and clearances have values specified in Clause 20 are not considered as accessible if the requirements of 12.103

are met.

For switches with a degree of protection IPX0, the fixing of covers or cover plates shall not

serve to fix any other part, except the knobs.

When the fixings of covers or cover plates also serve to fix the base, there shall be sufficient

means to maintain the base in position after removal of the cover or cover plate.

Decorative covers, cover plates or parts thereof not providing protection against electric shock

are not considered as covers or cover plates within the meaning of 12.103.

12.103.1 For covers and cover plates or parts thereof whose fixing is of the screw-type,

compliance is checked by inspection and by an installation test.

12.103.2 For covers and cover plates or parts thereof whose fixing is not dependent on

screws and whose removal is obtained by applying a force in a direction approximately

perpendicular to the mounting/supporting surface, compliance is checked by applying the test

described in 13.3.2 of IEC 60669-1:2017 under the conditions set out in 20.4 to 20.6 of

IEC 60669-1:2017.

12.104 Surface-type switches with degree of protection IPX0 shall be so constructed that,

when they are fixed and wired as in normal use, there are no free openings in their

enclosures.

Compliance is checked by inspection and by an installation test with conductors of the cross-

sectional area specified in Table 3 4.

NOTE Small gaps between enclosures and conduits or cables, or between enclosures and operating means are

neglected disregarded.

12.105 Knobs of rotary switches shall be securely coupled to the shaft or part operating the

mechanism.

The knob is subjected for 1 min to an axial pull of 100 N .

In addition, for knobs of switches having only one direction of operation, a torque of 1 Nm or

the actuating torque if this is greater, is applied 100 times in the direction opposite to the

direction of operation.

During the test, the knob shall not become detached.

NOTE Requirements for the fixation of other types of actuating members are under consideration.

12.106 Screws or other means for mounting the switch on a surface or in a box or enclosure

apart from panel mounting shall be easily accessible from the front. These means shall not

serve any other fixing purpose.

12.107 Other electrical accessories combined with switches shall comply with the

requirements of the standard for the accessory in question.

12.108 Switches other than those with degree of protection IPX0 shall be totally enclosed

when fitted with conduits or cables.

Surface-type switches other than those with degree of protection IPX0 shall have provision for

opening a drain hole at least 5 mm in diameter, or 20 mm in area with a width and length of

at least 3 mm.

– 14 – IEC 61058-2-4:2018 RLV © IEC 2018

The drain hole shall be effective in at least two positions of the switch when this is mounted

on a vertical wall, one of these with the conductors entering at the top and the other with the

conductors entering at the bottom.

Compliance is checked by measurement and by inspection during the relevant tests of 14.32.

NOTE A drain hole in the back of the enclosure is deemed to be effective only if the design of the enclosure

ensures a clearance of at least 5 mm from the wall, or provides a drainage channel of at least the size specified.

12.109 Switches to be installed in a box shall be so designed that the conductor ends can be

prepared after the box is mounted in position, but before the switch is fitted in the box.

In addition, the base shall have adequate stability when mounted in the box.

Compliance is checked by inspection and by an installation test with the appropriate cable

with conductors of the largest cross-sectional areas specified, for the relevant terminal size, in

Table 3 4.

12.110 Single pole surface type switches of an IP degree higher than X0 with an enclosure

having more than one inlet opening shall be provided with an additional terminal for

maintaining the continuity of a second current carrying conductor and complying with the

appropriate requirements of Clause 10 11, or with an adequate space for a floating terminal.

Compliance is checked by inspection and by the relevant tests of Clause 11.

NOTE For switches for Class I appliances, this terminal is additional to the terminal required according to

Clause 10.101.

12.111 Inlet openings shall allow the introduction of the conduit or the protective covering of

the sheathed cable so as to afford complete mechanical protection.

IPX0 surface-type switches shall be so constructed that the conduit or protective covering can

enter at least 1 mm into the enclosure.

