IEC 60092-504:2001

(Main)Electrical installations in ships - Part 504: Special features - Control and instrumentation

Electrical installations in ships - Part 504: Special features - Control and instrumentation

The contents of the corrigendum of January 2011 have been included in this copy.

General Information

- Status

- Published

- Publication Date

- 21-Mar-2001

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 22-Sep-2016

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Referred By

EN 1864:2008 - Inland navigation vessels - Wheelhouse - Ergonomic and safety requirements - Effective Date

- 09-Feb-2026

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60092-504:2001 - "Electrical installations in ships - Part 504: Special features - Control and instrumentation" is an IEC marine standard that specifies requirements for electrical, electronic and programmable equipment used for control, monitoring, alarm and protection systems on ships. This third edition (2001) consolidates guidance relevant to design, type testing, construction, installation, commissioning and documentation for shipboard control and instrumentation equipment. The copy includes the corrigendum of January 2011.

Key topics and technical requirements

The standard focuses on practical and safety-driven aspects of shipboard control and instrumentation, including:

- General requirements: dependability, safety, segregation, performance, usability and system integration.

- Environmental and type testing: references to environmental test standards (cold, dry heat, vibration, damp heat, salt mist) to ensure equipment robustness at sea.

- Design considerations: circuit design, signal levels, power supply, mutual effects and electrical subdivision for reliable operation.

- Construction and materials: accessibility, replacement, non‑interchangeability, cooling, internal wiring and mechanical features of cabinets and connectors.

- Installation and ergonomics: sensor siting, presentation of information, human‑machine interface and alarm systems.

- Specific installations: fire‑protection control, machinery alarm systems, automatic power‑supply control, motor starting, machinery protection, watertight/power‑operated doors and public address on passenger ships.

- Computer‑based systems: system safety, configuration, integration, power supply, data communications, user interfaces, alarm/control/safety functions, software requirements, tests and documentation.

- Unattended machinery spaces and reduced attendance: additional alarm, fire and flooding precautions.

- Commissioning, testing and documentation: operational tests, circuit diagrams and apparatus descriptions.

Practical applications and users

IEC 60092-504 is used by professionals involved in marine electrical and automation systems, including:

- shipbuilders and shipyards designing and installing control systems

- marine electrical and automation engineers specifying equipment and layouts

- equipment manufacturers and system integrators developing marine control hardware/software

- classification societies, flag state authorities and regulatory bodies assessing compliance

- shipowners and operators seeking reliable alarm, protection and automation systems

Applying this standard helps ensure safety, interoperability, maintainability and regulatory alignment of shipboard control and instrumentation.

Related standards (selected)

- IEC 60092 series (general ship electrical design)

- IEC 60068 series (environmental testing)

- IEC 60529 (IP codes)

- IEC 60533 (EMC for ships)

- IEC 60447 (man–machine interface)

- IEC 60945 (maritime navigation and radiocommunication equipment)

Keywords: IEC 60092-504, electrical installations in ships, control and instrumentation, marine automation, shipboard control systems, ship instrumentation standards.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Sponsored listings

Frequently Asked Questions

IEC 60092-504:2001 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electrical installations in ships - Part 504: Special features - Control and instrumentation". This standard covers: The contents of the corrigendum of January 2011 have been included in this copy.

The contents of the corrigendum of January 2011 have been included in this copy.

IEC 60092-504:2001 is classified under the following ICS (International Classification for Standards) categories: 47.020.60 - Electrical equipment of ships and of marine structures. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60092-504:2001 has the following relationships with other standards: It is inter standard links to EN 60947-1:2007/A2:2014, EN 61162-402:2005, EN 1864:2008, IEC 60092-504:2001/COR1:2011, IEC 60092-504:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60092-504:2001 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

60092-504

Third edition

2001-03

Electrical installations in ships –

Part 504:

Special features – Control and instrumentation

Installations électriques à bord des navires –

Partie 504:

Caractéristiques spéciales – Conduite et instrumentation

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/catlg-e.htm) enables

you to search by a variety of criteria including text searches, technical

committees and date of publication. On-line information is also available on

recently issued publications, withdrawn and replaced publications, as well as

corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/JP.htm) is also

available by email. Please contact the Customer Service Centre (see below) for

further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD

60092-504

Third edition

2001-03

Electrical installations in ships –

Part 504:

Special features – Control and instrumentation

Installations électriques à bord des navires –

Partie 504:

Caractéristiques spéciales – Conduite et instrumentation

© IEC 2001 ⎯ Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http://www.iec.ch

Commission Electrotechnique Internationale

PRICE CODE

XA

International Electrotechnical Commission

For price, see current catalogue

– 2 – 60092-504 © IEC:2001(E)

