IEC TR 62036:2007

(Main)Mineral insulating oils - Oxidation stability test method based on differential scanning calorimetry (DSC)

Mineral insulating oils - Oxidation stability test method based on differential scanning calorimetry (DSC)

To develop a rapid oxidation stability test method based on differential scanning calorimetry (DSC) to assess the oxidation stability of mineral insulating oils

Huiles minérales isolantes - Méthode d'essai pour évaluer la stabilité d'oxydation fondée sur l'analyse calorimétrique différentielle par balayage

Le but de la CEI 62036 est d'élaborer une méthode d'essai de la stabilité à l'oxydation rapide fondée sur l'analyse calorimétrique différentielle par balayage (DSC) pour évaluer la stabilité à l'oxydation des huiles minérales isolantes

General Information

- Status

- Published

- Publication Date

- 10-Apr-2007

- Technical Committee

- TC 10 - Fluids for electrotechnical applications

- Drafting Committee

- WG 18 - TC 10/WG 18

- Current Stage

- PPUB - Publication issued

- Start Date

- 11-Apr-2007

- Completion Date

- 15-May-2007

Overview

IEC TR 62036:2007 establishes a rapid oxidation stability test method for mineral insulating oils using Differential Scanning Calorimetry (DSC). This technical report, published by the International Electrotechnical Commission (IEC), addresses the need for a faster and more efficient method to assess the oxidation stability of mineral insulating oils commonly used in electrical transformers. Traditional testing methods, while effective, are time-consuming and less sensitive, prompting the development of this DSC-based approach to enable quicker quality control and monitoring.

Key Topics

- Purpose: To provide a rapid and reliable oxidation stability test method for mineral insulating oils using DSC technology.

- Test Principle: DSC measures the oxidation induction time (OIT) by detecting exothermic reactions as the oil sample is heated under controlled oxygen pressure.

- Temperature Effects: The test evaluates various temperature programs and heating rates to optimize sensitivity and reproducibility. Higher temperatures (up to 260 °C) are used for reaction onset, while slow heating rates improve peak detection in inhibited and uninhibited oils.

- Sample Size Impact: Analysis of different sample weights (1 mg, 4 mg, 10 mg) to determine the effect on oxidation induction time and ensure consistent results across varying test conditions.

- Reliability and Repeatability: Multiple laboratories and DSC instruments were assessed to ensure method reproducibility and robustness across different operational settings.

- Comparison with Existing Methods: The DSC method offers significant time savings over traditional oxidation stability tests such as IEC 61125, which require prolonged oxidation periods and extensive chemical analysis.

Applications

- Transformer Oil Quality Control: Enables rapid screening of mineral insulating oils for oxidation stability before delivery or during routine maintenance, ensuring the oil meets operational specifications.

- Predictive Maintenance: Faster oxidation stability assessments facilitate proactive monitoring of oil aging, helping prevent transformer failures caused by oil degradation.

- Refining and Manufacturing: Assists producers in optimizing refining processes by quickly evaluating the oxidation resistance of mineral oils derived from different crude sources.

- Research and Development: The method supports development of new insulating oil formulations with enhanced oxidation stability by providing timely and reproducible results.

- Standard Compliance: Helps manufacturers and utilities verify compliance with international standards and specifications through a standardized, rapid test method.

Related Standards

- IEC 61125: Traditional method for oxidation stability testing of mineral insulating oils, involving prolonged oxidation at 120 °C and measurement of acidity and sludge content.

- ISO/IEC Directives: Governs the preparation of IEC technical reports and ensures harmonization with related standardization activities.

- IEC Technical Committee 10 (TC 10): Responsible for standards related to fluids for electrotechnical applications, including mineral insulating oils.

