IEC 61010-2-032:2023

(Main)Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-032: Particular requirements for hand-held and hand-manipulated current sensors for electrical test and measurement

Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-032: Particular requirements for hand-held and hand-manipulated current sensors for electrical test and measurement

IEC 61010-2-032:2023 specifies safety requirements for hand-held and hand-manipulated current sensors intended for measuring, detecting or injecting current, or indicating current waveforms on circuits without physically opening the current path of the circuit being measured.

These current sensors are hand-manipulated before and/or after a test or measurement, but are not necessarily hand-held during the test or measurement. They can be stand-alone current sensors or accessories to other equipment or parts of combined equipment. These include measurement circuits which are part of electrical test and measurement equipment, laboratory equipment, or process control equipment.

This fifth edition cancels and replaces the fourth edition published in 2019. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a) In 1.1.1, definitions of current sensor types have been moved to a new Annex FF;

b) Clause 2, all normative references have been dated and new normative references have been added;

c) 3.2.103, a new definition protective fingerguard has been added which replaces the previous definition of protective barrier;

d) 4.4.2.101 is a new subclause about surge protective devices;

e) in 5.1.5.101.2, minimum ratings for voltage of measuring terminals are required;

f) Subclause 6.5.1 has been modified;

g) Subclause 6.5.5 is no longer used;

h) Subclause 6.6.101 modifies 6.6.101 and 6.6.102 of previous edition:

1) in 6.6.101.1, insulating material of group I may be allowed for determination of creepage distances of measuring circuit terminals;

2) in 6.6.101.2, clearances and creepage distances up to 3 000 V for measuring circuit terminals in unmated position have been defined;

3) in 6.6.101.3, requirements for measuring circuit terminals in partially mated position have been specified;

4) in 6.6.101.4, requirements for measuring circuit terminals in mated position have been specified;

5) Subclause 6.6.101.5 replaces 6.6.102;

i) Subclause 6.6.102 replaces 6.101 of previous edition with modifications;

j) Subclause 6.101.2 replaces 6.9.101.1 of previous edition with modifications;

k) Subclause 6.101.3 replaces 6.9.101.2 of previous edition with modifications;

l) Subclause 6.101.4 replaces 6.9.102 of previous edition with modifications;

m) in 8.101, jaw ends abrasion test has been modified;

n) 8.105 is a new subclause for input/output leads attachment has been added;

o) in 9.101.2, relocation of 101.3 of previous edition;

p) in 9.101.3, relocation of 101.4 of previous edition, extension to measurement category II and reference to IEC 61000-4-5 for tests:

q) Table 104 has been replaced by Table K.101:

r) in 9.102, relocation of Clause 102 of previous edition;

s) in 14.101, relocation of 14.102. Subclause 14.101 of previous edition has been deleted;

t) 101.3 is a new subclause for protections against hazard occurring from reading a voltage value in replacement of Clause EE.5 of previous edition;

u) in Table D.101, transients are disregarded for insulation between jaw ends and input/output circuits;

v) in Clause F.101, test voltages for routine test of jaws have been modified;

w) in K.2.1, another method for determination of clearances of secondary circuits is proposed;

x) in K.3.2, new Table K.15 and Table K.16 for clearance calculation;

y) K.3.101 is a new clause;

z) Clause K.4, redraft of the clause to propose a method for determination of Ut for circuits which reduce transient overvoltages;

aa) Table K.101 replaces Table 104;

bb) Subclause K.101.4 has been reviewed and tables and tests for solid insulation have been modified;

cc) Table K.104 of previous edition has been deleted;

dd) Annex AA: Figure AA.1 has been redesigned;

ee) Annex EE: addition of a new informative annex for determination of clearances for Table 101;

ff) Annex GG: this annex was Annex EE of previous edition and the current sensor type of

Exigences de sécurité pour appareils électriques de mesurage, de régulation et de laboratoire - Partie 2-032 : Exigences particulières pour les capteurs de courant, portatifs et manipulés manuellement, pour essai électrique et mesurage

L'IEC 61010-2-032:2023 spécifie les exigences de sécurité pour les capteurs de courant portatifs et manipulés à la main pour mesurer, détecter ou injecter du courant, ou afficher les formes d’onde du courant sur les circuits sans ouverture physique du chemin du courant sur le circuit mesuré.

Ces capteurs de courant sont manipulés manuellement avant et/ou après un essai ou un mesurage, mais il n’est pas nécessaire qu’ils soient portatifs pendant l’essai ou le mesurage. Les capteurs de courant peuvent être autonomes, ou accessoires d’autres appareils ou parties d’appareils combinés. Cela comprend les circuits de mesure qui font partie des appareils électriques d’essai et de mesure, du matériel de laboratoire ou des appareils de contrôle de procédés industriels.

Cette cinquième édition annule et remplace la quatrième édition parue en 2019. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l’édition précédente:

a) au paragraphe 1.1.1, les définitions des types de capteurs de courant ont été déplacées vers une nouvelle Annexe FF;

b) à l’Article 2, toutes les références normatives ont été datées et de nouvelles références normatives ont été ajoutées;

c) au paragraphe 3.2.103, une nouvelle définition de protège-doigts a été ajoutée pour remplacer la définition précédente de barrière de protection;

d) le paragraphe 4.4.2.101 est un nouveau paragraphe sur les dispositifs de protection contre les surtensions;

e) au paragraphe 5.1.5.101.2, des valeurs assignées minimales de tension des bornes des circuits de mesure sont exigées;

f) le paragraphe 6.5.1 a été modifié;

g) le paragraphe 6.5.5 a été supprimé;

h) le paragraphe 6.6.101 modifie les paragraphes 6.6.101 et 6.6.102 de l’édition précédente:

1) au paragraphe 6.6.101.1, les matériaux isolants du groupe I peuvent être admis pour la détermination des distances d’isolement des bornes des circuits de mesure;

2) au paragraphe 6.6.101.2, les distances d’isolement et les lignes de fuite inférieures à 3 000 V pour les bornes des circuits de mesure en position découplée ont été définies;

3) au paragraphe 6.6.101.3, des exigences relatives aux bornes des circuits de mesure en position partiellement couplée ont été spécifiées;

4) au paragraphe 6.6.101.4, des exigences relatives aux bornes des circuits de mesure en position couplée ont été spécifiées;

5) le paragraphe 6.6.101.5 remplace le paragraphe 6.6.102;

i) le paragraphe 6.6.102 remplace le paragraphe 6.101 de l’édition précédente avec des modifications;

j) le paragraphe 6.101.2 remplace le paragraphe 6.9.101.1 de l’édition précédente avec des modifications;

k) le paragraphe 6.101.3 remplace le paragraphe 6.9.101.2 de l’édition précédente avec des modifications;

l) le paragraphe 6.101.4 remplace le paragraphe 6.9.102 de l’édition précédente avec des modifications;

m) au paragraphe 8.101, l’essai d’abrasion des extrémités de la mâchoire a été modifié;

n) le paragraphe 8.105 est un nouveau paragraphe concernant la fixation des cordons d’entrée/sortie;

o) le paragraphe 101.3 de la précédente édition a été déplacé en 9.101.2;

p) le paragraphe 101.4 de la précédente édition a été déplacé au paragraphe 9.101.3. Ce paragraphe a été étendu à la catégorie de mesure II et fait référence à l’IEC 61000-4-5 pour les essais;

q) le Tableau 104 a été remplacé par le Tableau K.101;

r) l’Article 102 de la précédente édition a été déplacé en 9.102;

s) le paragraphe 14.102 a été déplacé en 14.101; le paragraphe 14.101 de l’édition précédente a été supprimé;

t) le paragraphe 101.3 est un nouveau paragraphe concernant les protections contre les dangers liés à la lecture d’une valeur de tension en remplacement de l’Article EE.5 de l’édition précédente;

u) dans le Tableau D.101, les surtensions transitoires ne sont pas prises en compte pour l’isolation entre les extrémités de la mâchoire et les circuits d’entrée/sortie;

v) à l’Article F.101, les tensions d

General Information

- Status

- Published

- Publication Date

- 19-Sep-2023

- Technical Committee

- TC 66 - Safety of measuring, control and laboratory equipment

- Drafting Committee

- WG 2 - TC 66/WG 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 20-Sep-2023

- Completion Date

- 22-Sep-2023

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61010-2-032:2023 - Part 2-032 of the IEC 61010 series - defines safety requirements for hand‑held and hand‑manipulated current sensors used in electrical test, measurement and laboratory environments. This fifth edition (2023) is a technical revision that replaces the 2019 edition and covers stand‑alone current sensors, accessories and combined equipment that measure, detect, inject or indicate current without opening the circuit under test.

