IEC 61010-031:2002

(Main)Safety requirements for electrical equipment for measurement, control and laboratory use - Part 031: Safety requirements for hand-held probe assemblies for electrical measurement and test

Safety requirements for electrical equipment for measurement, control and laboratory use - Part 031: Safety requirements for hand-held probe assemblies for electrical measurement and test

Deals with the safety of hand-held and hand-manipulated probe assemblies. They are for use in the interface between an electrical phenomenon and test or measurement equipment. Three main types are described: (A) Low-voltage and high-voltage, non-attenuating probe assemblies. For voltages less lthan 63 kV. They do not incorporate active components. (B) High-voltage attenuating or divider probe assemblies. For voltages less than 63 kV. They incorporate a divider function. (C) Low voltage attenuating or divider probe assemblies. For voltages less than 1 kV r.m.s or 1,5 kV d.c. They incorporate a signal conditioning function. It has the status of a group safety publication in accordance with IEC Guide 104.

Règles de sécurité pour appareils électriques de mesurage, de régulation et de laboratoire - Partie 031: Prescriptions de sécurité pour sondes équipées tenues à la main pour mesurage et essais électriques

Décrit la sécurité des sondes équipées tenues à la main et manipulées. Elles sont destinées à être utilisées dans l'interface entre un phénomène électrique et un instrument de mesure ou d'essai. Trois types principaux sont décrits; (A) Sondes équipées, sans atténuation, à basse tension et à haute tension. La tension est inférieure à 63 kV. Elles ne comportent aucun composant actif. (B) Sondes équipées à atténuateur ou diviseur à haute tension. La tension est inférieure à 63 kV. Elles comportent une fonction diviseur. (C) Sondes équipées à atténuateur ou diviseur à basse tension. La tnsion est inférieure à 1 kV efficace ou 1,5 kV continu. Elles comportent une fonction conditionneur de signal. Elle a le statut de publication groupée de sécurité conformément au guide CEI 104.

General Information

- Status

- Published

- Publication Date

- 09-Jan-2002

- Technical Committee

- TC 66 - Safety of measuring, control and laboratory equipment

- Drafting Committee

- WG 2 - TC 66/WG 2

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 29-May-2015

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61010-031:2002 is a critical international standard published by the International Electrotechnical Commission (IEC) that establishes comprehensive safety requirements for hand-held probe assemblies used in electrical measurement and testing. These probe assemblies serve as the essential interface between electrical phenomena and test or measurement equipment, making safety paramount for users and equipment alike. This standard specifically addresses hand-held and hand-manipulated probes designed for various voltage levels and applications, ensuring reliable protection against electric shock and mechanical hazards during electrical testing.

The standard classifies hand-held probe assemblies into three main types, each tailored for specific voltage ranges and technical functions:

- Type A: Low and high-voltage non-attenuating probes for voltages less than 63 kV, without active components.

- Type B: High-voltage attenuating or divider probes for voltages less than 63 kV.

- Type C: Low-voltage attenuating or divider probes incorporating signal conditioning, for voltages below 1 kV r.m.s or 1.5 kV d.c.

IEC 61010-031 plays a vital role in harmonizing safety practices worldwide, supporting manufacturers, testers, and end users in minimizing electrical hazards during measurement and diagnostic activities in laboratory and industrial environments.

Key Topics

Safety and Performance Requirements: The standard defines rigorous criteria for electrical insulation, clearances, creepage distances, and voltage withstand tests to prevent electric shock and fire hazards.

Mechanical Protection: It specifies mechanical resistance tests including rigidity, drop, and impact tests to ensure the durability and reliability of probe assemblies under typical handling conditions.

Testing Procedures: Detailed sequences of electrical and mechanical tests for each probe type verify compliance with safety parameters, including single-fault conditions to confirm resilience against failures.

Marking and Documentation: Requirements for clear labeling and warning signs on probe assemblies aid user awareness, complemented by comprehensive documentation to support safe usage.

Environmental Considerations: IEC 61010-031 covers the influence of environmental factors such as altitude and temperature on electrical safety to ensure performance in varied operational settings.

Applications

IEC 61010-031 is essential for a wide range of industries and scenarios where safe electrical measurement is crucial:

Electrical Testing and Troubleshooting: Ensures that portable probes used by electrical engineers and technicians meet safety standards during measurements of voltage, current, and other electrical parameters in the field or on-site.

Laboratory Environments: Supports safe operation of hand-held probes in research and testing laboratories handling sensitive and high-voltage measurements.

Industrial Control and Maintenance: Guides manufacturers and maintenance personnel in selecting and using safe probe assemblies for control systems diagnostics and verification.

Training and Education: Provides a reference framework for educational institutions and training programs involved in electrical safety practices.

By adhering to IEC 61010-031, organizations mitigate risks of electric shock, fire, and mechanical failure, enhancing worker safety and equipment reliability.

Related Standards

To complement IEC 61010-031, the following IEC standards and documents offer additional guidance on safety and measurement equipment:

IEC 61010-1: General safety requirements for electrical equipment for measurement, control, and laboratory use.

IEC 61010-2-030: Safety requirements for testing and measurement probes.

IEC Guide 104: Group safety publications, providing overarching principles for IEC safety standards.

ISO/IEC 61131 Series: Standards on programmable controllers relevant to control measurement equipment.

Organizations implementing IEC 61010-031 should also consult these related standards to ensure holistic compliance with international safety and performance criteria for electrical measurement systems.

Keywords: IEC 61010-031, hand-held probe assemblies, electrical measurement safety, probe assembly safety standard, electrical testing safety, high-voltage probes, attenuating probes, electrical measurement equipment, IEC safety standards, electrical shock protection, measurement control lab equipment safety.

IEC 61010-031:2002 - Safety requirements for electrical equipment for measurement, control and laboratory use - Part 031: Safety requirements for hand-held probe assemblies for electrical measurement and test Released:1/10/2002 Isbn:2831861241

IEC 61010-031:2002+AMD1:2008 CSV - Safety requirements for electrical equipment for measurement, control and laboratory use - Part 031: Safety requirements for hand-held probe assemblies for electrical measurement and test Released:6/24/2008 Isbn:2831897017

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

IEC 61010-031:2002 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Safety requirements for electrical equipment for measurement, control and laboratory use - Part 031: Safety requirements for hand-held probe assemblies for electrical measurement and test". This standard covers: Deals with the safety of hand-held and hand-manipulated probe assemblies. They are for use in the interface between an electrical phenomenon and test or measurement equipment. Three main types are described: (A) Low-voltage and high-voltage, non-attenuating probe assemblies. For voltages less lthan 63 kV. They do not incorporate active components. (B) High-voltage attenuating or divider probe assemblies. For voltages less than 63 kV. They incorporate a divider function. (C) Low voltage attenuating or divider probe assemblies. For voltages less than 1 kV r.m.s or 1,5 kV d.c. They incorporate a signal conditioning function. It has the status of a group safety publication in accordance with IEC Guide 104.

Deals with the safety of hand-held and hand-manipulated probe assemblies. They are for use in the interface between an electrical phenomenon and test or measurement equipment. Three main types are described: (A) Low-voltage and high-voltage, non-attenuating probe assemblies. For voltages less lthan 63 kV. They do not incorporate active components. (B) High-voltage attenuating or divider probe assemblies. For voltages less than 63 kV. They incorporate a divider function. (C) Low voltage attenuating or divider probe assemblies. For voltages less than 1 kV r.m.s or 1,5 kV d.c. They incorporate a signal conditioning function. It has the status of a group safety publication in accordance with IEC Guide 104.

