IEC 62496-2-5:2022

(Main)Optical circuit boards - Basic test and measurement procedures - Part 2-5: Flexibility test for flexible opto-electric circuits

Optical circuit boards - Basic test and measurement procedures - Part 2-5: Flexibility test for flexible opto-electric circuits

IEC 62496-2-5:2022 defines a test method for folding flexibility inspection of flexible opto-electric circuits with a flexibility tester endurance tester and presents a guideline for a step stress test method for finding the predetermined minimum mechanical folding radii below which the flexible opto-electric circuits can be damaged by intended folding distortion. Here, test samples are used instead of products for the flexibility test of their flexible opto-electric circuits, and the test samples have the same material, layer structure, processing technology and equipment as the products.

Cartes à circuits optiques - Procédures fondamentales d’essais et de mesures - Partie 2-5: Essai de flexibilité pour les circuits optoélectriques souples

IEC 62496-2-5:2022 définit une méthode d’essai pour l’examen de la flexibilité au pliage des circuits optoélectriques souples au moyen d’un appareil de contrôle de la flexibilité, et fournit un guide qui présente une méthode d’essai sous contrainte échelonnée destinée à déterminer les rayons de pliage mécanique minimaux prédéterminés en deçà desquels les circuits optoélectriques souples peuvent être endommagés par la distorsion induite par un pliage intentionnel. Des échantillons d’essai sont utilisés ici à la place des produits pour l’essai de flexibilité de leurs circuits optoélectriques souples, et ces échantillons d’essai sont constitués du même matériau, ont la même structure de couches et utilisent la même technologie et les mêmes équipements de traitement que les produits eux-mêmes.

General Information

- Status

- Published

- Publication Date

- 06-Dec-2022

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- JWG 9 - TC 86/JWG 9

- Current Stage

- PPUB - Publication issued

- Start Date

- 07-Dec-2022

- Completion Date

- 30-Dec-2022

Overview

IEC 62496-2-5:2022 is an international standard developed by the International Electrotechnical Commission (IEC) that defines basic test and measurement procedures for flexible opto-electric circuits. Specifically, Part 2-5 addresses the flexibility test for flexible opto-electric circuits. This standard introduces a test method using a flexibility endurance tester to inspect the folding flexibility of flexible opto-electric circuits. It also provides guidelines for a step stress test to identify the predetermined minimum mechanical folding radii, below which these circuits risk damage due to folding distortion.

The flexibility test uses test samples replicating the material composition, layer structure, and processing technology of actual products, ensuring test results are representative and reliable. IEC 62496-2-5:2022 plays a crucial role in quality assurance and reliability testing for manufacturers and developers of flexible optical circuit boards.

Key Topics

Scope and Purpose

Establishes a standardized test method for folding flexibility to assess mechanical endurance and performance integrity of flexible opto-electric circuits.Test Apparatus

Details the required equipment, including flexibility testers, folding jigs of varying radii, optical and electrical measurement sources, photo detectors, and control systems.Sample Preparation

Specifies the use of test samples with identical material and structural characteristics as final products. Covers types of flexible optical circuit boards:- Optical fiber-type flexible opto-electric circuit boards

- Planar waveguide optical circuit boards

Testing Procedures

Defines step-by-step processes for flexibility testing including:- Initial optical and electrical performance measurement

- Setting and folding of the sample on the folding jig

- Dynamic flexibility endurance testing

- Final optical, electrical, and mechanical performance assessments

Step Stress Test Guidelines

Provides methodology for gradually reducing folding radius to determine minimum safe bending radii before damage occurs.Reporting

Requires detailed documentation of test conditions, methodology, results, and performance changes for transparency and reproducibility.Normative References

Integrates relevant standards such as IEC 60068-1 for environmental testing, IEC 60793-2 for optical fiber specifications, and ISO 5626 for folding endurance determination.

Applications

IEC 62496-2-5:2022 is essential for industries involved with the design, manufacture, and quality control of flexible opto-electric circuits and optical circuit boards. Key applications include:

Advanced Electronics Manufacturing

Enabling development of flexible optical circuits used in telecommunication devices, wearable electronics, and flexible displays.Opto-Electronic Device Testing

Ensuring reliable performance of flexible opto-electric circuits in varying mechanical stress conditions.Research and Development

Guiding material scientists and engineers in evaluating new flexible materials and structures for optical circuits.Quality Assurance

Verifying the mechanical durability and folding endurance of opto-electric circuits before product release.Standardization Compliance

Assisting manufacturers to meet global compliance requirements for optical circuit board testing.

