IEC 61285:2004

(Main)Industrial-process control - Safety of analyser houses

Industrial-process control - Safety of analyser houses

describes the physical requirements for the safe operation of the process analyser measuring system installed in an AH in order to ensure its protection against fire, explosion and health hazards. This standard extends beyond IEC 60079-16 to include houses with Zone 2 interiors and to apply to toxic hazards. (Appropriate national guidelines on toxic hazards are to be followed.)

General Information

- Status

- Published

- Publication Date

- 11-Oct-2004

- Technical Committee

- SC 65B - Measurement and control devices

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 24-Feb-2015

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61285:2004 - Industrial-process control: Safety of analyser houses sets minimum physical safety requirements for buildings, rooms, cabinets or shelters that house process analysers (referred to as analyser houses, AHs). The standard aims to protect analysers and personnel from fire, explosion and health hazards, and it explicitly extends beyond IEC 60079-16 by addressing Zone 2 interiors and toxic inhalation hazards (while noting that appropriate national toxic-hazard guidelines must be followed).

Key topics and requirements

- Scope and definitions: Covers AHs, analyser cabinets/shelters, sample conditioning rooms (SCR), toxic materials, LEL (lower explosive limit), hazardous areas (Zones 0, 1, 2).

- Location and connections (Clause 4): Guidance on siting AHs within a plant, utilities, response time, safety and access considerations.

- Design, construction and layout (Clause 5): Structural requirements, dimensions, equipment arrangement, labelling, documentation and modular arrangements to support maintenance and safety.

- Explosion protection (Clause 6): Measures to reduce explosion risk while permitting maintenance with power on, including both artificial (mechanical) ventilation and natural ventilation strategies.

- Health hazard controls (Clause 7): Measures to prevent personnel exposure to toxic atmospheres inside AHs, including safety procedures, additional measures for abnormal conditions, and external hazard mitigation.

- Supporting material: Annex A (normative) evaluates leakage risk of modules; Annex B (informative) provides ventilation calculation guidance (assumes STP conditions).

Practical applications

IEC 61285 is used to design, operate and maintain analyser houses that support continuous process measurement and control. Typical practical uses include:

- Ensuring safe installation of analyser systems used for environmental monitoring, personnel protection, equipment protection, quality control, process optimization, and energy conservation.

- Selecting AH location and ventilation strategy to prevent hazardous atmospheres (below LEL and toxic exposure limits).

- Defining labelling, documentation and maintenance access rules so technicians can safely service analysers (including risk mitigation when working with Zone 2 interiors).

- Performing leakage risk assessments for modular analyser components and sizing ventilation per Annex B guidance.

Who should use this standard

- Process safety and instrumentation engineers

- Plant designers and facility managers

- Health, safety & environmental (HSE) professionals

- Maintenance teams and operations personnel

- Certification bodies and compliance auditors

Related standards

- IEC 60079-16 - Electrical apparatus for explosive gas atmospheres (artificial ventilation for analyser houses). IEC 61285 extends and complements this standard, particularly for Zone 2 interiors and toxic hazards.

Keywords: IEC 61285, analyser houses safety, explosion protection, toxic hazards, Zone 2, analyser ventilation, hazardous area, LEL, industrial-process control.

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

NSF International

Global independent organization facilitating standards development and certification.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

Sponsored listings

Frequently Asked Questions

IEC 61285:2004 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Industrial-process control - Safety of analyser houses". This standard covers: describes the physical requirements for the safe operation of the process analyser measuring system installed in an AH in order to ensure its protection against fire, explosion and health hazards. This standard extends beyond IEC 60079-16 to include houses with Zone 2 interiors and to apply to toxic hazards. (Appropriate national guidelines on toxic hazards are to be followed.)

describes the physical requirements for the safe operation of the process analyser measuring system installed in an AH in order to ensure its protection against fire, explosion and health hazards. This standard extends beyond IEC 60079-16 to include houses with Zone 2 interiors and to apply to toxic hazards. (Appropriate national guidelines on toxic hazards are to be followed.)