Keywords: mineral insulating oils, oxidation stability, differential scanning calorimetry, DSC, oxidation induction time, transformer oil testing, rapid test method, IEC TR 62036, electrical transformer maintenance, oil quality control, high pressure DSC, oxidation resistance, mineral oil refining, oil aging monitoring.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC TR 62036:2007 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Mineral insulating oils - Oxidation stability test method based on differential scanning calorimetry (DSC)". This standard covers: To develop a rapid oxidation stability test method based on differential scanning calorimetry (DSC) to assess the oxidation stability of mineral insulating oils

To develop a rapid oxidation stability test method based on differential scanning calorimetry (DSC) to assess the oxidation stability of mineral insulating oils

IEC TR 62036:2007 is classified under the following ICS (International Classification for Standards) categories: 29.040.10 - Insulating oils. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 62036:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

TECHNICAL IEC

REPORT

CEI

TR 62036

RAPPORT

First edition

TECHNIQUE

Première édition

2007-04

Mineral insulating oils –

Oxidation stability test method based on

differential scanning calorimetry (DSC)

Huiles minérales isolantes –

Méthode d’essai pour évaluer la stabilité

d’oxydation fondée sur l’analyse calorimétrique

différentielle par balayage

Reference number

Numéro de référence

IEC/CEI/TR 62036:2007

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de

référence, texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou

remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

TECHNICAL IEC

REPORT

CEI

TR 62036

RAPPORT

First edition

TECHNIQUE

Première édition

2007-04

Mineral insulating oils –

Oxidation stability test method based on

differential scanning calorimetry (DSC)

Huiles minérales isolantes –

Méthode d’essai pour évaluer la stabilité

d’oxydation fondée sur l’analyse calorimétrique

différentielle par balayage

PRICE CODE

M

Commission Electrotechnique Internationale CODE PRIX

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

Pour prix, voir catalogue en vigueur

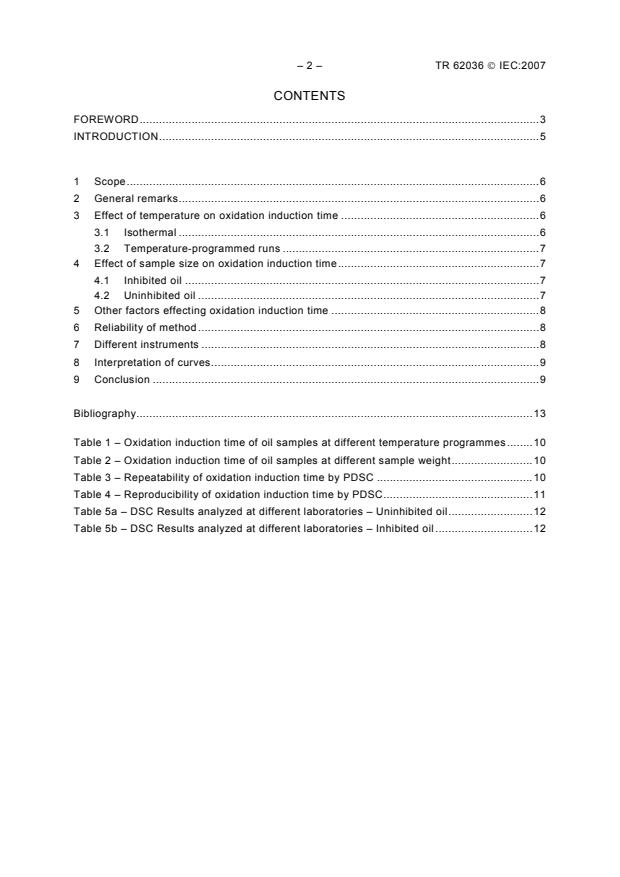

– 2 – TR 62036 © IEC:2007

CONTENTS

FOREWORD.3

INTRODUCTION.5

1 Scope.6

2 General remarks.6

3 Effect of temperature on oxidation induction time .6

3.1 Isothermal .6

3.2 Temperature-programmed runs .7

4 Effect of sample size on oxidation induction time.7

4.1 Inhibited oil .7

4.2 Uninhibited oil .7

5 Other factors effecting oxidation induction time .8

6 Reliability of method .8

7 Different instruments .8

8 Interpretation of curves.9

9 Conclusion .9

Bibliography.13

Table 1 – Oxidation induction time of oil samples at different temperature programmes.10