Related Standards

IEC 62496-2-5:2022 is part of the broader IEC 62496 series addressing optical circuit board technologies. Relevant related standards include:

- IEC 62496-1: Fundamental terminology and general test methods for optical circuit boards.

- IEC 62496-2-1: Measurement methods for optical attenuation and isolation in optical circuit boards.

- IEC 60793-2: Optical fiber product specifications essential for optical fiber-type circuit testing.

- IEC 60068-1: General environmental testing applicable to electronic and optical circuit board evaluation.

- ISO 5626: Paper folding endurance test methods, referenced for folding endurance measurement concepts.

Summary

IEC 62496-2-5:2022 establishes a comprehensive and standardized approach to testing the folding flexibility of flexible opto-electric circuits, safeguarding product reliability across various industries. By defining detailed test procedures, equipment requirements, and performance criteria, this standard enables manufacturers and developers to accurately assess mechanical endurance and minimize failure risks due to folding-induced damage. Adherence to IEC 62496-2-5 supports innovation and market readiness for flexible optical circuit solutions worldwide.

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 62496-2-5:2022 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Optical circuit boards - Basic test and measurement procedures - Part 2-5: Flexibility test for flexible opto-electric circuits". This standard covers: IEC 62496-2-5:2022 defines a test method for folding flexibility inspection of flexible opto-electric circuits with a flexibility tester endurance tester and presents a guideline for a step stress test method for finding the predetermined minimum mechanical folding radii below which the flexible opto-electric circuits can be damaged by intended folding distortion. Here, test samples are used instead of products for the flexibility test of their flexible opto-electric circuits, and the test samples have the same material, layer structure, processing technology and equipment as the products.

IEC 62496-2-5:2022 defines a test method for folding flexibility inspection of flexible opto-electric circuits with a flexibility tester endurance tester and presents a guideline for a step stress test method for finding the predetermined minimum mechanical folding radii below which the flexible opto-electric circuits can be damaged by intended folding distortion. Here, test samples are used instead of products for the flexibility test of their flexible opto-electric circuits, and the test samples have the same material, layer structure, processing technology and equipment as the products.

IEC 62496-2-5:2022 is classified under the following ICS (International Classification for Standards) categories: 33.180.01 - Fibre optic systems in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62496-2-5:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62496-2-5 ®

Edition 1.0 2022-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Optical circuit boards – Basic test and measurement procedures –

Part 2-5: Flexibility test for flexible opto-electric circuits

Cartes a circuits optiques – Procédures fondamentales d’essais et de mesures –

Partie 2-5: Essai de flexibilité pour les circuits optoélectriques souples

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Découvrez notre puissant moteur de recherche et consultez

webstore.iec.ch/advsearchform gratuitement tous les aperçus des publications. Avec un

La recherche avancée permet de trouver des publications IEC abonnement, vous aurez toujours accès à un contenu à jour

en utilisant différents critères (numéro de référence, texte, adapté à vos besoins.

comité d’études, …). Elle donne aussi des informations sur les

projets et les publications remplacées ou retirées. Electropedia - www.electropedia.org

Le premier dictionnaire d'électrotechnologie en ligne au monde,

IEC Just Published - webstore.iec.ch/justpublished

avec plus de 22 300 articles terminologiques en anglais et en

Restez informé sur les nouvelles publications IEC. Just

français, ainsi que les termes équivalents dans 19 langues

Published détaille les nouvelles publications parues.

additionnelles. Egalement appelé Vocabulaire

Disponible en ligne et une fois par mois par email.

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC Products & Services Portal - products.iec.ch

IEC 62496-2-5 ®

Edition 1.0 2022-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Optical circuit boards – Basic test and measurement procedures –

Part 2-5: Flexibility test for flexible opto-electric circuits

Cartes a circuits optiques – Procédures fondamentales d’essais et de mesures

–

Partie 2-5: Essai de flexibilité pour les circuits optoélectriques souples

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 33.180.01 ISBN 978-2-8322-6119-4

