IEC 61089

Round wire concentric lay overhead electrical stranded conductors

Round wire concentric lay overhead electrical stranded conductors

Specifies the electrical and mechanical characteristics of round wire concentric lay overhead electrical stranded conductors. Supersedes IEC 60207, 60208, 60209 and 60210. [

]This English-language version is derived from the original bilingual publication by leaving out all French-language pages. Missing page numbers correspond to the French-language pages.

Round wire concentric lay overhead electrical stranded conductors - Amendment A1

General Information

- Status

- Not Published

- Technical Committee

- ISO/IEC JTC 1/SC 7 - Software and systems engineering

- Current Stage

- PPUB - Publication issued

- Start Date

- 20-Jun-1991

Overview

IEC 61089 defines the electrical and mechanical characteristics for round wire concentric lay overhead electrical stranded conductors. The standard covers conductors made from aluminium, zinc‑coated steel and aluminium‑clad steel, and includes amendments (Amendment 1) that update designations, material references and stranding requirements. It supersedes older IEC documents on similar conductor types and provides the framework used by manufacturers and utilities for conductor specification, testing and selection.

Why it matters: IEC 61089 ensures consistent properties for overhead conductors - enabling predictable conductivity, tensile strength and mechanical behaviour in transmission and distribution lines.

Key Topics

Scope and materials: Specifies permitted wire materials: hard‑drawn aluminium (A1), aluminium alloys (A2, A3), zinc‑coated steel (S1A, S1B, S2A, S3A) and aluminium‑clad steel (SA1A, SA1B, SA2). The standard references IEC 60104, IEC 60888, IEC 60889 and IEC 61232 for wire properties.

Designation system: Standardised conductor codes (e.g. A1, A1/S1A, A1/SA1A, SA2) identify material combinations and construction (homogeneous vs composite conductors).

Stranding and lay ratios: Amendment 1 specifies lay ratio ranges for steel wires and cores - for example, lay ratios for 6‑wire layers of 7‑ and 19‑wire steel cores (16 to 26), and limits for homogeneous steel conductors (10 to 16). It also requires that upper layers do not have larger lay ratios than inner layers.

Mechanical requirements: Defines rated tensile strength (RTS) assessment, notably that RTS of homogeneous steel conductors equals the sum of RTS of individual wires. For composite conductors (e.g. A1/SA1A), RTS is calculated from component wire failure strengths with compatibility assumptions.

Conductivity rules: Conductivity of composite aluminium/steel conductors is calculated while neglecting the steel contribution (steel conductivity typically taken as 9% IACS for Sx conductors). Conductivity of aluminium‑clad steel (SAx) uses values from IEC 61232.

Joints and workmanship: Amendment states no joints are permitted in zinc‑coated or aluminium‑clad steel wires during stranding; steel wire ends must lie naturally after cutting and be readily replaceable by hand.

Applications

IEC 61089 is directly applicable to:

- Design and specification of overhead transmission and distribution conductors.

- Procurement documents and technical specifications for utilities and line contractors.

- Quality control, verification of conductor conductivity and tensile properties during manufacturing and inspection.

Practical benefits include predictable electrical performance, consistent mechanical strength, and easier interoperability between suppliers and network operators.

Related Standards

- IEC 60104 - Aluminium and aluminium alloys for conductors (referenced for aluminium wire properties).

- IEC 60888 - Zinc‑coated steel wires (properties and classes used in IEC 61089).

- IEC 60889 - Hard‑drawn aluminium wire specifications.

- IEC 61232 - Aluminium‑clad steel wires (used to determine SAx conductivity and properties).

Keywords: IEC 61089, overhead conductors, concentric lay, round wire, aluminium, zinc‑coated steel, aluminium‑clad steel, lay ratio, conductivity, rated tensile strength (RTS).

Frequently Asked Questions

IEC 61089 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Round wire concentric lay overhead electrical stranded conductors". This standard covers: Specifies the electrical and mechanical characteristics of round wire concentric lay overhead electrical stranded conductors. Supersedes IEC 60207, 60208, 60209 and 60210. [<BR>]This English-language version is derived from the original bilingual publication by leaving out all French-language pages. Missing page numbers correspond to the French-language pages.

Specifies the electrical and mechanical characteristics of round wire concentric lay overhead electrical stranded conductors. Supersedes IEC 60207, 60208, 60209 and 60210. [<BR>]This English-language version is derived from the original bilingual publication by leaving out all French-language pages. Missing page numbers correspond to the French-language pages.

IEC 61089 is classified under the following ICS (International Classification for Standards) categories: 29.060.10 - Wires; 29.240.20 - Power transmission and distribution lines. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61089 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

SIST IEC 61089:1999

01-november-1999

Round wire concentric lay overhead electrical stranded conductors - Amendment

A1

Round wire concentric lay overhead electrical stranded conductors

Ta slovenski standard je istoveten z: IEC 61089

ICS:

29.060.10 Žice Wires

29.240.20 Daljnovodi Power transmission and

distribution lines

SIST IEC 61089:1999 en

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

CEI

NORME

IEC

INTERNATIONALE

INTERNATIONAL

Première édition

STANDARD

First edition

1991-05

Conducteurs pour lignes aériennes

à brins circulaires, câblés en couches

concentriques

Round wire concentric lay overhead

electrical stranded conductors

© CEI 1991 Droits de reproducti réservés — Copyright — all rights reserved

on

or utilized in

Aucune partie de cette publication no peut être reproduite ni No part of this publication may be reproduced

utilisée sous quelque forme quo ce soit et par aucun pro- any tortu or by any means. electronic « mecharicai,

cédé. é ectrorêque

ou mêeanlw. y compds la photocopie et krekdlrg photocopying ad mkratikn, without pemdsslon

les microfilms. sans raccord écrit do l'éditeur.

In writing from the publisher.

Bureau Central de la Commission Electrotechnique Internationale 3, rue de Varembé Genève, Suisse

Commission Electrotechnique Internationale

CODE PRIX "

