IEC 62425:2007

(Main)Railway applications - Communication, signalling and processing systems - Safety related electronic systems for signalling

Railway applications - Communication, signalling and processing systems - Safety related electronic systems for signalling

Applies to all safety-related railway signalling systems/sub-system/equipment. The hazard analysis and risk assessment processes defined in IEC 62278 and this standard are necessary for all railway signalling systems/sub-systems/equipment, in order to identify any safety requirements.

Applications ferroviaires - Systèmes de signalisation, de télécommunications et de traitement - Systèmes électroniques de sécurité pour la signalisation

Est applicable à tous les systèmes/sous-systèmes/équipements de signalisation ferroviaire relatifs à la sécurité. Les processus d'analyse des situations dangereuses et d'évaluation des risques définis dans la CEI 62278 et dans la présente norme sont nécessaires pour tous les systèmes/sous-systèmes/équipements de signalisation ferroviaire, de manière à identifier les exigences de sécurité.

General Information

- Status

- Published

- Publication Date

- 17-Sep-2007

- Technical Committee

- TC 9 - Electrical equipment and systems for railways

- Current Stage

Relations

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Referred By

EN 62267:2009 - Railway applications - Automated urban guided transport (AUGT) - Safety requirements - Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 05-Sep-2023

IEC 62425:2007 Overview

IEC 62425:2007 is an international standard developed by the International Electrotechnical Commission (IEC) focused on railway applications, specifically addressing communication, signalling, and processing systems. Its core objective is to establish safety requirements for electronic systems used in railway signalling that are safety-related. This standard is applicable to all railway signalling systems, sub-systems, and equipment where safety is critical.

The standard mandates the application of hazard analysis and risk assessment processes, in alignment with IEC 62278, to identify and manage safety requirements systematically. It provides a comprehensive framework to ensure that safety-related electronic systems operate with the highest reliability and meet stringent safety acceptance and approval criteria.

Key Topics in IEC 62425

Scope and Definitions

Covers all safety-related railway signalling equipment, ensuring a unified understanding of terms and safety concepts.Safety Case and Management

Details requirements for the safety case, including evidence of quality and safety management across the lifecycle of signalling systems.Safety Lifecycle and Organisation

Outlines lifecycle phases such as hazard identification, design, validation, operation, maintenance, and decommissioning, supported by safety organization structures.Safety Integrity Levels (SILs)

Defines safety integrity levels essential for assessing risk and ensuring appropriate safety measures are implemented.Safety Acceptance and Approval Process

Describes structured processes for achieving safety acceptance, including documentation, safety reviews, and post-approval considerations.Hazard and Risk Assessment

Focuses on systematic processes to identify hazards, assess risks, and apply control measures to maintain safety integrity.Technical and Functional Safety Requirements

Specifies detailed technical requirements and failure mode identification to reduce systematic and random faults.

Practical Applications of IEC 62425

IEC 62425 provides practical benefits for designers, manufacturers, and operators of railway signalling systems:

Safety Assurance

Assures railway operators and stakeholders that signalling systems meet internationally recognized safety standards, minimizing risks to passengers and infrastructure.Design and Development Guidance

Supports the integration of safety from the initial design through to development, verification, validation, and deployment of signalling equipment.Lifecycle Safety Management

Facilitates comprehensive safety management, including documentation and hazard control, throughout system operation and maintenance.Compliance and Approval

Helps organizations prepare safety cases and achieve the necessary approvals for deploying safety-related signalling systems.Risk Mitigation

Promotes the use of SILs and safety techniques to handle fault detection, system failures, and hazardous conditions effectively.

These applications contribute to safer railway networks by enforcing rigorous electronic system safety standards.

Related Standards and References

IEC 62425 works closely alongside other IEC and international standards to ensure harmonized safety management in railway applications:

IEC 62278: Railway Applications – Specification and Demonstration of Reliability, Availability, Maintainability, and Safety (RAMS)

IEC 61508: Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems

IEC 61513: Nuclear Power Plants – Instrumentation and Control Important to Safety

ISO/IEC 27001: Information Security Management, relevant for managing data integrity in communication systems

Industry Best Practices: Includes guidance on safety lifecycle management, hazard analysis, and software safety assurance.