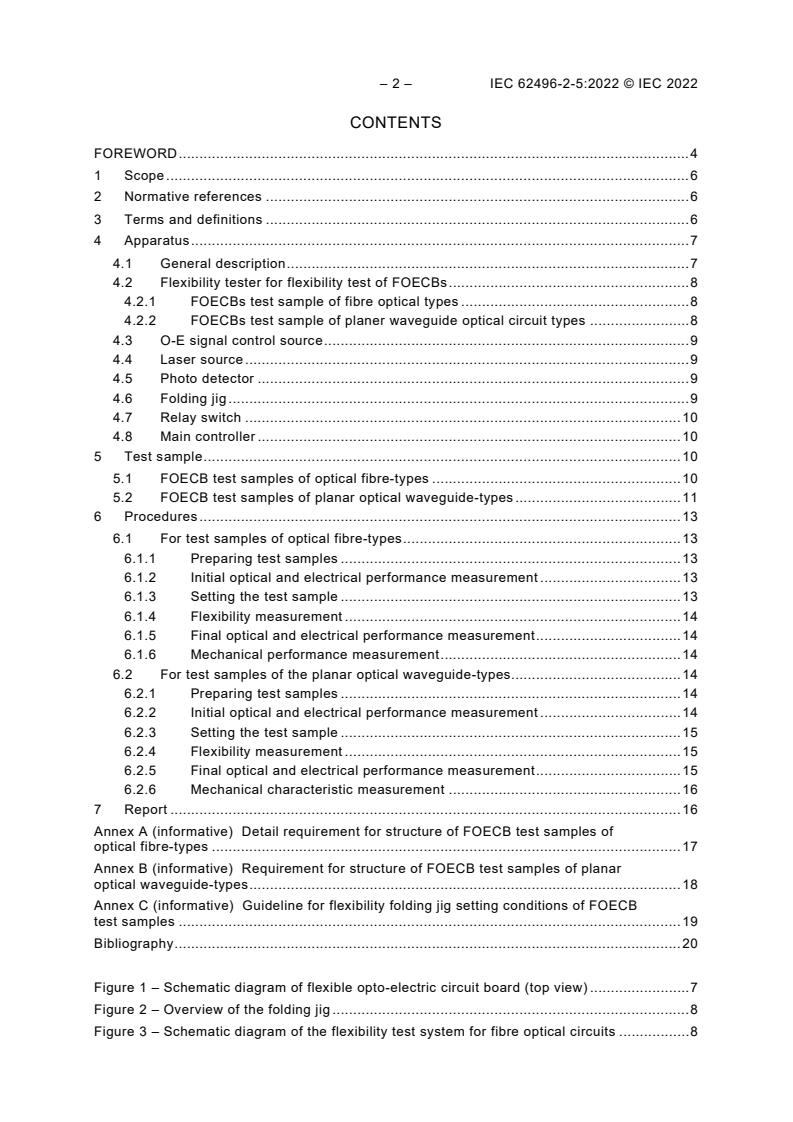

– 2 – IEC 62496-2-5:2022 © IEC 2022

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Apparatus . 7

4.1 General description . 7

4.2 Flexibility tester for flexibility test of FOECBs . 8

4.2.1 FOECBs test sample of fibre optical types . 8

4.2.2 FOECBs test sample of planer waveguide optical circuit types . 8

4.3 O-E signal control source . 9

4.4 Laser source . 9

4.5 Photo detector . 9

4.6 Folding jig . 9

4.7 Relay switch . 10

4.8 Main controller . 10

5 Test sample . 10

5.1 FOECB test samples of optical fibre-types . 10

5.2 FOECB test samples of planar optical waveguide-types . 11

6 Procedures . 13

6.1 For test samples of optical fibre-types . 13

6.1.1 Preparing test samples . 13

6.1.2 Initial optical and electrical performance measurement . 13

6.1.3 Setting the test sample . 13

6.1.4 Flexibility measurement . 14

6.1.5 Final optical and electrical performance measurement . 14

6.1.6 Mechanical performance measurement . 14

6.2 For test samples of the planar optical waveguide-types. 14

6.2.1 Preparing test samples . 14

6.2.2 Initial optical and electrical performance measurement . 14

6.2.3 Setting the test sample . 15

6.2.4 Flexibility measurement . 15

6.2.5 Final optical and electrical performance measurement . 15

6.2.6 Mechanical characteristic measurement . 16

7 Report . 16

Annex A (informative) Detail requirement for structure of FOECB test samples of

optical fibre-types . 17

Annex B (informative) Requirement for structure of FOECB test samples of planar

optical waveguide-types . 18

Annex C (informative) Guideline for flexibility folding jig setting conditions of FOECB

test samples . 19

Bibliography . 20

Figure 1 – Schematic diagram of flexible opto-electric circuit board (top view) . 7

