IEC 62278-2:2025

(Main)Railway applications - Specification and demonstration of reliability, availability, maintainability and safety (RAMS) - Part 2: Systems approach to safety

Railway applications - Specification and demonstration of reliability, availability, maintainability and safety (RAMS) - Part 2: Systems approach to safety

IEC 62278-2:2025 considers the safety-related generic aspects of the RAMS life cycle and defines methods and tools which are independent of the actual technology of the systems and subsystems.

This document provides:

a) methods for the understanding of the systems approach to safety which is a key concept of IEC 62278;

b) methods to derive the safety requirements and their safety integrity requirements for the system and to apportion them to the subsystems;

c) methods to derive the safety integrity levels (SIL) for the safety-related electronic functions;

d) guidance and methods for the following areas:

1) safety process;

2) safety demonstration and acceptance;

3) organization and independence of roles;

4) risk assessment;

5) specification of safety requirements;

6) apportionment of functional safety requirements;

7) design and implementation;

e) the user of this document with the methods to assure safety with respect to the system under consideration and its interactions;

f) guidance about the definition of the system under consideration, including identification of the interfaces and the interactions of this system with its subsystems or other systems, in order to conduct the risk analysis.

This document does not specify:

g) RAMS targets, quantities, requirements or solutions for specific railway applications;

h) rules or processes pertaining to the certification of railway products against the requirements of this document;

i) an approval process by the safety authority.

This document is applicable:

j) to the specification and demonstration of RAMS for all railway applications and at all levels of such an application, as appropriate, from complete railway systems to major systems and to individual and combined subsystems and components within these major systems, including those containing software; in particular:

1) to new systems;

2) to new systems integrated into existing systems already accepted, but only to the extent and insofar as the new system with the new functionality is being integrated. It is otherwise not applicable to any unmodified aspects of the existing system;

3) as far as reasonably practicable, to modifications and extensions of existing systems already accepted, but only to the extent and insofar as existing systems are being modified. It is otherwise not applicable to any unmodified aspect of the existing system;

k) at all relevant phases of the life cycle of an application;

l) for use by railway duty holders and the railway suppliers.

This document is not applicable to:

m) any unmodified aspect of the existing system;

n) existing systems which remain unmodified, including those systems already compliant with IEC 62278:2002.

IEC 62278-2:2025, together with IEC 62278-1, cancels and replaces IEC 62278:2002. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a) creation of this new Part 2 providing, for the first time, safety-related guidance and methods that support the safety management process provided in IEC 62278-1:2025.

The IEC 62278 series forms part of the railway sector specific application of IEC 61508. IEC 62278, IEC 62279 and IEC 62425 comprise the railway sector equivalent of the IEC 61508 series so far as railway communication, signalling and processing systems are concerned. When compliance with these documents has been demonstrated, further evaluation of compliance with the IEC 61508 series is not foreseen. A list of all parts in the IEC 62278 series, published under the general title Railway applications - Specification and demonstration of reliability, availability, maintainability and safety (RAMS), can be found on the IEC website.

Applications ferroviaires - Spécification et démonstration de la fiabilité, de la disponibilité, de la maintenabilité et de la sécurité (FDMS) - Partie 2: Approche systématique pour la sécurité

L'IEC 62278-2:2025 prend en considération les aspects génériques relatifs à la sécurité du cycle de vie FDMS et définit les méthodes et les outils qui sont indépendants de la technologie des systèmes et sous-systèmes.

Le présent document fournit:

a) une présentation de l'approche systématique pour la sécurité, un concept clé de l'IEC 62278 ;

b) les méthodes pour déterminer les exigences de sécurité et leurs exigences d'intégrité de sécurité concernant le système et pour les allouer aux différents sous-systèmes ;

c) les méthodes pour déterminer les niveaux d'intégrité de sécurité (SIL) pour les fonctions électroniques relatives à la sécurité ;

d) des lignes directrices et des méthodes concernant :

1) le processus de sécurité ;

2) la démonstration et l'acceptation de la sécurité ;

3) l'organisation et l'indépendance des rôles ;

4) l'appréciation du risque ;

5) la spécification des exigences de sécurité ;

6) l'allocation des exigences de sécurité fonctionnelle ;

7) la conception et la réalisation.

e) à l'utilisateur du présent document les méthodes permettant d'assurer la sécurité à l'égard du système en cours d'examen et de ses interactions ;

f) des lignes directrices sur la définition du système en cours d'examen, y compris l'identification des interfaces et interactions du système avec ses sous-systèmes ou d'autres systèmes afin de réaliser l'analyse du risque.

Le présent document ne spécifie pas :

g) les objectifs de FDMS, ni les grandeurs, les exigences ou les solutions pour des applications ferroviaires spécifiques ;

h) les règles ou les processus de certification des produits ferroviaires vis-à-vis des exigences du présent document ;

i) un processus d'homologation par l'autorité de tutelle en matière de sécurité.

Le présent document s'applique :

j) à la spécification et à la démonstration des exigences de FDMS pour toute application ferroviaire et à tout niveau d'une telle application, selon le cas, allant des systèmes ferroviaires complets aux grands systèmes et aux sous-systèmes et équipements (individuels et combinés) de ces grands systèmes, y compris ceux qui comportent des logiciels. Il est notamment applicable :

1) aux nouveaux systèmes ;

2) aux nouveaux systèmes intégrés dans des systèmes préexistants acceptés, mais seulement dans la mesure où, et dans la façon dont le nouveau système comprenant la nouvelle fonctionnalité y est intégré. Il ne s'applique cependant pas aux parties inchangées du système existant ;

3) dans toute la mesure du possible, aux modifications et extensions des systèmes préexistants, mais seulement dans la mesure où, et dans la façon dont les systèmes existants sont modifiés. Il ne s'applique cependant pas aux parties inchangées du système existant ;

k) à toutes les phases concernées du cycle de vie d'une application donnée ;

l) à l'utilisation des sociétés d'exploitation ferroviaire et des industries ferroviaires.

Le présent document ne s'applique pas aux :

m) parties inchangées du système existant ;

n) systèmes existants qui ne sont pas modifiés, y compris ceux déjà conformes à l'IEC 62278:2002.

L'IEC 62278-2:2025, conjointement à l'IEC 62278-1, annule et remplace l'IEC 62278:2002. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente :

a) rédaction de cette nouvelle Partie 2 qui fournit pour la première fois des lignes directrices et des méthodes de sécurité dans le cadre du processus de management de la sécurité défini dans l'IEC 62278-1:2025.

La série IEC 62278 représente une partie de l'application spécifique au domaine ferroviaire de l'IEC 61508. Les IEC 62278, IEC 62279 et IEC 62425 constituent l'équivalent relatif au secteur ferroviaire de la série IEC 61508 en ce qui concerne les systèmes de communication ferroviaire, de signalisation et de traitement. Dans les cas où la satisfaction aux exigences des documents cités ci-dessus a été démontrée, il n'est pas

General Information

- Status

- Published

- Publication Date

- 23-Jul-2025

- Technical Committee

- TC 9 - Electrical equipment and systems for railways

- Drafting Committee

- MT 62278 - TC 9/MT 62278

- Current Stage

- PPUB - Publication issued

- Start Date

- 24-Jul-2025

- Completion Date

- 25-Jul-2025

Relations

- Effective Date

- 26-Oct-2025

Overview

IEC 62278-2:2025 - "Railway applications - Specification and demonstration of reliability, availability, maintainability and safety (RAMS) - Part 2: Systems approach to safety" - provides technology‑neutral, safety‑related methods and tools for the RAMS life cycle. It focuses on a systems approach to safety: defining and apportioning safety requirements, deriving safety integrity levels (SILs) for safety‑related electronic functions, and guiding risk assessment, safety demonstration and acceptance across the life cycle of railway systems, subsystems and components.

