IEC 61207-3:2019

(Main)Gas Analyzers - Expression of performance - Part 3: Paramagnetic oxygen analysers

Gas Analyzers - Expression of performance - Part 3: Paramagnetic oxygen analysers

IEC 61207-3:2019 applies to the three main methods for measuring oxygen by its paramagnetic property, which are outlined in the introduction. It considers essential ancillary units and applies to analyzers installed indoors and outdoors. Safety-critical applications can require additional requirements from system and analyzer specifications not covered in this document. This document is intended:

- to specify terminology and definitions related to the functional performance of paramagnetic gas analyzers for the measurement of oxygen in a source gas;

- to unify methods used in making and verifying statements on the functional performance of such analyzers;

- to specify what tests are performed to determine the functional performance and how such tests are carried out;

- to provide basic documents to support the application of internationally recognized quality management standards.

This third edition cancels and replaces the second edition published in 2002. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

a) all references (normative and informative) have been updated, deleted or added to as appropriate;

b) all the terms, descriptions and definitions relating to the document have been updated where appropriate;

c) all references to “errors” have been replaced by “uncertainties” and appropriate updated definitions applied.

Analyseurs de gaz - Expression des performances - Partie 3 : Analyseurs d'oxygène paramagnétiques

IEC 61207-3:2019 traite des trois principales méthodes de mesure de l’oxygène par sa propriété paramagnétique présentées dans l'introduction. Elle porte sur des unités auxiliaires essentielles et concerne les analyseurs installés à l’intérieur comme à l’extérieur. Les applications présentant un risque particulier du point de vue de la sécurité peuvent nécessiter des exigences supplémentaires quant aux spécifications du système et de l'analyseur qui ne sont pas traitées dans la présente norme. La présente norme a pour objet:

- de spécifier la terminologie et les définitions relatives aux performances fonctionnelles des analyseurs de gaz paramagnétiques utilisés pour le mesurage de l'oxygène dans un gaz source;

- d’unifier les méthodes utilisées en fournissant et en vérifiant les indications relatives aux performances fonctionnelles de ces analyseurs;

- de spécifier les essais à effectuer pour déterminer les performances fonctionnelles et la manière de réaliser ces essais;

- fournir des documents de base appuyant l'application des normes de gestion de la qualité reconnues sur le plan international.

Cette troisième édition annule et remplace la deuxième édition parue en 2002. Cette édition constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) toutes les références (normatives et informatives) ont été mises à jour, retirées ou ajoutées comme il convient;

b) tous les termes, descriptions et définitions en rapport avec le document ont été mis à jour le cas échéant;

c) toutes les références aux "erreurs" ont été remplacées par le terme «incertitudes» et les définitions ont été mises à jour comme il convient.

General Information

- Status

- Published

- Publication Date

- 25-Jun-2019

- Technical Committee

- SC 65B - Measurement and control devices

- Drafting Committee

- WG 14 - TC 65/SC 65B/WG 14

- Current Stage

- PPUB - Publication issued

- Start Date

- 26-Jun-2019

- Completion Date

- 05-Jul-2019

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Revises

IEC 61207-3:2002 - Gas analyzers - Expression of performance - Part 3: Paramagnetic oxygen analyzers - Effective Date

- 05-Sep-2023

Overview

IEC 61207-3:2019 - "Gas analyzers - Expression of performance - Part 3: Paramagnetic oxygen analysers" is an international standard from the IEC that defines how to express and verify the functional performance of paramagnetic oxygen analyzers. This third edition (2019) updates terminology, references and testing conventions, and replaces previous references to “errors” with the modern concept of measurement uncertainties. It applies to analyzers installed indoors and outdoors and covers essential ancillary units and sampling systems, while noting that safety‑critical systems may require additional requirements beyond this document.

Key Topics

- Scope and purpose: Standardizes terminology, performance statements and verification methods for paramagnetic oxygen analyzers.

- Measurement methods covered: The three principal paramagnetic techniques - automatic null (auto‑balance), thermomagnetic (magnetic wind) and differential pressure (Quincke).

- Performance characterization: Procedures for specifying rated ranges (ambient temperature, sample temperature, pressure, flow, dew point, particulate content) and influence quantities.

- Testing procedures: How to perform compliance testing, including test equipment, interference gas testing, wet‑sample handling, and dynamic responses (delay time, rise/fall time).

- Sampling and ancillary systems: Requirements for sample conditioning (clean, dry, non‑condensing samples), sampling system descriptions and services.

- Terminology and uncertainty: Updated definitions and a shift from “errors” to uncertainties in performance claims.

- Normative references: Works with IEC 61207‑1 and references standards such as IEC 60654‑1, IEC 61115 and relevant ISO quality management standards (ISO 9001/9002/9003).

Applications

IEC 61207-3:2019 is relevant to industries and settings that require reliable oxygen measurement, including:

- Industrial process control (combustion control, furnaces, process optimization)

- Emissions and environmental monitoring

- Laboratory and metrology applications

- Medical and life‑science gas analysis (where applicable)

- OEMs, instrument manufacturers, system integrators and test laboratories specifying, designing, validating or certifying paramagnetic oxygen analyzers

Practical benefits include consistent performance specifications, reproducible compliance testing, and support for quality management and procurement decisions.

Related Standards

- IEC 61207-1 (Expression of performance - General) - to be used in conjunction with Part 3

- IEC 60654-1 (Climatic conditions for industrial measurement equipment)

- IEC 61115 (Performance of sample handling systems)

- ISO 9001 / ISO 9002 / ISO 9003 (Quality management references)

Keywords: IEC 61207-3:2019, paramagnetic oxygen analyzers, gas analyzers, expression of performance, measurement uncertainty, sampling systems, auto‑balance, thermomagnetic, Quincke.

Buy Documents

IEC 61207-3:2019 RLV - Gas Analyzers - Expression of performance - Part 3: Paramagnetic oxygen analysers Released:6/26/2019 Isbn:9782832271179

IEC 61207-3:2019 - Gas Analyzers - Expression of performance - Part 3: Paramagnetic oxygen analysers Released:6/26/2019 Isbn:9782832270462

Get Certified

Connect with accredited certification bodies for this standard

ECOCERT

Organic and sustainability certification.

Eurofins Food Testing Global

Global leader in food, environment, and pharmaceutical product testing.

