IEC 60730-2-6:2025

(Main)Automatic electrical controls - Part 2-6: Particular requirements for automatic electrical pressure sensing controls including mechanical requirements

Automatic electrical controls - Part 2-6: Particular requirements for automatic electrical pressure sensing controls including mechanical requirements

IEC 60730-2-6:2025 applies to automatic electrical pressure sensing controls

• for use in, on, or in association with equipment for household appliance and similar use;

NOTE 1 Throughout this document, the word "equipment" means "appliance and equipment" and "controls" means "pressure sensing controls".

• for building automation within the scope of ISO 16484 series and IEC 63044 series (HBES/BACS);

EXAMPLE 1 Independently mounted automatic electrical pressure sensing controls, controls in smart grid systems and controls for building automation systems within the scope of ISO 16484-2.

• for equipment that is used by the public, such as equipment intended to be used in shops, offices, hospitals, farms and commercial and industrial applications;

EXAMPLE 2 Automatic electrical pressure sensing controls for commercial catering, heating and air-conditioning equipment.

• that are smart enabled automatic electrical pressure sensing controls;

EXAMPLE 3 Smart grid automatic electrical pressure sensing controls, remote interfaces/control of energy-consuming equipment including computer or smart phone.

• that are AC or DC powered controls with a rated voltage not exceeding 690 V AC or 600 V DC;

• used in, on, or in association with equipment that use electricity, gas, oil, solid fuel, solar thermal energy, etc., or a combination thereof;

• utilized as part of a control system or controls which are mechanically integral with multifunctional controls having non-electrical outputs;

• using NTC or PTC thermistors and to discrete thermistors, requirements for which are contained in Annex J;

• that are mechanically or electrically operated, responsive to or controlling a pressure or vacuum;

• as well as manual controls when such are electrically and/or mechanically integral with automatic controls.

NOTE 2 Requirements for manually actuated mechanical switches not forming part of an automatic control are contained in IEC 61058-1-1.

This document is also applicable to individual pressure sensing controls utilized as part of a control system or pressure sensing controls which are mechanically integral with multi-functional controls having non-electrical outputs.

This document is also applicable to pressure sensing controls for appliances within the scope of IEC 60335-1.

This document applies to

- the inherent safety of pressure sensing controls, and

- functional safety of pressure sensing controls and safety related systems,

- pressure sensing controls where the performance (for example the effect of EMC phenomena) of the product can impair the overall safety and performance of the controlled system,

- the operating values, operating times, and operating sequences where such are associated with equipment safety.

This document specifies the requirements for construction, operation and testing of automatic electrical controls used in, on, or in association with an equipment.

This document does not

• apply to pressure sensing controls intended exclusively for industrial process applications unless explicitly mentioned in the relevant part 2 or the equipment standard. However, this document can be applied to evaluate automatic electrical controls intended specifically for industrial applications in cases where no relevant safety standard exists;

• take into account the response value of an automatic action of a pressure sensing control, if such a response value is dependent upon the method of mounting the control in the equipment. Where a response value is of significant purpose for the protection of the user, or surroundings, the value defined in the appropriate equipment standard or as determined by the manufacturer will apply;

• address the integrity of the output signal to the network devices, such as interoperability with other devices unless it has been evaluated as part of the control system.

This document contains requirements for electrical features of pressure sensing controls and requirements for mechanical featu

Dispositifs de commande électriques automatiques - Partie 2-6: Exigences particulières pour les dispositifs de commande électriques automatiques sensibles à la pression, y compris les exigences mécaniques

L'IEC 60730-2-6:2025 s'applique aux dispositifs de commande électrique automatiques sensibles à la pression

− utilisés dans, sur ou avec des matériels pour appareil domestique et usage analogue;

NOTE 1 Dans le présent document, le terme "matériel" signifie "appareil et matériel" et "dispositifs de commande" signifie "dispositifs de commande sensibles à la pression".

− pour l'automatisation des bâtiments qui relèvent du domaine d'application de la série ISO 16484 et de la série IEC 63044 (HBES/BACS);

EXEMPLE 1 Les dispositifs de commande électrique automatiques sensibles à la pression montés indépendamment, les dispositifs de commande des systèmes de réseau intelligent et les dispositifs de commande des systèmes d'automatisation des bâtiments qui relèvent du domaine d'application de l'ISO 16484-2.

− pour des matériels utilisés par le public, tels que les matériels destinés à être utilisés dans des magasins, des bureaux, des hôpitaux, des fermes et des applications commerciales et industrielles;

EXEMPLE 2 Les dispositifs de commande électrique automatiques sensibles à la pression pour les installations de restauration, de chauffage et d'air conditionné.

− qui sont des dispositifs de commande électrique automatiques activés intelligents sensibles à la pression;

EXEMPLE 3 Les dispositifs de commande électrique automatiques sensibles à la pression de réseau intelligent, les interfaces distantes/dispositifs de commande de matériels utilisateurs d'énergie électrique, y compris les ordinateurs ou les mobiles multifonctions.

− qui sont des dispositifs de commande à courant alternatif ou continu dont la tension assignée ne dépasse pas 690 V en courant alternatif ou 600 V en courant continu;

− qui sont utilisés dans, sur ou avec des matériels qui utilisent l'électricité, le gaz, le pétrole, des combustibles solides, l'énergie thermique solaire, etc. ou une combinaison de ces sources d'énergie;

− qui sont utilisés dans le cadre d'un système de commande ou de dispositifs de commande qui sont mécaniquement intégrés à des dispositifs de commande multifonctions comportant des sorties non électriques;

− qui utilisent des thermistances CTN ou CTP ainsi qu'aux dispositifs à thermistances discrètes, dont les exigences sont fournies à l'Annexe J;

− qui sont actionnés mécaniquement ou électriquement, qui commandent ou sont sensibles à la pression ou au vide;

− ainsi qu'aux dispositifs de commande manuels qui sont électriquement et/ou mécaniquement intégrés à des dispositifs de commande automatique.

NOTE 2 Les exigences relatives aux interrupteurs mécaniques à action manuelle qui ne font pas partie d'un dispositif de commande automatique sont contenues dans l'IEC 61058-1-1.

Le présent document s'applique également aux différents dispositifs de commande sensibles à la pression qui sont utilisés dans le cadre d'un système de commande ou aux dispositifs de commande sensibles à la pression qui sont mécaniquement intégrés à des dispositifs de commande multifonctions comportant des sorties non électriques.

Le présent document s'applique également aux dispositifs de commande sensibles à la pression pour appareils qui relèvent du domaine d'application de l'IEC 60335-1.

Le présent document s'applique

− à la sécurité intrinsèque des dispositifs de commande sensibles à la pression; et

− à la sécurité fonctionnelle des dispositifs de commande sensibles à la pression et des systèmes de sécurité;

− aux dispositifs de commande sensibles à la pression pour lesquels les performances (par exemple, l'effet des phénomènes CEM) du produit peuvent compromettre la sécurité et les performances globales du système commandé;

− aux valeurs de fonctionnement, aux temps de fonctionnement et aux séquences de fonctionnement lorsque ces éléments interviennent dans la sécurité du matériel.

Le présent document spécifie les exigences relatives à la construction, au fonctionnement et aux essais des dispositifs de commande électrique automatiques utilisés dans, s

General Information

- Status

- Published

- Publication Date

- 13-Aug-2025

- Technical Committee

- TC 72 - Automatic electrical controls

- Drafting Committee

- WG 6 - TC 72/WG 6

- Current Stage

- PPUB - Publication issued

- Start Date

- 14-Aug-2025

- Completion Date

- 15-Aug-2025

Relations

- Effective Date

- 14-Jun-2024

- Effective Date

- 26-Jan-2024

Overview

IEC 60730-2-6:2025 specifies particular requirements for automatic electrical pressure sensing controls, including mechanical requirements. It applies to pressure sensing controls used in household appliances, building automation (within ISO 16484 / IEC 63044 scope), public equipment (shops, hospitals, commercial/industrial sites), and smart‑enabled controls. The standard addresses construction, operation and testing for AC or DC powered controls (rated ≤ 690 V AC or ≤ 600 V DC) and covers inherent safety, functional safety, EMC‑related performance effects, and safety‑related operating values, times and sequences.