Keywords: IEC 61010-2-032:2023, hand-held current sensors, current probes, clamp meters, safety requirements, test and measurement.

Key topics and technical requirements

The standard focuses on practical safety and verification aspects for current sensors. Major topics include:

- Scope and definitions - Equipment included/excluded; new organization of sensor type definitions (moved to Annex FF).

- Marking and documentation - Required ratings, warnings and user instructions for safe use.

- Protection against electric shock - Requirements for insulation, protective fingerguards, basic and supplementary insulation, and protective impedances.

- Measuring circuit terminals - Minimum voltage ratings, clearances and creepage distances (including definitions up to 3 000 V for unmated measuring terminals), and considerations for mated/partially mated states.

- Construction and mechanical tests - Jaw abrasion tests, input/output lead attachment, routine test voltages for jaws and other mechanical durability tests.

- Surge and transient considerations - New subclauses on surge protective devices and references to transient testing (including measurement category II and IEC 61000‑4‑5).

- Test procedures and verification - Type and routine tests, test sequences, humidity preconditioning and single‑fault condition testing.

- Annexes and calculation methods - New and revised annexes (K, AA, EE, etc.) providing methods for clearance calculation, Ut determination for transient reduction circuits, and revised tables (e.g., Table K.101).

Practical applications

This standard is practical guidance for ensuring safe design, manufacture and use of current sensors such as:

- Clamp meters and current probes used by electricians and field technicians

- Hand‑manipulated current sensors used with oscilloscopes and multimeters in R&D and laboratories

- Accessories integrated into process control and test systems where current measurement is required without breaking the circuit

Who should use this standard

- Design and test engineers developing current probes and clamp meters

- Compliance and safety officers ensuring product certification to IEC requirements

- Manufacturers, test labs and notified bodies performing type and routine testing

- Procurement and maintenance teams specifying safe measurement equipment for field use

Related standards

- IEC 61010-1 (General requirements for electrical equipment for measurement, control and laboratory use) - referenced and included in the extended version.

- IEC 61000-4-5 - referenced for surge testing and transient immunity guidance.

This concise summary helps manufacturers and users understand the practical safety, testing and design implications of IEC 61010-2-032:2023 for hand‑held and hand‑manipulated current sensors.

IEC 61010-2-032:2023 EXV - Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-032: Particular requirements for hand-held and hand-manipulated current sensors for electrical test and measurement Released:9/20/2023 Isbn:9782832275696

IEC 61010-2-032:2023 - Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-032: Particular requirements for hand-held and hand-manipulated current sensors for electrical test and measurement Released:20. 09. 2023

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

IEC 61010-2-032:2023 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-032: Particular requirements for hand-held and hand-manipulated current sensors for electrical test and measurement". This standard covers: IEC 61010-2-032:2023 specifies safety requirements for hand-held and hand-manipulated current sensors intended for measuring, detecting or injecting current, or indicating current waveforms on circuits without physically opening the current path of the circuit being measured. These current sensors are hand-manipulated before and/or after a test or measurement, but are not necessarily hand-held during the test or measurement. They can be stand-alone current sensors or accessories to other equipment or parts of combined equipment. These include measurement circuits which are part of electrical test and measurement equipment, laboratory equipment, or process control equipment. This fifth edition cancels and replaces the fourth edition published in 2019. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) In 1.1.1, definitions of current sensor types have been moved to a new Annex FF; b) Clause 2, all normative references have been dated and new normative references have been added; c) 3.2.103, a new definition protective fingerguard has been added which replaces the previous definition of protective barrier; d) 4.4.2.101 is a new subclause about surge protective devices; e) in 5.1.5.101.2, minimum ratings for voltage of measuring terminals are required; f) Subclause 6.5.1 has been modified; g) Subclause 6.5.5 is no longer used; h) Subclause 6.6.101 modifies 6.6.101 and 6.6.102 of previous edition: 1) in 6.6.101.1, insulating material of group I may be allowed for determination of creepage distances of measuring circuit terminals; 2) in 6.6.101.2, clearances and creepage distances up to 3 000 V for measuring circuit terminals in unmated position have been defined; 3) in 6.6.101.3, requirements for measuring circuit terminals in partially mated position have been specified; 4) in 6.6.101.4, requirements for measuring circuit terminals in mated position have been specified; 5) Subclause 6.6.101.5 replaces 6.6.102; i) Subclause 6.6.102 replaces 6.101 of previous edition with modifications; j) Subclause 6.101.2 replaces 6.9.101.1 of previous edition with modifications; k) Subclause 6.101.3 replaces 6.9.101.2 of previous edition with modifications; l) Subclause 6.101.4 replaces 6.9.102 of previous edition with modifications; m) in 8.101, jaw ends abrasion test has been modified; n) 8.105 is a new subclause for input/output leads attachment has been added; o) in 9.101.2, relocation of 101.3 of previous edition; p) in 9.101.3, relocation of 101.4 of previous edition, extension to measurement category II and reference to IEC 61000-4-5 for tests: q) Table 104 has been replaced by Table K.101: r) in 9.102, relocation of Clause 102 of previous edition; s) in 14.101, relocation of 14.102. Subclause 14.101 of previous edition has been deleted; t) 101.3 is a new subclause for protections against hazard occurring from reading a voltage value in replacement of Clause EE.5 of previous edition; u) in Table D.101, transients are disregarded for insulation between jaw ends and input/output circuits; v) in Clause F.101, test voltages for routine test of jaws have been modified; w) in K.2.1, another method for determination of clearances of secondary circuits is proposed; x) in K.3.2, new Table K.15 and Table K.16 for clearance calculation; y) K.3.101 is a new clause; z) Clause K.4, redraft of the clause to propose a method for determination of Ut for circuits which reduce transient overvoltages; aa) Table K.101 replaces Table 104; bb) Subclause K.101.4 has been reviewed and tables and tests for solid insulation have been modified; cc) Table K.104 of previous edition has been deleted; dd) Annex AA: Figure AA.1 has been redesigned; ee) Annex EE: addition of a new informative annex for determination of clearances for Table 101; ff) Annex GG: this annex was Annex EE of previous edition and the current sensor type of