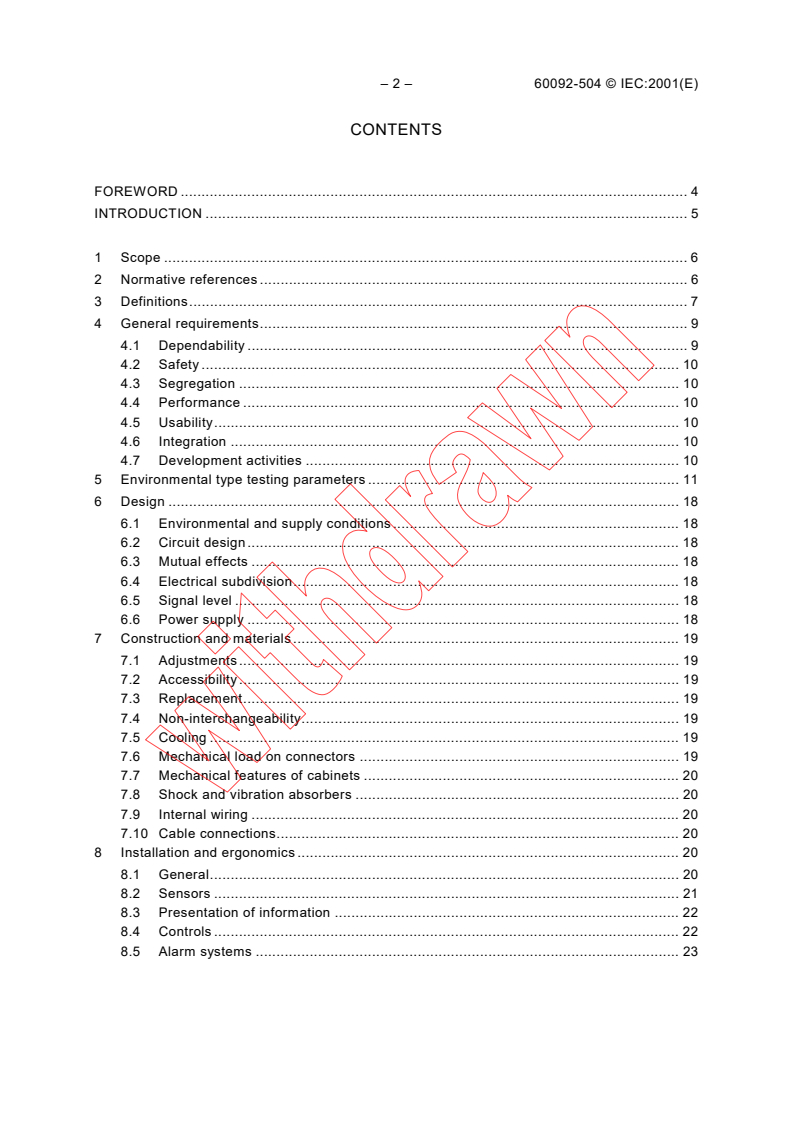

CONTENTS

FOREWORD . 4

INTRODUCTION .5

1 Scope . 6

2 Normative references . 6

3 Definitions. 7

4 General requirements. 9

4.1 Dependability . 9

4.2 Safety . 10

4.3 Segregation . 10

4.4 Performance . 10

4.5 Usability. 10

4.6 Integration . 10

4.7 Development activities . 10

5 Environmental type testing parameters . 11

6 Design . 18

6.1 Environmental and supply conditions . 18

6.2 Circuit design. 18

6.3 Mutual effects . 18

6.4 Electrical subdivision. 18

6.5 Signal level . 18

6.6 Power supply . 18

7 Construction and materials . 19

7.1 Adjustments. 19

7.2 Accessibility . 19

7.3 Replacement. 19

7.4 Non-interchangeability. 19

7.5 Cooling . 19

7.6 Mechanical load on connectors . 19

7.7 Mechanical features of cabinets . 20

7.8 Shock and vibration absorbers . 20

7.9 Internal wiring . 20

7.10 Cable connections. 20

8 Installation and ergonomics . 20

8.1 General. 20

8.2 Sensors . 21

8.3 Presentation of information . 22

8.4 Controls . 22

8.5 Alarm systems . 23

60092-504 © IEC:2001(E) – 3 –

9 Specific installations. 23

9.1 Fire protection control installations . 23

9.2 Machinery alarm installations . 28

9.3 Automatic control installations for electrical power supply . 30

9.4 Automatic starting installations for electrical motor-driven auxiliaries . 33

9.5 Machinery control installations. 35

9.6 Machinery protection (safety) systems . 37

9.7 Bow, inner, side shell and stern doors . 38

9.8 Power-operated watertight doors . 40

9.9 Public address systems on passenger ships . 42

10 Computer-based systems . 43

10.1 General. 43

10.2 System safety . 44

10.3 System configuration. 44

10.4 System integration . 45

10.5 Power supply . 45

10.6 Data communications links. 45

10.7 User interface . 46

10.8 Alarm, control and safety functions. 48

10.9 Software . 49

10.10 Tests . 50

10.11 Documentation. 51

11 Additional requirements for periodically unattended machinery spaces or for

reduced attendance. 53

11.1 Introduction. 53

11.2 General requirements. 53

11.3 Fire precautions . 53

11.4 Protection against flooding . 54

11.5 Control of propulsion machinery . 54

11.6 Alarm system . 54

11.7 Protection (safety) systems . 55

11.8 Special requirements for machinery, boiler and electrical installations. 55

12 Commissioning and testing. 56

12.1 Tests of completed installation . 56

12.2 Operational tests. 56

13 Documentation. 57

13.1 Apparatus description. 57

13.2 Circuit diagrams. 57

– 4 – 60092-504 © IEC:2001(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

ELECTRICAL INSTALLATIONS IN SHIPS –

Part 504: Special features –

Control and instrumentation

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International Organization

for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60092-504 has been prepared by IEC technical committee 18:

Electrical installations of ships and of mobile and fixed offshore units.

This third edition cancels and replaces the second edition, published in 1994, and constitutes a

technical revision.

The text of this standard is based on the following documents:

FDIS Report on voting

18/889/FDIS 18/890/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 3.

The committee has decided that the contents of this publication will remain unchanged until

2005. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version of this standard may be issued at a later date.

The contents of the corrigendum of January 2011 have been included in this copy.

60092-504 © IEC:2001(E) – 5 –

