IEC 62021-3:2014

(Main)Insulating liquids - Determination of acidity - Part 3: Test methods for non-mineral insulating oils

Insulating liquids - Determination of acidity - Part 3: Test methods for non-mineral insulating oils

IEC 62021-3:2014 describes two procedures for the determination of the acidity of unused and used electrical non-mineral insulating oils. Method A is potentiometric titration and Method B is colourimetric titration. The method may be used to indicate relative changes that occur in non-mineral insulating oil during use under oxidizing conditions regardless of the colour or other properties of the resulting non-mineral oil. The acidity can be used in the quality control of unused non-mineral insulating oil. As a variety of oxidation products present in used non-mineral insulating oil contribute to acidity and these products vary widely in their corrosion properties, the test cannot be used to predict corrosiveness of non-mineral insulating oil under service conditions.

Liquides isolants - Détermination de l'acidité - Partie 3: Méthodes d'essai pour les huiles non minérales isolantes

L'IEC 62021-3:2014 décrit deux procédures pour la détermination de l'acidité des huiles non minérales isolantes électriques neuves et usagées. La Méthode A est le titrage potentiométrique et la Méthode B est le titrage colorimétrique. La méthode peut être utilisée pour indiquer des modifications relatives qui se produisent dans une huile non minérale isolante pendant son utilisation par oxydation, indépendamment de la couleur ou d'autres propriétés de l'huile non minérale résultante. L'acidité peut être utilisée dans le contrôle de la qualité de l'huile non minérale isolante neuve. Comme divers produits d'oxydation présents dans l'huile non minérale isolante usagée contribuent à l'acidité et comme ces produits varient largement du point de vue de leurs propriétés de corrosion, l'essai ne peut pas être utilisé pour prévoir la corrosivité d'une huile non minérale isolante dans des conditions de service.

General Information

- Status

- Published

- Publication Date

- 18-Mar-2014

- Technical Committee

- TC 10 - Fluids for electrotechnical applications

- Drafting Committee

- WG 17 - TC 10/WG 17

- Current Stage

- PPUB - Publication issued

- Start Date

- 19-Mar-2014

- Completion Date

- 28-Feb-2014

Overview

IEC 62021-3:2014 is an internationally recognized standard published by the International Electrotechnical Commission (IEC) that specifies test methods for determining the acidity of non-mineral electrical insulating oils. This standard is critical for quality control and monitoring aging in both unused and used non-mineral insulating oils, particularly under oxidizing service conditions. The standard details two main analytical procedures-potentiometric titration and colourimetric titration-to measure acidity which affects oil performance but does not predict corrosiveness directly.

Key Topics

Scope and Purpose

IEC 62021-3:2014 focuses exclusively on non-mineral insulating oils, providing reliable methods to quantify acidity changes caused by oxidation and other processes during electrical equipment operation.Test Methods

Method A: Potentiometric Titration

This automated method uses an electrode system to precisely measure the acidity by detecting pH changes during titration with an alcoholic potassium hydroxide solution. It includes steps for calibration, electrode maintenance, and calculation ensuring accuracy and repeatability.Method B: Colourimetric Titration

Based on visual detection, this method uses an indicator dye (alkali blue 6B) and cobalt nitrate to identify the titration endpoint. It provides an economical and simpler alternative for acidity determination while maintaining reliability.

Sampling and Preparation

Detailed guidance on collecting oil samples to ensure representative and contamination-free testing is provided, alongside preparation and standardization of reagents and calibration of equipment.Analysis and Reporting

Clear instructions on carrying out blank titrations, sample titrations, calculation of acidity values, and documenting results are included to support consistent communication and quality records.Limitations

The standard explicitly notes that acidity measurement indicates relative changes in oil condition but cannot reliably substitute for corrosiveness evaluation due to the complex nature of oxidation products.

Applications

Electrical Equipment Maintenance

Utilities and industries use the IEC 62021-3 methods to monitor insulation oil condition in transformers, capacitors, and other high-voltage equipment to detect early degradation.Quality Control of Insulating Oils

Manufacturers of non-mineral insulating oils apply these standardized titration procedures to ensure product conformity before release, verifying acidity limits are met.Research and Development

Laboratories working on insulating oil formulations or degradation studies utilize these methods to analyze acidity changes during accelerated aging or service exposure tests.Compliance and Standardization

Organizations adhere to IEC 62021-3 to align with international best practices, facilitating consistency in testing across different labs and countries.