IEC 61010-2-032:2023 specifies safety requirements for hand-held and hand-manipulated current sensors intended for measuring, detecting or injecting current, or indicating current waveforms on circuits without physically opening the current path of the circuit being measured. These current sensors are hand-manipulated before and/or after a test or measurement, but are not necessarily hand-held during the test or measurement. They can be stand-alone current sensors or accessories to other equipment or parts of combined equipment. These include measurement circuits which are part of electrical test and measurement equipment, laboratory equipment, or process control equipment. This fifth edition cancels and replaces the fourth edition published in 2019. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) In 1.1.1, definitions of current sensor types have been moved to a new Annex FF; b) Clause 2, all normative references have been dated and new normative references have been added; c) 3.2.103, a new definition protective fingerguard has been added which replaces the previous definition of protective barrier; d) 4.4.2.101 is a new subclause about surge protective devices; e) in 5.1.5.101.2, minimum ratings for voltage of measuring terminals are required; f) Subclause 6.5.1 has been modified; g) Subclause 6.5.5 is no longer used; h) Subclause 6.6.101 modifies 6.6.101 and 6.6.102 of previous edition: 1) in 6.6.101.1, insulating material of group I may be allowed for determination of creepage distances of measuring circuit terminals; 2) in 6.6.101.2, clearances and creepage distances up to 3 000 V for measuring circuit terminals in unmated position have been defined; 3) in 6.6.101.3, requirements for measuring circuit terminals in partially mated position have been specified; 4) in 6.6.101.4, requirements for measuring circuit terminals in mated position have been specified; 5) Subclause 6.6.101.5 replaces 6.6.102; i) Subclause 6.6.102 replaces 6.101 of previous edition with modifications; j) Subclause 6.101.2 replaces 6.9.101.1 of previous edition with modifications; k) Subclause 6.101.3 replaces 6.9.101.2 of previous edition with modifications; l) Subclause 6.101.4 replaces 6.9.102 of previous edition with modifications; m) in 8.101, jaw ends abrasion test has been modified; n) 8.105 is a new subclause for input/output leads attachment has been added; o) in 9.101.2, relocation of 101.3 of previous edition; p) in 9.101.3, relocation of 101.4 of previous edition, extension to measurement category II and reference to IEC 61000-4-5 for tests: q) Table 104 has been replaced by Table K.101: r) in 9.102, relocation of Clause 102 of previous edition; s) in 14.101, relocation of 14.102. Subclause 14.101 of previous edition has been deleted; t) 101.3 is a new subclause for protections against hazard occurring from reading a voltage value in replacement of Clause EE.5 of previous edition; u) in Table D.101, transients are disregarded for insulation between jaw ends and input/output circuits; v) in Clause F.101, test voltages for routine test of jaws have been modified; w) in K.2.1, another method for determination of clearances of secondary circuits is proposed; x) in K.3.2, new Table K.15 and Table K.16 for clearance calculation; y) K.3.101 is a new clause; z) Clause K.4, redraft of the clause to propose a method for determination of Ut for circuits which reduce transient overvoltages; aa) Table K.101 replaces Table 104; bb) Subclause K.101.4 has been reviewed and tables and tests for solid insulation have been modified; cc) Table K.104 of previous edition has been deleted; dd) Annex AA: Figure AA.1 has been redesigned; ee) Annex EE: addition of a new informative annex for determination of clearances for Table 101; ff) Annex GG: this annex was Annex EE of previous edition and the current sensor type of

IEC 61010-2-032:2023 is classified under the following ICS (International Classification for Standards) categories: 19.080 - Electrical and electronic testing. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61010-2-032:2023 has the following relationships with other standards: It is inter standard links to IEC 61010-2-032:2019, IEC 61010-2-032:2019/COR1:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61010-2-032:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61010-2-032 ®

Edition 5.0 2023-09

EXTENDED VERSION

INTERNATIONAL

STANDARD

colour

inside

This extended version of IEC 61010-2-032:2023 includes the content of the references made to

IEC 61010-1:2010 and IEC 61010-1:2010/AMD1:2016

Safety requirements for electrical equipment for measurement, control, and

laboratory use –

Part 2-032: Particular requirements for hand-held and hand-manipulated current

sensors for electrical test and measurement

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61010-2-032 ®

Edition 5.0 2023-09

EXTENDED VERSION

INTERNATIONAL

STANDARD

colour

inside

This extended version of IEC 61010-2-032:2023 includes the content of the references made to

IEC 61010-1:2010 and IEC 61010-1:2010/AMD1:2016

Safety requirements for electrical equipment for measurement, control, and

laboratory use –

Part 2-032: Particular requirements for hand-held and hand-manipulated current

sensors for electrical test and measurement

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 19.080 ISBN 978-2-8322-7569-6

TC 66/Publication 61010-1 (2010), Third edition/I-SH 01

SAFETY REQUIREMENTS FOR ELECTRICAL EQUIPMENT

FOR MEASUREMENT, CONTROL, AND LABORATORY USE –

Part 1: General requirements

INTERPRETATION SHEET 1

This interpretation sheet has been prepared by IEC technical committee 66: Safety of

measuring, control and laboratory equipment.

The text of this interpretation sheet is based on the following documents:

ISH Report on voting

66/497A/ISH 66/505/RVD

Full information on the voting for the approval of this interpretation sheet can be found in the

report on voting indicated in the above table.

___________

IEC 61010-1:2010 contains a requirement in 6.8.3.1 pertaining to voltage testers for type tests

as follows:

“The generator shall be able to supply a power of at least 500 VA.”

This has given rise to the following questions:

How does one interpret the requirement for voltage testers in 6.8.3.1 of IEC 61010-1:2010?

Specifically, this subclause requires that “The generator shall be able to supply a power of at

least 500 VA.” Does this requirement apply throughout the rated output range of the voltage

tester? What is meant by the word “generator”? Is the “generator” the power supply within the

voltage tester, or the voltage tester output, or something else?

Interpretation:

“A voltage tester used for type tests must be able to deliver at least 500 VA at its full-rated

output voltage. It does not necessarily need to deliver 500 VA if set for lower voltages.

For example, a voltage tester that can deliver 100 mA at any test output voltage up to 5 000 V

(and a current corresponding to 500 VA above 5 000 V) would meet the requirement.

The requirements for voltage testers used for routine (production line) tests are included in

Annex F. The requirements of 6.8.3.1 do not apply to these voltage testers.”