IEC 61010-031:2002 is classified under the following ICS (International Classification for Standards) categories: 19.080 - Electrical and electronic testing. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61010-031:2002 has the following relationships with other standards: It is inter standard links to IEC 61010-031:2002/AMD1:2008, IEC 61010-031:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61010-031:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

NORME CEI

INTERNATIONALE IEC

61010-031

INTERNATIONAL

Première édition

STANDARD

First edition

2002-01

PUBLICATION GROUPÉE DE SÉCURITÉ

GROUPED SAFETY PUBLICATION

Règles de sécurité pour appareils électriques

de mesurage, de régulation et de laboratoire –

Partie 031:

Prescriptions de sécurité pour sondes équipées

tenues à la main pour mesurage et essais

électriques

Safety requirements for electrical equipment

for measurement, control and laboratory use –

Part 031:

Safety requirements for hand-held probe

assemblies for electrical measurement and test

Numéro de référence

Reference number

CEI/IEC 61010-031:2002

Numérotation des publications Publication numbering

Depuis le 1er janvier 1997, les publications de la CEI As from 1 January 1997 all IEC publications are

sont numérotées à partir de 60000. Ainsi, la CEI 34-1 issued with a designation in the 60000 series. For

devient la CEI 60034-1. example, IEC 34-1 is now referred to as IEC 60034-1.

Editions consolidées Consolidated editions

Les versions consolidées de certaines publications de la The IEC is now publishing consolidated versions of its

CEI incorporant les amendements sont disponibles. Par publications. For example, edition numbers 1.0, 1.1

exemple, les numéros d’édition 1.0, 1.1 et 1.2 indiquent and 1.2 refer, respectively, to the base publication,

respectivement la publication de base, la publication de the base publication incorporating amendment 1 and

base incorporant l’amendement 1, et la publication de the base publication incorporating amendments 1

base incorporant les amendements 1 et 2. and 2.

Informations supplémentaires Further information on IEC publications

sur les publications de la CEI

Le contenu technique des publications de la CEI est The technical content of IEC publications is kept

constamment revu par la CEI afin qu'il reflète l'état under constant review by the IEC, thus ensuring that

actuel de la technique. Des renseignements relatifs à the content reflects current technology. Information

cette publication, y compris sa validité, sont dispo- relating to this publication, including its validity, is

nibles dans le Catalogue des publications de la CEI available in the IEC Catalogue of publications

(voir ci-dessous) en plus des nouvelles éditions, (see below) in addition to new editions, amendments

amendements et corrigenda. Des informations sur les and corrigenda. Information on the subjects under

sujets à l’étude et l’avancement des travaux entrepris consideration and work in progress undertaken by the

par le comité d’études qui a élaboré cette publication, technical committee which has prepared this

ainsi que la liste des publications parues, sont publication, as well as the list of publications issued,

également disponibles par l’intermédiaire de: is also available from the following:

• Site web de la CEI (www.iec.ch) • IEC Web Site (www.iec.ch)

• Catalogue des publications de la CEI • Catalogue of IEC publications

Le catalogue en ligne sur le site web de la CEI The on-line catalogue on the IEC web site

(www.iec.ch/catlg-f.htm) vous permet de faire des (www.iec.ch/catlg-e.htm) enables you to search

recherches en utilisant de nombreux critères, by a variety of criteria including text searches,

comprenant des recherches textuelles, par comité technical committees and date of publication. On-

d’études ou date de publication. Des informations line information is also available on recently

en ligne sont également disponibles sur les issued publications, withdrawn and replaced

nouvelles publications, les publications rempla- publications, as well as corrigenda.

cées ou retirées, ainsi que sur les corrigenda.

• IEC Just Published

• IEC Just Published

Ce résumé des dernières publications parues

This summary of recently issued publications

(www.iec.ch/JP.htm) est aussi disponible par

(www.iec.ch/JP.htm) is also available by email.

courrier électronique. Veuillez prendre contact

Please contact the Customer Service Centre (see

avec le Service client (voir ci-dessous) pour plus

below) for further information.

d’informations.

• Service clients

• Customer Service Centre

Si vous avez des questions au sujet de cette

If you have any questions regarding this

publication ou avez besoin de renseignements

publication or need further assistance, please

supplémentaires, prenez contact avec le Service

contact the Customer Service Centre:

clients:

Email: custserv@iec.ch

Email: custserv@iec.ch

Tél: +41 22 919 02 11

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

Fax: +41 22 919 03 00

.

NORME CEI

INTERNATIONALE IEC

61010-031

INTERNATIONAL

Première édition

STANDARD

First edition

2002-01

PUBLICATION GROUPÉE DE SÉCURITÉ

GROUPED SAFETY PUBLICATION

Règles de sécurité pour appareils électriques

de mesurage, de régulation et de laboratoire –

Partie 031:

Prescriptions de sécurité pour sondes équipées

tenues à la main pour mesurage et essais

électriques

Safety requirements for electrical equipment

for measurement, control and laboratory use –

Part 031:

Safety requirements for hand-held probe

assemblies for electrical measurement and test

IEC 2002 Droits de reproduction réservés Copyright - all rights reserved

Aucune partie de cette publication ne peut être reproduite ni No part of this publication may be reproduced or utilized in

utilisée sous quelque forme que ce soit et par aucun procédé, any form or by any means, electronic or mechanical,

électronique ou mécanique, y compris la photocopie et les including photocopying and microfilm, without permission in

microfilms, sans l'accord écrit de l'éditeur. writing from the publisher.