Related Standards

- IEC 62021-1 – Test methods for acidity of mineral insulating oils, complementary to Part 3 focused on non-mineral oils.

- IEC 60422 – Guidelines for mineral insulating oil management, covering monitoring and maintenance practices.

- ISO 3104 – Similar testing related to petroleum products and lubricants acidity, useful for cross-reference.

- IEC 60475 – Standard on methods for measuring interfacial tension, often used alongside acidity tests for oil condition assessment.

By following IEC 62021-3:2014, electrical and oil industry professionals can ensure precise acidity measurement in non-mineral insulating oils, aiding in effective maintenance, quality assurance, and operational safety in electrical installations worldwide. This standard supports enhancing asset lifespan and reliability by providing internationally harmonized test techniques for non-mineral oil acidity determination.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 62021-3:2014 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Insulating liquids - Determination of acidity - Part 3: Test methods for non-mineral insulating oils". This standard covers: IEC 62021-3:2014 describes two procedures for the determination of the acidity of unused and used electrical non-mineral insulating oils. Method A is potentiometric titration and Method B is colourimetric titration. The method may be used to indicate relative changes that occur in non-mineral insulating oil during use under oxidizing conditions regardless of the colour or other properties of the resulting non-mineral oil. The acidity can be used in the quality control of unused non-mineral insulating oil. As a variety of oxidation products present in used non-mineral insulating oil contribute to acidity and these products vary widely in their corrosion properties, the test cannot be used to predict corrosiveness of non-mineral insulating oil under service conditions.

IEC 62021-3:2014 describes two procedures for the determination of the acidity of unused and used electrical non-mineral insulating oils. Method A is potentiometric titration and Method B is colourimetric titration. The method may be used to indicate relative changes that occur in non-mineral insulating oil during use under oxidizing conditions regardless of the colour or other properties of the resulting non-mineral oil. The acidity can be used in the quality control of unused non-mineral insulating oil. As a variety of oxidation products present in used non-mineral insulating oil contribute to acidity and these products vary widely in their corrosion properties, the test cannot be used to predict corrosiveness of non-mineral insulating oil under service conditions.

IEC 62021-3:2014 is classified under the following ICS (International Classification for Standards) categories: 29.040.10 - Insulating oils. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62021-3:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62021-3 ®

Edition 1.0 2014-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Insulating liquids – Determination of acidity –

Part 3: Test methods for non-mineral insulating oils

Liquides isolants – Détermination de l’acidité –

Partie 3: Méthodes d’essai pour les huiles non minérales isolantes

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 62021-3 ®

Edition 1.0 2014-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Insulating liquids – Determination of acidity –