Figure 2 – Overview of the folding jig . 8

Figure 3 – Schematic diagram of the flexibility test system for fibre optical circuits . 8

Figure 4 – Schematic diagram of the flexibility test system for planar waveguide optical

circuits . 9

Figure 5 – Flexibility folding jigs (from the left, folding radius r is 1,0 mm, 2,0 mm, 3,0

mm, 4,0 mm, 5,0 mm and 10,0 mm) . 10

Figure 6 – Schematic diagram of FOECB test samples of optical fibre-types . 11

Figure 7 – Schematic diagram of FOECB test samples of planar optical waveguide-

types. 12

Figure B.1 – Schematic diagram of the flexibility test system for planar waveguide

optical circuits . 18

Figure C.1 – An example of measurement result of optical loss versus bending

diameter . 19

– 4 – IEC 62496-2-5:2022 © IEC 2022

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

OPTICAL CIRCUIT BOARDS –

BASIC TEST AND MEASUREMENT PROCEDURES –

Part 2-5: Flexibility test for flexible opto-electric circuits

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 62496-2-5 has been prepared by IEC technical committee 86: Fibre optics. It is an

International Standard.

The text of this International Standard is based on the following documents:

Draft Report on voting

86/605/FDIS 86/609/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 62496 series, published under the general title Optical circuit boards,

can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

– 6 – IEC 62496-2-5:2022 © IEC 2022

OPTICAL CIRCUIT BOARDS –

BASIC TEST AND MEASUREMENT PROCEDURES –

Part 2-5: Flexibility test for flexible opto-electric circuits

1 Scope

This part of IEC 62496 defines a test method for folding flexibility inspection of flexible opto-

electric circuits with a flexibility tester endurance tester and presents a guideline for a step

stress test method for finding the predetermined minimum mechanical folding radii below which

the flexible opto-electric circuits can be damaged by intended folding distortion. Here, test

samples are used instead of products for the flexibility test of their flexible opto-electric circuits,

and the test samples have the same material, layer structure, processing technology and

equipment as the products.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068-1, Environmental testing – Part 1: General and guidance

IEC 60793-2 (all parts), Optical fibres – Part 2: Product specifications

IEC 62496-2-1, Optical circuit boards – Part 2-1: Measurements – Optical attenuation and

isolation

ISO 5626:1993, Paper – Determination of folding endurance

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 62496-1 and the

following apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1

flexible opto-electric circuit board

flexible circuit board that contains both optic and electric circuits integrated into a flexible sheet

Figure 1 – Schematic diagram of flexible opto-electric circuit board (top view)

Note 1 to entry: Figure 1 shows an example of the top view of a flexible opto-electric circuit board.

Note 2 to entry: There are two types of flexible opto-electric circuit board: optical fibre-types and planer optical

waveguide-types.

[SOURCE: ISO 5626:1993, Clause 1]

3.2

flexibility tester

instrument for folding endurance test of flexible sheets with interchangeable folding heads,

allowing a range of thickness up to 1,25 mm

Note 1 to entry: In general, it is called the MIT folding endurance tester.

4 Apparatus

4.1 General description

The flexibility test system for flexibility test of the flexible opto-electric circuit board (hereafter

FOECB) shall be used for finding of the minimum folding radii of both optic and electric circuits

of the FOECB before any functional damage occurs. An existing flexibility folding method has

been used for testing the folding flexibility of only electric circuits. However, in this document,

it shall be used for testing the folding flexibility of both optic and electric circuits.

Since the test sample for fibre optical type should be connected to the flexibility test system

through an optical fibre, real-time monitoring may be possible. Accordingly, the flexibility tester

shall be configured with a real-time monitoring system using a laser signal device to accurately

know the time of breakage of the optical fibres.

Generally, test samples for planar waveguide optical circuits are difficult to measure through

real-time monitoring because it is not easy to connect to a flexibility test device through an

optical fibre. Therefore, the test sample should be tested by connecting only electric circuits as

in the existing flexibility folding method. The failure time of the test sample should be measured

separately using a visual light on the planar waveguide circuits.

But, in case of that the test sample for planar waveguide optical circuits shall use optical fibres

with connector to coupling with the optical waveguide, flexibility test of the test samples can be

possible with real-time monitoring.

In addition, these tests should be measured in the process of replacing the holding jig.The test

sample shall be clamped by the folding jig within the main controller as shown in Figure 2.