Key topics and requirements

- Systems approach to safety: methods for defining the system under consideration, identifying interfaces and interactions, and conducting risk analysis.

- Safety process model: includes the hourglass model for risk assessment, hazard control and iterative revision of safety decisions.

- Risk assessment & acceptance: guidance on risk analysis techniques, consequence analysis, explicit quantitative and qualitative risk estimation, and principles for risk tolerability (ALARP, GAME, MEM provided as examples).

- Specification of safety requirements: categorization into functional, technical and contextual safety requirements and methods to document them.

- Apportionment & SIL allocation: methods to derive and apportion Safety Integrity Levels (SILs) to subsystems and electronic functions, including annexes with guidance and quantitative apportionment examples.

- Design, implementation & verification: guidance on causal analysis, hazard refinement, common cause failure analysis and demonstrations of quantified targets.

- Safety demonstration & acceptance: preparation and management of safety cases, responsibilities, dependencies between safety cases and modification handling.

- Organization and independence: roles, competence and independence requirements for designers, verifiers, validators and independent safety assessors.

- Annexes: practical material on SIL allocation, apportionment methods, common quantification mistakes, technique matrices and role specifications.

Practical applications & users

This standard is intended for practical use by:

- Railway duty holders and infrastructure/rolling stock suppliers

- Systems engineers and safety managers developing new railway systems or integrating new functionality into existing systems

- Project managers, independent safety assessors, designers and verifiers responsible for RAMS and safety cases

Applicable across all levels - from complete railway systems to major subsystems and software‑containing components - and at all relevant life‑cycle phases. Note: IEC 62278-2:2025 does not set specific RAMS numeric targets, provide product certification rules, nor specify approval processes by safety authorities.

Related standards

- IEC 62278-1:2025 - complements Part 2 with RAMS management and process requirements

- IEC 61508 - sector‑neutral functional safety framework (this IEC 62278 series implements the railway‑specific application)

- IEC 62279 and IEC 62425 - related railway sector standards for signalling, communication and processing systems

Keywords: IEC 62278-2:2025, RAMS, railway safety, systems approach to safety, SIL allocation, risk assessment, safety requirements, safety case, functional safety, railway standards.

Buy Documents

IEC 62278-2:2025 - Railway applications - Specification and demonstration of reliability, availability, maintainability and safety (RAMS) - Part 2: Systems approach to safety Released:7/24/2025 Isbn:9782832705841

IEC 62278-2:2025 - Applications ferroviaires - Spécification et démonstration de la fiabilité, de la disponibilité, de la maintenabilité et de la sécurité (FDMS) - Partie 2: Approche systématique pour la sécurité Released:7/24/2025 Isbn:9782832705841

IEC 62278-2:2025 - Railway applications - Specification and demonstration of reliability, availability, maintainability and safety (RAMS) - Part 2: Systems approach to safety Released:7/24/2025 Isbn:9782832705841

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

IEC 62278-2:2025 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Railway applications - Specification and demonstration of reliability, availability, maintainability and safety (RAMS) - Part 2: Systems approach to safety". This standard covers: IEC 62278-2:2025 considers the safety-related generic aspects of the RAMS life cycle and defines methods and tools which are independent of the actual technology of the systems and subsystems. This document provides: a) methods for the understanding of the systems approach to safety which is a key concept of IEC 62278; b) methods to derive the safety requirements and their safety integrity requirements for the system and to apportion them to the subsystems; c) methods to derive the safety integrity levels (SIL) for the safety-related electronic functions; d) guidance and methods for the following areas: 1) safety process; 2) safety demonstration and acceptance; 3) organization and independence of roles; 4) risk assessment; 5) specification of safety requirements; 6) apportionment of functional safety requirements; 7) design and implementation; e) the user of this document with the methods to assure safety with respect to the system under consideration and its interactions; f) guidance about the definition of the system under consideration, including identification of the interfaces and the interactions of this system with its subsystems or other systems, in order to conduct the risk analysis. This document does not specify: g) RAMS targets, quantities, requirements or solutions for specific railway applications; h) rules or processes pertaining to the certification of railway products against the requirements of this document; i) an approval process by the safety authority. This document is applicable: j) to the specification and demonstration of RAMS for all railway applications and at all levels of such an application, as appropriate, from complete railway systems to major systems and to individual and combined subsystems and components within these major systems, including those containing software; in particular: 1) to new systems; 2) to new systems integrated into existing systems already accepted, but only to the extent and insofar as the new system with the new functionality is being integrated. It is otherwise not applicable to any unmodified aspects of the existing system; 3) as far as reasonably practicable, to modifications and extensions of existing systems already accepted, but only to the extent and insofar as existing systems are being modified. It is otherwise not applicable to any unmodified aspect of the existing system; k) at all relevant phases of the life cycle of an application; l) for use by railway duty holders and the railway suppliers. This document is not applicable to: m) any unmodified aspect of the existing system; n) existing systems which remain unmodified, including those systems already compliant with IEC 62278:2002. IEC 62278-2:2025, together with IEC 62278-1, cancels and replaces IEC 62278:2002. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) creation of this new Part 2 providing, for the first time, safety-related guidance and methods that support the safety management process provided in IEC 62278-1:2025. The IEC 62278 series forms part of the railway sector specific application of IEC 61508. IEC 62278, IEC 62279 and IEC 62425 comprise the railway sector equivalent of the IEC 61508 series so far as railway communication, signalling and processing systems are concerned. When compliance with these documents has been demonstrated, further evaluation of compliance with the IEC 61508 series is not foreseen. A list of all parts in the IEC 62278 series, published under the general title Railway applications - Specification and demonstration of reliability, availability, maintainability and safety (RAMS), can be found on the IEC website.

IEC 62278-2:2025 considers the safety-related generic aspects of the RAMS life cycle and defines methods and tools which are independent of the actual technology of the systems and subsystems. This document provides: a) methods for the understanding of the systems approach to safety which is a key concept of IEC 62278; b) methods to derive the safety requirements and their safety integrity requirements for the system and to apportion them to the subsystems; c) methods to derive the safety integrity levels (SIL) for the safety-related electronic functions; d) guidance and methods for the following areas: 1) safety process; 2) safety demonstration and acceptance; 3) organization and independence of roles; 4) risk assessment; 5) specification of safety requirements; 6) apportionment of functional safety requirements; 7) design and implementation; e) the user of this document with the methods to assure safety with respect to the system under consideration and its interactions; f) guidance about the definition of the system under consideration, including identification of the interfaces and the interactions of this system with its subsystems or other systems, in order to conduct the risk analysis. This document does not specify: g) RAMS targets, quantities, requirements or solutions for specific railway applications; h) rules or processes pertaining to the certification of railway products against the requirements of this document; i) an approval process by the safety authority. This document is applicable: j) to the specification and demonstration of RAMS for all railway applications and at all levels of such an application, as appropriate, from complete railway systems to major systems and to individual and combined subsystems and components within these major systems, including those containing software; in particular: 1) to new systems; 2) to new systems integrated into existing systems already accepted, but only to the extent and insofar as the new system with the new functionality is being integrated. It is otherwise not applicable to any unmodified aspects of the existing system; 3) as far as reasonably practicable, to modifications and extensions of existing systems already accepted, but only to the extent and insofar as existing systems are being modified. It is otherwise not applicable to any unmodified aspect of the existing system; k) at all relevant phases of the life cycle of an application; l) for use by railway duty holders and the railway suppliers. This document is not applicable to: m) any unmodified aspect of the existing system; n) existing systems which remain unmodified, including those systems already compliant with IEC 62278:2002. IEC 62278-2:2025, together with IEC 62278-1, cancels and replaces IEC 62278:2002. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) creation of this new Part 2 providing, for the first time, safety-related guidance and methods that support the safety management process provided in IEC 62278-1:2025. The IEC 62278 series forms part of the railway sector specific application of IEC 61508. IEC 62278, IEC 62279 and IEC 62425 comprise the railway sector equivalent of the IEC 61508 series so far as railway communication, signalling and processing systems are concerned. When compliance with these documents has been demonstrated, further evaluation of compliance with the IEC 61508 series is not foreseen. A list of all parts in the IEC 62278 series, published under the general title Railway applications - Specification and demonstration of reliability, availability, maintainability and safety (RAMS), can be found on the IEC website.