Part 3: Test methods for non-mineral insulating oils

Liquides isolants – Détermination de l’acidité –

Partie 3: Méthodes d’essai pour les huiles non minérales isolantes

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX T

ICS 29.040.10 ISBN 978-2-8322-1404-6

– 2 – IEC 62021-3:2014 © IEC 2014

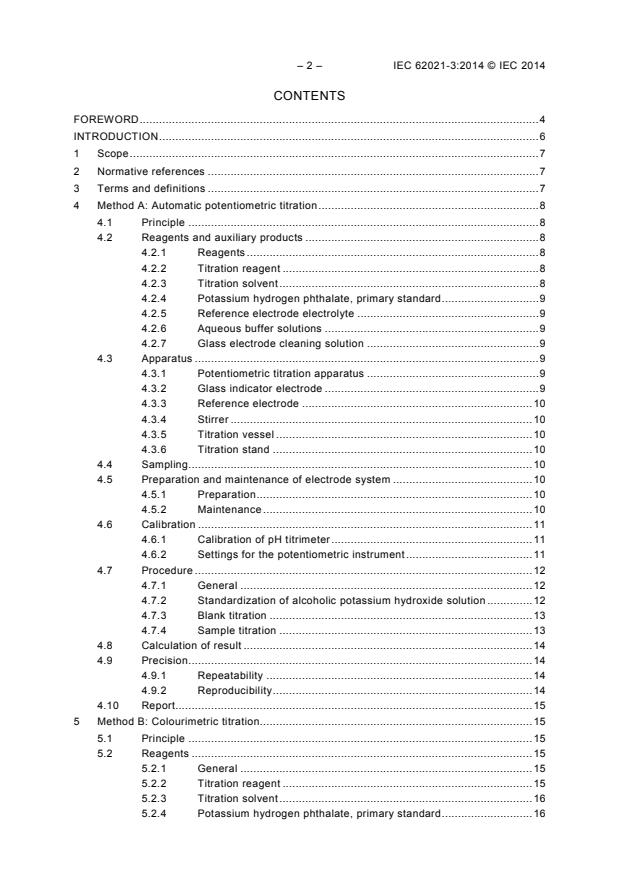

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Method A: Automatic potentiometric titration . 8

4.1 Principle . 8

4.2 Reagents and auxiliary products . 8

4.2.1 Reagents . 8

4.2.2 Titration reagent . 8

4.2.3 Titration solvent . 8

4.2.4 Potassium hydrogen phthalate, primary standard . 9

4.2.5 Reference electrode electrolyte . 9

4.2.6 Aqueous buffer solutions . 9

4.2.7 Glass electrode cleaning solution . 9

4.3 Apparatus . 9

4.3.1 Potentiometric titration apparatus . 9

4.3.2 Glass indicator electrode . 9

4.3.3 Reference electrode . 10

4.3.4 Stirrer . 10

4.3.5 Titration vessel . 10

4.3.6 Titration stand . 10

4.4 Sampling. 10

4.5 Preparation and maintenance of electrode system . 10

4.5.1 Preparation . 10

4.5.2 Maintenance . 10

4.6 Calibration . 11

4.6.1 Calibration of pH titrimeter . 11

4.6.2 Settings for the potentiometric instrument . 11

4.7 Procedure . 12

4.7.1 General . 12

4.7.2 Standardization of alcoholic potassium hydroxide solution . 12

4.7.3 Blank titration . 13

4.7.4 Sample titration . 13

4.8 Calculation of result . 14

4.9 Precision . 14

4.9.1 Repeatability . 14

4.9.2 Reproducibility . 14

4.10 Report. 15

5 Method B: Colourimetric titration. 15

5.1 Principle . 15

5.2 Reagents . 15

5.2.1 General . 15

5.2.2 Titration reagent . 15

5.2.3 Titration solvent . 16

5.2.4 Potassium hydrogen phthalate, primary standard . 16

5.2.5 Standard hydrochloric acid solution . 16

5.2.6 Alkali blue 6B indicator solution . 16

5.2.7 Cobalt nitrate solution . 16

5.3 Apparatus . 16

5.3.1 Titration vessel . 16

5.3.2 Stirrer . 16

5.3.3 Burette . 16

5.4 Sampling. 16

5.5 Procedure . 17

5.5.1 General . 17

5.5.2 Standardization of alcoholic potassium hydroxide solution . 17

5.5.3 Blank titration . 17

5.5.4 Sample titration . 18

5.6 Calculation of result . 18

5.7 Precision . 18

5.7.1 Repeatability . 18

5.7.2 Reproducibility . 19

5.8 Report. 19

Annex A (informative) Determination of acidity in non-mineral electrical insulating oils

by photometric titration . 20

A.1 Principle . 20

A.2 Reagents and solvents . 20

A.3 Preparation of titration solutions and solvents . 20

A.3.1 Potassium hydroxide alcoholic solution (0,01 mol/l) . 20

A.3.2 Potassium hydrogen phthalate solution (0,01 mol/l) . 20

A.3.3 Titration solvent . 21

A.4 Apparatus . 21

A.4.1 Volumetric titrator . 21

A.4.2 Titration vessel . 21

A.4.3 Titration stand . 21

A.4.4 Stirrer . 21

A.4.5 Recorder/printer . 21

A.4.6 Photometric sensor . 21

A.5 Sampling. 22

A.6 Procedure . 22

A.6.1 Preparation and maintenance of the titration system . 22

A.6.2 Determination of acidity of the titration solvent (blank titration) . 22

A.6.3 Determination of molarity of the potassium hydroxide alcoholic

solution (0,01 mol/l) . 22

A.6.4 Titration of soluble acidity in the oil sample. 23

A.7 Calculation of result . 23

A.8 Report. 23

Figure 1 – Potentiometric titration curve . 12

Figure A.1 – Molecular structure of para-naphtholbenzein indicator in a) acidic media

