IEC 61010-2-012:2019

(Main)Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-012: Particular requirements for climatic and environmental testing and other temperature conditioning equipment

Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-012: Particular requirements for climatic and environmental testing and other temperature conditioning equipment

IEC 61010-2-012:2019 specifies safety requirements for electrical equipment and its accessories within the categories a) through c), wherever it is intended to be used, whenever that equipment incorporates one or more of the following characteristics:

– A refrigerating system that is acted on or impacted by an integral heating function such that the combined heating and refrigerating system generates additional and/or more severe hazards than those for the two systems if treated separately.

– The materials being treated in the intended application introduce significant heat into the refrigerating system, so that the refrigerating system in the application yields additional and/or more severe hazards than those for the refrigerating system if operated at the maximum rated ambient temperature alone.

– An irradiation function for the materials being treated presenting additional hazards.

– A function to expose the materials being treated to excessive humidity, carbon dioxide, salt mist, or other substances which can result in additional hazards.

– A function of mechanical movement presenting additional hazards.

– Provision for an operator to walk in to the operating area to load or unload the materials being treated.

It has the status of a group safety publication in accordance with IEC Guide 104.

This second edition cancels and replaces the first edition published in 2016. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a) alignment with changes introduced by Amendment 1 of IEC 61010-1:2010;

b) changes related to the use of small capitals for defined terms only;

c) clarifications for cooling tests in 4.4.2.10;

d) requirements for overtemperature protection in 10.101, including deletion of the second part of the sentence in item b), and the deletion of item c);

e) changes pertaining to the accurate employment of terms "temperature", "operating temperature", "working temperature", "application temperature", "room temperature" and "ambient temperature" in 3.5.104, 3.5.105, 4.3.1, 4.3.2, 5.4.2, 8.2.1, 8.2.2, 11.7.2.101.2, 11.7.2.101.3, 13.2.102, 14.102, 15.101, 15.102, 15.103, Introduction and many other locations. For the purpose of clarification, the definition of 3.5.114, controlled temperature, is added.

Exigences de sécurité pour appareils électriques de mesurage, de régulation et de laboratoire - Partie 2-012: Exigences particulières pour appareils d'essais climatiques et d'environnement, et autres appareils de conditionnement de température

L'IEC 61010-2-012:2019 spécifie les exigences de sécurité pour les appareils électriques et leurs accessoires relevant des catégories a) à c) quelle que soit l'utilisation à laquelle ils sont destinés, lorsque ces appareils comprennent une ou plusieurs des caractéristiques suivantes:

– Un système frigorifique affecté ou influencé par une fonction de chauffage intégrée de sorte que le système frigorifique et de chauffage combiné engendre des dangers supplémentaires et/ou plus graves que ceux pour les deux systèmes s'ils sont traités séparément.

– Les matières traitées dans l'application prévue génèrent une chaleur importante dans le système frigorifique, de sorte que le système frigorifique dans l'application engendre des dangers supplémentaires et/ou plus graves que ceux pour le système frigorifique dans le cas où il est utilisé seul à la température ambiante assignée maximale.

– Une fonction d'exposition aux rayonnements pour les matières traitées qui présentent des dangers supplémentaires.

– Une fonction dédiée à l'exposition des matières traitées à une humidité excessive, au dioxyde de carbone, au brouillard salin ou à d'autres substances qui peuvent engendrer des dangers supplémentaires.

– Une fonction de mouvement mécanique qui présente des dangers supplémentaires.

– Un dispositif qui permet le déplacement de l'opérateur vers la zone de manœuvre afin de charger ou décharger les matières traitées.

Elle a le statut d'une publication groupée de sécurité conformément au Guide IEC 104.

Cette deuxième édition annule et remplace la première édition parue en 2016. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à la l'édition précédente:

a) alignement sur les modifications introduites par l'Amendement 1 de l'IEC 61010-1:2010;

b) modifications relatives à l'utilisation de petites capitales uniquement pour les termes définis;

c) clarifications concernant les essais de refroidissement au 4.4.2.10;

d) exigences relatives à la protection contre les surtempératures au 10.101, comprenant la suppression de la seconde partie de b) et c);

e) modifications relatives à l'emploi exact des termes "température", "température de fonctionnement", "température de service", "température d'application", "température ambiante" aux 3.5.104, 3.5.105, 4.3.1, 4.3.2, 5.4.2, 8.2.1, 8.2.2, 11.7.2.101.2, 11.7.2.101.3, 13.2.102, 14.102, 15.101, 15.102, 15.103, à l'Introduction et à d'autres nombreux endroits. Pour des besoins de clarification, la définition du 3.5.114, température régulée est ajoutée.

General Information

- Status

- Published

- Publication Date

- 11-Apr-2019

- Technical Committee

- TC 66 - Safety of measuring, control and laboratory equipment

- Drafting Committee

- MT 17 - TC 66/MT 17

- Current Stage

- PPUB - Publication issued

- Start Date

- 12-Apr-2019

- Completion Date

- 26-Apr-2019

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61010-2-012:2019 - "Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-012" specifies particular safety requirements for climatic and environmental testing and other temperature conditioning equipment. It applies where equipment includes interacting heating and refrigerating systems or other environmental-treatment functions (irradiation, excessive humidity, CO2, salt mist, mechanical movement) that introduce additional or more severe hazards than the individual systems. This second edition (2019) is a technical revision and a group safety publication in accordance with IEC Guide 104.

Key topics and technical requirements

- Scope and interaction rules: Defines when Part 2-012 applies versus Parts 2-010 (heating) and 2-011 (refrigerating systems) - specifically when combined functions or application loads create additional hazards.

- Hazard-focused clauses: Requirements cover protection against electric shock, mechanical hazards, fire spread, radiation (including lasers), sonic/ultrasonic pressure, liberated gases, explosion/implosion, and hazards from fluids/foreign objects.

- Temperature and cooling tests: Includes test procedures and tables (e.g., time–temperature conditions) for verifying equipment performance and safety under specified conditions.

- Overtemperature protection: New/clarified requirements for overtemperature protection (see clause 10.101) to reduce risk when heating and cooling functions interact.

- Terminology and definitions: Clarifications and consistent use of terms such as temperature, operating temperature, application temperature, ambient temperature, controlled temperature - the definition of controlled temperature is added.

- Components, interlocks and walk‑in equipment: Requirements for components and subassemblies, safety interlocks, and special provisions for walk‑in chambers (informative annex BB).

- Refrigerant and flammability considerations: Annexes address refrigerant-related safety, marking, and non‑sparking electrical device requirements (Annex DD, EE).

- Documentation and marking: Specific marking, instructions, and documentation obligations for safe installation and operation.

Practical applications and users

IEC 61010-2-012:2019 is essential for:

- Manufacturers and designers of climatic/environmental test chambers, thermal cycling chambers, walk‑in environmental rooms, and temperature conditioning equipment.

- Safety engineers, product compliance teams and testing labs preparing equipment certification to IEC 61010 series requirements.