Table 2 – Oxidation induction time of oil samples at different sample weight.10

Table 3 – Repeatability of oxidation induction time by PDSC .10

Table 4 – Reproducibility of oxidation induction time by PDSC.11

Table 5a – DSC Results analyzed at different laboratories – Uninhibited oil.12

Table 5b – DSC Results analyzed at different laboratories – Inhibited oil.12

TR 62036 © IEC:2007 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MINERAL INSULATING OILS –

OXIDATION STABILITY TEST METHOD BASED ON DIFFERENTIAL

SCANNING CALORIMETRY (DSC)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC 62036, which is a technical report, has been prepared by IEC technical committee 10:

Fluids for electrotechnical applications.

– 4 – TR 62036 © IEC:2007

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

10/676/DTR 10/690/RVC

Full information on the voting for the approval of this technical report can be found in the

report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

TR 62036 © IEC:2007 – 5 –

INTRODUCTION

The existing methods to assess oxidation stability of mineral insulating oil are very time

consuming. A faster method is necessary for effective quality control and status monitoring.

Differential scanning calorimetry (DSC) as a technique has been used for monitoring grease

and lubricants oxidation stability. The use of DSC for evaluation of oil oxidation stability was

originally suggested to IEC, TC 10 following publication of a literature review of DSC oxidation

tests performed on petroleum products (10/367/INF April 1996). During IEC’s TC 10 meeting

in Geneva, 1998, it was decided to set up a working group for development of a standard

based on DSC for rapid evaluation of mineral insulating oil oxidation stability.

– 6 – TR 62036 © IEC:2007

MINERAL INSULATING OILS –

OXIDATION STABILITY TEST METHOD BASED ON DIFFERENTIAL

SCANNING CALORIMETRY (DSC)

1 Scope

The purpose of IEC 62036, which is a technical report, is to develop a rapid oxidation stability

test method based on differential scanning calorimetry (DSC) to assess the oxidation stability

of mineral insulating oils.

2 General remarks

The main function of insulating oil is insulation and cooling. The expected life span of

transformer oil is 25 to 40 years, largely depending on operating temperature and electrical

load. Specifications are prepared and used to fulfil all criteria required for proper functioning

of the oil in service. Life expectancy from insulating oil has a large economic impact on the

cost of operation of a unit.

The oxidation stability test is an important test as this will evaluate, to some extent, the life of

the oil in service. Resistance of an oil oxidation is very much dependant on the refining

process and type of crude oil. Both under-refined and over-refined oils may exhibit poor

oxidation stability. The complex process of oxidation of in-service oils occurs slowly at the

normal operating temperature of the transformer and is dependant on temperature, oxygen

and catalyst. In the first stage of oil oxidation, radicals and peroxides are produced. These

compounds are unstable and rapidly convert to volatile and soluble acids and finally

producing insoluble material or sludge. All of these products have an adverse effect on

electrical and physical properties of oil. The oil may reach a stage where it is not fit for its

intended purpose.

To establish a long service life for the oil, an oxidation stability test is performed on the

unused oil. There are several standard test methods for evaluation of the oxidation stability of

transformer oil. The recommended international test method is IEC 61125. This test involves

oxidizing the oil at 120 °C for 164 h and then measuring the acidity, sludge and dielectric

dissipation factor (DDF). Other national test methods are based on the same principal and are

time consuming. On delivery, it is required to test the oil for compliance with the specification.

As this test is very time consuming, results are usually retrospective. Clearly, existing methods

are time consuming and not very sensitive. Although there is no direct relation between the oil

oxidation stability test and service life of the oil, oils that are very stable and resist oxidation

are clearly preferred. Therefore, a fast method of determining the oxidation stability is needed

for rapid evaluation of the oil and compliance to the specification.