February 2013 ICS 19.080, 71.040.10 French text overleaf

– 2 – IEC 61010-2-032:2023 EXV © IEC 2023

CONTENTS

FOREWORD . 11

INTRODUCTION to IEC 61010-1:2010 and IEC 61010-1:2010/AMD1:2016 . 15

INTRODUCTION . 16

1 Scope and object . 17

1.1 Scope . 17

1.1.1 Equipment included in scope . 17

1.1.2 Equipment excluded from scope . 17

1.1.3 Computing equipment . 17

1.2 Object . 18

1.2.1 Aspects included in scope . 18

1.2.2 Aspects excluded from scope . 18

1.3 Verification . 18

1.4 Environmental conditions . 18

1.4.1 Normal environmental conditions . 18

1.4.2 Extended environmental conditions . 19

2 Normative references . 19

3 Terms and definitions . 21

3.1 Equipment and states of equipment . 21

3.2 Parts and accessories . 22

3.3 Quantities . 23

3.4 Tests . 24

3.5 Safety terms . 24

3.6 Insulation . 26

4 Tests . 27

4.1 General . 27

4.2 Sequence of tests. 28

4.3 Reference test conditions . 28

4.3.1 Environmental conditions . 28

4.3.2 State of equipment . 28

4.4 Testing in SINGLE FAULT CONDITION . 30

4.4.1 General . 30

4.4.2 Application of fault conditions . 30

4.4.3 Duration of tests . 32

4.4.4 Conformity after application of fault conditions . 33

5 Marking and documentation . 33

5.1 Marking . 33

5.1.1 General . 33

5.1.2 Identification . 34

5.1.3 MAINS supply . 34

5.1.4 Fuses . 37

5.1.5 TERMINALS, connections and operating devices . 37

5.1.6 Switches and circuit-breakers . 39

5.1.7 Equipment protected by DOUBLE INSULATION or REINFORCED

INSULATION . 40

5.1.8 Field-wiring TERMINAL boxes . 40

5.2 Warning markings . 40

5.3 Durability of markings . 41

5.4 Documentation . 41

5.4.1 General . 41

5.4.2 Equipment RATINGS . 42

5.4.3 Equipment installation . 42

5.4.4 Equipment operation . 43

5.4.5 Equipment maintenance and service . 44

5.4.6 Integration into systems or effects resulting from special conditions . 44

6 Protection against electric shock . 44

6.1 General . 44

6.1.1 Requirements . 44

6.1.2 Exceptions . 44

6.2 Determination of ACCESSIBLE parts . 45

6.2.1 General . 45

6.2.2 Examination. 45

6.2.3 Openings above parts that are HAZARDOUS LIVE. 46

6.2.4 Openings for pre-set controls. 46

6.3 Limit values for ACCESSIBLE parts . 46

6.3.1 Levels in NORMAL CONDITION . 46

6.3.2 Levels in SINGLE FAULT CONDITION . 47

6.4 Primary means of protection . 50

6.4.1 General . 50

6.4.2 ENCLOSURES and PROTECTIVE BARRIERS . 50

6.4.3 BASIC INSULATION . 50

6.4.4 Impedance . 50

6.5 Additional means of protection in case of SINGLE FAULT CONDITIONS . 50

6.5.1 General . 50

6.5.2 Not used . 51

6.5.3 SUPPLEMENTARY INSULATION and REINFORCED INSULATION . 51

6.5.4 PROTECTIVE IMPEDANCE . 51

6.5.5 Not used . 52

6.5.6 Current- or voltage-limiting device . 52

6.6 Connections to external circuits . 52

6.6.1 General . 52

6.6.2 TERMINALS for external circuits . 53

6.6.3 Circuits with TERMINALS which are HAZARDOUS LIVE . 53

6.6.4 TERMINALS for stranded conductors . 53

6.6.101 Measuring circuit TERMINALS. 53

6.6.102 Input/output circuit leads . 56

6.7 Insulation requirements . 57

6.7.1 The nature of insulation . 57

6.7.2 Insulation for MAINS CIRCUITS of OVERVOLTAGE CATEGORY II with a

nominal supply voltage up to 300 V . 59

6.7.3 Insulation for secondary circuits derived from MAINS CIRCUITS of

OVERVOLTAGE CATEGORY II up to 300 V . 63

6.8 Procedure for voltage tests . 69

6.8.1 General . 69

6.8.2 Humidity preconditioning . 70

6.8.3 Test procedures . 71

– 4 – IEC 61010-2-032:2023 EXV © IEC 2023

6.9 Constructional requirements for protection against electric shock . 72

6.9.1 General . 72

6.9.2 Insulating materials . 72

6.9.3 Colour coding . 72

6.10 Connection to the MAINS supply source and connections between parts of

equipment . 72

6.10.1 MAINS supply cords . 72

6.10.2 Fitting of non-detachable MAINS supply cords . 73

6.10.3 Plugs and connectors . 75

6.11 Disconnection from supply source . 75

6.11.1 General . 75

6.11.2 Exceptions . 75

6.11.3 Requirements according to type of equipment . 76

6.11.4 Disconnecting devices . 76

6.101 Protection against hazardous live conductors . 77

6.101.1 General . 77

6.101.2 Protection by a PROTECTIVE FINGERGUARD . 77

6.101.3 Insulation of HAND-HELD or hand-manipulated parts for

Type A current sensors . 78

6.101.4 Insulation of input/output circuits . 79

7 Protection against mechanical HAZARDS . 79

7.1 General . 79

7.2 Sharp edges . 80

7.3 Moving parts . 80

7.3.1 General . 80

7.3.2 Exceptions . 80

7.3.3 RISK assessment for mechanical HAZARDS to body parts . 80

7.3.4 Limitation of force and pressure . 81

7.3.5 Gap limitations between moving parts . 82

7.4 Stability . 84

7.5 Provisions for lifting and carrying . 85

7.5.1 General . 85

7.5.2 Handles and grips . 85

7.5.3 Lifting devices and supporting parts. 85

7.6 Wall mounting . 85

7.7 Expelled parts . 86

8 Resistance to mechanical stresses . 86

8.1 General . 86

8.2 ENCLOSURE rigidity tests . 87

8.2.1 Static test . 87

8.2.2 Impact test . 87

8.3 Drop test . 88

8.3.1 Equipment other than HAND-HELD EQUIPMENT and DIRECT PLUG-IN

................................................................................................. 88

EQUIPMENT

8.3.2 HAND-HELD EQUIPMENT and DIRECT PLUG-IN EQUIPMENT . 89

8.101 JAW ENDS abrasion test . 89

8.102 JAW impact test . 90

8.103 Pressure test at high temperature for insulation of flexible current sensors . 91

8.104 Pull test for endcaps of flexible current sensors . 93

8.105 Attachment of the input/output leads . 93

8.105.1 General . 93

8.105.2 Pull test . 94

8.105.3 Flexing test . 94

9 Protection against the spread of fire and arc flash . 96

9.1 General . 96

9.2 Eliminating or reducing the sources of ignition within the equipment . 98

9.3 Containment of fire within the equipment, should it occur . 98

9.3.1 General . 98

9.3.2 Constructional requirements . 98

9.4 Limited-energy circuit . 101

9.5 Requirements for equipment containing or using flammable liquids . 102

9.6 Overcurrent protection . 102

9.6.1 General . 102

9.6.2 PERMANENTLY CONNECTED EQUIPMENT . 103

9.6.3 Other equipment . 103

9.101 Protection of measuring circuits . 103

9.101.1 General . 103

9.101.2 Protection against mismatches of inputs and ranges . 103

9.101.3 Protection against mains overvoltages . 106

9.102 Prevention of hazard from arc flash and short-circuits . 107

9.102.1 General . 107

9.102.2 Protection against short-circuits during clamping . 107

9.102.3 Protection against short-circuits in closed position . 109

10 Equipment temperature limits and resistance to heat . 109

10.1 Surface temperature limits for protection against burns . 109

10.2 Temperatures of windings . 110

10.3 Other temperature measurements . 110

10.4 Conduct of temperature tests . 111

10.4.1 General . 111

10.4.2 Temperature measurement of heating equipment . 111

10.4.3 Equipment intended for installation in a cabinet or a wall . 111

10.5 Resistance to heat. 112

10.5.1 Integrity of CLEARANCES and CREEPAGE DISTANCES . 112

10.5.2 Non-metallic ENCLOSURES . 112

10.5.3 Insulating material . 112

10.5.101 Resistance to heat of current sensors . 113

10.101 Other temperatures of current sensors . 113

11 Protection against HAZARDS from fluids and solid foreign objects . 114

11.1 General . 114

11.2 Cleaning . 114

11.3 Spillage . 114

11.4 Overflow . 114

11.5 Battery electrolyte . 115

11.6 Equipment RATED with a degree of ingress protection (IP code) . 115

11.6.1 General . 115

11.6.2 Conditions for testing . 115

11.6.3 Protection against solid foreign objects (including dust) . 116

11.6.4 Protection against water . 116

– 6 – IEC 61010-2-032:2023 EXV © IEC 2023

11.7 Fluid pressure and leakage . 116

11.7.1 Maximum pressure . 116

11.7.2 Leakage and rupture at high pressure . 117

11.7.3 Leakage from low-pressure parts . 118

11.7.4 Overpressure safety device . 118

12 Protection against radiation, including laser sources, and against sonic and

ultrasonic pressure . 119

12.1 General . 119

12.2 Equipment producing ionizing radiation . 119

12.2.1 Ionizing radiation . 119

12.2.2 Accelerated electrons . 120

12.3 Optical radiation . 120

12.4 Microwave radiation . 121

12.5 Sonic and ultrasonic pressure . 121

12.5.1 Sound level . 121

12.5.2 Ultrasonic pressure. 122

12.6 Laser sources . 122

13 Protection against liberated gases and substances, explosion and implosion . 123

13.1 Poisonous and injurious gases and substances . 123

13.2 Explosion and implosion . 123

13.2.1 Components . 123

13.2.2 Batteries and battery charging . 123

13.2.3 Implosion of cathode ray tubes . 124

14 Components and subassemblies . 124

14.1 General . 124

14.2 Motors . 125

14.2.1 Motor temperatures . 125

14.2.2 Series excitation motors . 125

14.3 Overtemperature protection devices . 126

14.4 Fuse holders . 126

14.5 MAINS voltage selection devices . 126

14.6 MAINS transformers tested outside equipment . 126

14.7 Printed wiring boards . 127

14.8 Circuits used to limit TRANSIENT OVERVOLTAGES . 127

14.101 Probe assemblies and accessories . 127

15 Protection by interlocks . 128

15.1 General . 128

15.2 Prevention of reactivating . 128

15.3 Reliability . 128

16 HAZARDS resulting from application . 128

16.1 REASONABLY FORESEEABLE MISUSE . 128

16.2 Ergonomic aspects . 128

17 RISK assessment . 129

101 Measuring circuits . 129

101.1 General . 129

101.2 Current sensor with an internal current transformer . 130

101.3 Indicating devices . 130

101.3.1 General . 130

101.3.2 Battery level . 130

101.3.3 Over-range indication . 131

101.3.4 Permanent overvoltages . 131

Annex A (normative) Measuring circuits for touch current (see 6.3) . 133

Annex B (normative) Standard test fingers (see 6.2) . 136

Annex C (normative) Measurement of CLEARANCES and CREEPAGE DISTANCES . 138

Annex D (normative) Parts between which insulation requirements are specified (see

