IEC 60730-2-11:2025

(Main)Automatic electrical controls - Part 2-11: Particular requirements for energy regulators

Automatic electrical controls - Part 2-11: Particular requirements for energy regulators

IEC 60730-2-11:2025 applies to energy regulators

• for use in, on, or in association with equipment for household appliance and similar use;

NOTE 1 Throughout this document, the word "equipment" means "appliance and equipment" and "controls" means "energy regulators".

• for equipment that is used by the public, such as equipment intended to be used in shops, offices, hospitals, farms and commercial and industrial applications;

EXAMPLE 1 Energy regulators for commercial catering, heating and air-conditioning equipment.

• that are smart enabled energy regulators;

EXAMPLE 2 Smart grid control, remote interfaces/control of energy-consuming equipment including computer or smart phone.

• that are AC or DC powered controls with a rated voltage not exceeding 690 V AC or 600 V DC;

• used in, on, or in association with equipment that use electricity, gas, oil, solid fuel, solar thermal energy, etc., or a combination thereof;

• utilized as part of a control system or controls which are mechanically integral with multifunctional controls having non-electrical outputs;

• using NTC or PTC thermistors and to discrete thermistors, requirements for which are contained in Annex J;

• that are mechanically or electrically operated, responsive to or controlling such characteristics as temperature, pressure, passage of time, humidity, light, electrostatic effects, flow, or liquid level, current, voltage, acceleration, or combinations thereof;

• as well as manual controls when such are electrically and/or mechanically integral with automatic controls.

NOTE 2 Requirements for manually actuated mechanical switches not forming part of an automatic control are contained in IEC 61058-1-1.

This document applies to

- the inherent safety of energy regulators, and

- functional safety of energy regulators of low complexity safety related systems and controls,

- controls where the performance (for example the effect of EMC phenomena) of the product can impair the overall safety and performance of the controlled system,

- the operating values, operating times, and operating sequences where such are associated with equipment safety.

- manual energy regulators which are electrically and/or mechanically integral with automatic controls.

- energy regulators incorporating electronic devices, requirements for which are contained in Annex H.

- the electrical and functional safety of controls capable of receiving and responding to communications signals, including signals for power billing rate and demand response.

The signals can be transmitted to or received from external units being part of the control (wired), or to and from external units which are not part of the control (wireless) under test.

This document specifies the requirements for construction, operation and testing of automatic energy regulators used in, on, or in association with an equipment.

This document does not

• apply to automatic energy regulators intended exclusively for industrial process applications unless explicitly mentioned in the relevant part 2 or the equipment standard. However, this document can be applied to evaluate automatic energy regulators intended specifically for industrial applications in cases where no relevant safety standard exists.

• take into account the response value of an automatic action of an energy regulator, if such a response value is dependent upon the method of mounting the energy regulator in the equipment. Where a response value is of significant purpose for the protection of the user, or surroundings, the value defined in the appropriate equipment standard or as determined by the manufacturer will apply.

• address the integrity of the output signal to the network devices, such as interoperability with other devices unless it has been evaluated as part of the control system.

This fourth edition cancels and replaces the third edition published in 2019. This edition constitutes a technical revision.

This edition includes the following

Dispositifs de commande électrique automatiques - Partie 2-11: Exigences particulières pour les régulateurs d'énergie

L'IEC 60730-2-11:2025 s'applique aux régulateurs d'énergie

• utilisés dans, sur ou avec des matériels pour appareil domestique et usage analogue;

NOTE 1 Dans le présent document, le terme "matériel" signifie "appareil et matériel" et "dispositifs de commande" signifie "régulateurs d'énergie".

• pour des matériels utilisés par le public, tels que les matériels destinés à être utilisés dans des magasins, des bureaux, des hôpitaux, des fermes et des applications commerciales et industrielles;

EXEMPLE 1 Les régulateurs d'énergie pour les installations de restauration, de chauffage et d'air conditionné.

• qui sont des régulateurs d'énergie activés intelligents;

EXEMPLE 2 Les dispositifs de commande de réseau intelligent, les interfaces distantes/dispositifs de commande de matériels utilisateurs d'énergie électrique, y compris les ordinateurs ou les mobiles multifonctions.