Key topics and requirements

The standard complements IEC 60730-1 and contains detailed technical requirements and tests, including:

- Construction and materials - enclosure, mounting, and mechanical integrity requirements.

- Protection against electric shock - insulation, covers and protective earthing provisions.

- Terminals, terminations and connectors - requirements for internal and external conductors.

- Creepage, clearance and solid insulation - electrical separation distances for safety.

- Components and electronic circuits - transformers, capacitors, relays, thermistors (Annex J), and fault assessment for inherent and functional safety.

- Mechanical strength and endurance - impact, flexing, hydrostatic tests and lifecycle aging.

- Environmental and climatic tests - moisture, dust, temperature, transportation and storage stresses.

- Heating, tracking and fire resistance - thermal tests and resistance to tracking.

- Controls using software - software‑related requirements, error avoidance, memory tests and functional safety considerations.

- Marking and technical information - required labeling, warning markings and documentation for safe installation and use.

Note: IEC 60730-2-6 does not generally apply to industrial process controls unless explicitly referenced by the relevant part 2 or equipment standard; it also does not cover interoperability of output signals unless evaluated as part of the control system.

Practical applications

IEC 60730-2-6 is used to design, test and certify pressure sensing controls for:

- Household appliances (e.g., boilers, water heaters, cookers)

- HVAC and building automation systems (including HBES/BACS)

- Commercial catering and industrial equipment for public use

- Smart grid and remote‑controlled energy systems with pressure control elements

Compliance ensures safety, reliability and regulatory acceptance of pressure sensing controls in consumer, commercial and building automation products.

Who should use this standard

- Appliance and control manufacturers

- Product safety and compliance engineers

- Test laboratories and certification bodies

- System integrators and OEMs designing HVAC and building automation systems

Related standards

- IEC 60730-1 (general requirements)

- ISO 16484 series and IEC 63044 series (building automation)

- IEC 60335-1 (appliances safety)

- IEC 61058-1-1 (manual mechanical switches - note on exclusions)

Keywords: IEC 60730-2-6, automatic electrical pressure sensing controls, pressure sensing controls, mechanical requirements, functional safety, building automation, IEC standard.

Buy Documents

IEC 60730-2-6:2025 - Automatic electrical controls - Part 2-6: Particular requirements for automatic electrical pressure sensing controls including mechanical requirements Released:8/14/2025 Isbn:9782832705988

IEC 60730-2-6:2025 EXV - Automatic electrical controls - Part 2-6: Particular requirements for automatic electrical pressure sensing controls including mechanical requirements Released:8/14/2025 Isbn:9782832706619

IEC 60730-2-6:2025 - Dispositifs de commande électriques automatiques - Partie 2-6: Exigences particulières pour les dispositifs de commande électriques automatiques sensibles à la pression, y compris les exigences mécaniques Released:8/14/2025 Isbn:9782832705988

IEC 60730-2-6:2025 - Automatic electrical controls - Part 2-6: Particular requirements for automatic electrical pressure sensing controls including mechanical requirements Released:8/14/2025 Isbn:9782832705988

Frequently Asked Questions

IEC 60730-2-6:2025 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Automatic electrical controls - Part 2-6: Particular requirements for automatic electrical pressure sensing controls including mechanical requirements". This standard covers: IEC 60730-2-6:2025 applies to automatic electrical pressure sensing controls • for use in, on, or in association with equipment for household appliance and similar use; NOTE 1 Throughout this document, the word "equipment" means "appliance and equipment" and "controls" means "pressure sensing controls". • for building automation within the scope of ISO 16484 series and IEC 63044 series (HBES/BACS); EXAMPLE 1 Independently mounted automatic electrical pressure sensing controls, controls in smart grid systems and controls for building automation systems within the scope of ISO 16484-2. • for equipment that is used by the public, such as equipment intended to be used in shops, offices, hospitals, farms and commercial and industrial applications; EXAMPLE 2 Automatic electrical pressure sensing controls for commercial catering, heating and air-conditioning equipment. • that are smart enabled automatic electrical pressure sensing controls; EXAMPLE 3 Smart grid automatic electrical pressure sensing controls, remote interfaces/control of energy-consuming equipment including computer or smart phone. • that are AC or DC powered controls with a rated voltage not exceeding 690 V AC or 600 V DC; • used in, on, or in association with equipment that use electricity, gas, oil, solid fuel, solar thermal energy, etc., or a combination thereof; • utilized as part of a control system or controls which are mechanically integral with multifunctional controls having non-electrical outputs; • using NTC or PTC thermistors and to discrete thermistors, requirements for which are contained in Annex J; • that are mechanically or electrically operated, responsive to or controlling a pressure or vacuum; • as well as manual controls when such are electrically and/or mechanically integral with automatic controls. NOTE 2 Requirements for manually actuated mechanical switches not forming part of an automatic control are contained in IEC 61058-1-1. This document is also applicable to individual pressure sensing controls utilized as part of a control system or pressure sensing controls which are mechanically integral with multi-functional controls having non-electrical outputs. This document is also applicable to pressure sensing controls for appliances within the scope of IEC 60335-1. This document applies to - the inherent safety of pressure sensing controls, and - functional safety of pressure sensing controls and safety related systems, - pressure sensing controls where the performance (for example the effect of EMC phenomena) of the product can impair the overall safety and performance of the controlled system, - the operating values, operating times, and operating sequences where such are associated with equipment safety. This document specifies the requirements for construction, operation and testing of automatic electrical controls used in, on, or in association with an equipment. This document does not • apply to pressure sensing controls intended exclusively for industrial process applications unless explicitly mentioned in the relevant part 2 or the equipment standard. However, this document can be applied to evaluate automatic electrical controls intended specifically for industrial applications in cases where no relevant safety standard exists; • take into account the response value of an automatic action of a pressure sensing control, if such a response value is dependent upon the method of mounting the control in the equipment. Where a response value is of significant purpose for the protection of the user, or surroundings, the value defined in the appropriate equipment standard or as determined by the manufacturer will apply; • address the integrity of the output signal to the network devices, such as interoperability with other devices unless it has been evaluated as part of the control system. This document contains requirements for electrical features of pressure sensing controls and requirements for mechanical featu

IEC 60730-2-6:2025 applies to automatic electrical pressure sensing controls • for use in, on, or in association with equipment for household appliance and similar use; NOTE 1 Throughout this document, the word "equipment" means "appliance and equipment" and "controls" means "pressure sensing controls". • for building automation within the scope of ISO 16484 series and IEC 63044 series (HBES/BACS); EXAMPLE 1 Independently mounted automatic electrical pressure sensing controls, controls in smart grid systems and controls for building automation systems within the scope of ISO 16484-2. • for equipment that is used by the public, such as equipment intended to be used in shops, offices, hospitals, farms and commercial and industrial applications; EXAMPLE 2 Automatic electrical pressure sensing controls for commercial catering, heating and air-conditioning equipment. • that are smart enabled automatic electrical pressure sensing controls; EXAMPLE 3 Smart grid automatic electrical pressure sensing controls, remote interfaces/control of energy-consuming equipment including computer or smart phone. • that are AC or DC powered controls with a rated voltage not exceeding 690 V AC or 600 V DC; • used in, on, or in association with equipment that use electricity, gas, oil, solid fuel, solar thermal energy, etc., or a combination thereof; • utilized as part of a control system or controls which are mechanically integral with multifunctional controls having non-electrical outputs; • using NTC or PTC thermistors and to discrete thermistors, requirements for which are contained in Annex J; • that are mechanically or electrically operated, responsive to or controlling a pressure or vacuum; • as well as manual controls when such are electrically and/or mechanically integral with automatic controls. NOTE 2 Requirements for manually actuated mechanical switches not forming part of an automatic control are contained in IEC 61058-1-1. This document is also applicable to individual pressure sensing controls utilized as part of a control system or pressure sensing controls which are mechanically integral with multi-functional controls having non-electrical outputs. This document is also applicable to pressure sensing controls for appliances within the scope of IEC 60335-1. This document applies to - the inherent safety of pressure sensing controls, and - functional safety of pressure sensing controls and safety related systems, - pressure sensing controls where the performance (for example the effect of EMC phenomena) of the product can impair the overall safety and performance of the controlled system, - the operating values, operating times, and operating sequences where such are associated with equipment safety. This document specifies the requirements for construction, operation and testing of automatic electrical controls used in, on, or in association with an equipment. This document does not • apply to pressure sensing controls intended exclusively for industrial process applications unless explicitly mentioned in the relevant part 2 or the equipment standard. However, this document can be applied to evaluate automatic electrical controls intended specifically for industrial applications in cases where no relevant safety standard exists; • take into account the response value of an automatic action of a pressure sensing control, if such a response value is dependent upon the method of mounting the control in the equipment. Where a response value is of significant purpose for the protection of the user, or surroundings, the value defined in the appropriate equipment standard or as determined by the manufacturer will apply; • address the integrity of the output signal to the network devices, such as interoperability with other devices unless it has been evaluated as part of the control system. This document contains requirements for electrical features of pressure sensing controls and requirements for mechanical featu