IEC 62278-2:2025 is classified under the following ICS (International Classification for Standards) categories: 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62278-2:2025 has the following relationships with other standards: It is inter standard links to IEC 62278:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62278-2:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62278-2 ®

Edition 1.0 2025-07

INTERNATIONAL

STANDARD

Railway applications - Specification and demonstration of reliability, availability,

maintainability and safety (RAMS) -

Part 2: Systems approach to safety

ICS 45.060.01 ISBN 978-2-8327-0584-1

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or

by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either

IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC copyright

or have an enquiry about obtaining additional rights to this publication, please contact the address below or your local

IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Discover our powerful search engine and read freely all the

The advanced search enables to find IEC publications by a publications previews, graphical symbols and the glossary.

variety of criteria (reference number, text, technical With a subscription you will always have access to up to date

committee, …). It also gives information on projects, content tailored to your needs.

replaced and withdrawn publications.

Electropedia - www.electropedia.org

The world's leading online dictionary on electrotechnology,

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published containing more than 22 500 terminological entries in English

details all new publications released. Available online and and French, with equivalent terms in 25 additional languages.

once a month by email. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer

Service Centre: sales@iec.ch.

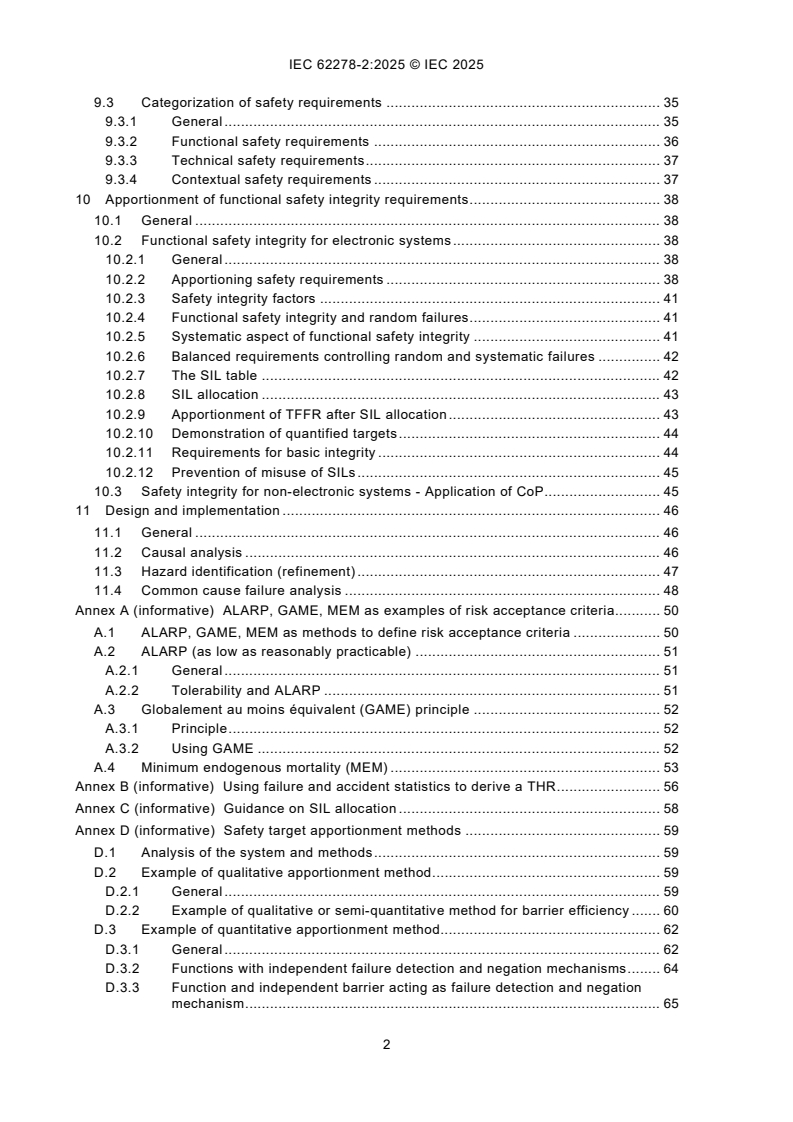

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 9

3 Terms and definitions . 9

4 Abbreviated terms . 9

5 Safety process . 10

5.1 Hourglass model for risk assessment and hazard control . 10

5.2 A. Risk assessment . 11

5.2.1 General . 11

5.2.2 Conducting risk assessment . 12

5.3 B. Outcome of the risk assessment. 12

5.4 C. Hazard control . 12

5.5 D. Revision of risk assessment . 13

5.6 Responsibilities . 14

6 Safety demonstration and acceptance . 14

6.1 General . 14

6.2 Safety demonstration and safety acceptance process . 14

6.3 Responsibility in managing the safety case . 18

6.4 Modifications after safety acceptance . 18

6.5 Dependencies between safety cases . 18

6.6 Relationship between safety cases and system architecture . 19

7 Organization and independence of roles . 20

7.1 General . 20

7.2 Early phases of the life cycle (phases 1 to 4) . 21

7.3 Later phases of the life cycle (starting from phase 5) . 21

7.4 Personnel competence . 23

8 Risk assessment . 24

8.1 General . 24

8.2 Risk analysis . 24

8.2.1 General . 24

8.2.2 The risk model . 24

8.2.3 Techniques for the consequence analysis . 26

8.2.4 Expert judgement . 27

8.3 Risk acceptance principles and risk evaluation . 28

8.3.1 Use of code of practice . 28

8.3.2 Use of a reference system . 28

8.3.3 Use of explicit risk estimation . 29

8.4 Application of explicit risk estimation . 30

8.4.1 Quantitative approach . 30

8.4.2 Variability using quantitative risk estimates . 33

8.4.3 Qualitative and semi-quantitative approaches . 34

9 Specification of system safety requirements . 35

9.1 General . 35

9.2 Safety requirements . 35

9.3 Categorization of safety requirements . 35

9.3.1 General . 35

9.3.2 Functional safety requirements . 36

9.3.3 Technical safety requirements . 37

9.3.4 Contextual safety requirements . 37

10 Apportionment of functional safety integrity requirements . 38

10.1 General . 38

10.2 Functional safety integrity for electronic systems . 38

10.2.1 General . 38

10.2.2 Apportioning safety requirements . 38

10.2.3 Safety integrity factors . 41

10.2.4 Functional safety integrity and random failures . 41

10.2.5 Systematic aspect of functional safety integrity . 41

10.2.6 Balanced requirements controlling random and systematic failures . 42

10.2.7 The SIL table . 42

10.2.8 SIL allocation . 43

10.2.9 Apportionment of TFFR after SIL allocation . 43

10.2.10 Demonstration of quantified targets . 44

10.2.11 Requirements for basic integrity . 44

10.2.12 Prevention of misuse of SILs . 45

10.3 Safety integrity for non-electronic systems - Application of CoP. 45

11 Design and implementation . 46

11.1 General . 46

11.2 Causal analysis . 46

11.3 Hazard identification (refinement) . 47

11.4 Common cause failure analysis . 48

Annex A (informative) ALARP, GAME, MEM as examples of risk acceptance criteria. 50