In order to evaluate high pressure differential scanning calorimetry (PDSC) as a technique for

testing oxidation stability of transformer oil and to establish a suitable method, transformer oil

samples were analysed under varying conditions.

3 Effect of temperature on oxidation induction time

3.1 Isothermal

Six samples of transformer oil (A-F) were analysed using PDSC at different temperature

programmes. Samples B and D were inhibited transformer oil, the remainder were uninhibited

and sample F was a used oil. Oxygen at 300 psi was applied in each case and the sample

weight was kept constant at 4 mg. The results are shown in Table 1. It was found that below

165 °C, no phase transition occurred in any of the six samples. Temperatures higher than

expected, of up to 260 °C were required to give peaks in a reasonable time. At the lower

TR 62036 © IEC:2007 – 7 –

temperature, only sample D gave a peak at around 45 min. When this sample was run at

170 °C, the peak become sharper and clear and occurred at an onset of around 40 min. At

175 °C, the peak occurred at around 30 min and was sharper still. The same trend was

observed in sample B, showing decreasing induction time with increasing temperature, but

oxidation occurred after a slightly longer time. Sample B and D were inhibited oils, which

showed a clear and sharp peak following the rapid oxidation and depletion of the inhibitor.

3.2 Temperature-programmed runs

The uninhibited oils, A, C, E and F showed no clearly defined peak in the thermograms of

isothermal runs. Oxidation did not occur when the samples were run at a heating rate of

50 °C/min or 25 °C/min, or the curves were poorly defined. The samples were then run at a

heating rate of 10 °C/min (TP 2) and more clearly defined exotherms were obtained. As with

the inhibited oil samples, the uninhibited oils showed a broader, shallower peak with

increasing heating rate, but the area under the peak remained the same. As the heating rate

was increased from 2 °C to 5 °C, the oxidation induction time (OIT) decreased, but there was

little change in the OIT between the heating rates of 5 °C and 10 °C. At a heating rate of

10 °C/min, all of the samples showed oxidation induction times between 16 min and 19 min

and therefore could not be distinguished from one another. When the samples were run using

a heating rate of 5 °C/min up to 180 °C, then 2 °C/min up to 210 °C (TP 3), there was a wider

spread in the OITs obtained. This temperature programme was used because it was found

that a slow heating rate was required to give clearly defined peaks for uninhibited oils, and

oxidation usually occurred in the 180 °C – 210 °C range.

Oxidation of the inhibited oils B and D occurred at approximately the same time as it had done

at 10 °C/min, but the uninhibited oils oxidized more rapidly. Samples E and C could not be

distinguished, as they both had 0ITs of around 11 min and samples B and D were also very

similar. The samples overall showed approximately the same ranking with the different

temperature programmes. However, when the samples were run at 2 °C/min up to 180 °C,

then 1 °C/min up to 210 °C (TP 4), the samples could be distinguished by their oxidation

induction times. Again, the ranking was similar as with the other temperature programmes.

This very slow rate of heating also clarified the peak obtained in the thermogram of sample F,

which was a used oil and showed the most broad peak due to the complicated oxidation

process in used oil. The used oil did not, however show the poorest oxidation stability.

4 Effect of sample size on oxidation induction time

Sample B (inhibited oil) and sample A (uninhibited oil) were analyzed by PDSC under 300 psi

of oxygen, as above, using a temperature programme of 130 °C – 180 °C at 2 °C/min, 180 °C

– 210 °C at 1 °C/min. Each sample was analyzed at weights of 1 mg, 4 mg and 10 mg. The

oxidation induction time at the various sample sizes is given in Table 2.

4.1 Inhibited oil

The results showed that oxidation induction time increases with increasing sample size, in

inhibited oil. This may be due to limited oxygen diffusion through the larger samples. The

repeatability between triplicate determinations is good and is unaffected by sample weight.