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http://www.iec.ch

CODE PRIX

Commission Electrotechnique Internationale

XB

PRICE CODE

International Electrotechnical Commission

Pour prix, voir catalogue en vigueur

For price, see current catalogue

– 2 – 61010-031 CEI:2002

SOMMAIRE

AVANT-PROPOS.6

1 Domaine d'application et objet.10

1.1 Domaine d’application .10

1.2 Objet .10

1.3 Vérification .12

1.4 Conditions d'environnement .12

2 Références normatives.12

3 Définitions .14

3.1 Parties et accessoires .14

3.2 Grandeurs électriques .16

3.3 Essais .16

3.4 Termes de sécurité.16

3.5 Isolation .18

4 Essais .24

4.1 Généralités.24

4.2 Séquence d’essais .26

4.3 Conditions de référence pour les essais .26

4.4 Essai en CONDITION DE PREMIER DÉFAUT.28

5 Marquage, indications et documentations .32

5.1 Marquage et indications .32

5.2 Avertissements.36

5.3 Durabilité du marquage .38

5.4 Documentation .38

6 Protection contre les chocs électriques.40

6.1 Généralités.40

6.2 Détermination des parties ACCESSIBLES .42

6.3 Limites admissibles pour les parties ACCESSIBLES.46

6.4 Prescriptions d’isolation pour la protection contre les chocs électriques .52

6.5 DISTANCES DANS L’AIR et LIGNES DE FUITE .60

6.6 Essais de rigidité diélectrique.72

6.7 Prescriptions relatives à la construction pour la protection

contre les chocs électriques .78

7 Protection contre les DANGERS mécaniques .84

8 Résistance mécanique aux chocs et impacts .84

8.1 Essai de rigidité.86

8.2 Essai de chute.86

8.3 Essai d'oscillation.88

9 Limites de température de l’appareil et protection contre la propagation du feu .88

9.1 Généralités.88

9.2 Essais thermiques .90

10 Résistance à la chaleur .90

10.1 Intégrité des DISTANCES DANS L’AIR et des LIGNES DE FUITE.90

10.2 Résistance à la chaleur .90

61010-031 IEC:2002 – 3 –

CONTENTS

FOREWORD.7

1 Scope and object .11

1.1 Scope.11

1.2 Object .11

1.3 Verification .13

1.4 Environmental conditions .13

2 Normative references.13

3 Definitions .15

3.1 Parts and accessories .15

3.2 Electrical quantities .17

3.3 Tests.17

3.4 Safety terms .17

3.5 Insulation.19

4 Tests .25

4.1 General .25

4.2 Sequence of tests.27

4.3 Reference test conditions .27

4.4 Testing in SINGLE FAULT CONDITION .29

5 Marking and documentation .33

5.1 Marking .33

5.2 Warning markings .37

5.3 Durability of markings .39

5.4 Documentation .39

6 Protection against electric shock.41

6.1 General .41

6.2 Determination of ACCESSIBLE parts .43

6.3 Permissible limits for ACCESSIBLE parts .47

6.4 Insulation requirements for protection against electric shock .53

6.5 CLEARANCES and CREEPAGE DISTANCES.61

6.6 Dielectric strength tests .73

6.7 Constructional requirements for protection against electric shock .79

7 Protection against mechanical HAZARDS .85

8 Mechanical resistance to shock and impact.85

8.1 Rigidity test .87

8.2 Drop test .87

8.3 Impact swing test.89

9 Temperature limits and protection against the spread of fire.89

9.1 General .89

9.2 Temperature tests .91

10 Resistance to heat .91

10.1 Integrity of CLEARANCES and CREEPAGE DISTANCES .91

10.2 Resistance to heat.91

– 4 – 61010-031 CEI:2002

11 Protection contre les dangers provenant des fluides.92

11.1 Généralités.47

11.2 Nettoyage.92

11.3 SONDES ÉQUIPÉES avec protection spéciale.47

12 Composants .92

12.1 Généralités.92

12.2 Fusibles .94

12.3 Composants de HAUTE INTÉGRITÉ .94

Annexe A (normative) Circuits de mesure du courant ACCESSIBLE (voir 6.3) .98

Annexe B (normative) Doigts d'épreuve normalisés (voir 6.2) .106

Annexe C (normative) Mesure des DISTANCES DANS L’AIR et des LIGNES DES FUITES.110

Annexe D (informative) Index des termes définis .118

Bibliographie.120

Figure 1 – Exemples de SONDES ÉQUIPÉES de type A et C .22

Figure 2 – Exemples de SONDES ÉQUIPÉES de type B.24

Figure 3 – Méthodes de détermination des parties ACCESSIBLES (voir 6.2)

et des essais de tension (voir 6.4.1) .44

Figure 4 – Exemple d’application de la feuille métallique pour la mesure

du courant ACCESSIBLE .46

Figure 5 – Niveau de capacité chargée en CONDITION DE PREMIER DÉFAUT (voir 6.3.2.3) .50

Figure 6 – Protection contre le contact avec la POINTE DE TOUCHE (voir 6.4.4) .58

Figure 7 – Essai de flexion.82

Figure 8 – Essai de flexion pour les câbles utilisés dans les SONDES ÉQUIPÉES (voir

6.7.4).84

Figure 9 – Essai d'oscillation (voir 8.3).88

Figure A.1 – Circuit de mesure d'un courant continu et d'un courant alternatif

avec des fréquences allant jusqu'à 1 MHz.98

Figure A.2 – Circuits de mesure d'un courant continu et d'un courant alternatif

sinusoïdal avec des fréquences allant jusqu'à 100 Hz.100

Figure A.3 – Circuit de mesure du courant pour brûlures électriques.102

Figure A.4 – Circuit de mesure du courant pour contact en AMBIANCE HUMIDE.104

Figure B.1 – Doigt d'épreuve rigide.106

Figure B.2 – Doigt d'épreuve articulé .108

Tableau 1 – Symboles .34

Tableau 2 – Coefficient multiplicateur pour les DISTANCES DANS L’AIR

jusqu’à 5 000 m d’altitude .62

Tableau 3 – DISTANCES DANS L’AIR pour les catégories de mesure II, III et IV.64

Tableau 4 – Valeurs des DISTANCES DANS L’AIR pour le calcul de 6.5.2.2.68

Tableau 5 – LIGNES DE FUITE .70

Tableau 6 – Tensions d’essai pour L’ISOLATION PRINCIPALE .76

Tableau 7 – Coefficients de correction pour tension d’essai selon l’altitude du site

d’essai .78

Tableau 8 – Force de traction pour l'attache du câble .82

Tableau C.1 – Relation entre les degrés DE POLLUTION et la largeur des rainures .110

61010-031 IEC:2002 – 5 –

11 Protection against hazards from fluids.93

11.1 General .93

11.2 Cleaning.93

11.3 Specially protected PROBE ASSEMBLIES .47

12 Components .93

12.1 General .93

12.2 Fuses .95

12.3 HIGH-INTEGRITY components .95

Annex A (normative) Measuring circuits for ACCESSIBLE current (see 6.3).99

Annex B (normative) Standard test fingers (see 6.2). 107

Annex C (normative) Measurement of CREEPAGE DISTANCES and CLEARANCES . 111

Annex D (informative) Index of defined terms . 119

Bibliography . 121

Figure 1 – Examples of type A and C PROBE ASSEMBLIES.23

Figure 2 – Examples of type B PROBE ASSEMBLIES.25

Figure 3 – Methods for determination of ACCESSIBLE parts (see 6.2)

and for voltage tests of (see 6.4.1) .45

Figure 4 – Example of application of metal foil for ACCESSIBLE current measurement.47

Figure 5 – Charged capacitance level in SINGLE FAULT CONDITION (see 6.3.2.3).51

Figure 6 – Protection against touching a PROBE TIP (see 6.4.4) .59

Figure 7 – Flexing test.83

Figure 8 – Flexing test for cable used in PROBE ASSEMBLIES (see 6.7.4).85

Figure 9 – Impact swing test (see 8.3) .89

Figure A.1 – Measuring circuit for d.c. and for a.c. with frequencies up to 1 MHz.99

Figure A.2 – Measuring circuits for d.c. and for a.c. with sinusoidal frequencies

up to 100 Hz . 101

Figure A.3 – Current measuring circuit for electrical burns . 103

Figure A.4 – Current measuring circuit for WET CONTACT . 105

Figure B.1 – Rigid test finger . 107

Figure B.2 – Jointed test finger. 109

Table 1 – Symbols .35

Table 2 – Multiplication factors for CLEARANCE for altitudes up to 5 000 m .63

Table 3 – CLEARANCES for measurement categories II, III and IV.65

Table 4 – CLEARANCE values for the calculation of 6.5.2.2.69

Table 5 – CREEPAGE DISTANCES .71

Table 6 – Test voltages for BASIC INSULATION .77

Table 7 – Correction factors for test voltage according to test site altitude .79

Table 8 – Pull force for cable attachment.83

Table C.1 – Relation between POLLUTION degrees and width of grooves . 111

– 6 – 61010-031 CEI:2002

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

RÈGLES DE SÉCURITÉ POUR APPAREILS ÉLECTRIQUES DE MESURAGE,

DE RÉGULATION ET DE LABORATOIRE –

Partie 031: Prescriptions de sécurité pour sondes équipées

tenues à la main pour mesurage et essais électriques

AVANT-PROPOS

1) La CEI (Commission Électrotechnique Internationale) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI, entre autres activités, publie des Normes

internationales. Leur élaboration est confiée à des comités d'études, aux travaux desquels tout Comité national

intéressé par le sujet traité peut participer. Les organisations internationales, gouvernementales et non

gouvernementales, en liaison avec la CEI, participent également aux travaux. La CEI collabore étroitement

avec l'Organisation Internationale de Normalisation (ISO), selon des conditions fixées par accord entre les

deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux intéressés

sont représentés dans chaque comité d’études.

3) Les documents produits se présentent sous la forme de recommandations internationales. Ils sont publiés

comme normes, spécifications techniques, rapports techniques ou guides et agréés comme tels par les

Comités nationaux.

4) Dans le but d'encourager l'unification internationale, les Comités nationaux de la CEI s'engagent à appliquer de

façon transparente, dans toute la mesure possible, les Normes internationales de la CEI dans leurs normes

nationales et régionales. Toute divergence entre la norme de la CEI et la norme nationale ou régionale

correspondante doit être indiquée en termes clairs dans cette dernière.

5) La CEI n’a fixé aucune procédure concernant le marquage comme indication d’approbation et sa responsabilité

n’est pas engagée quand un matériel est déclaré conforme à l’une de ses normes.