International Electrotechnical Commission

PRICE CODE V

Meautriapoanaa 3nearpoTexHwlecaaa H0Mttccua

IEC

• •

Pour pr&, voir catalogue en vigueur

For price, see current catalogue

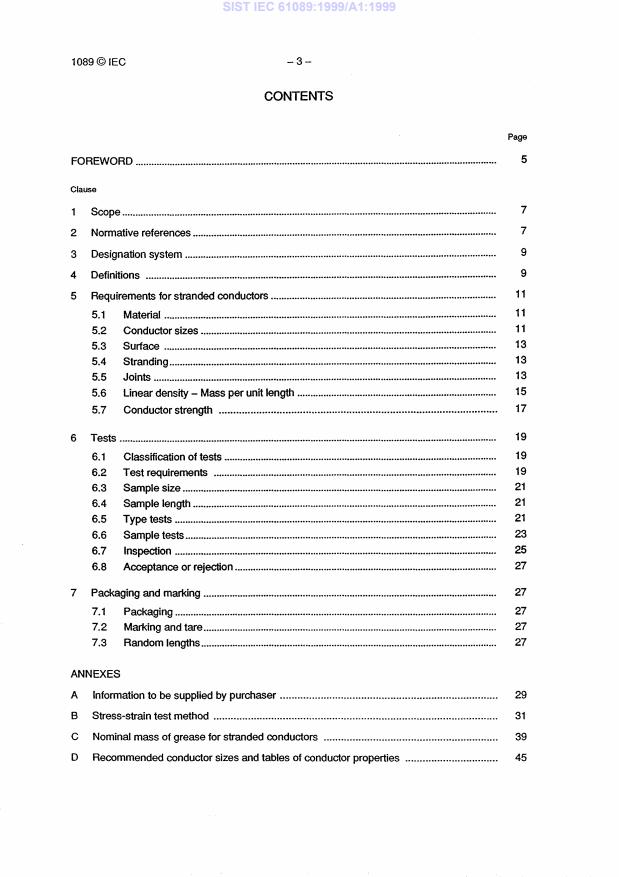

1089©IEC – 3 –

CONTENTS

Page

5 FOREWORD

Clause

1 Scope

2 Normative references

3 Designation system

4 Definitions

5 Requirements for stranded conductors

5.1 Material

5.2 Conductor sizes

5.3 Surface

5.4 Stranding 13

5.5 Joints

5.6 Linear density – Mass per unit length

5.7 Conductor strength

6 Tests

6.1 Classification of tests 19

6.2 Test requirements

6.3 Sample size

6.4 Sample length

6.5 Type tests

6.6 Sample tests 23

6.7 Inspection

6.8 Acceptance or rejection

7 Packaging and marking

7.1 Packaging

7.2 Marking and tare

7.3 Random lengths

ANNEXES

A Information to be supplied by purchaser 29

B Stress-strain test method 31

C Nominal mass of grease for stranded conductors 39

D Recommended conductor sizes and tables of conductor properties 45

- 5 -

1089©IEC

COMMISSION

INTERNATIONAL ELECTROTECHNICAL

ROUND WIRE CONCENTRIC LAY OVERHEAD

ELECTRICAL STRANDED CONDUCTORS

FOREWORD

1) The formal decisions or agreements of the IEC on technical matters, prepared by Technical Committees on

which all the National Committees having a special interest therein are represented, express, as nearly as

possible, an international consensus of opinion on the subjects dealt with.

They have the form of recommendations for international use and they are accepted by the National

2)

Committees in that sense.

In order to promote international unification, the IEC expresses the wish that all National Committees

3)

should adopt the text of the IEC recommendation for their national rules in so far as national conditions will

permit. Any divergence between the IEC recommendation and the corresponding national rules should, as

far as possible, be clearly indicated in the latter.

This standard has been prepared by IEC Technical Committee No. 7: Bare aluminium

conductors.

The text of this standard is based on the following documents:

Report on Voting

Six Months' Rule Report on Voting Two Months' Procedure

7(00)431 7(00)433

7(00)429 7(00)430

Full information on the voting for the approval of this standard can be found in the Voting

Reports indicated in the above table.

This standard replaces the following publications:

IEC 207: 1966,

Aluminium stranded conductors.

IEC 208: 1966, Aluminium alloy stranded conductors (aluminium-magnesium-silicon type).

IEC 209: 1966, Aluminium conductors, steel-reinforced.

IEC 210: 1966, Aluminium alloy conductors, steel-reinforced.

Annexes A, B and C form an integral pa rt of this International Standard.

Annex D is for information only.

1089©IEC - 7 -

ROUND WIRE CONCENTRIC LAY OVERHEAD

ELECTRICAL STRANDED CONDUCTORS

1 Scope

1.1 This International Standard specifies the electrical and mechanical characteristics of

round wire concentric lay overhead electrical stranded conductors made of combinations

of any of the following metal wires:

a) hard-drawn aluminium as per IEC 889 designated Al*;

b) aluminium alloy type B as per IEC 104 designated A2*;

c) aluminium alloy type A as per IEC 104 designated A3* (and when applicable to the

following cores, as per IEC 888);

d) regular strength steel, designated S1A or S1 B, where A and B are zinc coating

classes, corresponding respectively to classes 1 and 2;

e) high strength steel, designated S2A or S2B;

f) extra high strength steel, designated S3A.

1.2 The conductor designations included in this standard are:

Al, A2, A3,

Al/S1A, Al/S1B, Al/S2A, Al/S2B, Al/S3A, A2/S1A,

A2/S 1 B, A2/S3A, A3/S 1 A,

A3/S 1 B, A3/S3A, Al /A2, A1 /A3.

2 Normative references

The following standards contain provisions which, through reference in this text, constitute

provisions of this International Standard. At the time of publication of this standard, the

editions indicated were valid. All standards are subject to revision, and parties to agree-

ments based on this International Standard are encouraged to investigate the possibility of

applying the most recent editions of the standards indicated below. Members of IEC and

ISO maintain registers of currently valid International Standards.

IEC 104: 1987, Aluminium-magnesium-silicon alloy wire for overhead line conductors.

IEC 888: 1987,

Zinc-coated steel wires for stranded conductors.

IEC 889: 1987,

Hard-drawn aluminium wire for overhead line conductors.

The resistivity of these metals is as follows (in increasing order):

Al: 28,264 nS1m (corresponding to 61% IACS),

A2: 32,530 nQm (corresponding to 53% IACS),

A3:

32,840 nam (corresponding to 52,5% IACS).

1089©IEC - 9 -

3 Designation system

3.1 A designation system is used to identify stranded conductors made of aluminium,

with or without steel wires.

3.2 Homogeneous aluminium conductors are designated Ax, where x identifies the type

of aluminium.

3.3 Composite aluminium conductors are designated Ax/Ay, where Ax identifies external

wires (or the envelope) and Ay identifies internal wires (or the core).

3.4 Composite aluminium-steel conductors are designated Ax/Syz, where Ax identifies

the external aluminium wires (envelope), and Syz identifies the steel core. In the

designation of steel wires, y represents the type of steel (regular, high or extra high

strength) and z represents the class of zinc coating (A or B).

3.5 Conductors are identified as follows:

a) a code number giving the equivalent conductive section of Al aluminium expressed

in mm2;

b) a designation identifying the type of wires constituting the conductor. For composite

conductors the first designation applies to the envelope and the second to the core;

c) one or two numbers giving the stranding of the conductor. For composite conduc-

tors, the first number identifies the number of wires of the envelope and the second

identifies the number of wires of the core.

Examples:

500-Al-37: Conductor made of 37 wires of Al aluminium. Its area is 500 mm2.

500-A2-37: Conductor made of 37 wires of A2 aluminium with a total conductive area

equivalent to 500 mm 2 of Al aluminium. From the tables of annex D we find its actual

area is equal to 575 mm2.

500-A1 /S1 A-45/7: Conductor made of 45 wires of Al aluminium and 7 wires of regular

strength steel with class 1 zinc coating. The area of Al aluminium is 500 mm 2 and, from

the tables of annex D, the area of S1 A steel is 34,6 mm2.

500-A3/S3A-54/7: Conductor made of 54 wires of A3 aluminium and 7 wires of extra

high strength steel with class 1 zinc coating. The A3 aluminium area is equivalent in

conductivity to 500 mm 2 of Al aluminium (the actual area of A3 aluminium is 581 mm2

and of steel is 75,3 mm 2, which can be obtained from the tables of annex D).

