IEC 60092-302-2:2025

(Main)Electrical installations in ships - Part 302-2: Low voltage switchgear and controlgear assemblies - Marine power

Electrical installations in ships - Part 302-2: Low voltage switchgear and controlgear assemblies - Marine power

IEC 60092-302-2:2025 defines the specific requirements of low voltage marine power switchgear and controlgear assemblies (mpsc-assemblies) as follows:

- stationary assemblies with enclosure for which the rated voltage does not exceed 1 000 V AC or 1500 V DC;

- assemblies intended for use in conjunction with the power generation, distribution and conversion of electric energy, and for the control of electric energy consuming equipment.

Due to the marine application and the risks associated with loss of power, additional safety factors have been applied to minimise the risk of failure, such as applying an additional safety factor on clearance distances.

This document applies to all assemblies whether they are designed, manufactured and verified on a one-off basis or fully standardised and manufactured in quantity.

Either the manufacture or assembly, or both, of the MPSC assembly can be carried out by others than the original manufacturer.

This document does not apply to individual devices and self-contained components, such as motor starters, fuse switches, electronic equipment, which comply with the relevant product standards.

This second edition cancels and replaces the first edition published in 2019. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a) amended and updated in line with, and correctly referenced to the updated clauses of IEC 61439-1:2020 and IEC 61439-2:2020;

b) explanation of the need to special consideration for marine applications added;

c) Figure 201 updated;

d) adjustment has been made to the "safety factors" for creepage and clearance distances.

General Information

- Status

- Published

- Publication Date

- 09-Oct-2025

- Drafting Committee

- MT 6 - TC 18/MT 6

- Current Stage

- PPUB - Publication issued

- Start Date

- 10-Oct-2025

- Completion Date

- 31-Oct-2025

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60092-302-2:2025 is the International Electrotechnical Commission (IEC) standard that defines specific requirements for low-voltage marine power switchgear and controlgear assemblies (MPSC‑assemblies) used on ships. It applies to stationary enclosures with rated voltages up to 1 000 V AC or 1 500 V DC and covers assemblies for power generation, distribution, conversion and the control of electrical loads. This second edition (2025) updates the 2019 edition and introduces technical revisions aligned with the latest IEC 61439 series.

Key topics and requirements

- Scope and definitions: Clarifies terms such as main switchboard, emergency switchboard, motor control centre (MCC) and distribution board specific to marine use.

- Marine-specific safety factors: Additional safety margins (for example, on clearance and creepage distances) are required because of the high consequences of power loss at sea.

- Design and constructional requirements: Covers service conditions, enclosure design, interface characteristics, and constructional practices for shipboard switchgear.

- Performance and verification: Includes requirements for performance, design verification, routine verification and temperature-rise limits; short-circuit verification checklists are provided.

- Electromagnetic compatibility (EMC): Annex J addresses EMC considerations specific to ships with metallic hulls.

- Information and documentation: Specifies information to be supplied by manufacturers and items subject to agreement between manufacturer and user (Annex AAA).

- Manufacturing flexibility: Applies to one-off custom assemblies and standardized production, and allows manufacture/assembly by parties other than the original manufacturer.

- Exclusions: Does not apply to individual devices and self-contained components (e.g., motor starters, fuse switches, electronic devices) covered by their relevant product standards (such as IEC 60947).

Practical applications

IEC 60092-302-2:2025 is directly used to specify, design, test and procure shipboard low-voltage switchgear systems, including:

- Main and emergency switchboards on commercial and offshore vessels

- Motor control centres for propulsion or auxiliary systems

- Distribution boards feeding ship services and critical safety loads

- Panels associated with power conversion and distribution on ships and mobile offshore units

Who should use this standard

- Marine electrical engineers and ship designers

- Switchgear and controlgear manufacturers and assemblers

- Shipbuilders, shipowners and fleet managers

- Classification societies and surveyors

- Procurement and compliance teams specifying shipboard electrical systems

Related standards

- IEC 61439-1:2020 and IEC 61439-2:2020 (low-voltage switchgear and controlgear assemblies - general rules and power assemblies)

- IEC 60092 series (electrical installations in ships)

- IEC 60533 (EMC for shipboard installations)

- IEC 60947 series (individual switching devices)

Keywords: IEC 60092-302-2:2025, marine power, MPSC-assembly, low voltage switchgear, ships, clearance, creepage, IEC 61439, main switchboard, emergency switchboard, motor control centre.

Buy Documents

IEC 60092-302-2:2025 - Electrical installations in ships - Part 302-2: Low voltage switchgear and controlgear assemblies - Marine power

IEC 60092-302-2:2025 RLV - Electrical installations in ships - Part 302-2: Low voltage switchgear and controlgear assemblies - Marine power Released:10/10/2025

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Sponsored listings

Frequently Asked Questions

IEC 60092-302-2:2025 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electrical installations in ships - Part 302-2: Low voltage switchgear and controlgear assemblies - Marine power". This standard covers: IEC 60092-302-2:2025 defines the specific requirements of low voltage marine power switchgear and controlgear assemblies (mpsc-assemblies) as follows: - stationary assemblies with enclosure for which the rated voltage does not exceed 1 000 V AC or 1500 V DC; - assemblies intended for use in conjunction with the power generation, distribution and conversion of electric energy, and for the control of electric energy consuming equipment. Due to the marine application and the risks associated with loss of power, additional safety factors have been applied to minimise the risk of failure, such as applying an additional safety factor on clearance distances. This document applies to all assemblies whether they are designed, manufactured and verified on a one-off basis or fully standardised and manufactured in quantity. Either the manufacture or assembly, or both, of the MPSC assembly can be carried out by others than the original manufacturer. This document does not apply to individual devices and self-contained components, such as motor starters, fuse switches, electronic equipment, which comply with the relevant product standards. This second edition cancels and replaces the first edition published in 2019. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) amended and updated in line with, and correctly referenced to the updated clauses of IEC 61439-1:2020 and IEC 61439-2:2020; b) explanation of the need to special consideration for marine applications added; c) Figure 201 updated; d) adjustment has been made to the "safety factors" for creepage and clearance distances.

IEC 60092-302-2:2025 defines the specific requirements of low voltage marine power switchgear and controlgear assemblies (mpsc-assemblies) as follows: - stationary assemblies with enclosure for which the rated voltage does not exceed 1 000 V AC or 1500 V DC; - assemblies intended for use in conjunction with the power generation, distribution and conversion of electric energy, and for the control of electric energy consuming equipment. Due to the marine application and the risks associated with loss of power, additional safety factors have been applied to minimise the risk of failure, such as applying an additional safety factor on clearance distances. This document applies to all assemblies whether they are designed, manufactured and verified on a one-off basis or fully standardised and manufactured in quantity. Either the manufacture or assembly, or both, of the MPSC assembly can be carried out by others than the original manufacturer. This document does not apply to individual devices and self-contained components, such as motor starters, fuse switches, electronic equipment, which comply with the relevant product standards. This second edition cancels and replaces the first edition published in 2019. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) amended and updated in line with, and correctly referenced to the updated clauses of IEC 61439-1:2020 and IEC 61439-2:2020; b) explanation of the need to special consideration for marine applications added; c) Figure 201 updated; d) adjustment has been made to the "safety factors" for creepage and clearance distances.