- Certification bodies and conformity assessment organizations assessing electrical and mechanical safety of environmental testing equipment.

- Procurement teams and end users in electronics, automotive, aerospace, materials testing, pharmaceuticals and R&D who need to specify compliant environmental test systems.

Practical uses include designing safe refrigerating/heating interactions, selecting overtemperature protection, specifying safe refrigerants and interlocks, and preparing accurate operator documentation.

Related standards

- IEC 61010-1 (general requirements) - Part 2-012 supplements or modifies clauses of Part 1 and must be used in conjunction.

- IEC 61010-2-010 (heating systems) and IEC 61010-2-011 (refrigerating systems) - used for equipment that contains only one function; Part 2-012 applies when interactions yield additional hazards.

Keywords: IEC 61010-2-012:2019, climatic and environmental testing, temperature conditioning equipment, safety requirements, refrigerating system, overtemperature protection, controlled temperature, environmental test chamber.

Buy Documents

IEC 61010-2-012:2019 RLV - Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-012: Particular requirements for climatic and environmental testing and other temperature conditioning equipment Released:4/12/2019 Isbn:9782832268384

IEC 61010-2-012:2019 - Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-012: Particular requirements for climatic and environmental testing and other temperature conditioning equipment Released:4/12/2019 Isbn:9782832267134

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

IEC 61010-2-012:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-012: Particular requirements for climatic and environmental testing and other temperature conditioning equipment". This standard covers: IEC 61010-2-012:2019 specifies safety requirements for electrical equipment and its accessories within the categories a) through c), wherever it is intended to be used, whenever that equipment incorporates one or more of the following characteristics: – A refrigerating system that is acted on or impacted by an integral heating function such that the combined heating and refrigerating system generates additional and/or more severe hazards than those for the two systems if treated separately. – The materials being treated in the intended application introduce significant heat into the refrigerating system, so that the refrigerating system in the application yields additional and/or more severe hazards than those for the refrigerating system if operated at the maximum rated ambient temperature alone. – An irradiation function for the materials being treated presenting additional hazards. – A function to expose the materials being treated to excessive humidity, carbon dioxide, salt mist, or other substances which can result in additional hazards. – A function of mechanical movement presenting additional hazards. – Provision for an operator to walk in to the operating area to load or unload the materials being treated. It has the status of a group safety publication in accordance with IEC Guide 104. This second edition cancels and replaces the first edition published in 2016. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) alignment with changes introduced by Amendment 1 of IEC 61010-1:2010; b) changes related to the use of small capitals for defined terms only; c) clarifications for cooling tests in 4.4.2.10; d) requirements for overtemperature protection in 10.101, including deletion of the second part of the sentence in item b), and the deletion of item c); e) changes pertaining to the accurate employment of terms "temperature", "operating temperature", "working temperature", "application temperature", "room temperature" and "ambient temperature" in 3.5.104, 3.5.105, 4.3.1, 4.3.2, 5.4.2, 8.2.1, 8.2.2, 11.7.2.101.2, 11.7.2.101.3, 13.2.102, 14.102, 15.101, 15.102, 15.103, Introduction and many other locations. For the purpose of clarification, the definition of 3.5.114, controlled temperature, is added.

IEC 61010-2-012:2019 specifies safety requirements for electrical equipment and its accessories within the categories a) through c), wherever it is intended to be used, whenever that equipment incorporates one or more of the following characteristics: – A refrigerating system that is acted on or impacted by an integral heating function such that the combined heating and refrigerating system generates additional and/or more severe hazards than those for the two systems if treated separately. – The materials being treated in the intended application introduce significant heat into the refrigerating system, so that the refrigerating system in the application yields additional and/or more severe hazards than those for the refrigerating system if operated at the maximum rated ambient temperature alone. – An irradiation function for the materials being treated presenting additional hazards. – A function to expose the materials being treated to excessive humidity, carbon dioxide, salt mist, or other substances which can result in additional hazards. – A function of mechanical movement presenting additional hazards. – Provision for an operator to walk in to the operating area to load or unload the materials being treated. It has the status of a group safety publication in accordance with IEC Guide 104. This second edition cancels and replaces the first edition published in 2016. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) alignment with changes introduced by Amendment 1 of IEC 61010-1:2010; b) changes related to the use of small capitals for defined terms only; c) clarifications for cooling tests in 4.4.2.10; d) requirements for overtemperature protection in 10.101, including deletion of the second part of the sentence in item b), and the deletion of item c); e) changes pertaining to the accurate employment of terms "temperature", "operating temperature", "working temperature", "application temperature", "room temperature" and "ambient temperature" in 3.5.104, 3.5.105, 4.3.1, 4.3.2, 5.4.2, 8.2.1, 8.2.2, 11.7.2.101.2, 11.7.2.101.3, 13.2.102, 14.102, 15.101, 15.102, 15.103, Introduction and many other locations. For the purpose of clarification, the definition of 3.5.114, controlled temperature, is added.

IEC 61010-2-012:2019 is classified under the following ICS (International Classification for Standards) categories: 19.080 - Electrical and electronic testing. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61010-2-012:2019 has the following relationships with other standards: It is inter standard links to IEC 61010-2-012:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61010-2-012:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61010-2-012 ®

Edition 2.0 2019-04

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

GROUP SAFETY PUBLICATION

Safety requirements for electrical equipment for measurement, control, and

laboratory use –

Part 2-012: Particular requirements for climatic and environmental testing and

other temperature conditioning equipment

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61010-2-012 ®

Edition 2.0 2019-04

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

GROUP SAFETY PUBLICATION

Safety requirements for electrical equipment for measurement, control, and

laboratory use –

Part 2-012: Particular requirements for climatic and environmental testing and

other temperature conditioning equipment

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 19.080 ISBN 978-2-8322-6838-4

– 2 – IEC 61010-2-012:2019 RLV © IEC 2019

CONTENTS

FOREWORD . 4

INTRODUCTION . 7

1 Scope and object . 10

2 Normative references . 11

3 Terms and definitions . 12

4 Tests . 17

5 Marking and documentation . 24

6 Protection against electric shock . 33

7 Protection against mechanical HAZARDS . 35

8 Resistance to mechanical stresses . 37

9 Protection against the spread of fire . 37

10 Equipment temperature limits and resistance to heat . 39

11 Protection against HAZARDS from fluids and solid foreign objects . 43

12 Protection against radiation, including laser sources, and against sonic and

ultrasonic pressure . 58

13 Protection against liberated gases and substances, explosion and implosion . 60

14 Components and subassemblies . 62

15 Protection by interlocks . 63

16 HAZARDS resulting from application . 65

17 RISK assessment . 66

Annexes . 67

Annex K (normative) Insulation requirements not covered by 6.7 . 68

Annex L (informative) Index of defined terms . 69

Annex AA (informative) Useful symbols . 71

Annex BB (informative) Protection for of people who are inside WALK-IN EQUIPMENT . 74

Annex CC (informative) Safety requirements for components and piping . 76

Annex DD (informative) Equipment containing FLAMMABLE REFRIGERANTS – Information

and marking requirements. 81

Annex EE (normative) Non-sparking "n" electrical device . 84

Bibliography . 85

Figure 101 – Schema of a REFRIGERATING SYSTEM incorporating a CONDENSER . 8

Figure 102 – Flow chart illustrating the selection process . 9

Figure 103 – Details of scratching TOOL tip . 53

Table 1 – Symbols . 24

Table 101 – Time-temperature conditions . 30

Table 102 – Maximum temperatures for MOTOR-COMPRESSORS . 40

Table 103 – Minimum temperature for the determination of SATURATED-VAPOUR

PRESSURE of the REFRIGERANT . 48

Table 104 – REFRIGERANT flammability parameters . 56

Table 105 – Lamp or lamp systems considered photobiologically safe .