– 8 – IEC 62496-2-5:2022 © IEC 2022

a) Photograph diagram of the folding jig b) Photograph of a folding jig and test sample

Figure 2 – Overview of the folding jig

4.2 Flexibility tester for flexibility test of FOECBs

4.2.1 FOECBs test sample of fibre optical types

The flexibility test system for fibre optical circuits should be configured to stop the folding action

of the test sample if any damage starts to appear in its optical and electrical sections. Therefore,

the flexibility test system shall be composed of an optic-electric signal control source (hereafter

referred as O-E signal control source), test sample, and main controller, as shown in Figure 3.

Figure 3 – Schematic diagram of the flexibility test system for fibre optical circuits

4.2.2 FOECBs test sample of planer waveguide optical circuit types

The flexibility test system for planer waveguide optical circuits shall be constructed in the same

form as the folding flexibility test method for existing electrical circuits, as shown in Figure 4.

Figure 4 – Schematic diagram of the flexibility test system

for planar waveguide optical circuits

4.3 O-E signal control source

An O-E signal control source shall be composed of a laser source, photo detector, relay switch,

electric power source, optical fibre, and optical connectors. The O-E signal control source

supplies an optical signal to the test sample, and allows the photo detector to control the relay

switch based on detected optical signal for on-off switching of the electric signal flow (current)

within the flexibility test system.

4.4 Laser source

The optical output power of the laser source shall have enough larger of the minimum detected

power of optical detector and attenuation (optical loss) of samples. The laser source in the O-

E signal control source sends an optical signal to the test sample via its optical input terminal

connected to the protruded optical fibre. The wavelength and mode of the laser source should

be chosen according to the application to be used. The launching mode of the laser source

should be appropriate to the application of the relevant specification of O-E circuit board.

4.5 Photo detector

The minimum detected optical power of the photo detector shall be enough to detect the optical

power after attenuating the optical power by the test sample and light source power. The photo

detector detects the optic signal flow in the test sample. The photo detector output controls the

relay switch inside the O-E signal control source. Therefore, the output current of the photo

detector should be above the minimum operating voltage of the relay switch with a proper

resistance for the current output. The photo detector shall have enough response frequency to

detect the optical power change (deviation) by the attenuation change caused by the folding

distortion. At minimum, the response frequency for the photo detector should be 10 times or

more than the folding duration (0° to 90°), or kHz order will be necessary.

4.6 Folding jig

The size of the jig shall be selected according to the test samples. Several types of folding jigs

with different bending radii are required to apply various bending tests to the test sample.

Folding jigs of 6 different curvature radii (1,0 mm, 2,0 mm, 3,0 mm, 4,0 mm, 5,0 mm, and

10,0 mm) should be prepared (see Figure 5).

– 10 – IEC 62496-2-5:2022 © IEC 2022

Figure 5 – Flexibility folding jigs (from the left, folding radius r is

1,0 mm, 2,0 mm, 3,0 mm, 4,0 mm, 5,0 mm and 10,0 mm)

4.7 Relay switch

The switching time shall be at least one tenth of the folding speed. The relay switch plays a role

of direct on-off switching control of the electric circuit in the flexibility test system. That is, once

the photo detector detects the optic signal flow in the test sample, the relay switch stays in the

on-state. If the photo detector fails to detect the optic signal flow in the test sample, the relay

switch turns to the off-state. The relay switch operates the flexibility test system depending on

the detected optical signal output at the photo detector, which is subject to the physical state

of the test sample (e.g., either broken or non-broken state of the optic circuit).

4.8 Main controller

The main controller shall control the electrical current to fold the folding jig with enough

accuracy to test. The main controller supplies an electric current to the test sample and

mechanically controls the folding action of the test sample. The main controller may consist of

the main controller and the mechanical control means of folding, separately. Generally, the

main controller emits the electric signal by itself to perform the mechanical folding operation on

the test sample. The typical electric current flowing through the main controller ranges from

1 mA to 10 mA.

5 Test sample

5.1 FOECB test samples of optical fibre-types

Test samples of optical fibre-types shall have a pigtailed shape (see Figure 6). The optical

fibres used in the test samples may be single-mode and/or multimode fibres. Depending on

applications, glass optical fibres, polymer optical fibres, and specialty optical fibres may be

used to form the optical circuits.

The optical circuits shall be positioned at a central part of the entire FOECB test samples. The

electrical circuits shall be positioned at peripheral areas of the optical circuit in a symmetrical

structure. The symmetrical structure shall have superior characteristics in size stability from the

viewpoint of design and reliability for the FOECB test samples, as shown in Figure 6.