and b) basic media . 24

Figure A.2 – UV spectra of para-naphtholbenzein indicator in toluene/2-propanol/water

solution in acidic media (curve a) and basic media (curve b) . 24

– 4 – IEC 62021-3:2014 © IEC 2014

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

INSULATING LIQUIDS – DETERMINATION OF ACIDITY –

Part 3: Test methods for non-mineral insulating oils

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62021-3 has been prepared by IEC technical committee 10: Fluids

for electrotechnical applications.

The text of this standard is based on the following documents:

FDIS Report on voting

10/936/FDIS 10/942/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62021 series, published under the general title Insulating liquids –

Determination of acidity, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

· reconfirmed,

· withdrawn,

· replaced by a revised edition, or

· amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

– 6 – IEC 62021-3:2014 © IEC 2014

INTRODUCTION

Health and safety

This International Standard does not purport to address all the safety problems associated

with its use. It is the responsibility of the user of the standard to establish appropriate health

and safety practices and determine the applicability of regulatory limitations prior to use.

The insulating liquids which are the subject of this standard should be handled with due

regard to personal hygiene. Direct contact with the eyes may cause slight irritation. In the

case of eye contact, irrigation with copious quantities of clean running water should be carried

out and medical advice sought.

Some of the procedures referenced in this standard involve the use of processes that could

lead to a hazardous situation. Attention is drawn to the relevant standard for guidance.

Environment

This standard involves non-mineral insulating oils, chemicals, used sample containers and

fluid-contaminated solids. The disposal of these items should be carried out according to local

regulations with regard to their impact on the environment. Every precaution should be taken

to prevent the release into the environment of these oils.

INSULATING LIQUIDS – DETERMINATION OF ACIDITY –

Part 3: Test methods for non-mineral insulating oils

1 Scope

This part of IEC 62021 describes two procedures for the determination of the acidity of

unused and used electrical non-mineral insulating oils. Method A is potentiometric titration

and Method B is colourimetric titration.

NOTE 1 In unused and used non-mineral insulating oils, the constituents that may be considered to have acidic

characteristics include organic acids, phenolic compounds, some oxidation products, resins, organometallic salts

and additives.

The method may be used to indicate relative changes that occur in non-mineral insulating oil

during use under oxidizing conditions regardless of the colour or other properties of the

resulting non-mineral oil.

The acidity can be used in the quality control of unused non-mineral insulating oil.

As a variety of oxidation products present in used non-mineral insulating oil contribute to

acidity and these products vary widely in their corrosion properties, the test cannot be used to

predict corrosiveness of non-mineral insulating oil under service conditions.

NOTE 2 The acidity results obtained by potentiometric test method may or may not be numerically the same as

those obtained by colourimetric methods, but they are generally of the same magnitude.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60475, Method of sampling insulating liquids

ISO 5725 (all parts), Accuracy (trueness and precision) of measurement methods and results

ISO 6619, Petroleum products and lubricants – Neutralization number – Potentiometric

titration method

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

acidity

quantity of base, expressed in milligrams of potassium hydroxide per gram of sample,

required to titrate potentiometrically or colourimetrically a test portion in a specified solvent to

the end point

3.2

non-mineral insulating oil

insulating liquid, not derived from petroleum crudes

– 8 – IEC 62021-3:2014 © IEC 2014

3.3

unused oil

non-mineral insulating oil that has not been used in, or been in contact with, electrical

equipment

4 Method A: Automatic potentiometric titration

4.1 Principle

Any acid-base titration may be conducted potentiometrically. The test portion of the insulating

fluid is dissolved in solvent and titrated potentiometrically with alcoholic potassium hydroxide

using a glass-indicating electrode and a reference electrode. The potential difference (which

can be expressed as pH after calibration) is measured after the successive addition of known

increments of alcoholic potassium hydroxide.