Table 106 – Lamp or lamp systems considered photobiologically safe under certain

conditions .

Table AA.1 – Useful symbols . 71

Table CC.1 – Parameters of pressure vessels according to EN 14276-1 . 76

Table CC.2 – Parameters of piping according to EN 14276-2 . 78

Table CC.3 – Components and piping requirements . 79

Table CC.4 – Minimum wall thickness for copper and steel tubing . 80

– 4 – IEC 61010-2-012:2019 RLV © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SAFETY REQUIREMENTS FOR ELECTRICAL EQUIPMENT

FOR MEASUREMENT, CONTROL, AND LABORATORY USE –

Part 2-012: Particular requirements for climatic and environmental

testing and other temperature conditioning equipment

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 61010-2-012 has been prepared by IEC technical committee 66:

Safety of measuring, control and laboratory equipment.

It has the status of a group safety publication in accordance with IEC Guide 104.

This second edition cancels and replaces the first edition published in 2016. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) alignment with changes introduced by Amendment 1 of IEC 61010-1:2010;

b) changes related to the use of small capitals for defined terms only;

c) clarifications for cooling tests in 4.4.2.10;

d) requirements for overtemperature protection in 10.101, including deletion of the second

part of the sentence in item b), and the deletion of item c);

e) changes pertaining to the accurate employment of terms "temperature", "operating

temperature", "working temperature", "application temperature", "room temperature" and

"ambient temperature" in 3.5.104, 3.5.105, 4.3.1, 4.3.2, 5.4.2, 8.2.1, 8.2.2, 11.7.2.101.2,

11.7.2.101.3, 13.2.102, 14.102, 15.101, 15.102, 15.103, Introduction and many other

locations. For the purpose of clarification, the definition of 3.5.114, CONTROLLED

, is added.

TEMPERATURE

The text of this International Standard is based on the following documents:

FDIS Report on voting

66/687/FDIS 66/688/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 61010 series, published under the general title, Safety

requirements for electrical equipment for measurement, control, and laboratory use, can be

found on the IEC website.

IEC 61010-2-012 is to be used in conjunction with the latest edition of IEC 61010-1. It was

established on the basis of the third edition (2010) and its Amendment 1 (2016), hereinafter

referred to as Part 1.

This Part 2-012 supplements or modifies the corresponding clauses in IEC 61010-1 so as to

convert that publication into the IEC standard: Particular requirements for climatic and

environmental testing and other temperature conditioning equipment.

Where a particular subclause of Part 1 is not mentioned in this Part 2-012, that subclause

applies as far as is reasonable. Where this Part 2-012 states "addition", "modification",

"replacement", or "deletion", the relevant requirement, test specification, or note in Part 1

should be adapted accordingly.

In this standard:

1) the following print types are used:

– requirements and definitions: in roman type;

– NOTES: in smaller roman type;

– 6 – IEC 61010-2-012:2019 RLV © IEC 2019

– conformity and tests: in italic type;

– terms used throughout this standard which have been defined in Clause 3: SMALL

ROMAN CAPITALS.

2) subclauses, figures, tables and notes which are additional to those in Part 1 are numbered

starting from 101. Additional annexes are lettered starting from AA.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this standard using a

colour printer.

INTRODUCTION

This Part 2-012, in conjunction along with Part 2-010 and Part 2-011, taken together, address

the specific HAZARDS associated with the heating and cooling of materials by equipment and

are segregated organized as follows:

Specifically addresses the HAZARDS associated with equipment incorporating heating

IEC 61010-2-010

systems.

Specifically addresses the HAZARDS associated with equipment incorporating REFRIGERATING

IEC 61010-2-011

SYSTEMS.

Specifically addresses the HAZARDS associated with equipment incorporating both heating

and REFRIGERATING SYSTEMS that interact with each other such that the combined heating

and cooling REFRIGERATING SYSTEM yield additional or more severe HAZARDS for the two

IEC 61010-2-012

systems than if treated separately. It also addresses the HAZARDS associated with the

treatment of materials by other factors like irradiation, excessive humidity, CO and

MECHANICAL MOVEMENT, etc.

Guidance for the application of the appropriate Part 2 standard(s)

When the equipment includes only a material heating system, and no REFRIGERATING SYSTEM

or other environmental factors apply, then Part 2-010 applies without needing Part 2-011 or

REFRIGERATING SYSTEM, and no

Part 2-012. Similarly, when the equipment includes only a

material heating system or other environmental factors apply, then Part 2-011 applies without

needing Part 2-010 or Part 2-012. However, when the equipment incorporates both a material

heating system, and a REFRIGERATING SYSTEM or the materials being treated in the intended

application introduce significant heat into the REFRIGERATING SYSTEM, a determination should

be made as to whether the interaction between the two systems will generate additional or

HAZARDS than if the systems were evaluated separately (application CONTROLLED

more severe

TEMPERATURE, see flow chart for selection process). If the interaction of the heating and

cooling functions yields no additional or more severe HAZARDS, then both Part 2-010 and

Part 2-011 apply for their respective functions. Conversely, if additional or more severe

HAZARDS result from the combining of the heating and cooling functions, or if the equipment

incorporates additional material treatment factors, then Part 2-012 applies, but not Part 2-010

or Part 2-011.

What HAZARDS are applicable for a REFRIGERATING SYSTEM?

The typical HAZARDS for a REFRIGERATING SYSTEM (see Figure 101) consisting of a MOTOR-

COMPRESSOR, a CONDENSER, an expansion device and an EVAPORATOR include but are not

limited to:

– The maximum temperature of LOW-PRESSURE SIDE (return temperature) to the MOTOR-

COMPRESSOR. A MOTOR-COMPRESSOR incorporates a REFRIGERANT cooled motor and it

should be established that the maximum temperatures of the LOW-PRESSURE SIDE under

RATINGS within the motor.

least favourable condition do not exceed the insulation

– The maximum pressure of LOW-PRESSURE SIDE at the inlet to the MOTOR-COMPRESSOR. The

housing of the MOTOR-COMPRESSOR is exposed to this pressure and so the design RATING

of the MOTOR-COMPRESSOR housing should accommodate the worst-case pressures whilst

providing the correct safety margin for a pressure vessel.