4 Definitions

The following definitions apply in this International Standard:

aluminium: All types of aluminium and aluminium alloys listed.

conductor: A material intended to be used for carrying electric current consisting of a

plurality of uninsulated wires twisted together.

- 11 -

1089 © IEC

concentric lay stranded conductor: A conductor composed of a central core surrounded

by one or more adjacent layers of wires being laid helically in opposite directions.

direction of lay: The direction of twist of a layer of wires as it moves away from the

viewer. A right-hand lay is a clockwise direction and a left-hand lay is an anti-clockwise

direction.

Alternative definition: The direction of lay is defined as right-hand or left-hand. With right-

hand lay, the wires conform to the direction of the central part of the letter Z when the

conductor is held vertically. With left-hand lay, the wires conform to the direction of the

central part of the letter S when the conductor is held vertically.

lay length: The axial length of one complete turn of the helix formed by an individual wire

in a stranded conductor.

lay ratio: Means the ratio of the lay length to the external diameter of the corresponding

layer of wires in the stranded conductor.

lot: A group of conductors manufactured by the same manufacturer under similar condi-

tions of production. A lot may consist of part or all of the purchased quantity.

nominal: The name or identifying value of a measurable property by which a conductor or

component of a conductor is identified and to which tolerances are applied. Nominal

values should be target values.

steel ratio: The ratio of steel area to aluminium area as a percentage in Ax/Syz

conductors.

wire: A filament of drawn metal having a constant circular cross-section.

5 Requirements for stranded conductors

5.1 Material

Stranded conductors shall be made up of round aluminium wires and, when applicable, of

round zinc-coated steel wires. All wires shall have before stranding the properties speci-

fied in IEC 104, IEC 888 and IEC 889.

5.2 Conductor sizes

A list of conductor sizes is given as guidance in annex D and it is recommended that for

new designs of conductor sizes should be selected from those listed. Conductors for

existing or established designs of overhead lines as well as sizes and strandings not

included in this standard may be designed and supplied as agreed upon by the manu-

facturer and purchaser and the relevant requirements of this standard shall apply.

1089 ©IEC - 13 -

5.3 Surface

rf rfections visible to the unaided eye

The su ace of the conductor shall be free from all impe

(normal corrective lenses accepted), such as nicks, indentations, etc., not consistent with

good commercial practice.

5.4 Stranding

5.4.1 All wires of the conductor shall be concentrically stranded.

5.4.2 Adjacent wire layers shall be stranded with reverse lay directions. The direction of

lay of the external layer shall be "right-hand" except when specifically indicated in the

purchase order.

5.4.3 The wires in each layer shall be evenly and closely stranded around the underlying

wire or wires.

5.4.4 The lay ratios for the zinc-coated steel wire layers shall be as follows:

the lay ratio for the six-wire layer of 7 and 19-wire steel cores shall be not less than

a)

16 nor more than 26;

b) the lay ratio for the 12-wire layer of 19-wire steel core shall be not less than 14 nor

more than 22.

5.4.5 The lay ratios for the aluminium layers of all types of conductor shall be as follows:

a) the lay ratio for the outside layer of aluminium wires shall be not less than 10 nor

more than 14;

b) the lay ratios for the inner layers of aluminium wires shall be not less than 10 nor

more than 16.

5.4.6 In a 19-wire steel core, the lay ratio of the 12-wire layer shall be not greater than

the lay ratio of the 6-wire layer. Similarly, in a conductor having multiple layers of alu-

minium wires, the lay ratio of any aluminium layer shall be not greater than the lay ratio of

the aluminium layer immediately beneath it.

5.4.7 All steel wires shall lie naturally in their position in the stranded core, and where

the core is cut, the wire ends shall remain in position or be readily replaced by hand and

then remain approximately in position. This requirement also applies to the outer layer of

aluminium wires of a conductor.

5.4.8 Before stranding, aluminium and steel wires shall have approximately uniform

temperatures.

5.5

Joints

5.5.1 There shall be no joints of any kind made in the zinc-coated steel core wire or wires

during stranding.

5.5.2 No more than one jointed aluminium finished wire as permitted in the references of

5.1 shall be used per length of conductor.

1089©IEC – 15 –

5.5.3 During stranding, no aluminium wire welds shall be made for the purpose of achiev-

ing the required conductor length.

5.5.4 Joints are permitted in aluminium wires unavoidably broken during stranding,

provided such breaks are not associated with either inherently defective wire or with the

use of short lengths of aluminium wires. Joints shall conform to the geometry of original

wire, i.e. joints shall be dressed smoothly with a diameter equal to that of the parent wires

and shall not be kinked.

Joints in aluminium wires shall not exceed those specified in table 1. These joints shall

not be closer than 15 m from a joint in the same wire or in any other aluminium wire of the

completed conductor.

Joints shall be made by electric butt welding, electric butt cold upset welding or cold

pressure welding (note 1) and other approved methods. These joints shall be made in

accordance with good commercial practice. The first type of joints shall be electrically

annealed for approximately 250 mm on both sides of the weld.

Table 1 – Number of joints permitted

in aluminium conductors

Number of aluminium Joints permitted per

layers conductor length

1 2

3 4

4 5

5.5.5 While the joints specified in 5.5.4 are not required to meet the requirements of un-

jointed wires (note 2), they shall withstand a stress of not less than 75 MPa for annealed

electric buttwelded joints, and not less than 130 MPa for cold pressure and electric butt

cold upset welded joints. The manufacturer shall demonstrate that the proposed welding

method is capable of meeting the specified strength requirements.

NOTES

1 It is a practice in some countries to require the annealing of cold pressure joints made in A2 or A3 material.

2 The behaviour of properly spaced wire joints in stranded conductor is related to both tensile strength

and elongation. Because of higher elongation properties, the lower strength annealed electric buttwelded

joint gives a similar overall pe rformance to that of a cold pressure or an electric butt cold upset welded

joint.

5.6

Linear density – Mass per unit length

5.6.1 The masses given in the tables of annex D have been calculated for each size and

stranding of conductor using densities for the aluminium and zinc-coated steel wires as

given in the standards listed in 5.1, the stranding increments given in table 2, and the

cross-sectional areas for aluminium and zinc-coated steel wires based on their theoretical

unrounded diameters.

1089©!EC - 17 --

5.6.2 The increments (note 1) in per cent, for mass due to stranding, based on the mean

lay ratios given in 5.4.4 and 5.4.5, shall be taken as given in table 2.

5.6.3 Whenever a conductor is to be greased (note 2), the nominal mass of grease shall

be calculated according to the method given in annex C.

NOTES

1 The mass of a stranded conductor is affected by the lay factor. With the exception of the centre wire,

all wires are longer than the stranded conductor and the increase in mass depends upon the lay ratio

employed.

2 Grease requirements are under consideration.

Table 2 - Standard* increments due to stranding

Increment (increase)

Stranding of conductor

Aluminium Steel Mass Electrical

resistance

Number of Number of Number of Number of

Aluminium Steel

wires layers** wires layers**

6 1 1 - 1,52 - 1,52

18 2 1 - 1,90 - 1,90

1,31

7 1 - - 1,31 -

18 1 - 1,90 - 1,90

22 2 7 1 2,04 0,43 2,04

26 2 7 1 2,16 0,43 2,16

19 - 1,80

2 - - 1,80

37 3 - - 2,04 - 2,04

61 4 - - 2,19 - 2,19

45 3 7 1 2,23 0,43 2,23

54 3 1 2,33

7 2,33 0,43

72 4 7 1 2,32 0,43 2,32

84 4 7 1 2,40 0,43 2,40

91 5 - - 2,30 - 2,30

54 2 2,33

3 19 2,33 0,77

72 4 19 2 2,32 0,77 2,32

84 4 19 2,40

2 0,77 2,40

* These increments have been calculated using average lay ratios for each applicable layer of aluminium or

steel.