• qui sont des dispositifs de commande à courant alternatif ou continu dont la tension assignée ne dépasse pas 690 V en courant alternatif ou 600 V en courant continu;

• qui sont utilisés dans, sur ou avec des matériels qui utilisent l'électricité, le gaz, le pétrole, des combustibles solides, l'énergie thermique solaire, etc. ou une combinaison de ces sources d'énergie;

• qui sont utilisées dans le cadre d'un système de commande ou de dispositifs de commande qui sont mécaniquement intégrés à des dispositifs de commande multifonctions comportant des sorties non électriques;

• qui utilisent des thermistances CTN ou CTP ainsi qu'aux dispositifs à thermistances discrètes, dont les exigences sont fournies à l'Annexe J;

• à commande mécanique ou électrique, qui réagissent à des caractéristiques telles que la température, la pression, le passage du temps, l'humidité, la lumière, les effets électrostatiques, le débit ou le niveau d'un liquide, le courant, la tension, l'accélération, ou une combinaison de ces caractéristiques, ou qui les régulent;

• ainsi qu'aux dispositifs de commande manuels qui sont électriquement et/ou mécaniquement intégrés à des dispositifs de commande automatique.

NOTE 2 Les exigences relatives aux interrupteurs mécaniques à action manuelle qui ne font pas partie d'un dispositif de commande automatique sont contenues dans l'IEC 61058-1-1.

Le présent document s'applique

− à la sécurité intrinsèque des régulateurs d'énergie; et

− à la sécurité fonctionnelle des régulateurs d'énergie des systèmes et dispositifs de commande de sécurité peu complexe;

− aux dispositifs de commande pour lesquels les performances (par exemple, l'effet des phénomènes CEM) du produit peuvent compromettre la sécurité et les performances globales du système commandé;

− aux valeurs de fonctionnement, aux temps de fonctionnement et aux séquences de fonctionnement lorsque ces éléments interviennent dans la sécurité du matériel;

− aux régulateurs d'énergie manuels qui sont électriquement et/ou mécaniquement intégrés à des dispositifs de commande automatique;

− aux régulateurs d'énergie qui incorporent des dispositifs électroniques, dont les exigences figurent à l'Annexe H;

− à la sécurité électrique et la sécurité fonctionnelle des dispositifs de commande capables de recevoir et de répondre à des signaux de communication, y compris les signaux propres au taux de facturation de l'électricité et à la gestion de la demande.

Les signaux peuvent être transmis ou reçus d'unités externes qui font partie intégrante du dispositif de commande (câblé), ou vers et depuis des unités externes qui ne font pas partie intégrante du dispositif de commande (non câblé) soumis à l'essai.

Le présent document spécifie les exigences relatives à la construction, au fonctionnement et aux essais des régulateurs d'énergie automatiques utilisés dans, sur ou avec du matériel.

Le présent document

• ne s'applique pas aux régulateurs d'énergie automatiques destinés exclusivement à des applications de processus industriels, sauf mention particulière dans la partie 2 applicable ou la norme

General Information

- Status

- Published

- Publication Date

- 06-Aug-2025

- Technical Committee

- TC 72 - Automatic electrical controls

- Drafting Committee

- WG 6 - TC 72/WG 6

- Current Stage

- PPUB - Publication issued

- Start Date

- 07-Aug-2025

- Completion Date

- 08-Aug-2025

Relations

- Effective Date

- 10-May-2024

Overview - IEC 60730-2-11:2025 for energy regulators

IEC 60730-2-11:2025 is the fourth edition of the IEC standard covering automatic electrical controls with particular requirements for energy regulators. It specifies safety, construction, operation and testing requirements for energy regulators used in household appliances, public-use equipment (shops, offices, hospitals, commercial and industrial installations), and smart‑enabled energy regulators (including wired and wireless interfaces for demand response and power‑billing signals). The standard applies to AC/DC controls up to 690 V AC / 600 V DC and covers regulators that monitor or control temperature, pressure, time, humidity, flow, level, electrical parameters and combinations thereof.

Key topics and technical requirements

- Scope of application: household and similar equipment, public-use equipment, smart grid and remote‑control capable regulators. Excludes regulators intended exclusively for industrial process applications unless referenced.

- Safety and functional requirements: inherent safety, functional safety for low‑complexity safety‑related systems, and safety where product performance (e.g., EMC effects) can impair controlled-system safety.

- Construction and components: requirements for terminals, enclosures, materials, earthing, threaded parts, creepage/clearance, insulation, and protection against electric shock.

- Electronic and thermistor devices: provisions for electronic components (Annex H) and NTC/PTC or discrete thermistors (Annex J).

- Communications and interoperability: electrical and functional safety of controls that receive/respond to communications signals (wired/wireless) for demand response and billing.

- Testing and verification: tests for electric strength, insulation resistance, moisture/dust resistance, endurance, mechanical strength, heating, fault assessment for electronics, environmental stress, and EMC considerations.