IEC 60730-2-6:2025 is classified under the following ICS (International Classification for Standards) categories: 97.120 - Automatic controls for household use. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60730-2-6:2025 has the following relationships with other standards: It is inter standard links to IEC 60730-2-6:2015/AMD1:2019, IEC 60730-2-6:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60730-2-6:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60730-2-6 ®

Edition 4.0 2025-08

INTERNATIONAL

STANDARD

Automatic electrical controls -

Part 2-6: Particular requirements for automatic electrical pressure sensing

controls including mechanical requirements

ICS 97.120 ISBN 978-2-8327-0598-8

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or

by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either

IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC copyright

or have an enquiry about obtaining additional rights to this publication, please contact the address below or your local

IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Discover our powerful search engine and read freely all the

The advanced search enables to find IEC publications by a publications previews, graphical symbols and the glossary.

variety of criteria (reference number, text, technical With a subscription you will always have access to up to date

committee, …). It also gives information on projects, content tailored to your needs.

replaced and withdrawn publications.

Electropedia - www.electropedia.org

The world's leading online dictionary on electrotechnology,

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published containing more than 22 500 terminological entries in English

details all new publications released. Available online and and French, with equivalent terms in 25 additional languages.

once a month by email. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer

Service Centre: sales@iec.ch.

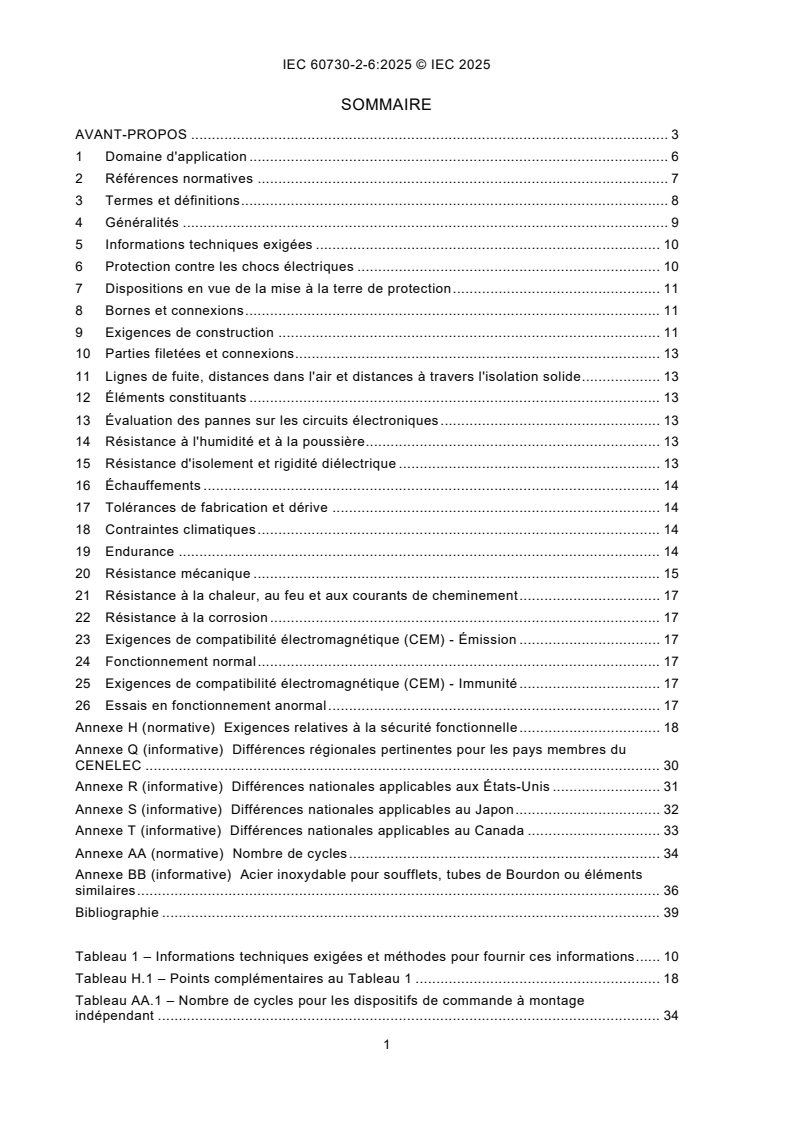

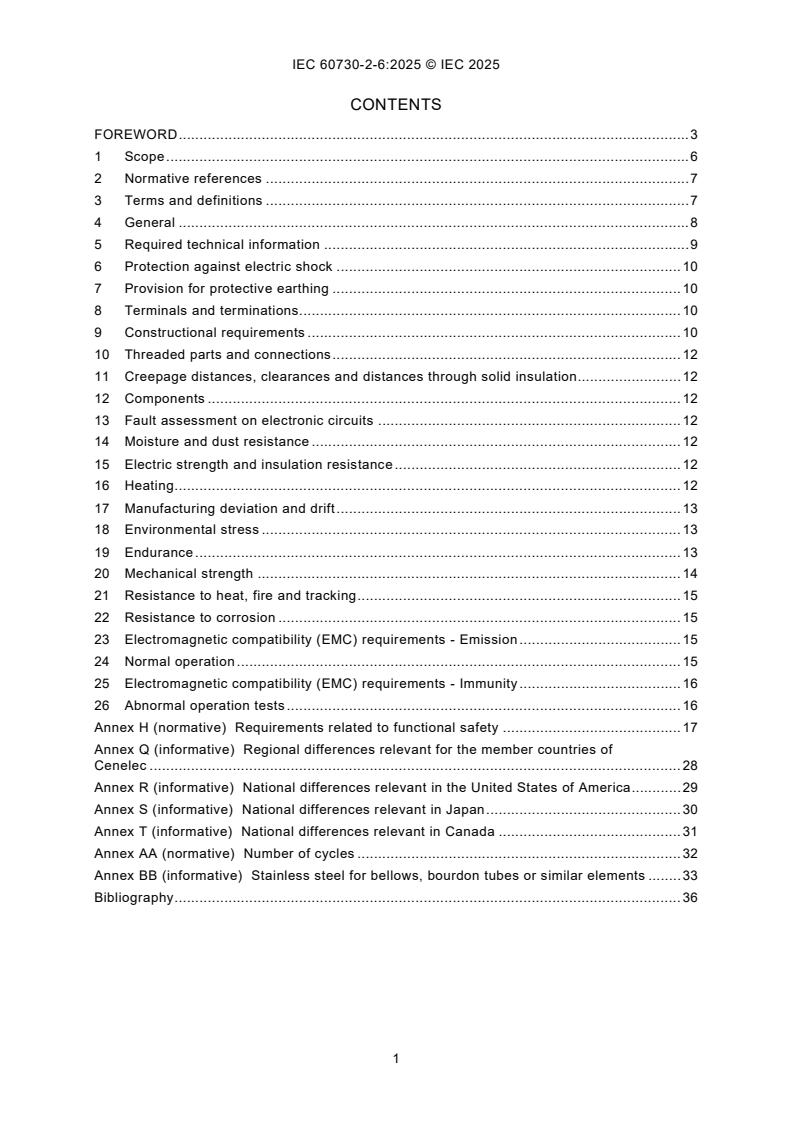

CONTENTS

FOREWORD . 3

1 Scope . 6

2 Normative references . 7

3 Terms and definitions . 7

4 General . 8

5 Required technical information . 9

6 Protection against electric shock . 10

7 Provision for protective earthing . 10

8 Terminals and terminations. 10

9 Constructional requirements . 10

10 Threaded parts and connections . 12

11 Creepage distances, clearances and distances through solid insulation . 12

12 Components . 12

13 Fault assessment on electronic circuits . 12

14 Moisture and dust resistance . 12

15 Electric strength and insulation resistance . 12

16 Heating . 12

17 Manufacturing deviation and drift . 13

18 Environmental stress . 13

19 Endurance . 13

20 Mechanical strength . 14

21 Resistance to heat, fire and tracking . 15

22 Resistance to corrosion . 15

23 Electromagnetic compatibility (EMC) requirements - Emission . 15

24 Normal operation . 15

25 Electromagnetic compatibility (EMC) requirements - Immunity . 16

26 Abnormal operation tests . 16

Annex H (normative) Requirements related to functional safety . 17

Annex Q (informative) Regional differences relevant for the member countries of

Cenelec . 28

Annex R (informative) National differences relevant in the United States of America . 29