IEC 61285:2004 is classified under the following ICS (International Classification for Standards) categories: 13.110 - Safety of machinery; 25.040.40 - Industrial process measurement and control. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61285:2004 has the following relationships with other standards: It is inter standard links to IEC 61285:2015, IEC 61285:1994. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61285:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 61285

Second edition

2004-10

Industrial-process control –

Safety of analyser houses

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 61285

Second edition

2004-10

Industrial-process control –

Safety of analyser houses

IEC 2004 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale U

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

– 2 – 61285 © IEC:2004(E)

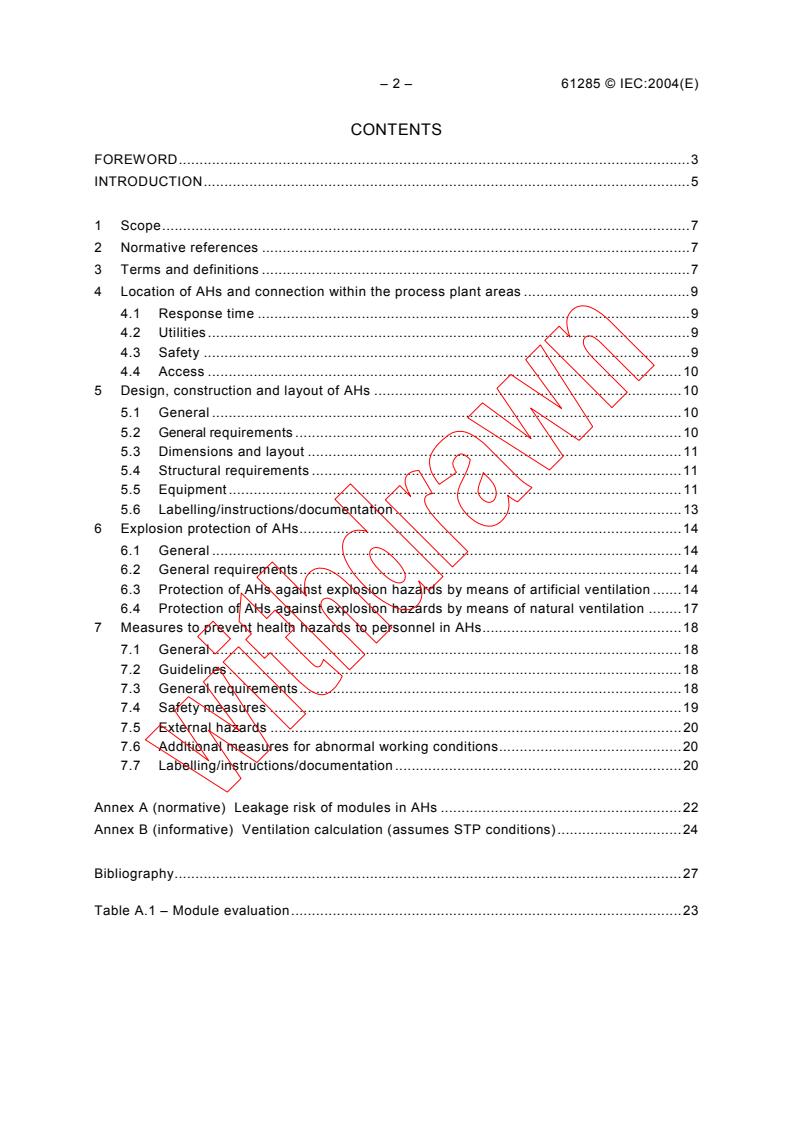

CONTENTS

FOREWORD.3

INTRODUCTION.5

1 Scope.7

2 Normative references .7

3 Terms and definitions .7

4 Location of AHs and connection within the process plant areas .9

4.1 Response time .9

4.2 Utilities.9

4.3 Safety .9

4.4 Access .10

5 Design, construction and layout of AHs .10

5.1 General .10

5.2 General requirements .10

5.3 Dimensions and layout .11

5.4 Structural requirements .11

5.5 Equipment.11

5.6 Labelling/instructions/documentation.13

6 Explosion protection of AHs.14

6.1 General .14

6.2 General requirements.14

6.3 Protection of AHs against explosion hazards by means of artificial ventilation .14

6.4 Protection of AHs against explosion hazards by means of natural ventilation .17

7 Measures to prevent health hazards to personnel in AHs.18

7.1 General .18

7.2 Guidelines .18

7.3 General requirements.18

7.4 Safety measures .19

7.5 External hazards .20

7.6 Additional measures for abnormal working conditions.20

7.7 Labelling/instructions/documentation.20

Annex A (normative) Leakage risk of modules in AHs .22

Annex B (informative) Ventilation calculation (assumes STP conditions).24

Bibliography.27

Table A.1 – Module evaluation.23

61285 © IEC:2004(E) – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

INDUSTRIAL-PROCESS CONTROL –

SAFETY OF ANALYSER HOUSES

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61285 has been prepared by subcommittee 65D: Analysing

equipment, of IEC technical committee 65: Industrial-process measurement and control.