6) L’attention est attirée sur le fait que certains des éléments de la présente Norme internationale peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 61010-031 a été établie par le comité d'études 66 de la CEI:

Sécurité des appareils de mesure, de commande et de laboratoire.

Cette nouvelle édition annule et remplace la première édition de la CEI 61010-2-031 (1993).

Elle a le statut d'une publication groupée de sécurité conformément au Guide 104 de la CEI.

La CEI 61010-031 est une norme autonome. Par conséquent il n'y a pas lieu de se référer à

la CEI 61010-1, sauf comme indiqué dans la note en 1.1.

Le texte de cette norme est issu des documents suivants:

FDIS Rapport de vote

66/262/FDIS 66/272/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote ayant

abouti à l'approbation de cette norme.

Cette publication a été rédigée selon les Directives ISO/CEI, Partie 3.

Les annexes A, B et C font partie intégrante de cette norme.

61010-031 IEC:2002 – 7 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

SAFETY REQUIREMENTS FOR ELECTRICAL EQUIPMENT

FOR MEASUREMENT, CONTROL AND LABORATORY USE –

Part 031: Safety requirements for hand-held probe assemblies

for electrical measurement and test

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International Organization

for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61010-031 has been prepared by IEC technical committee 66:

Safety of measuring, control and laboratory equipment.

This new edition cancels and replaces the first edition of IEC 61010-2-031 (1993).

It has the status of a group safety publication in accordance with IEC Guide 104.

IEC 61010-031 is a stand-alone standard and consequently no reference is required to

IEC 61010-1, except as mentioned in the note to 1.1.

The text of this standard is based on the following documents:

FDIS Report on voting

66/262/FDIS 66/272/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 3.

Annexes A, B and C form an integral part of this standard.

– 8 – 61010-031 CEI:2002

Dans la présente norme, les caractères d'imprimerie suivants sont employés:

– prescriptions et définitions: caractères romains;

– NOTES: petits caractères romains;

– conformité et essais: caractères italiques;

– termes définis à l'article 3 et utilisés dans toute cette norme: CARACTÈRES ROMAINS EN

PETITES CAPITALES.

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant 2004.

A cette date, la publication sera

• reconduite;

• supprimée;

• remplacée par une édition révisée, ou

• amendée.

61010-031 IEC:2002 – 9 –

In this standard the following print types are used:

– requirements and definitions: in roman type;

– NOTES: in smaller roman type;

– conformity and tests: in italic type;

– terms used throughout this standard which have been defined in clause 3: SMALL ROMAN

CAPITALS.

The committee has decided that the contents of this publication will remain unchanged until 2004.

At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 10 – 61010-031 CEI:2002

RÈGLES DE SÉCURITÉ POUR APPAREILS ÉLECTRIQUES DE MESURAGE,

DE RÉGULATION ET DE LABORATOIRE –

Partie 031: Prescriptions de sécurité pour sondes équipées

tenues à la main pour mesurage et essais électriques

1 Domaine d'application et objet

1.1 Domaine d’application

La présente partie de la CEI 61010 s’applique aux SONDES ÉQUIPÉES tenues à la main et

manipulées, correspondant aux types décrits ci-dessous, ainsi qu’à leurs accessoires

destinés aux usages professionnels, industriels (processus) et éducatifs. Ces SONDES

ÉQUIPÉES sont destinées à être utilisées dans l’interface entre un phénomène électrique et

un instrument de mesure ou d’essai. Elles peuvent être liées à l'appareil ou en être des

accessoires détachables.

a) SONDES ÉQUIPÉES, sans atténuation, à basse tension et à haute tension (type A). SONDES

ÉQUIPÉES, sans atténuation ASSIGNÉES pour connexion directe à des tensions supérieures

à 33 V efficaces ou à 46,7 V crête ou à 70 V continu mais ne dépassant pas 63 kV. Elles

ne comportent aucun composant actif, et ne sont pas non plus conçues pour assurer la

fonction de diviseur capacitif ou de mise en forme de signaux, mais elles peuvent contenir

des composants passifs ne provoquant pas d’atténuation tels que des fusibles.

b) SONDES ÉQUIPÉES à atténuateur ou diviseur à haute tension (type B). SONDES ÉQUIPÉES à

atténuateur ou diviseur ASSIGNÉES pour connexion directe sur des tensions secondaires

supérieures à 1 kV mais n’excédant pas 63 kV. La fonction diviseur peut être réalisée

dans sa totalité à l’intérieur de la SONDE ÉQUIPÉE, ou en partie dans l’appareil de mesurage

ou d’essai destiné à être utilisé avec la SONDE ÉQUIPÉE.

c) SONDES ÉQUIPÉES à atténuateur ou diviseur à basse tension (type C). SONDES ÉQUIPÉES à

atténuateur, à diviseur ou autre conditionneur de signal pour connexion directe à des

tensions supérieures à 33 V efficaces ou à 46,7 V crête ou à 70 V continu, mais ne

dépassant pas 1 kV efficace ou 1,5 kV continu. La fonction conditionneur de signal peut

être réalisée dans sa totalité à l’intérieur de la SONDE ÉQUIPÉE, ou en partie à l’intérieur de

l’appareil de mesurage ou d’essai destiné à être utilisé avec la SONDE ÉQUIPÉE.

NOTE Les SONDES ÉQUIPÉES

– qui ne correspondent pas aux définitions des types A, B ou C, ou,

– qui sont conçues pour être alimentées à partir d’un réseau de distribution basse tension, ou,

– qui incorporent d'autres fonctionnalités non particulièrement adressées dans cette présente norme

1)

peuvent avoir aussi besoin d’être conformes aux prescriptions pertinentes des autres parties de la CEI 61010 [6] .

1.2 Objet

1.2.1 Aspects inclus dans le domaine d'application

L’objet de cette norme est de garantir que la conception et la construction assurent une

protection adéquate de l’OPÉRATEUR et de la zone environnante contre

a) les chocs électriques et les brûlures (voir articles 6, 10 et 11);

b) les DANGERS d’ordre mécanique (voir articles 7, 8 et 11);

c) les températures excessives (voir article 9);

d) la propagation du feu à partir de la SONDE ÉQUIPÉE (voir article 9).

NOTE L’attention est attirée sur l’existence de règles supplémentaires qui peuvent être spécifiées par les

responsables nationaux de la santé et de la sécurité des travailleurs.

________

1)

Les chiffres entre crochets renvoient à la bibliographie.

61010-031 IEC:2002 – 11 –

SAFETY REQUIREMENTS FOR ELECTRICAL EQUIPMENT

FOR MEASUREMENT, CONTROL AND LABORATORY USE –

Part 031: Safety requirements for hand-held probe assemblies

for electrical measurement and test

1 Scope and object

1.1 Scope

This part of IEC 61010 applies to hand-held and hand-manipulated PROBE ASSEMBLIES of the

types described below, and related accessories which are intended for professional, industrial

process, and educational use. These PROBE ASSEMBLIES are for use in the interface between an

electrical phenomenon and test or measurement equipment. They may be fixed to the

equipment or be detachable accessories for the equipment.

a) Low-voltage and high-voltage, non-attenuating PROBE ASSEMBLIES (type A). Non-attenuating

PROBE ASSEMBLIES that are RATED for direct connection to voltages exceeding 33 V r.m.s. or

46,7 V peak or 70 V d.c., but not exceeding 63 kV. They do not incorporate active

components, nor are they intended to provide a voltage divider function or a signal

conditioning function, but they may contain passive non-attenuating components such as

fuses.

b) High-voltage attenuating or divider PROBE ASSEMBLIES (type B). Attenuating or divider

PROBE ASSEMBLIES that are RATED for direct connection to secondary voltages exceeding

1 kV but not exceeding 63 kV. The divider function may be carried out wholly within the

PROBE ASSEMBLY, or partly within the test or measurement equipment to be used with the

PROBE ASSEMBLY.

c) Low-voltage attenuating or divider PROBE ASSEMBLIES (type C). Attenuating, divider or other

signal conditioning PROBE ASSEMBLIES for direct connection to voltages exceeding 33 V

r.m.s or 46,7 V peak or 70 V d.c., but not exceeding 1 kV r.m.s. or 1,5 kV d.c. The signal

conditioning function may be carried out wholly within the PROBE ASSEMBLY, or partly within

the test or measurement equipment intended to be used with the PROBE ASSEMBLY.