A.1 ALARP, GAME, MEM as methods to define risk acceptance criteria . 50

A.2 ALARP (as low as reasonably practicable) . 51

A.2.1 General . 51

A.2.2 Tolerability and ALARP . 51

A.3 Globalement au moins équivalent (GAME) principle . 52

A.3.1 Principle . 52

A.3.2 Using GAME . 52

A.4 Minimum endogenous mortality (MEM) . 53

Annex B (informative) Using failure and accident statistics to derive a THR . 56

Annex C (informative) Guidance on SIL allocation . 58

Annex D (informative) Safety target apportionment methods . 59

D.1 Analysis of the system and methods . 59

D.2 Example of qualitative apportionment method . 59

D.2.1 General . 59

D.2.2 Example of qualitative or semi-quantitative method for barrier efficiency . 60

D.3 Example of quantitative apportionment method. 62

D.3.1 General . 62

D.3.2 Functions with independent failure detection and negation mechanisms . 64

D.3.3 Function and independent barrier acting as failure detection and negation

mechanism . 65

D.3.4 Apportionment of a probability safety target . 67

D.3.5 Apportionment of a "per hour" safety target . 67

Annex E (informative) Common mistakes in quantification . 69

E.1 General . 69

E.2 Mixing failure rates with probabilities . 69

E.3 Using formulas out of their range of applicability . 70

Annex F (informative) Techniques and methods for safety analysis . 71

Annex G (informative) Key system safety roles and responsibilities . 73

Bibliography . 78

Figure 1 – The hourglass model . 11

Figure 2 – Illustration of hazards with respect to the system boundary . 13

Figure 3 – Example of safety acceptance processes. 17

Figure 4 – Examples of dependencies between safety cases . 19

Figure 5 – Independence of roles in the early phases (phases 1 to 4) of the life cycle . 21

Figure 6 – Independence of roles in later phases of the life cycle (starting from phase 5) . 23

Figure 7 – An example of risk model . 25

Figure 8 – Tolerable rates in an example of risk model . 31

Figure 9 – Requirements classification . 36

Figure 10 – Apportionment of functional safety requirements . 39

Figure 11 – Categorization of safety integrity measures . 42

Figure 12 – Common cause failures . 48

Figure 13 – Impact of functional dependence in a fault tree analysis . 48

Figure A.1 – Differential risk aversion . 54

Figure D.1 – Example of qualitative apportionment method . 60

Figure D.2 – Interpretation of failure and repair times . 63

Figure D.3 – Combination of two functions with independent failure detection and

negation mechanism . 64

Figure D.4 – Allocation of safety integrity requirements . 65

Figure D.5 – Combination of function and independent barrier acting as failure detection

and negation mechanism . 66

Figure D.6 – Example of quantified apportionment . 68

Figure E.1 – Example of FTA case . 69

Table 1 – Examples of hazards . 26

Table 2 – SIL quantitative and qualitative measures . 43

Table A.1 – Overview of ALARP, GAME, MEM . 50

Table D.1 – Efficiency based on the component's failures . 61

Table D.2 – Efficiency based on the component's knowledge . 61

Table D.3 – Efficiency based on the use of the component . 61

Table D.4 – Efficiency based on the maintenance of the component . 62

Table F.1 – Techniques and methods for safety analysis . 71

Table F.2 – Techniques and measures for BI and SILs . 72

Table G.1 – Role specification for designer . 73

Table G.2 – Role specification for verifier . 74

Table G.3 – Role specification for validator . 75

Table G.4 – Role specification for independent safety assessor . 76

Table G.5 – Role specification for project manager. 77

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

Railway applications -

Specification and demonstration of reliability, availability, maintainability

and safety (RAMS) -

Part 2: Systems approach to safety

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising all

national electrotechnical committees (IEC National Committees). The object of IEC is to promote international co-

operation on all questions concerning standardization in the electrical and electronic fields. To this end and in addition

to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports, Publicly

Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may participate

in this preparatory work. International, governmental and non-governmental organizations liaising with the IEC also

participate in this preparation. IEC collaborates closely with the International Organization for Standardization (ISO)

in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all interested

IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any services

carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or other

damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and expenses arising

out of the publication, use of, or reliance upon, this IEC Publication or any other IEC Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a) patent(s).

IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in respect thereof.

As of the date of publication of this document, IEC had not received notice of (a) patent(s), which may be required

to implement this document. However, implementers are cautioned that this may not represent the latest information,

which may be obtained from the patent database available at https://patents.iec.ch shall not be held responsible for

identifying any or all such patent rights.

IEC 62278-2 has been prepared by IEC technical committee 9: Electric systems and equipment

for railways. It is an International Standard.

This first edition, together with IEC 62278-1, cancels and replaces IEC 62278:2002. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) creation of this new Part 2 providing, for the first time, safety-related guidance and methods

that support the safety management process provided in IEC 62278-1:2025.

The text of this International Standard is based on the following documents:

Draft Report on voting

9/3208/FDIS 9/3235/RVD

Full information on the voting for its approval can be found in the report on voting indicated in the

above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available at

www.iec.ch/members_experts/refdocs. The main document types developed by IEC are described

in greater detail at www.iec.ch/publications.

The IEC 62278 series forms part of the railway sector specific application of IEC 61508.

IEC 62278, IEC 62279 and IEC 62425 comprise the railway sector equivalent of the IEC 61508

series so far as railway communication, signalling and processing systems are concerned. When

compliance with these documents has been demonstrated, further evaluation of compliance with

the IEC 61508 series is not foreseen.

A list of all parts in the IEC 62278 series, published under the general title Railway applications -

Specification and demonstration of reliability, availability, maintainability and safety (RAMS), can

be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the specific

document. At this date, the document will be

– reconfirmed,

– withdrawn, or

– revised.

INTRODUCTION

IEC 62278:2002 was aimed at introducing the application of a systematic RAMS management

process in the railway sector. Through the application of IEC 62278:2002 and the experiences

gained over the last years, the need for revision and restructuring became apparent with a need

to deliver a systematic and coherent approach to RAMS applicable to all the railway application

fields including signalling, rolling stock and fixed installations.

This document provides railway duty holders and the railway suppliers with a process which will

enable the implementation of a consistent approach to the management of reliability, availability,

maintainability and safety, denoted by the acronym RAMS.

Processes for the specification and demonstration of RAMS requirements are cornerstones of this

document. This document promotes a common understanding and approach to the management

of RAMS.

The IEC 62278 series is derived from the European Standard series EN 50126:2017, consisting of

EN 50126-1:2017 and EN 50126-2:2017.

With regard to safety, IEC 62278-1 provides a safety management process which is supported by

guidance and methods described in this document.

IEC 62278-1 and IEC 62278-2 are independent from the technology used. As far as safety is

concerned, IEC 62278 takes the perspective of safety with a functional approach.

The application of this document can be adapted to the specific requirements for the system under

consideration.

This document can be applied systematically by the railway duty holders and railway suppliers,

throughout all phases of the life cycle of a railway application, to develop railway-specific RAMS

requirements and to achieve compliance with these requirements. The system level approach

developed by this document facilitates assessment of the RAMS interactions between elements of

railway applications even if they are of complex nature.