6.4, 6.5.3 and 6.101) . 142

Annex E (informative) Guideline for reduction of POLLUTION DEGREES . 146

Annex F (normative) ROUTINE TESTS . 147

Annex G (informative) Leakage and rupture from fluids under pressure . 150

Annex H (normative) Qualification of conformal coatings for protection against

POLLUTION . 155

Annex I (informative) Line-to-neutral voltages for common MAINS supply systems . 158

Annex J (informative) RISK assessment . 160

Annex K (normative) Insulation requirements not covered by 6.7 . 163

Annex L (informative) Index of defined terms . 192

Annex AA (normative) MEASUREMENT CATEGORIES . 194

Annex BB (informative) HAZARDS pertaining to measurements performed in certain

environments . 197

Annex CC (informative) 4 mm "banana" TERMINALS . 200

Annex DD (informative) Flowchart for insulation according to the type of circuit . 202

Annex EE (informative) Determination of CLEARANCES for Table 101 . 205

Annex FF (normative) Type of current sensors . 206

Annex GG (normative) CLAMP MULTIMETER . 208

Bibliography . 210

Figure 1 – Measurements through openings in ENCLOSURES . 46

Figure 2 – Maximum duration of short-term ACCESSIBLE voltages in SINGLE FAULT

CONDITION (see 6.3.2 a)) . 48

Figure 3 – Capacitance level versus voltage in NORMAL CONDITION and SINGLE FAULT

(see 6.3.1 c) and 6.3.2 c)) . 49

CONDITION

Figure 4 – Acceptable arrangement of protective means against electric shock . 51

Figure 6 – Distance between conductors on an interface between two layers . 61

Figure 7 – Distance between adjacent conductors along an interface of two inner

layers. 62

Figure 8 – Distance between adjacent conductors located between the same two

layers. 63

Figure 9 – Detachable MAINS supply cords and connections . 73

Figure 101 – CLEARANCE between the PROTECTIVE FINGERGUARD to the JAWS and to the

HAZARDOUS LIVE conductor . 78

Figure 10 – Impact test using a sphere . 88

Figure 102 – Abrasion test of the JAW ENDS . 90

Figure 103 – Impact points for JAW impact test . 91

Figure 104 – Indentation device . 92

Figure 105 – Example of a current sensor with strain reliefs . 94

– 8 – IEC 61010-2-032:2023 EXV © IEC 2023

Figure 106 – Flexing test . 95

Figure 11 – Flow chart to explain the requirements for protection against

the spread of fire . 97

Figure 12 – Baffle . 100

Figure 13 – Area of the bottom of an ENCLOSURE to be constructed as specified in

9.3.2 c) 1) . 100

Figure 107 – Test probe to check protection against short-circuits . 108

Figure 108 – Use of the test probe of Figure 107 . 108

Figure 14 – Ball-pressure test apparatus. 113

Figure 16 – Ratio between test pressure and maximum working pressure . 118

Figure 15 – Flow chart for conformity options 14.1 a), b), c) and d) . 125

Figure A.1 – Measuring circuit for a.c. with frequencies up to 1 MHz and for d.c. . 133

Figure A.2 – Measuring circuits for sinusoidal a.c. with frequencies up to 100 Hz and

for d.c. . 134

Figure A.3 – Current measuring circuit for electrical burns . 135

Figure A.4 – Current measuring circuit for wet contact . 135

Figure B.1 – Rigid test finger . 136

Figure B.2 – Jointed test finger . 137

Figure C.1 – Examples of methods of measuring CLEARANCES and CREEPAGE DISTANCES . 141

Figures D.1a) to d) – Protection between HAZARDOUS LIVE circuits and ACCESSIBLE

parts . 143

Figures D.1e) to h) – Protection between HAZARDOUS LIVE circuits and circuits with

ACCESSIBLE external TERMINALS . 143

Figures D.2 a) and D.2 b) – Protection between a HAZARDOUS LIVE internal circuit and

an ACCESSIBLE part which is not bonded to other ACCESSIBLE parts . 144

Figures D.2 c) and D.2 d) – Protection between a HAZARDOUS LIVE primary circuit and

circuits which have ACCESSIBLE external TERMINALS . 144

Figure D.3 – Protection of external ACCESSIBLE TERMINALS of two HAZARDOUS LIVE

circuits . 144

Figure D.101 – Parts of current sensors (see also Table D.101) . 145

Figure G.1 – Conformity verification process (see G.2) . 151

Figure H.1 – Test sequence and conformity . 157

Figure J.1 – Iterative process of RISK assessment and RISK reduction . 160

Figure J.2 – RISK reduction . 161

Figure K.1 – Distance between conductors on an interface between two layers . 167

Figure K.2 – Distance between adjacent conductors along an interface of an inner

layer . 168

Figure K.3 – Distance between adjacent conductors located between the same two

layers. 169

Figure K.4 – Example of recurring peak voltage . 182

Figure K.101 – CLEARANCES between the conductor, the input/output circuit and the

enclosure of a Type A current sensor . 184

Figure K.102 – Test circuit for evaluation of TRANSIENT OVERVOLTAGE attenuation . 186

Figure AA.1 – Example to identify the locations of MEASUREMENT CATEGORIES . 195

Figure CC.1 – Recommended dimensions of 4 mm TERMINALS . 201

Figure DD.1 – Requirements for CLEARANCE, CREEPAGE DISTANCE and solid insulation . 204

Figure FF.1 – Examples of current sensors and their parts . 207

Figure GG.1 – Examples of CLAMP MULTIMETERS . 208

Table 1 – Symbols . 36

Table 101 – CLEARANCES for unmated measuring circuit TERMINALS. 54

Table 3 – Multiplication factors for CLEARANCES of equipment RATED for operation at

altitudes up to 5 000 m . 58

TABLE 4 – CLEARA

...