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Sponsored listings

Frequently Asked Questions

IEC 61207-3:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Gas Analyzers - Expression of performance - Part 3: Paramagnetic oxygen analysers". This standard covers: IEC 61207-3:2019 applies to the three main methods for measuring oxygen by its paramagnetic property, which are outlined in the introduction. It considers essential ancillary units and applies to analyzers installed indoors and outdoors. Safety-critical applications can require additional requirements from system and analyzer specifications not covered in this document. This document is intended: - to specify terminology and definitions related to the functional performance of paramagnetic gas analyzers for the measurement of oxygen in a source gas; - to unify methods used in making and verifying statements on the functional performance of such analyzers; - to specify what tests are performed to determine the functional performance and how such tests are carried out; - to provide basic documents to support the application of internationally recognized quality management standards. This third edition cancels and replaces the second edition published in 2002. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) all references (normative and informative) have been updated, deleted or added to as appropriate; b) all the terms, descriptions and definitions relating to the document have been updated where appropriate; c) all references to “errors” have been replaced by “uncertainties” and appropriate updated definitions applied.

IEC 61207-3:2019 applies to the three main methods for measuring oxygen by its paramagnetic property, which are outlined in the introduction. It considers essential ancillary units and applies to analyzers installed indoors and outdoors. Safety-critical applications can require additional requirements from system and analyzer specifications not covered in this document. This document is intended: - to specify terminology and definitions related to the functional performance of paramagnetic gas analyzers for the measurement of oxygen in a source gas; - to unify methods used in making and verifying statements on the functional performance of such analyzers; - to specify what tests are performed to determine the functional performance and how such tests are carried out; - to provide basic documents to support the application of internationally recognized quality management standards. This third edition cancels and replaces the second edition published in 2002. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) all references (normative and informative) have been updated, deleted or added to as appropriate; b) all the terms, descriptions and definitions relating to the document have been updated where appropriate; c) all references to “errors” have been replaced by “uncertainties” and appropriate updated definitions applied.

IEC 61207-3:2019 is classified under the following ICS (International Classification for Standards) categories: 19.040 - Environmental testing; 71.040.40 - Chemical analysis. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61207-3:2019 has the following relationships with other standards: It is inter standard links to IEC 61207-3:2002/COR1:2003, IEC 61207-3:2002/COR2:2003, IEC 61207-3:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61207-3:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61207-3 ®

Edition 3.0 2019-06

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Gas analyzers – Expression of performance –

Part 3: Paramagnetic oxygen analyzers

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61207-3 ®

Edition 3.0 2019-06

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Gas analyzers – Expression of performance –

Part 3: Paramagnetic oxygen analyzers

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 19.040; 71.040.40 ISBN 978-2-8322-7117-9

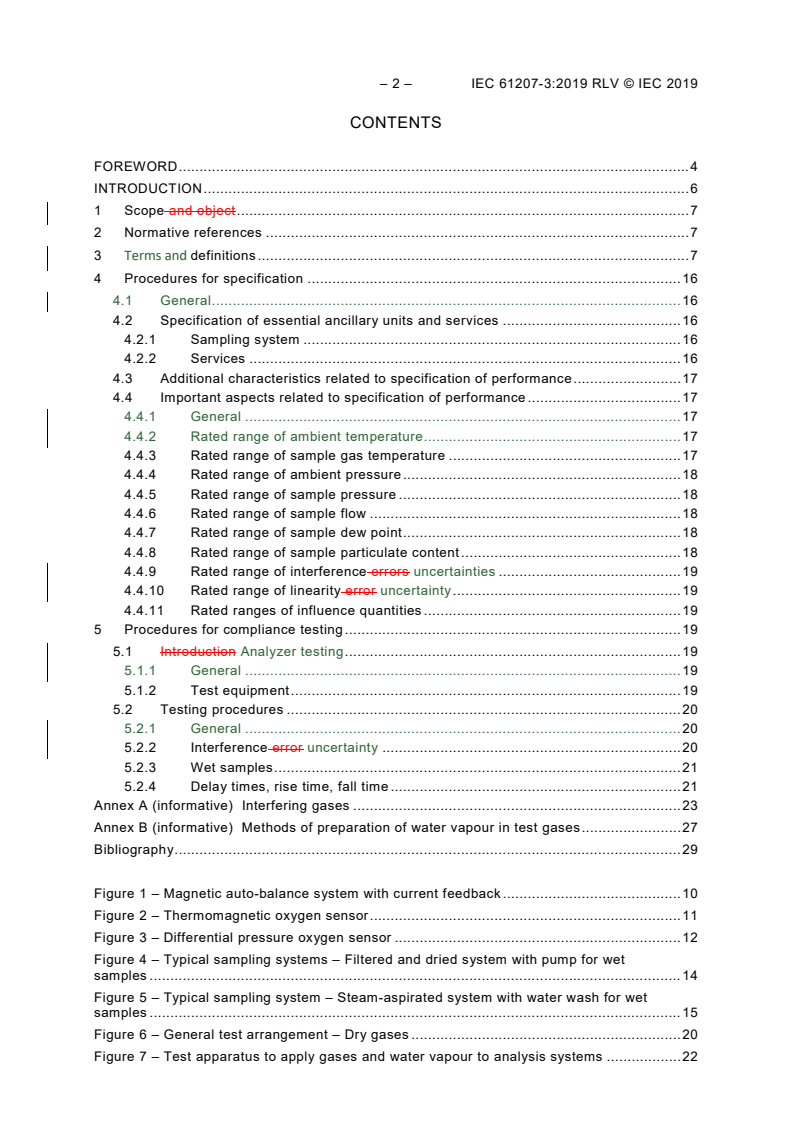

– 2 – IEC 61207-3:2019 RLV © IEC 2019

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope and object . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Procedures for specification . 16

4.1 General . 16

4.2 Specification of essential ancillary units and services . 16

4.2.1 Sampling system . 16

4.2.2 Services . 16

4.3 Additional characteristics related to specification of performance . 17

4.4 Important aspects related to specification of performance . 17

4.4.1 General . 17

4.4.2 Rated range of ambient temperature . 17

4.4.3 Rated range of sample gas temperature . 17

4.4.4 Rated range of ambient pressure . 18

4.4.5 Rated range of sample pressure . 18

4.4.6 Rated range of sample flow . 18

4.4.7 Rated range of sample dew point . 18

4.4.8 Rated range of sample particulate content . 18

4.4.9 Rated range of interference errors uncertainties . 19

4.4.10 Rated range of linearity error uncertainty . 19

4.4.11 Rated ranges of influence quantities . 19

5 Procedures for compliance testing . 19

5.1 Introduction Analyzer testing . 19

5.1.1 General . 19

5.1.2 Test equipment . 19

5.2 Testing procedures . 20

5.2.1 General . 20

5.2.2 Interference error uncertainty . 20

5.2.3 Wet samples . 21

5.2.4 Delay times, rise time, fall time . 21

Annex A (informative) Interfering gases . 23

Annex B (informative) Methods of preparation of water vapour in test gases . 27

Bibliography . 29

Figure 1 – Magnetic auto-balance system with current feedback . 10

Figure 2 – Thermomagnetic oxygen sensor . 11

Figure 3 – Differential pressure oxygen sensor . 12

Figure 4 – Typical sampling systems – Filtered and dried system with pump for wet

samples . 14

Figure 5 – Typical sampling system – Steam-aspirated system with water wash for wet

samples . 15

Figure 6 – General test arrangement – Dry gases . 20

Figure 7 – Test apparatus to apply gases and water vapour to analysis systems . 22

Table A.1 – Zero correction factors for current gases . 23

– 4 – IEC 61207-3:2019 RLV © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

GAS ANALYZERS –

EXPRESSION OF PERFORMANCE –

Part 3: Paramagnetic oxygen analyzers

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 61207-3 has been prepared by sub-committee 65B: Measurement

and control devices, of IEC technical committee 65: Industrial-process measurement, control

and automation.