This document promotes co-operation between the stakeholders of railways in the achievement of

an optimal combination of RAMS and cost for railway applications.

The process defined by this document assumes that railway duty holders and railway suppliers

have business-level policies addressing quality, performance and safety. The approach defined in

this document is consistent with the application of quality management requirements contained

within ISO 9001.

1 Scope

This document considers the safety-related generic aspects of the RAMS life cycle and defines

methods and tools which are independent of the actual technology of the systems and subsystems.

This document provides:

a) methods for the understanding of the systems approach to safety which is a key concept of

IEC 62278;

b) methods to derive the safety requirements and their safety integrity requirements for the system

and to apportion them to the subsystems;

c) methods to derive the safety integrity levels (SIL) for the safety-related electronic functions;

d) guidance and methods for the following areas:

1) safety process;

2) safety demonstration and acceptance;

3) organization and independence of roles;

4) risk assessment;

5) specification of safety requirements;

6) apportionment of functional safety requirements;

7) design and implementation;

e) the user of this document with the methods to assure safety with respect to the system under

consideration and its interactions;

f) guidance about the definition of the system under consideration, including identification of the

interfaces and the interactions of this system with its subsystems or other systems, in order to

conduct the risk analysis.

This document does not specify:

g) RAMS targets, quantities, requirements or solutions for specific railway applications;

h) rules or processes pertaining to the certification of railway products against the requirements

of this document;

i) an approval process by the safety authority.

This document is applicable:

j) to the specification and demonstration of RAMS for all railway applications and at all levels of

such an application, as appropriate, from complete railway systems to major systems and to

individual and combined subsystems and components within these major systems, including

those containing software; in particular:

1) to new systems;

2) to new systems integrated into existing systems already accepted, but only to the extent

and insofar as the new system with the new functionality is being integrated. It is otherwise

not applicable to any unmodified aspects of the existing system;

3) as far as reasonably practicable, to modifications and extensions of existing systems

already accepted, but only to the extent and insofar as existing systems are being modified.

It is otherwise not applicable to any unmodified aspect of the existing system;

k) at all relevant phases of the life cycle of an application;

l) for use by railway duty holders and the railway suppliers.

This document is not applicable to:

m) any unmodified aspect of the existing system;

n) existing systems which remain unmodified, including those systems already compliant with

IEC 62278:2002.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any amendments)

applies.

IEC 62278-1:2025, Railway applications - Specification and demonstration of reliability,

availability, maintainability and safety (RAMS) - Part 1: Generic RAMS process

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 62278-1 apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

– IEC Electropedia: available at https://www.electropedia.org/

– ISO Online browsing platform: available at https://www.iso.org/obp

4 Abbreviated terms

ALARP as low as reasonably practicable

CBA cost benefit analysis

CCF common cause failure analysis

CoP code of practice

DRA differential risk aversion

ERE explicit risk estimation

EMC electromagnetic compatibility

ETA event tree analysis

FMECA failure mode, effects and criticality analysis

FTA fault tree analysis

GA generic application

GASC generic application safety case

GP generic product

GPSC generic product safety case

GAME globalement au moins equivalent (globally at least equivalent)

HAZOP hazard and operability study

IM infrastructure manager

LRU line replaceable unit

MDT mean down time

MEM minimum endogenous mortality

RAMS reliability, availability, maintainability and safety

RAP risk acceptance principle

RBD reliability block diagram

RRA rapid ranking analysis

RU railway undertaking

SA specific application

SASC specific application safety case

SDR safe down rate

SDT safe down time

SIL safety integrity level

SRAC safety-related application condition

TFFR tolerable functional unsafe failure rate

THR tolerable hazard rate

5 Safety process

5.1 Hourglass model for risk assessment and hazard control

In this subclause 5.1, the hourglass model in Figure 1 is introduced: it offers a simplified approach

that, although not containing all aspects implied in the life cycle model, helps to clarify some

issues.

The hourglass model provides an overview of the major safety-related activities that are needed

to ensure an acceptable safety level for a technical system, including the corresponding

responsibility areas.

Technical system means a product or an assembly of products including the design,

implementation and support documentation. The development of a technical system starts with its

requirements specification and ends with its acceptance. The design of relevant interfaces

considering interactions with human operators and their behaviour is considered, while human

operators themselves and their actions are not included in a technical system. Both the

maintenance process (described in the maintenance manuals) and the operation are specified but

are not considered parts of the technical system itself. They can be restricted by "application

conditions".

The purpose of this model is to highlight the separation between risk analysis as part of risk

assessment (at the railway system level) and hazard analysis as part of hazard control (at the level

of the system under consideration).

This enhances co-operation between the relevant stakeholders, clarifying responsibilities and

interfaces and has the advantages of reducing complexity and facilitating modularization.

The hourglass model describes two main aspects:

– risk assessment, deriving safety requirements for operational and technical issues (including

maintenance); and

– hazard control, satisfying given functional safety requirements coming from upper levels by

determining and analysing causes and designing and implementing control measures.

Figure 1 – The hourglass model

NOTE In Figure 1, Part A (risk assessment) is associated with phases 1 to 3 in the life cycle as depicted in Figure 7 in

IEC 62278-1:2025. Part B corresponds to phase 4 and part C to phases 5 to 9. Part D shows the "feedback of subsequent

hazard identification into risk analysis" (see Figure 7 in IEC 62278-1:2025).

5.2 A. Risk assessment

5.2.1 General

Risk assessment is performed at the railway system level.

It relies on a system definition and includes risk analysis and risk evaluation.

It defines the high-level system safety requirements, in particular safety requirements for the

system under consideration from the perspective of the railway duty holder and the operator. It

takes into account safety-related operational aspects, previous experience and the regulatory

requirements for the railway application.

The main task for this activity is the risk analysis, which is derived from the system definition. The

risk analysis includes hazard identification, consequence analysis, and selection of risk

acceptance principle (RAP).

The specification of safety requirements is the final result of risk assessment; in Figure 1 it is

allocated to box B, because it constitutes an interface (together with system requirement

specifications and the list of identified hazards) between different responsibilities.

5.2.2 Conducting risk assessment

The level of detail in a risk assessment should be adequate to enable the risk to be properly

considered. The purpose is not to catalogue every trivial hazard, nor is it expected that hazards

beyond the limits of current knowledge will always be identified. A risk assessment should reflect

a reasonable analysis of hazards and their associated risks within the railway operation and within

the applied technology itself. Where considered worthwhile, risk assessments should be correlated

with historical records of accidents and the records of causes.

When possible, consideration of technical implementation and architecture should be avoided in

this first stage, i.e. the system to be developed should be considered as a black box, of which

functions and hazards are evaluated only at the boundaries. These boundaries are well defined

interfaces between the operational environment and the system under consideration.

As an example, an "unintentional train motion" is a hazard for a train. It can be observed as an

abstraction at the boundary of the "system train" and it can lead to different accidents depending

on the operational context (e.g. collision in connection with over-speed while running or fall of

persons in connection with a train moving in a station while expected to stand still).

Assumptions defined during the risk assessment shall be checked and updated throughout the life

cycle phases.

5.3 B. Outcome of the risk assessment

The results of the risk assessment are a set of safety requirements associated with clearly-

identified functions, systems or operating rules. They are part of the system requirement

specification which establishes the technical interface between the stakeholders.

NOTE The project organizational structure and responsibilities are other factors to consider in understanding and

controlling risk. Organizational aspects and requirements are given in Clause 7.