Where a strong point of inflection is detected from the first derivative of the titration curve, this

should be used as the end point. If only a weak inflection point is present, the potential

difference corresponding to pH of 11,5 has been found more reproducible and less

instrument-dependent.

4.2 Reagents and auxiliary products

4.2.1 Reagents

Only reagents of recognized analytical grade and de-ionized water or water of equivalent

purity shall be used.

4.2.2 Titration reagent

Standard alcoholic solution between 0,01 mol/l and 0,05 mol/l potassium hydroxide (KOH).

EXAMPLE Preparation of 0,01 mol/l potassium hydroxide in 2-propanol.

Add 0,6 g of potassium hydroxide to 1 000 ml ± 10 ml of 2-propanol. Boil gently for 10 min to

effect solution. Cool and stopper the flask.

Allow the solution to stand in the dark for 2 days and then filter the supernatant liquid through

a 5 µm membrane filter. Store in a suitable amber glass bottle.

The concentration of this solution is approximately 0,01 mol/l and shall be standardized as

described in 4.7.2.

Store in such a manner that the solution is protected from atmospheric carbon dioxide by

means of a guard tube containing soda-lime absorbent and in such a way that it does not

come into contact with cork, rubber or saponifiable stopcock grease.

Commercial alcoholic potassium hydroxide solution may be used, if necessary diluting to

0,01 mol/l with 2-propanol. This shall be standardized as described in 4.7.2.

NOTE 1 For oils with high acidity, which may give an extended titration time, it may be helpful to carry out a pre-

test using 0,1 mol/l potassium hydroxide titrant to determine a suitable titrant concentration.

NOTE 2 For periodic tests on equipment in service, faster titration may be achieved by the use of 0,05 or

0,1 mol/l potassium hydroxide by agreement between the laboratory and the equipment owner, although this may

result in poorer precision and detection limit.

4.2.3 Titration solvent

The titration solvent is as follows:

– 2-propanol (isopropanol, IPA), pure.

2-propanol is the preferred solvent. It should be noted that the use of other solvents might

change the dissociation potential and thus the neutralisation point.

4.2.4 Potassium hydrogen phthalate, primary standard

This should be dried before use for 2 h at 105 °C.

A 0,1 mol/l solution of hydrochloric acid in de-ionized water, prepared as in ISO 6619, may be

used. Other acids may be used, e.g. benzoic acid, provided they are certified against a

primary standard.

4.2.5 Reference electrode electrolyte

Prepare a solution of potassium chloride in de-ionized water, or lithium chloride in ethanol, at

the concentration recommended by the electrode manufacturer. Commercially available

solutions may be used where available.

4.2.6 Aqueous buffer solutions

Buffer solutions of suitable pH for calibration of electrodes, for example, pH 4, pH 7 and

pH 11 or close to pH 12.

4.2.7 Glass electrode cleaning solution

Weigh 8 g of ammonium peroxydisulfate into a glass beaker. Carefully add 100 ml of 98 %

sulphuric acid and gently stir. Before use, the solution should be left overnight for the solid to

dissolve completely.

WARNING Ammonium peroxydisulfate is a strong oxidizing agent. Sulphuric acid is a strong

corrosive agent. Handle carefully.

Commercially available cleaning solutions as recommended by the electrode manufacturer

may be used.

4.3 Apparatus

4.3.1 Potentiometric titration apparatus

An automatic pH titrimeter or an instrument for a potentiometric titration capable of titrating to

a fixed end-point using either variable or fixed titrant increments.

The instrument shall be protected from stray electrical fields so that no change of the reading

is produced by touching any part of the system with a grounded lead.

An automatic burette with a dispensing accuracy of ±0,005 ml or better is required.

A reservoir for the titrating solution. It should be fitted with a guard tube containing soda lime

or other carbon dioxide absorbing material.

4.3.2 Glass indicator electrode

A glass electrode specifically designed for non-aqueous titrations is recommended.

The electrode shall be connected to the potentiometer by means of a suitably screened cable

such that the resistance between the screening and the entire length of the electrical

connection is greater than 50 000 MΩ.

– 10 – IEC 62021-3:2014 © IEC 2014

4.3.3 Reference electrode

The electrode shall be made of glass and shall be reserved for non-aqueous titrations.