– The maximum temperature of HIGH-PRESSURE SIDE to the CONDENSER. The temperatures of

the HIGH-PRESSURE SIDE under most unfavourable conditions may present a temperature

HAZARD if the OPERATOR is exposed to them or if the electrical insulation is degraded.

– The maximum pressure of HIGH-PRESSURE SIDE at the outlet to the MOTOR-COMPRESSOR.

The REFRIGERANT components downstream of the MOTOR-COMPRESSOR up to the expansion

device are exposed to this pressure and so the design RATING of these components should

accommodate the worst-case pressures whilst providing the appropriate safety margin for

a pressure vessel.

– 8 – IEC 61010-2-012:2019 RLV © IEC 2019

– The maximum application CONTROLLED TEMPERATURES, namely, the SOAKED TEMPERATURE

CONDITIONS,from which the heat is being extracted, may impact the maximum temperature

of LOW-PRESSURE SIDE to the MOTOR-COMPRESSOR as well as present a temperature HAZARD

if the OPERATOR is exposed to them or if the electrical insulation is degraded. Whether this

application CONTROLLED TEMPERATURE is derived from an integral heating function of the

device or from the heat dissipated from the material being cooled, the impact under worst

case conditions should be evaluated.

– The current draw of the equipment should be established when including the worst-case

running conditions of the REFRIGERATING SYSTEM including any defrost cycles that may

apply.

The worst-case conditions should be determined for the equipment and will include both the

NORMAL USE conditions as well as the most unfavourable testing results under

least favourable

SINGLE FAULT CONDITIONS.

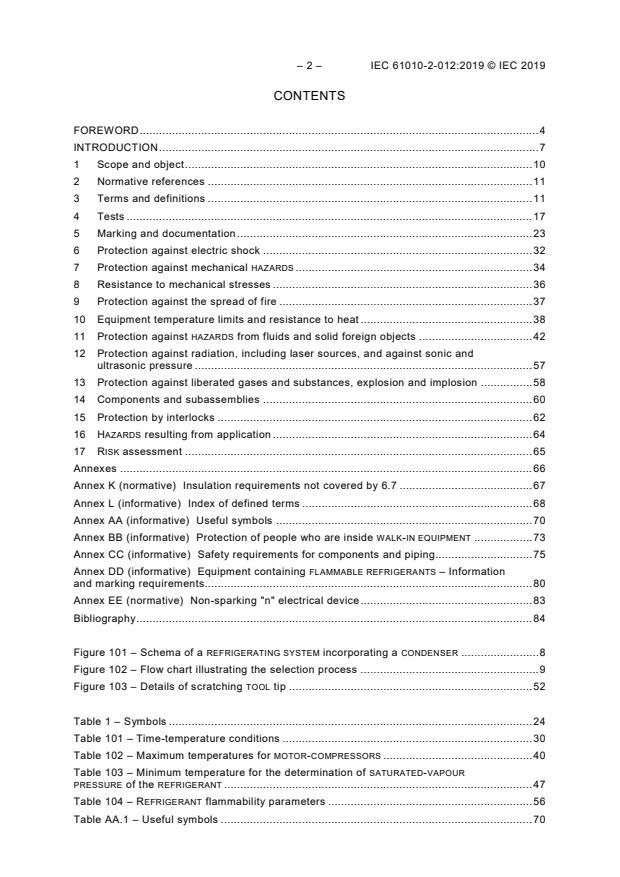

Figure 101 – Schema of a REFRIGERATING SYSTEM incorporating a CONDENSER

The selection process is illustrated in the following flow chart (see Figure 102).

Figure 102 – Flow chart illustrating the selection process

– 10 – IEC 61010-2-012:2019 RLV © IEC 2019

SAFETY REQUIREMENTS FOR ELECTRICAL EQUIPMENT

FOR MEASUREMENT, CONTROL AND LABORATORY USE –

Part 2-012: Particular requirements for climatic and environmental

testing and other temperature conditioning equipment

1 Scope and object

This clause of Part 1 is applicable except as follows:

1.1.1 Equipment included in scope

Replacement:

Replace the first second paragraph by the following:

This group safety publication is primarily intended to be used as a product safety standard for

the products mentioned in the scope, but shall also be used by technical committees in the

preparation of their publications for products similar to those mentioned in the scope of this

standard, in accordance with the principles laid down in IEC Guide 104 and lSO/lEC Guide 51.

This part of IEC 61010 specifies safety requirements for electrical equipment and its

accessories within the categories a) through c), wherever it is intended to be used, whenever

that equipment incorporates one or more of the following characteristics:

– A REFRIGERATING SYSTEM that is acted on or impacted by an integral heating function such

that the combined heating and cooling REFRIGERATING SYSTEM generates additional and/or

more severe HAZARDS than those for the two systems if treated separately.

– The materials being treated in the intended application introduce significant heat into the

REFRIGERATING SYSTEM, so that the cooling REFRIGERATING SYSTEM in the application yields

additional and/or more severe HAZARDS than those for the cooling REFRIGERATING SYSTEM if

operated at the maximum RATED ambient temperature alone.

– An irradiation function for the materials being treated presenting additional HAZARDS.

– A function to expose the materials being treated to excessive humidity, carbon dioxide,

salt mist, or other substances which may can result in additional HAZARDS.

– A function of MECHANICAL MOVEMENT presenting additional HAZARDS.

– Provision for an OPERATOR to walk in to the operating area to load or unload the materials

being treated.

Addition:

Add the following text after the last paragraph:

NOTE 101 Examples of such equipment include environmental testing and plant growth TEST CHAMBERS,

refrigerating CIRCULATORS which incorporate heating, and recirculating coolers for extracting heat.

If It is possible that all or part of the equipment falls within the scope of one or more other

Part 2 standards of IEC 61010 as well as within the scope of this standard, it should also

meet. In that case, the requirements of those other Part 2 standards also apply. This

document is intended for application when one or more of the additional HAZARDS described in

the above dashed listed items are introduced. However, when the equipment incorporates

only a REFRIGERATING SYSTEM or only a heating function or a combination of the two without

introducing the additional HAZARDS described in the above list, then the application of

IEC 61010-2-011 or IEC 61010-2-010 or both, as applicable, shall be considered appropriate,

apply instead of this Part 2-012.

See further information in the flow chart (Figure 102) for selection process and guidance in

the Introduction.

NOTE 102 Subclause 3.1.107 and Annex BB provide the definition and requirements for the protection of people

who are inside WALK-IN EQUIPMENT.

1.1.2 Equipment excluded from scope

Addition:

Add the following items after item j):

aa) equipment for the heating, cooling, and ventilation of laboratories;

bb) sterilizing equipment.