By referencing and complementing these standards, IEC 62425 ensures that safety-related electronic signalling systems meet broad technical and regulatory expectations required in modern rail networks.

Keywords: IEC 62425, railway signalling safety, electronic safety systems, safety integrity levels, hazard analysis, railway communication standards, safety management, signalling equipment approval, railway system lifecycle safety

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

IEC 62425:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Railway applications - Communication, signalling and processing systems - Safety related electronic systems for signalling". This standard covers: Applies to all safety-related railway signalling systems/sub-system/equipment. The hazard analysis and risk assessment processes defined in IEC 62278 and this standard are necessary for all railway signalling systems/sub-systems/equipment, in order to identify any safety requirements.

Applies to all safety-related railway signalling systems/sub-system/equipment. The hazard analysis and risk assessment processes defined in IEC 62278 and this standard are necessary for all railway signalling systems/sub-systems/equipment, in order to identify any safety requirements.

IEC 62425:2007 is classified under the following ICS (International Classification for Standards) categories: 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62425:2007 has the following relationships with other standards: It is inter standard links to EN IEC 62290-1:2025, EN IEC 61133:2021, EN 62267:2009, EN 62290-1:2014, IEC 62425:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62425:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62425

Edition 1.0 2007-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Railway applications – Communication, signalling and processing systems –

Safety related electronic systems for signalling

Applications ferroviaires – Systèmes de signalisation, de télécommunications et

de traitement – Systèmes électroniques de sécurité pour la signalisation

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 62425

Edition 1.0 2007-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Railway applications – Communication, signalling and processing systems –