IEC 61010-2-032 ®

Edition 5.0 2023-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Safety requirements for electrical equipment for measurement, control, and

laboratory use –

Part 2-032: Particular requirements for hand-held and hand-manipulated current

sensors for electrical test and measurement

Exigences de sécurité pour appareils électriques de mesurage, de régulation et

de laboratoire –

Partie 2-032: Exigences particulières pour les capteurs de courant, portatifs et

manipulés manuellement, pour essai électrique et mesurage

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur les adapté à vos besoins.

projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au monde,

Restez informé sur les nouvelles publications IEC. Just

avec plus de 22 300 articles terminologiques en anglais et en

Published détaille les nouvelles publications parues.

français, ainsi que les termes équivalents dans 19 langues

Disponible en ligne et une fois par mois par email.

additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61010-2-032 ®

Edition 5.0 2023-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Safety requirements for electrical equipment for measurement, control, and

laboratory use –

Part 2-032: Particular requirements for hand-held and hand-manipulated current

sensors for electrical test and measurement

Exigences de sécurité pour appareils électriques de mesurage, de régulation et

de laboratoire –

Partie 2-032: Exigences particulières pour les capteurs de courant, portatifs et

manipulés manuellement, pour essai électrique et mesurage

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 19.080 ISBN 978-2-8322-7423-1

– 2 – IEC 61010-2-032:2023 © IEC 2023

CONTENTS

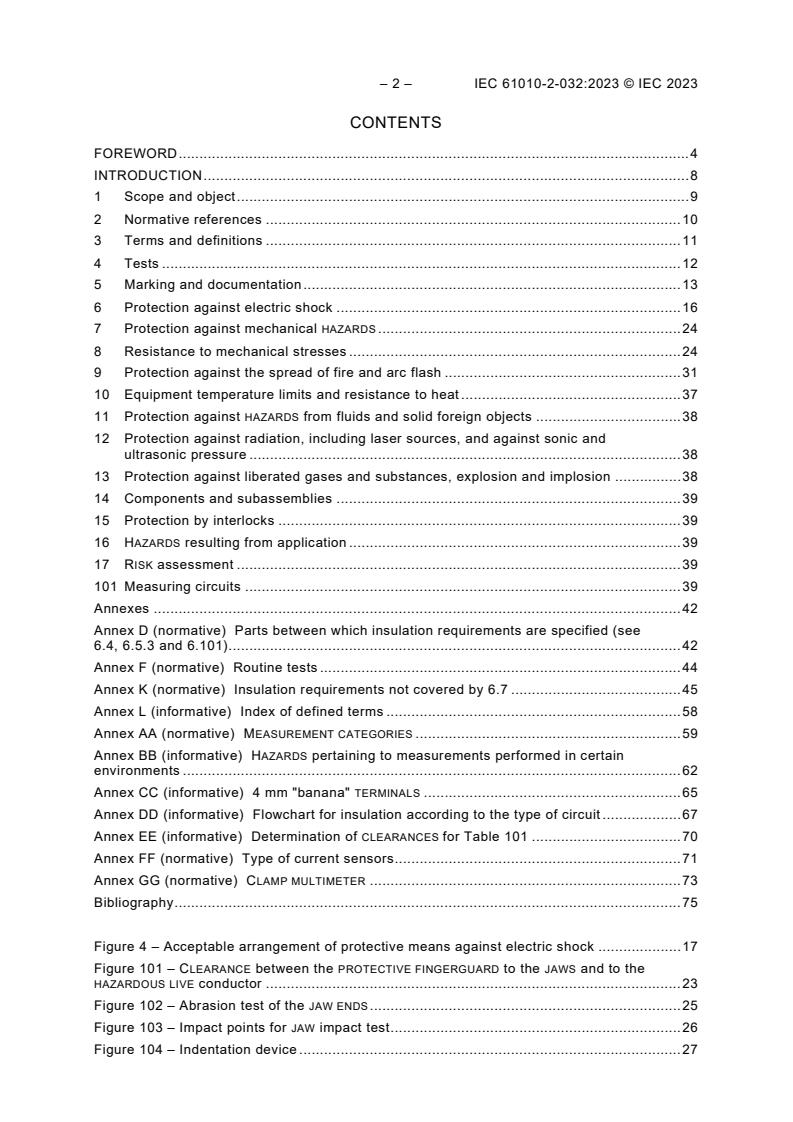

FOREWORD . 4

INTRODUCTION . 8

1 Scope and object . 9

2 Normative references . 10

3 Terms and definitions . 11

4 Tests . 12

5 Marking and documentation . 13

6 Protection against electric shock . 16

7 Protection against mechanical HAZARDS . 24

8 Resistance to mechanical stresses . 24

9 Protection against the spread of fire and arc flash . 31

10 Equipment temperature limits and resistance to heat . 37

11 Protection against HAZARDS from fluids and solid foreign objects . 38

12 Protection against radiation, including laser sources, and against sonic and

ultrasonic pressure . 38

13 Protection against liberated gases and substances, explosion and implosion . 38

14 Components and subassemblies . 39

15 Protection by interlocks . 39

16 HAZARDS resulting from application . 39

17 RISK assessment . 39

101 Measuring circuits . 39

Annexes . 42

Annex D (normative) Parts between which insulation requirements are specified (see

6.4, 6.5.3 and 6.101) . 42

Annex F (normative) Routine tests . 44

Annex K (normative) Insulation requirements not covered by 6.7 . 45

Annex L (informative) Index of defined terms . 58

Annex AA (normative) MEASUREMENT CATEGORIES . 59

Annex BB (informative) HAZARDS pertaining to measurements performed in certain

environments . 62

Annex CC (informative) 4 mm "banana" TERMINALS . 65

Annex DD (informative) Flowchart for insulation according to the type of circuit . 67

Annex EE (informative) Determination of CLEARANCES for Table 101 . 70

Annex FF (normative) Type of current sensors . 71

Annex GG (normative) CLAMP MULTIMETER . 73

Bibliography . 75

Figure 4 – Acceptable arrangement of protective means against electric shock . 17

Figure 101 – CLEARANCE between the PROTECTIVE FINGERGUARD to the JAWS and to the

HAZARDOUS LIVE conductor . 23

Figure 102 – Abrasion test of the JAW ENDS . 25

Figure 103 – Impact points for JAW impact test . 26

Figure 104 – Indentation device . 27

Figure 105 – Example of a current sensor with strain reliefs . 29

Figure 106 – Flexing test . 30

Figure 107 – Test probe to check protection against short-circuits . 36

Figure 108 – Use of the test probe of Figure 107 . 36

Figure D.101 – Parts of current sensors (see also Table D.101) . 42

Figure K.101 – CLEARANCES between the conductor, the input/output circuit and the

enclosure of a Type A current sensor . 49

Figure K.102 – Test circuit for evaluation of TRANSIENT OVERVOLTAGE attenuation . 52

Figure AA.1 – Example to identify the locations of MEASUREMENT CATEGORIES . 60

Figure CC.1 – Recommended dimensions of 4 mm TERMINALS . 66

Figure DD.1 – Requirements for CLEARANCE, CREEPAGE DISTANCE and solid insulation . 69

Figure FF.1 – Examples of current sensors and their parts . 72

Figure GG.1 – Examples of CLAMP MULTIMETERS . 73

Table 1 – Symbols . 13

Table 101 – CLEARANCES for unmated measuring circuit TERMINALS. 18

Table 102 – Energy level for JAW impact test . 26

Table 103 – Pull forces for endcaps of flexible current sensors . 28

Table 104 – Pull forces for input/output lead attachment test . 31

Table 105 – Thickness of the test probe of Figure 107 and test voltages. 37

Table D.101 – Insulation requirements for current sensors . 43

Table K.15 – CLEARANCE values for the calculation of K.3.2 . 46

Table K.16 – Test voltages based on CLEARANCES . 47

Table K.101 – Impulse voltages for circuits connected to MAINS . 51

Table K.102 – CLEARANCES for measuring circuits RATED for MEASUREMENT CATEGORIES . 53

Table K.103 – Impulse test voltages for testing electric strength of solid insulation for

measuring circuits RATED for MEASUREMENT CATEGORIES . 54

Table K.104 – a.c. test voltages for testing electric strength of solid insulation for

measuring circuits RATED for MEASUREMENT CATEGORIES . 54

Table K.105 – Minimum values for distance or thickness of solid insulation for

measuring circuits RATED for MEASUREMENT CATEGORIES . 56

Table AA.1 – Characteristics of MEASUREMENT CATEGORIES . 61

Table EE.1 – CLEARANCE values for Table 101 . 70

– 4 – IEC 61010-2-032:2023 © IEC 2023

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SAFETY REQUIREMENTS FOR ELECTRICAL EQUIPMENT

FOR MEASUREMENT, CONTROL, AND LABORATORY USE –

Part 2-032: Particular requirements for hand-held and hand-manipulated

current sensors for electrical test and measurement

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 61010-2-032 has been prepared by IEC technical committee 66: Safety of measuring,

control and laboratory equipment. It is an International Standard.