NOTE PROBE ASSEMBLIES which

– are not within the definitions of types A, B or C, or,

– which are designed to be powered from a low-voltage mains supply, or

– include other features not specifically addressed in this standard

1)

may also need to meet the relevant requirements of other parts of IEC 61010 [6] .

1.2 Object

1.2.1 Aspects included in scope

The object of this standard is to ensure that the design and methods of construction used

provide adequate protection for the OPERATOR and the surrounding area against:

a) electric shock or burn (see clauses 6, 10 and 11);

b) mechanical HAZARDS (see clauses 7, 8 and 11);

c) excessive temperature (see clause 9);

d) spread of fire from the PROBE ASSEMBLY (see clause 9).

NOTE Attention is drawn to the existence of additional requirements which may be specified by national

authorities responsible for health and safety of labour forces.

________

1)

Figures in square brackets refer to the bibliography.

– 12 – 61010-031 CEI:2002

1.2.2 Aspects exclus du domaine d'application

Cette norme ne couvre pas

a) la fiabilité de fonctionnement, les qualités de fonctionnement ni les autres caractéristiques

de la SONDE ÉQUIPÉE;

b) la qualité de l'emballage de transport;

c) la maintenance (réparations);

d) la protection du personnel de maintenance (réparations).

NOTE Il est attendu que le personnel de maintenance prenne des précautions raisonnables pour faire face aux

DANGERS évidents, mais il convient que la conception des SONDES ÉQUIPÉES protège contre les incidents d’une

manière adaptée, et que la documentation de maintenance indique tout DANGER résiduel.

1.3 Vérification

Cette norme spécifie également les méthodes de vérification, par contrôle et par ESSAIS DE

TYPE, de la conformité de la SONDE ÉQUIPÉE aux prescriptions de cette norme.

1.4 Conditions d'environnement

Cette norme est applicable aux SONDES ÉQUIPÉES conçues pour être sûres au moins dans les

conditions suivantes:

a) altitude jusqu’à 2 000 m ou supérieure à 2 000 m si spécifié par le fabricant;

b) températures de 5 °C à 40 °C; ou inférieures à 5 °C ou supérieures à 40 °C si spécifié par

le fabricant;

c) humidité relative maximale de 80 % pour des températures jusqu’à 31 °C, avec

décroissance linéaire jusqu’à 50 % d’humidité relative à 40 °C;

d) degré de POLLUTION ASSIGNÉ applicable.

2 Références normatives

Les documents normatifs suivants contiennent des dispositions qui, par suite de la référence

qui y est faite, constituent des dispositions valables pour la présente partie de la CEI 61010.

Pour les références datées, les amendements ultérieurs ou les révisions de ces publications

ne s’appliquent pas. Toutefois, les parties prenantes aux accords fondés sur la présente

partie de la CEI 61010 sont invitées à rechercher la possibilité d'appliquer les éditions les

plus récentes des documents normatifs indiqués ci-après. Pour les références non datées, la

dernière édition du document normatif en référence s’applique. Les membres de la CEI et de

l'ISO possèdent le registre des Normes internationales en vigueur.

CEI 60027 (toutes les parties), Symboles littéraux à utiliser en électrotechnique

CEI 60060 (toutes les parties), Techniques des essais à haute tension

CEI 60417 (toutes les parties), Symboles graphiques utilisables sur le matériel

CEI 60529, Degrés de protection procurés par les enveloppes (Code IP)

CEI 60664-3, Coordination de l’isolement des matériels dans les systèmes (réseaux) à basse

tension – Partie 3: Utilisation de revêtements pour réaliser la coordination de l’isolement des

cartes imprimées équipées

ISO 7000, Symboles graphiques utilisables sur le matériel – Index et tableau synoptique

61010-031 IEC:2002 – 13 –

1.2.2 Aspects excluded from scope

This standard does not cover

a) reliable function, performance or other properties of the PROBE ASSEMBLY;

b) effectiveness of transport packaging;

c) servicing (repair);

d) protection of servicing (repair) personnel.

NOTE Servicing personnel are expected to be reasonably careful in dealing with obvious HAZARDS, but the design

should protect against mishap in an appropriate manner, and the service documentation should point out any

residual HAZARDS.

1.3 Verification

This standard also specifies methods of verifying, through inspection and TYPE TESTING, that

the PROBE ASSEMBLY meets the requirements of this standard.

1.4 Environmental conditions

This standard applies to PROBE ASSEMBLIES designed to be safe at least under the following

conditions:

a) altitude up to 2 000 m, or above 2 000 m if specified by the manufacturer;

b) temperature 5 °C to 40 °C; or below 5 °C or above 40 °C if specified by the manufacturer;

c) maximum relative humidity 80 % for temperatures up to 31 °C decreasing linearly to 50 %

relative humidity at 40 °C;

d) applicable RATED POLLUTION degree.

2 Normative references

The following normative documents contain provisions which, through reference in this text,

constitute provisions of this part of IEC 61010. For dated references, subsequent amendments

to, or revisions of, any of these publications do not apply. However, parties to agreements

based on this part of IEC 61010 are encouraged to investigate the possibility of applying the

most recent editions of the normative documents indicated below. For undated references,

the latest edition of the normative document referred to applies. Members of IEC and ISO

maintain registers of currently valid International Standards.

IEC 60027 (all parts), Letter symbols to be used in electrical technology

IEC 60060

...