Safety related electronic systems for signalling

Applications ferroviaires – Systèmes de signalisation, de télécommunications et

de traitement – Systèmes électroniques de sécurité pour la signalisation

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

XD

CODE PRIX

ICS 45.060 ISBN 2-8318-9310-0

– 2 – 62425 © IEC:2007

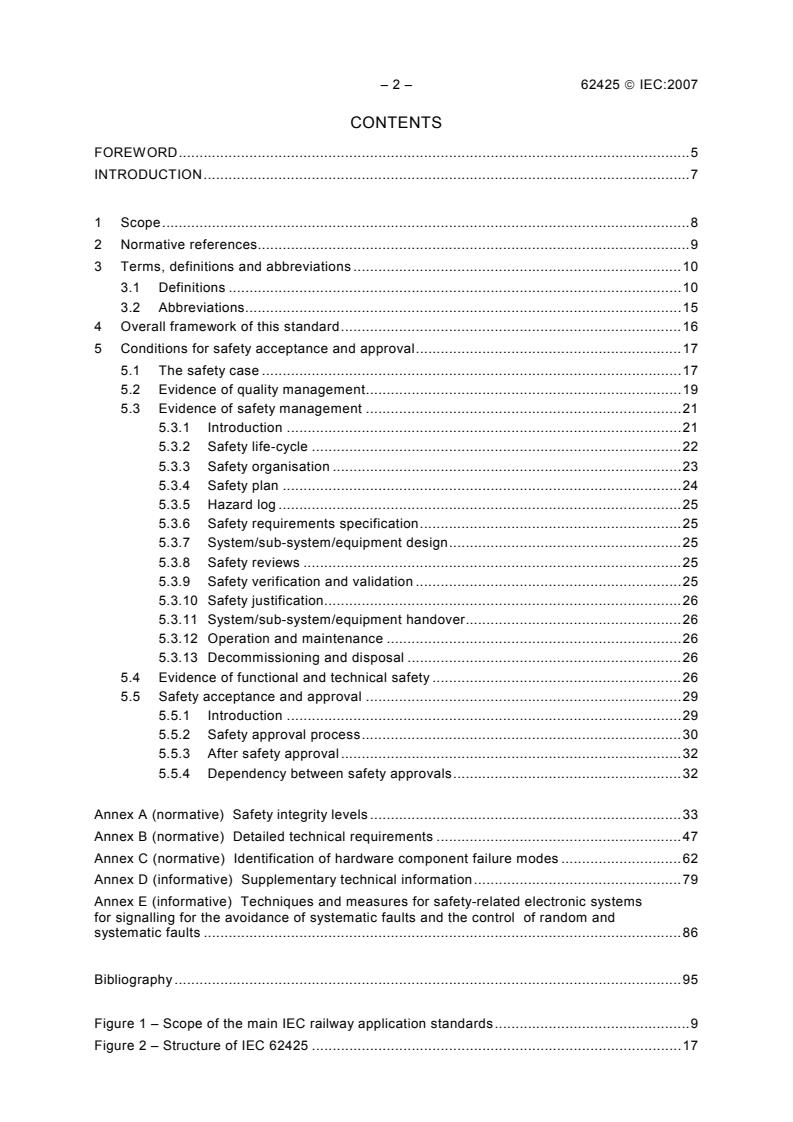

CONTENTS

FOREWORD.5

INTRODUCTION.7

1 Scope.8

2 Normative references.9

3 Terms, definitions and abbreviations .10

3.1 Definitions .10

3.2 Abbreviations.15

4 Overall framework of this standard.16

5 Conditions for safety acceptance and approval.17

5.1 The safety case .17

5.2 Evidence of quality management.19

5.3 Evidence of safety management .21

5.3.1 Introduction .21

5.3.2 Safety life-cycle .22

5.3.3 Safety organisation .23

5.3.4 Safety plan .24

5.3.5 Hazard log .25

5.3.6 Safety requirements specification.25

5.3.7 System/sub-system/equipment design.25

5.3.8 Safety reviews .25

5.3.9 Safety verification and validation .25

5.3.10 Safety justification.26

5.3.11 System/sub-system/equipment handover.26

5.3.12 Operation and maintenance .26

5.3.13 Decommissioning and disposal .26

5.4 Evidence of functional and technical safety .26

5.5 Safety acceptance and approval .29

5.5.1 Introduction .29

5.5.2 Safety approval process.30

5.5.3 After safety approval.32

5.5.4 Dependency between safety approvals.32

Annex A (normative) Safety integrity levels .33

Annex B (normative) Detailed technical requirements .47

Annex C (normative) Identification of hardware component failure modes .62

Annex D (informative) Supplementary technical information.79

Annex E (informative) Techniques and measures for safety-related electronic systems

for signalling for the avoidance of systematic faults and the control of random and

systematic faults .86

Bibliography .95

Figure 1 – Scope of the main IEC railway application standards.9

Figure 2 – Structure of IEC 62425 .17

62425 © IEC:2007 – 3 –

Figure 3 – Structure of safety case .19

Figure 4 – Example of system life-cycle (from IEC 62278) .21

Figure 5 – Example of design and validation portion of system life-cycle .23

Figure 6 – Arrangements for independence .24

Figure 7 – Structure of technical safety report.29

Figure 8 – Typical safety acceptance and approval process .31

Figure 9 – Examples of dependencies between safety cases/safety approval .32

Figure A.1 – Safety requirements and safety integrity .34

Figure A.2 – Global process overview.36

Figure A.3 – Example risk analysis process .37

Figure A.4 – Definition of hazards with respect to the system boundary.38

Figure A.5 – Example hazard control process .40

Figure A.6 – Interpretation of failure and repair times .41

Figure A.7 – Treatment of functional independence by FTA .42

Figure A.8 – Relationship between SILs and techniques .45

Figure B.1 – Influences affecting the independence of items.52

Figure B.2 – Detection and negation of single faults.55

Figure C.1 – Example of a 4-terminal resistor, using a hybrid thick layer technique .65

Figure D.1 – Example of a fault analysis method .83

Table A.1 – SIL-table .45

Table C.1 – Resistors.68

Table C.2 – Capacitors.69

Table C.3 – Electromagnetic components.69

Table C.4 – Diodes .71

Table C.5 – Transistors.72

Table C.6 – Controlled rectifiers .73

Table C.7 – Surge suppressors .74

Table C.8 – Opto-electronic components .75

Table C.9 – Filters.76

Table C.10 – Interconnection assemblies .76

Table C.11 – Fuses.77

Table C.12 – Switches and push/pull buttons.77

Table C.13 – Lamps .77

Table C.14 – Batteries.78

Table C.15 – Transducers/sensors (not including those with internal electronic circuitry).78

Table C.16 – Integrated circuits.78

Table D.1 – Examples of measures to detect faults in large-scale integrated circuits by

means of periodic on-line testing, with comparison (SW or HW), in a 2-out-of-n system .