Annex S (informative) National differences relevant in Japan . 30

Annex T (informative) National differences relevant in Canada . 31

Annex AA (normative) Number of cycles . 32

Annex BB (informative) Stainless steel for bellows, bourdon tubes or similar elements . 33

Bibliography . 36

Table 1 – Required technical information and methods of providing these information . 9

Table H.1 – Additional items to Table 1 . 17

Table AA.1 – Number of cycles for independently mounted controls . 32

Table AA.2 – Cycling rate for independently mounted controls . 32

Table BB.1 - Stainless steel for bellows, bourdon tubes or similar elements. 33

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

Automatic electrical controls -

Part 2-6: Particular requirements for automatic electrical pressure

sensing controls including mechanical requirements

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC 60730-2-6 has been prepared by IEC technical committee 72: Automatic electrical controls.

It is an International Standard.

This fourth edition cancels and replaces the third edition published in 2015 and its

Amendment 1:2019. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

Adoption of IEC 60730-1:2022 with all of its significant changes to IEC 60730-1:2013,

IEC 60730-1:2013/AMD 1:2015 and IEC 60730-1:2013/AMD2:2020.

The text of this International Standard is based on the following documents:

Draft Report on voting

72/1486/FDIS 72/1504/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts of the IEC 60730 series, under the general title: Automatic electrical controls,

can be found on the IEC website.

This part 2-6 is intended to be used in conjunction with IEC 60730-1. It was established on the

basis of the sixth edition of that standard (2022). Consideration may be given to future editions

of, or amendments to, IEC 60730-1.

This part 2-6 supplements or modifies the corresponding clauses in IEC 60730-1, so as to

convert that publication into the IEC standard: Particular requirements for automatic electrical

pressure sensing controls including mechanical requirements.

Where this part 2-6 states "addition", "modification" or "replacement", the relevant requirement,

test specification or explanatory matter in part 1 should be adapted accordingly.

When a particular subclause of Part 1 is not mentioned in this Part 2, that subclause applies.

In the development of a fully international standard, it has been necessary to take into

consideration the differing requirements resulting from practical experience in various parts of

the world and to recognize the variation in national electrical systems and wiring rules.

The reader's attention is drawn to the fact that Annex Q, Annex R, Annex S and Annex T list all

of the "in-some-country" clauses on differing practices of a less permanent nature relating to

the subject of this document.

In this publication:

The following print types are used:

– requirements proper: in roman type;

– test specifications: in italic type;

– explanatory matter: in smaller roman type;

– defined terms: bold type.

Subclauses, notes or items which are additional to those in Part 1 are numbered starting from

101, additional annexes are lettered AA, BB, etc.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

– reconfirmed,

– withdrawn, or

– revised.

1 Scope

This clause of Part 1 is replaced by the following:

This document applies to automatic electrical pressure sensing controls

– for use in, on, or in association with equipment for household appliance and similar use;

NOTE 1 Throughout this document, the word "equipment" means "appliance and equipment" and "controls" means

"pressure sensing controls".

– for building automation within the scope of ISO 16484 series and IEC 63044 series

(HBES/BACS);

EXAMPLE 1 Independently mounted automatic electrical pressure sensing controls, controls in smart grid

systems and controls for building automation systems within the scope of ISO 16484-2.

– for equipment that is used by the public, such as equipment intended to be used in shops,

offices, hospitals, farms and commercial and industrial applications;

EXAMPLE 2 Automatic electrical pressure sensing controls for commercial catering, heating and air-conditioning

equipment.

– that are smart enabled automatic electrical pressure sensing controls;

EXAMPLE 3 Smart grid automatic electrical pressure sensing controls, remote interfaces/control of energy-

consuming equipment including computer or smart phone.

– that are AC or DC powered controls with a rated voltage not exceeding 690 V AC or 600 V

DC;

– used in, on, or in association with equipment that use electricity, gas, oil, solid fuel, solar

thermal energy, etc., or a combination thereof;

– utilized as part of a control system or controls which are mechanically integral with

multifunctional controls having non-electrical outputs;

– using NTC or PTC thermistors and to discrete thermistors, requirements for which are

contained in Annex J;

– that are mechanically or electrically operated, responsive to or controlling a pressure or

vacuum;

– as well as manual controls when such are electrically and/or mechanically integral with

automatic controls.

NOTE 2 Requirements for manually actuated mechanical switches not forming part of an automatic control are

contained in IEC 61058-1-1.

This document is also applicable to individual pressure sensing controls utilized as part of a

control system or pressure sensing controls which are mechanically integral with multi-

functional controls having non-electrical outputs.

This document is also applicable to pressure sensing controls for appliances within the scope

of IEC 60335-1.

This document applies to

– the inherent safety of pressure sensing controls, and

– functional safety of pressure sensing controls and safety related systems,

– pressure sensing controls where the performance (for example the effect of EMC

phenomena) of the product can impair the overall safety and performance of the controlled

system,

– the operating values, operating times, and operating sequences where such are associated

with equipment safety.

This document specifies the requirements for construction, operation and testing of automatic

electrical controls used in, on, or in association with an equipment.

This document does not

– apply to pressure sensing controls intended exclusively for industrial process applications

unless explicitly mentioned in the relevant part 2 or the equipment standard. However, this

document can be applied to evaluate automatic electrical controls intended specifically for

industrial applications in cases where no relevant safety standard exists;

– take into account the response value of an automatic action of a pressure sensing control,

if such a response value is dependent upon the method of mounting the control in the

equipment. Where a response value is of significant purpose for the protection of the user,

or surroundings, the value defined in the appropriate equipment standard or as determined

by the manufacturer will apply;

– address the integrity of the output signal to the network devices, such as interoperability

with other devices unless it has been evaluated as part of the control system.

This document contains requirements for electrical features of pressure sensing controls and

requirements for mechanical features that affect their intended operation.

NOTE Subclause 20.101, as it pertains to gas and/or oil controls, is under consideration pending review or revision

of ISO 22967, ISO 22968 and ISO 23550, if applicable.

In general, these pressure sensing controls are integrated or incorporated with the equipment

or are intended to be integrated in, or on the equipment. This document also covers these

controls when they are independently mounted. In-line cord controls are not covered by this

document.

2 Normative references

This clause of Part 1 is applicable.

3 Terms and definitions

This clause of Part 1 is applicable except as follows:

3.2 Definitions of types of control according to purpose

Additional definitions:

3.2.101

pressure limiter

pressure sensing control which is intended to keep a pressure below or above a predetermined

value during normal operating conditions and which can have provision for setting by the user

Note 1 to entry: A pressure limiter may be of the automatic or of the manual reset type. It does not make the

reverse operation during the normal duty cycle of the equipment.

3.2.102

pressure operating control

pressure sensing control set at a high or low pressure, or both, between which limits the

equipment is normally intended to operate

3.2.103

pressure cut-out

pressure sensing control intended to keep a pressure below or above one particular value

during abnormal operating conditions of the equipment and which has no provisions for setting

by the user

Note 1 to entry: A pressure cut-out may be of the automatic or of the manual reset type.

Note 2 to entry: A pressure cut-out will provide a Type 2 action.

Note 3 to entry: A pressure cut-out may have an adjustable stop intended to be set by the control manufacturer,

the equipment manufacturer or the installer.