IEC 61010-031

Edition 1.1 2008-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

GROUP SAFETY PUBLICATION

PUBLICATION GROUPÉE DE SÉCURITÉ

Safety requirements for electrical equipment for measurement, control and

laboratory use –

Part 031: Safety requirements for hand-held probe assemblies for electrical

measurement and test

Règles de sécurité pour appareils électriques de mesurage, de régulation et de

laboratoire –

Partie 031: Prescriptions de sécurité pour sondes équipées tenues à la main

pour mesurage et essais électriques

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61010-031

Edition 1.1 2008-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

GROUP SAFETY PUBLICATION

PUBLICATION GROUPÉE DE SÉCURITÉ

Safety requirements for electrical equipment for measurement, control and

laboratory use –

Part 031: Safety requirements for hand-held probe assemblies for electrical

measurement and test

Règles de sécurité pour appareils électriques de mesurage, de régulation et de

laboratoire –

Partie 031: Prescriptions de sécurité pour sondes équipées tenues à la main

pour mesurage et essais électriques

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CR

CODE PRIX

ICS 19.080 ISBN 2-8318-9701-7

– 2 – 61010-031 © IEC:2002+A1:2008

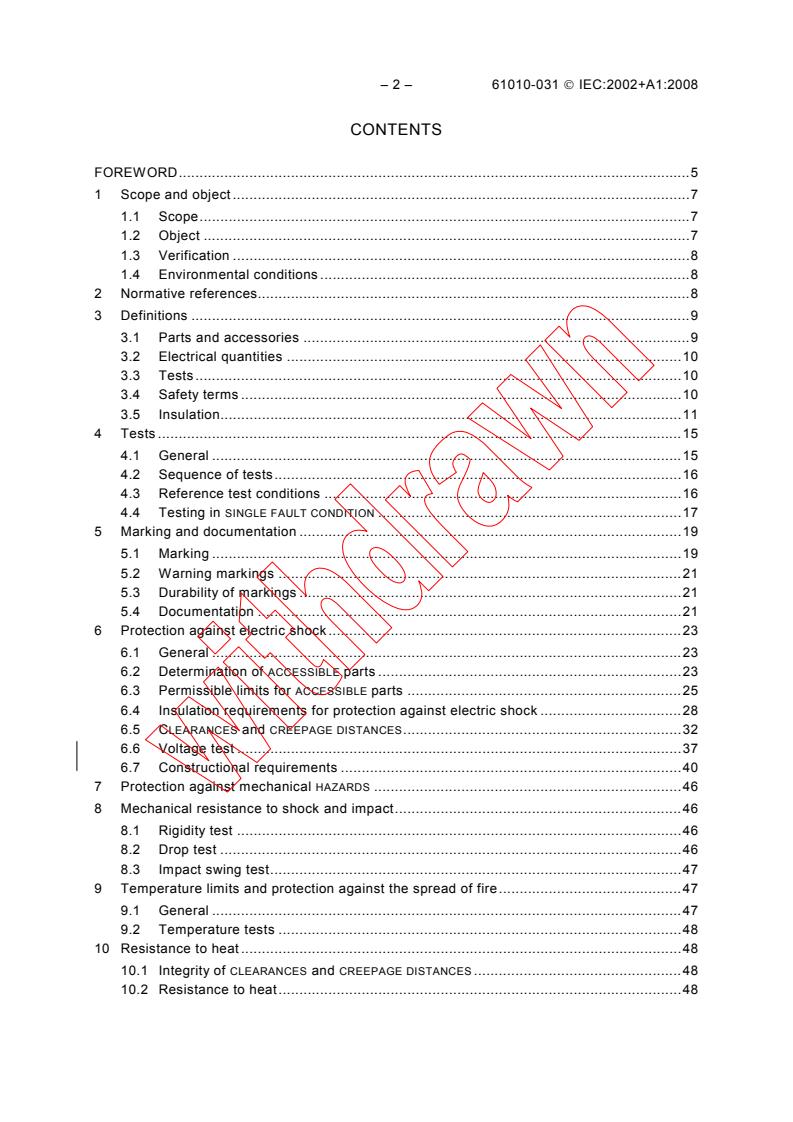

CONTENTS

FOREWORD.5

1 Scope and object .7

1.1 Scope.7

1.2 Object .7

1.3 Verification .8

1.4 Environmental conditions .8

2 Normative references.8

3 Definitions .9

3.1 Parts and accessories .9

3.2 Electrical quantities .10

3.3 Tests.10

3.4 Safety terms .10

3.5 Insulation.11

4 Tests .15

4.1 General .15

4.2 Sequence of tests.16

4.3 Reference test conditions .16

4.4 Testing in SINGLE FAULT CONDITION .17

5 Marking and documentation .19

5.1 Marking .19

5.2 Warning markings .21

5.3 Durability of markings .21

5.4 Documentation .21

6 Protection against electric shock.23

6.1 General .23

6.2 Determination of ACCESSIBLE parts .23

6.3 Permissible limits for ACCESSIBLE parts .25

6.4 Insulation requirements for protection against electric shock .28

6.5 CLEARANCES and CREEPAGE DISTANCES.32

6.6 Voltage test .37

6.7 Constructional requirements .40

7 Protection against mechanical HAZARDS .46

8 Mechanical resistance to shock and impact.46

8.1 Rigidity test .46

8.2 Drop test .46

8.3 Impact swing test.47

9 Temperature limits and protection against the spread of fire.47

9.1 General .47

9.2 Temperature tests .48

10 Resistance to heat .48

10.1 Integrity of CLEARANCES and CREEPAGE DISTANCES .48

10.2 Resistance to heat.48

61010-031 © IEC:2002+A1:2008 – 3 –

11 Protection against hazards from fluids.49

11.1 General .49

11.2 Cleaning.49

11.3 Specially protected PROBE ASSEMBLIES .49

12 Components .49

12.1 General .49

12.2 Fuses .50

12.3 HIGH-INTEGRITY components .50

13 Prevention of HAZARD from arc flash and short-circuits .51

13.1 General .51

13.2 Exposed conductive parts .51

Annex A (normative) Measuring circuits for ACCESSIBLE current (see 6.3).52

Annex B (normative) Standard test fingers (see 6.2).56

Annex C (normative) Measurement of CREEPAGE DISTANCES and CLEARANCES .58

Annex D (informative) Index of defined terms .62

Bibliography .63

Figure 1 – Examples of type A and C PROBE ASSEMBLIES.13

Figure 2 – Examples of type B PROBE ASSEMBLIES.14

Figure 10 – Examples of type D PROBE ASSEMBLIES.15

Figure 3 – Methods for determination of ACCESSIBLE parts (see 6.2)

and for voltage tests of (see 6.4.1) .24

Figure 4 – Example of application of metal foil for ACCESSIBLE current measurement.25

Figure 5 – Charged capacitance level in NORMAL CONDITION and SINGLE-FAULT CONDITION

(see 6.3.1.3 and 6.3.2.3) .27

Figure 6 – Protection against touching a PROBE TIP (see 6.4.4) .31

Figure 7 – Flexing test.42

Figure 8 – Flexing test for cable used in PROBE ASSEMBLIES (see 6.7.4).43

Figure 11 – Treatment of the insulation of probe cable.45

Figure 12 – Pulley for the treatment of Figure 11 .45

Figure 9 – Impact swing test (see 8.3) .47

Figure A.1 – Measuring circuit for d.c. and for a.c. with frequencies up to 1 MHz.52

Figure A.2 – Measuring circuits for d.c. and for a.c. with sinusoidal frequencies

up to 100 Hz .53

Figure A.3 – Current measuring circuit for electrical burns .54

Figure A.4 – Current measuring circuit for wet contact .55

Figure B.1 – Rigid test finger .56

Figure B.2 – Jointed test finger.57

– 4 – 61010-031 © IEC:2002+A1:2008

Table 1 – Symbols .20

Table 2 – Multiplication factors for CLEARANCE for altitudes up to 5 000 m .33

Table 3 – CLEARANCES for measurement categories II, III and IV.34

Table 4 – CLEARANCE values for the calculation of 6.5.2.2.35

Table 5 – CREEPAGE DISTANCES .36

Table 6 – Test voltages for BASIC INSULATION .39

Table 7 – Correction factors for test voltage according to test site altitude .40

Table 8 – Pull force for cable attachment.41

Table 9 – Forces for flexing/pull test for single core probe cable .43

Table C.1 – Relation between POLLUTION degrees and width of grooves .58

61010-031 © IEC:2002+A1:2008 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

SAFETY REQUIREMENTS FOR ELECTRICAL EQUIPMENT

FOR MEASUREMENT, CONTROL AND LABORATORY USE –

Part 031: Safety requirements for hand-held probe assemblies

for electrical measurement and test

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61010-031 has been prepared by IEC technical committee 66:

Safety of measuring, control and laboratory equipment.

It has the status of a group safety publication in accordance with IEC Guide 104.

IEC 61010-031 is a stand-alone standard and consequently no reference is required to

IEC 61010-1, except as mentioned in the note to 1.1.

This consolidated version of IEC 61010-031 consists of the first edition (2002) [documents

66/262/FDIS and 66/272/RVD] and its amendment 1 (2008) [documents 66/383/CDV and

66/394/RVC].

The technical content is therefore identical to the base edition and its amendment and has

been prepared for user convenience.

It bears the edition number 1.1.

– 6 – 61010-031 © IEC:2002+A1:2008

A vertical line in the margin shows where the base publication has been modified by

amendment 1.

Annexes A, B and C form an integral part of this standard.

In this standard the following print types are used:

– requirements and definitions: in roman type;

– NOTES: in smaller roman type;

– conformity and tests: in italic type;

– terms used throughout this standard which have been defined in clause 3: SMALL ROMAN

CAPITALS.