Table E.1 – Safety planning and quality assurance activities (referred to in 5.2 and

5.3.4) .88

Table E.2 – System requirements specification (referred to in 5.3.6) .88

Table E.3 – Safety organisation (referred to in 5.3.3) .89

Table E.4 – Architecture of system/sub-system/equipment (referred to in 5.4).89

– 4 – 62425 © IEC:2007

Table E.5 – Design features (referred to in 5.4) .90

Table E.6 – Failure and hazard analysis methods (referred to in 5.4) .91

Table E.7 – Design and development of system/sub-system/equipment (referred to in

5.3.7) .91

Table E.8 – Design phase documentation (referred to in 5.2) .92

Table E.9 – Verification and validation of the system and product design (referred to in

5.3.9) .93

Table E.10 – Application, operation and maintenance (referred to in 5.3.12 and 5.4) .94

62425 © IEC:2007 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

RAILWAY APPLICATIONS –

COMMUNICATION, SIGNALLING AND PROCESSING SYSTEMS –

SAFETY RELATED ELECTRONIC SYSTEMS FOR SIGNALLING

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62425 has been prepared by IEC technical committee 9: Electrical

equipment and systems for railways.

It was submitted to the National Committees for voting under the Fast Track Procedure as the

following documents:

FDIS Report on voting

9/1057/FDIS 9/1087/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This document is based on EN 50129.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 6 – 62425 © IEC:2007

The committee has decided that the contents of this publication will remain unchanged until the

maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

62425 © IEC:2007 – 7 –

INTRODUCTION

This standard is the first International Standard defining requirements for the acceptance and

approval of safety-related electronic systems in the railway signalling field. This standard is

derived from the European Standard EN 50129.

Safety-related electronic systems for signalling include hardware and software aspects. To

install complete safety-related systems, both parts within the whole life-cycle of the system

have to be taken into account. The requirements for safety-related hardware and for the overall

system are defined in this standard. Other requirements are defined in associated IEC

standards.

This standard is the common base for safety acceptance and approval of electronic systems

for railway signalling applications. The aim of railway authorities and railway industry is to

develop railway systems based on common standards. The safety authorities having

jurisdiction can apply this standard to the relevant matters they choose. On this basis, cross-

acceptance of safety approvals for sub-systems and equipment can be applied by the different

national safety authorities. Cross-acceptance is applicable to generic approval, not to specific

applications.

The standard consists of the main part (Clause 1 to Clause 5) and Annexes A, B, C, D and E.

The requirements defined in the main part of the standard and in Annexes A, B and C are

normative, whilst Annexes D and E are informative.

This standard is in line with, and uses relevant sections of IEC 62278: "Railway applications –

Specification and demonstration of reliability, availability, maintainability and safety (RAMS)".

This standard and IEC 62278 are based on the system life-cycle and are in line with

IEC 61508-1, which is replaced by the set of IEC 62278/ IEC 62279/ IEC 62425, as far as

railway communication, signalling and processing systems are involved. Meeting the

requirements in these standards is sufficient to ensure that further compliance to IEC 61508-1

need not be evaluated.

Because this standard is concerned with the evidence to be presented for the acceptance of

safety-related systems, it specifies those life-cycle activities which shall be completed before

the acceptance stage, followed by additional planned activities to be carried out after the

acceptance stage. Safety justification for the whole of the life-cycle is therefore required.

This standard is concerned with what evidence is to be presented. Except where considered

appropriate, it does not specify who should carry out the necessary work, since this may vary in

different circumstances.

For safety-related systems which include programmable electronics, additional conditions for

the software are defined in IEC 62279.