IEC 60092-302-2:2025 is classified under the following ICS (International Classification for Standards) categories: 47.020.60 - Electrical equipment of ships and of marine structures. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60092-302-2:2025 has the following relationships with other standards: It is inter standard links to IEC 60092-302-2:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60092-302-2:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60092-302-2 ®

Edition 2.0 2025-10

INTERNATIONAL

STANDARD

Electrical installations in ships -

Part 302-2: Low voltage switchgear and controlgear assemblies - Marine power

ICS 47.020.60 ISBN 978-2-8327-0744-9

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or

by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either

IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC copyright

or have an enquiry about obtaining additional rights to this publication, please contact the address below or your local

IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Discover our powerful search engine and read freely all the

The advanced search enables to find IEC publications by a publications previews, graphical symbols and the glossary.

variety of criteria (reference number, text, technical With a subscription you will always have access to up to date

committee, …). It also gives information on projects, content tailored to your needs.

replaced and withdrawn publications.

Electropedia - www.electropedia.org

The world's leading online dictionary on electrotechnology,

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published containing more than 22 500 terminological entries in English

details all new publications released. Available online and and French, with equivalent terms in 25 additional languages.

once a month by email. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer

Service Centre: sales@iec.ch.

CONTENTS

FOREWORD . 2

INTRODUCTION . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Symbols and abbreviations . 6

5 Interface characteristics . 7

6 Information . 7

7 Service conditions . 8

8 Constructional requirements . 8

9 Performance requirements . 11

10 Design verification . 11

11 Routine verification . 12

Annexes . 17

Annex J – Electromagnetic compatibility (EMC) . 17

Annex AAA (informative) Items subject to agreement between the assembly

manufacturer and the user . 18

Bibliography . 23

Figure 201 – Relationship of standards . 4

Table 1 – Minimum clearances in air (8.3.2) . 13

Table 2 – Minimum creepage distances for marine applications main and emergency

switchboards (8.3.3) . 13

Table 201 – Earth continuity of doors, lids or similar . 14

Table 6 – Temperature-rise limits (9.2) . 15

Table 13 – Short-circuit verification by comparison with reference design: check list

(IEC 61439-1:2020, 10.5.3.3, 10.11.3 and 10.11.4) . 16

Table 15 – Climatic conditions . 16

Table AAA.1 – Items subject to agreement between the assembly manufacturer and

the user . 18

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

Electrical installations in ships -

Part 302-2: Low voltage switchgear and controlgear assemblies -

Marine power

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC 60092-302-2 has been prepared by IEC technical committee 18: Electrical installations of

ships and of mobile and fixed offshore units. It is an International Standard.

This second edition cancels and replaces the first edition published in 2019. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) amended and updated in line with, and correctly referenced to the updated clauses of IEC

61439-1:2020 and IEC 61439-2:2020;

b) explanation of the need to special consideration for marine applications added;

c) Figure 201 updated;

d) adjustment has been made to the "safety factors" for creepage and clearance distances.

The text of this International Standard is based on the following documents:

Draft Report on voting

18/1994/FDIS 18/2007/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

This International Standard is to be used in conjunction with IEC 61439-1:2020 and

IEC 61439-2:2020.

This document supplements or modifies the corresponding clauses in IEC 61439-1:2020 and

IEC 61439-2:2020. Where this document states "addition", "deletion", "replacement" or

“amendment”, the relevant text of IEC 61439-1:2020 and IEC 61439-2:2020 is adapted

accordingly. When no modification of the text of IEC 61439-1:2020 is in IEC 61439-2:2020, the

modification in this document is referred directly to the IEC 61439-1:2020.

Clauses and subclauses which are additional to those of IEC 61439-1:2020 and

IEC 61439-2:2020 are numbered starting from 201. Additional annexes are numbered starting

from AAA.

In this document, terms written in small capitals are defined in Clause 3.

Where the abbreviated term PSC-assembly is used in applicable clauses of IEC 61439-2:2020,

this refers to MPSC-assembly.

A list of all parts in the IEC 60092 series, published under the general title Electrical

installations in ships, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

– reconfirmed,

– withdrawn, or

– revised.

INTRODUCTION

This part of IEC 60092 forms a series of International Standards for electrical installations in

sea-going ships, incorporating good practice and coordinating, as far as possible, existing rules.

These standards form a code of practical interpretation and amplification of the requirements

of the International Convention for the Safety of Life at Sea, a guide for future regulations which

can be prepared and a statement of practice for use by ship owners, shipbuilders and

appropriate organizations.

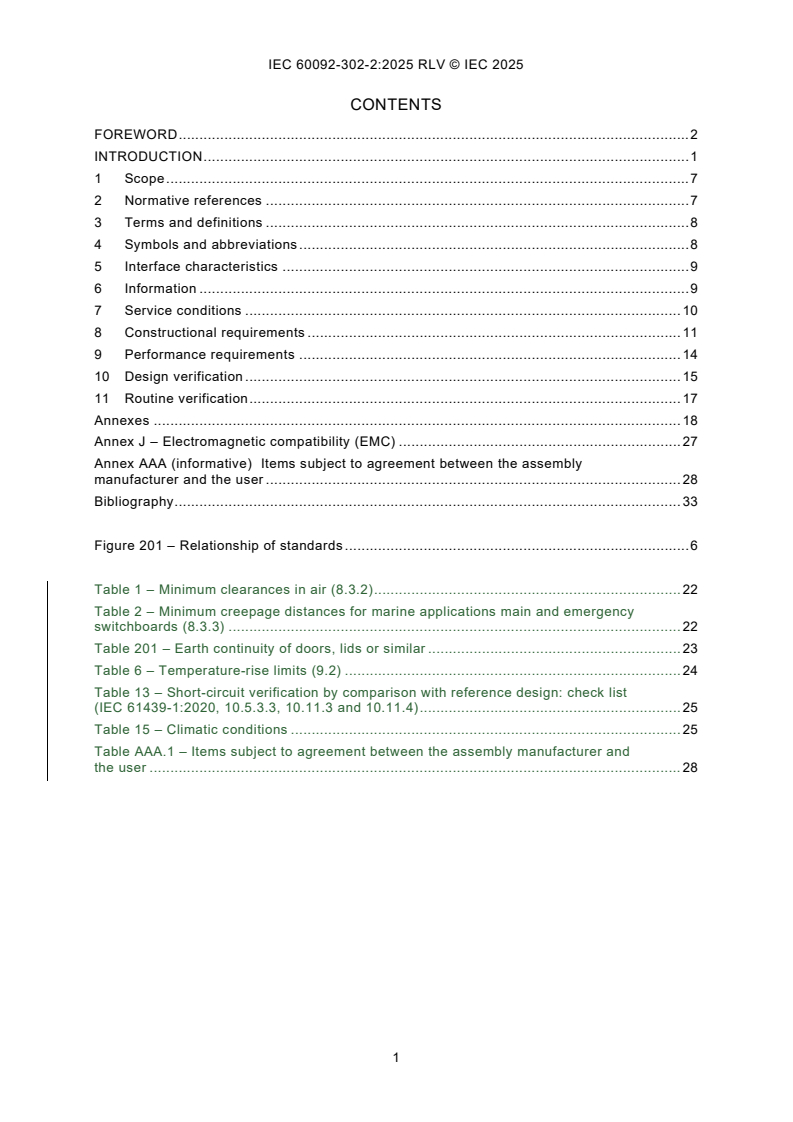

The IEC 61439 series specifies the requirements for land based low voltage switchgear and