On the basis of the selected risk acceptance principles, safety requirements can refer to codes of

practice (CoPs), to reference systems, or give explicit targets derived from an explicit risk

estimation (ERE).

Safety requirements include required safety-related functions, which can be assessed

quantitatively (e.g. maximum rates of hazards), semi-quantitatively or qualitatively (e.g. use of

trained drivers for controlling human errors).

Safety requirements should be assessed with an holistic approach to the system under

consideration, i.e. the residual risk of the whole system after introducing safety requirements

should be assessed taking into consideration all identified hazards.

5.4 C. Hazard control

The hazard control stage in the hourglass model ensures that the system under consideration is

compliant with the safety requirements. Hazard control is performed for a specific system

architecture.

The major impacts of human factors, operational and general maintenance rules as well as

procedures are part of the preceding risk analysis and are likely to have already been taken into

account in the safety requirements. Therefore, during hazard control, the designer of the system

under consideration can focus on the internal causes of the identified hazards.

The main task is the "hazard analysis" comprising:

– a dedicated hazard identification focusing on the system under consideration (refinement);

– causal analysis;

– a common cause failure analysis (see 11.4 for details).

Hazard identification is a recurring task, iterating on several levels during development of the

system under consideration. In order to distinguish between different tasks (and related

documents), the hazard identification has been quoted twice in Figure 1.

a) During risk assessment, hazard identification focuses on high-level hazards derived from the

system functions (black box) and related operation of the system as well as its environment.

b) Within the hazard control, a refined iterated hazard identification focuses on hazards and their

causes derived from the technical solutions, i.e. from defined architecture and internal

interfaces of the system under consideration, and potential new hazards introduced by the

system itself.

Both kinds of identified hazards shall be addressed during hazard control. Figure 2 shows the

general case where the cause of a hazard at the railway system level consists of a hazard on the

level of the system under consideration, with respect to its boundary. The boundary for a hazard

identification is always given in the system definition that limits the scope of the task. This implies

that the hazards are structured hierarchically. Hence a hierarchical approach to hazard analysis

and hazard logging should be used.

Figure 2 – Illustration of hazards with respect to the system boundary

Figure 2 is hazard-oriented and shows a "bow-tie" shape, suggesting that several causes can lead

to the same hazard and one hazard can lead to several different accidents.

EXAMPLE The hazard at railway system level is a train passing a signal at danger and entering another train's route,

potentially leading to a collision (the accident). The cause at railway system level (the hazard at the level of system

under consideration) is too long a braking distance. The cause at the subsystem level is that the brakes were not applied

by the driver (or applied too late). The external occurrence barrier is provided by safety equipment ordering an emergency

brake.

The demonstration of compliance with the safety requirements for the system under consideration

can be performed in various forms of verification. These forms depend on the nature of the

underlying requirements set at the beginning of the hazard control.

5.5 D. Revision of risk assessment

During the hazard control stage, fulfilment of safety requirements is possibly not reached in the

first iteration. Three potential causes are:

– additional hazards are identified at the level of the system under consideration;

– a need for new operational rules arises;

– additional external safety measures are required to fulfil the safety targets.

In all these cases, a revision of the risk assessment is necessary.

This revision should also take into account the application conditions that can arise at the level of

the system under consideration.

5.6 Responsibilities

Risk assessment is mainly within the responsibility of the railway duty holders and operators. If no

risk assessment is provided by the railway duty holder or operator, the roles and responsibilities

may be contracted to other parties (manufacturers and suppliers), provided that they have a

documented and suitable range of competencies to consider the whole operational context in

detail. They shall assess the risk resulting from introducing changes to the operational context,

taking into account safety-related operational aspects, previous experience and regulatory

requirements. In any case the railway duty holders should accept the results of the risk

assessment.

The supplier of the technical system is responsible for the hazard control. In the case that several

suppliers are in charge for different systems under consideration, the railway duty holder is

responsible for organizing an overall hazard control.

Legal requirements relevant for railway duty holder and supplier can also exist.

6 Safety demonstration and acceptance

6.1 General

This Clause 6 provides additional details on safety demonstration and safety acceptance

processes for the system under consideration. Except where considered appropriate, it does not

specify who should carry out the work at each stage, since this can vary in different circumstances.

Safety demonstration evidence is based on the safety case. The purpose and content of the safety

case are defined in IEC 62278-1:2025, Clause 8.

In terms of safety processes, the development of a system can be categorized in three types.

– Generic product: The system is considered from a generic point of view, applicable to different

classes of applications.

Analyses are carried out within an operational context which is application-independent.

– Generic application: The system is considered suitable for multiple applications of the same

class.

Analyses are carried out within an operational context which is application-dependent. The

safety process includes the definition of the application design process.

– Specific application: The system is considered for a specific application (includi

...

IEC 62278-2 ®

Edition 1.0 2025-07

NORME

INTERNATIONALE

Applications ferroviaires - Spécification et démonstration de la fiabilité, de la

disponibilité, de la maintenabilité et de la sécurité (FDMS) -

Partie 2: Approche systématique pour la sécurité

ICS 45.060.01 ISBN 978-2-8327-0584-1

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications gratuitement tous les aperçus des publications, symboles

IEC en utilisant différents critères (numéro de référence, graphiques et le glossaire. Avec un abonnement, vous aurez

texte, comité d’études, …). Elle donne aussi des toujours accès à un contenu à jour adapté à vos besoins.

informations sur les projets et les publications remplacées

ou retirées. Electropedia - www.electropedia.org

Le premier dictionnaire d'électrotechnologie en ligne au

IEC Just Published - webstore.iec.ch/justpublished monde, avec plus de 22 500 articles terminologiques en

Restez informé sur les nouvelles publications IEC. Just anglais et en français, ainsi que les termes équivalents

dans 25 langues additionnelles. Egalement appelé

Published détaille les nouvelles publications parues.

Disponible en ligne et une fois par mois par email. Vocabulaire Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-

nous: sales@iec.ch.