3.3 Definitions relating to the function of controls

Additional definitions:

3.3.101

pressure medium

medium used to transmit the pressure to the pressure sensing element

Note 1 to entry: Pressure medium as used in this document refers to either gases or liquids.

3.3.102

permanent operation

continuous monitoring of the protective function during the operation of the appliance or

system for longer than 24 h

Note 1 to entry: 24 h is considered the typical time interval between a first and a second fault.

3.3.103

non-permanent operation

continuous monitoring of the protective function during the operation of the appliance or

system for less than 24 h

Note 1 to entry: 24 h is considered the typical time interval between a first and a second fault.

3.8 Definitions relating to component parts of controls

Additional definition:

3.8.101

vent

that opening from the atmospheric side of a diaphragm to the atmosphere through which air is

discharged or drawn in when the control is functioning

4 General

This clause of Part 1 is applicable except as follows:

4.3 General notes on tests

4.3.2 Conditions of test

4.3.2.7 Replacement:

The rates of pressure change declared in Table 1 requirement 31, and used in Clause 19 (i.e.

α , β , α , β ) shall have test tolerances as declared by the manufacturer.

1 1 2 2

4.3.4 Instructions for test

4.3.4.1 According to submission

Additional subclause:

4.3.4.1.101 The values in Annex AA apply for the testing of independently mounted pressure

sensing controls in Clause 19. Values for integrated and incorporated controls are specified

in the appropriate equipment standard.

5 Required technical information

5.2 Methods of providing technical information

This clause of Part 1 is applicable except as follows:

Table 1 – Required technical information and methods of providing these information

Clause or

Method

Information

subclause

Replacement:

X

19 Number of cycles of actuation (M) for each manual action Annex AA,

Preferred values are: 100 000 cycles; 30 000 cycles; 10 000 cycles; 19.10, 19.11

j j j

6 000 cycles; 3 000 cycles ; 300 cycles ; 30 cycles

NOTE For controls with more than one manual action, a different value can

be declared for each. If a control has more than one intended "OFF" position,

then a cycle of actuation is regarded as a movement from one "OFF" position

to the next "OFF" position.

X

20 Number of automatic cycles (A) for each automatic action. Annex AA,

Preferred values are: 300 000 cycles; 200 000 cycles; 100 000 cycles; 13.1.3.3,

a

Table 14,

30 000 cycles; 20 000 cycles; 10 000 cycles; 6 000 cycles; 3 000 cycles ;

a b bd c

19.7.6,

1 000 cycles ; 300 cycles ; 30 cycles ; 1 cycle .

19.8.4

1) Not applicable to thermostats or to other fast cycling actions.

2) Applicable only to manual reset.

3) Applicable only to actions which require the replacement of a part after

each operation.

4) Can only be reset during manufacturer servicing.

NOTE For controls having more than one automatic action, a different value

can be declared for each.

29 Not applicable

38 Not applicable

42 Operating pressure (or pressures) 3.3.11, 17,

H.17.4

52 Not applicable

Additional items:

101 Pressure medium 3.3.101,

X

9.3.101,

20.101

102 Operating differential 3.3.25,

D

H.17.4

H.17.6

103 Maximum working pressure 3.3.28, 9,

D

19, 20

Addition to Footnote h:

For pressure sensing controls, limits of activating quantity are specified either in the applicable appliance

standard, by the appliance manufacturer or as declared by the pressure sensing control manufacturer

(see 19.7 and 19.8).

6 Protection against electric shock

This clause of Part 1 is applicable.

7 Provision for protective earthing

This clause of Part 1 is applicable.

8 Terminals and terminations

This clause of Part 1 is applicable.

9 Constructional requirements

This clause of Part 1 is applicable except as follows:

9.4 Actions

Additional subclause:

9.4.101 Type 2.N action (for sensing actions, no increase in the operating value as a

result of any leakage from the sensing element or from parts connecting the

sensing element to the switch head)

A Type 2.N action shall be so designed that in the event of a leak in the sensing element, or

in any other part between the sensing element and the switch head, the declared disconnection

or interruption is provided before the sum of the declared operating pressure and drift is

exceeded.

Compliance is checked by the following test:

The operating pressure of a Type 2.N control shall be measured under the conditions of

Clause 17. If the control has means for setting, it shall be set to the highest value.

After this measurement, a hole is artificially produced in the sensing element and the

measurement of the operating pressure is repeated.

No positive drift is allowed beyond the declared value.

A separate shroud or sleeve may be employed for protection of the sensing element to achieve

conformance with Clause 20.

NOTE The test can be replaced by theoretical computations of the physical mode of operation.

9.11 Requirements during mounting, use, maintenance and servicing

Additional subclauses:

9.11.101 Parts in contact with a diaphragm shall have no sharp burrs, projections or the like

which chafe or abrade the diaphragm.

Compliance is checked by inspection before and after the tests of Clause 19.

9.11.102 An operating spring shall be retained and arranged to prevent abrasion, binding,

buckling or interference with its free movement.

Compliance is checked by inspection before and after the tests of Clause 19.

9.11.103 If failure of any part of the control would allow unsafe leakage of a hazardous fluid,

that part shall be made of a material having a melting point (solidus temperature) of not less

than 510 °C and a tensile strength of not less than 68 MPa at 204 °C.

Such parts shall not sag, distort, melt, oxidize or show leakage of fluid during any of the tests

specified herein.

Compliance is checked by inspection before and after the tests of Clause 19.

9.11.104 A part including a sheath, capillary tube, bellows or diaphragm shall be resistant to

atmospheric corrosion and attack by the fluid it can normally contact in service, if failure of the

part will permit external fluid leakage of a combustible fluid or cause the control to malfunction.

NOTE Brass alloys containing less than 81 % copper and more than 9 % zinc are not considered resistant to the

corrosive effects of fuel oils.

9.11.105 A control in which a flexible diaphragm, bellows or similar construction constitutes

the only flammable gas or fluid seal shall have the atmospheric side of the diaphragm or bellows

enclosed in a casing designed to limit external fluid leakage in the event of a diaphragm or

bellows rupture or shall have provisions for connection of a vent pipe or tubing intended to be

routed to the outdoors or other safe location.

2 2

9.11.106 A control designed to supervise the pressure of fuel oil of 1,00 mm /s to 600 mm /s

viscosity is not required to conform to 20.101 and 20.102, provided three samples of the control,

when subjected to a 100 000 cycle endurance test, show no evidence of leakage during the test

and when subjected to a hydrostatic test of four times the maximum working pressure, following

the endurance test, and the control conforms to one of the following:

a) the bellows, Bourdon tube, diaphragm or similar element is made of stainless steel or

material of equivalent resistance to corrosion designated material class A, if leakage from

a ruptured element will be into the control enclosure, in which case such leakage is to be

released to the exterior of the control before entering any opening provided for conduit

connection, or

b) the bellows, Bourdon tube, diaphragm or similar element is made of stainless steel or

material of equivalent resistance to corrosion designated material class B, if leakage from

a ruptured element will be to the exterior of the control enclosure only.

NOTE 1 Suitable class A and B materials are shown in Annex BB.

NOTE 2 1 mm /s = 1 centistoke.

Additional subclauses:

9.101 Construction requirements relating to operating mechanism

9.101.1 If screws and nuts serve to attach operating parts to movable members, they shall be

swaged or otherwise locked.

9.101.2 The operating mechanism of a manually operated switch shall not subject parts to

damage.

9.101.3 Operating parts shall be separated by barriers or by their physical location from

conductors to be connected to the control to avoid interference with the movement of such parts

by the conductors.

Compliance with 9.101.1 to 9.101.3 inclusive is checked by inspection.

9.102 A pressure cut-out shall not reset or be resettable manually or otherwise at a value

above the maximum or below the minimum operating pressure, whichever is declared.

9.103 A pressure cut-out with a manually operated reset device shall be trip-free.

Compliance with 9.102 and 9.103 is checked by inspection.

10 Threaded parts and connections

This clause of Part 1 is applicable.

11 Creepage distances, clearances and distances through solid insulation

This clause of Part 1 is applicable.

12 Components

This clause of Part 1 is applicable.

13 Fault assessment on electronic circuits

This clause of Part 1 is applicable except as follows:

13.1 Fault assessment for inherent safety

13.1.3 Component fault assessment

13.1.3.8 Compliance criteria

Item c) is not applicable.