controlgear assemblies. The IEC 60092-302 series has been developed in line with Figure 201,

which illustrates opportunities to develop relevant marine standards.

The IEC 60092 series remains the principal series of standards for electrical installations in

ships, and the applicable standards are applied accordingly. Wherever there are differences

between the IEC 61439 series and the IEC 60092 series, the IEC 60092 series takes

precedence.

Figure 201 – Relationship of standards

1 Scope

This part of IEC 60092 defines the specific requirements of low voltage marine power

switchgear and controlgear assemblies (MPSC-assemblies) as follows:

– stationary assemblies with enclosure for which the rated voltage does not exceed

1 000 V AC or 1500 V DC;

– assemblies intended for use in conjunction with the power generation, distribution and

conversion of electric energy, and for the control of electric energy consuming equipment.

Due to the marine application and the risks associated with loss of power, additional safety

factors have been applied to minimise the risk of failure, such as applying an additional safety

factor on clearance distances.

This document applies to all assemblies whether they are designed, manufactured and verified

on a one-off basis or fully standardised and manufactured in quantity.

Either the manufacture or assembly, or both, of the MPSC assembly can be carried out by

others than the original manufacturer.

This document does not apply to individual devices and self-contained components, such as

motor starters, fuse switches, electronic equipment, which comply with the relevant product

standards.

NOTE Individual devices and components include those that are covered by the IEC 60947 series.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60092 (all parts), Electrical installations in ships

IEC 60092-101:2018, Electrical installations in ships - Part 101: Definitions and general

requirements

IEC 60092-201:2019, Electrical installations in ships - Part 201: System design - General

IEC 60533, Electrical and electronic installations in ships - Electromagnetic compatibility (EMC)

- Ships with a metallic hull

IEC 61439-1:2020, Low-voltage switchgear and controlgear assemblies - Part 1: General rules

IEC 61439-2:2020, Low-voltage switchgear and controlgear assemblies - Part 2: Power

switchgear and controlgear assemblies

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

– IEC Electropedia: available at http://www.electropedia.org/

– ISO Online browsing platform: available at http://www.iso.org/obp

Clause 3 of IEC 61439-2:2020 is applicable except as follows.

3.1 General terms

Additional terms and definitions:

3.1.201

marine power switchgear and controlgear assembly

MPSC-assembly

low-voltage switchgear and controlgear assembly used to distribute and control energy for all

types of loads, intended specifically for marine applications on ships, operated by skilled or

instructed persons only

Note 1 to entry: It is not excluded for a MPSC-assembly to be located in an area accessible to ordinary persons.

3.1.202

main switchboard

MPSC-assembly which is directly supplied by the main source of electrical power and is intended

to control and distribute electrical energy to the ship's services

3.1.203

motor control centre

MCC

MPSC-assembly which is supplied by main or emergency switchboards and is intended to control

and distribute electrical energy

Note 1 to entry: It is possible for the MCC to be a section or sections of the main switchboard.

3.1.204

emergency switchboard

MPSC-assembly which is normally supplied by the main switchboard but, in the event of failure

of the main electrical power system, is directly supplied by the emergency source of electrical

power and is intended to control and distribute electrical energy to the emergency services

3.1.205

distribution board

MPSC-assembly which is supplied by a main or emergency switchboard, or distribution boards

and is used to distribute and control energy to other distribution boards, final distribution boards

or final sub circuits

4 Symbols and abbreviations

Clause 4 of IEC 61439-2:2020 is applicable.

5 Interface characteristics

IEC 61439-2:2020, Clause 5, is applicable except as follows.

5.2 Voltage ratings

5.2.3 Rated insulation voltage (U ) (of a circuit of an assembly)

i

Replacement of IEC 61439-1:2020, 5.2.3:

The rated insulation voltage of a circuit of an assembly is the voltage value to which dielectric

test voltages and creepage distances are referred.

Due to the criticality of power availability for main and emergency switchboards, a multiplication

factor of 1,5 times has been applied for required creepage distances (see Table 2 where the

factor is applied). For single-phase circuits derived from IT systems (see IEC 60364-5-52), the

rated insulation voltage should be at least equal to the voltage between phases of the supply.

While it is advisable to use the above safety factor for all internal components and devices, it

is not a requirement for those that have been tested in accordance with their own product

standard to have this safety factor applied.

NOTE A safety factor has intentionally not been applied to the dielectric test voltage requirements to maintain

compatibility with product standards.

5.5 Rated frequency (f )

n

Replacement of the second paragraph of IEC 61439-1:2020, 5.5:

The frequency should be within the limits specified in IEC 60092-101 for the incorporated

components. The tolerance shall be within 95 % and 105 % of the rated frequency.

6 Information

IEC 61439-2:2020, Clause 6, is applicable except as follows.

6.1 Assembly designation marking

Replacement of IEC 61439-1:2020, 6.1, item d):

d) IEC 60092-302-2;

Addition of item h):

h) ambient air temperature (see 7.1.1 and 7.1.2).

6.3 Device and/or component identification

Addition to IEC 61439-1:2020, 6.3:

Individual circuits and their devices shall have the following durable and permanent markings

and meet the requirements of IEC 60092-201:2019, 5.3:

a) rated current of the circuit I and assigned settings of adjustable protective devices (see

nc

IEC 61439-1:2020, 6.2.2, for documentation of settings requirements);

b) when, for fuse systems above 500 V, the fuseholders permit the insertion of fuse links for

lower rated voltage, special warning labels or symbols, for example "Caution 690 V fuse

links only".

c) arranging warning labels where polarized circuit-breakers are installed in DC systems to

guard against the possibility of incorrect connections during maintenance or replacement;

d) permanent markings on withdrawable and/or removable parts along with relevant fixed parts

of an assembly in order to identify where the parts can be correctly reassembled.

Compliance is checked according to the test of IEC 61439-1 2020, 10.2.7, and by inspection.