In IPX0 surface-type switches, the inlet opening for conduit entries, or at least two of them

if there are more than one, shall be capable of accepting conduit sizes of 16, 20, 25 or 32 or a

combination of at least two of any of these sizes.

Compliance is checked by inspection during the test of 12.109 and by measurement.

NOTE Inlet openings of adequate size may can also be obtained by the use of knock-outs or of suitable insertion

pieces.

If ordinary surface-type switches are intended for back entry from a conduit they shall be so

designed that they have provision for back entry from a conduit perpendicular to the mounting

surface of the switch.

Compliance is checked by inspection.

If the switch is provided with membranes in inlet openings, these shall be replaceable.

Compliance is checked by inspection.

12.112 Switches classified according to 7.1.102.2 shall have cord anchorages at the

declared outlet facilities for flexible cables such that the conductors are relieved from strain,

including twisting, where they are connected to the terminals, and such that their covering is

protected from abrasion and kept in position.

12.112.1 It shall be clear how the relief from strain and the prevention of twisting is intended

to be effected.

12.112.2 The inlet or bushing shall be provided with a smoothly rounded opening.

12.112.3 Makeshift methods such as tying the cable into a knot, or tying the ends with string

shall not be used.

12.112.4 Cord anchorages of switches shall be of insulating material, or, if of metal, be insu-

lated from accessible metal parts or accessible insulating surfaces, by insulation complying

with the requirements for supplementary insulation.

The cord anchorages shall be so designed that their parts do not fall out when the cover is

removed, even if the switches are not fitted with their cables.

12.112.5 Cord anchorages shall further be so designed that:

• for any attachment method, the cable is not fixed by penetration of its insulation in such a

way that the insulation of the cable is cut or otherwise significantly damaged.

NOTE A slight deformation of the insulation, in such a way that the insulation of the cable is

not cut or otherwise significantly damaged, is allowed;

• the cable cannot touch clamping screws of the cord anchorage if these screws are

accessible or electrically connected to accessible metal parts;

• the cable is not clamped by a screw which bears directly on the cable, except where the

screw is made of insulating material;

• at least one part is securely fixed to the switch;

• replacement of the cable does not require the use of a special purpose tool;

• they are suitable for the different types of cables which may be connected.

12.112.6 Cord anchorages shall be so designed and located that replacement of the cable is

easily possible.

12.112.7 Screws, if any, which have to be operated when replacing the cable, shall not

serve to fix any other component, unless either the switch is rendered inoperable or

manifestly incomplete if they are omitted or incorrectly replaced, or the component intended to

be fixed cannot be removed without the aid of a tool when replacing the cable.

Compliance is checked by inspection and by a pull test in an apparatus similar to that shown

in Figure 101, followed by a torque test in an apparatus similar to that shown in Figure 102:

• three new switches are tested with PVC sheathed cables as declared by the manufacturer

having the smallest and largest cross-sectional area as specified in Table 102 101. Before

the test the free length of the cable shall be cut to 150 mm ± 5 mm;

• switches provided with entries specially designed for the connection of PVC insulated flat

cables (60227 IEC 52) are tested with flat cables only.

– 16 – IEC 61058-2-4:2018 RLV © IEC 2018

Table 102 101 – Rated currents for resistor loads and related types of cables

Rated current for Number of cores Nominal cross- Types of cables Overall diameter

resistor load sectional area of

Min. Max.