Additional requirements for safety-related data communication are defined in IEC 62280-1 and

IEC 62280-2.

– 8 – 62425 © IEC:2007

RAILWAY APPLICATIONS –

COMMUNICATION, SIGNALLING AND PROCESSING SYSTEMS –

SAFETY RELATED ELECTRONIC SYSTEMS FOR SIGNALLING

1 Scope

This International Standard is applicable to safety-related electronic systems (including sub-

systems and equipment) for railway signalling applications.

The scope of this standard, and its relationship with other IEC standards, are shown in

Figure 1.

This standard is intended to apply to all safety-related railway signalling systems/sub-

system/equipment. However, the hazard analysis and risk assessment processes defined in

IEC 62278 and this standard are necessary for all railway signalling systems/sub-

systems/equipment, in order to identify any safety requirements. If analysis reveals that no

safety requirements exist (i.e.: that the situation is non-safety-related), and provided the

conclusion is not revised as a consequence of later changes, this safety standard ceases to be

applicable.

This standard applies to the specification, design, construction, installation, acceptance,

operation, maintenance and modification/extension phases of complete signalling systems, and

also to individual sub-systems and equipment within the complete system. Annex C includes

procedures relating to electronic hardware components.

This standard applies to generic sub-systems and equipment (both application-independent

and those intended for a particular class of application), and also to systems/sub-

systems/equipment for specific applications.

This standard is not applicable to existing systems/sub-systems/equipment (i.e. those which

had already been accepted prior to the creation of this standard). However, as far as

reasonably practicable, this standard should be applied to modifications and extensions to

existing systems, sub-systems and equipment.

This standard is primarily applicable to systems/sub-systems/equipment which have been

specifically designed and manufactured for railway signalling applications. It should also be

applied, as far as reasonably practicable, to general-purpose or industrial equipment (e.g.:

power supplies, modems, etc.), which is procured for use as part of a safety-related signalling

system. As a minimum, evidence shall be provided in such cases to demonstrate

– either that the equipment is not relied on for safety,

– or that the equipment can be relied on for those functions which relate to safety.

This standard is applicable to the functional safety of railway signalling systems. It is not

intended to deal with the occupational health and safety of personnel; this subject is covered by

other standards.

62425 © IEC:2007 – 9 –

Total railway

system

Complete railway

signaling system

IEC 62278

(RAMS)

IEC 62279

IEC 62280-1

(Software)

et IEC 62280-2

IEC 62425

(Communication)

Individual

(System safety)

sub-system

Individual intem

of equipment

IEC 1726/07

Figure 1 – Scope of the main IEC railway application standards

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

NOTE 1 Additional informative references are included in the Bibliography.

IEC 60664 (all parts), Insulation coordination for equipment within low-voltage systems

IEC 61508-1, Functional safety of electrical/electronic/ programmable electronic safety-related

systems – Part 1: General requirements

IEC 62236 (all parts), Railway applications – Electromagnetic compatibility

IEC 62236-4, Railway applications – Electromagnetic compatibility – Part 4: Emission and

immunity of the signalling and telecommunications apparatus

IEC 62278, Railway applications – The specification and demonstration of reliability,

availability, maintainability and safety (RAMS)

IEC 62279, Railway applications – Communications, signalling and processing systems –

Software for railway control and protection systems

IEC 62280-1, Railway applications – Communication, signalling and processing systems –

Part 1: Safety-related communication in closed transmission systems

IEC 62280-2, Railway applications – Communication, signalling and processing systems –

Part 2: Safety-related communication in open transmission systems

– 10 – 62425 © IEC:2007

EN 50124-1, Railway applications – Insulation coordination – Part 1: Basic requirements –

Clearances and creepage distances for all electrical and electronic equipment

EN 50125-1, Railway applications – Environmental conditions for equipment – Part 1:

Equipment on board rolling stock

EN 50125-3, Railway applications – Environmental conditions for equipment – Part 3:

Equipment for signalling and telecommunications

EN 50155, Railway applications – Electronic equipment used on rolling stock

NOTE 2 EN 50124 (series), EN 50125 (series) and EN 50155 will be converted to IEC standards according to

the merging strategy between IEC TC9 and CENELEC TC9X.