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until the maintenance result date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date,

the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

61010-031 © IEC:2002+A1:2008 – 7 –

SAFETY REQUIREMENTS FOR ELECTRICAL EQUIPMENT

FOR MEASUREMENT, CONTROL AND LABORATORY USE –

Part 031: Safety requirements for hand-held probe assemblies

for electrical measurement and test

1 Scope and object

1.1 Scope

This part of IEC 61010 applies to hand-held and hand-manipulated PROBE ASSEMBLIES of the

types described below, and related accessories which are intended for professional, industrial

process, and educational use. These PROBE ASSEMBLIES are for use in the interface between an

electrical phenomenon and test or measurement equipment. They may be fixed to the

equipment or be detachable accessories for the equipment.

a) Low-voltage and high-voltage, non-attenuating PROBE ASSEMBLIES (type A). Non-attenuating

PROBE ASSEMBLIES that are RATED for direct connection to voltages exceeding 33 V r.m.s. or

46,7 V peak or 70 V d.c., but not exceeding 63 kV. They do not incorporate active

components, nor are they intended to provide a voltage divider function or a signal

conditioning function, but they may contain passive non-attenuating components such as

fuses.

b) High-voltage attenuating or divider PROBE ASSEMBLIES (type B). Attenuating or divider

PROBE ASSEMBLIES that are RATED for direct connection to secondary voltages exceeding

1 kV but not exceeding 63 kV. The divider function may be carried out wholly within the

PROBE ASSEMBLY, or partly within the test or measurement equipment to be used with the

PROBE ASSEMBLY.

c) Low-voltage attenuating or divider PROBE ASSEMBLIES (type C). Attenuating, divider or other

signal conditioning PROBE ASSEMBLIES for direct connection to voltages exceeding 33 V

r.m.s or 46,7 V peak or 70 V d.c., but not exceeding 1 kV r.m.s. or 1,5 kV d.c. The signal

conditioning function may be carried out wholly within the PROBE ASSEMBLY, or partly within

the test or measurement equipment intended to be used with the PROBE ASSEMBLY.

d) Low-voltage attenuating and non-attenuating PROBE ASSEMBLIES (type D), that are RATED for

direct connection only to voltages not exceeding 33 V r.m.s., or 46,7 V peak, or 70 V d.c.,

and are suitable for currents exceeding 8 A.

NOTE PROBE ASSEMBLIES which

– are not within the definitions of types A, B, C, or D, or,

– which are designed to be powered from a low-voltage mains supply, or

– include other features not specifically addressed in this standard

1)

may also need to meet the relevant requirements of other parts of IEC 61010 [6] .

1.2 Object

1.2.1 Aspects included in scope

The object of this standard is to ensure that the design and methods of construction used

provide adequate protection for the OPERATOR and the surrounding area against:

a) electric shock or burn (see clauses 6, 10 and 11);

HAZARDS (see clauses 7, 8 and 11);

b) mechanical

c) excessive temperature (see clause 9);

________

1)

Figures in square brackets refer to the bibliography.

– 8 – 61010-031 © IEC:2002+A1:2008

d) spread of fire from the PROBE ASSEMBLY (see clause 9);

e) arc flash (see Clause 13).

NOTE Attention is drawn to the existence of additional requirements which may be specified by national

authorities responsible for health and safety of labour forces.

1.2.2 Aspects excluded from scope

This standard does not cover

a) reliable function, performance or other properties of the PROBE ASSEMBLY;

b) effectiveness of transport packaging;

c) servicing (repair);

d) protection of servicing (repair) personnel.

NOTE Servicing personnel are expected to be reasonably careful in dealing with obvious HAZARDS, but the design

should protect against mishap in an appropriate manner, and the service documentation should point out any

residual HAZARDS.

1.3 Verification

This standard also specifies methods of verifying, through inspection and TYPE TESTING, that

the PROBE ASSEMBLY meets the requirements of this standard.

1.4 Environmental conditions

This standard applies to PROBE ASSEMBLIES designed to be safe at least under the following

conditions:

a) altitude up to 2 000 m, or above 2 000 m if specified by the manufacturer;

b) temperature 5 °C to 40 °C; or below 5 °C or above 40 °C if specified by the manufacturer;

c) maximum relative humidity 80 % for temperatures up to 31 °C decreasing linearly to 50 %

relative humidity at 40 °C;

d) applicable RATED POLLUTION degree.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60027 (all parts), Letter symbols to be used in electrical technology

IEC 60060 (all parts), High-voltage test techniques

IEC 60417 (all parts), Graphical symbols for use on equipment

IEC 60529, Degrees of protection provided by enclosures (IP Code)

IEC 60664-3, Insulation coordination for equipment within low-voltage systems – Part 3: Use of

coatings to achieve insulation coordination of printed board assemblies

ISO 7000, Graphical symbols for use on equipment – Index and synopsis

61010-031 © IEC:2002+A1:2008 – 9 –

3 Definitions

For the purpose of this part of IEC 61010, the following definitions apply.

Unless otherwise specified, the terms "voltage" and "current" mean the r.m.s. values of an

alternating, direct or composite voltage or current. Where the term "mains" is used, it refers to

the low-voltage electricity supply system (above the values of 6.3.2.1).

3.1 Parts and accessories

3.1.1

TERMINAL

component provided for the connection of a device (equipment) to external conductors

[IEV 151-01-03, modified]

NOTE TERMINALS can contain one or several contacts and the term includes sockets, pins, connectors, etc.

3.1.2

ENCLOSURE

part providing protection of equipment against certain external influences and, in any direction,

protection against direct contact

3.1.3

BARRIER

part providing protection against direct contact from any usual direction of access

NOTE ENCLOSURES and BARRIERS may provide protection against the spread of fire (see 9.1).

3.1.4

PROBE ASSEMBLY

device for making temporary contact between test or measurement equipment and a point on

an electrical circuit being measured or tested. It includes the cable and the means for making a

connection with the test or measurement equipment

NOTE See Figures 1, 2, and 10 for examples of PROBE ASSEMBLIES and an explanation of the function of their

parts.

3.1.5

PROBE TIP

part of the PROBE ASSEMBLY which makes the connection to the point being measured or tested

3.1.6

REFERENCE CONNECTOR

device used to connect a reference point in the test or measurement equipment (usually the

functional earth TERMINAL) to a reference point on the electrical circuit being measured or

tested

3.1.7

TOOL

external device, including a key or coin, used to aid a person to perform a mechanical function

– 10 – 61010-031 © IEC:2002+A1:2008

3.2 Electrical quantities

3.2.1

RATED (value)

quantity value assigned, generally by a manufacturer, for a specified operating condition of a

component, device or equipment

[IEV 151-04-03]

3.2.2

RATING

RATED values and operating conditions

set of

[IEV 151-04-04]

3.2.3

WORKING VOLTAGE

highest voltage which can continuously appear across an insulation during NORMAL USE

NOTE Both open-circuit conditions and normal operating conditions are taken into account.

3.3 Tests

3.3.1

TYPE TEST

test of one or more samples of equipment (or parts of equipment) made to a particular design,

to show that the design and construction meet one or more requirements of this standard

NOTE This is an amplification of the IEV 151-04-15 definition to cover both design and construction requirements.

3.4 Safety terms

3.4.1

ACCESSIBLE (of a part)

able to be touched with a standard test finger or test pin, when used as specified in 6.2

3.4.2

HAZARDOUS LIVE

capable of rendering an electric shock or electric burn in NORMAL CONDITION or SINGLE FAULT

CONDITION (see 6.3.1 for values applicable to NORMAL CONDITION and 6.3.2 for the higher values

deemed to be appropriate in SINGLE FAULT CONDITION)

3.4.3

HIGH INTEGRITY

not liable to become defective in such a manner as to cause a risk of HAZARD; a HIGH INTEGRITY

part is considered as not subject to failure when tests under fault conditions are made

3.4.4

PROTECTIVE IMPEDANCE

component, assembly of components or the combination of BASIC INSULATION and a current or

voltage limiting device, the impedance, construction and reliability of which are such that when

connected between parts which are HAZARDOUS LIVE and ACCESSIBLE conductive parts,

it provides protection to the extent required by this standard in NORMAL CONDITION and SINGLE

FAULT CONDITION

61010-031 © IEC:2002+A1:2008 – 11 –

3.4.5

NORMAL USE

operation, including stand-by, according to the instructions for use or for the obvious intended

purpose

NOTE In most cases, NORMAL USE also implies NORMAL CONDITION, because the instructions for use will warn

against using the equipment when it is not in NORMAL CONDITION.