7 Service conditions

IEC 61439-1:2020, Clause 7, is applicable except as follows.

7.1 Normal service conditions

7.1.1 Climate conditions

Amendment, in the first paragraph:

Table 15 of this document applies.

7.1.2 Pollution degree

Addition to IEC 61439-1:2020, 7.1.2:

For ships, pollution degree 3 is applicable. If lower pollution degree is required, this has to be

proven by evidence.

Additional subclauses to IEC 61439-1:2020, 7.1:

7.1.201 Vibration

MPSC-assemblies shall be unaffected by vibration likely to occur under normal service. Design

parameters of IEC 60092-101:2018, 4.6.3.5, shall apply.

7.1.202 Angular deviation and motion

MPSC-assemblies shall be unaffected by movement of the ship likely to occur under normal

service. Design parameters of IEC 60092-101:2018, 4.6.3.4, shall apply.

8 Constructional requirements

IEC 61439-2:2020, Clause 8, is applicable except as follows.

8.4.2.3 Barriers or enclosures

Replacement of IEC 61439-1:2020, 8.4.2.3, item b):

After isolation of the supply to live parts, against which the barriers or enclosures afford basic

protection, restoration of the supply being possible only after replacement or reclosure of the

barriers or enclosures.

8.4.3 Fault protection

IEC 61439-2:2020, 8.4.3, is applicable except as follows.

8.4.3.2.2 Requirements for earth continuity providing protection against the

consequences of faults within the class I assembly

Addition, under item b):

NOTE The requirements for doors, lids and similar have been organized in Table 201.

Additional subclause:

8.4.3.201 Protection against electric shock for maintenance accessibility

If earth bars (protective conductor) are installed in main or emergency switchboards, MCCs and

distribution boards, the earth bar shall be installed and located to ensure their easy access and

access to their terminations, during and after installation. When switchgear or controlgear are

located behind the doors of the assemblies, live parts shall be protected against inadvertent

touching by means of barriers or enclosure having at least IP2X.

8.4.6.2.3 Requirements related to accessibility for maintenance

Addition to IEC 61439-1:2020, 8.4.6.2.3:

It shall be possible to replace or maintain a device used for isolation of its main source of

electrical power without complete blackout of the ship.

NOTE See IEC 60092-201:2019, Clause 8.

Where polarized circuit breakers are installed in DC systems, and in all other similar cases,

warning labels shall be arranged to guard against the possibility of incorrect connection during

maintenance.

8.5.4 Installation of switching devices and components

Addition to IEC 61439-1:2020, 8.5.4:

Wherever possible, components of main circuits with different nominal voltages shall be

installed separately with internal separation provided for each level of voltage.

8.6.2 Auxiliary circuits

Addition to IEC 61439-1:2020, 8.6.2:

Wiring shall comply with the relevant requirements given in the cable standards within the

IEC 60092 series. Other types of cable or wire may be used if the IEC 60092 series does not

cover this type of cable or wire, provided these meet the applicable IEC product Standards and

are suitable for marine application.

8.6.3 Bare and insulated conductors

Addition to IEC 61439-1:2020, 8.6.3:

Cables shall comply with the relevant requirements given in the cable standards within the

IEC 60092 series. Other types of cable or wire may be used if the IEC 60092 series does not

cover this type of cable or wire, provided these meet the applicable IEC product Standards and

are suitable for marine application.

Additional subclauses to IEC 61439-1:2020, 8.6.3:

8.6.3.201 Busbars

8.6.3.201.1 General

Busbars shall be of a composition suited for operation in a salt-laden atmosphere.

EXAMPLE Electrolytic copper or copper-clad aluminium.

8.6.3.201.2 Sub-division of main switchboard main busbar

The MPSC-assembly shall meet the specific requirement of the system as detailed in

IEC 60092-201:2019, Clause 8.

Where there is a functional requirement for more than one incoming device within the assembly,

the main busbars of the assembly shall be subdivided into at least two isolated parts; this is to

be done by an appropriate isolation device such as a multipole switch disconnector or circuit

breaker.

8.6.3.201.3 Busbar phase or polarity arrangements

Where practicable, the following standard pattern of busbar phase and polarity arrangements

shall be used.

a) For AC MPSC-assemblies, busbar L1, L2, L3 shall be counted from front to rear, top to bottom

or left to right (when viewed from the front of the switchgear assembly).

b) Polarities on DC switchgear and controlgear busbars and connections shall be positive,

neutral and negative, counting from front to rear, top to bottom or left to right.

8.101 Internal separation of PSC-assemblies

Addition after the first paragraph:

Incoming and section interconnection devices and any circuit with I above 600 A used within

nc

main and emergency switchboards shall be contained in their own compartment providing at

least a degree of protection of IP XXB.

Deletion of Note 2.

Additional subclauses:

8.201 Constructional requirements for marine applications

8.201.1 Structural parts of aluminium alloy

If aluminium alloy is used in construction, the material shall be suitable for the use in the marine

environment. Measures shall be taken to avoid galvanic corrosion, especially where in contact

with other materials.

8.201.2 Handrails or handles

Every main or emergency switchboard, MCC and distribution board required for essential and

emergency services shall be provided with an insulated handrail or insulated handles to enable

these assemblies to be operated safely during the vessels possible motion. These should be

suitably located on a fixed part on the front of the assemblies. Where access to the rear of the

above-mentioned switchboards is necessary for operational, maintenance, or similar purposes,

an insulated handrail or insulated handles should be suitably located on a fixed part of the

assembly.

8.201.3 Door latching

Hinged doors which require to be opened for operation, maintenance or similar purposes shall

be provided with a latching or locking facility to keep the door open during normal movement of

the ship.

9 Performance requirements

IEC 61439-2:2020, Clause 9, is applicable except as follows.

9.1.3.1 Impulse withstand voltages of main circuits

Addition at the end of IEC 61439-1:2020, 9.1.3.1:

The rated impulse withstand voltage for a given rated operational voltage shall not be less than

that corresponding in IEC 61439-1:2020, Annex G, to the nominal voltage of the supply system

of the circuit at the point where the assembly is to be used and with the overvoltage category III.

9.2 Temperature-rise limits

Addition at the end of IEC 61439-1:2020, 9.2:

The temperature-rise

...

IEC 60092-302-2 ®

Edition 2.0 2025-10

INTERNATIONAL

STANDARD

REDLINE VERSION

Electrical installations in ships -

Part 302-2: Low voltage switchgear and controlgear assemblies - Marine power

ICS 47.020.60 ISBN 978-2-8327-0780-7

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or

by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either

IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC copyright

or have an enquiry about obtaining additional rights to this publication, please contact the address below or your local

IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Discover our powerful search engine and read freely all the

The advanced search enables to find IEC publications by a publications previews, graphical symbols and the glossary.

variety of criteria (reference number, text, technical With a subscription you will always have access to up to date

committee, …). It also gives information on projects, content tailored to your needs.

replaced and withdrawn publications.