This second edition cancels and replaces the first edition published in 1994. This edition

constitutes a technical revision.

The main changes with respect to the previous edition are listed below:

a) incorporation of previously issued corrigendum;

b) minor updates to several sections and references

The text of this standard is based on the following documents:

FDIS Report on voting

65D/107/FDIS 65D/110/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

– 4 – 61285 © IEC:2004(E)

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

61285 © IEC:2004(E) – 5 –

INTRODUCTION

Process analysers measure the characteristics of a process stream continuously and

automatically. The process sample is introduced automatically and the system is designed for

unattended operation and minimal maintenance.

This document is designed to set forth minimum safety requirements for typical analyser

houses (AHs). It shall be superseded in all cases by national, local, or corporate

requirements, which may be more stringent.

The measured output is transmitted continuously for process control, operator action or

documentation. Process analysers are used for

– environmental analysis;

– personnel protection;

– equipment protection;

– quality measurement/control;

– process control (plant optimization);

– energy conservation.

In the simplest case, the analyser sensor is mounted directly in the material to be measured,

and there is no need to extract a sample. In other cases, a sample is extracted from the main

stream and transported to the analyser. The system may include many functional elements

such as

– sample extraction;

– sample transport;

– sample conditioning;

– sample stream disposal and/or return to process;

– utilities and auxiliary materials supply;

– stream switching;

– automatic or manual calibration and validation system;

– signal processing;

– performance monitoring and control.

(See IEC 61115.)

Analyser elements can be arranged modularly and located separately. There are advantages

in grouping analysers and systems and further advantages in enclosing them. Advantages

include

– lower cost of installation of utilities and signals;

protection of personnel and complex modules and equipment from adverse ambient

conditions;

ease of maintenance;

safety.

Analysers are constructed to various standards: some are ex-proof, some intrinsically safe,

some suitable for Zone 2 and some suitable only for a non-hazardous area. Not all analysers

are available in all variants.

Process plants usually include all zones 0, 1, 2 and non-hazardous.

– 6 – 61285 © IEC:2004(E)

The selection of the AH location, the source of ventilation air, and the classification of the

house interior and its analysers is an economic exercise.

Factors include the distance from the sample point to the AH , classification of the area

around the AH, distance from the AH to the source of non-hazardous air, and the cost of

analysers of classification appropriate to the house interior.

61285 © IEC:2004(E) – 7 –

INDUSTRIAL-PROCESS CONTROL –

SAFETY OF ANALYSER HOUSES

1 Scope

This International Standard describes the physical requirements for the safe operation of the

process analyser measuring system installed in an AH in order to ensure its protection against

fire, explosion and health hazards. This standard extends beyond IEC 60079-16 to include

houses with Zone 2 interiors and to apply to toxic hazards. (Appropriate national guidelines on

toxic hazards are to be followed.)

This standard does not address facilities where dust is the hazard.

Clause 4 addresses the location of the AH and connection within the process plant areas.

Clause 5 addresses the design, construction and layout of the AH. It does not address parts

of the analyser measuring system installed in other locations such as sample conditioning

rooms (SCR) or switchgear rooms.

Clause 6 addresses measures for reducing the danger of explosion for AHs while permitting

maintenance of equipment with the power on and the case open.

NOTE For most fluids, the major constraint is that the concentration of vapours, which are hazardous for

personnel, is lower than the lower explosive (flammable) limit (LEL) (see Clause 7).

–6

Using n-Pentane as an example, the LEL is 1,4 % or 14 000 × 10 . The level immediately

dangerous to life or health (which is the maximum level from which a worker could escape

within 30 min without any escape-impairing symptoms or any irreversible health effects) is

–

only 0,5 % or 5 000 × 10 .

Classification of a house interior as Zone 1 may imply that no technician can enter without

protective equipment such as breathing gear. Placing an AH in a Zone 1 area would usually

imply that no technician could approach the house without wearing protective equipment.