3 Terms, definitions and abbreviations

For the purposes of this document, the following terms, definitions and abbreviations apply.

3.1 Definitions

3.1.1

accident

an unintended event or series of events that results in death, injury, loss of a system or

service, or environmental damage

3.1.2

assessment

the process of analysis to determine whether the design authority and the validator have

achieved a product that meets the specified requirements and to form a judgement as to

whether the product is fit for its intended purpose

3.1.3

authorisation

the formal permission to use a product within specified application constraints

3.1.4

availability

the ability of a product to be in a state to perform a required function under given conditions at

a given instant of time or over a given time interval assuming that the required external

resources are provided

3.1.5

causal analysis

analysis of the reasons how and why a particular hazard may come into existence

3.1.6

common-cause failure

failure common to items which are intended to be independent

3.1.7

consequence analysis

analysis of events which are likely to happen after a hazard has occurred

3.1.8

configuration

the structuring and interconnection of the hardware and software of a system for its intended

application

62425 © IEC:2007 – 11 –

3.1.9

cross-acceptance

the status achieved by a product that has been accepted by one authority to the relevant

standards and is acceptable to other authorities without the necessity for further assessment

3.1.10

design

the activity applied in order to analyse and transform specified requirements into acceptable

design solutions which have the required safety integrity

3.1.11

design authority

the body responsible for the formulation of a design solution to fulfil the specified requirements

and for overseeing the subsequent development and setting-to-work of a system in its intended

environment

3.1.12

diversity

a means of achieving all or part of the specified requirements in more than one independent

and dissimilar manner

3.1.13

equipment

a functional physical item

3.1.14

error

a deviation from the intended design which could result in unintended system behaviour or

failure

3.1.15

fail-safe

a concept which is incorporated into the design of a product such that, in the event of a failure,

it enters or remains in a safe state

3.1.16

failure

a deviation from the specified performance of a system

NOTE A failure is the consequence of a fault or error in the system.

3.1.17

fault

an abnormal condition that could lead to an error in a system

NOTE A fault can be random or systematic.

3.1.18

fault detection time

time span which begins at the instant when a fault occurs and ends when the existence of the

fault is detected

3.1.19

function

a mode of action or activity by which a product fulfils its purpose

3.1.20

hazard

a condition that could lead to an accident

– 12 – 62425 © IEC:2007

3.1.21

hazard analysis

the process of identifying hazards and analysing their causes, and the derivation of

requirements to limit the likelihood and consequences of hazards to a tolerable level

3.1.22

hazard log

the document in which all safety management activities, hazards identified, decisions made

and solutions adopted, are recorded or referenced

3.1.23

human error

a human action (mistake), which can result in unintended system behaviour/failure

3.1.24

implementation

the activity applied in order to transform the specified designs into their physical realisation

3.1.25

independence (functional)

freedom from any mechanism which can affect the correct operation of more than one function

as a result of either systematic or random failure

3.1.26

independence (human)

freedom from involvement in the same intellectual, commercial and/or management entity

3.1.27

independence (physical)

freedom from any mechanism which can affect the correct operation of more than one

system/sub-system/equipment as a result of random failures

3.1.28

individual risk

a risk which is related to a single individual only

3.1.29

maintainability

the probability that a given active maintenance action, for an item under given conditions of use

can be carried out within a stated time interval when the maintenance is performed under

stated conditions and using stated procedures and resources

3.1.30

maintenance

the combination of all technical and administrative actions, including supervision actions,

intended to retain an item in, or restore it to, a state in which it can perform its required

function

3.1.31

negation

enforcement of a safe state following detection of a hazardous fault

3.1.32

negation time

time span which begins when the existence of a fault is detected and ends when a safe state is

enforced

62425 © IEC:2007 – 13 –

3.1.33

product

a collection of elements, interconnected to form a system/sub-system/equipment, in a manner

which meets the specified requirements

3.1.34

quality

a user perception of the attributes of a product

3.1.35

railway authority

the body with the overall accountability to a safety authority for operating a safe railway system