** Number of layers of each type of wire not including the central wire.

5.7 Conductor strength

5.7.1 The rated tensile strength of a homogeneous aluminium conductor shall be taken as

the sum of the minimum tensile strength of all wires as defined in 5.7.4.

5.7.2 The rated tensile strength of composite Ax/Syz conductors shall be the sum of

the tensile strength of the aluminium po rt

ion plus the strength of steel corresponding

to an elongation compatible with that of aluminium at rupture load. For the purpose of

1089©IEC - 19 -

specification and practicability, this strength of steel is conservatively established as the

stress corresponding at 1% elongation in a 250 mm gauge length.

5.7.3 The rated tensile strength of composite aluminium conductors (Al/A2 or Al/A3)

shall be taken as the sum of the tensile strength of Al portion plus 95% of the tensile

strength of A2 or A3 portion.

5.7.4 The tensile strength of any single wire is the product of its nominal area and the

appropriate minimum stress given in the standards listed in 5.1.

6 Tests

6.1 Classification of tests

6.1.1

Type tests

Type tests are intended to verify the main characteristics of a conductor which depend

mainly on its design. They are carried out once for a new design or manufacturing process

of conductor and then subsequently repeated only when the design or manufacturing

process is changed.

Type tests shall be carried out only on a conductor which meets the requirements of all

the relevant sample tests.

6.1.2 Sample tests

Sample tests are intended to guarantee the quality of conductors and compliance with the

requirements of this standard.

6.2 Test requirements

Test requirements are as follows:

6.2.1 Type tests

a) joints in aluminium wires;

b) stress-strain curves;

c) breaking strength of conductor.

6.2.2

Sample tests

a) on wire before stranding:

- as per the applicable wire standards;

b) on the conductor:

- cross-sectional area;

- overall diameter;

- linear density;

-

surface condition;

- lay ratio and direction of lay.

1089©IEC -21 -

6.3 Sample size

Samples for the tests specified in 6.2.2 shall be taken at random from the outer end

ace condition of the

of 10% of the drums of conductor. However, the inspection of the su rf

conductor shall be carried out on every drum prior to lagging.

6.4 Sample length

6.4.1 Samples for tests on individual aluminium and zinc-coated steel core wires shall be

taken before stranding and tested in accordance with the standards listed in 5.1.

6.4.2 Samples for tests of individual wires after stranding when requested, shall consist

of a 1,5 m length or cut from the outer end of the coils or drums of conductors.

6.4.3 The sample length required for tensile and stress-strain tests shall be at least

400 times the diameter of the conductor but not less than 10 m.

The length of samples in this subclause is the minimum required for a good accuracy of

stress-strain curves. In cases where the manufacturer can demonstrate to the satisfaction

of the purchaser with significant comparative test results that a shorter length can give

equally accurate results then a short length of samples may be used.

6.5 Type tests

6.5.1 Stress-strain curves shall be supplied as a type test when requested by the

purchaser and shall represent the best knowledge of the behaviour of the purchased

conductor under load.

6.5.2 If agreed between purchaser and supplier when placing an order, stress-strain tests

shall be performed on the conductor and, when applicable, on the steel core, in

accordance with the method given in annex B.

6.5.3 Tensile test of the conductor

When tests for breaking strength of conductors are required, these shall withstand, without

the fracture of any wire not less than 95% of their rated tensile strength calculated accord-

ing to 5.7.

The breaking strength of conductors shall be determined by pulling a conductor in a

suitable tensile testing machine having an accuracy of at least ±1%. It is recommended

that the rate of increase of load should be as in B.6.8 of annex B. For the purposes of this

test, appropriate fittings shall be installed on the ends of the conductor samples. During

this test, the breaking strength of the conductor shall be determined by the load attained

at which one or more wires of the conductor are fractured. A retest, up to a total of three

tests, may be made if wire fracture occurs within 1 cm of the end fittings and the tensile

strength falls below the specified breaking strength requirements.

1089©IEC - 23 -

6.5.4

Welding of aluminium wires

The manufacturer shall demonstrate to the purchaser that the method used for jointing

aluminium wires meets the strength requirements of 5.5.5 by supplying recent test results

or by performing the necessary tests.

6.6

Sample tests

6.6.1 Cross-sectional area

rtion of a stranded conductor shall

6.6.1.1 The cross-sectional area of the aluminium po

be taken as the sum of the areas of the aluminium wires composing the conductor based

on the diameter measurements made in accordance with 6.6.1.3.

This area shall not vary from the nominal value by more than ±2% in any sample and by

more than ±1,5% for the average of any four measured values at locations selected at

random with a minimum spacing of 20 cm.

6.6.1.2 The area of steel core, where applicable, shall be taken as the sum of the areas

of the solid wires composing the steel core based on the diameter measurements made in

accordance with 6.6.1.3.

6.6.1.3 The diameter of a wire shall include the metallic coating, where applicable, and

shall be measured using a micrometer caliper having flat su rfaces on both the anvil and

the end of the spindle and graduated to be read in micrometres. The diameter d in milli-

metres shall be the average of three diameter measurements, each of which is the

average of the maximum and minimum readings at a point taken near each end and in the

centre of the sample.

6.6.2 Conductor diameter

The conductor diameter shall be measured midway between the closing die and the

capstan on the stranding machine.

Measurements shall be made with a caliper graduated to be read in 0,01 mm. The

diameter shall be the average of two readings, rounded to two decimals of a millimetre,

taken at right angles to each other at the same location.

The diameter of the conductor shall not vary by:

±1% for diameters larger than or equal to 10 mm;

±0,1 mm for diameters smaller than 10 mm.

6.6.3 Linear density - Mass per unit length

The linear density (mass per unit length) of the conductor shall be determined by using

apparatus capable of achieving an accuracy of ±0,1%.

The mass of the conductor per unit length without grease shall not vary from its nominal

value given in the tables by more than ±2%.

The mass of grease in a conductor shall be determined from the difference between the

mass of the conductor with grease and its mass after removing all the grease. The mass

of grease shall correspond at least to the minimum values specified in annex C.

1089 ©EC – 25 –

6.6.4 Breaking strength of wires

When required, breaking strength tests shall be made on wires obtained from conductors

after stranding. The specimen of wires shall be taken from the conductor sample and shall

be removed from its position and straightened, care being taken not to stretch it in so

doing.

The cross-sectional area of the wire is determined from the diameter measurements

indicated in 6.6.1.3. Then the straightened wire shall be installed in a suitable tensile test-

ing machine. The load shall be applied gradually with a rate of separation of the jaws not

less than 25 mm per minute and not greater than 100 mm per minute.

The load at failure divided by the cross-sectional area of the wire shall be not less than

95% of the applicable stress requirements prior to stranding. (The 5% reduction accounts

for handling and twisting of wires during stranding.)