- Documentation and marking: required technical information, marking, warnings, and user instructions.

Practical applications and who uses this standard

- Appliance manufacturers designing thermostats, timers and energy regulators for cookers, HVAC, water heating and commercial catering equipment.

- OEMs integrating smart enabled controls and IoT interfaces for demand response, remote control, or power‑billing signals.

- Test laboratories and compliance engineers performing safety, EMC and environmental testing of energy regulators.

- Product safety managers and certification bodies assessing conformity for market access.

Related standards

- IEC 60730-1:2022 - referenced general requirements for automatic electrical controls.

- IEC 61058-1-1 - referenced for manually actuated mechanical switches not forming part of automatic controls.

This standard is essential for ensuring the electrical and functional safety of modern energy regulators, especially where smart communications and interoperability affect overall system safety and performance.

Frequently Asked Questions

IEC 60730-2-11:2025 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Automatic electrical controls - Part 2-11: Particular requirements for energy regulators". This standard covers: IEC 60730-2-11:2025 applies to energy regulators • for use in, on, or in association with equipment for household appliance and similar use; NOTE 1 Throughout this document, the word "equipment" means "appliance and equipment" and "controls" means "energy regulators". • for equipment that is used by the public, such as equipment intended to be used in shops, offices, hospitals, farms and commercial and industrial applications; EXAMPLE 1 Energy regulators for commercial catering, heating and air-conditioning equipment. • that are smart enabled energy regulators; EXAMPLE 2 Smart grid control, remote interfaces/control of energy-consuming equipment including computer or smart phone. • that are AC or DC powered controls with a rated voltage not exceeding 690 V AC or 600 V DC; • used in, on, or in association with equipment that use electricity, gas, oil, solid fuel, solar thermal energy, etc., or a combination thereof; • utilized as part of a control system or controls which are mechanically integral with multifunctional controls having non-electrical outputs; • using NTC or PTC thermistors and to discrete thermistors, requirements for which are contained in Annex J; • that are mechanically or electrically operated, responsive to or controlling such characteristics as temperature, pressure, passage of time, humidity, light, electrostatic effects, flow, or liquid level, current, voltage, acceleration, or combinations thereof; • as well as manual controls when such are electrically and/or mechanically integral with automatic controls. NOTE 2 Requirements for manually actuated mechanical switches not forming part of an automatic control are contained in IEC 61058-1-1. This document applies to - the inherent safety of energy regulators, and - functional safety of energy regulators of low complexity safety related systems and controls, - controls where the performance (for example the effect of EMC phenomena) of the product can impair the overall safety and performance of the controlled system, - the operating values, operating times, and operating sequences where such are associated with equipment safety. - manual energy regulators which are electrically and/or mechanically integral with automatic controls. - energy regulators incorporating electronic devices, requirements for which are contained in Annex H. - the electrical and functional safety of controls capable of receiving and responding to communications signals, including signals for power billing rate and demand response. The signals can be transmitted to or received from external units being part of the control (wired), or to and from external units which are not part of the control (wireless) under test. This document specifies the requirements for construction, operation and testing of automatic energy regulators used in, on, or in association with an equipment. This document does not • apply to automatic energy regulators intended exclusively for industrial process applications unless explicitly mentioned in the relevant part 2 or the equipment standard. However, this document can be applied to evaluate automatic energy regulators intended specifically for industrial applications in cases where no relevant safety standard exists. • take into account the response value of an automatic action of an energy regulator, if such a response value is dependent upon the method of mounting the energy regulator in the equipment. Where a response value is of significant purpose for the protection of the user, or surroundings, the value defined in the appropriate equipment standard or as determined by the manufacturer will apply. • address the integrity of the output signal to the network devices, such as interoperability with other devices unless it has been evaluated as part of the control system. This fourth edition cancels and replaces the third edition published in 2019. This edition constitutes a technical revision. This edition includes the following