1.2 Object

1.2.1 Aspects included in scope

Addition:

Add two new items to the list the following items after item g):

aa) biohazards (see 13.101);

bb) hazardous chemical substances (see 13.102).

2 Normative references

This clause of Part 1 is applicable, except as follows:

Addition:

IEC 60079-15:2010, Explosive atmospheres – Part 15: Equipment protection by type of

protection "n"

IEC 60079-20-1, Explosive atmospheres – Part 20-1: Material characteristics for gas and

vapour classification – Test methods and data

IEC 60335-2-24:2010, Household and similar electrical appliances – Safety – Part 2-24:

Particular requirements for refrigerating appliances, ice-cream appliances and ice makers

IEC 60335-2-24:2010/AMD1:2012

IEC 60335-2-34:2012, Household and similar electrical appliances – Safety – Part 2-34:

Particular requirements for motor-compressors

IEC 60335-2-34:2012/AMD1:2015

IEC 60335-2-34:2012/AMD2:2016

IEC 60950-1:2005, Information technology equipment – Safety – Part 1: General requirements

IEC 62471, Photobiological safety of lamps and lamp systems

IEC TR 62471-2, Photobiological safety of lamps and lamp systems – Part 2: Guidance on

manufacturing requirements relating to non-laser optical radiation safety

– 12 – IEC 61010-2-012:2019 RLV © IEC 2019

ISO 7010:2011, Graphical symbols – Safety colours and safety signs – Registered safety

signs (available at https://www.iso.org/obp)

3 Terms and definitions

This clause of Part 1 is applicable except as follows:

3.1 Equipment and states of equipment

Addition:

Add the following new terms and definitions:

3.1.101

BATH

complete device intended for application of CONTROLLED TEMPERATURES to SPECIMENS by

immersion in a temperature-controlled liquid HEAT TRANSFER MEDIUM

3.1.102

CIRCULATOR

equipment intended for application of CONTROLLED TEMPERATURES to an APPLICATION SYSTEM

by external circulating of a temperature-controlled liquid HEAT TRANSFER MEDIUM

3.1.103

TEST CHAMBER

ENCLOSURE or space in some part of which specified conditions can be achieved, in particular,

temperature, humidity, irradiation, low air pressure, mould growth and salt spray

3.1.104

COMBINED TEST CHAMBER

special TEST CHAMBER combined with the function of MECHANICAL MOVEMENT, for example, for

vibration, shock, impact, and similar dynamic tests

3.1.105

INCUBATOR

special TEST CHAMBER, primarily for incubation of microorganisms and tissue culture

3.1.106

SHAKER

equipment to disperse or dissolve one substance in another by MECHANICAL MOVEMENT without

the use of blades or stirrers that might destroy the structure of the substance, in particular,

shaking BATH and shaking INCUBATOR

3.1.107

WALK-IN EQUIPMENT

TEST CHAMBER or INCUBATOR, the door of which allows the OPERATOR to enter and remain

inside the equipment even with the door closed

3.1.108

DRYING-OUT

period to wait or procedure to be carried out before operation to return the equipment to

NORMAL CONDITION if it has been transported or stored in humid conditions, or moved from a

cold environment to a much warmer one where condensation could occur, and could cause

the equipment to then fail to meet all the safety requirements of this document

3.1.109

STANDSTILL

period to wait or procedure to be carried out before operation to return the equipment to

NORMAL CONDITION if it has been transported, moved, shaken, tilted or inverted and which

could cause the equipment to then fail to meet all the safety requirements of this document

3.2 Parts and accessories

Addition:

Add the following new terms and definitions:

3.2.101

RESISTANCE-HEATING DEVICE

part of resistance-heating equipment, comprising one or more heating resistors, typically

composed of metallic conductors or an electrically conductive compound suitably insulated

and protected

[SOURCE: IEC 60050-426:2008, 426-08-08, modified – "resistance-heating unit" has been

replaced with "resistance-heating equipment".]

3.2.102

REFRIGERATING SYSTEM

combination of interconnected REFRIGERANT-containing parts constituting one closed

REFRIGERANT circuit in which the REFRIGERANT is circulated for the purpose of extracting and

rejecting heat

[SOURCE: ISO 5149:1993, 1.3.47 ISO 5149-1:2014, 3.1.9, modified – the term "(heat pump)"

has been deleted from the term and the words "(i.e. cooling and heating)" have been deleted

from the definition and the note.]

3.2.103

CASCADE SYSTEM

REFRIGERATING SYSTEM consisting of two or more independent refrigeration circuits where the

CONDENSER of one system rejects heat directly to the EVAPORATOR of another

[SOURCE: EN 378-1:2008, 3.1.12, modified – "REFRIGERATING SYSTEM consisting of" has been

included.]

3.2.104

MOTOR-COMPRESSOR

refrigerating subassembly consisting of the mechanical mechanism of the compressor and the

motor, both of which are enclosed in the same sealed housing, with no external shaft seals,

and with the motor operating in a REFRIGERANT atmosphere with or without oil

Note 1 to entry: The housing may be permanently sealed, such as by welding or brazing (hermetic MOTOR-

COMPRESSOR), or may be sealed by gasketted joints (semi-hermetic MOTOR-COMPRESSOR). A TERMINAL box, a

TERMINAL boxcover, and other electrical components or an electronic control system may be included.

[SOURCE: IEC 60335-2-34:2012/AMD1:2015, 3.101, modified – "appliance" has been replaced

by "refrigerating subassembly".]

3.2.105

CONDENSER

heat exchanger in which vaporized REFRIGERANT is liquified by removal of heat

[SOURCE: ISO 5149:1993, 1.3.11 ISO 5149-1:2014, 3.4.4, modified – "refrigerant vapour" has

been replaced by "vaporized REFRIGERANT".]

– 14 – IEC 61010-2-012:2019 RLV © IEC 2019

3.2.106

CONDENSING UNIT

specific refrigerating subassembly combination for a given REFRIGERANT, consisting of one or

more MOTOR-COMPRESSORS, CONDENSERS, liquid receivers (when required) and the regularly

furnished accessories

[SOURCE: ISO 5149:1993, 1.3.12, modified – “machine” has been replaced by “subassembly”]

3.2.107

EVAPORATOR

heat exchanger in which liquid REFRIGERANT is vaporized by absorption of heat

[SOURCE: IEC 60335-2-40:2009 2018, 3.110, modified – "refrigerant liquid" has been

replaced by "liquid refrigerant".]