6.6.5

Surface condition

The surface of the conductor shall comply with the requirements of 5.3.

6.6.6

Lay ratio and direction of lay

The lay ratio of each layer of the conductor shall be obtained through the ratio of the

measured lay length to the external diameter of the applicable layer.

The obtained values shall comply with the requirements of 5.4. In addition the direction of

each layer shall be noted and shall also comply with the requirements of 5.4.

6.7 Inspection

6.7.1 All tests and inspection shall be made at the manufacturer's plant prior to shipment

unless mutually agreed between the manufacturer and the purchaser at the time of pur-

chase and shall be so conducted as not to interfere unnecessarily with the manufacturer's

operations. The manufacturer shall afford the inspector, representing the purchaser, all

necessary and sufficient testing facilities in order to satisfy him that the material is being

furnished in accordance with this standard.

6.7.2 When inspection is to be made by the purchaser before shipment, the tests shall

all be made within 10 days after receipt of a notice by the purchaser that the material is

ready to test, and the material shall be accepted or rejected at the manufacturer's plant.

If the purchaser does not have a representative present at the manufacturer's plant to test

the material at the expiration of the said 10 days, the manufacturer shall make the tests

herein provided for and furnish to the purchaser, when requested, official copies of the

results of such tests, and the purchaser shall accept or reject the material in accordance

with the results of such tests. Alternatively, the manufacturer may provide relevant test

results if these have already been carried out in production.

1089 0O IEC – 27 –

6.8 Acceptance or rejection

6.8.1 Failure of a test specimen to comply with any one of the requirements of this

standard shall constitute grounds for rejection of the lot represented by the specimen.

6.8.2 If any lot is so rejected, the manufacturer shall have the right to test, only once, all

individual drums of conductors in the lot and submit those which meet the requirements for

acceptance.

7 Packaging and marking

7.1 Packaging

The conductor shall be suitably protected against damage which could occur in ordinary

handling and shipping.

NOTE - The following shall be agreed upon between the manufacturer and the purchaser at the time of

placing the order or at the earliest possible time:

a) the type and size of package and method of packing;

b) the packaging size and drum bore requirements and also the availability of the inner end of the conduc-

tor for grounding purposes, where conductor stringing practices require special consideration.

7.2 Marking and tare

The gross, net and tare weight, length (or length and number of pieces, if more than one

length is agreed upon to be supplied on the same drum), designation, and any other

necessary identification shall be suitably marked inside the package. This same inform-

ation, together with the purchase order number, the manufacturer's serial number (if any)

and all shipping marks and other information shall appear on the outside of each package.

7.3

Random lengths

Random lengths of conductors unavoidably obtained during production shall not exceed

5% of the length providing that no piece is less than 50% of the contractual length.

1089©IEC - 29 -

Annex A

(normative)

Information to be supplied by purchaser

When making an enquiry or placing an order the purchaser shall furnish the following

information:

a)

quantity of conductors;

b) cross-sectional area, designation and stranding of conductor;

c) length of conductor per drum, its tolerance, and where applicable, matching of

conductor lengths;

d) type and size of package and method of packing;

e) special packaging requirements, if any;

f) lagging requirements, if any;

g) if inspection is required and the place of inspection;

h) whether tests on wires after stranding are required;

i) whether conductor breaking strength tests are required;

j) whether conductor stress-strain tests are required;

k) direction of lay. If this information is omitted, the direction of the external lay shall

be right-hand;

I) requirements for grease, if any (type, properties, etc.).

1089©IEC -31 -

Annex B

(normative)

Stress-strain test method

B.1 Sample length

A conductor length as given in 6.4.3 shall be tested to obtain representative stress-strain

curves.

B.2 Test temperature

The temperature of the sample shall be recorded and shall not vary by more than ±2 °C

during the test. Temperature readings shall be taken at the beginning and end of each

hold period.

B.3 Sample preparation

Great care shall be taken in the preparation of test samples. Relative displacements as

small as 1 mm between the steel core and the aluminium layers of the conductor cause

significant changes in the measured stress-strain curves. The sample preparation shall be

as follows:

B.3.1 Before removing the sample from the drum, fit a bolted clamp 5 m ±1 m from the

end of the conductor length. The clamp shall apply sufficient pressure to prevent relative

wire movements in the conductor.

B.3.2 Unwind the desired length of conductor from the drum and install another bolted

clamp at the required distance from the first clamp. Apply adhesive tape and cut the

conductor at a distance from the clamp just far enough to allow room for applying

dead-end fittings.

B.3.3 During transpo rtation to the test laboratory, the sample shall be properly protected

from damage. The diameter of the coil or drum of the sample shall be at least 50 times the

conductor diameter.

B.3.4 End fittings such as compression, epoxy type or solder type approved by the

purchaser shall be used for stress-strain tests. The wires shall not be unwound, cleaned

or greased prior to application of the end fittings.

B.3.5 Care shall be taken not to damage any wire during the end preparation of the

sample.

B.3.6 The application of the end fitting shall not introduce any slack in the wires which

might alter the stress-strain curves of the conductor.

1089 ©IEC – 33 –

B.4 Requirements (only for compression fittings)

B.4.1 Whenever compression fittings are used for testing Ax/Syz conductors, the

methodology indicated in B.4.2 to B.4.4 shall be used.

B.4.2 Slide the aluminium sleeve on to the conductor. Cut back the aluminium wires to

allow room for the steel terminal, the extrusion of the steel terminal and the extrusion of

aluminium wires by the aluminium compression sleeve. The space required between the

aluminium wires and the steel terminal, before crimping, is typically 30 mm to 40 mm.

Slide the compression steel dead-end terminal on to the steel core. Crimp the steel

terminal, with a 2% to 10% maximum overlap, starting from the outer core end.

B.4.3 Pull the aluminium sleeve on to the steel terminal. Leave 40 mm of space if the

conductor diameter is less than or equal to 30 mm and 50 mm of space if the conductor

diameter is greater than 30 mm, between the end of the aluminium sleeve and the

shoulder of the steel terminal for extrusion. Make the first crimp on the tapered mouth of

the aluminium sleeve. This locks the sleeve in place and inhibits extrusion of aluminium

towards the test span. Proceed to crimp in the direction away from the span in small bites

of 20 % on uncompressed metal. Stop crimping before the filler hole in the sleeve is

reached; the steel terminal and core are too small to suppo rt the crimped aluminium

sleeve in this region. Continue crimping towards the eye, on the other side of the terminal

pad to lock the sleeve on to the expanded portion of the steel terminal.

B.4.4 The aluminium sleeve shall be oriented so that there is no interference with conduc-

tor movement during the test.

B.5 Test set-up

B.5.1 The test sample shall be supported in a trough over its full length and the trough

adjusted so that the conductor will not lift by more than 10 mm when under tension. This

shall be ascertained by measurement rather than by tensioning the conductor.

B.5.2 The distance between the clamp indicating the gauge length and the mouth of the

terminal sleeve shall be monitored with a caliper during the test to ensure that, after

the 85% load cycle, when unloaded to the preload, it does not change by more than 1 mm

from the value before the test (During the test the distance may change by more than

1 mm.) A resolution of 0,1 mm is adequate.