Electropedia - www.electropedia.org

The world's leading online dictionary on electrotechnology,

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published containing more than 22 500 terminological entries in English

details all new publications released. Available online and and French, with equivalent terms in 25 additional languages.

once a month by email. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer

Service Centre: sales@iec.ch.

CONTENTS

FOREWORD . 2

INTRODUCTION . 1

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Symbols and abbreviations . 8

5 Interface characteristics . 9

6 Information . 9

7 Service conditions . 10

8 Constructional requirements . 11

9 Performance requirements . 14

10 Design verification . 15

11 Routine verification . 17

Annexes . 18

Annex J – Electromagnetic compatibility (EMC) . 27

Annex AAA (informative) Items subject to agreement between the assembly

manufacturer and the user . 28

Bibliography . 33

Figure 201 – Relationship of standards . 6

Table 1 – Minimum clearances in air (8.3.2) . 22

Table 2 – Minimum creepage distances for marine applications main and emergency

switchboards (8.3.3) . 22

Table 201 – Earth continuity of doors, lids or similar . 23

Table 6 – Temperature-rise limits (9.2) . 24

Table 13 – Short-circuit verification by comparison with reference design: check list

(IEC 61439-1:2020, 10.5.3.3, 10.11.3 and 10.11.4) . 25

Table 15 – Climatic conditions . 25

Table AAA.1 – Items subject to agreement between the assembly manufacturer and

the user . 28

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

Electrical installations in ships -

Part 302-2: Low voltage switchgear and controlgear assemblies -

Marine power

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes made

to the previous edition IEC 60092-302-2:2019. A vertical bar appears in the margin wherever a

change has been made. Additions are in green text, deletions are in strikethrough red text.

IEC 60092-302-2 has been prepared by IEC technical committee 18: Electrical installations of

ships and of mobile and fixed offshore units. It is an International Standard.

This second edition cancels and replaces the first edition published in 2019. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) amended and updated in line with, and correctly referenced to the updated clauses of IEC

61439-1:2020 and IEC 61439-2:2020;

b) explanation of the need to special consideration for marine applications added;

c) Figure 201 updated;

d) adjustment has been made to the "safety factors" for creepage and clearance distances.

The text of this International Standard is based on the following documents:

Draft Report on voting

18/1994/FDIS 18/2007/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

This International Standard is to be used in conjunction with IEC 61439-1:2020 and

IEC 61439-2:2020.

This document supplements or modifies the corresponding clauses in IEC 61439-1:2020 and

IEC 61439-2:2020. Where this document states "addition", "deletion", "replacement" or

“amendment”, the relevant text of IEC 61439-1:2020 and IEC 61439-2:2020 is adapted

accordingly. When no modification of the text of IEC 61439-1:2020 is in IEC 61439-2:2020, the

modification in this document is referred directly to the IEC 61439-1:2020.

Clauses and subclauses which are additional to those of IEC 61439-1:2020 and

IEC 61439-2:2020 are numbered starting from 201. Additional annexes are numbered starting

from AAA.

In this document, terms written in small capitals are defined in Clause 3.

Where the abbreviated term PSC-assembly is used in applicable clauses of IEC 61439-2:2020,

this refers to MPSC-assembly.

A list of all parts in the IEC 60092 series, published under the general title Electrical

installations in ships, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

– reconfirmed,

– withdrawn, or

– revised.

INTRODUCTION

This part of IEC 60092 forms a series of International Standards for electrical installations in

sea-going ships, incorporating good practice and coordinating, as far as possible, existing rules.

These standards form a code of practical interpretation and amplification of the requirements

of the International Convention for the Safety of Life at Sea, a guide for future regulations which

may can be prepared and a statement of practice for use by ship owners, shipbuilders and

appropriate organizations.

The IEC 61439 series identifies specifies the requirements for land based low voltage

switchgear and controlgear assemblies. The IEC 60092-302 series has been developed in line

with Figure 201, which shows the future intention to develop appropriate marine standards for

final distribution boards to be operated by ordinary persons; and busbar trunking systems

illustrates opportunities to develop relevant marine standards.

The IEC 60092 series remains the principal series of standards for electrical installations in

ships, and the applicable standards are applied accordingly. Wherever there are differences

between the IEC 61439 series and the IEC 60092 series, the IEC 60092 series takes

precedence.

IEC 61439-1

IEC 61439-2 IEC 61439-3 IEC 61439-4 IEC 61439-5 IEC 61439-6

IEC IEC IEC

60092 302 2

IEC60092 60092

Si

IEC

Key

a

Under consideration.

NOTE At the time of publication, IEC 60092-302-3 and IEC 60092-302-6 are not developed. The figure shows that

these standards are potential future projects to align with the IEC 61439 series.

Figure 201 – Relationship of standards

1 Scope

This part of IEC 60092 defines the specific requirements of low voltage marine power

switchgear and controlgear assemblies (MPSC-assemblies) as follows:

– stationary assemblies with enclosure for which the rated voltage does not exceed

1 000 V AC or 1500 V DC;

– assemblies intended for use in conjunction with the power generation, distribution and

conversion of electric energy, and for the control of electric energy consuming equipment.

Due to the marine application and the risks associated with loss of power, additional safety

factors have been applied to minimise the risk of failure, such as applying an additional safety

factor on clearance distances.

This document applies to all assemblies whether they are designed, manufactured and verified

on a one-off basis or fully standardised and manufactured in quantity.

Either the manufacture and/or assembly, or both, of the MPSC assembly can be carried out by

others than by the original manufacturer.

This document does not apply to individual devices and self-contained components, such as

motor starters, fuse switches, electronic equipment, which comply with the relevant product

standards.

NOTE Individual devices and components include those that are covered by the IEC 60947 series.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60092 (all parts), Electrical installations in ships

IEC 60092-101:2018, Electrical installations in ships - Part 101: Definitions and general

requirements

IEC 60092-201:2019, Electrical installations in ships - Part 201: System design - General

IEC 60533, Electrical and electronic installations in ships - Electromagnetic compatibility (EMC)

- Ships with a metallic hull

IEC 61439-1:20112020, Low-voltage switchgear and controlgear assemblies - Part 1: General

rules

IEC 61439-2:20112020, Low-voltage switchgear and controlgear assemblies - Part 2: Power

switchgear and controlgear assemblies

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

– IEC Electropedia: available at http://www.electropedia.org/

– ISO Online browsing platform: available at http://www.iso.org/obp

Clause 3 of IEC 61439-2:20112020 is applicable except as follows.

3.1 General terms

Additional terms and definitions:

3.1.201

marine power switchgear and controlgear assembly

MPSC-assembly

low-voltage switchgear and controlgear assembly used to distribute and control energy for all

types of loads, intended specifically for marine applications specifically, in on ships, operated

by skilled or instructed persons only

Note 1 to entry: It is not excluded for a MPSC-assembly to be located in an area accessible to ordinary persons.