IEC 60730-2-11:2025 applies to energy regulators • for use in, on, or in association with equipment for household appliance and similar use; NOTE 1 Throughout this document, the word "equipment" means "appliance and equipment" and "controls" means "energy regulators". • for equipment that is used by the public, such as equipment intended to be used in shops, offices, hospitals, farms and commercial and industrial applications; EXAMPLE 1 Energy regulators for commercial catering, heating and air-conditioning equipment. • that are smart enabled energy regulators; EXAMPLE 2 Smart grid control, remote interfaces/control of energy-consuming equipment including computer or smart phone. • that are AC or DC powered controls with a rated voltage not exceeding 690 V AC or 600 V DC; • used in, on, or in association with equipment that use electricity, gas, oil, solid fuel, solar thermal energy, etc., or a combination thereof; • utilized as part of a control system or controls which are mechanically integral with multifunctional controls having non-electrical outputs; • using NTC or PTC thermistors and to discrete thermistors, requirements for which are contained in Annex J; • that are mechanically or electrically operated, responsive to or controlling such characteristics as temperature, pressure, passage of time, humidity, light, electrostatic effects, flow, or liquid level, current, voltage, acceleration, or combinations thereof; • as well as manual controls when such are electrically and/or mechanically integral with automatic controls. NOTE 2 Requirements for manually actuated mechanical switches not forming part of an automatic control are contained in IEC 61058-1-1. This document applies to - the inherent safety of energy regulators, and - functional safety of energy regulators of low complexity safety related systems and controls, - controls where the performance (for example the effect of EMC phenomena) of the product can impair the overall safety and performance of the controlled system, - the operating values, operating times, and operating sequences where such are associated with equipment safety. - manual energy regulators which are electrically and/or mechanically integral with automatic controls. - energy regulators incorporating electronic devices, requirements for which are contained in Annex H. - the electrical and functional safety of controls capable of receiving and responding to communications signals, including signals for power billing rate and demand response. The signals can be transmitted to or received from external units being part of the control (wired), or to and from external units which are not part of the control (wireless) under test. This document specifies the requirements for construction, operation and testing of automatic energy regulators used in, on, or in association with an equipment. This document does not • apply to automatic energy regulators intended exclusively for industrial process applications unless explicitly mentioned in the relevant part 2 or the equipment standard. However, this document can be applied to evaluate automatic energy regulators intended specifically for industrial applications in cases where no relevant safety standard exists. • take into account the response value of an automatic action of an energy regulator, if such a response value is dependent upon the method of mounting the energy regulator in the equipment. Where a response value is of significant purpose for the protection of the user, or surroundings, the value defined in the appropriate equipment standard or as determined by the manufacturer will apply. • address the integrity of the output signal to the network devices, such as interoperability with other devices unless it has been evaluated as part of the control system. This fourth edition cancels and replaces the third edition published in 2019. This edition constitutes a technical revision. This edition includes the following

IEC 60730-2-11:2025 is classified under the following ICS (International Classification for Standards) categories: 97.120 - Automatic controls for household use. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60730-2-11:2025 has the following relationships with other standards: It is inter standard links to IEC 60730-2-11:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60730-2-11:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60730-2-11 ®

Edition 4.0 2025-08

INTERNATIONAL

STANDARD

EXTENDED VERSION

This full version of IEC 60730-2-11:2025 includes the content of the references made

to IEC 60730-1:2022

Automatic electrical controls –

Part 2-11: Particular requirements for energy regulators

ICS 97.120 ISBN 978-2-8327-0642-8

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or

by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either

IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC copyright

or have an enquiry about obtaining additional rights to this publication, please contact the address below or your local

IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Discover our powerful search engine and read freely all the

The advanced search enables to find IEC publications by a publications previews, graphical symbols and the glossary.

variety of criteria (reference number, text, technical With a subscription you will always have access to up to date

committee, …). It also gives information on projects, content tailored to your needs.

replaced and withdrawn publications.

Electropedia - www.electropedia.org

The world's leading online dictionary on electrotechnology,

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published containing more than 22 500 terminological entries in English

details all new publications released. Available online and and French, with equivalent terms in 25 additional languages.

once a month by email. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer

Service Centre: sales@iec.ch.