The test samples of the optical fibre-types shall have a protruded structure with a length of l9

at one side. The protruded length (l ) shall be maintained with sufficient length over 100 mm

for easy connection with other fibres (e.g., fibre fusion splicing). The other side of the test

samples shall have a continuous fibre bending area over a 6-mm diameter with a non-end state

as shown in Figure 6. The bending state over the 6-mm diameter for glass optical fibres shall

be maintained to minimize their optical bending loss.

A detail requirement for structure of FOECB test samples of optical fibre-types is described in

Annex A.

A position mark shall be assigned on the test sample for locating the folding position with a

clamp of the flexibility test system.

The size of the test samples should be confirmed in accordance with the flexibility folding jigs

(see 4.6). As illustrated in Figure 6, the nominal dimensions of the total length (l ) of the test

sample shall be 130 mm within 10 % tolerance, and the nominal dimensions of the width (l ) of

the test sample shall be 2,5 mm to 50 mm within 10 % tolerance. It is recommended that the

length (l ) of the test samples from its one edge to the clamp position mark and the length (l )

2 3

from the clamp position mark of the bending area to the other edge are chosen to be 100 mm

and 30 mm, respectively. The bending diameter (l ) of the optical circuit, spacing (l ) between

4 8

two optical circuit lines, and the number of optical circuits shall be decided in accordance with

the user’s requirements. The pattern width (l ) of the electrical circuit lines also shall be decided

in accordance with the user’s requirements. The thickness (l ) of the FOECB test samples is

very critical because it influences the minimum mechanical folding radius r. The thickness of

the test sample shall be from 150 µm to 500 μm for the FOECB test samples of the general

glass fibres defined in IEC 60793-2 series with polymer over-clad protection. The thickness of

the test samples should be same as that for products. If there are any differences, the thickness

of the test samples shall be decided in accordance with the user’s requirements.

Key

1 electric circuit

2 optic circuit

3 position mark for clamp (folding)

a side view of test sample

b top view of test sample

Figure 6 – Schematic diagram of FOECB test samples of optical fibre-types

5.2 FOECB test samples of planar optical waveguide-types

The optical circuits shall be positioned at a central part of the entire FOECB test samples. The

electrical circuits shall be positioned at a peripheral area of the optical circuit in a symmetrical

structure. The symmetrical structure shall have superior characteristics in size stability from the

viewpoint of design and reliability for the FOECB test samples as shown in Figure 7.

The test samples of the planar optical waveguide-types shall have a non-protruded structure at

both side (see Figure 7). The number of optical circuit lines shall be at least three for crosstalk

testing.

– 12 – IEC 62496-2-5:2022 © IEC 2022

A requirement for structure of FOECB test samples of planar optical waveguide-types is

described in Annex B.

A position mark shall be assigned on the test sample for locating the folding position with a

clamp of the flexibility test system.

The size of the test samples should be confirmed in accordance with the flexibility folding jigs

) of the test

(see 4.6). As illustrated in Figure 7, the nominal dimensions of the total length (l

sample shall be 130 mm within 10 % tolerance, and the nominal dimensions of the width (l ) of

the test sample shall be 2,5 mm to 50 mm within 10 % tolerance. It is recommended that the

length (l ) of test samples from its one edge to the clamp position mark are chosen to be 100

mm. The optical circuits shall be composed of over three optical waveguides. The spacing (l )

between two optical waveguides shall be decided in accordance with the user’s requirements.

The pattern width (l ) of the electrical circuit lines also shall be decided in accordance with the

user’s requirements. The thickness (l ) of the FOECB test sample is very critical because it

influences the minimum mechanical folding radius r. The thickness of test samples shall be

from 50 µm to 1 000 µm for FOECB test samples of the planar optical waveguide-types. The

thickness of the test samples should be same as that for products. If there are any differences,

the thickness of the test samples shall be decided in accordance with the user’s requirements.

Key

1 electric circuit

2 optic circuit

3 position mark for clamp (folding)

a side view of test sample

b top view of test sample

X1, X2, X3: input port of optical circuit

X1’, X2’, X3’: output port of optical circuit

Figure 7 – Schematic diagram of FOECB test samples

of planar optical waveguide-types

6 Procedures

6.1 For test samples of optical fibre-types

6.1.1 Preparing test samples

Prepare a number of the test samples having the same physical conditions in the same

fabrication processes.