B.5.3 The conductor strain shall be evaluated from the measured displacements at the

two ends of the gauge length of the conductor. The gauge reference targets shall be

attached to the bolted clamps which lock the conductor wires together. Target plates may

be used with dial gauges or displacement transducers and care shall be taken to position

the plates perpendicular to the conductor. Twisting the conductor, li

fting it and moving it

from side to side by the maximum amounts expected during the test should introduce no

more than 0,3 mm error in the reading.

1089©IEC – 35 –

NOTES

1 Slack may cause the stranded wires to bulge radially outwards by several millimetres. The bulge

disappears at higher tensions as a result of elastic strain and reappears when the tension is released.

2 Pinging noises at higher tensions may be an indication that layers of wire are slipping or the aluminium

is slipping on the steel core because the bolted clamps are not tight enough. The result of loose bolted

clamps is that, as the slack moves towards the span, the targets are carried with them and the measured

strain will be less than the true strain.

B.6 Test loads for conductors

The loading conditions for stress-strain tests for conductors shall be as follows:

B.6.1 Load initially to 2% of RTS (rated tensile strength) to straighten the conductor. After

straightening remove the load' and set the strain gauges to zero at zero tension.

B.6.2 For non-continuous stress-strain data recordings, take the strain readings at inter-

vals of 2,5% RTS rounded off to the nearest kN.

B.6.3 Load to 30% RTS and hold for 0,5 h. Take readings after 5, 10, 15 and 30 min

during the hold period. Release to the initial load.

B.6.4 Re-load to 50% RTS and hold for 1 h. Take readings after 5, 10, 15, 30, 45 and

60 min. Release to the initial load.

B.6.5 Re-load to 70% RTS and hold for 1 h. Take readings after 5, 10, 15, 30, 45 and

60 min. Release to the initial load.

B.6.6 Re-load to 85% RTS and hold for 1 h. Take readings after 5, 10, 15, 30, 45 and

60 min. Release to the initial load.

B.6.7 After the fourth application of load, again apply tension, increasing uniformly, until

the actual breaking strength is reached. Simultaneous readings of tension and elongation

shall be taken up to 85% 2 RTS at the same intervals as for previous loading.

B.6.8 The rate of increase of load shall be uniform during testing. The time required to

reach 30% RTS shall not be less than 1 min nor more than 2 min. The same rate of load-

ing shall thereafter be maintained throughout the tests.

NOTES

1 When wedge type dead-end clamps are used for testing, removing the load may loosen the grip of the wedge;

consequently in this case, the initial load of 2% RTS shall be kept while setting strain gauges to zero.

2 Extra caution should be exercised when testing conductors, especially Al designation, above 70% RTS.

1089©IEC - 37 -

B.7 Test loads for steel core only

The loading conditions for stress-strain tests for the steel core of Ax/Syz shall be as

follows:

B.7.1 The test shall consist of successive applications of load applied in a manner similar

to that for the conductor at 30, 50, 70 and 85% RTS.

B.7.2 The steel core shall be loaded until the elongation at the beginning of each hold

period corresponds to that obtained on the conductor at 30, 50, 70 and 85% RTS,

respectively.

B.8 Stress-strain curves

Obtain the stress-strain curve by drawing a smooth line through the 0,5 and 1 h points at

30, 50, 70 and 85% RTS loading. To obtain the typical curve, remove from the lower end

the presence of any aluminium slack that can be related to any observed extrusion enter-

ing the span from the compression dead-ends. Adjust the typical curve to pass through

zero. Both the laboratory and the typical stress-strain curves shall be submitted to the

purchaser.

1089 0 IEC – 39 –

Annex C

(normative)

Nominal mass of grease for stranded conductors

When it is required for bare conductors to be greased in order to reduce the risk of corro-

sion in some environments, the mass of grease can be calculated using the method given

in this annex.

Assuming the grease will completely fill the voids between the wires, the volume of grease

in any given layer of conductor (see figure C.1) can be calculated from the following

equation:

-D2) - nnd 2

V=(D g (Equation C.1)

where:

De is the external diameter of the layer

Di

is the internal diameter of the layer

d is the diameter of the wire in the layer

n is the number of wires in the layer

Vg is the volume of grease in the layer

Figure C.1

For conductors having multiple layers, the total mass of grease can be obtained by adding

the values obtained for each layer.

Since there is a geometric relationship between all parameters of equation C.1, it is

possible to express the total mass of grease in a conductor by the following relation:

Mg = k da

(Equation C.2)

where:

k is the factor which depends on the conductor stranding and the grease density and the fill factor (per-

centage of theoretical volume)

da is the wire diameter (in mm)

Mg

is the mass of grease (in kg/km)

1089 © IEC -41 -

are given in table C.1 for four cases of grease applications, a grease density

Values of k

of 0,87 g/cm3, and a minimum fill factor of 0,70:

Case 1: Steel core only greased (figure C.2).

Case 2: All the conductor is greased except the outer layer (figure C.3).

Case 3: All the conductor is greased including the outer layer (figure C.4).

rface of the wires in the outer

Case 4: All the conductor is greased except the outer su

layer (figure C.5).

Figure C.3 Figure C.4

Figure C.2

Figure C.5

1089 © IEC - 43 -

Table C.1 - Coefficients k for mass of grease

k1

Stranding

k2 k3 k4

All conductor All conductor All conductor

Aluminium Steel Steel core

greased greased greased

greased

except outer including outer except outer su rface

layer layer of wires in

outer layer

Case 1 Case 2 Case 3 Case 4

6 0,96

1 - - 0,46

7 - - -

0,96 0,46

18 1 - 0,96

2,87 1,87

22 0,30

7 1,57 3,81 2,69

26 7 0,58 2,17 4,72 3,37

19 - - 0,96 2,87 1,87

7 0,96 2,87 5,74 4,21

37 - - 2,87 5,74 4,21

61 - - 5,74 9,57

7,27

45 7 0,43 4,25

7,60 6,27

7 0,96 5,74 9,57 7,27

19 1,03 5,82 9,64 7,33

7 0,43 7,60 11,90 8,97

72 19 0,46

7,63 11,94 9,42

7 0,96 9,57 14,35

11,11

19 1,03 9,64 14,43 11,18

91 - -

9,57 14,35 11,11

1089 ©IEC – 45 –

Annex D

(informative)

Recommended conductor sizes and

tables of conductor properties

D.1 Scope

D.1.1 This annex contains recommended sizes for each of the conductor types listed in

1.2. It also contains all the conductor properties listed in tables D.1 to D.16 where each

table is applicable to only one conductor type.

D.1.2 The series of code numbers is common to all tables and it follows Renard series

R5, R10 and R20, depending on the range of conductor size.

D.1.3 The code number which precedes the conductor designation (example: 500 in

500-A2-37) represents the equivalent conductive area of Al aluminium.

D.1.4 Conductors with the same code number have the same d.c. resistance* inde-

pendent of their type, designation or stranding. Thus the proposed conductor sizes allow

an easier selection of the best conductor type when the conductivity (or the current-

carrying capacity) is specified from system studies.

D.2 Calculation of conductor properties

Conductors are specified with a code number followed by a material designation and then

by a stranding.

Examples: 500-A2-37

630-Al/Si B-45/7

Starting from this input all the conductor properties can be calculated and each value

obtained is rounded to the number of significant figures compatible with the requirements

of this standard.