each conductor

2 mm mm

A mm

4,8 6,0

Up to and including 2 0,5 60227 IEC 52

5,2 6,4

0,75 60227 IEC 52

3,2 × 5,2 3,9 × 6,4

60227 IEC 52 fl

5,0 6,2

3 0,5 60227 IEC 52

5,4 6,8

0,75 60227 IEC 52

5,2 6,4

Over 3 and up to 2 0,75 60227 IEC 52

and including 6

3,2 × 5,2 3,9 × 6,4

60227 IEC 52 fl

6,0 7,6

60227 IEC 53

3,8 × 6,0 5,2 × 7,6

60227 IEC 53 fl

5,4 6,8

3 0,75 60227 IEC 52

6,4 8,8

60227 IEC 53

7,6 9,4

4 1,0 60227 IEC 53

5,2 6,4

Over 6 and up to 2 0,75 60227 IEC 52

and including 16

3,2 × 5,2 3,9 × 6,4

60227 IEC 52 fl

6,0 7,6

60227 IEC 53

3,8 × 6,0 5,2 × 7,6

60227 IEC 53 fl

6,4 8,0

1,0 60227 IEC 53

7,4 9,0

1,5 60227 IEC 53

5,4 6,8

3 0,75 60227 IEC 52

6,4 8,0

60227 IEC 53

6,8 8,4

1,0 60227 IEC 53

8,0 9,8

1,5 60227 IEC 53

7,6 9,4

4 1,0 60227 IEC 53

9,0 11,0

1,5 60227 IEC 53

7,4 9,0

Over 16 and up to 2

and including 25

12,0 15,0

8,0 9,8

3 1,5 60227 IEC 53

9,6 12,5

9,0 11,0

4 4 60245 IEC 66

14,5 18,0

8,9 11,0

Over 25 and up to 2

and including 32

13,5 18,5

9,6 12,0

3 2,5 60227 IEC 53

14,5 20,0

10,5 13,0

4 6 60245 IEC 66

16,5 22,0

10,0 12,0

Over 32 and up to 2

and including 40

18,5 24,0

11,0 13,0

3 4 60227 IEC 53

20,0 25,5

Rated current for Number of cores Nominal cross- Types of cables Overall diameter

resistor load sectional area of

Min. Max.

each conductor

2 mm mm

A mm

12,0 14,0

4 10 60245 IEC 66

21,5 28,0

10,0 12,0

Over 40 and up to 2

and including 63

18,5 24,0

11,0 13,0

3 4 60227 IEC 53

20,0 25,5

12,0 14,0

4 10 60245 IEC 66

21,5 28,0

Conductors of the cable are introduced into the terminals, and the terminal metal screws are

tightened just sufficiently to prevent the conductors from easily changing their position.

The cord anchorage is used in the normal way, metal clamping screws being tightened with

two-thirds of the torque specified in Table 16 10 and clamping screws of insulating material

with two-thirds of the torque specified in Table 104 103. After reassembly of the switch, its

component parts shall fit snugly and it shall not be possible to push the cable into the switch

to any appreciable extent.

The switch is first fixed in a test apparatus similar to that shown in Figure 101 so that the axis

of the cable is vertical where it enters the switch. The cable is then subjected 100 times to a

pull of:

• 60 N if the rated current is not more than 16 A;

• 100 N if the rated current is more than 16 A.

The pulls are applied without jerks, each time for 1 s.

Immediately after this test, the cable is subjected for 1 min to a torque as specified in

Table 103 102 with an apparatus similar to that shown in Figure 102.

Table 103 102 – Torque values for torque test

Flexible cable

Rated current for

2 … 5 × 1

resistor load

2 × 0,5 2 × 0,75 3 × 0,5 3 × 0,75

(or larger)

Up to and including 16 A 0,1 Nm 0,15 Nm 0,15 Nm 0,25 Nm 0,25 Nm

Over 16 A 0,425 Nm

The torque is applied as near as possible to the switch.

During the tests, neither the cable nor the switch shall be damaged within the meaning of this

document. After the tests, the cable shall not have been displaced longitudinally by more than

2 mm, and there shall be no appreciable strain at the connection. Creepage distances and

clearances shall not have been reduced below the value specified in Clause 20.

For the measurement of the longitudinal displacement a mark is made on the cable while it is

subjected to the first pull. After the tests the displacement of the mark on the cable in relation

to the switch is measured while the cable is subjected to an additional pull.

– 18 – IEC 61058-2-4:2018 RLV © IEC 2018

12.112.8 Switches shall be designed so that the cables incur no damage due to the bending

likely to occur in normal use.