Certain alternative electrode-electrolyte combinations have been found to give satisfactory

results, although the precision using these alternatives has not been determined. Combined

electrodes may be used provided they otherwise conform to this standard and have at least a

similar speed of response.

4.3.4 Stirrer

The stirrer should have a variable speed and be fitted with a propeller, paddle or magnetic bar

of chemically inert surface material. It shall be electrically grounded to avoid any change in

the meter reading during the course of the titration.

4.3.5 Titration vessel

This should be as small as possible, sufficient to contain the solvent, sample, stirrer and

electrodes and be inert to the reagents. Glass vessels are preferred to prevent build-up of

electrostatic charge.

4.3.6 Titration stand

This should comprise a suitable stand to support the beaker, electrodes, stirrer and burette.

4.4 Sampling

Samples shall be taken following the procedure given in IEC 60475.

Ensure that the test portion is representative by thoroughly mixing, as any sediment present

may be acidic or have adsorbed acidic material from the liquid phase.

4.5 Preparation and maintenance of electrode system

4.5.1 Preparation

Although electrodes are not particularly fragile, they should be handled carefully at all times.

Rinse the electrodes with 2-propanol and finally with de-ionized water.

Following each titration immerse the electrodes in de-ionized water to remove any surplus

electrolyte adhering to the outside of the electrode and allow excess water to drain off. The

immersion time should be sufficient to prevent any memory effects on subsequent titrations.

When in use, any plug that is present on the reference electrode should be removed and the

electrolyte level in the electrode kept above that of liquid in the titration vessel to prevent

entry of contaminants into the electrode.

4.5.2 Maintenance

4.5.2.1 Glass electrode

Clean the electrode weekly by immersing the tip in 0,1 mol/l hydrochloric acid for 12 h

followed by washing with de-ionized water. If more aggressive cleaning is required, immerse

the electrode tip in cleaning solution (see 4.2.7) for 5 min and follow this by thorough washing

with de-ionized water. This treatment should be carried out on a monthly basis when the

electrode is in regular use.

When not in use, immerse the lower half of the electrode in de-ionized water. Do not allow the

electrode to dry out. If this occurs it may be possible to reactivate by immersing in cleaning

solution (see 4.2.7) as detailed above.

4.5.2.2 Reference electrode

Drain and fill the electrode with electrolyte solution (see 4.2.5) according to the

manufacturer’s recommendations. When using the sleeve-type electrode, carefully remove the

ground-glass sleeve and thoroughly wipe both ground-glass sleeve surfaces. Replace the

sleeve loosely and allow a few drops of electrolyte to drain through to flush the ground-glass

joint and to wet the ground surfaces thoroughly with electrolyte. Set the sleeve in place and

refill with electrolyte (see 4.2.5).

When not in use, immerse the electrode in electrolyte (see 4.2.5) keeping the level of the

electrolyte in the electrode above that of the immersion fluid level. The filling apertures should

be covered during storage.

The electrode should be cleaned as necessary (at least weekly) by flushing with de-ionized

water.

4.6 Calibration

4.6.1 Calibration of pH titrimeter

Determine the pH reading for the buffer solutions (see 4.2.6) on a daily basis. The value of

the titration end-point of pH 11,5 is then extrapolated and shall be entered into the

instrumental programme.

The linearity and slope of the potentiometric titrator over the pH range 4 to 11 should comply

with the electrode manufacturer’s tolerances.

Temperature correction shall be applied.

Owing to the significant effect of temperature on the pH of the buffer solutions (see 4.2.6), it

is desirable to keep the temperature as close to the buffer manufacturer's calibration

temperature as possible.

4.6.2 Settings for the potentiometric instrument

Set a potential for an end point titration (usually between –50 mV and –100 mV), which allows

the recording of the whole titration curve. For this purpose, use the titration procedure as

described in 4.7.3 with the addition of 100 µl of 0,1 mol/l hydrochloric acid (see 4.2.4). See

Figure 1.

– 12 – IEC 62021-3:2014 © IEC 2014

DET U001

400,000

350,000

300,000

350,250,000000

200,000

150,000

100,000

50,000

0,000

–50,000

0,000 0,050 0,100 0,150 0,200 0,250 0,300

V/ml

IEC 043714

Key

Black dotted line first derivative

Red dotted line exact volume of titrant added (ml).