The number of test samples should be at least 18 including 3 test samples per jig for 6 different

test jigs with folding radii of 1,0 mm, 2,0 mm, 3,0 mm, 4,0 mm, 5,0 mm and 10,0 mm.

The test sample should be 2,5 mm to 50 mm wide with a sufficient length (over 100 mm length)

to be suitable for the test instrument being used. Edges of test samples should be clean-cut to

align parallel to the edge on the opposite end.

The test sample should be initially free from any folds, wrinkles or blemishes. The portion of the

test sample where the folding action takes place should not contain any watermark traces.

Take care not to handle with bare hands any part of the test piece that is exposed between the

clamps.

6.1.2 Initial optical and electrical performance measurement

Before applying the flexibility folding test, the optical attenuation and electrical performances

of the test samples shall be measured both for no-bended and bended conditions. Optical

performance shall be measured according to IEC 62496-2-1. Electrical performance shall be

measured by LCR meter.

6.1.3 Setting the test sample

Since the test sample of the optical fibre-types has a protruded structure, both the optical fibre

and electric cable shall be connected to the test sample (see Figure 3).

The procedure for connecting the test sample to the flexibility test system is as follows:

a) Connect the optic fibres to the protruded fibres of the test sample

b) Make the optic fibre and electric wire connections between the test sample and an O-E

signal control source

c) Mount the test sample to a folding jig in flexibility test system

The flexibility folding conditions for the test samples shall be as follows:

– A set of 100, 500, 1 000, 5 000 and 10 000 folding cycles is used as the basis point for

finding an appearance of breakage and/or crack of the test samples

– Folding radius r: 1,0 mm to 10,0 mm

– Pulling force: 5 N to 15 N

– Folding speed: 30 cycles/min to 175 cycles/min

– Folding angle: 135° ± 5°

A general guideline for the flexibility folding jig setting conditions of the FOECB test samples is

described in Annex C.

Record the pulling force, thickness and the width (cross-section) of the test sample and the

bending angle. If required, the temperature chamber of controllable from −40 °C to +100 °C

should be prepared. The test ambient temperature should be decided between users and

manufacturers.

– 14 – IEC 62496-2-5:2022 © IEC 2022

6.1.4 Flexibility measurement

Appearance of any breakage and/or crack of the test sample during the folding test process

should be monitored through the monitor panel of the flexibility tester main controller. The

folding test shall be repeated with the flexibility folding jigs of a series of different radii (see

Figure 3) by replacing one by one. The flexibility folding test should be started with the jig of a

large folding radius r value (10,0 mm) at the beginning, and repeated by replacing it with

another jig of gradually reduced folding radius r until any breakage and/or crack of the test

sample starts to appear during the folding process. Once any damage appears during the

folding process, then the folding radius r of the jig shall be regarded as a critical point value for

the folding limit of the test sample.

Any damage and delamination during the folding test cannot be observed during real-time

monitoring, so appeared damage cannot be used as a termination criteria. Therefore, the

damage and delamination appearance test during the folding test process also shall be

regarded as the termination criteria.

6.1.5 Final optical and electrical performance measurement

After the final folding test, the test sample should be kept in the standard atmospheric condition

defined in IEC 60068-1 during more than or equal to 2 hours. Then, measure the optical

attenuation and electrical performance of the test sample in the same conditions as ones used

for the same measurement before the folding test. Calculate the deviation of the measured

optical attenuation and electrical resistance values between before and after the folding test.

6.1.6 Mechanical performance measurement

After the final optical and electrical characteristic measurement, inspect the test samples for

any peeling and buckling of the circuit layer. If required, optical fibres dimensions, optical fibres

pitch (relative core locations), the peeling strength should be measured.

6.2 For test samples of the planar optical waveguide-types

6.2.1 Preparing test samples

Prepare a number of the test samples having the same physical conditions in the same

fabrication processes.

The number of the test samples should be at least 18, including 3 test samples per jig for 6

different test jigs with folding radii of 1,0 mm, 2,0 mm, 3,0 mm, 4,0 mm, 5,0 mm and 10,0 mm.

The test sample should be 2,5 mm to 50 mm wide with a sufficient length (over 100 mm length)

to be suitable for the test instrument being used. Edges of the test samples should be clean-

cut to align parallel to the edge on the opposite end.

The test sample should be initially free from any folds, wrinkles or blemishes. The portion of the

test sample where the folding action takes place should not contain any watermark traces.

Take care not to handle with bare hands any part of the test piece that is exposed between the

clamps.