INTRODUCTION

IEC 60092 forms a series of International Standards intended to ensure safety in the design,

selection, installation, maintenance and use of electrical equipment for the generation, storage,

distribution and utilization of electrical energy for all purposes in seagoing ships.

This part of IEC 60092 also incorporates and co-ordinates, as far as possible, existing rules

and forms a code of interpretation, where applicable, of the requirements of the International

Maritime Organization, and serves as a guide for future regulations which may be prepared and

as a statement of practice for use by shipowners, shipbuilders and appropriate organizations,

and by constructors and appropriate organizations.

This standard is based on equipment and practices which are in current use, but it is not

intended in any way to impede development of new or improved techniques.

– 6 – 60092-504 © IEC:2001(E)

ELECTRICAL INSTALLATIONS IN SHIPS –

Part 504: Special features –

Control and instrumentation

1 Scope

This part of IEC 60092 deals with electrical, electronic and programmable equipment intended

for control, monitoring, alarm and protection systems for use in ships.

2 Normative references

The following normative documents contain provisions which, through reference in this text,

constitute provisions of this part of IEC 60092. For dated references, subsequent amendments

to, or revisions of, any of these publications do not apply. However, parties to agreements

based on this part of IEC 60092 are encouraged to investigate the possibility of applying the

most recent editions of the normative documents indicated below. For undated references, the

latest edition of the normative document referred to applies. Members of IEC and ISO maintain

registers of currently valid International Standards.

IEC 60050 (all parts), International Electrotechnical Vocabulary (IEV)

IEC 60068-2-1, Environmental testing – Part 2: Tests – Tests A: Cold

IEC 60068-2-2, Environmental testing – Part 2: Tests – Tests B: Dry heat

IEC 60068-2-6, Environmental testing – Part 2: Tests – Tests Fc: Vibration (sinusoidal)

IEC 60068-2-30, Environmental testing – Part 2: Tests – Tests Db and guidance: Damp heat,

cyclic (12 + 12-hour cycle)

IEC 60068-2-52, Environmental testing – Part 2: Tests – Tests Kb: Salt mist, cyclic (sodium

chloride solution)

IEC 60092 (all parts), Electrical installations in ships

IEC 60092-101, Electrical installations in ships – Part 101: Definitions and general

requirements

IEC 60092-201, Electrical installations in ships – Part 201: System design – General

IEC 60092-202, Electrical installations in ships – Part 202: System design – Protection

IEC 60092-204, Electrical installations in ships – Part 204: System design – Electric and

electrohydraulic steering gear

IEC 60092-302, Electrical installations in ships – Part 302: Low voltage switchgear and

controlgear assemblies

IEC 60092-375, Electrical installations in ships. Shipboard telecommunication cables and radio-

frequency cables. General instrumentation, control and communication cables

IEC 60092-376, Electrical installations in ships – Part 376: Shipboard multicore cables for

control circuits

IEC 60092-401, Electrical installations in ships – Part 401: Installation and test of completed

installation

60092-504 © IEC:2001(E) – 7 –

IEC 60092-501, Electrical installations in ships – Part 501: Special features – Electric

propulsion plant

IEC 60092-502, Electrical installations in ships – Part 502: Tankers – Special features