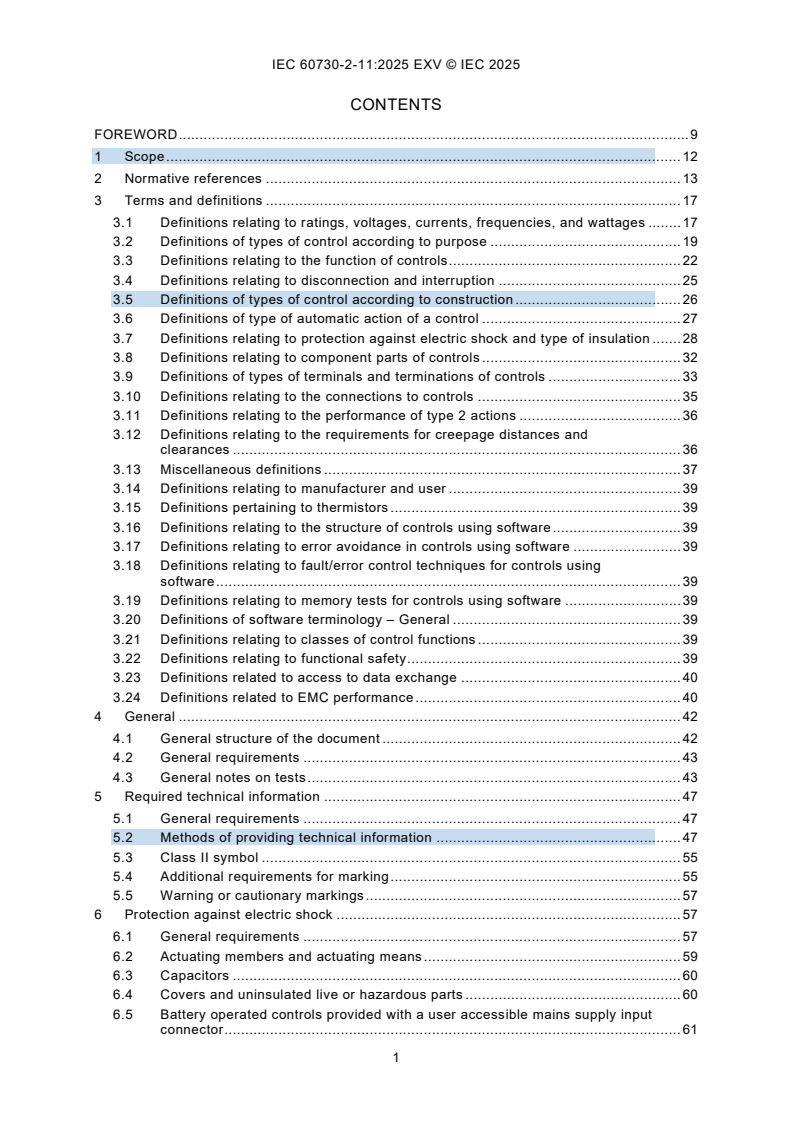

CONTENTS

FOREWORD . 9

1 Scope . 12

2 Normative references . 13

3 Terms and definitions . 17

3.1 Definitions relating to ratings, voltages, currents, frequencies, and wattages . 17

3.2 Definitions of types of control according to purpose . 19

3.3 Definitions relating to the function of controls . 22

3.4 Definitions relating to disconnection and interruption . 25

3.5 Definitions of types of control according to construction . 26

3.6 Definitions of type of automatic action of a control . 27

3.7 Definitions relating to protection against electric shock and type of insulation . 28

3.8 Definitions relating to component parts of controls . 32

3.9 Definitions of types of terminals and terminations of controls . 33

3.10 Definitions relating to the connections to controls . 35

3.11 Definitions relating to the performance of type 2 actions . 36

3.12 Definitions relating to the requirements for creepage distances and

clearances . 36

3.13 Miscellaneous definitions . 37

3.14 Definitions relating to manufacturer and user . 39

3.15 Definitions pertaining to thermistors . 39

3.16 Definitions relating to the structure of controls using software . 39

3.17 Definitions relating to error avoidance in controls using software . 39

3.18 Definitions relating to fault/error control techniques for controls using

software . 39

3.19 Definitions relating to memory tests for controls using software . 39

3.20 Definitions of software terminology – General . 39

3.21 Definitions relating to classes of control functions . 39

3.22 Definitions relating to functional safety . 39

3.23 Definitions related to access to data exchange . 40

3.24 Definitions related to EMC performance . 40

4 General . 42

4.1 General structure of the document . 42

4.2 General requirements . 43

4.3 General notes on tests . 43

5 Required technical information . 47

5.1 General requirements . 47

5.2 Methods of providing technical information . 47

5.3 Class II symbol . 55

5.4 Additional requirements for marking . 55

5.5 Warning or cautionary markings . 57

6 Protection against electric shock . 57

6.1 General requirements . 57

6.2 Actuating members and actuating means . 59

6.3 Capacitors . 60

6.4 Covers and uninsulated live or hazardous parts . 60

6.5 Battery operated controls provided with a user accessible mains supply input

connector . 61

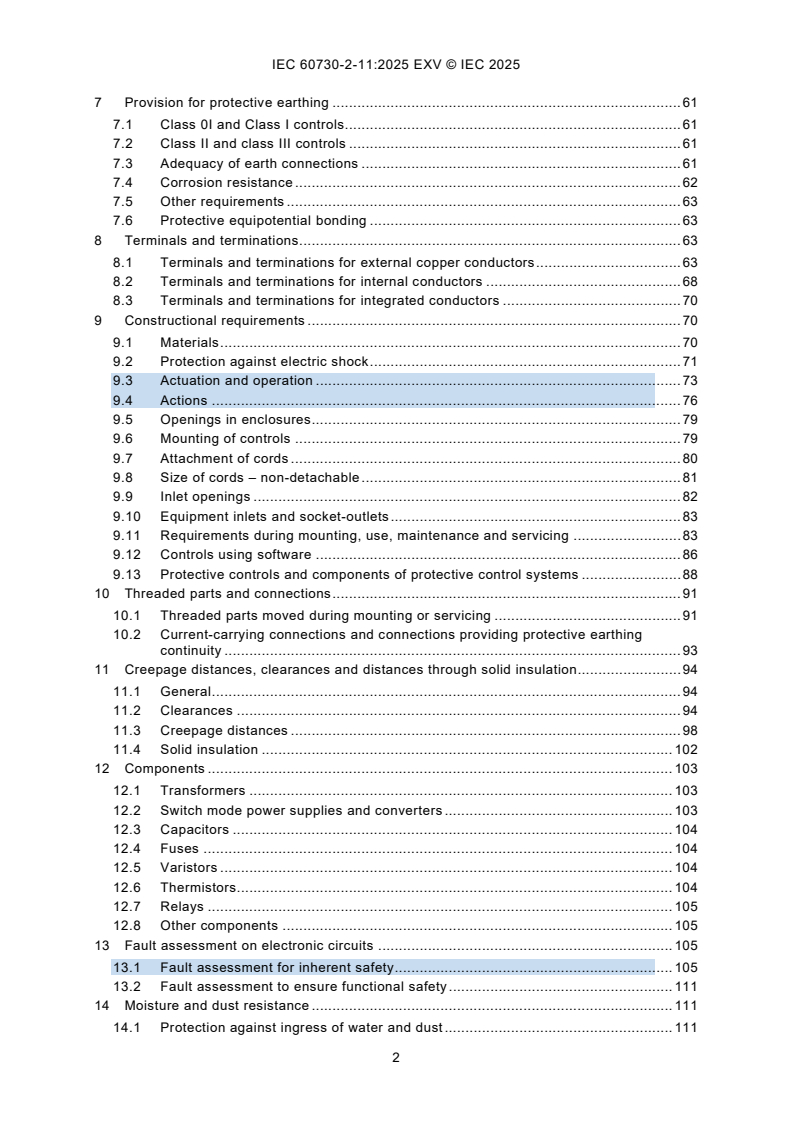

7 Provision for protective earthing . 61

7.1 Class 0I and Class I controls. 61

7.2 Class II and class III controls . 61

7.3 Adequacy of earth connections . 61

7.4 Corrosion resistance . 62

7.5 Other requirements . 63

7.6 Protective equipotential bonding . 63

8 Terminals and terminations. 63

8.1 Terminals and terminations for external copper conductors . 63

8.2 Terminals and terminations for internal conductors . 68

8.3 Terminals and terminations for integrated conductors . 70

9 Constructional requirements . 70

9.1 Materials . 70

9.2 Protection against electric shock . 71

9.3 Actuation and operation . 73

9.4 Actions . 76

9.5 Openings in enclosures . 79

9.6 Mounting of controls . 79

9.7 Attachment of cords . 80