4.2 Uninhibited oil

With uninhibited oil, however, there is little difference in oxidation induction time with sample

size. The 10 mg sample showed slightly longer oxidation induction time, but this was within

the margin of error for repeatability. Repeatability is also slightly poorer with the larger sample

size and the peak is larger and more spread out, giving poorer resolution. If the sample size is

very large, the accuracy is reduced, because the heat flow may be variable within the sample.

Smaller sample sizes produce smaller peaks, better resolution and better accuracy.

Therefore, the sample size should be as small as possible. A suitable sample size is normally

10 mg to 15 mg, however, much smaller sample sizes should be used with volatile products to

minimize any decontamination of the DSC cell. A sensible sample size of 4 mg was chosen in

this case, so as not to introduce sample handling difficulties.

– 8 – TR 62036 © IEC:2007

5 Other factors effecting oxidation induction time

As well as heating rate and sample size, there are many other factors which may effect the

results, such as purge gas, sample pan type, sample homogenity, particle size (if applicable)

and computational effects. Sample pans used were aluminium, which were found to give

repeatable results. The purge gas used was nitrogen, in a pure, dry form. This is suitable for

temperature ranges between -100 °C and 400 °C. The rate of flow of 30 ml/min was found to

be a little slow, since decomposition products would condense on the DSC cell, so this was

increased to 60 ml/min; however, a flow rate above 60 ml/min produced turbulence and a

noisy baseline. It was also found necessary to use a flow-through cover to allow the removal

of decomposition products from the DSC cell; in addition, it was decided that local exhaust

ventilation was required to remove the vaporized oil from the atmosphere.

6 Reliability of method

The high pressure DSC method for analyzing oxidation stability of transformer oils was found

to show good repeatability between triplicate runs, however, some difficulty was encountered

with the reproducibility of the technique. Results are shown in Table 3.

As can be seen from the results, the repeatability between triplicate determinations is good.

When samples were run on the same day by the same operator, the standard deviation

between OIT determinations was less than 0,5 min for the unused oils and only slightly higher

for the used oil sample.

The results in Table 4 show that repeatability is generally good between samples run on the

same instrument by the same operator but on different days. At TP3 (5 °C/min) this was true

for all the samples except sample F, the used oil, which showed a larger discrepancy. At the

slower temperature programme, this variation was slightly higher, up to 2 min, and 2,5 mins

for the used oil. Isothermal runs of the inhibited samples, B and D showed variation of 0,6 min

and 1,1 min, respectively, between runs on different days, ignoring the results on Day 1. On

this particular day, the results of oxidation induction time were markedly different from the

results on the other two days, and this was counted as an anomaly, which may have been due

to deterioration of the samples themselves, which were left in laboratory light for some time.

There were thought to be numerous reasons for the remaining variation. The main reason

may have been the calculation of oxidation induction time, which was found to account for

variation of up to 2 min. In the Pyris software, tangents to the onset curve and baseline are

drawn with the mouse and extrapolated to the point at which the lines intersect. This depends

on where the tangent to the curve is taken from and any changes in baseline heat flow or in

the shape of the curve may result in a relatively large difference in calculated onset time. This

is exacerbated by noisy baselines, which were common with the technique and may be due to

changes in gas flow rate or pressure, the volatility of the samples, or interference from the

glass woof plugs in the DSC cell cover. Generally, differential scanning calorimetry is a

sensitive technique and variables such as gas flow rate and pressure, equilibration time and

temperature and humidity of the room, should be kept constant.

7 Different instruments

Thirty-one samples of unused insulating oil consisting of 13 inhibited oils and 18 uninhibited

oils were analyzed by PDSC by three different laboratories. Laboratory 1 used Perkin-Elmer

DSC 7. Samples were analyzed at a heating rate of 130 °C to 260 °C at 5 °C/min, under

300 psi of oxygen. The second laboratory used TA Instruments heat flux type. Air was applied

at 300 psi at a flow rate of 60 ml/min and the samples were analyzed from 100 °C to 350 °C at

20 °C/min. The samples were run in duplicate and the mean oxidation onset temperature

calculated. At the third laboratory, samples were analyzed on a TA instrument, at a heating

rate of 2 °C/min from 130 °C to 210 °C for the uninhibited oils and isothermally at 180 °C for

the inhibited oils, under oxygen at 300 psi. Results are shown in Tables 5a and 5b.