D.2.1 Total area of aluminium wires, Aa

resistivity of Ax

A a = code number x (in mm2)

resistivity of Al

* Some differences in the d.c. resistance can occur due to rounding errors and to the influence of stranding increments.

These differences are very minor and affect only the fourth decimal.

1089©IEC – 47 –

This area is rounded to three significant figures for conductors smaller than 1 000 mm2

and four figures for conductors larger than 1 000 mm2.

D.2.2 Aluminium wire diameter, da

Aa

(in mm)

da =

V^

it Number of aluminium wires

The values of d given in the tables are rounded to two decimals. However, other

a

conductor properties before rounding are calculated using the unrounded wire diameter.

D.2.3 Steel wire diameter, ds

In layers of wires with uniform diameter, the number of wires increases by 6 from one

layer to the following layer.

Therefore when all layers of a conductor have identical diameters, the total number of

wires is one of the following: 7, 19, 37, 61, 91, etc.

If the total number of wires is different from one of those indicated above, the steel wire

diameter is different from that of the aluminium wire.

At the interf

ace between the steel and aluminium layers a geometrical relation can be

established between the total diameter of the steel core Ds, the number of wires n of the

first aluminium layer around the steel core, and da the diameter of the aluminium wire.

This relation is the following:

da 3

Ds n-3

and allows calculation of the steel wire diameter d

s from the calculated Ds.

Similarly, to da note that ds is rounded to two decimal figures.

D.2.4

Conductor diameter, D

The overall conductor diameter is computed from the number of layers of aluminium and,

where applicable, steel wires multiplied by their corresponding unrounded wire diameters.

The resulting value is rounded to three significant figures.

1089 ©IEC - 49 -

D.2.5

Linear mass, Mc

The cross-sectional areas of steel and aluminium wires are multiplied by the applicable

3 for Ax wires and 7,78 kg/dm3 for Syz wires.

densities at 20 °C of 2,70 kg/dm

T

...

SLOVENSKI STANDARD

01-november-1999

Round wire concentric lay overhead electrical stranded conductors - Amendment

A1

Round wire concentric lay overhead electrical stranded conductors

Ta slovenski standard je istoveten z: IEC 61089

ICS:

29.060.10 Žice Wires

29.240.20 Daljnovodi Power transmission and

distribution lines

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

INTERNATIONAL IEC

STANDARD 61089

AMENDMENT 1

1997-05

Amendment 1

Round wire concentric lay overhead

electrical stranded conductors

This English-language version is derived from the original

bilingual publication by leaving out all French-language

pages. Missing page numbers correspond to the French-

language pages.

IEC 1997 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical,

including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

H

Commission Electrotechnique Internationale

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

61089 Amend. 1 © IEC:1997 – 3 –

FOREWORD

This amendment has been prepared by IEC technical committee 7: Overhead electrical

conductors.

The text of this amendment is based on the following documents:

FDIS Report on voting

7/502/FDIS 7/506/RVD

Full information on the voting for the approval of this amendment can be found in the report on

voting indicated in the above table.

––––––––

Page 7

1 Scope

Amend as follows:

1.1 This International Standard specifies the electrical and mechanical characteristics of

round wire, concentric lay, overhead, electrical and stranded conductors made of combinations

of any of the following metal wires:

a) Aluminium wires

*

– hard drawn aluminium as per IEC 60889 designated A1 ;

– aluminium alloy type B as per IEC 60104, designated A2*;

– aluminium alloy type A as per IEC 60104, designated A3*.

b) Zinc coated steel wires (as per IEC 60888):

– regular strength steel, designated S1A or S1B, where A and B are zinc coating

classes, corresponding respectively to classes 1 and 2;

– high strength steel, designated S2A or S2B,

– extra high strength steel, designated S3A.

c) Aluminium-clad steel wires (as per IEC 61232):

– class 20SA, types A and B, designated respectively SA1A and SA1B;

– class 27SA, designated as SA2.

–––––––––

*

The resistivity of these metals is as follows (in increasing order):

A1: 28,264 nΩm (corresponding to 61 % IACS),

A2: 32,530 nΩm (corresponding to 53 % IACS),

A3: 32,840 nΩm (corresponding to 52,5 % IACS).

61089 Amend. 1 © IEC:1997 – 5 –

1.2 The conductor designations included in this standard are:

A1, A2, A3,

A1/S1A, A1/S1B, A1/S2A, A1/S2B, A1/S3A,

A2/S1A, A2/S1B, A2/S3A,

A3/S1A, A3/S1B, A3/S3A,

A1/A2, A1/A3,

A1/SA1A, A2/SA1A, A3/SA1A,

S1A, S1B, S2A, S3A,

SA1A, SA1B, SA2.

NOTE – Conductors made of the same wire designation are called homogeneous conductors (e.g. A1, A2, S1A,

SA2, etc.). Furthermore, whenever reference is made to steel wires or conductors, these can either be

aluminium-clad or zinc-coated (Sx or SAx).

2 Normative references

Add, to the list, the title of the following standard:

IEC 61232: 1993, Aluminium-clad steel wires for electrical purposes

Page 9

3 Designation system

Add the following paragraphs at the end of 3.2:

Homogeneous conductors made of zinc-coated steel wires are designated S1A, S1B, S2A,

S3A.

Homogeneous conductors made of aluminium-clad steel wires are designated SA1A, SA1B or

SA2.

Add the following paragraph at the end of 3.4:

When aluminium-clad steel wires SA1A are used in a composite conductor instead of zinc-

coated wires, the designation becomes Ax/SA1A.

Add the following paragraphs at the end of 3.5:

500-A1/SA1A-54/7: Conductor made of 54 wires of A1 aluminium and 7 wires of aluminium-

clad steel class 20SA wires, type A (SA1A). The area of the A1 aluminium wires is equal to

2 2

484 mm and 62,8 mm for the aluminium-clad steel wires which can be found in the tables

of annex D.

40-SA1A-19: Conductor made of 19 wires of aluminium-clad steel wires class 20SA, type A

(SA1A). The area of aluminium-clad steel wires is 120 mm

which has the same conductivity

as 40 mm of A1 aluminium wires.

40-S1A-19: Conductor made of 19 wires of regular strength steel wires, with a zinc coating

type A (S1A). The area of steel wires is 271,1 mm which has the same conductivity as 40

mm of A1 aluminium wires.

61089 Amend. 1 © IEC:1997 – 7 –

4 Definitions

Amend, on page 11, the definition of “steel ratio” as follows:

steel ratio: The ratio of steel cross-sectional area to aluminium cross-sectional area given as

a percentage.

Page 11

5.1 Material

Amend as follows:

Conductors shall be made up of round aluminium wires, or round steel wires (zinc-coated or

aluminium-clad) or their combinations. All wires shall have before stranding the properties

specified in IEC 60104, IEC 60888, IEC 60889, and IEC 61232.

Page 13

5.4 Stranding

Amend 5.4.4 as follows:

5.4.4 The lay ratios for steel wires (zinc-coated or aluminium-clad) shall be as follows:

a) The lay ratio for the 6-wire layer of the 7 and 19-wire steel cores shall be not less than 16

nor more than 26.

b) The lay ratio for the 12-wire layer of 19-wire steel core shall be not less than 14 nor more

than 22.

c) The lay ratio for homogeneous steel conductors shall not be less than 10 nor more than

16 for all layers.