3.1.36

random failure integrity

the degree to which a system is free from hazardous random faults

3.1.37

random fault

unpredictable occurrence of a fault

3.1.38

redundancy

the provision of one or more additional measures, usually identical, to provide fault tolerance

3.1.39

reliability

the ability of an item to perform a required function under given conditions for a given period of

time

3.1.40

repair

measures for re-establishing the required state of a system/sub-system/equipment after a

fault/failure

3.1.41

risk

the combination of the frequency, or probability, and the consequence of a specified hazardous

event

3.1.42

safe state

a condition which continues to preserve safety

3.1.43

safety

freedom from unacceptable levels of risk of harm

3.1.44

safety acceptance

the safety status given to a product by the final user

3.1.45

safety approval

the safety status given to a product by the requisite authority when the product has fulfilled a

set of pre-determined conditions

– 14 – 62425 © IEC:2007

3.1.46

safety authority

the body responsible for delivering the authorisation for the operation of the safety related

system

3.1.47

safety case

the documented demonstration that the product complies with the specified safety

requirements

3.1.48

safety integrity

the ability of a safety-related system to achieve its required safety functions under all the stated

conditions within a stated operational environment and within a stated period of time

3.1.49

safety integrity level

a number which indicates the required degree of confidence that a system will meet its

specified safety functions with respect to systematic failures

3.1.50

safety life-cycle

the additional series of activities carried out in conjunction with the system life-cycle for safety-

related systems

3.1.51

safety management

the management structure which ensures that the safety process is properly implemented

3.1.52

safety plan

the implementation details of how the safety requirements of the project will be achieved

3.1.53

safety process

the series of procedures that are followed to enable all safety requirements of a product to be

identified and met

3.1.54

safety-related

carries responsibility for safety

3.1.55

signalling system

particular kind of system used on a railway to control and protect the operation of trains

3.1.56

stress profile

the degree and number of external influences which a product can withstand whilst performing

its required functionality

3.1.57

sub-system

a portion of a system which fulfils a specialised function

62425 © IEC:2007 – 15 –

3.1.58

system

a set of sub-systems which interact according to a design

3.1.59

systematic failure integrity

the degree to which a system is free from unidentified hazardous errors and the causes thereof

3.1.60

systematic fault

an inherent fault in the specification, design, construction, installation, operation or

maintenance of a system, sub-system or equipment

3.1.61

system life-cycle

the series of activities occurring during a period of time that starts when a system is conceived

and ends at decommissioning when the system is no longer available for use

3.1.62

technical safety report

documented technical evidence for the safety of the design of a system/sub-system/equipment

3.1.63

validation

the activity applied in order to demonstrate, by test and analysis, that the product meets in all

respects its specified requirements

3.1.64

verification

the activity of determination, by analysis and test, at each phase of the life-cycle, that the

requirements of the phase under consideration meet the output of the previous phase and that

the output of the phase under consideration fulfils its requirements

3.2 Abbreviations

ATP automatic train protection

CENELEC European committee for electrotechnical standardisation

CCF common-cause failure

DC direct current

EMC electromagnetic compatibility

EMI electromagnetic interference

EN European standard

ESD electrostatic discharge

FMEA failure modes and effects analysis

FR failure rate

FTA fault tree analysis

H hazard

HW hardware

IEC International electrotechnical commission

IRSE Institution of railway signal engineers

ISO International standards organisation

RAMS reliability, availability, maintainability and safety

– 16 – 62425 © IEC:2007

SDR safe down rate

SDT safe down time

SIL safety integrity level

SW software

THR tolerable hazard rate

UIC International union of railways

4 Overall framework of this standard

Clause 5 of this International Standard requires that a systematic, documented approach be

taken to

– evidence of quality management,

– evidence of safety management,

– evidence of functional and technical safety,

– safety acceptance and approval.

Annex A (normative) defines the interpretation and use of safety integrity levels.

Annex B (normative) contains detailed technical requirements for safety-related systems/sub-

systems/equipment.

Annex C (normative) contains procedures and information for identifying the credible failure

modes of hardware components.