This third edition cancels and replaces the second edition published in 2002. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) all references (normative and informative) have been updated, deleted or added to as

appropriate;

b) all the terms, descriptions and definitions relating to the document have been updated

where appropriate;

c) all references to “errors” have been replaced by “uncertainties” and appropriate updated

definitions applied.

The text of this International Standard is based on the following documents:

FDIS Report on voting

65B/1155/FDIS 65B/1157/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

This International Standard is to be used in conjunction with IEC 61207-1:2010.

A list of all parts in the IEC 61207 series, published under the general title Gas analyzers –

Expression of performance, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

– 6 – IEC 61207-3:2019 RLV © IEC 2019

INTRODUCTION

Paramagnetic oxygen analyzers respond to the partial pressure of oxygen in the measured

gas, and not the volumetric concentration is then determined by knowledge of the total

pressure, as in many other gas analyzers. Due to this fact, many paramagnetic oxygen

analyzers use pressure compensation (see 4.4.4 and 4.4.5). They are used in a wide range of

industrial, laboratory, medical, and other applications where the rated measuring range of the

analyzer is between 0 % to 1 % and 0 % to 100 %, at reference pressure (usually near

atmospheric).

Only a few gases display significant paramagnetism (for example, oxygen, nitric oxide and

nitrogen dioxide), and oxygen has a particularly strong the strongest paramagnetic

susceptibility (see Annex A) among gases. By employing this particular property of oxygen,

analyzers have been designed that can be highly specific to the measurement in most

industrial and medical applications, where, for example, high background levels of

hydrocarbons or moisture may be present.

There are several different techniques described for measuring the paramagnetic properties

of oxygen by its paramagnetic property, but three main methods have evolved over many

years of commercial application.

The three methods are:

– automatic null balance;

– thermomagnetic or magnetic wind;

– differential pressure or Quincke.

These methods all require the sample gas to be clean and dry non-condensing, though some

versions work at elevated temperatures so that samples that are likely to condense at a lower

temperature can be analyzed. Because of this requirement, analyzers often require a sample

system to condition the sample prior to measurement.

GAS ANALYZERS –

EXPRESSION OF PERFORMANCE –

Part 3: Paramagnetic oxygen analyzers

1 Scope and object

This part of IEC 61207 applies to the three main methods for measuring oxygen by its

paramagnetic property, which are outlined in the introduction. It considers essential ancillary

units and applies to analyzers installed indoors and outdoors.

NOTE Safety-critical applications can require an additional requirement of requirements from

system and analyzer specifications not covered in this document.

This document is intended

– to specify terminology and definitions related to the functional performance of para-

magnetic gas analyzers for the measurement of oxygen in a source gas;

– to unify methods used in making and verifying statements on the functional performance of

such analyzers;

– to specify what tests should be are performed to determine the functional performance and

how such tests should be are carried out;

– to provide basic documents to support the application of internationally recognized quality

management standards of quality assurance (ISO 9001, ISO 9002 and ISO 9003).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60654-1:1993, Industrial-process measurement and control equipment – Operating

conditions – Part 1: Climatic conditions

IEC 61115:1992, Expression of performance of sample handling systems for process

analyzers

IEC 61207-1:1994, Expression of performance of gas analyzers – Part 1: General

ISO 9001:2000, Quality management systems – Requirements

ISO 9002:1994, Quality systems – Model for quality assurance in production, installation and

servicing

ISO 9003:1994, Quality systems – Model for quality assurance in final inspection and test

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

– 8 – IEC 61207-3:2019 RLV © IEC 2019

NOTE Although cgs (centimetre-gram-second) units have been used in this document, SI (Système International)

units (such as defined in IUPAC [1] ) can also be used.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

magnetic susceptibility

measure (X) of the variation of the intensity of a magnetic field H, existing in a vacuum, when

the vacuum is substituted (filled) by the test substance, expressed as:

H − H

X =

H

where

H is the magnetic field intensity in vacuum

H is the magnetic field intensity in the test substance

Note 1 to entry: H – H is also known as the magnetisation MV (magnetic dipole per unit volume) and therefore

this is also the volume magnetic susceptibility.

3.2

paramagnetism

property of substances causing an increase of the magnetic field intensity (X > 0)

3.3

diamagnetism

property of substances causing a diminution of the magnetic field intensity

(X < 0 because H < H)

3.4

specific magnetic susceptibility

ratio of magnetic susceptibility to the density derived as follows:

X

X =

s

D

where

−3

D is the density of the considered substance, expressed in g·cm at 273,15 K (0 °C) and,

101,3 kPa (= 1 bar).

3 −1

Note 1 to entry: The measuring unit of X is therefore cm ·g . This is also known as the mass magnetic

s

susceptibility.

3.5

molar magnetic susceptibility

X

m

specific magnetic susceptibility multiplied by the molecular weight mass (M) of the substance

considered:

X X⋅ M

ms

__________

Numbers in square brackets refer to the bibliography

=

where

−1

M is expressed in g per mole (g·mol ) (for oxygen M = 32 31,998 8)

3 −1

Note 1 to entry: The measuring unit of X is therefore cm ·mol .

m

Note 12 to entry: Electrons determine the magnetic properties of matter in two ways:

– an electron can be considered as a small sphere of negative charge spinning on its axis. This spinning charge

produces a magnetic moment;

– an electron travelling in an orbit around a nucleus will also produce a magnetic moment.

It is the combination of the spin moment and the orbital moment that governs the resulting magnetic properties of

an individual atom or ion.

In paramagnetic materials, the main contribution to the magnetic moment comes from unpaired electrons. It is the

configuration of the orbital electrons and their spin orientations that establish the paramagnetism of the oxygen

molecule and distinguish it from most other gases.