14 Moisture and dust resistance

This clause of Part 1 is applicable except as follows:

14.1 Protection against ingress of water and dust

14.1.1 Addition:

The tests in this subclause are not intended to determine the suitability of the seal between the

control and the equipment.

15 Electric strength and insulation resistance

This clause of Part 1 is applicable.

16 Heating

This clause of Part 1 is applicable.

17 Manufacturing deviation and drift

This clause of Part 1 is applicable.

18 Environmental stress

This clause of Part 1 is applicable.

19 Endurance

This clause of Part 1 is applicable except as follows:

19.1 General requirements

19.1.5 Compliance criteria

Replacement:

Compliance with 19.1.2 and 19.1.3 is checked by the tests of 19.15.

19.1.6 Test sequence and conditions

19.1.6.2 Addition:

The tests of Clause 19 shall be conducted at the declared maximum working pressure and

operating differential as declared in Table 1, requirement 102 and 103.

19.15 Test for particular purpose controls

Additional subclauses:

19.15.101 Pressure operating controls

Subclauses 19.1 to 19.5 inclusive are applicable.

Subclause 19.6 is not applicable.

Subclauses 19.7 and 19.8 are applicable.

Subclause 19.9 is applicable, but only to slow-make, slow-break automatic actions.

Subclauses 19.10 to 19.13 inclusive are applicable but only to those pressure operating

controls which have a manual action (including an actuating means providing setting by the

user).

Subclause 19.14 is applicable.

19.15.102 Pressure limiter

Subclauses 19.1 to 19.5 inclusive are applicable.

Subclause 19.6 is not applicable.

Subclauses 19.7 and 19.8 are applicable except that, where necessary, the reset operation, if

required, is obtained by actuation. This actuation shall be as specified in 19.4 for accelerated

speed, as soon as permitted by the mechanism, or as declared by the manufacturer in Table 1,

requirement 31.

Subclause 19.9 is applicable, but only to slow-make, slow-break automatic actions, the same

conditions for manual reset for 19.7 and 19.8 being used.

Subclauses 19.10 to 19.13 inclusive are applicable but only to those pressure limiters which

have a manual action (including an actuating means providing setting by the user).

Subclauses 19.10 to 19.13 inclusive are not applicable to the normal reset manual action,

which is tested during the automatic test of 19.7 to 19.9 inclusive. If the pressure limiter has

other manual actions which are not tested during the automatic test, then these subclauses

are applicable.

Subclause 19.14 is applicable.

20 Mechanical strength

This clause of Part 1 is applicable except as follows:

Additional subclauses:

20.101 Medium leakage

Parts of pressure limiters or pressure cut-outs which are subjected to pressure of a fluid to

be supervised shall not leak externally at a rate in excess of 200 cm /h, when tested with air or

nitrogen at a pressure of 1,5 times the maximum working pressure of the control.

To determine compliance, the control shall be connected to a system capable of supplying

clean air or nitrogen at the specified test pressure. Any by-pass or other openings not essential

to the operation of the control during the test shall be sealed. Air or nitrogen shall be admitted

and maintained at the specified test pressure. In the case of a diaphragm element, which, in

normal usage, is subjected to pressure on both sides of the diaphragm, the test pressure shall

be applied to both sides of the diaphragm slowly and without shock to avoid stressing the

diaphragm excessively.

Leakage shall be observed by an apparatus capable of indicating accurately a flow rate of

200 cm /h for the test fluid employed. A control with a maximum working pressure of 35 kPa

or more can be considered as conforming to the above if, when the fluid-containing parts of the

control are submerged in water to a depth of approximately 25 mm while under the test

pressure, no bubble indicating leakage is observed within 10 s after the parts are submerged.

To conform to 9.11.105, a control shall not allow leakage under conditions of ruptured

diaphragm or bellows from an unthreaded vent opening or around pins, stems or linkages

passing through the housing in excess of the following rate, when the control is tested to its

maximum working pressure:

a) 0,03 m /h of a 0,64 specific gravity gas for a control for use only with fuel gases having

specific gravity less than 1,0;

NOTE 1 In the countries members of CENELEC, the leakage rate is 70 l/h.

b) 0,014 m /h of a 1,53 specific gravity gas for a control for use with liquified petroleum gases;

NOTE 2 In the countries members of CENELEC, the leakage rate is 70 l/h.

c) 0,001 m /h of water for a control for use with flammable liquids such as gasoline, kerosene

and fuel oils up to 1,2 mm /s;

3 2

d) 0,002 m /h of the lightest grade fuel oil heavier than 1,2 mm /s for which a control shall be

used.

20.102 Strength of parts (hydrostatic)

20.102.1 A pressure sensing control employing a Bourdon tube, a flexible metal bellows, a

diaphragm or the like rated 2 000 kPa or more, which is not contained within an enclosure, shall

withstand for 1 min without bursting a hydraulic pressure equal to four times the maximum

working pressure of the control.

The control under test shall be filled with water to exclude air and is connected to a hydraulic

pump. The pressure shall be raised gradually to the required test pressure.

Leakage at a gasket or fitting during this test is permitted provided the leakage does not occur

below 50 % of the required test pressure and the test can be continued to four times maximum

working pressure.

20.102.2 A pressure sensing control employing a Bourdon tube, a flexible metal bellows, a

diaphragm or the like that is contained within an enclosure shall comply with 20.102.1 or shall

– withstand for 1 min without visible leakage a hydraulic pressure of two times the maximum

working pressure, and

– withstand for 1 min a hydraulic pressure equal to four times the maximum working pressure

or, if this pressure cannot be reached without damage to the equipment, at least three times

maximum working pressure. Also, it shall be demonstrated that the enclosure can either

relieve pressure equal to four times maximum working pressure without rupturing in a

manner likely to endanger persons or surroundings, or that it can withstand the test

pressure.

The test is conducted as in 20.102.1.

20.102.3 A pressure limiter or pressure cut-out shall be capable of withstanding for 1 min

without bursting a hydraulic pressure equal to four times the maximum working pressure.

The control under test shall be filled with water to exclude air and connected to a hydraulic

pump. The pressure shall be raised gradually to the required test pressure.

21 Resistance to heat, fire and tracking

This clause of Part 1 is applicable.

22 Resistance to corrosion

This clause of Part 1 is applicable.

23 Electromagnetic compatibility (EMC) requirements - Emission

This clause of Part 1 is applicable.

24 Normal operation

This clause of Part 1 is applicable.

25 Electromagnetic compatibility (EMC) requirements - Immunity

This clause of Part 1 is applicable.

26 Abnormal operation tests

This clause of Part 1 is applicable.

Annex H

(normative)

Requirements related to functional safety

This annex of Part 1 is applicable except as follows:

H.3 Terms and definitions

H.3.21.2 Addition:

Note 101 to entry: In general, pressure cut-outs perform class B or C control functions.

H.3.21.3 Addition:

Note 101 to entry: In general, pressure cut-outs used on closed water heater systems perform class C control

functions.

H.5 Information

Table H.1 – Additional items to Table 1

Additional items:

Information Clause or Method

subclause

H.101 The output condition of pressure cut-outs, Type 2 operating controls and H.25.1.103,

H.25.1.104, X

Type 2 limiters after operation

H.25.1.105

H.102 Frequency of the defined state test function H.13.2.2.2,

H.13.2.3.2, X

H.13.2.3.3

H.103 The control is for permanent operation or non-permanent operation 3.3.102

3.3.103,

X

H.13.2.2.2,

H.13.2.3.2

Additional footnote:

For example, conducting or non-conducting, as applicable.

H.13 Fault assessment on electronic circuits

H.13.2 Fault assessment to ensure functional safety

H.13.2.2 Class B control function

H.13.2.2.2 First fault

Modification:

Replace item b) as follows:

b) the control shall react within the fault reaction time (see Table H.1, requirement H.11) by

proceeding to the defined state provided that a subsequent restart under the same fault

conditions results in the system returning to the same defined state condition;

Replace item c) as follows, adding the new Note:

c) for systems with non-permanent operation according to Table H.1 requirement H.103, the

control shall continue to operate as intended, the fault shall be detected during the next

start-up sequence. The compliance criteria shall be a) or b).

NOTE 101 Requirements for systems with permanent operation are under consideration.