SOMMAIRE

AVANT-PROPOS . 5

INTRODUCTION . 7

1 Domaine d'application . 8

2 Références normatives . 9

3 Termes et définitions . 9

4 Abréviations . 9

5 Processus de sécurité . 10

5.1 Le modèle du sablier pour l'appréciation du risque et la maîtrise des situations

dangereuses . 10

5.2 A. Appréciation du risque . 11

5.2.1 Généralités . 11

5.2.2 Réalisation de l'appréciation du risque . 12

5.3 B. Résultats de l'appréciation du risque . 12

5.4 C. Maîtrise des situations dangereuses . 13

5.5 D. Révision de l'appréciation du risque . 14

5.6 Responsabilités . 14

6 Démonstration et acceptation de la sécurité . 14

6.1 Généralités . 14

6.2 Processus de démonstration et d'acceptation de la sécurité . 15

6.3 Responsabilité de gestion du dossier de sécurité . 18

6.4 Modifications après l'acceptation de la sécurité . 18

6.5 Dépendances entre les dossiers de sécurité . 18

6.6 Relation entre les dossiers de sécurité et l'architecture système . 20

7 Organisation et indépendance des rôles . 20

7.1 Généralités . 20

7.2 Phases précoces du cycle de vie (phases 1 à 4). 21

7.3 Phases ultérieures du cycle de vie (à partir de la phase 5) . 22

7.4 Compétences du personnel . 23

8 Appréciation du risque . 24

8.1 Généralités . 24

8.2 Analyse du risque . 24

8.2.1 Généralités . 24

8.2.2 Modèle de risque. 24

8.2.3 Techniques d'analyse des conséquences . 27

8.2.4 Expertise . 28

8.3 Principes d'acceptation du risque et évaluation du risque . 28

8.3.1 Utilisation d'un code de bonne pratique . 28

8.3.2 Utilisation d'un système de référence . 29

8.3.3 Utilisation de l'estimation du risque explicite . 30

8.4 Application de l'estimation du risque explicite . 31

8.4.1 Approche quantitative . 31

8.4.2 Variabilité sur la base des estimations du risque quantitatives . 34

8.4.3 Approches qualitatives et semi-quantitatives . 36

9 Spécification des exigences de sécurité du système . 36

9.1 Généralités . 36

9.2 Exigences de sécurité . 36

9.3 Classification des exigences de sécurité . 37

9.3.1 Généralités . 37

9.3.2 Exigences de sécurité fonctionnelle . 37

9.3.3 Exigences de sécurité technique . 38

9.3.4 Exigences de sécurité contextuelle . 39

10 Allocation des exigences d'intégrité de sécurité fonctionnelle . 39

10.1 Généralités . 39

10.2 Intégrité de sécurité fonctionnelle des systèmes électroniques . 40

10.2.1 Généralités . 40

10.2.2 Allocation des exigences de sécurité . 40

10.2.3 Facteurs d'intégrité de sécurité . 43

10.2.4 Intégrité de sécurité fonctionnelle et défaillances aléatoires . 43

10.2.5 Aspect systématique de l'intégrité de sécurité fonctionnelle . 44

10.2.6 Équilibre des exigences contrôlant les défaillances aléatoires et

systématiques . 44

10.2.7 Tableau des SIL . 45

10.2.8 Allocation des SIL . 46

10.2.9 Allocation du TFFR après affectation des SIL . 46

10.2.10 Démonstration des objectifs quantifiés . 46

10.2.11 Exigences spécifiques relatives à l'intégrité de base . 46

10.2.12 Prévention de la mauvaise utilisation des SIL . 48

10.3 Intégrité de sécurité des systèmes non électroniques - Application d'un code de

bonne pratique . 48

11 Conception et réalisation . 49

11.1 Généralités . 49

11.2 Analyse des causes . 49

11.3 Identification dangers (affinage) . 50

11.4 Analyse des défaillances de cause commune . 51

Annexe A (informative) Utilisation des méthodes ALARP, GAME et MEM comme

exemples de critères d'acceptation du risque . 53

A.1 Utilisation des méthodes ALARP, GAME et MEM pour définir les critères

d'acceptation du risque . 53

A.2 Principe ALARP (aussi bas que cela est raisonnablement possible) . 54

A.2.1 Généralités . 54

A.2.2 Acceptabilité et ALARP . 55

A.3 Principe GAME (globalement au moins équivalent) . 55

A.3.1 Principe . 55

A.3.2 Utilisation du principe GAME . 56

A.4 Principe MEM (mortalité endogène minimale) . 57

Annexe B (informative) Utilisation des statistiques de défaillances et d'accidents pour

déterminer un THR . 59

Annexe C (informative) Lignes directrices relatives à l'allocation des SIL . 61

Annexe D (informative) Méthodes d'allocation des objectifs de sécurité. 62

D.1 Analyse du système et des méthodes . 62

D.2 Exemple de méthode d'allocation qualitative . 62

D.2.1 Généralités . 62

D.2.2 Exemple de méthode qualitative ou semi-quantitative pour l'efficience de la

barrière . 63

D.3 Exemple de méthode d'allocation quantitative . 65

D.3.1 Généralités . 65

D.3.2 Fonctions avec mécanismes indépendants de détection et de passivation

des défaillances . 67

D.3.3 Fonction et barrière indépendante faisant office de mécanisme de

détection et de passivation des défaillances . 69

D.3.4 Allocation d'un objectif de sécurité de probabilité . 70

D.3.5 Allocation d'un objectif de sécurité "par heure" . 70

Annexe E (informative) Erreurs courantes de quantification . 72

E.1 Généralités . 72

E.2 Confusion entre taux et probabilités de défaillance . 72

E.3 Utilisation des formules hors de leur plage d'applicabilité . 73

Annexe F (informative) Techniques et méthodes d'analyse de sécurité . 74

Annexe G (informative) Rôles et responsabilités essentielles de la sécurité du système . 76

Bibliographie . 81

Figure 1 – Le modèle du sablier . 11

Figure 2 – Représentation des dangers par rapport aux frontières du système . 13

Figure 3 – Exemple de processus d'acceptation de la sécurité . 17

Figure 4 – Exemples de dépendances entre des dossiers de sécurité . 19

Figure 5 – Indépendance des rôles dans les phases précoces du cycle de vie (phases 1

à 4) . 22

Figure 6 – Indépendance des rôles dans les phases ultérieures du cycle de vie (à partir

de la phase 5) . 23

Figure 7 – Exemple de modèle de risque . 25

Figure 8 – Taux acceptables dans un exemple de modèle de risque . 32

Figure 9 – Classification des exigences . 37

Figure 10 – Allocation des exigences de sécurité fonctionnelle . 41

Figure 11 – Catégorisation des mesures d'intégrité de sécurité . 45

Figure 12 – Défaillances de cause commune . 51

Figure 13 – Influence de la dépendance fonctionnelle dans une analyse par arbre de

panne . 52

Figure A.1 – Aversion différentielle du risque . 58

Figure D.1 – Exemple de méthode d'allocation qualitative . 63

Figure D.2 – Interprétation des temps de défaillance et de réparation . 66

Figure D.3 – Combinaison de deux fonctions avec mécanisme indépendant de détection

et de passivation des défaillances . 67

Figure D.4 – Allocation des exigences d'intégrité de sécurité . 68

Figure D.5 – Combinaison d'une fonction et d'une barrière indépendante faisant office de

mécanisme de détection et de passivation des défaillances. 69

Figure D.6 – Exemple d'allocation quantifiée . 71

Figure E.1 – Exemple de cas AAP . 72

Tableau 1 – Exemples de dangers . 27

Tableau 2 – Mesures quantitatives et qualitatives du SIL. 45

Tableau A.1 – Présentation des méthodes ALARP, GAME et MEM. 53

Tableau D.1 – Efficience basée sur les défaillances du composant . 64

Tableau D.2 – Efficience basée sur la connaissance du composant. 64

Tableau D.3 – Efficience basée sur l'utilisation du composant . 64

Tableau D.4 – Efficience basée sur la maintenance du composant . 65

Tableau F.1 – Techniques et méthodes d'analyse de sécurité . 74

Tableau F.2 – Techniques et mesures pour la BI et les SIL . 75

Tableau G.1 – Spécification du rôle du concepteur . 76

Tableau G.2 – Spécification du rôle du chargé de vérification . 77

Tableau G.3 – Spécification du rôle du chargé de validation . 78

Tableau G.4 – Spécification du rôle de l'évaluateur de sécurité indépendant . 79

Tableau G.5 – Spécification du rôle du chef de projet . 80

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

Applications ferroviaires -

Spécification et démonstration de la fiabilité, de la disponibilité, de la

maintenabilité et de la sécurité (FDMS) -

Partie 2 : Approche systématique pour la sécurité

AVANT-PROPOS

1) La Commission Électrotechnique Internationale (IEC) est une organisation mondiale de normalisation composée de

l'ensemble des comités électrotechniques nationaux (Comités nationaux de l'IEC). L'IEC a pour objet de favoriser la

coopération internationale pour toutes les questions de normalisation dans les domaines de l'électricité et de

l'électronique. À cet effet, l'IEC - entre autres activités - publie des Normes internationales, des Spécifications

techniques, des Rapports techniques, des Spécifications accessibles au public (PAS) et des Guides (ci-après

dénommés "Publication(s) de l'IEC"). Leur élaboration est confiée à des comités d'études, aux travaux desquels tout

Comité national intéressé par le sujet traité peut participer. Les organisations internationales, gouvernementales et

non gouvernementales, en liaison avec l'IEC, participent également aux travaux. L'IEC collabore étroitement avec

l'Organisation Internationale de Normalisation (ISO), selon des conditions fixées par accord entre les deux

organisations.