IEC 60447, Man-machine interface (MMI) – Actuating principles

IEC 60529, Degrees of protection provided by enclosures (IP Code)

IEC 60533, Electrical and electronic installations in ships – Electromagnetic compatibility

IEC 60945, Maritime navigation and radiocommunication equipment and systems – General

requirements – Methods of testing and required test results

IEC 61000-4-2, Electromagnetic compatibility (EMC) – Part 4: Testing and measurement

techniques – Section 2: Electrostatic discharge immunity test. Basic EMC Publication

IEC 61000-4-3, Electromagnetic compatibility (EMC) – Part 4: Testing and measurement

techniques – Section 3: Radiated, radio-frequency, electromagnetic field immunity test

IEC 61000-4-4, Electromagnetic compatibility (EMC) – Part 4: Testing and measurement

techniques – Section 4: Electrical fast transient/burst immunity test. Basic EMC Publication

IEC 61000-4-5, Electromagnetic compatibility (EMC) – Part 4: Testing and measurement

techniques – Section 5: Surge immunity test

IEC 61000-4-6, Electromagnetic compatibility (EMC) – Part 4: Testing and measurement

techniques – Section 6: Immunity to conducted disturbances, induced by radio-frequency fields

IEC 61000-4-11, Electromagnetic compatibility (EMC) – Part 4: Testing and measuring

techniques – Section 11: Voltage dips, short interruptions and voltage variations immunity tests

CISPR 16-1, Specification for radio disturbance and immunity measuring apparatus and

methods – Part 1: Radio disturbance and immunity measuring apparatus

CISPR 16-2, Specification for radio disturbance and immunity measuring apparatus and

methods – Part 2: Methods of measurement of disturbances and immunity

IMO Assembly Resolution A.830 (19)1995, Code on Alarms and Indicators

NOTE Other informative IMO documents are referenced within the text of this standard.

3 Definitions

For the purposes of this part of IEC 60092, the following definitions, having special application

to the control, monitoring, alarm and protection equipment, apply. For definitions of general and

more particular terms, reference is made to IEC 60050 (IEV) and other normative documents.

3.1

accuracy

quality which characterizes the closeness of a measured value to the corresponding true value

3.2

alarm functions

functions intended to alert relevant personnel, by visual and audible means, in the event of any

condition requiring their attention

___________

See IMO 867E:1996, Code on Alarms and Indicators, 1995

– 8 – 60092-504 © IEC:2001(E)

3.3

availability

ability of an item to be in a state to perform a required function under given conditions at a

given time interval, assuming that the required external resources are provided

3.4

centralized control

control of all operations of a controlled system from one central control position

3.5

computer-based system

system that consists of one or more programmable electronic devices with their connections,

peripherals and software necessary to carry out automatically specified functions

NOTE The following types of programmable devices could form part of a computer system: main-frame, mini-

computer, micro-processor-based computer, programmable logic controller.

3.6

control functions

functions intended to regulate the behavior of equipment or systems

3.7

control position (control station)

group of control devices by which an operator can control the performance of a machine,

apparatus, process or assembly of machines and apparatus.

NOTE A control position will generally enable an operator to verify the achievement of the desired conditions by

means of an appropriate monitoring system

3.8

dependability

extent to which a system can be relied upon to perform its intended functions under defined

operational and environmental conditions

3.9

essential services

functions necessary for the propulsion, steering and safety of the ship and its personnel

3.10

fail-to-safe

principle by which a failure or malfunction of a component of the system causes its output to

automatically adjust to a predetermined safe state

NOTE The safe state, according to the application, will be predetermined in terms of priority for the safety of the

ship and may generally be taken as the least critical one for the main components and auxiliaries of, for example,

the propulsion/manoeuvring plant.