Replace item d) as follows:

d) the control shall continue to operate as intended.

Replace the last two paragraphs with the following:

The fault reaction time shall be declared by the manufacturer (see Table H.1,

requirement H.11).

For permanent operation as declared by the manufacturer (see Table H.1, requirement

H.103), item c) is under consideration.

For a control function, where a mechanical actuator is part of a circuit that characterizes the

defined state, a test up to, but not including, the switching contacts is sufficient. If the test of

the defined state fails, the control shall initiate the safety shut-down. Frequency of test is as

declared by the manufacturer (see Table H.1, requirement H.102). Internal faults of the

components of the checking circuits are not considered.

H.13.2.3 Class C control function

H.13.2.3.2 First fault

Modification:

Replace item b) as follows:

b) the control reacting within the fault reaction time (see Table H.1, requirement H.11) by

proceeding to defined state provided that subsequent restart under the same fault

condition results in the system returning to the defined state condition;

Replace item c) follows, adding the new Note:

c) for systems with non-permanent operation, according to Table H.1, requirement H.103,

the control shall continue to operate as intended, the fault shall be detected during the next

start-up sequence. The compliance criteria shall be a) or b).

NOTE Requirements for systems with permanent operation are under consideration.

Replace item d) as follows:

d) The control shall continue to operate as intended.

Replace the last sentence with the following:

The fault reaction time shall be declared by the manufacturer (see Table H.1,

requirement H.11).

For permanent operation as declared by the manufacturer (see Table H.1, requirement

H.103), item c) is under consideration.

For a control function, where a mechanical actuator is part of a circuit that characterizes the

defined state, a test up to, but not including, the switching contacts is sufficient. If the test of

the defined state fails, the control shall initiate the safety shut-down. Frequency of test is as

declared by the manufacturer (see Table H.1, requirement H.102). Internal faults of the

components of the checking circuits are not considered.

H.13.2.3.3 Second fault

Modification:

Replace second sentence and items a) and b) with the following:

During assessment, for systems with non-permanent operation, the second fault shall only

be considered to occur when a start-up sequence has been performed after the first fault. For

systems with permanent operation, the second fault occurs 24 h after the first fault.

Replace the last two sentences with the following:

The fault reaction time, as well as the applicability of item c) of H.13.2.3.2, shall be as declared

by the manufacturer.

For a control function, where a mechanical actuator is part of a circuit that characterizes the

defined state, a test up to, but not including, the switching contacts is sufficient. If the test of

the defined state fails, the control shall initiate the safety shut-down. Frequency of test is as

declared by the manufacturer (see Table H.1, requirement H.102). Internal faults of the

components of the checking circuits are not considered.

H.13.2.4 Faults during defined state

Replacement:

H.13.2.4 is not applicable.

H.17 Manufacturing deviation and drift

H.17.4 Replacement:

The operating pressure and operating differential shall be as declared in Table 1, requirements

42 and 102. The allowable deviation and drift shall not be applied for the purpose

...

IEC 60730-2-6 ®

Edition 4.0 2025-08

INTERNATIONAL

STANDARD

EXTENDED VERSION

This full version of IEC 60730-2-6:2025 includes the content of the references made to

IEC 60730-1:2022

Automatic electrical controls -

Part 2-6: Particular requirements for automatic electrical pressure sensing

controls including mechanical requirements

ICS 97.120 ISBN 978-2-8327-0661-9

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or

by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either

IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC copyright

or have an enquiry about obtaining additional rights to this publication, please contact the address below or your local

IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Discover our powerful search engine and read freely all the

The advanced search enables to find IEC publications by a publications previews, graphical symbols and the glossary.

variety of criteria (reference number, text, technical With a subscription you will always have access to up to date

committee, …). It also gives information on projects, content tailored to your needs.

replaced and withdrawn publications.

Electropedia - www.electropedia.org

The world's leading online dictionary on electrotechnology,

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published containing more than 22 500 terminological entries in English

details all new publications released. Available online and and French, with equivalent terms in 25 additional languages.

once a month by email. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer

Service Centre: sales@iec.ch.