3.2.108

HIGH-PRESSURE SIDE

part of a REFRIGERATING SYSTEM operating approximately at the CONDENSER pressure

[SOURCE: ISO 5149:1993, 1.3.24 ISO 5149-1:2014, 3.1.7]

3.2.109

LOW-PRESSURE SIDE

REFRIGERATING SYSTEM operating approximately at the EVAPORATOR pressure

part of a

[SOURCE: ISO 5149:1993, 1.3.30 ISO 5149-1:2014, 3.1.8]

3.2.110

CIRCULATING PUMP

pressure and/or suction pump transporting the liquid HEAT TRANSFER MEDIUM in a BATH or

CIRCULATOR

3.2.111

CIRCULATING FAN

propeller fan or centrifugal impeller designed to circulate the air in a TEST CHAMBER or an

INCUBATOR with or without any air duct

3.2.112

HUMIDIFIER

electric device that generates a water mist or steam and releases it into a room, greenhouse

or other ENCLOSURE

3.2.113

BATH TANK

open or enclosed vessel containing the HEAT TRANSFER MEDIUM, in a BATH or CIRCULATOR

3.2.114

LIQUID CONNECTION

pipe fitting through which liquid is expelled from or discharged into a vessel or a heat

exchanger

3.2.115

VENTILATOR

device for replacing air inside a TEST CHAMBER or an INCUBATOR by with outside air

3.2.116

TEMPERATURE-LIMITING DEVICE

temperature-actuated device that is designed to prevent unsafe temperatures

[SOURCE: EN 378-1:2008, 3.6.5]

3.2.117

LIQUID LEVEL CUT OUT

liquid level-actuated device designed to prevent unsafe liquid levels

[SOURCE: EN 378-1:2008, 3.6.12]

3.2.118

PRESSURE-LIMITING DEVICE

pressure-actuated device (for example, a high-pressure switch) which is designed to stop the

operation of the pressure-imposing element and may also operate an alarm

3.2.119

PRESSURE-RELIEF DEVICE

valve or disc designed to relieve excessive pressure automatically

[SOURCE: ISO 5149: 1993, 1.3.40 ISO 5149-1:2014, 3.6.7, modified – "pressure relief valve

or bursting disc device" has been replaced with "valve or disc" in the definition.]

3.2.120

FLAMMABLE LIQUID

liquid capable of producing a flammable gas or vapour which, when mixed with air in certain

proportions, will form an EXPLOSIVE GAS ATMOSPHERE under any foreseeable operating

conditions

3.2.121

HEAT TRANSFER MEDIUM

medium used to transfer heat to the material being processed

3.2.122

REFRIGERANT

fluid used for heat transfer in a REFRIGERATING SYSTEM, which absorbs heat at a low

temperature and a low pressure of the fluid and rejects heat at a higher temperature and a

higher pressure of the fluid, usually involving changes of state of the fluid

[SOURCE: ISO 5149:1993, 1.3.45 ISO 817:2014, 3.1.35, modified – the term "phase" has

been replaced with "state" in the definition.]

3.2.123

FLAMMABLE REFRIGERANT

REFRIGERANT with a flammability classification of group 2 or 3 A2L, A2 or A3 in accordance

with ISO 5149 ISO 817

[SOURCE: IEC 60335-2-24:2010 and IEC 60335-2-24:2010/AMD1:2012AMD2:2017, 3.109]

3.2.124

SPECIMEN

any material, substance, or product designated to be processed, for example, in a BATH, TEST

CHAMBER or an INCUBATOR

– 16 – IEC 61010-2-012:2019 RLV © IEC 2019

3.2.125

APPLICATION SYSTEM

system or device intended to work with a CIRCULATOR to carry out a functional purpose

3.5 Safety terms

Addition:

Add the following new terms and definitions:

3.5.101

SATURATED-VAPOUR PRESSURE

vapour pressure at which the liquid and vapour can exist in equilibrium at a

given temperature

3.5.102

MAXIMUM ALLOWABLE PRESSURE

PS

maximum pressure for which the equipment is designed, as specified by the manufacturer

Note 1 to entry: This note applies to the French language only.

[SOURCE: EN 378-1:2008, 3.3.2]

3.5.103

RATED PRESSURE

MAXIMUM ALLOWABLE PRESSURE for pressure components of equipment with regard to their

ability to withstand pressures as specified by the manufacturer

3.5.104

ACTIVE COOLING CONTROL RANGE

ACC RANGE

working CONTROLLED TEMPERATURE range that is achieved by an active REFRIGERATING SYSTEM

Note 1 to entry: This note applies to the French language only.

3.5.105

FLASH POINT

lowest liquid temperature at which, under certain standardized conditions, a liquid gives off

vapours in quantity such as to be capable of forming an ignitable vapour/air mixture

Note 1 to entry: At the FLASH POINT, the vapour may cease to burn when the ignition source is removed.

[SOURCE: IEC 60050-426:2008, 426-02-14]

3.5.106

FIRE POINT

lowest temperature at which a substance ignites and continues to burn for at least 5 s after a

small flame has been applied to its surface under standardized conditions

3.5.107

AUTO IGNITION TEMPERATURE

lowest temperature at which a substance will spontaneously ignite in a normal atmosphere

without an external ignition source, such as a flame or spark

Note 1 to entry: Once ignited, the substance will continue to burn until it is either completely consumed or the

temperature of the remainder of the substance is reduced to or below its FIRE POINT.

3.5.108

LOWER EXPLOSIVE LIMIT

LEL

concentration of flammable gas or vapour in air, below which an EXPLOSIVE GAS ATMOSPHERE

will not be formed

Note 1 to entry: This note applies to the French language only.

[SOURCE: IEC 60050-426:2008, 426-02-09]

3.5.109

EXPLOSIVE GAS ATMOSPHERE

mixture with air, under atmospheric conditions, of flammable substances in the form of gas or

vapour which, after ignition, permits self sustaining flame propagation

[SOURCE: IEC 60050-426:2008, 426-01-07]

3.5.110

SOAKED TEMPERATURE CONDITION

temperature conditions when the ambient temperature of the equipment under test (EUT)

equals to ±2,0 °C of maximum ambient of 1.4.1 for NORMAL USE, storage or transport, and the

operating CONTROLLED TEMPERATURE of the EUT equals to ±2,0 °C of the maximum ACC

RANGE with the MOTOR-COMPRESSOR running or, the maximum RATED operating CONTROLLED

TEMPERATURE with the MOTOR-COMPRESSOR off

Note 1 to entry: This note applies to the French language only.

3.5.111

MECHANICAL MOVEMENT

general description for the motion of materials being processed, for example in a SHAKER or

COMBINED TEST CHAMBER

3.5.112

MOVEMENT FREQUENCY

number of complete cycles of MECHANICAL MOVEMENT

3.5.113

MOVEMENT AMPLITUDE

maximum radius, distance, or angle of the MECHANICAL MOVEMENT

3.5.114

CONTROLLED TEMPERATURE

temperature where the EVAPORATOR is located and to which the LOW-PRESSURE SIDE of the

equipment is exposed, as a result of heat transfer either by active heating or from the

APPLICATION SYSTEM or SPECIMEN

Note 1 to entry: For a heat pump system, where a four-way valve is used to shift between heat and cool, the

function of CONDENSER and EVAPORATOR is exchanged.