3.11

function

elementary operation performed by the system which, in conjunction with other elementary

operations (system functions), enables the system to perform a task

3.12

indication functions

functions intended to inform relevant personnel, by visual and/or audible means, of any

equipment or system status

60092-504 © IEC:2001(E) – 9 –

3.13

integrity

capability of a system to satisfactorily perform the required functions under all the stated

conditions within a stated period of time

3.14

machinery control room

room or spaces where centralized controls and measuring and monitoring equipment for main

equipment and essential auxiliary machinery are located together with the appropriate means

of communication

3.15

maintainability

ability of an item under given conditions of use, to be retained in, or restored to, a state in

which it can perform a required function, when maintenance is performed under given

conditions and using stated procedures and resources

3.16

monitoring functions

functions intended to collect data from equipment and systems for the purpose of display and

recording

3.17

protection functions

functions intended to prevent damage to equipment or systems in the event of a fault

3.18

reliability

ability of an item to perform a required function under given conditions for a given time interval

3.19

safety functions

functions intended to prevent harm or danger to personnel

3.20

software

program, procedures and associated documentation pertaining to the operation of a computer

system and including application (user) program, middleware and operating system (firmware)

program

3.21

system

collection of components organised to accomplish a specific function or set of functions

3.22

usability

extent to which a system can be used by specified users to achieve specified goals with

effectiveness, efficiency and satisfaction in a specified context of use

4 General requirements

4.1 Dependability

Systems shall be suitable for the user, the task and the application.

– 10 – 60092-504 © IEC:2001(E)

System integrity shall be appropriate for the functions supported, with due regard to factors

such as availability, reliability and maintainability.

4.2 Safety

Systems shall be designed such that risk of harm to persons or the environment is reduced to

a level acceptable to the appropriate authority, both in normal operation and under failure

conditions. Functions shall be designed on the fail-to-safe principle.

4.3 Segregation

Systems shall be designed such that failure of one component part or sub-system will not

unduly affect any other system, sub-system or component and, as far as is practicable, shall be

detectable.

Protection (safety) functions shall be independent of control and monitoring (alarm) functions.

As far as is practicable, control and monitoring (alarm) functions shall also be independent.

Standby systems, or other redundancy arrangements, are to be functionally independent.

4.4 Performance

Systems shall maintain specified levels of performance in operation, and where necessary,

under fault conditions.

Repeatability and accuracy shall be adequate for the proposed use and shall be maintained at

their specified value during their expected lifetime and normal use.

Systems shall be stable throughout their operational range.

4.5 Usability

Systems shall be readily usable under all intended operating conditions and shall support

effective and efficient operation.

Adequate safeguards against incorrect operation shall be provided.

4.6 Integration

Where safety of personnel may directly depend on correct system operation or failure, such

systems shall not be integrated with, or be mutually dependent upon, any other system, except

those providing complementary functions.

Where safety may indirectly depend on system operation or failure, the integrity of the

integrated system shall be to the satisfaction of the appropriate authority.

4.7 Development activities

Activities undertaken in the development process, from initial design through to eventual

realisation, and any modifications in use thereafter, shall be planned and structured in a

systematic manner, and are to be properly managed. Persons responsible for carrying out

these activities shall be competent to do so.

Activities, scopes, responsibilities and competencies shall be documented.

60092-504 © IEC:2001(E) – 11 –

5 Environmental type testing parameters

Where equipment or systems are subject to type testing, the test procedures and severities

specified in table 1 shall apply.

NOTE Compliance with IMO Res. A.813(19) will require all ship’s electrical and electronic equipment to be tested

to the relevant electromagnetic compatibility standard.

Table 1 – Type tests, test procedures and severities

a

Test Procedure

Severity Other information

according to

1 Visual Examination of the equipment for:

inspection

– conformity to drawings and design

data;

– compliance with applicable

IEC standards;

– quality of workmanship and

construction.

2 Functional Standard atmospheric conditions:

test to

– temperature: 25 °C ± 10 °C

equipment

specification

– relative humidity: 60 % ± 30 %

– air pressure: 96 kPa ± 10 kPa

3 High voltage Rated insulation Test voltage AC Frequency of test voltage: 50 Hz or

test voltage U 60 Hz.

n

V

V Separate circuits to be tested

against each other.

All circuits connected with each

other are to be tested against earth.

Contact pieces are to be tested

across their open points of contact.

Printed circuits with electronic

components which could be subject

to damage may be removed during

the test.

Un ≤ 65 2 × Un + 500

1 500

66 < U ≤ 250

n

2 000

251 < U ≤ 500

n

501 < U ≤ 690 2 500

n

Period of application of test voltage:

1 min

___________

IMO A.813 (19):1995, General requirements for electromagnetic compatibility (EMC) for all electrical and

electronic ships equipment

– 12 – 60092-504 © IEC:2001(E)

Table 1 (continued)

a

Test Procedure

Severity Other information

according to

4a Power IEC 61000-4-11 AC supply

supply

variations

Combination Voltage Frequency Each combination shall be tested.

No. variation variation

(permanent) (permanent)

% %

1+6 +5

2+6 –5

3 –10 –5

4 –10 +5

Voltage Frequency

transient transient

(duration 1,5 s) (duration 5 s)

5+20 +10

6 –20 –10

DC supply

Voltage tolerance ±10 %

continuous

Voltage cyclic variation 5 %

Voltage ripple 10 %

Electrical battery supply:

+30 % to –25 % for equipment connected to

charging battery or as determined by the

charging/discharging characteristics, including

ripple voltage from the charging device;

+20 % to –25 % for equipment not connected

to the battery during charging.