Figure 1 – Potentiometric titration curve

Most instruments calculate automatically the first derivative of the potential titration curve and

the exact volume of titrant added.

4.7 Procedure

4.7.1 General

Set up the apparatus in accordance with the manufacturer’s instructions.

Rinse and fill the burette with an alcoholic solution of potassium hydroxide between 0,01 mol/l

and 0,05 mol/l (see 4.2.2).

Standardize the 0,01 mol/l or 0,05 mol/l alcoholic potassium hydroxide solution at least every

two weeks against potassium hydrogen phthalate (see 4.7.2).

Carry out a blank titration on the solvent (see 4.7.3) each day and after changing to a fresh

batch of solvent.

Prepare and titrate a sample of the non-mineral insulating oil against alcoholic potassium

hydroxide (see 4.7.4).

4.7.2 Standardization of alcoholic potassium hydroxide solution

Standardize the alcoholic potassium hydroxide solution potentiometrically against 0,1 g to

0,16 g of the potassium hydrogen phthalate, weighed to an accuracy of 0,0002 g and

dissolved in approximately 100 ml of carbon dioxide free water.

Depending on the capacity of the titration vessel, the amount of potassium hydrogen

phthalate may need to be less than 0,1 g, with a smaller volume of water used to dissolve it.

The volume of water shall be enough to dissolve the phthalate and to ensure the complete

immersion of the electrode bulb.

U/mV

Calculate the molarity to the nearest 0,0005, expressed as mol/l, using the following formula.

1000 × m × p

Molarity =

204,23 ×V

(1)

where

m is the mass of potassium hydrogen phthalate in g;

p is the purity of potassium hydrogen phthalate;

204,23 is the molecular weight of potassium hydrogen phthalate, in g/mol;

V is the volume of alcoholic KOH solution (see 4.2.2) used to titrate the solution, in ml.

Alternatively, standard 0,1 mol/l acid may be used to standardize the alcoholic KOH (see

4.2.4).

V × M

A A

Molarity =

V

B

(2)

where

V is the volume of 0,1 mol/l standard hydrochloric acid used to titrate the solution, in ml;

A

M is the molarity of the standard hydrochloric acid in mol/l;

A

V is the volume of potassium hydroxide solution, in ml.

B

4.7.3 Blank titration

Perform a blank titration in duplicate as in 4.7.4, on 20 ml ± 0,1 ml of the solvent (see 4.2.3)

daily and after changing to a fresh batch of solvent.

Blank titrations shall be continued until two consecutive titrations differ by no more than

0,005 ml, based on 20 ml of solvent and the mean of these is calculated as V (see 4.8).

Where a higher solvent volume than 20 ml is required because of apparatus constraints, the

same volume of solvent shall be used for the sample titration.

High values may arise from carbon dioxide absorption or inherent 2-propanol acidity. If the

blank value is greater than 0,06 ml (based on 20 ml of solvent), steps shall be taken to

remove the cause of the high values.

4.7.4 Sample titration

Prepare the sample for titration as described in 4.4 and weigh 5 g ± 0,1 g of the non-mineral

insulating oil to the nearest 0,01 g into the titration vessel. Add 20 ml ± 0,1 ml of titration

solvent (see 4.2.3).

The amount of solvent added may depend on the testing device used, the volume and shape

of vessel, etc. Add an amount of titration solvent sufficient to ensure the complete immersion

of electrode’s bulb.

Place the titration vessel on the titration stand and stir the solution until the sample has

dissolved and the pH reading is constant, taking care to limit the speed of stirring to avoid

spattering and/or stirring air into the solution.

– 14 – IEC 62021-3:2014 © IEC 2014

Carry out the titration with a solution between 0,01 mol/l and 0,05 mol/l potassium hydroxide,

following the instrument manufacturer’s recommendations, to an end-point of pH 11,5 or to

the determined end-point potential (see 4.6.2).

NOTE Dynamic titrant addition is preferred to reduce the overall analysis time.

If the titration time exceeds 15 min, it may be necessary to prevent carbon dioxide absorption

by blanketing the solution with nitrogen.