6.2.2 Initial optical and electrical performance measurement

Before applying the flexibility folding test, the optical performance (attenuation and crosstalk)

and electric performance of the test samples shall be measured both for no-bended and bended

conditions.

Optic performance should be measured according to IEC 62496-2-1. Electrical performance

shall be measured by LCR meter.

6.2.3 Setting the test sample

Since the test sample of the planar waveguide-types has a non-protruded structure, only the

electric cable should be connected to the test sample (see Figure B.1).

The procedure for connecting the test sample to the flexibility test system is as follows:

a) Mount the test sample to a folding jig in flexibility test system

b) Make the electric wire connections between the test sample and a main controller

Take care of the test sample not to cause any damage during the mounting process.

The flexibility folding conditions for the test sample are as follows:

– A set of 100, 500, 5 000, and 10 000 folding cycles is used as the basis point for finding an

appearance of breakage and/or crack of the test sample

– Folding radius r: 1,0 mm to 10,0 mm

– Pulling force: 5 N to 15 N

– Folding speed: 90 cycles/min to 175 cycles/min

– Folding angle: 135° ± 5°

Record the pulling force, thickness and the width (cross-section) of the test sample and the

bending angle. If required, the temperature chamber of controllable from −40 °C to +100 °C

should be prepared. The test ambient temperature should be decided between users and

manufacturers.

6.2.4 Flexibility measurement

Appearance of any breakage and/or crack of electric circuits inside the test sample during the

folding test process should be monitored through the monitor panel of the flexibility tester main

controller. The folding test shall be repeated with the flexibility folding jigs of a series of different

radii (see Figure 3) by replacing one by one. The flexibility folding test should be started with

the jig of a large folding radius r value (10,0 mm) at the beginning, and repeated by replacing

it with another jig of gradually reduced folding radius r until any breakage and/or crack of the

test sample starts to appear during the folding process. Once any damage appears during the

folding process, then the folding radius r of the jig shall be regarded as a critical point value for

the folding limit of the test sample.

After the end of the flexibility folding test, whether the optical circuit in the test sample is

damaged or not, should be determined through evaluation of separate optical performance.

Any damage and delamination during the folding test cannot be observed during real-time

monitoring, so appeared damage cannot be used as a termination criteria. Therefore, the

damage and delamination appearance test during the folding test process also shall be

regarded as the termination criteria.

6.2.5 Final optical and electrical performance measurement

After the folding test, the test sample should be kept in the standard atmospheric condition

(defined in IEC 60068-1) more than or equal to 2 hours. Measure the optical performance

(attenuation and crosstalk) and electrical performance same as the measurement condition

before the folding test. Calculate the deviation of optical performance (attenuation and

crosstalk)/electrical resistance values between before and after the folding test.

– 16 – IEC 62496-2-5:2022 © IEC 2022

6.2.6 Mechanical characteristic measurement

After the final optical and electrical characteristic test, inspect the test samples for any peeling

and buckling of the circuit layers. If required in the relevant document, optical core dimensions,

optical core pitch (relative core locations), and peeling strength should be measured.

7 Report

In cases where the specification of the present flexibility measurement shall be included in the

report, the following shall be explained in detail:

a) model number of the test sample

b) manufacturer information of the rest sample

c) material type of the test sample

d) layer structure of the test sample

e) test sample size: W (Width) × L (Length) × T (Thickness) (mm)

f) test sample type: optical fibre-types (single-mode or multimode) or planar optical

waveguide-types (single-mode or multimode)

g) type of light source, its launching condition

h) type of optical detector and its response frequency

i) ambient temperature and humidity conditions

j) flexibility folding test conditions (folding radius, pulling force, folding cycle, folding angle)

k) optical performance (attenuation and crosstalk) and electric performance (resistance

values) before and after folding test

l) average limit of flexibility (folding cycle number at folding radius) should be reported at least

with three specimens

Annex A

(informative)

Detail requirement for structure of FOECB

test samples of optical fibre-types

Test samples of optical fibre-types can be broken suddenly during the flexibility folding test. In

particular, optical circuits composed of glass fibres are relatively rigid compared to those with

polymer fibres, and can be easily broken in repeated folding processes. Accordingly, optical

attenuation values and electrical resistance values of test samples of optical fibre-types should

be monitored in real-time to confirm the presence of breakage during the flexibility folding test.

Accordingly, one side of test samples of optical fibre-types should be formed with a protruding

optical fibre, and the opposite side thereof should be formed with a non-protruding structure.

When the test sample is m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...