Replace the text of 5.4.6 by the following:

5.4.6 In a conductor having multiple layers of wires, the lay ratio of any layer shall be not

greater than the lay ratio of the layer immediately beneath it.

Amend 5.4.7 as follows:

5.4.7 All steel wires shall lie naturally in their position after stranding, and when cut, the wire

ends shall remain in position or be readily replaced by hand and then remain approximately in

position. This requirement also applies to the outer layer of aluminium wires of a conductor.

Although it is desirable that all steel wires of a steel conductor remain in position after being

cut, it may be difficult to achieve this property for steel conductors with more than 19 wires.

61089 Amend. 1 © IEC:1997 – 9 –

5.5 Joints

Amend 5.5.1 as follows:

5.5.1 During stranding, there shall be no joints of any kind made in the zinc-coated or

aluminium-clad steel wire or wires.

Page 17

5.7 Conductor strength

Add, on page 19, the following new text to 5.7.2:

The rated tensile strength (RTS) of homogeneous steel conductors (Sxy or SAx) shall be taken

as the sum of RTS of all wires at failure.

NOTE – RTS of A1/SA1A is calculated with the failure strength of component wires, based on the assumption

that wires have compatible elongations at rupture.

Add, after 5.7.4, the following new subclause:

5.8 Conductivity

The conductivity of composite conductors made of a combination of aluminium and steel wires

is calculated while neglecting the contribution of the conductivity of steel wires.

NOTE – An exception to this rule can be admitted, following an agreement between concerned parties, in the

case of optical ground wires (OPGW) which are currently being studied by technical committee 7.

The conductivity of homogeneous conductors with aluminium-clad steel wires (SAx) is

calculated based on the relevant conductivity in IEC 61232.

The conductivity of homogeneous zinc-coated steel conductors (Sx) is calculated based on an

average conductivity of 9 % IACS.

– 10 – 61089 amend. 1 © CEI:1997

Page 65

Ajouter les tableaux conducteurs suivants à la fin de l'annexe D:

Add the following conductor tables at the end of annex D:

Tableau D.17 – Données pour conducteurs du type S1A

Table D.17 – Data for type S1A conductors

Code Section Nombre de Diamètre Masse Résistance Résistance

numérique fils linéique à la traction en courant

Fils Conducteur

continu

Area Diameter Linear Rated DC

Code Number of

mass strength resistance

number wires Wire Conductor

mm mm mm kg/km kN W/km

4 27,1 7 2,22 6,66 213,3 36,3 7,1445

6,3 42,7 7 2,79 8,36 335,9 55,9 4,5362

10 67,8 7 3,51 10,53 533,2 87,4 2,8578

12,5 84,7 7 3,93 11,78 666,5 109,3 2,2862

16 108,4 7 4,44 13,32 853,1 139,9 1,7861

16 108,4 19 2,70 13,48 857,0 142,1 1,7944

25 169,4 19 3,37 16,85 1339,1 218,6 1,1484

40 271,1 19 4,26 21,31 2142,6 349,7 0,7177

40 271,1 37 3,05 21,38 2148,1 349,7 0,7196

63 427,0 37 3,83 26,83 3383,2 550,8 0,4569

NOTE – Les propriétés des conducteurs sont basées sur une résistance en courant continu de 9 % IACS.

Conductor properties are based on a d.c. resistance of 9 % IACS.

Tableau D.18 – Données pour conducteurs du type S1B

Table D.18 – Data for type S1B conductors

Code Section Nombre de Diamètre Masse Résistance Résistance en

numérique fils linéique à la traction courant continu

Fils Conducteur

Area Diameter Linear Rated DC

Code Number of

mass strength resistance

number wires Wire Conductor

mm mm mm kg/km kN W/km

4 27,1 7 2,22 6,66 213,3 33,6 7,1445

6,3 42,7 7 2,79 8,36 335,9 51,7 4,5362

10 67,8 7 3,51 10,53 533,2 80,7 2,8578

12,5 84,7 7 3,93 11,78 666,5 100,8 2,2862

16 108,4 7 4,44 13,32 853,1 129,0 1,7861

16 108,4 19 2,70 13,48 857,0 131,2 1,7944

25 169,4 19 3,37 16,85 1339,1 201,6 1,1484

40 271,1 19 4,26 21,31 2142,6 322,6 0,7177

40 271,1 37 3,05 21,38 2148,1 322,6 0,7196

63 427,0 37 3,83 26,83 3383,2 508,1 0,4569

NOTE – Les propriétés des conducteurs sont basées sur une résistance en courant continu de 9 % IACS.

Conductor properties are based on a d.c. resistance of 9 % IACS.

61089 Amend. 1 © IEC:1997 – 11 –

Tableau D.19 – Données pour conducteurs du type S2A

Table D.19 – Data for type S2A conductors

Code Section Nombre de Diamètre Masse Résistance à Résistance

numérique fils linéique la traction en courant

Fils Conducteur

continu

Area Diameter Linear Rated DC

Code Number of

mass strength resistance

number wires Wire Conductor

mm mm mm kg/km kN W/km

4 27,1 7 2,22 6,66 213,3 39,3 7,1445

6,3 42,7 7 2,79 8,36 335,9 60,2 4,5362

10 67,8 7 3,51 10,53 533,2 93,5 2,8578

12,5 84,7 7 3,93 11,78 666,5 116,9 2,2862

16 108,4 7 4,44 13,32 853,1 199,7 1,7861

16 108,4 19 2,70 13,48 857,0 152,9 1,7944

25 169,4 19 3,37 16,85 1339,1 238,9 1,1484

40 271,1 19 4,26 21,31 2142,6 374,1 0,7177

40 271,1 37 3,05 21,38 2148,1 382,3 0,7196

63 427,0 37 3,83 26,83 3383,2 589,3 0,4569

NOTE – Les propriétés des conducteurs sont basées sur une résistance en courant continu de 9 % IACS.

Conductor properties are based on a d.c. resistance of 9 % IACS.

Tableau D.20 – Données pour conducteurs du type S3A

Table D.20 – Data for type S3A conductors

Code Section Nombre de Diametre Masse Résistance Résistance

numérique fils linéique à la traction en courant

Fils Conducteur

continu

Area Diameter Linear Rated DC

Code Number of

mass strength resistance

number wires Wire Conductor

mm mm mm kg/km kN W/km

4 27,1 7 2,22 6,66 213,3 43,9 7,1445

6,3 42,7 7 2,79 8,36 335,9 67,9 4,5362

10 67,8 7 3,51 10,53 533,2 103,0 2,8578

12,5 84,7 7 3,93 11,78 666,5 128,8 2,2862

16 108,4 7 4,44 13,32 853,1 164,8 1,7861

16 108,4 19 2,70 13,48 857,0 172,4 1,7944

25 169,4 19 3,37 16,85 1339,1 262,6 1,1484

40 271,1 19 4,26 21,31 2142,6 412,1 0,7177

40 271,1 37 3,05 21,38 2148,1 420,2 0,7196

63 427,0 37 3,83 26,83 3383,2 649,0 0,4569

NOTE – Les propriétés des conducteurs sont basées sur une résist

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...