2) Les décisions ou accords officiels de l'IEC concernant les questions techniques représentent, dans la mesure du

possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de l'IEC intéressés

sont représentés dans chaque comité d'études.

3) Les Publications de l'IEC se présentent sous la forme de recommandations internationales et sont agréées comme

telles par les Comités nationaux de l'IEC. Tous les efforts raisonnables sont entrepris afin que l'IEC s'assure de

l'exactitude du contenu technique de ses publications ; l'IEC ne peut pas être tenue responsable de l'éventuelle

mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'encourager l'uniformité internationale, les Comités nationaux de l'IEC s'engagent, dans toute la mesure

possible, à appliquer de façon transparente les Publications de l'IEC dans leurs publications nationales et régionales.

Toutes divergences entre toutes Publications de l'IEC et toutes publications nationales ou régionales

correspondantes doivent être indiquées en termes clairs dans ces dernières.

5) L'IEC elle-même ne fournit aucune attestation de conformité. Des organismes de certification indépendants

fournissent des services d'évaluation de conformité et, dans certains secteurs, accèdent aux marques de conformité

de l'IEC. L'IEC n'est responsable d'aucun des services effectués par les organismes de certification indépendants.

6) Tous les utilisateurs doivent s'assurer qu'ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à l'IEC, à ses administrateurs, employés, auxiliaires ou mandataires, y

compris ses experts particuliers et les membres de ses comités d'études et des Comités nationaux de l'IEC, pour

tout préjudice causé en cas de dommages corporels et matériels, ou de tout autre dommage de quelque nature que

ce soit, directe ou indirecte, ou pour supporter les coûts (y compris les frais de justice) et les dépenses découlant

de la publication ou de l'utilisation de cette Publication de l'IEC ou de toute autre Publication de l'IEC, ou au crédit

qui lui est accordé.

8) L'attention est attirée sur les références normatives citées dans cette publication. L'utilisation de publications

référencées est obligatoire pour une application correcte de la présente publication.

9) L'IEC attire l'attention sur le fait que la mise en application du présent document peut entraîner l'utilisation d'un ou

de plusieurs brevets. L'IEC ne prend pas position quant à la preuve, à la validité et à l'applicabilité de tout droit de

brevet revendiqué à cet égard. À la date de publication du présent document, l'IEC n'avait pas reçu notification qu'un

ou plusieurs brevets pouvaient être nécessaires à sa mise en application. Toutefois, il y a lieu d'avertir les

responsables de la mise en application du présent document que des informations plus récentes sont susceptibles

de figurer dans la base de données de brevets, disponible à l'adresse https://patents.iec.ch. L'IEC ne saurait être

tenue pour responsable de ne pas avoir identifié de tels droits de brevets.

L'IEC 62278-2 a été établi par le comité d'études 9 de l'IEC : Matériels et systèmes électriques

ferroviaires. Il s'agit d'une Norme internationale.

Cette première édition, conjointement à l'IEC 62278-1, annule et remplace l'IEC 62278:2002. Cette

édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition

précédente :

a) rédaction de cette nouvelle Partie 2 qui fournit pour la première fois des lignes directrices et

des méthodes de sécurité dans le cadre du processus de management de la sécurité défini

dans l'IEC 62278-1:2025.

Le texte de cette Norme internationale est issu des documents suivants :

Projet Rapport de vote

9/3208/FDIS 9/3235/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote ayant

abouti à l'approbation du présent document.

La langue employée pour l'élaboration de cette Norme internationale est l'anglais.

Ce document a été rédigé selon les Directives ISO/IEC, Partie 2, il a été développé selon les

Directives ISO/IEC, Partie 1 et les Directives ISO/IEC, Supplément IEC, disponibles sous

www.iec.ch/members_experts/refdocs. Les principaux types de documents développés par l'IEC

sont décrits plus en détails à l'adresse www.iec.ch/standardsdev/publications.

La série IEC 62278 représente une partie de l'application spécifique au domaine ferroviaire de

l'IEC 61508. Les IEC 62278, IEC 62279 et IEC 62425 constituent l'équivalent relatif au secteur

ferroviaire de la série IEC 61508 en ce qui concerne les systèmes de communication ferroviaire,

de signalisation et de traitement. Dans les cas où la satisfaction aux exigences des documents

cités ci-dessus a été démontrée, il n'est pas prévu de démontrer davantage la conformité à la série

IEC 61508.

Une liste de toutes les parties de la série IEC 62278, publiées sous le titre général Applications

ferroviaires — Spécification et démonstration de la fiabilité, de la disponibilité, de la maintenabilité

et de la sécurité (FDMS), se trouve sur le site web de l'IEC.

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant la date de

maintenance indiquée sur le site web de l'IEC sous http://webstore.iec.ch dans les données

relatives à la publication recherchée. À cette date, la publication sera

– reconduite,

– supprimée, ou

– révisée.

INTRODUCTION

L'IEC 62278:2002 visait à introduire l'application d'un processus systématique de management de

la FDMS dans le domaine ferroviaire. L'application de l'IEC 62278:2002 et l'expérience acquise

au cours de ces dernières années ont révélé la nécessité de mettre en œuvre une démarche de

révision et de restructuration avec la volonté d'établir une approche systématique et cohérente de

la FDMS applicable à tous les domaines d'application ferroviaire, notamment la signalisation, le

matériel roulant et les installations fixes.

Le présent document fournit aux sociétés d'exploitation ferroviaire et aux industries ferroviaires

un processus permettant de mettre en œuvre une démarche cohérente de management de la

fiabilité, de la disponibilité, de la maintenabilité et de la sécurité, désignée par l'acronyme FDMS.

Les processus relatifs à la spécification et à la démonstration des exigences de FDMS sont les

pierres angulaires du présent document. Le présent document encourage une vision et une

démarche communes de management de la FDMS.

La série IEC 62278 est dérivée de la série de Normes européennes EN 50126:2017, comprenant

l'EN 50126-1:2017 et l'EN 50126-2:2017.

En ce qui concerne la sécurité, l'IEC 62278-1 fournit un processus de management de la sécurité

étayé par les lignes directrices et les méthodes décrites dans le présent document.

L'IEC 62278-1 et l'IEC 62278-2 ne sont pas liée à la technologie utilisée. En ce qui concerne la

sécurité, l'IEC 62278 adopte la perspective de la sécurité avec une approche fonctionnelle.

L'application du présent document peut être adaptée aux exigences spécifiques pour le système

en cours d'examen.

Le présent document peut être systématiquement appliqué par les sociétés d'exploitation et les

industries ferroviaires tout au long des phases du cycle de vie d'une application ferroviaire afin de

développer des exigences de FDMS spécifiques au domaine ferroviaire et de satisfaire à ces

exigences. L'approche système définie par le présent document facilite l'appréciation des

interactions relatives à la FDMS entre les éléments des applications ferroviaires, même si elles

sont complexes.

Le présent document promeut la synergie entre les parties prenantes du domaine ferroviaire afin

de parvenir au meilleur compromis entre les performances de FDMS et les coûts des applications