3.1.202

main switchboard

MPSC-assembly which is directly supplied by the main source of electrical power and is intended

to control and distribute electrical energy to the ship's services

3.1.203

motor control centre

MCC

MPSC-assembly which is supplied by main or emergency switchboards and is intended to control

and distribute electrical energy

Note 1 to entry: It is possible for the MCC to be a section or sections of the main switchboard.

3.1.204

emergency switchboard

MPSC-assembly which is normally supplied by the main switchboard but, in the event of failure

of the main electrical power system, is directly supplied by the emergency source of electrical

power and is intended to control and distribute electrical energy to the emergency services

3.1.205

distribution board

MPSC-assembly which is supplied by a main or emergency switchboard, or distribution boards

and is used to distribute and control energy to other distribution boards, final distribution boards

or final sub circuits

Note 1 to entry: The definition of "section board" as defined in previous versions of IEC 60092-302 has been

replaced by the one of "distribution board".

4 Symbols and abbreviations

Clause 4 of IEC 61439-2:20112020 is applicable.

5 Interface characteristics

IEC 61439-2:20112020, Clause 5, is applicable except as follows.

5.2 Voltage ratings

5.2.3 Rated insulation voltage (U ) (of a circuit of an assembly)

i

Replacement of IEC 61439-1:20112020, 5.2.3:

The rated insulation voltage of a circuit of an assembly is the voltage value to which dielectric

test voltages and creepage distances are referred.

Due to the potential effects of the marine environment on creepage distances, the rated

insulation voltage of a circuit shall be 1,5 times higher than the values stated for U and for U

n e

for the same circuit up to a final maximum of U 1 000 V AC or 1 250 V DC. Any DC application

i

requiring U exceeding 1 250 V DC shall need to have special consideration.

i

Due to the criticality of power availability for main and emergency switchboards, a multiplication

factor of 1,5 times has been applied for required creepage distances (see Table 2 where the

factor is applied). For single-phase circuits derived from IT systems (see IEC 60364-5-52), the

rated insulation voltage should be at least equal to the voltage between phases of the supply.

While it is advisable to use the above safety factor for all internal components and devices, it

is not a requirement for those that have been tested in accordance with their own product

standard need not to have this safety factor applied.

NOTE A safety factor has intentionally not been applied to the dielectric test voltage requirements to maintain

compatibility with product standards.

5.6 Other characteristics

Replacement of item g) of IEC 61439-1:2011:

g) operated by skilled and instructed persons only;

5.5 Rated frequency (f )

n

Replacement of the second paragraph of IEC 61439-1:2020, 5.5:

The frequency should be within the limits specified in IEC 60092-101 for the incorporated

components. The tolerance shall be within 95 % and 105 % of the rated frequency.

6 Information

IEC 61439-2:20112020, Clause 6, is applicable except as follows.

6.1 Assembly designation marking

Replacement of IEC 61439-1:2020, 6.1, item d):

d) IEC 60092-302-2;

Addition of item eh):

eh) ambient air temperature (see 7.1.1.1 and 7.1.1.2).

6.3 Device and/or component identification

Addition to IEC 61439-1:2020, 6.3:

Individual circuits and their devices shall have the following durable and permanent markings

and meet the requirements of IEC 60092-201:2019, 5.3:

a) rated current of the circuit I and assigned settings of adjustable protective devices (see

nc

IEC 61439-1:20112020, 6.2.2, for documentation of settings requirements);

b) when, for fuse systems above 500 V, the fuseholders permit the insertion of fuse links for

lower rated voltage, special warning labels or symbols, for example "Caution 690 V fuse

links only".

c) arranging warning labels where polarized circuit-breakers are installed in DC systems to

guard against the possibility of incorrect connections during maintenance or replacement;

d) permanent markings on withdrawable and/or removable parts along with relevant fixed parts

of an assembly shall be provided with permanent markings in order to identify where the

parts can be correctly reassembled.

Compliance is checked according to the test of IEC 61439-1:20112020, 10.2.7, and by

inspection.

7 Service conditions

IEC 61439-1:20112020, Clause 7, is applicable except as follows.

7.1.1.1 Ambient air temperature for indoor installations

Replacement:

The ambient air temperature does not exceed +45 °C, and its average over a period of 24 h

does not exceed +40 °C.

The lower limit of the ambient air temperature is 5 °C.

NOTE Where the ambient air temperature of the assembly is different, details of calculation methods are given in

10.10.3.201.

7.1.1.2 Ambient air temperature for outdoor installations

Replacement:

The ambient air temperature does not exceed +45 °C, and its average over a period of 24 h

does not exceed +40 °C.

The lower limit of the ambient air temperature is –25 °C.

NOTE Where the ambient air temperature of the assembly is different, details of calculation methods are given in

10.10.3.201.

7.1.2.1 Humidity conditions for indoor installations

Replacement:

In other parts of the IEC 60092 series, where no "high air temperature" has been specified as

a design parameter for equipment, the relative humidity of the air does not exceed 95 % at a

maximum temperature of +45 °C.

Moderate condensation should be borne in mind which can occasionally occur due to variations

in temperature.

7.1 Normal service conditions

7.1.1 Climate conditions

Amendment, in the first paragraph:

Table 15 of this document applies.

7.1.2 Pollution degree

Addition to IEC 61439-1:2020, 7.1.2:

For ships, pollution degree 3 is applicable. If lower pollution degree is required, this has to be

proven by evidence.

Additional subclauses to IEC 61439-1:2020, 7.1:

7.1.201 Vibration

MPSC-assemblies shall be unaffected by vibration likely to occur under normal service. Design

parameters are detailed in 4.6.3.5 of IEC 60092-101:2018, 4.6.3.5, shall apply.

7.1.202 Angular deviation and motion

MPSC-assemblies shall be unaffected by movement of the ship likely to occur under normal

service. Design parameters are detailed in 4.6.3.4 of IEC 60092-101:2018, 4.6.3.4, shall apply.

8 Constructional requirements

IEC 61439-2:20112020, Clause 8, is applicable except as follows.

8.2.2 Protection against contact with live parts, ingress of solid foreign bodies and

water

Deletion of Note 1 in 8.2.2 of IEC 61439-1:2011.

8.3.2 Clearances

Deletion of the note in 8.3.2 of IEC 61439-1:2011.

8.3.3 Creepage distances

Replacement of the third paragraph in 8.3.3 of IEC 61439-1:2011:

Creepage distances shall correspond to a pollution degree as specified in 7.1.3 and to the

corresponding material group at the rated insulation voltage given in Table 2. Devices that have

been tested in accordance with their own product standard need not have this safety factor

applied.

Deletion of Note 2 in 8.3.3 of IEC 61439-1:2011.

8.4.2.3 Barriers or enclosures

Replacement of IEC 61439-1:2020, 8.4.2.3, item b):

After isolation of the supply to live parts, against which the barriers or enclosures afford basic

protection, restoration of the supply being possible only after replacement or reclosure of the

barriers or enclosures.