Cord guards shall not be integral with the cable.

Exempted from this requirement are switches with terminals classified according to 7.2.3

7.20.2, where the method of attachment is such that the cable can be replaced without the aid

of a special purpose tool by a special cable with for example a moulded-on cord guard. For

those terminals it shall not be possible to fit a cable without a cord guard during servicing.

Compliance is checked by subjecting the switch, fitted with the cable, or range of cables,

for which it is designed, to the following tests.

The switch is mounted in the flexing apparatus similar to that shown in Figure 103. For the

purpose of the test, the following conditions apply.

a) The test is performed only once with a cable of the maximum dimension attached.

b) For switches having a rated current over 3 A, a cable of type 60227 IEC 53 shall be used.

The axis of oscillation is so chosen that the weight attached to the cable, and the cable itself,

make the minimum lateral movement during the test. Switches with flat cables are mounted so

that the major axis of the cross-section is parallel to the axis of oscillation. Each cable

passing through the inlet opening is loaded with a weight having a mass of 1 kg. A current

equal to the current passing through that particular core when the switch is operated at rated

voltage is passed through each core, the voltage between the cores being the maximum rated

voltage. The oscillating member is moved backwards and forwards through an angle of 22,5°

(on either side of the vertical), the number of flexings (that is one movement through 45°)

being 5 000, and the rate of the flexing being 60 flexings per minute.

During the test there shall be no interruption of the test current and no short circuit between

conductors.

After the test, the switch shall show no damage within the meaning of this document.

12.112.9 The space for the external conductors inside the switch shall be adequate to allow

the conductors to be easily introduced and connected, and the cover, if any, fitted without risk

of damage to the conductors or their insulation. It shall be possible to check that the

conductors are correctly connected and positioned before the cover is fitted.

Compliance is checked by inspection and by connecting cables with cores of the maximum

cross-sectional area specified in table 102 according to Table 101.

12.112.10 Switches with terminals for the connection of the earth conductor (earthing

continuity) and classified according to 7.2.8 7.20.4 or 7.20.5 shall be designed with ample

space for slack of the protective earth conductor in such a way that, if the strain relief should

fail, the connection of the protective earth conductor is subjected to strain after the

connections of the current-carrying conductors and that, in case of excessive stresses, the

protective earth conductor will break after the current-carrying conductors.

Compliance is checked by the following test:

• the cable is connected to the switch in such a way that the current-carrying conductors are

led from the strain relief to the corresponding terminals along the shortest possible path;

• after they are correctly connected, the core of the protective earth conductor is led to its

terminal and cut off at a distance 8 mm longer than necessary for its correct connection;

• the protective earth conductor is then connected to its terminal. It must shall then be

possible to house the loop, which is formed by the protective earth conductor owing to its

surplus length, freely in the wiring space without squeezing or pressing the core when the

cover of the switch is remounted and fixed correctly.

13 Mechanism

Clause 13 of IEC 61058-1:2016 is applicable.

14 Protection against ingress of solid foreign objects, dust, ingress of water,

and protection against humid conditions

Clause 14

...

IEC 61058-2-4 ®

Edition 2.0 2018-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Switches for appliances –

Part 2-4: Particular requirements for independently mounted switches

Interrupteurs pour appareils –

Partie 2-4: Exigences particulières pour les interrupteurs à montage indépendant

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 21 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC -

Glossaire IEC - std.iec.ch/glossary

webstore.iec.ch/advsearchform

67 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC et en français, extraites des articles Termes et Définitions des

en utilisant différents critères (numéro de référence, texte, publications IEC parues depuis 2002. Plus certaines entrées

comité d’études,…). Elle donne aussi des informations sur les antérieures extraites des publications des CE 37, 77, 86 et

projets et les publications remplacées ou retirées. CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just Si vous désirez nous donner des commentaires sur cette

Published détaille les nouvelles publications parues. publication ou si vous avez des questions contactez-nous:

Disponible en ligne et aussi une fois par mois par email. sales@iec.ch.