TR 62036 © IEC:2007 – 9 –

Results from both Table 5a and 5b clearly indicate that the DSC results obtained at the three

different laboratories show basically the same trend when the samples were analyzed under

different conditions and using different instruments. Better correlation was obtained for

laboratory 1 and 3. This correlation is better for uninhibited oils than for inhibited oils.

8 Interpretation of curves

Characterization of thermal events in the DSC trace is not easy. In many cases it was found

that the particular shape of curves obtained was not reproducible. This may be due to

changes in the sample itself, or operating variables such as heating rate, pan type or

instrument used. For example, all of the thermograms obtained with the TA Instrument

showed multiple peaks, compared to single peaks obtained with the Perkin Elmer instrument,

for the same set of samples. This may have been due to impurities or reaction of different

parts of molecules, but was more likely due to instrumental factors such as degree of thermal

contact. It has so far been assumed that the exothermic peak obtained in the thermograms of

the oils is representative of oxidation. This may not be the case and it may be due to some

other exothermic reaction when the oil is subject to extreme conditions of heat and oxygen.

Generally, melting, crystal transitions, vaporization and sublimation are observed as

endothermic reactions, whereas curing, crystallization and decomposition are exothermic

reactions.

9 Conclusion

High temperature differential scanning calorimetry (PDSC) provides an alternative method

which is fast, simple and reliable. It was found that PDSC could be applied to the oxidation

stability of uninhibited mineral insulating oil by measuring the onset time of the oxidation

exotherm under high pressure and temperature when applying a slow thermal ramp. The

sample size and heating rate effect the onset time and the technique was found to be

sensitive to any change in cooling rate, gas flow rate or calibration variables. The method is

capable of distinguishing inhibited oils from uninhibited oils. Repeatability of method is

acceptable and if care is taken, reproducible results may be obtained and the onset time

found to correlate to the induction period measured in the existing IEC 61125. However, the

relationship between thermal onset time and other physical characteristics of the oil was poor.

The type and manufacture of the DSC equipment has an influence on the results.

– 10 – TR 62036 © IEC:2007

Table 1 – Oxidation induction time of oil samples at different temperature programmes

Temperature Oxidation induction time (OIT) in minutes

program

Sample A Sample B Sample C Sample D Sample E Sample F

TP1 165 °C ND ND ND 46,88 ND ND

TP1 170 °C ND ND ND 41,76 ND ND

TP1 175 °C ND 33,96 ND 30,52 ND ND

TP1 180 °C ND 22,37 ND 21,12 ND ND

TP2 17,78 19,35 16,73 19,03 17,95 17,20

TP3 12,21 19,36 10,78 18,18 14,55 11,17

TP4 23,13 37,06 19,82 33,22 30,15 26,81

TP1 = isothermal at 165 °C, 170 °C, 175 °C and 180 °C

TP2 = 25 °C – 260 °C at 10 °C/min, hold for 10 min at 260 °C

TP3 = 130 °C – 180 °C at 5 °C/min, 180 °C -210 °C at 2 °C/min

TP4 = 130 °C – 180 °C at 2 °C/min, 180 °C -210 °C at 1 °C/min

ND = onset of peak is not clearly detectable in thermogram

OIT is given as an average of triplicate runs.