4 Tests

This clause of Part 1 is applicable except as follows:

4.3 Reference test conditions

4.3.1 Environmental conditions

Addition:

– 18 – IEC 61010-2-012:2019 RLV © IEC 2019

Add the following text after item d):

Since the operating temperatures, pressures and current draw for a REFRIGERATING SYSTEM

are significantly impacted by ambient temperatures in a non-linear way, linear extrapolation of

test data is not possible. Therefore, tests to establish the temperatures, pressures, and

current draw for a REFRIGERATING SYSTEM shall be conducted under the following

environmental conditions:

aa1) an ambient temperature of 40 °C, or the maximum RATED operating ambient

temperature, if higher;

bb2) the temperature of water supply is the maximum as specified by the manufacturer (see

5.4.3);

cc3) a relative humidity not exceeding the limits of 1.4.1 d), or the maximum RATED

operating relative humidity at the maximum RATED operating ambient temperature, if

higher.

If, as permitted by Note 2 of 1.4.1, a REFRIGERATING SYSTEM has an operating ambient

temperature RATING below 40 °C, the NORMAL CONDITION tests shall be performed in an

environment that matches the maximum RATED operating ambient temperature, and then

repeated at an environmental ambient temperature of 40 °C. See 4.4.2.106 4.3.2.114.

4.3.2 State of equipment

4.3.2.1 General

Replacement:

Replace the first paragraph and note by the following:

Unless otherwise specified, each test shall be carried out on the equipment assembled for

NORMAL USE, and under the least favourable combination of the conditions given in 4.3.2.2 to

4.3.2.13 and 4.3.2.101 to 4.3.2.113 4.3.2.114 if applicable.

When measuring temperatures, pressures, and current draws of equipment incorporating a

REFRIGERATING SYSTEM, the tests shall be started from a SOAKED TEMPERATURE CONDITION when

all pressures have fully equalized. Tests at the extremes of the input voltage (±10 %) shall

start under these voltage conditions and achieve a stable state but need not start from a

SOAKED TEMPERATURE CONDITION.

In case of doubt, a test may have to be made with more than one combination of conditions,

for example, when the equipment is operated at or cycled in between its maximum and

minimum operating CONTROLLED TEMPERATURES or operated in combination with excessive

humidity, low air pressure, radiation, or conditions of precipitation.

Addition:

Add the following new subclauses:

4.3.2.101 Heat load

Where the equipment or materials being processed require either the provision or extraction

of heat, the equipment under test (EUT) shall be loaded with a heat source/sink within the

manufacturer's specified conditions of use (including maximum RATED and none).

NOTE DIN 12876 (all parts) provides procedures for determining cooling capacity and efficient heating capacity of

the equipment.

4.3.2.102 Humidity and steam

Where equipment generates humidity or is intended for connection to a steam supply, it shall

be set to generate or be supplied with them within the manufacturer's specified conditions of

use (including maximum RATED and none).

4.3.2.103 Lamp and lamp systems

Illumination that provides part of the primary function (whether it be integral or an accessory),

shall be installed and operated within the manufacturer's specified conditions of use (including

maximum, off and cycled).

NOTE An example is a Xenon arc lamp used in a weather durability TEST CHAMBER.

4.3.2.104 MECHANICAL MOVEMENT

Equipment with a function of MECHANICAL MOVEMENT (for materials or HEAT TRANSFER MEDIUM)

shall be set to expose the equipment and any materials being processed to the worst

conditions (including maximum, off and cycled).

4.3.2.105 Spray generating systems

Spray generating systems of equipment shall be operated within the manufacturer's specified

conditions of use (including maximum, off and cycled).

4.3.2.106 VENTILATORS

VENTILATORS shall be operated within the manufacturer's specified conditions of use (including

maximum, off and cycled).

4.3.2.107 Pressures other than those of REFRIGERANT

Where equipment generates or uses pressures other than local atmospheric it shall be set to

generate, or be supplied with pressure(s) within the manufacturer's specified conditions of use

(including maximum RATED and none).

4.3.2.108 REFRIGERANT pressure

Where a heating system (or HEAT TRANSFER MEDIUM) can apply a CONTROLLED TEMPERATURE to

the REFRIGERATING SYSTEM which is outside its ACC RANGE, the equipment shall be set to

apply the maximum CONTROLLED TEMPERATURE allowed by the controls or interlocks with the

MOTOR-COMPRESSOR off or maximum ACC RANGE with the MOTOR-COMPRESSOR on, whichever

is least favourable.

Where a heating system (or HEAT TRANSFER MEDIUM) can apply a CONTROLLED TEMPERATURE to

the REFRIGERATING SYSTEM which could affect the pressure in the system, the most

unfavourable condition for pressure shall be established including:

– MOTOR-COMPRESSOR running throughout;

– MOTOR-COMPRESSOR started during test;

– outside its ACC RANGE with the MOTOR-COMPRESSOR off and the equipment set to apply the

maximum CONTROLLED TEMPERATURE allowed by the controls or interlocks.

4.3.2.109 Exhaust and condensate

The least favourable conditions which result in production of exhaust, vapours and/or

...

IEC 61010-2-012 ®

Edition 2.0 2019-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

GROUP SAFETY PUBLICATION

PUBLICATION GROUPÉE DE SÉCURITÉ

Safety requirements for electrical equipment for measurement, control, and

laboratory use –

Part 2-012: Particular requirements for climatic and environmental testing and

other temperature conditioning equipment

Règles de sécurité pour appareils électriques de mesurage, de régulation et de

laboratoire –

Partie 2-012: Exigences particulières pour les appareils d'essais climatiques et

d'environnement, et autres appareils de conditionnement de température

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61010-2-012 ®

Edition 2.0 2019-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

GROUP SAFETY PUBLICATION

PUBLICATION GROUPÉE DE SÉCURITÉ

Safety requirements for electrical equipment for measurement, control, and

laboratory use –

Part 2-012: Particular requirements for climatic and environmental testing and

other temperature conditioning equipment

Règles de sécurité pour appareils électriques de mesurage, de régulation et de

laboratoire –

Partie 2-012: Exigences particulières pour les appareils d'essais climatiques et

d'environnement, et autres appareils de conditionnement de température

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 19.080 ISBN 978-2-8322-6713-4

– 2 – IEC 61010-2-012:2019 © IEC 2019

CONTENTS

FOREWORD . 4

INTRODUCTION . 7

1 Scope and object . 10

2 Normative references . 11

3 Terms and definitions . 11

4 Tests . 17

5 Marking and documentation . 23

6 Protection against electric shock . 32

7 Protection against mechanical HAZARDS . 34

8 Resistance to mechanical stresses . 36

9 Protection against the spread of fire . 37

10 Equipment temperature limits and resistance to heat . 38

11 Protection against HAZARDS from fluids and solid foreign objects . 42

12 Protection against radiation, including laser sources, and against sonic and

ultrasonic pressure . 57

13 Protection against liberated gases and substances, explosion and implosion . 58

14 Components and subassemblies . 60

15 Protection by interlocks . 62

16 HAZARDS resulting from application . 64

17 RISK assessment . 65

Annexes . 66

Annex K (normative) Insulation requirements not covered by 6.7 . 67

Annex L (informative) Index of defined terms . 68

Annex AA (informative) Useful symbols . 70

Annex BB (informative) Protection of people who are inside WALK-IN EQUIPMENT . 73