Clause 7 addresses those measures for protecting personnel from materials in the

atmosphere of AHs that are hazardous to health.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60079-16:1990, Electrical apparatus for explosive gas atmospheres – Part 16: Artificial

ventilation for the protection of analyser(s) houses

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

– 8 – 61285 © IEC:2004(E)

3.1

analyser cabinet

small housing in which analysers are installed individually or grouped together. Maintenance

is performed from outside the cabinet with the door(s) open

3.2

analyser shelter

structure with one or more sides open and free from obstruction to the natural passage of air,

in which one or more analysers are installed. The maintenance of the analysers is normally

performed in the protection of the shelter

3.3

analyser house (AH)

enclosed building or part of a building containing process analysers and associated

equipment where streams for analysis are brought in and which is regularly entered by

authorized personnel

NOTE Within the scope of this standard, the term AH is used regardless of the structure configuration as either a

room, cabinet or building and whether or not it is an integral part of, or attached to, another structure.

3.4

sample conditioning room

SCR

room that is separated from the AH and has modules for sample conditioning, auxiliary

material, or sample disposal equipment.

3.5

toxic material

material that is a health hazard by inhalation from the surrounding atmosphere. Atmospheric

routes such as skin absorption or ingestion are not addressed

3.6

safety back-up

additional personnel, in constant contact with a person or persons in dangerous working

conditions, who could assist or get additional help

3.7

external and internal hazards

distinction is made between "external" and "internal" explosion hazards. An external explosion

hazard exists when the AH is erected at a location where flammable material can be

introduced from the outside resulting in dangerous concentrations of flammable gases and

vapours inside the AH. An internal explosion hazard exists when a flammable mixture can

result from the leakage of samples or auxiliary supplies inside the AH

3.8

lower explosive limit

LEL

lower flammable limit

LFL

volume ratio of the flammable gas or vapour in air below which an explosive gas atmosphere

will not be formed

3.9

explosive gas atmosphere

mixture with air, under atmospheric conditions, of a flammable material in the form of gas or

vapour in which, after ignition, combustion spreads through the unconsumed mixture

61285 © IEC:2004(E) – 9 –

3.10

hazardous area

area in which an explosive gas atmosphere is present, or may be expected to be present, in

quantities such as to require special precautions for the construction, installation and use of

the analysers (includes Zones 0, 1, and 2 – Division 1 and 2 are also utilized as hazardous

area definitions in many regions – refer to appropriate authorities and standards for detail

definitions)

3.11

non-hazardous area

area in which an explosive gas atmosphere is not expected to be present in quantities such as

to require special precautions for the construction, installation and use of the analysers

3.12

Zone 0

area in which an explosive gas atmosphere is present continuously or for long periods

3.13

Zone 1

area in which an explosive gas atmosphere is likely to occur in normal operation

3.14

Zone 2

area in which an explosive gas atmosphere is not likely to occur in normal operation and, if it

does occur, is likely to do so only infrequently and will exist for a short period only

3.15

flashpoint

lowest liquid temperature at which, under certain standardized conditions, a liquid gives off

vapours in a quantity such as to be capable of forming an ignitable vapour/air mixture

3.16

ignition temperature (T-rating)

lowest temperature of a heated surface at which, under specified conditions, the ignition of a

flammable substance in the form of a gas or vapour mixture with air will occur

4 Location of AHs and connection within the process plant areas

When determining the location of the AH, the following factors should be considered.

4.1 Response time

Line lengths from sample points to the analysers shall be estimated and the necessary flow

rates calculated to determine whether resultant dead times, sample deterioration and flow

rates are acceptable.

4.2 Utilities

Connection lengths to all utilities such as air, steam, electricity, sample return, signals, etc.

shall be estimated.

4.3 Safety

4.3.1 Location

The AH should be located a safe distance from sources of toxic or flammable release, and in

a place where accumulation of these materials is not likely to occur.

– 10 – 61285 © IEC:2004(E)

4.3.2 Escape

Escape routes shall be determined and remain unobstructed and where possible be oriented

away from hazardous areas.

4.3.3 Area classification

Area classification for the AH interior and for the ventilation air source shall be determined by

the process plant safety authority or user.

4.3.4 Peripheral hazards

Consideration shall be given to the possibility of analysers or their sample lines creating a

hazard in the AH or any adjacent room.

4.4 Access

Access is needed both for maintenance personnel and for supplies. AHs should be located at

ground level or with access to an elevator. Consideration should be given to the requirements

of heavy supplies such as gas cylinders and safe removal/installation of analysers.