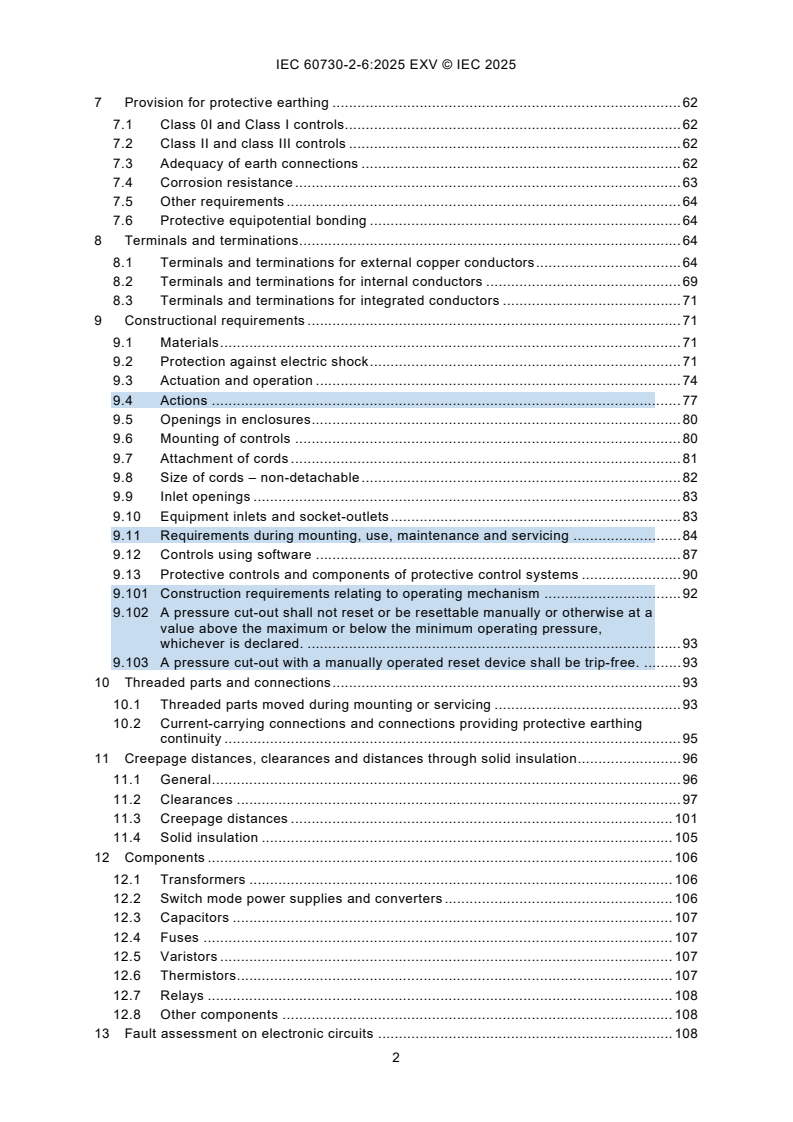

CONTENTS

FOREWORD . 9

1 Scope . 12

2 Normative references . 13

3 Terms and definitions . 17

3.1 Definitions relating to ratings, voltages, currents, frequencies, and wattages . 17

3.2 Definitions of types of control according to purpose . 20

3.3 Definitions relating to the function of controls . 22

3.4 Definitions relating to disconnection and interruption . 26

3.5 Definitions of types of control according to construction . 27

3.6 Definitions of type of automatic action of a control . 28

3.7 Definitions relating to protection against electric shock and type of insulation . 28

3.8 Definitions relating to component parts of controls . 32

3.9 Definitions of types of terminals and terminations of controls . 34

3.10 Definitions relating to the connections to controls . 36

3.11 Definitions relating to the performance of type 2 actions . 37

3.12 Definitions relating to the requirements for creepage distances and

clearances . 37

3.13 Miscellaneous definitions . 38

3.14 Definitions relating to manufacturer and user . 40

3.15 Definitions pertaining to thermistors . 40

3.16 Definitions relating to the structure of controls using software . 40

3.17 Definitions relating to error avoidance in controls using software . 40

3.18 Definitions relating to fault/error control techniques for controls using

software . 40

3.19 Definitions relating to memory tests for controls using software . 40

3.20 Definitions of software terminology – General . 40

3.21 Definitions relating to classes of control functions . 40

3.22 Definitions relating to functional safety . 40

3.23 Definitions related to access to data exchange . 40

3.24 Definitions related to EMC performance . 41

4 General . 43

4.1 General structure of the document . 43

4.2 General requirements . 44

4.3 General notes on tests . 44

5 Required technical information . 48

5.1 General requirements . 48

5.2 Methods of providing technical information . 48

5.3 Class II symbol . 56

5.4 Additional requirements for marking . 56

5.5 Warning or cautionary markings . 58

6 Protection against electric shock . 58

6.1 General requirements . 58

6.2 Actuating members and actuating means . 60

6.3 Capacitors . 61

6.4 Covers and uninsulated live or hazardous parts . 61

6.5 Battery operated controls provided with a user accessible mains supply input

connector . 61

7 Provision for protective earthing . 62

7.1 Class 0I and Class I controls. 62

7.2 Class II and class III controls . 62

7.3 Adequacy of earth connections . 62

7.4 Corrosion resistance . 63

7.5 Other requirements . 64

7.6 Protective equipotential bonding . 64

8 Terminals and terminations. 64

8.1 Terminals and terminations for external copper conductors . 64

8.2 Terminals and terminations for internal conductors . 69

8.3 Terminals and terminations for integrated conductors . 71

9 Constructional requirements . 71

9.1 Materials . 71

9.2 Protection against electric shock . 71

9.3 Actuation and operation . 74

9.4 Actions . 77

9.5 Openings in enclosures . 80

9.6 Mounting of controls . 80

9.7 Attachment of cords . 81

9.8 Size of cords – non-detachable . 82

9.9 Inlet openings . 83

9.10 Equipment inlets and socket-outlets . 83

9.11 Requirements during mounting, use, maintenance and servicing . 84

9.12 Controls using software . 87

9.13 Protective controls and components of protective control systems . 90

9.101 Construction requirements relating to operating mechanism . 92

9.102 A pressure cut-out shall not reset or be resettable manually or otherwise at a

value above the maximum or below the minimum operating pressure,

whichever is declared. . 93

9.103 A pressure cut-out with a manually operated reset device shall be trip-free. . 93

10 Threaded parts and connections . 93

10.1 Threaded parts moved during mounting or servicing . 93

10.2 Current-carrying connections and connections providing protective earthing

continuity . 95

11 Creepage distances, clearances and distances through solid insulation . 96

11.1 General . 96

11.2 Clearances . 97

11.3 Creepage distances . 101

11.4 Solid insulation . 105

12 Components . 106

12.1 Transformers . 106

12.2 Switch mode power supplies and converters . 106

12.3 Capacitors . 107

12.4 Fuses . 107

12.5 Varistors . 107

12.6 Thermistors. 107

12.7 Relays . 108

12.8 Other components . 108

13 Fault assessment on electronic circuits . 108

13.1 Fault assessment for inherent safety . 108

13.2 Fault assessment to ensure functional safety . 114

14 Moisture and dust resistance . 114

14.1 Protection against ingress of water and dust . 114

14.2 Protection against humid conditions . 115

14.3 Touch current test for in-line cord controls and free-standing controls . 116

15 Electric strength and insulation resistance . 117

15.1 Insulation resistance . 117

15.2 Electric strength . 117

15.3 Additional tests for in-line cord and free-standing controls . 119

16 Heating . 120

17 Manufacturing deviation and drift . 124

18 Environmental stress . 124

18.1 Transportation and storage . 124

18.2 Environmental stress of temperature . 124

19 Endurance . 125

19.1 General requirements . 125

19.2 Electrical conditions for the tests . 126

19.3 Thermal conditions for the tests . 132

19.4 Manual and mechanical conditions for the tests . 132

19.5 Dielectric strength requirements. 133

19.6 Ageing test . 133

19.7 Overvoltage test or overload test in all countries using an overload test of

automatic action at accelerated rate . 133

19.8 Test of automatic action at accelerated rate . 134

19.9 Test of automatic action at slow rate . 134

19.10 Overvoltage test or overload test in all countries that use the overload test of

manual action at accelerated speed . 135

19.11 Test of manual action at slow speed . 135

19.12 Test of manual action at high speed which has multiple poles, and where

polarity reversal occurs during the action . 135

19.13 Test of manual action at accelerated speed . 135

19.14 Evaluation of compliance . 136

19.15 Test for particular purpose controls . 136

20 Mechanical strength . 137

20.1 General requirements . 137

20.2 Impact resistance . 138

20.3 Free-standing controls . 138

20.4 In-line cord controls . 139

20.5 Pull-cord actuated controls . 139

20.6 Foot actuated controls . 139

20.7 Actuating member and actuating means . 140

20.8 Flexing – test . 140

20.9 Cord anchorages – test . 141

20.101 Medium leakage . 141

20.102 Strength of parts (hydrostatic) . 142

21 Resistance to heat, fire and tracking . 143

21.1 General requirements . 143

21.2 Integrated, incorporated and in-line cord controls. 143

21.3 Independently mounted, free-standing controls . 144

22 Resistance to corrosion . 145

22.1 Resistance to rusting . 145

23 Electromagnetic compatibility (EMC) requirements – Emission . 145

23.1 General requirement . 145

23.2 High frequency emission . 145

23.3 Low frequency emission . 149

24 Normal operation . 149

25 Electromagnetic compatibility (EMC) requirements – Immunity . 149

25.1 General . 149

25.2 EMC test plan and report . 150

25.3 Immunity requirements . 152

25.4 Performance criteria . 155

25.5 Surge immunity test . 156

25.6 Electrical fast transient immunity test . 156

25.7 Radio-frequency electromagnetic field immunity . 157

25.8 Electrostatic discharge . 157

25.9 Immunity to power-frequency magnetic fields . 157

25.10 Test of the influence of voltage dips and voltage interruption in the power

supply network . 157

26 Abnormal operation tests . 158

26.1 Abnormal temperature test . 158

26.2 Overload tests . 159

26.3 Battery short-circuit test . 160

Annex A (normative) Indelibility of markings . 177

Annex B (normative) Measurement of creepage distances and clearances in air . 179

Annex C (informative) Nominal voltages of supply systems for different modes of

overvoltage control . 183

Annex D (normative) Overvoltage categories . 185

Annex E (informative) Typical usage of controls and related overvoltage categories . 186

Annex F (normative) Pollution degrees . 187

F.1 Pollution . 187

F.2 Degrees of pollution in the micro-environment . 187

Annex G (normative) Resistance to heat, fire and tracking tests . 188

G.1 Glow-wire test . 188

G.2 Proof tracking test . 188

G.3 Ball pressure test . 188

Annex H (normative) Requirements related to functional safety . 190

H.3 Terms and definitions. 190

H.5 Information . 201

H.9 Constructional requirements . 203

H.13 Fault assessment on electronic circuits . 219

H.17 Manufacturing deviation and drift . 223

H.19 Endurance . 225

H.25 Electromagnetic compatibility (EMC) requirements – Immunity. 226

Annex I (normative) Requirements for certain types of DC supplied controls . 244

I.1 Scope . 244

Annex J (normative) Requirements for thermistor elements and controls using

thermistors. 246

J.1 Scope . 246

Annex K (normative) Circuit for measuring touch current . 263

Annex L (normative) Printed circuit board coating performance test . 264

Annex M (normative) Printed circuit board protection . 266

Annex N (informative) Explanatory notes for surge immunity test . 269

N.1 Different source impedances . 269

N.2 Application of the tests. 269

N.3 Installation classification . 270

Annex O (informative) Guidance for applying Clause 11 . 273

Annex P (normative) Requirements for SELV and PELV . 276

P.1 Overview of the requirements for SELV and PELV . 276

P.2 Protection against electric shock by SELV system or PELV system . 276

P.3 Protective measures for SELV system and PELV system . 277

Annex Q (informative) Regional differences relevant for the member countries of

Cenelec . 279

Annex R (informative) National differences relevant in the United States of America . 283

R.2 Normative references . 283

Annex S (informative) National differences relevant in Japan . 284

S.2 Normative references . 284

Annex T (informative) National differences relevant in Canada . 285

T.2 Normative references . 285

Annex AA (normative) Number of cycles . 286

AA.1 Number of cycles for independently mounted controls . 286