IEC 61058-2-4 ®

Edition 2.0 2018-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Switches for appliances –

Part 2-4: Particular requirements for independently mounted switches

Interrupteurs pour appareils –

Partie 2-4: Exigences particulières pour les interrupteurs à montage indépendant

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.120.40 ISBN 978-2-8322-6090-6

– 2 – IEC 61058-2-4:2018 © IEC 2018

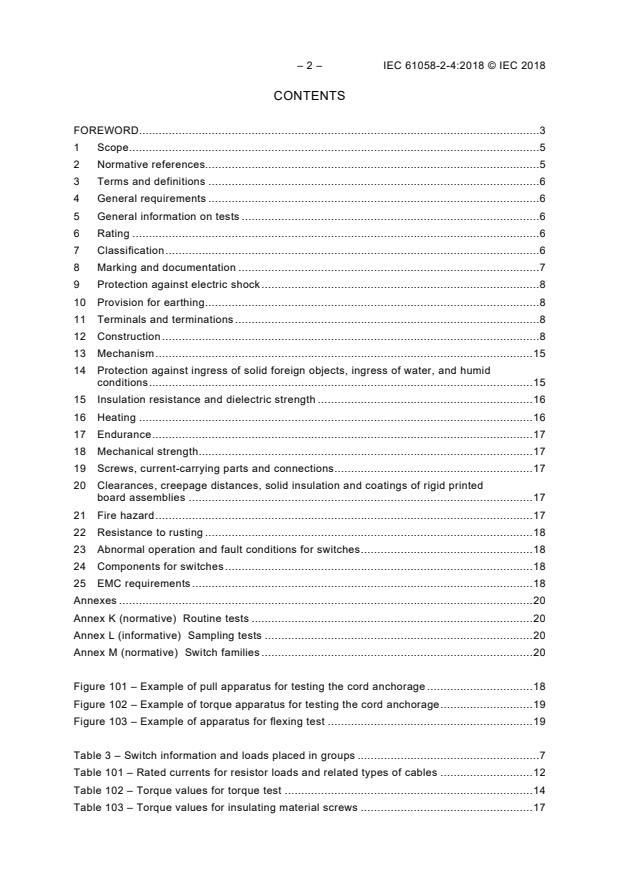

CONTENTS

FOREWORD . 3

1 Scope . 5

2 Normative references. 5

3 Terms and definitions . 6

4 General requirements . 6

5 General information on tests . 6

6 Rating . 6

7 Classification . 6

8 Marking and documentation . 7

9 Protection against electric shock . 8

10 Provision for earthing . 8

11 Terminals and terminations . 8

12 Construction . 8

13 Mechanism . 15

14 Protection against ingress of solid foreign objects, ingress of water, and humid

conditions . 15

15 Insulation resistance and dielectric strength . 16

16 Heating . 16

17 Endurance . 17

18 Mechanical strength . 17

19 Screws, current-carrying parts and connections . 17

20 Clearances, creepage distances, solid insulation and coatings of rigid printed

board assemblies . 17

21 Fire hazard . 17

22 Resistance to rusting . 18

23 Abnormal operation and fault conditions for switches . 18

24 Components for switches . 18

25 EMC requirements . 18

Annexes . 20

Annex K (normative) Routine tests . 20

Annex L (informative) Sampling tests . 20

Annex M (normative) Switch families . 20

Figure 101 – Example of pull apparatus for testing the cord anchorage . 18

Figure 102 – Example of torque apparatus for testing the cord anchorage . 19

Figure 103 – Example of apparatus for flexing test . 19

Table 3 – Switch information and loads placed in groups . 7

Table 101 – Rated currents for resistor loads and related types of cables . 12

Table 102 – Torque values for torque test . 14

Table 103 – Torque values for insulating material screws . 17

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SWITCHES FOR APPLIANCES –

Part 2-4: Particular requirements for

independently mounted switches

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61058-2-4 has been prepared by subcommittee 23J: Switches for

appliances, of IEC technical committee 23: Electrical accessories.