Annex CC (informative) Safety requirements for components and piping . 75

Annex DD (informative) Equipment containing FLAMMABLE REFRIGERANTS – Information

and marking requirements. 80

Annex EE (normative) Non-sparking "n" electrical device . 83

Bibliography . 84

Figure 101 – Schema of a REFRIGERATING SYSTEM incorporating a CONDENSER . 8

Figure 102 – Flow chart illustrating the selection process . 9

Figure 103 – Details of scratching TOOL tip . 52

Table 1 – Symbols . 24

Table 101 – Time-temperature conditions . 30

Table 102 – Maximum temperatures for MOTOR-COMPRESSORS . 40

Table 103 – Minimum temperature for the determination of SATURATED-VAPOUR

PRESSURE of the REFRIGERANT . 47

Table 104 – REFRIGERANT flammability parameters . 56

Table AA.1 – Useful symbols . 70

Table CC.1 – Parameters of pressure vessels according to EN 14276-1 . 76

Table CC.2 – Parameters of piping according to EN 14276-2 . 77

Table CC.3 – Components and piping requirements . 78

Table CC.4 – Minimum wall thickness for copper and steel tubing . 79

– 4 – IEC 61010-2-012:2019 © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SAFETY REQUIREMENTS FOR ELECTRICAL EQUIPMENT

FOR MEASUREMENT, CONTROL, AND LABORATORY USE –

Part 2-012: Particular requirements for climatic and environmental

testing and other temperature conditioning equipment

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61010-2-012 has been prepared by IEC technical committee 66:

Safety of measuring, control and laboratory equipment.

It has the status of a group safety publication in accordance with IEC Guide 104.

This second edition cancels and replaces the first edition published in 2016. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) alignment with changes introduced by Amendment 1 of IEC 61010-1:2010;

b) changes related to the use of small capitals for defined terms only;

c) clarifications for cooling tests in 4.4.2.10;

d) requirements for overtemperature protection in 10.101, including deletion of the second

part of the sentence in item b), and the deletion of item c);

e) changes pertaining to the accurate employment of terms "temperature", "operating

temperature", "working temperature", "application temperature", "room temperature" and

"ambient temperature" in 3.5.104, 3.5.105, 4.3.1, 4.3.2, 5.4.2, 8.2.1, 8.2.2, 11.7.2.101.2,

11.7.2.101.3, 13.2.102, 14.102, 15.101, 15.102, 15.103, Introduction and many other

locations. For the purpose of clarification, the definition of 3.5.114, CONTROLLED

TEMPERATURE, is added.

The text of this International Standard is based on the following documents:

FDIS Report on voting

66/687/FDIS 66/688/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 61010 series, published under the general title, Safety

requirements for electrical equipment for measurement, control, and laboratory use, can be

found on the IEC website.

IEC 61010-2-012 is to be used in conjunction with the latest edition of IEC 61010-1. It was

established on the basis of the third edition (2010) and its Amendment 1 (2016), hereinafter

referred to as Part 1.

This Part 2-012 supplements or modifies the corresponding clauses in IEC 61010-1 so as to

convert that publication into the IEC standard: Particular requirements for climatic and

environmental testing and other temperature conditioning equipment.

Where a particular subclause of Part 1 is not mentioned in this Part 2-012, that subclause

applies as far as is reasonable. Where this Part 2-012 states "addition", "modification",

"replacement", or "deletion", the relevant requirement, test specification, or note in Part 1

should be adapted accordingly.

In this standard:

1) the following print types are used:

– requirements and definitions: in roman type;

– NOTES: in smaller roman type;

– conformity and tests: in italic type;

– terms used throughout this standard which have been defined in Clause 3: SMALL

ROMAN CAPITALS.

2) subclauses, figures, tables and notes which are additional to those in Part 1 are numbered

starting from 101. Additional annexes are lettered starting from AA.

– 6 – IEC 61010-2-012:2019 © IEC 2019

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this standard using a

colour printer.

INTRODUCTION

This Part 2-012, along with Part 2-010 and Part 2-011, taken together, address the specific

HAZARDS associated with the heating and cooling of materials by equipment and are organized

as follows:

Specifically addresses the HAZARDS associated with equipment incorporating heating

IEC 61010-2-010

systems.

Specifically addresses the HAZARDS associated with equipment incorporating REFRIGERATING

IEC 61010-2-011

SYSTEMS.

Specifically addresses the HAZARDS associated with equipment incorporating both heating

and REFRIGERATING SYSTEMS that interact with each other such that the combined heating

and REFRIGERATING SYSTEM yield additional or more severe HAZARDS for the two systems

IEC 61010-2-012

than if treated separately. It also addresses the HAZARDS associated with the treatment of

materials by other factors like irradiation, excessive humidity, CO and MECHANICAL

MOVEMENT, etc.

Guidance for the application of the appropriate Part 2 standard(s)

When the equipment includes only a material heating system, and no REFRIGERATING SYSTEM

or other environmental factors apply, then Part 2-010 applies without needing Part 2-011 or

REFRIGERATING SYSTEM, and no

Part 2-012. Similarly, when the equipment includes only a

material heating system or other environmental factors apply, then Part 2-011 applies without

needing Part 2-010 or Part 2-012. However, when the equipment incorporates both a material

heating system, and a REFRIGERATING SYSTEM or the materials being treated in the intended

application introduce significant heat into the REFRIGERATING SYSTEM, a determination should

be made as to whether the interaction between the two systems will generate additional or

HAZARDS than if the systems were evaluated separately (CONTROLLED

more severe

TEMPERATURE, see flow chart for selection process). If the interaction of the heating and

cooling functions yields no additional or more severe HAZARDS, then both Part 2-010 and

Part 2-011 apply for their respective functions. Conversely, if additional or more severe

HAZARDS result from the combining of the heating and cooling functions, or if the equipment

incorporates additional material treatment factors, then Part 2-012 applies, but not Part 2-010

or Part 2-011.

What HAZARDS are applicable for a REFRIGERATING SYSTEM?

The typical HAZARDS for a REFRIGERATING SYSTEM (see Figure 101) consisting of a MOTOR-

COMPRESSOR, a CONDENSER, an expansion device and an EVAPORATOR include but are not

limited to:

– The maximum temperature of LOW-PRESSURE SIDE (return temperature) to the MOTOR-

COMPRESSOR. A MOTOR-COMPRESSOR incorporates a REFRIGERANT cooled motor and it

should be established that the maximum temperatures of the LOW-PRESSURE SIDE under

RATINGS within the motor.

least favourable condition do not exceed the insulation