This fifth edition cancels and replaces the fourth edition published in 2019. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) In 1.1.1, definitions of current sensor types have been moved to a new Annex FF;

b) Clause 2, all normative references have been dated and new normative references have

been added;

c) 3.2.103, a new definition PROTECTIVE FINGERGUARD has been added which replaces the

PROTECTIVE BARRIER;

previous definition of

d) 4.4.2.101 is a new subclause about surge protective devices;

e) in 5.1.5.101.2, minimum RATINGS for voltage of measuring TERMINALS are required;

f) Subclause 6.5.1 has been modified;

g) Subclause 6.5.5 is no longer used;

h) Subclause 6.6.101 modifies 6.6.101 and 6.6.102 of previous edition:

1) in 6.6.101.1, insulating material of group I may be allowed for determination of CREEPAGE

DISTANCES of measuring circuit TERMINALS;

2) in 6.6.101.2, CLEARANCES and CREEPAGE DISTANCES up to 3 000 V for measuring circuit

TERMINALS in unmated position have been defined;

3) in 6.6.101.3, requirements for measuring circuit TERMINALS in partially mated position

have been specified;

4) in 6.6.101.4, requirements for measuring circuit TERMINALS in mated position have been

specified;

5) Subclause 6.6.101.5 replaces 6.6.102;

i) Subclause 6.6.102 replaces 6.101 of previous edition with modifications;

j) Subclause 6.101.2 replaces 6.9.101.1 of previous edition with modifications;

k) Subclause 6.101.3 replaces 6.9.101.2 of previous edition with modifications;

l) Subclause 6.101.4 replaces 6.9.102 of previous edition with modifications;

m) in 8.101, JAW ENDS abrasion test has been modified;

n) 8.105 is a new subclause for input/output leads attachment has been added;

o) in 9.101.2, relocation of 101.3 of previous edition;

p) in 9.101.3, relocation of 101.4 of previous edition, extension to MEASUREMENT CATEGORY II

and reference to IEC 61000-4-5 for tests;

q) Table 104 has been replaced by Table K.101;

r) in 9.102, relocation of Clause 102 of previous edition;

s) in 14.101, relocation of 14.102. Subclause 14.101 of previous edition has been deleted;

HAZARD occurring from reading a voltage

t) 101.3 is a new subclause for protections against

value in replacement of Clause EE.5 of previous edition;

u) in Table D.101, transients are disregarded for insulation between JAW ENDS and input/output

circuits;

v) in Clause F.101, test voltages for routine test of JAWS have been modified;

w) in K.2.1, another method for determination of CLEARANCES of secondary circuits is proposed;

x) in K.3.2, new Table K.15 and Table K.16 for CLEARANCE calculation;

y) K.3.101 is a new clause;

z) Clause K.4, redraft of the clause to propose a method for determination of U for circuits

t

which reduce TRANSIENT OVERVOLTAGES;

aa) Table K.101 replaces Table 104;

bb) Subclause K.101.4 has been reviewed and tables and tests for solid insulation have been

modified;

cc) Table K.104 of previous edition has been deleted;

dd) Annex AA: Figure AA.1 has been redesigned;

ee) Annex EE: addition of a new informative annex for determination of CLEARANCES for

Table 101;

ff) Annex GG: this annex was Annex EE of previous edition and the current sensor type of a

CLAMP MULTIMETER is type A or type B.

– 6 – IEC 61010-2-032:2023 © IEC 2023

The text of this International Standard is based on the following documents:

Draft Report on voting

66/788A/FDIS 66/798/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts of the IEC 61010 series, under the general title Safety requirements for

electrical equipment for measurement, control, and laboratory use, can be found on the IEC

website.

This document is to be used in conjunction with IEC 61010-1:2010 and

IEC 61010-1:2010/AMD1:2016.

This document supplements or modifies the corresponding clauses in IEC 61010-1 so as to

convert that publication into the IEC standard: Particular requirements for hand-held and

hand-manipulated current sensors for electrical test and measurement.

Where a particular subclause of IEC 61010-1 is not mentioned in this document, that subclause

applies as far as is reasonable. Where this document states "addition", "modification",

"replacement", or "deletion", the relevant requirement, test specification or note in IEC 61010-1

should be adapted accordingly.

In this standard:

a) the following print types are used:

– requirements: in roman type;

– NOTES: in small roman type;

– conformity and tests: in italic type;

– terms used throughout this standard which have been defined in Clause 3: SMALL ROMAN

CAPITALS;

b) subclauses, figures, tables and notes which are additional to those in IEC 61010-1 are

numbered starting from 101. Additional annexes are lettered starting from AA and additional

list items are lettered from aa).

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

– 8 – IEC 61010-2-032:2023 © IEC 2023

INTRODUCTION

IEC 61010-1 specifies the safety requirements that are generally applicable to all equipment

within its scope. For certain types of equipment, the requirements of IEC 61010-1 and its

amendment will be supplemented or modified by the special requirements of one or more

standard from the IEC 61010-2 series which is/are read in conjunction with the requirements of

IEC 61010-1.

1) IEC 61010-2-030:2023 specifies the safety requirements for equipment with testing or

measuring circuits which are connected for test or measurement purposes to devices or

circuits outside the measurement equipment itself.

2) This document specifies the safety requirements for hand-held and hand-manipulated

current sensors for measuring, detecting or injecting current, or indicating current

waveforms on circuits without physically opening the current path of the circuit being

measured.

Most of the requirements of IEC 61010-2-030:2023 have been included in this document.

Equipment within the scopes of both IEC 61010-2-030:2023 and this document is

considered to be covered by the requirements of this document.

However, for current sensors in combined equipment with protective bonding and automatic

disconnection of the supply, IEC 61010-2-030:2023 and this document are read in

conjunction.

3) IEC 61010-2-033:2023 specifies the safety requirements for hand-held multimeters and

other meters for domestic and professional use, capable of measuring mains voltage,

intended to measure voltage and other electrical quantities such as resistance or current.

All relevant requirements of IEC 61010-2-030 have been included in IEC 61010-2-033:2023.

4) IEC 61010-2-034:2023 specifies the safety requirements for measurement equipment for

insulation resistance and test equipment for electric strength which are connected to units,

lines or circuits for test or measurement purposes.

All relevant requirements of IEC 61010-2-030:2023 have been included in

IEC 61010-2-034:2023. However, for equipment within the scope of this document and

IEC 61010-2-034:2023, these standards are read in conjunction.

IEC 61010-031 specifies the safety requirements for hand-held and hand-manipulated probe

assemblies and their related accessories intended to be used in particular with equipment in

the scope of IEC 61010-2-030, this document, IEC 61010-2-033 and IEC 61010-2-034. These

probe assemblies are for non-contact or direct electrical connection between a part and

electrical test and measurement equipment. They may be fixed to the equipment or be

detachable accessories for the equipment.

SAFETY REQUIREMENTS FOR ELECTRICAL EQUIPMENT

FOR MEASUREMENT, CONTROL, AND LABORATORY USE –

Part 2-032: Particular requirements for hand-held and hand-manipulated

current sensors for electrical test and measurement

1 Scope and object

IEC 61010-1:2010, Clause 1 and IEC 61010-1:2010/AMD1:2016, Clause 1 apply except as

follows:

1.1.1 Equipment included in scope

Replace the existing text with the following:

This document specifies safety requirements for HAND-HELD and hand-manipulated current

sensors intended for measuring, detecting or injecting current, or indicating current waveforms

on circuits without physically opening the current path of the circuit being measured.

These current sensors are hand-manipulated before and/or after a test or measurement, but

are not necessarily HAND-HELD during the test or measurement. They can be stand-alone current

sensors or accessories to other equipment or parts of combined equipment. These include

measurement circuits which are part of electrical test and measurement equipment, laboratory

equipment, or process control equipment.