Note 23 to entry: When paramagnetic gases are placed within an external magnetic field, the flux within the gas is

higher than it would be in a vacuum, thus paramagnetic gases are attracted to the part of the magnetic field with

the strongest magnetic flux. On the contrary, diamagnetic substances contain magnetic dipoles which cancel out

some lines of force from the external field; thus diamagnetic gases are subject to repulsion by the magnetic flux.

Note 34 to entry: The molar magnetic susceptibility of oxygen is inversely proportional to the absolute

temperature T. According to Van Vleck [2] the molar susceptibility of oxygen can be approximated by Equation (4).

8L ⋅ µ

B

For oxygen, X = (4)

m

3kT

where

3 −1

X is the molar susceptibility of oxygen, expressed in cm ·mol ;

m

23 −1

L is the Avogadro constant = 6,022 7 × 10 mol ;

−24 2

µ is the Bohr magneton = 9,274 × 10 A·m ;

B

−23 −1

k is the Boltzmann constant = 1,38 × 10 J·K ;

T is the temperature, expressed in K (kelvin).

Equation (4) can be written as follows:

−6 3 −1

X = × 10 cm ·mol (only for oxygen).

m

T

Note 5 to entry: A full understanding of paramagnetism and diamagnetism can be obtained from physics and

inorganic chemistry textbooks. The explanation in this document is to give the user of paramagnetic oxygen

analyzers a simple understanding of the physical property utilized.

3.6

automatic null balance analyzer

analyzer that uses, as a general principle of operation, the displacement of a body

this type of

containing a vacuum or a diamagnetic gas, from a region of high magnetic field by

paramagnetic oxygen molecules

Note 1 to entry: See Figure 1.

– 10 – IEC 61207-3:2019 RLV © IEC 2019

Figure 1 – Magnetic auto-balance system with current feedback

Note 2 to entry: The measuring cell typically employs a glass dumb-bell, with the spheres containing nitrogen,

suspended on a torsion strip between magnetic pole pieces or magnets that concentrate the flux produce a very

strong magnetic field gradient around the dumb-bell. The measuring cell has to be placed in a magnetic circuit. The

dumb-bell is then deflected when oxygen molecules enter the measuring cell, a force being exerted on the dumb-

bell by the oxygen molecules which are attracted to the strongest part of the magnetic field. By use of an optical

levers, a feed-back magnetic actuation coil, and suitable electronics to generate a feedback signal that nulls the

magnetic susceptibility force, an output that is directly proportional to the partial pressure of oxygen can be

achieved. The transducer is usually can be maintained at a constant temperature to prevent the variations in

magnetic susceptibility with to temperature from introducing errors uncertainties. Alternatively, built-in temperature

sensors may be used to provide temperature compensation of the oxygen reading. Additionally, the elevated

temperature helps in applications where the sample is not particularly dry. Some analyzers are designed so that

the transducer operates at a temperature in excess of 373,15 K (100 °C) to further facilitate applications where

condensates would form at a lower temperature. Paramagnetic sensor orientation may also affect the oxygen

measurement uncertainty and this may be corrected by using a compensation algorithm using, for example, a

three-dimensional accelerometer to determine the sensor orientation relative to its orientation during calibration.

Due to the mechanical nature of this type of device, there is some inherent susceptibility to vibrational and

gyroscopic motion, potentially resulting in increased measurement uncertainty.

3.7

thermomagnetic (magnetic-wind) analyzer

3.7.1

magnetic wind analyzer

this type of analyzer utilizes that uses the temperature dependence of the magnetic

susceptibility to generate a magnetically induced gas flow which can then be measured by a

flow sensor

Note 1 to entry: The sample gas passes into a chamber designed in such a way that the inlet splits the flow.

Note 2 to entry: See Figure 2.

Figure 2 – Thermomagnetic oxygen sensor

Note 3 to entry: The two flows recombine at the outlet. A connecting tube is placed centrally with the flow sensor

wound on it. Half of the connecting tube is placed between the poles of a strong magnet. The flow sensor is

effectively two coils of wire heated to about 353,15 K (80 °C) by passage of a current. The cold oxygen molecules

are diverted by the magnetic field into the central tube, and, as they heat up, their magnetic susceptibility is

reduced and more cold oxygen molecules enter the connecting tube. A flow of oxygen is generated in this way

through the transversal connecting tube, with the effect of cooling the first coil (which is placed in the magnetic

field area), while the temperature of the second coil is not essentially influenced by this transversal flow. Since the

two coils are wound with thermosensitive wire (for example, platinum wire) and connected together to build a

Wheatstone bridge, the resulting unbalance current is a nearly proportional function of the oxygen partial pressure

in the test gas.

More recent analyzers use more refined measuring cells, toroidal shaped resistors instead of the two-coil flow

sensor, and employ temperature control to minimize ambient temperature changes.

As this method relies on heat transfer, the thermal conductivity of background gases will affect the oxygen reading

and the composition of the background has to be known. Some analyzers can give a first-order correction for this

by utilizing further compensation devices.

Thermomagnetic analyzers do not produce a strictly linear output and additional signal processing is required to

linearize the output.

– 12 – IEC 61207-3:2019 RLV © IEC 2019

3.8

differential pressure ( Quincke) analyzer

3.8.1

differential pressure analyzer

this type of analyzer utilizes that uses a pneumatic balance system established by using a

flowing reference gas (such as nitrogen or air)

Note 1 to entry: The measuring cell is designed so that at the reference gas inlet the flow is divided into two

paths. These flows recombine at the reference gas outlet, where the sample is also introduced. A differential

pressure sensor (or microflow sensor) is positioned across the two reference gas flows so that any imbalance is

detected. A magnet is situated in the vicinity of the reference gas outlet in one arm of the measuring cell so that

oxygen in the sample is attracted into the arm, thereby causing a small back pressure which is detected by the

pressure sensor (see Figure 3).

Figure 3 – Differential pressure oxygen sensor

Note 2 to entry: Differential pressure analyzers are independent of thermal conductivity of background gases, and

as only the reference gas comes in contact with the sensor, corrosion problems are minimal. Some instruments use

pulsed magnetic fields to improve tilt sensitivity, and certain designs compensate for vibration effects.

3.9

hazardous area

area where there is a possibility of release of potentially flammable gases, vapours or dusts.

Restrictions in the use of electrical equipment apply in hazardous areas

area in which an explosive gas atmosphere is present, or may be expected to be present, in

quantities such as to require special precautions for the construction, installation and use of

devices

3.10

essential ancillary unit

essential ancillary units are those unit without which the analyzer will not operate within

specifications

EXAMPLE: Calibration systems, reference gas systems, sample systems.

3.11

sample systems

see figures 4 and 5 for typical sampling systems. For full details of sample systems require-

ments, see IEC 61115.