8.4.3 Fault protection

8.4.3 of IEC 61439-1:2011 is applicable except as follows.

IEC 61439-2:2020, 8.4.3, is applicable except as follows.

8.4.3.2.2 Requirements for earth continuity providing protection against the

consequences of faults within the class I assembly

Addition, under item b):

NOTE The requirements for doors, lids and similar have been organized in Table 201.

Additional paragraph subclause:

8.4.3.201 Protection against electric shock for maintenance accessibility maintenance

If earth bars (protective conductor) are installed in main and or emergency switchboards, MCCs

and distribution boards, the earth bar shall be installed and located to ensure their easy access

and access to their terminations, during and after installation. When switchgear or controlgear

are located behind the doors of the assemblies, live parts shall be protected against inadvertent

touching by means of barriers or enclosure having at least IP2X.

8.4.6 Operating and servicing conditions

8.4.6 of IEC 61439-1:2011 is applicable except as follows.

8.4.6.2.3 Requirements related to accessibility for maintenance

Addition to IEC 61439-1:2020, 8.4.6.2.3:

It shall be possible to replace or maintain all devices a device used for isolation of the its main

source of electrical power without complete blackout of the main source of electrical power ship.

NOTE See IEC 60092-201:2019, Clause 8.

Where polarized circuit breakers are installed in DC systems, and in all other similar cases,

warning labels shall be arranged to guard against the possibility of incorrect connection during

maintenance.

8.5 Incorporation of switching devices and components

8.5 of IEC 61439-1:2011 is applicable except as follows.

8.5.4 Installation of switching devices and components

Addition to IEC 61439-1:2020, 8.5.4:

Wherever possible, components of main circuits with different nominal voltages shall be

installed separate from each other separately with internal separation provided for each level

of voltage.

8.6 Internal electrical circuits and connections

8.6 of IEC 61439-1:2011 is applicable except as follows.

8.6.2 Auxiliary circuits

Addition to IEC 61439-1:2020, 8.6.2:

Wiring shall comply with the relevant requirements given in the cable standards within the

IEC 60092 series. Other types of cable or wire may be used if the IEC 60092 series does not

cover this type of cable or wire, provided these meet the applicable IEC product Standards and

are suitable for marine application.

8.6.3 Bare and insulated conductors

Addition to IEC 61439-1:2020, 8.6.3:

Cables shall comply with the relevant requirements given in the cable standards within the

IEC 60092 series. Other types of cable or wire may be used if the IEC 60092 series does not

cover this type of cable or wire, provided these meet the applicable IEC product Standards and

are suitable for marine application.

Additional subclauses to IEC 61439-1:2020, 8.6.3:

8.6.3.201 Busbars

8.6.3.201.1 General

Busbars shall be of a composition suited for operation in a salt-laden atmosphere.

EXAMPLE Electrolytic copper or copper-clad aluminium.

8.6.3.201.2 Sub-division of main switchboard main busbar

The MPSC-assembly shall meet the specific requirement of the system as detailed in

IEC 60092-201:2019, Clause 8.

Where there is a functional requirement for more than one incoming device within the assembly,

the main busbars of the assembly shall be subdivided into at least two isolated parts; this is to

be done by an appropriate isolation device such as a multipole switch disconnector or circuit

breaker.

8.6.3.201.3 Busbar phase or polarity arrangements

Where practicable, a the following standard pattern of busbar phase and polarity arrangements

shall be used. Examples for such a pattern as viewed from the front of the assembly are as

follows:

a) For AC MPSC-assemblies, busbar L1, L2, L3. counting shall be counted from front to rear,

top to bottom or left to right (when viewed from the front of the switchgear assembly).

b) Polarities on DC switchgear and controlgear busbars and connections to shall be positive,

neutral and negative, counting from front to rear, top to bottom or left to right.

8.8 Terminals for external conductors

Deletion of Note 1 of IEC 61439-1:2011.

8.101 Internal separation of PSC-assemblies

8.101 of IEC 61439-2:2011 is applicable except as follows.

Addition after the second first paragraph:

Incoming and section interconnection devices and any circuit with I above 600 A used within

nc

main and emergency switchboards shall be contained in their own compartment providing at

least a degree of protection of IP XXB.

Replacement of Note 1:

NOTE 1 The degree of protection IP 2X covers the degree of protection IP XXB.

Deletion of Note 2.

Additional subclauses:

8.201 Constructional requirements for marine applications

8.201.1 Structural parts of aluminium alloy

If aluminium alloy is used in construction, the material shall be suitable for the use in the marine

environment, and precautions. Measures shall be taken to avoid galvanic corrosion, especially

where in contact with other materials.

8.201.2 Handrails or handles

Every main or emergency switchboard, MCC and distribution board required for essential and

emergency services shall be provided with an insulated handrail or insulated handles to enable

these assemblies to be operated safely during the vessels possible motion. These should be

suitably located on a fixed part on the front of the assemblies. Where access to the rear of the

above-mentioned switchboards is necessary for operational, maintenance, or similar purposes,

an insulated handrail or insulated handles should be suitably located on a fixed part of the

assembly.

8.201.3 Door latching

Hinged doors which may require to be opened for operation, maintenance or similar purposes

shall be provided with a latching or locking facility to keep the door open during normal

movement of the ship.

9 Performance requirements

IEC 61439-2:20112020, Clause 9, is applicable except as follows.

9.1.3.1 Impulse withstand voltages of main circuits

Addition at the end of IEC 61439-1:20112020, 9.1.3.1:

The rated impulse withstand voltage for a given rated operational voltage shall not be less than

that corresponding in IEC 61439-1:2020, Annex G, to the nominal voltage of the supply system

of the circuit at the point where the assembly is to be used and with the overvoltage category III.

9.2 Temperature-rise limits

Delete Note 2 of IEC 61439-1:2011.

Addition at the end of IEC 61439-1:20112020, 9.2:

The temperature-rise limits given in Table 6 of this document apply for a mean ambient daily

average air temperature up to 40 °C. MPSC-assemblies are required to operate in a higher

ambient temperature under service conditions (see 7.1) (see Table 15 of this document). A

reduction of the permissible rises shown to reflect the raised ambient should be made. During

verification, a different ambient air temperature is permissible (see IEC 61439-1:2020,

10.10.2.3.4).

NOTE For environments exceeding 40 °C, additional cooling devices such as fans or air conditioning can be

considered to ensure safe operation of the equipment.

10 Design verification

Clause 10 of IEC 61439-1:2011 is applicable with the following additions.