NOTE 1 Combined equipment is equipment that is electrically connected to a current sensor by means of a

permanent connection which can be detached only by the use of a TOOL.

NOTE 2 Some current sensors are also known as current clamps, CLAMP MULTIMETERS and current probes.

The types of current sensors covered by this document are defined in Annex FF.

1.1.2 Equipment excluded from scope

Add the following new paragraph:

This document does not apply to current sensors used as FIXED EQUIPMENT.

1.2.1 Aspects included in scope

Replace item c) of the second paragraph with the following new item c):

c) spread of fire or arc flash from the current sensor (see Clause 9);

Replace the third paragraph with the following two new paragraphs:

Requirements for protection against HAZARDS arising from NORMAL USE, REASONABLY

FORESEEABLE MISUSE and ergonomic factors are specified in Clause 16, Clause 101 and

Annex GG.

Annex BB provides guidance to equipment manufacturers on HAZARDS that should be

considered for equipment intended for performing tests and measurements on hazardous

conductors, including MAINS conductors and telecommunication network conductors.

– 10 – IEC 61010-2-032:2023 © IEC 2023

2 Normative references

IEC 61010-1:2010, Clause 2 and IEC 61010-1:2010/AMD1:2016, Clause 2 apply except as

follows:

Replace the following existing normative references:

IEC 60068-2-75, Environmental testing – Part 2-75: Tests – Test Eh: Hammer tests

IEC 60364-4-44:2007, Low-voltage electrical installations – Part 4-44: Protection for safety –

Protection against voltage disturbances and electromagnetic disturbances

IEC 60364-4-44:2007/AMD1:2015

IEC 61010-031, Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 031: Safety requirements for hand-held probe assemblies for electrical

measurement and test

IEC 61180 (all parts), High-voltage test techniques for low-voltage equipment

IEC 61180-1, High-voltage test techniques for low-voltage equipment – Part 1: Definitions, test

and procedure requirements

IEC 61180-2, High-voltage test techniques for low-voltage equipment – Part 2: Test equipment

IEC 62262, Degrees of protection provided by enclosures for electrical equipment against

external impacts (IK code)

with the following new normative references:

IEC 60068-2-75:2014, Environmental testing – Part 2-75: Tests – Test Eh: Hammer tests

IEC 60364-4-44:2007, Low-voltage electrical installations – Part 4-44: Protection for safety –

Protection against voltage disturbances and electromagnetic disturbances

IEC 60364-4-44:2007/AMD1:2015

IEC 60364-4-44:2007/AMD2:2018

IEC 61010-031:2022, Safety requirements for electrical equipment for measurement, control,

and laboratory use – Part 031: Safety requirements for hand-held and hand-manipulated probe

assemblies for electrical test and measurement

IEC 61180:2016, High-voltage test techniques for low-voltage equipment – Definitions, test and

procedure requirements, test equipment

IEC 62262:2002, Degrees of protection provided by enclosures for electrical equipment against

external mechanical impacts (IK code)

IEC 62262:2002/AMD1:2021

Add the following new normative reference:

IEC 61000-4-5:2014, Electromagnetic compatibility (EMC) – Part 4-5: Testing and

measurement techniques – Surge immunity test

IEC 61000-4-5:2014/AMD1:2017

___________

"IEC 61180:2016" replaces everywhere IEC 61180, IEC 61180-1 and IEC 61180-2 are referenced in

IEC 61010-1.

3 Terms and definitions

IEC 61010-1:2010, Clause 3 and IEC 61010-1:2010/AMD1:2016, Clause 3 apply except as

follows:

3.1 Equipment and states of equipment

Add the following two new terms and definitions:

3.1.101

HAND-HELD

intended to be supported by one hand during NORMAL USE

3.1.102

CLAMP MULTIMETER

HAND-HELD multi-range and multifunction measuring instrument intended to measure current on

a live MAINS without physically opening the conductors, voltage on a live MAINS and other

electrical quantities such as resistance

3.2 Parts and accessories

Add the following three new terms and definitions:

3.2.101

JAW

part of a current sensor which surrounds or partially surrounds the conductor under test

3.2.102

JAW END

part of the JAW where opening occurs while clamping around a conductor

3.2.103

PROTECTIVE FINGERGUARD

part of the enclosure that indicates the limit of safe access and that reduces the risk of the

operator touching HAZARDOUS LIVE parts

3.5 Safety terms

Replace the definition of 3.5.4 with the following new definition:

3.5.4

MAINS

electricity supply system

Add the following new term and definition:

3.5.101

MEASUREMENT CATEGORY

classification of testing and measuring circuits according to the type of MAINS to which they are

intended to be connected

– 12 – IEC 61010-2-032:2023 © IEC 2023

3.6 Insulation

Add the following new term and definition:

3.6.101

UNINSULATED CONDUCTOR

conductor which is not insulated by solid insulation or which is insulated by solid insulation that

does not meet the requirements for BASIC INSULATION for the relevant voltage to earth

4 Tests

IEC 61010-1:2010, Clause 4 and IEC 61010-1:2010/AMD1:2016, Clause 4 apply except as

follows:

4.3.2.5 MAINS supply

Replace the existing title and text with the following:

4.3.2.5 Power supply

The following requirements apply:

a) the voltage of the power supply connected to the MAINS shall be between 90 % and 110 %

of any RATED supply voltage for which the current sensor can be set or, if the current sensor

is RATED for a greater fluctuation, at any supply voltage within the fluctuation range;

b) the MAINS frequency shall be any RATED frequency;

c) current sensors for both a.c. and d.c. shall be connected to an a.c. or d.c. supply;

d) current sensors powered from MAINS by single-phase a.c. shall be connected both with

normal and reverse polarity;

e) if the means of connection permit reversal, battery-operated and d.c. current sensors shall

be connected with both reverse and normal polarity.

4.3.2.6 Input and output voltages

Replace the existing title and text with the following:

4.3.2.6 Input and output voltages or currents

Input and output voltages or currents, including floating voltages but excluding the supply

voltage Connected to the MAINS, shall be set to any voltage or current within their RATED range,

in normal and reverse polarity if possible.

4.4.2.8 Outputs

Replace the text with the following:

Outputs shall be open-circuited and short-circuited, one at a time.

Add the following new subclause:

4.4.2.101 Surge protective devices

MAINS CIRCUITS or in circuits measuring MAINS shall be

Surge protective devices used in

short-circuited and open-circuited.

5 Marking and documentation

IEC 61010-1:2010, Clause 5 and IEC 61010-1:2010/AMD1:2016, Clause 5 apply except as

follows:

5.1.2 Identification

Add the following new list items and add a new paragraph before the conformity statement:

aa) for current sensors designed for use only with a specific model of equipment, a clear

identification of the equipment, or with symbol 14 of Table 1 if this information is available

only in the documentation;

bb) for Type A current sensors, with symbol 102 of Table 1;

cc) for Type B and Type C current sensors, with symbol 101 of Table 1;

dd) for Type D current sensors, with symbol 101 and symbol 14 of Table 1.

The relevant symbol (14, 101 or 102) shall be marked adjacent to the JAWS or adjacent to the

marking of the MEASUREMENT CATEGORY for the JAWS, if present (see 5.1.5.101 and 5.1.5.102).

Table 1 – Symbols

Add the following two new symbols:

Number Symbol Reference Description

Do not apply current sensor to or remove from

HAZARDOUS LIVE UNINSULATED CONDUCTORS, which

may render electric shock, electric burn, or arc

flash

To indicate that the current sensor can safely be

102 IEC 60417-6300 (2016-03) used with UNINSULATED HAZARDOUS LIVE

CONDUCTORS

5.1.5 TERMINALS, connections and operating devices

Add the following new subclause:

5.1.5.101 Measuring circuit TERMINALS

5.1.5.101.1 General

Some measuring circuit TERMINALS for the current sensor within the scope of this document also

TERMINALS.

serve as output