Maintenance access to process equipment such as a heat exchanger shall also be

considered.

5 Design, construction and layout of AHs

5.1 General

Analysers and analyser sampling systems require varying degrees of protection depending on

the sample and the type of analyser, the importance of the application and the environment in

which it has to operate. Where the construction and maintenance requirements are not

suitable for the working environment, additional protection such as AHs should be provided.

This additional protection is to ensure satisfactory performance of the instrument and to

facilitate maintenance.

The selection of the housing depends on a number of factors such as

– classification of the area in which the analyser and/or sample system is to be located;

– range of ambient conditions at the site, including temperature, rain, humidity, snow, wind,

dust, sand, direct sunlight, and corrosive atmosphere;

– environment specified by the analyser vendor for reliable, accurate, and safe operation;

– protection required for equipment and personnel during maintenance;

– maintenance and accessibility requirements of the system components;

– process conditions/environment of the area in which the AH is to be located (for example,

loading, unloading or transferring of chemicals or equipment, noise, vibration, chemical

releases, etc.).

This clause primarily describes AH located in hazardous (classified environments) and/or into

which flammable or toxic samples are introduced. Those AH located in an unclassified area

and into which no flammable or toxic samples, services, calibration mixtures or air from a

hazardous location are introduced need only provide the environment necessary for accurate

and reliable operation.

5.2 General requirements

This clause addresses the general requirements for safe operation of an AH regardless of

leakage or flammable material (see Clause 6) or material hazardous to health (see Clause 7).

61285 © IEC:2004(E) – 11 –

5.3 Dimensions and layout

The size of the AH depends on the number, size and access requirements of the analysers

and auxiliary equipment. Allowance shall be made for any ventilation, drainage, spare parts

storage, electrical distribution, local recording, etc. Recommended minimum dimensions are

2,5 m length and width and 2,3 m headroom. The absolute minimum unobstructed headroom

should be 2,0 m. Spare space of 30 % is recommended to facilitate later equipment addition.

Suspended ceilings, cable trenches and other dead air spaces should be avoided.

5.4 Structural requirements

5.4.1 Construction materials

Construction materials should be fire-retardant and resistant to attack from substances with

which they could come into contact.

5.4.2 Walls

Local requirements such as for anti-static properties, corrosion, fire and weather resistance

shall be determined and appropriate material selected. Where equipment is supported from

the walls, appropriate reinforcement may be required. Wall penetrations should be minimized

and sealed where appropriate with materials meeting the relevant structural and safety

requirements (for example, watertight, fire-retardant, flame-resistant, mechanical strength,

etc.).

5.4.3 Floors and foundation

Floors should be non-porous, non-slip and resistant to materials likely to be spilled on them.

Requirements for floor cleaning, such as a slight slope and drain, should be considered. If a

floor drain is installed, it should be free draining to the outside of the AH, where the liquid can

be properly disposed of. Measures should be taken to prevent the entry of extraneous liquids.

Such measures can include raising the floor above the exterior grade level or providing a step

or ramp at the entrance or by appropriately sealing the house at the base.

5.4.4 Doors

Doors shall open outwards and be self-closing. Doors shall be fitted with a "panic bar" so that

they may be opened from the inside even if locked. The doors shall contain windows with

shatter-resistant safety glass. A second door or emergency exit such as a kick-out panel,

remote from the first, should be considered, if access to the main door can be impeded either

internally or externally.

NOTE Where the AH is part of a building, other safety considerations may override this.

5.4.5 Windows

Unless the AH is classified non-hazardous and is located in a non-hazardous area, any

windows should be fixed closed and vapour-tight.

5.4.6 Roof

The roof shall be designed for appropriate loads (for example, snow, equipment, people, etc.)

5.5 Equipment

5.5.1 Lighting

Lighting or emergency lights shall be operational at all times. Minimum light level should be

that required for maintenance work or the level specified by authorities having jurisdiction.

– 12 – 61285 © IEC:2004(E)

5.5.2 Communications

Where safety alarm(s) from the surrounding plant cannot be detected inside the AH, they shall

be repeated inside the AH. Consideration should be given to the installation of a verbal

communications link to a permanently manned location.