9.8 Size of cords – non-detachable . 81

9.9 Inlet openings . 82

9.10 Equipment inlets and socket-outlets . 83

9.11 Requirements during mounting, use, maintenance and servicing . 83

9.12 Controls using software . 86

9.13 Protective controls and components of protective control systems . 88

10 Threaded parts and connections . 91

10.1 Threaded parts moved during mounting or servicing . 91

10.2 Current-carrying connections and connections providing protective earthing

continuity . 93

11 Creepage distances, clearances and distances through solid insulation . 94

11.1 General . 94

11.2 Clearances . 94

11.3 Creepage distances . 98

11.4 Solid insulation . 102

12 Components . 103

12.1 Transformers . 103

12.2 Switch mode power supplies and converters . 103

12.3 Capacitors . 104

12.4 Fuses . 104

12.5 Varistors . 104

12.6 Thermistors. 104

12.7 Relays . 105

12.8 Other components . 105

13 Fault assessment on electronic circuits . 105

13.1 Fault assessment for inherent safety . 105

13.2 Fault assessment to ensure functional safety . 111

14 Moisture and dust resistance . 111

14.1 Protection against ingress of water and dust . 111

14.2 Protection against humid conditions . 112

14.3 Touch current test for in-line cord controls and free-standing controls . 113

15 Electric strength and insulation resistance . 114

15.1 Insulation resistance . 114

15.2 Electric strength . 114

15.3 Additional tests for in-line cord and free-standing controls . 116

16 Heating . 117

16.101 Energy regulators for use in or on cooking appliances . 121

17 Manufacturing deviation and drift . 121

18 Environmental stress . 122

18.1 Transportation and storage . 122

18.2 Environmental stress of temperature . 122

19 Endurance . 122

19.1 General requirements . 122

19.2 Electrical conditions for the tests . 124

19.3 Thermal conditions for the tests . 129

19.4 Manual and mechanical conditions for the tests . 129

19.5 Dielectric strength requirements. 130

19.6 Ageing test . 130

19.7 Overvoltage test or overload test in all countries using an overload test of

automatic action at accelerated rate . 130

19.8 Test of automatic action at accelerated rate . 131

19.9 Test of automatic action at slow rate . 131

19.10 Overvoltage test or overload test in all countries that use the overload test of

manual action at accelerated speed . 131

19.11 Test of manual action at slow speed . 132

19.12 Test of manual action at high speed which has multiple poles, and where

polarity reversal occurs during the action . 132

19.13 Test of manual action at accelerated speed . 132

19.14 Evaluation of compliance . 133

19.15 Test for particular purpose controls . 133

20 Mechanical strength . 133

20.1 General requirements . 133

20.2 Impact resistance . 134

20.3 Free-standing controls . 135

20.4 In-line cord controls . 135

20.5 Pull-cord actuated controls . 136

20.6 Foot actuated controls . 136

20.7 Actuating member and actuating means . 136

20.8 Flexing – test . 137

20.9 Cord anchorages – test . 137

20.101 Push-and-turn or pull-and-turn actuation . 138

21 Resistance to heat, fire and tracking . 139

21.1 General requirements . 139