Annex D (informative) contains supplementary technical information.

Annex E (informative) contains tables of techniques/measures to be used for various levels of

safety integrity.

The bibliography contains references to documents that have been consulted during the

preparation of this standard.

The structure of this standard is summarised in Figure 2.

62425 © IEC:2007 – 17 –

IEC 62425

Clause 1 Clause 2 Clause 3 Clause 4 Clause 5

5.1 5.2 5.3 5.4 5.5

Normative

Annex A Annex B

B.1 B.2 B.3 B.4 B.5 B.6

Annex C

Bibliography Annex D Annex E

Informative

IEC 1727/07

Figure 2 – Structure of IEC 62425

5 Conditions for safety acceptance and approval

5.1 The safety case

This standard defines the conditions that shall be satisfied in order for a safety-related

electronic railway system/sub-system/equipment to be accepted as adequately safe for its

intended application.

The conditions for safety acceptance are presented in this standard under three subclauses,

namely

5.2 Evidence of quality management

5.3 Evidence of safety management

5.4 Evidence of functional and technical safety

All of these conditions shall be satisfied, at equipment, sub-system and system levels, before

the safety-related system can be accepted as adequately safe.

The documentary evidence that these conditions have been satisfied shall be included in a

structured safety justification document, known as the safety case. The safety case forms part

of the overall documentary evidence to be submitted to the relevant safety authority in order to

obtain safety approval for a generic product, a class of application or a specific application. For

an explanation of the safety approval process, see 5.5.

– 18 – 62425 © IEC:2007

The safety case contains the documented safety evidence for the system/sub-system/

equipment, and shall be structured as follows:

− Part 1 Definition of system (or sub-system/equipment)

This shall precisely define or reference the system/sub-system/equipment to which the safety

case refers, including version numbers and modification status of all requirements, design and

application documentation.

− Part 2 Quality management report

This shall contain the evidence of quality management, as specified in 5.2.

− Part 3 Safety management report

This shall contain the evidence of safety management, as specified in 5.3.

− Part 4 Technical safety report

This shall contain the evidence of functional and technical safety, as specified in 5.4.

− Part 5 Related safety cases

This shall contain references to the safety cases of any sub-systems or equipment on which

the main safety case depends.

It shall also demonstrate that all the safety-related application conditions specified in each of

the related sub-system/equipment safety cases are

• either fulfilled in the main safety case,

• or carried forward into the safety-related application conditions of the main safety case.

− Part 6 Conclusion

This shall summarise the evidence presented in the previous parts of the safety case, and

argue that the relevant system/sub-system/equipment is adequately safe, subject to

compliance with the specified application conditions.

The structure of the safety case is illustrated in Figure 3.

Large volumes of detailed evidence and supporting documentation need not be included in the

safety case and in its parts, provided precise references are given to such documents and

provided the base concepts used and the approaches taken are clearly specified.

62425 © IEC:2007 – 19 –

Part 6: Conclusion

Part 5: Related

safety

cases

Part 4: Technical

safety

report

Part 3: Safety

management report

Part 2: Quality

management report

Part 1: Definition of system

SAFETY

CASE

IEC 1728/07

Figure 3 – Structure of safety case

5.2 Evidence of quality management

The first condition for safety acceptance that shall be satisfied is that the quality of the system,

sub-system or equipment has been, and shall continue to be, controlled by an effective quality

management system throughout its life-cycle. Documentary evidence to demonstrate this shall

be provided in the quality management report, which forms Part 2 of the safety case.

The purpose of the quality management system is to minimise the incidence of human errors at

each stage in the life-cycle, and thus to reduce the risk of systematic faults in the system, sub-

system or equipment.

The quality management system shall be applicable throughout the system/sub-system/

equipment life-cycle, as defined in IEC 62278. An example of a system life-cycle diagram (from

IEC 62278) is reproduced as Figure 4.

NOTE Examples of aspects which should be controlled by the quality management system and included in the

quality management report:

– organisational structure;

– quality planning and procedures;

– specification of requirements;

– design control;

– design verification and reviews;

–

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...