4b Power IEC 61000-4-11 Three interruptions during 5 minutes Verification of the following:

supply

30 s break time – specified action of the equipment

failure

on loss and restoration of supply;

– there is no corruption of program

or data held in programmable

electronic systems, where

applicable.

60092-504 © IEC:2001(E) – 13 –

Table 1 (continued)

a

Test Procedure

according to Severity Other information

5 Insulation Rated Test voltage Minimum insulation Between all circuits and earth; on

b

resistance supply resistance the supply terminals where

V

voltage appropriate.

Resistance shall be measured

V

before and after high voltage test,

damp heat test, cold test and salt

mist test.

Before After test

test

MΩ

MΩ

U ≤ 65 2 × U 10 1

n n

min. 24

500 100 10

U > 65

n

6 Cold with IEC 60068-2-1 +5 °C ± 3 °C –25 °C ± 3 °C Initial measurement of insulation

gradual resistance (see test 6)

Test Ab for 2 h 2 h

change of

non-heat Equipment not operating during

temperature

c

dissipating conditioning except for operational

equipment tests

IEC 60068-2-1 Operational test during last hour at

test temperature

Test Ad for

heat Insulation resistance measurement

dissipating and operational test after recovery

equipment

7 Dry heat IEC 60068-2-2 55 °C ± 2 °C 70 °C ± 2 °C Equipment operating during

with gradual conditioning

16 h 2 h

change of

Operational test during last hour at

temperature

Test Bb for

d

test temperature

non-heat

dissipating Operational test after recovery

equipment

IEC 60068-2-2 55 °C ± 2 °C 70 °C ± 2 °C Equipment operating during

conditioning with cooling system

Test Bd for 16 h 2 h

on if provided

heat

dissipating Operational test during last hour at

equipment test temperature

Operational test after recovery

– 14 – 60092-504 © IEC:2001(E)

Table 1 (continued)

a

Test Procedure Severity Other information

according to

Damp IEC 60068-2-30 Temperature: 55 °C Measurement of insulation

heat, resistance before test

Test Db Humidity: 95 %

cyclic

Equipment operating during

(12 h+12 h

Duration: two cycles

the complete first cycle and

j

cycle)

(12 h + 12 h)

switched off during second

cycle except for functional

test

Functional test during the

first 2 h of the first cycle at

the test temperature and

during the last 2 h of the

second cycle at the test

temperature

Recovery at standard

atmosphere conditions

Insulation resistance

measurements and

performance test

e

9Salt mist IEC 60068-2-52 Four spraying periods with a storage of 7 days Initial measurement of

after each insulation resistance and

Test Kb

initial functional test

Equipment in its normal

position during test

Equipment not operating

during conditioning

Operational test on day 7 of

each spraying period

Insulation resistance

measurement and

performance test 4 h to 6 h

after the recovery period

10 Vibration IEC 60068-2-6 For general For equipment mounted on During the vibration test,

(sinu- applications reciprocating machines, operational conditions are to

Test Fc

soidal) installed in steering gear be demonstrated.

+3

2 Hz to 13,2 Hz compartment or similar

−0

Tests to be carried out in

locations

three mutually perpendicular

amplitude ±1 mm

+3 planes.

13,2 Hz to 100 Hz 2 Hz to 25 Hz

−

acceleration ±0,7 g

It is recommended as

Amplitude ±1,6 mm

guidance that Q does not

Endurance at:

exceed 5.

25 Hz to 100 Hz

– each resonance

If sweep test is chosen,

frequency at which Acceleration ±4 g

where several resonance

an amplification

frequencies are detected

Endurance at:

factor Q ≥ 2 is

close to each other, duration

recorded;

– each resonance frequency

of test shall be 120 min.

at which an amplification

– 30 Hz if no

factor Q ≥ 2 is recorded;

resonance

frequency is

–30 Hz if no resonance

recorded.

frequency is recorded.

90 min

40 Hz to 2 000 Hz acceleration ±10 g Only for extreme conditions

e.g. on exhaust manifolds of

90 min

diesel engines

60092-504 © IEC:2001(E) – 15 –

Table 1 (continued)

a

Test Procedure Severity Other information

according to

11a Inclination 22,5° Each direction

a, i

steady

Equipment operating

11b Inclination 22,5° Each direction

dynamic

0,1 Hz Equipment operating

Duration of test not less than 15 min

12 Enclosure IEC 60529 Dependent on location See table 5 of IEC 60092-201 for

protection minimum requirements.