5.5.3 Piping and valves

Under normal operation, piping, containers and apparatus in the AH shall not have any

openings that would permit hazardous material to escape into the AH. The functions and

content of piping and valves shall be clearly marked. Isolation valves shall be external to the

AH. Streams for disposal should be collected in closed systems or transported to facilities

outside the AH. Any lines capable of delivering unacceptable high quantities of hazardous

material under fault conditions into the AH shall have automatic shut-off valves, flow

restrictors or excess flow preventers outside and before the point of entry into the AH.

5.5.4 Utilities

5.5.4.1 Hazardous quantities

The quantity of hazardous auxiliary materials should be restricted to the minimum necessary

to operate the analyser systems.

5.5.4.2 Hazard identification

Any fire, explosion or health hazard should be clearly identified.

5.5.4.3 Asphyxiants (for example nitrogen, carbon dioxide)

5.5.4.3.1 Any asphyxiant line connected into the AH shall have a flow restrictor or excess

flow preventer in the line outside the AH, to limit the flow to assist in meeting the

requirements of the ventilation system.

5.5.4.3.2 When a potential low oxygen hazard exists (for example, instrument air backed up

with nitrogen) in the AH, the air inside the AH has to be monitored by low oxygen detectors.

They shall be installed with fail-safe alarms, both locally and in a remote permanently manned

location.

5.5.4.4 Hazardous auxiliary supplies should be stored outside the AH.

5.5.4.5 If the storage of auxiliary gases or calibration gases in pressurized cylinders inside

the AH is unavoidable, they shall be protected against rise in pressure when heated by fire.

This can be accomplished by storage in insulated and continuously ventilated cabinets or

through rupture disks and relief valves, which are installed at the cylinders immediately ahead

of the pressure-reducing stations. Gases escaping from the rupture discs shall be safely

carried to the outside of the AH. Exceptions to these measures may be made in agreement

with local authorities.

5.5.5 Fire extinguishers

An appropriate fire extinguisher should be located at the door(s)

5.5.6 Ventilation

Ventilation may be installed for climate control, corrosion protection, protection from

asphyxiation, explosion protection (see Clause 6) and/or personnel safety (see Clause 7).

61285 © IEC:2004(E) – 13 –

5.5.6.1 General

All ventilation shall provide a minimum of five air changes per hour. The ventilation air source

should be preferably in a non-hazardous area. If this is not available, Zone 2 air may be used

if the equipment installed in the AH is suitable for a Zone 2 or worse location, or it is

monitored at the intake point by means of one or more gas detectors, which discontinue

ventilation airflow when a value of 20 % or less of LEL is exceeded.

Dust filtration should be installed in the ventilation inlet.

5.5.6.2 Temperature

For safe performance of the monitoring instruments and alarm systems temperature shall be

kept in their recommended operating range

5.6 Labelling/instructions/documentation

5.6.1 Entrance

An indelible marked sign indicating the type of hazard is to be posted on the entrance to the

AH stating that entering the AH is allowed only for authorized personnel. Information as to the

organization responsible for the AH is to be included on the sign (name, department,

telephone number, etc.).

5.6.2 Alarms

If required, the following AH safety-related local alarms/indicators shall be generated and dis-

played as applicable:

a) ventilation failure (purge and/or overpressure);

b) flammable gas (concentration shall not exceed 20 % LEL);

c) toxic gas (concentration exceeds allowable levels);

d) oxygen deficiency

NOTE Oxygen concentration needs to be above 18 % or statutory requirements;

e) fire or smoke;

f) automatic extinguisher released;

g) gas/fire detection instrument fault.

NOTE The relative densities of the hazard(s) and the air flow dictate the placement of flammable or toxic gas

detectors. It may be necessary to detect light gases near the roof level and heavy gases near the floor level.

NOTE The records from the gas detectors provide assurance that the house interior requirements have been met.

Alarms shall be reported at the following locations:

a) inside the AH a common audible alarm or a highly noticeable visual light (for example,

strobe lamp);

b) at a continuously manned process location;

c) discrete alarm lamps shall be provided outside near the entrance of the AH for toxic,

asphyxiant, and LEL and should be considered for other alarms.

NOTE A positive indication of a non-hazardous condition is recommended.

5.6.3 Safety procedures

The AH safety procedures shall be documented and be kept in a readily accessible location

inside the AH. Any person working in the AH shall have adequate training for this location.

– 14 – 61285 © IEC:2004(E)

5.6.4 Additional data

The following items, as appropriate, should be included in th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...