A sample system is a system of component parts assembled on a panel or in an analyzer

house with the purpose of transporting the sample gas from the sampling point to the analyzer

and presenting the sample in such a manner that reliable measurements can be obtained

Note 1 to entry: The components used can include

– pressure regulators;

– flow meters;

– flow controllers;

– filtration units;

– pumps;

– valves (manual and/or electrically operated);

– catch or knockout pots;

– coolers;

– heaters;

– drying units;

– scrubbing units.

Note 2 to entry: See Figure 4 and Figure 5 for examples of typical sampling systems. For full details of sample

system requirements, see IEC 61115 [3]. These components will usually be designed as a sample system by the

user or, more often, by a manufacturer, so that the analyzer requirements defined in the specification are within the

rated operating range. The required system design is therefore very dependent on the sample conditions of the

process. Variations in sample pressure, temperature, dust loading, and pressure of other gases and vapours will

affect the final sample system design.

– 14 – IEC 61207-3:2019 RLV © IEC 2019

Figure 4 – Typical sampling systems –

Filtered and dried system with pump for wet samples

Figure 5 – Typical sampling system – Steam-aspirated system

with water wash for wet samples

3.12

sample dew point

dew point of a sample expressed in K and is the temperature at or below which condensation

occurs

Note 1 to entry: The analyzer should be operated at a minimum of 5 K above the sample dew point to prevent

formation of condensate.

Note 2 to entry: The presence of condensation at the inlet of an analyzer will usually cause malfunction.

Condensate may form from water vapour or other vapours depending on the nature of the sample.

3.13

reference gas

the Quincke analyzer requires a reference gas of known constant composition

Note 1 to entry: Pure nitrogen is usually employed. The reference gas can have an oxygen content, for example

air. This has the effect of giving a suppressed zero and is useful when measuring high oxygen concentrations as it

reduces the influence of barometric pressure.

– 16 – IEC 61207-3:2019 RLV © IEC 2019

4 Procedures for specification

4.1 General

The procedures are detailed in IEC 61207-1. This covers:

– operation and storage requirements;

– specification of ranges of measurement and output signals;

– limits of errors uncertainties;

– recommended reference values and rated ranges of influence quantities (see IEC 60654-1).

In this part of IEC 61207, requirements for essential ancillary units and services are given.

Additional characteristics for specification of performance and important aspects of

performance relevant to paramagnetic analyzers are detailed.

4.2 Specification of essential ancillary units and services

4.2.1 Sampling system

The sampling system must shall be specified to supply the sample within the rated range of

influence quantities of the analyzer.

NOTE 1 Simple elements of the sampling system may be included in the analyzer. Sample

flow meters, sample flow regulation, bypass flow meters, bypass flow regulations, sample

filters are often part of the analyzer.

NOTE 2 If certain system elements are included in the analyzer the rated range of influence

quantities will be less severe compared to an analyzer without any sampling system.

The sampling system will add a delay in addition to the response time of the analyzer. Hence,

the sample system response time should be specified.

The chemical composition of the sample stream must shall be considered in the system

specification. Special precautions need to be taken for flammable samples, toxic samples or

corrosive samples.

Some materials are permeable to oxygen (for example, silicones) and should be avoided the

measurement uncertainties that may be introduced by them should be considered and

avoided if necessary. For systems measuring very high concentrations of oxygen, the

sampling system components should be clean for oxygen service to prevent any dangerous

reactions with flammable contaminants.

4.2.2 Services

4.2.2.1 General

Paramagnetic oxygen analyzers will require facilities for calibration after installation. Bottled

calibration gases and pressure regulation facilities are generally required. Quincke analyzers

will additionally require facilities for supplying the reference gas.

NOTE Nitrogen is usually employed for zero calibration. The span gas will usually be a known concentration of

oxygen in nitrogen typically about 80 % of the measuring range. Air contains between 20,64 % and 20,95 % O by

volume due to varying humidity. Dry air or instrument air at 20,95 % O can therefore be used for span calibrations.

If the oxygen level of the sample gas is high, then 100 % O is usually used as the span gas.

4.2.2.2 Rated range of calibration and reference gas pressure

Calibration and reference gas pressure shall be within the rated range of sample pressure for

the analyzer, to prevent possible damage to the paramagnetic sensor.

4.2.2.3 Rated range of calibration and reference gas flow

Calibration and reference gas flow shall be within the rated range of sample flow for the

analyzer. For minimum errors uncertainties, the calibration gas flow should be set the same

as the sample flow. Excessively high calibration and reference gas flows can damage the

paramagnetic sensor, particularly from a large pressure impulse, which may occur if the flow

outlet becomes blocked and then quickly released.

4.3 Additional characteristics related to specification of performance

4.3.1 The following additional characteristics to those detailed in IEC 61207-1 may be

required to be specified to define the performance of a paramagnetic analyzer or its suitability

for a particular application. Depending on the analyzer design details or application, some of

these additional terms may be omitted.

4.3.2 Hazardous classification of the area in which the analyzer is to be located. General

purpose analyzers will not be suitable for location in hazardous areas.

4.3.3 Flammable gases or vapours should only be sampled by analyzers which are

specified as suitable and should be vented from the analyzer in a safe manner.

4.3.4 If the sample gas is toxic, this should be specified, as special maintenance ins-

tructions may be required to ensure leak-free operation. Installation of the analyzer must shall

also take into account how the sample gas is vented, returned to process, or otherwise dealt

with.

4.3.5 The attitude orientation of the analyzer should be considered. In fixed installations,

analyzers should be located positioned in an upright attitude manner so that any errors

uncertainties due to tilt are minimized. For moving installations that move (for example,

ships), the rated range of tilt should be specified.

4.3.6 The vibration sensitivity of the analyzer should be considered. For applications where

the vibration levels are outside the rated range of the analyzer, anti-vibration mountings are

recommended.

4.3.7 The response time of the analyzer and its sampling system should be considered.

The response time specified for the analyzer will usually be considerably less than the

sampling system, but is dependent on the sampling system design.

NOTE Some paramagnetic analyzers are designed with adjustable sample flow and bypass flow sample systems.

4.4 Important aspects related to specification of performance

4.4.1 General

Although covered in IEC 61207-1, the following aspects are particularly relevant to

paramagnetic analyzers.

4.4.2 Rated range of ambient temperature

The performance of an analyzer is normally ambient temperature-dependent and will have a

defined operating range of temperatures within which it will operate within its specification.