21.2 Integrated, incorporated and in-line cord controls. 139

21.3 Independently mounted, free-standing controls . 140

22 Resistance to corrosion . 141

22.1 Resistance to rusting . 141

23 Electromagnetic compatibility (EMC) requirements – Emission . 141

23.1 General requirement . 141

23.2 High frequency emission . 142

23.3 Low frequency emission . 145

24 Normal operation . 145

25 Electromagnetic compatibility (EMC) requirements – Immunity . 145

25.1 General . 145

25.2 EMC test plan and report . 146

25.3 Immunity requirements . 148

25.4 Performance criteria . 151

25.5 Surge immunity test . 152

25.6 Electrical fast transient immunity test . 152

25.7 Radio-frequency electromagnetic field immunity . 153

25.8 Electrostatic discharge . 153

25.9 Immunity to power-frequency magnetic fields . 153

25.10 Test of the influence of voltage dips and voltage interruption in the power

supply network . 153

26 Abnormal operation tests . 154

26.1 Abnormal temperature test . 154

26.2 Overload tests . 155

26.3 Battery short-circuit test . 156

Annex A (normative) Indelibility of markings . 173

Annex B (normative) Measurement of creepage distances and clearances in air . 175

Annex C (informative) Nominal voltages of supply systems for different modes of

overvoltage control . 179

Annex D (normative) Overvoltage categories . 181

Annex E (informative) Typical usage of controls and related overvoltage categories . 182

Annex F (normative) Pollution degrees . 183

F.1 Pollution . 183

F.2 Degrees of pollution in the micro-environment . 183

Annex G (normative) Resistance to heat, fire and tracking tests . 184

G.1 Glow-wire test . 184

G.2 Proof tracking test . 184

G.3 Ball pressure test . 184

Annex H (normative) Requirements related to functional safety . 186

H.3 Terms and definitions. 186

H.5 Information . 197

H.9 Constructional requirements . 198

H.13 Fault assessment on electronic circuits . 215

H.17 Manufacturing deviation and drift . 219

H.19 Endurance . 220

H.25 Electromagnetic compatibility (EMC) requirements – Immunity. 221

Annex I (normative) Requirements for certain types of DC supplied controls . 234

I.1 Scope . 234

Annex J (normative) Requirements for thermistor elements and controls using

thermistors. 236

J.1 Scope . 236

Annex K (normative) Circuit for measuring touch current . 253

Annex L (normative) Printed circuit board coating performance test . 254

Annex M (normative) Printed circuit board protection . 256

Annex N (informative) Explanatory notes for surge immunity test . 259

N.1 Different source impedances . 259

N.2 Application of the tests. 259

N.3 Installation classification . 260

Annex O (informative) Guidance for applying Clause 11 . 263

Annex P (normative) Requirements for SELV and PELV . 266

P.1 Overview of the requirements for SELV and PELV . 266

P.2 Protection against electric shock by SELV system or PELV system . 266

P.3 Protective measures for SELV system and PELV system . 267

Annex Q (informative) Regional differences relevant for the member countries of

Cenelec . 269

Annex R (informative) National differences relevant in the United States of America . 273