This second edition cancels and replaces the first edition published in 1995 and constitutes a

technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) overall format modified to support the revised structure of the series;

b) Annexes K and M have been included as an integral part of this document;

c) Annex L has been included for information purposes only.

– 4 – IEC 61058-2-4:2018 © IEC 2018

The text of this International Standard is based on the following documents:

CDV Report on voting

23J/433/CDV 23J/441/RVC

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

This document is to be used in conjunction with IEC 61058-1:2016.

This document supplements or modifies the corresponding clauses in IEC 61058-1, so as to

convert that publication into the IEC standard: Particular requirements for independently

mounted switches.

When a particular subclause of IEC 61058-1 is not mentioned in this document, that

subclause applies as far as reasonable. Where this document states "addition", "modification"

or "replacement", the relevant text of IEC 61058-1 is to be adapted accordingly.

In this document:

1) the following print types are used:

– requirements proper: in roman type;

– test specifications: in italic type;

– explanatory matter: in smaller roman type.

2) subclauses, figures or tables which are additional to those in IEC 61058-1 are numbered

starting from 101.

A list of all the parts in the IEC 61058 series, under the general title Switches for appliances,

can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

SWITCHES FOR APPLIANCES –

Part 2-4: Particular requirements for

independently mounted switches

1 Scope

Clause 1 of IEC 61058-1:2016 is applicable, except as follows.

Addition:

This document applies to independently mounted switches for appliances (mechanical or

electronic) actuated by hand, by foot or by other human activity, to operate or control

electrical appliances and other equipment for household or similar purposes with a rated

voltage not exceeding 480 V and a rated current not exceeding 63 A.

These switches are intended to be operated by a person, via an actuating member or by

actuating a sensing unit. The actuating member or sensing unit can be integral with or

arranged separately, either physically or electrically, from the switch and involve transmission

of a signal, for example, electrical, optical, acoustic or thermal, between the actuating

member or sensing unit and the switch.

Switches which incorporate additional control functions governed by the switch function are

within the scope of this document.

This document also covers the indirect actuation of the switch when the operation of the

actuating member or sensing unit is provided by a remote control or by a part of an appliance

or equipment, such as a door.

NOTE 1 Electronic switches can be combined with mechanical switches giving full disconnection or micro-

disconnection.

NOTE 2 Electronic switches without a mechanical switch in the supply circuit provide only electronic

disconnection. Therefore, the circuit on the load side is always considered to be live.

NOTE 3 For switches used in tropical climates, additional requirements can apply.

NOTE 4 Attention is drawn to the fact that the standards for appliances can contain additional or alternative

requirements for switches.

NOTE 5 Throughout this document, the word "appliance" means "appliance or equipment".

2 Normative references

Clause 2 of IEC 61058-1:2016 is applicable except as follows.

Addition:

IEC 60227-5, Polyvinyl chloride insulated cables of rated voltages up to and including

450/750 V – Part 5: Flexible cables (cords)

IEC 60245-4, Rubber insulated cables – Rated voltages up to and including 450/750 V –

Part 4: Cords and flexible cables

– 6 – IEC 61058-2-4:2018 © IEC 2018

IEC 60669-1:2017, Switches for household and similar fixed-electrical installations – Part 1:

General requirements

IEC 61058-1:2016, Switches for appliances – Part 1: General requirements

3 Terms and definitions

Clause 3 of IEC 61058-1:2016 is applicable, except as follows.

3.3 Terms and definitions relating to the different types of switches

Additional terms and definitions:

3.3.101

independently mounted switch

switch intended to be mounted away from the controlled appliance or equipment

3.3.102

design A switch

switch where the cover or coverplate can be removed without displacement of the

conductor(s)

3.3.103

design B switch

switch where the cover or coverplate cannot be removed without displacement of the

conductor(s)

4 General requirements

Clause 4 of IEC 61058-1:2016 is applicable.