4.4.3 Rated range of sample gas temperature

NOTE The magnetic susceptibility of oxygen is temperature-dependent, and large errors

uncertainties in the measurement value occur unless the analyzer is designed to compensate

for the temperature of the sensor. In practice, the temperature of the paramagnetic sensor will

depend on ambient temperature and gas temperature. Process paramagnetic oxygen

analyzers usually employ temperature-controlled sensors (in addition to temperature

– 18 – IEC 61207-3:2019 RLV © IEC 2019

compensation) to minimize effects of sample temperature changes and ambient temperature

changes. Simple analyzers may not have temperature-controlled sensors, in which case

calibration should precede measurements so that ambient temperature effects and sample

temperature effects are taken into account.

4.4.4 Rated range of ambient pressure

NOTE Measurement values are dependent on sample pressure. If the analyzer is vented to

atmosphere, so that the sample within the sensor is at ambient pressure, changes in

errors uncertainties in the measured value. For analyzers where

barometric reading will cause

the measured value is directly proportional to the sample pressure (automatic null balance

analyzer), error uncertainty can occur in O readings (% O ),

2 2

PP −

mc

∆×O = O (5)

mm

P

c

where

O is the oxygen reading at time of measurement in % O ;

m 2

P is the absolute ambient pressure at time of measurement in kPa;

m

P is the absolute ambient pressure at time of calibration in kPa.

c

Barometric pressure compensation is usually offered by manufacturers to minimize this type

of error uncertainty.

4.4.5 Rated range of sample pressure

If the sample is returned to the process stream (assuming process pressure is within the rated

range of sample pressure), variations in process pressure will cause similar errors

uncertainties to those described in 4.4.4.

Sample pressure compensation is usually offered by manufacturers of process analyzers so

that this type of error uncertainty is minimized.

4.4.6 Rated range of sample flow

Errors Uncertainties in indicated value due to sample flow can be minimized by setting the

calibration flow rates to the expected sample flow rates.

4.4.7 Rated range of sample dew point

Samples must shall be supplied within the rated range of the sample dew point to increase

performance reliability. Also, differences in indicated value will occur if the measurement is

made on a wet basis compared to a dry basis.

NOTE 1 If the rated range of sample dew point for an analyzer is low, then the sampling system may can have to

remove water vapour from the sample. If, for example, 10 % water vapour were removed by the sample system, the

corresponding indicated oxygen value would be 100/90 times greater than the value in the wet sample.

NOTE 2 Some oxygen analyzers are designed so that the sensor is controlled at temperatures within the range

333,15 K to 393,15 K (60 °C to 120 °C). This will enable relatively wet samples to be analyzed reliably. For

example, a sample saturated with water vapour at 294,15 K (21 °C) contains approximately 2,5 % water vapour.

This wet sample would normally be within the rated range of the sample dew point for an analyzer wherein the

sensor is controlled at 333,15 K (60 °C). However, the water content in the sample will produce a volumetric error

compared to a measurement made on a dry basis where the water has been removed prior to measurement.

4.4.8 Rated range of sample particulate content

Paramagnetic oxygen analyzers usually require a relatively clean sample to ensure reliable

), and

operation. The rated range of particulates defined in mass per cubic metre (mg/m

maximum particulate size in microns (µm) should not be exceeded.

4.4.9 Rated range of interference errors uncertainties

NOTE Paramagnetic oxygen analyzers are by design specifically measuring the magnetism of

the sample gas. Oxygen has a high magnetic susceptibility and the measurement is therefore

quite specific, but see Annex A for interferences of other common gases. Nitrogen oxide, in

particular, has a significant cross-interference.

Some oxygen analyzers will have interference errors uncertainties from properties of gases

other than the magnetic susceptibility. For example, gases of high thermal conductivity in the

errors uncertainties in the indicated value in magnetic wind analyzers,

sample may introduce

though modern analyzers may partially compensate for this.

Water vapour content shall be in the rated range of the sample dew point (see 4.4.7).

Interference errors uncertainties, other than those due to volumetric effects, may occur.

4.4.10 Rated range of linearity error uncertainty

Some analyzers are inherently linear and have very small linearity errors uncertainties.

4.4.11 Rated ranges of influence quantities

Ranges for climatic conditions, mechanical conditions and main supply conditions are

specified in IEC 60654-1.

NOTE In addition, paramagnetic oxygen analyzers may can be affected by the presence of nearby magnetic

material fields.

5 Procedures for compliance testing

5.1 Introduction Analyzer testing

5.1.1 General

The tests considered in Clause 5 apply to the complete analyzer as supplied by the

manufacturer and include all essential ancillary equipment. The analyzer will be set up by the

manufacturer, or in accordance with his instruction, prior to testing.

5.1.2 Test equipment

The following test equipment for verification of values that confirm the performance of

paramagnetic oxygen analyzers will be required.

a) Gas mixing equipment to prepare the required test gases (certified calibration gases can

be used).

b) Equipment to present the test gases to the analyzer at the required pressure, flow and

temperature. Gases have to be switched over to enable response time measurements.

c) Equipment to measure interference errors uncertainties. This will also include temperature

controlled bubblers or other moisture generation equipment so that the effects of water

vapour can be measured.

d) An environmental chamber will be required to measure appropriate influence errors

uncertainties, such as temperature or humidity.

e) Equipment for determining influence quantities from variation in supply voltage, frequency

and supply interruption.

uncertainties due to electromagnetic

f) Equipment to determine influence errors

susceptibility. Radiated emissions may have to be determined.

g) Equipment to determine influence errors uncertainties under vibration.

Figure 6 shows the general test arrangement for dry gases.

– 20 – IEC 61207-3:2019 RLV © IEC 2019

* Dead space to be minimized to avoid uncertainties in response time measurement.

Figure 6 – General test arrangement – Dry gases

5.2 Testing procedures

5.2.1 General

The following relevant testing procedures are detailed in IEC 61207-1.

– Intrinsic error uncertainty.

– Linearity error uncertainty.

– Repeatability err

...