On completion of the titration, record the burette reading V (see 4.8) at the pH reading of 10

or determine the value of the first derivative of the potentiometric titration curve (see Figure

1).

Rinse the electrodes and burette tip with titration solvent (see 4.2.3). Re-hydrate the glass

electrode by immersing the bulb in de-ionized water (see 4.5.1) and allow excess water to

drain off. Where oxidized oil is analysed, the electrode should be immersed in de-ionized

water containing a few drops of hydrochloric acid, followed by rinsing in de-ionized water.

If further titrations are not to be carried out immediately, the electrodes shall be stored in

the de-ionized water.

4.8 Calculation of result

Calculate the acidity to the nearest 0,01, expressed as mg KOH/g of oil using the following

formula:

(V −V )× M ×56,1

1 0

Acidity =

m

(3)

where

V is the volume of alcoholic KOH solution (see 4.2.2) used to titrate the test portion, in ml;

V is the volume of alcoholic KOH solution (see 4.2.2) used for blank titration, in ml;

M is the molarity of alcoholic KOH solution (see 4.2.2), in mol/l;

56,1 is the molecular weight of potassium hydroxide, in g/mol;

m is the mass of the test portion used in g.

4.9 Precision

4.9.1 Repeatability

The difference between successive test results obtained by the same operator with the same

apparatus under constant operating conditions on identical test material would, in the long

run, in the normal and correct operation of the test method, exceed the values shown below

only in one case in 20:

– unused synthetic esters and silicones: 6 % of the mean value;

– unused natural esters: 9 % of the mean value;

– used oils: 12 % of the mean value.

NOTE The repeatability values for unused oils only apply where the result is significantly above the quantification

limit, which has been established as 0,014 mg KOH/g oil.

4.9.2 Reproducibility

The difference between two single and independent results obtained by different operators

working in different laboratories on identical test material would, in the long run, in the normal

and correct operation of the test method, exceed the values shown below only in one case in

20:

– unused oils: 28 % of the mean value;

– used oils: 35 % of the mean value.

NOTE Repeatability and reproducibility limits were established in accordance with ISO 5725 for used oil. Those

for unused oil have been taken from ISO 6619.

4.10 Report

The test report shall contain at least the following information:

– the type and identification of the product tested;

– a reference to this standard;

– the result of the test (see 4.8) expressed to the nearest 0,01 mg KOH/g of oil;

– any deviation, by agreement or otherwise, from the procedure specified;

– the date of the test.

5 Method B: Colourimetric titration

5.1 Principle

The test portion is dissolved in a specified solvent and titrated colourimetrically with alcoholic

potassium hydroxide to a specified colour using Alkali Blue 6B indicator.

NOTE Colourimetric titration may not be suitable to highly coloured oils.

5.2 Reagents

5.2.1 General

Only reagents of recognized analytical grade and de-ionized water or water of equivalent

purity shall be used.

5.2.2 Titration reagent

Standard alcoholic solution between 0,01 mol/l and 0,05 mol/l potassium hydroxide (KOH).

EXAMPLE Preparation of 0,01 mol/l potassium hydroxide in 2-propanol.

Add 0,6 g of potassium hydroxide to 1 000 ml ± 10 ml of 2-propanol. Boil gently for 10 min to

effect solution. Cool and stopper the flask.

Allow the solution to stand in the dark for 2 days and then filter the supernatant liquid through

a 5 µm membrane filter. Store in a suitable amber glass bottle.

The concentration of this solution is approximately 0,01 mol/l and shall be standardized as

described in 5.5.2.

Commercial alcoholic potassium hydroxide solution may be used, if necessary diluting to

0,01 mol/l with 2-propanol. This shall be standardized as described in 5.5.2.

Store and use in such a manner that the solution is protected from atmospheric carbon

dioxide and in such a way that it does not come into contact with cork, rubber or saponifiable

stopcock grease. The solution may be protected by inert gas or by means of a guard tube

containing soda-lime absorbent.

NOTE 1 For oils with high acidity, which may give an extended titration time, it may be helpful to carry out a pre-

test using 0,1 mol/l potassium hydroxide titrant to determine a suitable titrant concentration.

– 16 – IEC 62021-3:2014 ©

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...