5 General information on tests

Clause 5 of IEC 61058-1:2016 is applicable.

6 Rating

Clause 6 of IEC 61058-1:2016 is applicable.

7 Classification

Clause 7 of IEC 61058-1:2016 is applicable except as follows.

7.5 Degree of protection against solid foreign objects

Replacement:

The degree of protection against solid foreign objects is declared.

With the exception of IP0X and IP1X, all IP ratings are allowed.

7.11 According to resistance to ignitability by the glow wire temperature

Subclause 7.11.1 of IEC 61058-1:2016 is not applicable.

7.22 According to the type of forced cooling

Subclause 7.22.2 of IEC 61058-1:2016 is not applicable.

Additional subclauses:

7.101 According to design

7.101.1 design A switch;

7.101.2 design B switch.

NOTE 1 See definitions 3.3.102 and 3.3.103.

NOTE 2 If a switch has a base which cannot be separated from the cover or cover plate, and requires an

intermediate plate which can be removed for redecorating the wall, it is considered to be of design A, provided the

intermediate plate meets the requirements specified for covers and cover plates.

7.102 According to outlet facilities

7.102.1 switch with inlet/outlet facilities for rigid cables;

7.102.2 switch with inlet facilities for rigid cables and outlet facilities for flexible cables.

8 Marking and documentation

Clause 8 of IEC 61058-1:2016 is applicable with the following modifications to Table 3:

Table 3 – Switch information and loads placed in groups

Modification:

Means of information

Common Unique

Characteristic Subclause

No.

type type

reference reference

CT UT

2 SWITCH ENVIRONMENT/MOUNTING

2.1 Degree of protection provided for the switch when 7.5 and 7.6 Marking Marking

mounted according to documentation

(IP code of IEC 60529)

NOTE Additional letters listed in IEC 60529 are not

used.

4 ELECTRICAL LOAD/CONNECTION

4.1 Rated voltage or rated voltage range 6.1 Marking Marking

– 8 – IEC 61058-2-4:2018 © IEC 2018

Additional rows:

101 SWITCH DESIGN

101.1 Type of switch design 7.101.1 and Document- Document-

7.101.2 ation ation

102 OUTLET FACILITIES

102.1 Type of outlet facilities 7.102 Document- Document-

ation ation

9 Protection against electric shock

Clause 9 of IEC 61058-1:2016 is applicable, except as follows.

9.1 Addition of the following sentence to a):

The switch shall be fitted with the conductor of the smallest or largest nominal cross-sectional

area according to Table 4 whichever is more unfavourable, or with a rigid conduit, a pliable

conduit or a flexible conduit.

Addition to d):

This test finger, with an electrical indicator, is not applied to membranes in inlet openings and

is applied to thin-walled knock-outs with a force of only 10 N.

Additional subclause:

9.101 Switches operated by means of a removable key or by means of an intermediate part,

such as a cord, a chain or a rod, shall be so designed that the key or intermediate part can

only touch parts which are insulated from live parts.

The key or intermediate part shall be insulated from metal parts of the mechanism, unless the

clearances and creepage distances between live parts and metal parts of the mechanism

have at least the values specified in 20.2.5 and 20.4.5.

Compliance is checked by inspection, by the test of 15.3 and, if necessary, by measurement.

NOTE Lacquer or enamel is not considered to be insulating material for the purpose of 9.101.

10 Provision for earthing

Clause 10 of IEC 61058-1:2016 is applicable.

11 Terminals and terminations

Clause 11 of IEC 61058-1:2016 is applicable.

12 Construction

Clause 12 of IEC 61058-1:2016 is not applicable.

Additional subclauses:

12.101 Insulating linings, barriers and the like, shall have adequate mechanical strength and

shall be secured in a reliable manner.

Compliance is checked by inspection after the tests of Clause 18.