IEC 61207-3 ®

Edition 3.0 2019-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Gas analyzers – Expression of performance –

Part 3: Paramagnetic oxygen analyzers

Analyseurs de gaz – Expression des performances –

Partie 3: Analyseurs d'oxygène paramagnétiques

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61207-3 ®

Edition 3.0 2019-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Gas analyzers – Expression of performance –

Part 3: Paramagnetic oxygen analyzers

Analyseurs de gaz – Expression des performances –

Partie 3: Analyseurs d'oxygène paramagnétiques

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 19.040; 71.040.40 ISBN 978-2-8322-7046-2

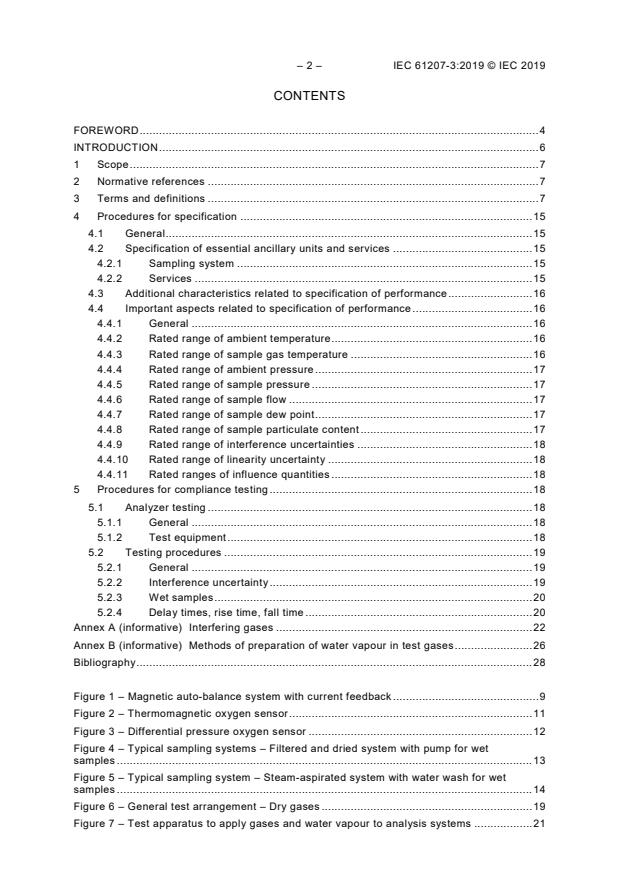

– 2 – IEC 61207-3:2019 © IEC 2019

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Procedures for specification . 15

4.1 General . 15

4.2 Specification of essential ancillary units and services . 15

4.2.1 Sampling system . 15

4.2.2 Services . 15

4.3 Additional characteristics related to specification of performance . 16

4.4 Important aspects related to specification of performance . 16

4.4.1 General . 16

4.4.2 Rated range of ambient temperature . 16

4.4.3 Rated range of sample gas temperature . 16

4.4.4 Rated range of ambient pressure . 17

4.4.5 Rated range of sample pressure . 17

4.4.6 Rated range of sample flow . 17

4.4.7 Rated range of sample dew point . 17

4.4.8 Rated range of sample particulate content . 17

4.4.9 Rated range of interference uncertainties . 18

4.4.10 Rated range of linearity uncertainty . 18

4.4.11 Rated ranges of influence quantities . 18

5 Procedures for compliance testing . 18

5.1 Analyzer testing . 18

5.1.1 General . 18

5.1.2 Test equipment . 18

5.2 Testing procedures . 19

5.2.1 General . 19

5.2.2 Interference uncertainty . 19

5.2.3 Wet samples . 20

5.2.4 Delay times, rise time, fall time . 20

Annex A (informative) Interfering gases . 22

Annex B (informative) Methods of preparation of water vapour in test gases . 26

Bibliography . 28

Figure 1 – Magnetic auto-balance system with current feedback . 9

Figure 2 – Thermomagnetic oxygen sensor . 11

Figure 3 – Differential pressure oxygen sensor . 12

Figure 4 – Typical sampling systems – Filtered and dried system with pump for wet

samples . 13

Figure 5 – Typical sampling system – Steam-aspirated system with water wash for wet

samples . 14

Figure 6 – General test arrangement – Dry gases . 19

Figure 7 – Test apparatus to apply gases and water vapour to analysis systems . 21

Table A.1 – Zero correction factors for current gases . 23

– 4 – IEC 61207-3:2019 © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

GAS ANALYZERS –

EXPRESSION OF PERFORMANCE –

Part 3: Paramagnetic oxygen analyzers

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61207-3 has been prepared by sub-committee 65B: Measurement

and control devices, of IEC technical committee 65: Industrial-process measurement, control

and automation.

This third edition cancels and replaces the second edition published in 2002. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) all references (normative and informative) have been updated, deleted or added to as

appropriate;

b) all the terms, descriptions and definitions relating to the document have been updated

where appropriate;

c) all references to “errors” have been replaced by “uncertainties” and appropriate updated

definitions applied.

The text of this International Standard is based on the following documents:

FDIS Report on voting

65B/1155/FDIS 65B/1157/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

This International Standard is to be used in conjunction with IEC 61207-1:2010.

A list of all parts in the IEC 61207 series, published under the general title Gas analyzers –

Expression of performance, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 61207-3:2019 © IEC 2019

INTRODUCTION

Paramagnetic oxygen analyzers respond to the partial pressure of oxygen in the measured

gas, and the volumetric concentration is then determined by knowledge of the total pressure,

as in many other gas analyzers. Due to this fact, many paramagnetic oxygen analyzers use

pressure compensation (see 4.4.4 and 4.4.5). They are used in a wide range of industrial,

laboratory, medical, and other applications where the rated measuring range of the analyzer

is between 0 % to 1 % and 0 % to 100 %, at reference pressure (usually near atmospheric).

Only a few gases display significant paramagnetism (for example, oxygen, nitric oxide and

nitrogen dioxide), and oxygen has the strongest paramagnetic susceptibility (see Annex A)

among gases. By employing this particular property of oxygen, analyzers have been designed

that can be highly specific to the measurement in most industrial and medical applications,

where, for example, high background levels of hydrocarbons or moisture may be present.

There are several different techniques described for measuring oxygen by its paramagnetic

property, but three main methods have evolved over many years of commercial application.

The three methods are:

– automatic null balance;

– thermomagnetic or magnetic wind;

– differential pressure or Quincke.

These methods all require the sample gas to be clean and non-condensing, though some

versions work at elevated temperatures so that samples that are likely to condense at a lower

temperature can be analyzed. Because of this requirement, analyzers often require a sample

system to condition the sample prior to measurement.

GAS ANALYZERS –

EXPRESSION OF PERFORMANCE –

Part 3: Paramagnetic oxygen analyzers

1 Scope

This part of IEC 61207 applies to the three main methods for measuring oxygen by its

paramagnetic property, which are outlined in the introduction. It considers essential ancillary

units and applies to analyzers installed indoors and outdoors.

Safety-critical applications can require additional requirements from system and analyzer

specifications not covered in this document.