10.10.2.3.1 General

Addition:

To reduce the testing required to determine the rated current of a circuit I at the maximum

permissible temperature rise ∆T , the current rating may be calculated from the actual test

current I if the measured temperature rise ∆T of the current carrying parts (e.g. busbars and

2 2

terminals) deviates from the permissible value by not more than ±5 K, using the following

formula :

0.61

I ∆T

1 1

=

I ∆T

2 2

where

I is the current at which the temperature rise test is carried out;

I is the current rating to be determined at the specific ambient air temperature between

20 °C and 55 °C;

∆T is the temperature rise measured by test with a current of I ;

1 1

∆T is the maximum permissible temperature rise at the specific ambient air temperature

between 20 °C and 55 °C.

NOTE The formula can only be applied if the power loss of the devices and conductors is substantially proportional

to I .

Care shall be taken to ensure that all other measurement points will not reach their maximum

temperature at this higher current. The most critical location of highest temperature point shall

be identified either by test or thermal simulation.

Care is required when determining the number of points where this calculation is applied so as

to ensure the effects of changing several currents having an influence on other measuring

points (including internal air temperature) due to the changed power loss.

___________

Formula reproduced from Copper Development Association, Publication No. 22:1996, with the permission of

Copper Development Association Inc.

10.10.3.5 Functional units – Device substitution

Replacement of 10.10.3.5 of IEC 61439-1:2011, including its title

10.10.3.5 Functional units – Temperature-rise considerations for device substitution

A device within a circuit may be substituted with a similar device from another series from the

same or a different device manufacturer to that used in the original verification, provided that

the power loss and terminal temperature rise of the substituting device is the same or lower

than the device used in the original verification, when both are tested in accordance with the

devices' product standard.

Alternatively, the substitution is possible if the following conditions are met.

a) The temperature rise at the terminals of the original device, when tested in the assembly,

is at least 10 K below the limit permitted by the assembly standard.

a) The substituting device has a temperature rise limit on the terminals declared by the

manufacturer of the substituting device, no less than the temperature rise limit on the

terminals declared by the manufacturer of the original device. If there is no declared

temperature rise limit, the default temperature rise limit is that permitted by the device

standard.

b) The power loss of the substituting device does not exceed that of the original device.

Alternatively, when the original device and the substituted device are from the same device

manufacturer, the device manufacturer may issue a declaration of temperature rise

performance. The declaration shall confirm that the substituting device can replace the original

device with no further need for verification in respect of temperature rise.

In addition, for each of the above options, the physical arrangement within the functional unit

shall be maintained. The rating of a functional unit shall not be increased. The physical

arrangements shall include terminal shields, conductor type, material, and connection sizes,

mounting orientation, clearances to other parts, ventilation arrangements and terminal

arrangement.

The performance data on terminal temperatures and power loss may be obtained from the

device manufacturer or from comparison tests undertaken by those responsible for the

substitution. Any test shall be conducted on new samples.

Refer to Table D.1 for other design characteristics, including short-circuit withstand, that require

consideration when substituting devices.

10.1 General

Replacement of the eleventh paragraph, beginning with "The performance of the assembly" of

IEC 61439-1:2020, 10.1:

It is possible that the assembly is affected by the verification tests (e.g. short-circuit test). In

normal circumstances, these tests should not be performed on an assembly that is intended to

be placed in service. However, if the assembly is intended to be put in service, extensive checks

shall be conducted to determine if no detrimental consequences have occurred due to the test.

If these have occurred, the affected part shall be replaced.

NOTE For small series, it is not feasible to build an additional switchboard only for testing purposes.

10.9.3.5 Verification assessment

Replacement of IEC 61439-1:2020, 10.9.3.5:

Clearances shall be verified by measurement, or verification of measurements on design

drawings, employing the measurement methods stated in IEC 61439-1:2020, Annex F. The

clearances shall be at least the values specified in Table 1.

It shall be verified by assessment of the device manufacturer's data that all incorporated devices

are suitable for the specified rated impulse withstand voltage (U ).

imp

10.10.3.20110.10.3.6 Calculation of currents based on adjustment of ambient air

temperature

Replacement of IEC 61439-1:2020, 10.10.3.6:

To facilitate the probable variation of locations of an assembly in the vessel, the following

methodology may can be used the to adjust the rated current of the assembly. Once a

temperature rise test has been carried out applying the temperature rise limits for a daily

average ambient air temperature of 40 °C, then up to a daily average ambient air temperature

of 55 °C, the rated currents verified by testing can be adjusted by calculation, assuming that

the over-temperature of each component or device is proportional to the power loss generated

in this component.

Caution should be taken to ensure the devices being assessed have a power loss substantially

proportional to I and which is not applied to devices that have substantially fixed losses. By

agreement between the user and the manufacturer, in assemblies where the power loss of

conductors and devices is substantially proportional to I , the rated current of the circuits at

ambient air temperatures (outside the enclosure) between 20 °C and 55 °C may can be

calculated using the following formula :

0,61

IT∆

=

IT∆

22

where

I is the current at which the temperature rise test is carried out;

I is the current rating to be determined at the specific ambient air temperature between

20 °C and 55 °C;

∆T is the temperature rise measured by test with a current of I ;

1 1

∆T is the maximum permissible temperature rise at the specific ambient air temperature

between 20 °C and 55 °C.

I cannot exceed 95 % of the rated current of any device within the circuit being considered; for

example, a circuit including a 1 600 A circuit-breaker cannot be assigned a current rating

greater than 1 520 A.

11 Routine verification

IEC 61439-2:20112020, Clause 11, is applicable except as follows.

___________

Formula Reproduced from Copper Development Association, Publication no. 22:1996, Formula (8), with the

permission of Copper Development Association Inc.

Table 1 – Minimum clearances in air (8.3.2)

Replace Table 1 of IEC 61439-1:2011 with the following

Table 1 – Minimum clearances in air (8.3.2)

a

Rated impulse withstand voltage,

Minimum clearance

U

imp

kV mm

≤ 2,5 4

4,0 8

6,0 14

8,0 20

12,0 35

a

Based on inhomogeneous field conditions and pollution degree 3.

NOTE This table reflects a safety multiplication factor to take into account the

marine environment.

Table 2 – Minimum creepage distances (8.3.3)

Replace Table 2 of IEC 61439-1:2011 with the following

Table 2 – Minimum creepage distances (8.3.3)

Rated Minimum creepage distance

insulation mm

voltage U

i

Pollution degree

1 2 3

b b b

Material group Material group Material group

All material I II IIIa and I II IIIa IIIb

c

groups IIIb

V

32 2,25 2,25 2,25 2,25 2,25 2,25 2,25 2,25

40 2,25 2,25 2,25 2,25 2,25 2,4 2,7 2,7

50 2,25 2,25 2,25 2,25 2,25 2,55 2,85 2,85

63 2,25 2,25 2,25 2,25 2,4 2,7 3 3

80 2,25 2,25 2,25 2,25 2,55 2,85 3,15 3,15

100 2,25 2,25 2,25 2,25 2,7 3 3,3 3,3

125 2,25 2,25 2,25 2,25 2,85 3,15 3,6 3,6

160 2,25 2,25 2,25 2,4 3 3,3 3,75 3,75