Table 2 – Oxidation induction time of oil samples at different sample weight

Sample Oxidation induction time (OIT) in minutes

weight

Sample A Sample B

mg

1 24,32 24,11 24,16 30,95 31,58 30,63

4 24,21 24,11 24,12 35,00 35,74 35,07

10 24,18 25,77 26,93 40,61 40,31 40.44

Table 3 – Repeatability of oxidation induction time by PDSC

Oxidation induction time (OIT) in minutes

Sample A Sample B Sample C Sample D Sample E Sample F

Run 1 12,51 19,45 10,76 18,16 14,43 10,72

Run 2 12,44 19,34 10,68 18,24 14,74 11,92

Run 3 11,67 19,29 10,89 18,14 14,49 10,86

Average 12,21 19,36 10,78 18,18 14,55 11,17

Standard deviation 0,5 0,1 0,1 <0,1 0,2 0,7

TR 62036 © IEC:2007 – 11 –

Table 4 – Reproducibility of oxidation induction time by PDSC

Temperature Oxidation induction time (OIT) in minutes

programme

Sample A Sample B Sample C Sample D Sample E SampleF

Day 1 / TP3 12,21 19,36 10,78 18,18 14,55 11,17

Day 2 / TP3 12,10 19,66 9,89 18,31 14,26 14,82

Average 12,16 19,51 10,34 18,25 14,41 13,00

Standard deviation <0,1 0,2 0,6 0,1 0,2 2,6

Day 1 / TP4 23,13 37,06 19,82 33,22 30,15 26,81

Day 2 / TP4 24,15 35,27 20,67 32,88 27,63 23,21

Average 23,64 36,17 20,25 33,05 28,89 25,01

Standard deviation 0,7 1,3 0,6 0,2 1,8 2,5

Day 1 / TP1 (175 °C) ND 14,82 ND 6,66 ND ND

Day 2 / TP1 (175 °C) ND 33,15 ND 30,52 ND ND

Day 3 / TP1 (175 °C) __ 33,96 __ 28,99 __ __

Average __ 33.56 __ 29.76 __ __

Standard deviation __ 0.6 __ 1.1 __ __

– 12 – TR 62036 © IEC:2007

Table 5a – DSC Results analyzed at different laboratories – Uninhibited oil

Sample reference OIT, min. Lab 1 OIT, min. Lab 2 OIT, min. Lab3

9503.023U 12,53 219,3 31,92

9503.476U 12,55 210,7 33,65

9503.479U 14,53 218,3 37,39

9503.484U 11,02 203,5 29,13

9503.491U 12,28 205,4 33,29

9504.121U 11,34 204,7 29,80

9504.123U 13,88 229,6 36,06

9504.133U 10,25 204,5 28,09

9505.081U 12,84 212,0 35,87

9505.082U 15,44 233,4 38,55

9505.170U 14,50 284,7 41,60

9505.182U 12,70 210,5 33,97

9505.304U 13,66 216,2 36,98

9505.305U 11,01 202,7 29,50

9505.306U 11,98 208,9 32,05

9506.115U 11,46 208,3 30,30

9511.122U 10,13 205,3 26,85

9511.125U 10,68 213,1 26,40

Table 5b – DSC Results analyzed at different laboratories – Inhibited oil

Sample reference OIT, min. Lab1 OIT, min. Lab2 OIT, min. Lab3

9503.4891 15,10 231,8 21,27

9504.1201 15,39 229,7 25,86

9504.1241 14,82 230,3 20,03

9505.0801 15,92 225,8 40,99

9505.0841 15,49 236,8 22,22

9505.3071 14,75 232,5 20,56

9505.3091 14,85 232,5 16,63

9507.1811 14,27 229,9 17,80

9510.2031 15,61 228,6 37,36

9511.1241 14,83 232,5 22,32

TR 62036 © IEC:2007 – 13 –

Bibliography

IEC 61165:1992, Unused hydrocarbon-based insulating liquids – Test methods for evaluating

the oxidation stability

___________

– 14 – TR 62036 © CEI:2007

SOMMAIRE

AVANT-PROPOS.15

INTRODUCTION.17

1 Domaine d’application .18

2 Remarques générales .18

3 Effet de la température sur le temps d’induction de l’oxydation.19

3.1 Isothermique .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...