12.102 Switches shall be so constructed as to permit:

• easy introduction and connection of the conductors in the terminals;

• adequate space between the underside of the base and the surface on which the base is

mounted or between the sides of the base and the enclosure (cover or box) so that, after

installation of the switch, the insulation of the conductors does not come in contact with

live parts of different polarity or with moving parts of the mechanism, such as the spindle

of a rotary switch;

NOTE This requirement does not imply that the metal parts of the terminals are necessarily protected by

insulating barriers or insulating shoulders to avoid contact, due to incorrect installation of the terminal metal

parts, with the insulation of the conductor.

• easy fixing of the base to a wall or in a box and correct positioning of the conductors. For

surface-type switches, mounted on a mounting plate, a wiring channel may be needed to

comply with this requirement.

In addition, switches classified according to 7.101.1 (design A switch) shall permit an easy

positioning and removal of the cover or cover plate, without displacing the conductors.

Compliance is checked by inspection and by an installation test with conductors of the largest

cross-sectional area for the relevant terminal size, in Table 4.

12.103 Covers and cover plates or parts thereof, which are intended to ensure protection

against electric shock, shall be held in place at two or more points by effective fixing.

Covers and cover plates or parts thereof may be fixed by means of a single fixing, for

example by a screw, provided that they are retained in position by another means (e.g. by a

shoulder).

It is recommended that the fixings of covers and cover plates or parts thereof be captive. The

use of tight fixing washers of cardboard or the like is deemed to be an adequate method for

securing screws intended to be captive.

NOTE Live parts and non-earthed metal parts separated from live parts in such a way that creepage distances

and clearances have values specified in Clause 20 are not considered as accessible if the requirements of 12.103

are met.

For switches with a degree of protection IPX0, the fixing of covers or cover plates shall not

serve to fix any other part, except the knobs.

When the fixings of covers or cover plates also serve to fix the base, there shall be sufficient

means to maintain the base in position after removal of the cover or cover plate.

Decorative covers, cover plates or parts thereof not providing protection against electric shock

are not considered as covers or cover plates within the meaning of 12.103.

For covers and cover plates or parts thereof whose fixing is of the screw-type, compliance is

checked by inspection and by an installation test.

For covers and cover plates or parts thereof whose fixing is not dependent on screws and

whose removal is obtained by applying a force in a direction approximately perpendicular to

the mounting/supporting surface, compliance is checked by applying the test described in

13.3.2 of IEC 60669-1:2017 under the conditions set out in 20.4 to 20.6 of IEC 60669-1:2017.

– 10 – IEC 61058-2-4:2018 © IEC 2018

12.104 Surface-type switches with degree of protection IPX0 shall be so constructed that,

when they are fixed and wired as in normal use, there are no free openings in their

enclosures.

Compliance is checked by inspection and by an installation test with conductors of the cross-

sectional area specified in Table 4.

NOTE Small gaps between enclosures and conduits or cables, or between enclosures and operating means are

disregarded.

12.105 Knobs of rotary switches shall be securely coupled to the shaft or part operating the

mechanism.

The knob is subjected for 1 min to an axial pull of 100 N .

In addition, for knobs of switches having only one direction of operation, a torque of 1 Nm or

the actuating torque if this is greater, is applied 100 times in the direction opposite to the

direction of operation.

During the test, the knob shall not become detached.

NOTE Requirements for the fixation of other types of actuating members are under consideration.

12.106 Screws or other means for mounting the switch on a surface or in a box or enclosure

apart from panel mounting shall be easily accessible from the front. These means shall not

serve any other fixing purpose.

12.107 Other electrical accessories combined with switches shall comply with the

requirements of the standard for the accessory in question.

12.108 Switches other than those with degree of protection IPX0 shall be totally enclosed

when fitted with conduits or cables.

Surface-type switches other than those with degree of protection IPX0 shall have provision for

opening a drain hole at least 5 mm in diameter, or 20 mm in area with a width and length of

at least 3 mm.

The drain hole shall be effective in at least two positions of the switch when this is mounted

on a vertical wall, one of these with the conductors entering at the top and the other with the