13 Electrostatic IEC 61000-4-2 Contact discharge: 6 kV Electrostatic discharge as may

discharge occur when persons touch the

Air discharge: 8 kV

appliance

Interval between single discharges: 1 s

The test is to be confined to the

points and surfaces that can

No. of pulses: 10 per polarity

normally be reached by the

According to level 3 severity standard operator.

f

.

Performance criterion B: see note

14 Electro- IEC 61000-4-3 Frequency range: 80 MHz – 2 GHz Electromagnetic fields radiated by

magnetic field different transmitters

Modulation: 80 % AM at 1 000 Hz

If for tests of equipment an input

Field strength: 10 V/m

signal with a modulation frequency

–3 of 1 000 Hz is necessary, a

Frequency sweep rate: ≤1,5 × 10

modulation frequency of 400 Hz may

decades/s (or 1 %/3 sec) be chosen.

g

Performance criterion A: see note .

According to level 3 severity standard.

15 Conducted low IEC 60533 AC: Distortions in the power supply

frequency system generated for instance by

Frequency range: rated frequency to

electronic consumers and coupled in

th

200 harmonic;

as harmonics

Test voltage (r.m.s.): 10 % of supply to

Method of the test in accordance

th th

15 harmonic reducing to 1 % at 100

with IEC 60945

harmonic and maintain this level to the

th

g

200 harmonic, max 2 W Performance criterion A: see note .

DC:

Frequency range: 50 Hz – 10 kHz;

Test voltage (r.m.s.): 10 % of supply,

max. 2 W

16 Conducted IEC 61000-4-6 Frequency range: 150 kHz – 80 MHz Electromagnetic fields coupled as

radio high frequency into the test

h

Amplitude: 3 V r.m.s.

frequency specimen via the connecting lines

Modulation: 80 % AM at 1 000 Hz

If for tests of equipment an input

signal with a modulation frequency

Frequency sweep range

–3 of 1 000 Hz is necessary, a

≤ 1,5 × 10 decades/s (or 1 %/3 sec.)

modulation frequency of 400 Hz may

According to level 2 severity standard be chosen.

g

Performance criterion A: see note .

– 16 – 60092-504 © IEC:2001(E)

table 1 (continued)

Test Procedure Severity Other information

(note 1) according to

17 Burst/fast IEC 61000-4-4 Single pulse time: 5 ns (between 10 % Arcs generated when actuating

transients and 90 % value) electrical contacts

Pulse width: 50 ns (50 % value) Interference effect occurring on the

power supply, as well as the

Amplitude (peak): 2 kV line/line on power

external wiring of the test specimen

supply port;

f

Performance criterion B: see note .

1 kV lines/earth on I/O data control and

signal lines;

Pulse period: 300 ms;

Burst duration: 15 ms;

Duration/polarity: 5 min

According to level 3 severity standard

18 Surge/show IEC 61000-4-5 Interference generated for instance,

Pulse rise time: 1,2 μs, (between 10 %

transient by switching "ON" or "OFF" high

and 90 % value)

power inductive consumers

Pulse width: 50 μs (50 % value)

Test procedure in accordance with

Amplitude (peak): 1 kV line/earth;

figure 10 of the standard for

equipment where power and signal

0,5 kV line/line

lines are identical

Repetition rate >1 pulse/min

f

Performance criterion B: see note .

No. of pulses: five per polarity

Application: continuous

According to level 2 severity standard

19 Radiated CISPR 16-1 For equipment installed in the bridge and Procedure in accordance with the

emission deck zone standard but distance 3 m between

CISPR 16-2

equipment and antenna

Frequency range: Limits:

0,15 – 0,3 MHz 80 – 52 dBμV/m

0,3 – 30 MHz 52 – 34 dBμV/m

30 – 2 000 MHz 54 dBμV/m

except for:

156 – 165 MHz 24 dBμV/m

For equipment installed in the general

power distribution zone

Frequency range: Limits:

0,15 – 30 MHz 80 – 50 dB V/m

μ

30 – 100 MHz 60 – 54 dBμV/m

100 – 2 000 MHz 54 dBμV/m

except for:

156 – 165 MHz 24 dBμV/m

60092-504 © IEC:2001(E) – 17 –

Table 1 (continued)

a

Test Procedure Severity Other information

according to

20 Conducted CISPR 16-1 For equipment installed in the bridge and

emission deck zone

CISPR 16-2

Frequency range: Limits:

10 – 150 kHz 96 – 50 dBμV

150 – 350 kHz 60 – 50 dBμV

350 kHz – 30 MHz 50 dBμV

For equipment installed in the general

power distribution zone

Frequency range: Limits:

10 – 150 kHz 120 – 69 dBμV

0,15 – 0.5 MHz 79 dBμV

0,5 – 30 MHz 73 dBμV

21 Flame IEC 60092-101 Flame application: The burnt-out or damaged part of

retardancy the specimen is not to exceed

– 5 times, 15 s each

60 mm in length

(cables)

Interval between each application:

– 15 s

a

The static inclination test is not required on equipment with no moving parts.

b

Insulation resistance test to be carried out before and after damp heat test, cold test and salt mist test.

c

For equipment installed in non-weather-protected locations or cold locations, test is to be carried out at

–25 °C.

d

Dry heat at 70 °C is to be carried out to withstand a high degree of heat, e.g. for equipment to be mounted in

consoles, housings.

e

Salt mist test to be carried out for equipment to be installed in non-weatherprotected areas, for example on open

deck.

f

Performance criterion B: the equipment under test (EUT) shall continue to operate as intended after the tests. No

degradation of performance or loss of function is allowed as defined in the technical specification published by

the manufacturer. During the test, degradation or loss of function or performance which is self-recoverable is,

however, allowed but no change of actual operating state or stored data is allowed.

Recovery times shall be consistent with continued safe operation, taking due account of the need to preserve

essential services.

g

Performance criterion A: the equipment under test (EUT) shall continue to operate as intended during and after

the test. No degradation of performance or loss of function is allowed, as defined in the technical specification

published by the manufacturer.

h

For equipment installed on the bridge and deck zone the test levels shall be increased to 10 V r.m.s. for spot

frequencies in accordance with IEC 60945 at 2 ; 3 ; 4 ; 6,2 ; 8,2 ; 12,6 ; 16,5 ; 18,8 ; 22 ; 25 MHz.

i

On ships for the carriage of liquid gases and chemicals, the emergency power supply must also remain

operational with the ship flooded up to maximum athwarthship inclination of 30°.

j

This test shall be carried out for equipment located in non-air-conditioned spaces.

– 18 – 60092-504 © IEC:2001(E)

6 Design

6.1 Environmental and supply conditions

Equipment shall be designed to operate satisfactorily within the expected environmental and

supply conditions, with due regard to the limits specified in Annex B of IEC 60092-101.

6.2 Circuit design

Circuits shall be designed to enable efficient test, calibration, maintenance and repair.

Preferably, they shall be suitable for repair by unit or card replacement. In some cases, it may

be desirable to provide simulation circuits or similar means to check correct operation of the

equipment.

6.3 Mutual effects

Systems shall be arranged such that faults will not affect any function provided by any other

system.

6.4 Electrical subdivision

Design of circuits shall be such that there is no direct connection to any point of the ship's main

power supply system, e.g. isolating transformers shall be used for power supplies. The chassis

may not form part of any circuit, except earthing for functional reasons.

It is recommended that extensive systems be subdivided and the supplies to the sections be

electrically separated or individually protected.

Control circuits shall be separated from signal and indicating circuits in such a way that faults

in the indicating circuits will not impair the operation of the equipment or apparatus, and vice

versa.

6.5 Signal level

Signal levels shall be kept high enough to overcome the effects of contact corrosion and noise

pick-up.

Transducers and amplifiers shall be situated as close to each other as it is practicable.

Particular attention shall be paid to the earthing (grounding) of screens and signal reference

systems.

To avoid possible interference on control and instrumentation cables, suitable installation

features shall be provided, such as:

– screening and/or twisted pairs;

– use of balanced input amplifiers;

– separation between signal and other cables.

6.6 Power supply

6.6.1 Independent supplies

Where required, redundant power supplies shall be independent and the system selectively fed.

60092-504 © IEC:2001(E) – 19 –

6.6.2 Capacity

The capacity of any back-up source shall be sufficient to ensure the normal operation of the

system until safety conditions are reached.

6.6.3 Protection

Each circuit shall be separately protected against short-circuit and overloads.

7 Construction and materials

7.1 Adjustments

Where necessary, equipment shall be arranged for simple adjustment. The set points shall be

readily identifiable and suitable means shall be provided to protect against changes, e.g. due to

environmental effect.

7.2 Accessibility

Ease of access to interchangeable parts for repairs and maintenance shall be ensured.

As far as is practicable, equipment shall be free of voltage, temperature, or other such factors

which may present unsafe working conditions.

7.3 Replacement

Each replaceable assembly shall be simple to replace and shall be constructed for easy and

safe handling.

7.4 Non-interchangeability

Preferably, all replaceable parts shall be so arranged that it is not possible to connect them

incorrectly or to use incorrect replacements. Where this is not practicable, the replaceabl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...