This document is intended

– to specify terminology and definitions related to the functional performance of para-

magnetic gas analyzers for the measurement of oxygen in a source gas;

– to unify methods used in making and verifying statements on the functional performance of

such analyzers;

– to specify what tests are performed to determine the functional performance and how such

tests are carried out;

– to provide basic documents to support the application of internationally recognized quality

management standards.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 61207-1, Expression of performance of gas analyzers – Part 1: General

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

NOTE Although cgs (centimetre-gram-second) units have been used in this document, SI (Système International)

units (such as defined in IUPAC [1] ) can also be used.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

__________

Numbers in square brackets refer to the bibliography

– 8 – IEC 61207-3:2019 © IEC 2019

3.1

magnetic susceptibility

measure (X) of the variation of the intensity of a magnetic field H, existing in a vacuum, when

the vacuum is substituted (filled) by the test substance, expressed as:

H −H

X=

H

where

H is the magnetic field intensity in vacuum

H is the magnetic field intensity in the test substance

Note 1 to entry: H – H is also known as the magnetisation MV (magnetic dipole per unit volume) and therefore

this is also the volume magnetic susceptibility.

3.2

paramagnetism

property of substances causing an increase of the magnetic field intensity (X > 0)

3.3

diamagnetism

property of substances causing a diminution of the magnetic field intensity

(X < 0 because H < H)

3.4

specific magnetic susceptibility

ratio of magnetic susceptibility to the density derived as follows:

X

X =

s

D

where

−3

D is the density of the considered substance, expressed in g·cm at 273,15 K, 101,3 kPa

3 −1

Note 1 to entry: The measuring unit of X is therefore cm ·g . This is also known as the mass magnetic

s

susceptibility.

3.5

molar magnetic susceptibility

X

m

specific magnetic susceptibility multiplied by the molecular mass (M) of the substance

considered:

X X⋅M

ms

where

−1

M is expressed in g per mole (g·mol ) (for oxygen M = 31,998 8)

3 −1

Note 1 to entry: The measuring unit of X is therefore cm ·mol .

m

Note 2 to entry: Electrons determine the magnetic properties of matter in two ways:

– an electron can be considered as a small sphere of negative charge spinning on its axis. This spinning charge

produces a magnetic moment;

– an electron travelling in an orbit around a nucleus will also produce a magnetic moment.

It is the combination of the spin moment and the orbital moment that governs the resulting magnetic properties of

an individual atom or ion.

=

In paramagnetic materials, the main contribution to the magnetic moment comes from unpaired electrons. It is the

configuration of the orbital electrons and their spin orientations that establish the paramagnetism of the oxygen

molecule and distinguish it from most other gases.

Note 3 to entry: When paramagnetic gases are placed within an external magnetic field, the flux within the gas is

higher than it would be in a vacuum, thus paramagnetic gases are attracted to the part of the magnetic field with

the strongest magnetic flux. On the contrary, diamagnetic substances contain magnetic dipoles which cancel out

some lines of force from the external field; thus diamagnetic gases are subject to repulsion by the magnetic flux.

Note 4 to entry: The molar magnetic susceptibility of oxygen is inversely proportional to the absolute temperature.

According to Van Vleck [2] the molar susceptibility of oxygen can be approximated by Equation (4).

8L⋅µ

B

For oxygen, X = (4)

m

3kT

where

3 −1

X is the molar susceptibility of oxygen, expressed in cm ·mol ;

m

23 −1

L is the Avogadro constant = 6,022 7 × 10 mol ;

−24 2

µ is the Bohr magneton = 9,274 × 10 A·m ;

B

−23 −1

k is the Boltzmann constant = 1,38 × 10 J·K ;

T is the temperature, expressed in K (kelvin).

Equation (4) can be written as follows:

−6 3 −1

X = × 10 cm ·mol (only for oxygen).

m

T

Note 5 to entry: A full understanding of paramagnetism and diamagnetism can be obtained from physics and

inorganic chemistry textbooks. The explanation in this document is to give the user of paramagnetic oxygen

analyzers a simple understanding of the physical property utilized.

3.6

automatic null balance analyzer

analyzer that uses, as a general principle of operation, the displacement of a body containing

a vacuum or a diamagnetic gas, from a region of high magnetic field by paramagnetic oxygen

molecules

Note 1 to entry: See Figure 1.

Figure 1 – Magnetic auto-balance system with current feedback

Note 2 to entry: The measuring cell typically employs a glass dumb-bell, with the spheres containing nitrogen,

suspended on a torsion strip between magnetic pole pieces or magnets that produce a very strong magnetic field

gradient around the dumb-bell. The dumb-bell is then deflected when oxygen molecules enter the measuring cell, a

force being exerted on the dumb-bell by the oxygen molecules which are attracted to the strongest part of the

– 10 – IEC 61207-3:2019 © IEC 2019

magnetic field. By use of an optical lever, a magnetic actuation coil, and suitable electronics to generate a

feedback signal that nulls the magnetic susceptibility force, an output that is directly proportional to the partial

pressure of oxygen can be achieved. The transducer can be maintained at a constant temperature to prevent the

variations in magnetic susceptibility to temperature from introducing uncertainties. Alternatively, built-in

temperature sensors may be used to provide temperature compensation of the oxygen reading. Additionally, the

elevated temperature helps in applications where the sample is not particularly dry. Some analyzers are designed

so that the transducer operates at a temperature in excess of 373,15 K (100 °C) to further facilitate applications

where condensates would form at a lower temperature. Paramagnetic sensor orientation may also affect the

oxygen measurement uncertainty and this may be corrected by using a compensation algorithm using, for example,

a three-dimensional accelerometer to determine the sensor orientation relative to its orientation during calibration.

Due to the mechanical nature of this type of device, there is some inherent susceptibility to vibrational and

gyroscopic motion, potentially resulting in increased measurement uncertainty.

3.7

thermomagnetic analyzer

3.7.1

magnetic wind analyzer

analyzer that uses the temperature dependence of the magnetic susceptibility to generate a

magnetically induced gas flow which can then be measured by a flow sensor

Note 1 to entry: The sample gas passes into a chamber designed in such a way that the inlet splits the flow.

Note 2 to entry: See Figure 2.

Figure 2 – Thermomagnetic oxygen sensor

Note 3 to entry: The two flows recombine at the outlet. A connecting tube is placed centrally with the flow sensor

wound on it. Half of the connecting tube is placed between the poles of a strong magnet. The flow sensor is

effectively two coils of wire heated to about 353,15 K (80 °C) by passage of a current. The cold oxygen molecules

are diverted by the magnetic field into the central tube, and, as they heat up, their magnetic susceptibility is

reduced and more cold oxygen molecules enter the connecting tube. A flow of oxygen is generated in this way

through the transversal connecting tube, with the effect of cooling the first coil (which is placed in the magnetic

field area), while the temperature of the second coil is not essentially influenced by this transversal flow. Since the

two coils are wound with thermosensitive wire (for example, platinum wire) and connected together to build a

Wheatstone bridge, the resulting unbalance current is a nearly proportional function of the oxygen partial pressure

in the test gas.