3.4.6

NORMAL CONDITION

condition in which all means for protection against HAZARDS are intact

3.4.7

SINGLE FAULT CONDITION

condition in which one means for protection against HAZARD is defective or one fault is present

which could cause a HAZARD

NOTE If a SINGLE FAULT CONDITION results unavoidably in another SINGLE FAULT CONDITION, the two failures are

considered as one SINGLE FAULT CONDITION.

3.4.8

OPERATOR

person operating equipment for its intended purpose

NOTE The OPERATOR should have received training appropriate for this purpose.

3.4.9

RESPONSIBLE BODY

individual or group responsible for the use and maintenance of equipment, and for ensuring

that OPERATORS are adequately trained

3.4.10

WET LOCATION

Location where water or another conductive liquid may be present and is likely to cause

reduced human body impedance due to wetting of the contact between the human body and

the equipment, or wetting of the contact between the human body and the environment

3.4.11

HAZARD

potential source of harm (see 1.2)

3.5 Insulation

3.5.1

BASIC INSULATION

insulation, the failure of which could cause a risk of electric shock

NOTE BASIC INSULATION may serve also for functional purposes.

3.5.2

SUPPLEMENTARY INSULATION

independent insulation applied in addition to BASIC INSULATION in order to provide protection

against electric shock in the event of a failure of BASIC INSULATION

3.5.3

DOUBLE INSULATION

insulation comprising both BASIC INSULATION and SUPPLEMENTARY INSULATION

– 12 – 61010-031 © IEC:2002+A1:2008

3.5.4

REINFORCED INSULATION

insulation which provides protection against electric shock not less than that provided by

DOUBLE INSULATION

NOTE REINFORCED INSULATION may comprise several layers which cannot be tested singly as SUPPLEMENTARY

INSULATION or BASIC INSULATION.

3.5.5

POLLUTION

any addition of foreign matter, solid, liquid or gaseous (ionized gases), that may produce a

reduction of dielectric strength or surface resistively

3.5.6

POLLUTION DEGREE

a numeral indicating the level of POLLUTION that may be present in the environment

3.5.6.1

POLLUTION DEGREE 1

no POLLUTION or only dry, non-conductive POLLUTION

NOTE The POLLUTION has no influence.

3.5.6.2

POLLUTION DEGREE 2

only non-conductive POLLUTION. Occasionally, however, a temporary conductivity caused by

condensation must be expected

3.5.6.3

POLLUTION DEGREE 3

conductive POLLUTION occurs or dry non-conductive POLLUTION occurs which becomes conduc-

tive due to condensation which is to be expected

3.5.7

CLEARANCE

shortest distance in air between two conductive parts

3.5.8

CREEPAGE DISTANCE

shortest distance along the surface of the insulating material between two conductive parts

[IEV 151-03-37]

61010-031 © IEC:2002+A1:2008 – 13 –

IEC 2597/01

Key

1 Typical connectors 5 Crocodile clip

2 PROBE TIP 6 Reference connector

3 Probe body 7 BNC connector

4 To equipment 8 Examples of accessories

Figure 1 – Examples of type A and C PROBE ASSEMBLIES

– 14 – 61010-031 © IEC:2002+A1:2008

IEC 2598/01

Key

1 PROBE TIP

2 To equipment

3 Reference connector

4 BARRIER

5 Hand-held area of probe body

Figure 2 – Examples of type B PROBE ASSEMBLIES

61010-031 © IEC:2002+A1:2008 – 15 –

IEC 076/08

Key

1 connector

2 jaw

3 hand-held area of crocodile clip or clamp

Figure 10 – Examples of type D PROBE ASSEMBLIES

4 Tests

4.1 General

Tests in this standard are TYPE TESTS to be carried out on samples of PROBE ASSEMBLIES or

their parts. Their only purpose is to check that the design and construction ensure conformity

with this standard.

Tests on components or parts of the PROBE ASSEMBLY meeting the requirements of the relevant

standards need not be repeated during TYPE TESTS of the whole PROBE ASSEMBLY.

If a PROBE ASSEMBLY is of more than one probe type (see 1.1), each type shall be tested

according to its applicable requirements.

– 16 – 61010-031 © IEC:2002+A1:2008

Conformity with the requirements of this standard is checked by carrying out all applicable

tests, except that a test may be omitted if examination of the PROBE ASSEMBLY demonstrates

conclusively that it would pass the test. Tests are carried out under

a) reference test conditions (see 4.3);

b) SINGLE FAULT CONDITIONS (see 4.4).

NOTE 1 If the RATED range of environmental conditions for PROBE ASSEMBLIES is wider than that stated in 1.4,

the manufacturer should make sure (for example, by suitable alteration of test requirements or additional tests) that

the safety requirements of this standard are still fulfilled.

NOTE 2 If when carrying out a conformity test, there is any uncertainty about the exact value of the applied or

measured quantity (for example, voltage) due to the tolerance,

– the manufacturer should ensure that at least the specified test value is applied;

– the test house should ensure that no more than the specified test value is applied.

NOTE 3 PROBE ASSEMBLIES which have been TYPE TESTED may no longer be suitable for their intended function

because of the residual effect of stresses resulting from tests. For this reason TYPE TESTS should never be carried

out (for example, by the RESPONSIBLE BODY) after the PROBE ASSEMBLIES have left the manufacturer.

4.2 Sequence of tests

The sequence of tests is optional unless otherwise specified in the standard. The PROBE

ASSEMBLIES under test shall be carefully inspected after each test. If the result of a test causes

doubt whether any earlier tests would have been passed if the sequence had been reversed,

these earlier tests shall be repeated. Tests under fault conditions may be destructive and may

follow those under reference test conditions.

4.3 Reference test conditions

4.3.1 Environmental conditions

Unless otherwise specified in this standard, the following environmental conditions (but not

conflicting with those of 1.4) shall exist in the test location:

a) a temperature of 15 °C to 35 °C;

b) a relative humidity of not more than 75 %;

c) an air pressure of 75 kPa to 106 kPa;

d) no hoarfrost, dew, percolating water, rain, solar irradiation, etc.

4.3.2 State of PROBE ASSEMBLIES

Unless otherwise specified, tests shall be carried out on the PROBE ASSEMBLIES assembled for

NORMAL USE and under the least favourable combination of the conditions given in 4.3.3 to 4.3.9.

When dimensions or mass make it unsuitable to carry out particular tests on a complete PROBE

ASSEMBLY, tests on sub-assemblies are allowed, provided it is verified that the assembled

PROBE ASSEMBLY will be in accordance with this standard.

4.3.3 Position of the PROBE ASSEMBLY

The PROBE ASSEMBLY shall be in any position of NORMAL USE and with any ventilation

unimpeded

4.3.4 Accessories

Accessories and OPERATOR interchangeable parts available from, or recommended by, the

manufacturer for use with the PROBE ASSEMBLY under test shall be either connected or not

connected.

61010-031 © IEC:2002+A1:2008 – 17 –

4.3.5 Covers and removable parts

Covers or parts which can be removed without using a TOOL shall be removed or not removed.

4.3.6 Input and output voltages

Input and output voltages, including floating voltages shall be set to any voltage within the

RATED voltage range.

4.3.7 Controls

Controls which the OPERATOR can adjust by hand shall be set to any position except for

combinations of settings prohibited by the manufacturer, as shown by marking on the PROBE

ASSEMBLY.

4.3.8 Connections