R.2 Normative references . 273

Annex S (informative) National differences relevant in Japan . 274

S.2 Normative references . 274

Annex T (informative) National differences relevant in Canada . 275

T.2 Normative references . 275

Bibliography . 276

Figure 1 – Example of ports . 40

Figure 2 – Structure of the document with respect to inherent safety and functional

safety . 43

Figure 3 – Example of an electronic circuit with low power points . 106

Figure 4 – Test pin probe 13 of IEC 61032:1997 . 156

Figure 5 – Test finger probe B of IEC 61032:1997 . 157

Figure 6 – Test fingernail . 158

Figure 7 – Impact test for free-standing controls . 159

Figure 8 – Tumbling barrel . 159

Figure 9 – Apparatus for testing durability of markings on rating labels . 160

Figure 10 – Apparatus for flexing test . 160

Figure 11 – Screw terminals and stud terminals . 161

Figure 12 – Pillar terminals . 162

Figure 13 – Mantle terminals . 163

Figure 14 – Saddle and lug terminals . 164

Figure 15 – Tabs. 165

Figure 16 – Tabs for non-reversible connectors . 166

Figure 17 – Receptacles . 167

Figure 18 – Measurement of creepage distance and clearance . 168

Figure 19 – Diagram for touch current measurement at operating temperature for

single-phase connection of class II controls . 169

Figure 20 – Diagram for touch current measurement at operating temperature for

single-phase connection of controls other than class II . 169

Figure 21 – Diagram for touch current measurement at operating temperature for

three-phase connection of class II controls . 170

Figure 22 – Diagram for touch current measurement at operating temperature for

three-phase connection of controls other than class II . 171

Figure 23 – Diagram for touch current measurement at operating temperature for

single-phase connection of controls to three-wire, ground neutral supply other than

class II . 171

Figure 24 – Diagram for touch current measurement at operating temperature for

two‑phase connection of controls to three-wire, ground neutral supply other

than class II . 172

Figure B.1 – Narrow groove . 176

Figure B.2 – Wide groove . 176

Figure B.3 – V-shaped groove . 176

Figure B.4 – Rib . 176

Figure B.5 – Uncemented joint with narrow groove . 177

Figure B.6 – Uncemented joint with wide groove . 177

Figure B.7 – Uncemented joint with narrow and wide grooves . 177

Figure B.8 – Diverging side walls . 178

Figure B.9 – Narrow recess . 178

Figure B.10 – Wide recess . 178

Figure B.11 – Conductive floating part . 178

Figure H.1 – V-Model for the software life cycle . 206

Figure H.2 – Voltage variation test . 224

Figure J.1 – Generic test circuit for inrush-current limiting thermistor endurance test . 252

Figure K.1 – Circuit for measuring touch currents . 253

Figure L.1 – Test sample . 255

Figure M.1 – Example of type 1 protection . 257

Figure M.2 – Example of type 2 protection . 258

Figure N.1 – Example of surge protection by shielding in buildings with common earth

reference systems . 261

Figure N.2 – Example of secondary surge protection in buildings with separate

common earth reference systems . 262

Figure N.3 – Example of primary and secondary surge protection of indoor/outdoor

equipment . 262

Figure O.1 – Guidance flowchart for application of requirements of Clause 11 . 264

Table 1 – Required technical information and methods of providing these information . 50

Table 2 – Cross-sectional area of conductors . 64

Table 3 – Terminal conductors . 66

Table 4 – Conductor pull test values . 67

Table 5 – Nominal cross-sectional areas of conductors . 68

Table 6 – Axial force values for tab insertion and withdrawal . 70

Table 7 – Minimum cord conductor sizes . 82

Table 8 – Data exchange . 87

Table 9 – Threaded parts torque test values . 92

Table 10 – Rated impulse voltage for equipment energized directly from the supply

mains (from IEC 60664-1:2007, Table F.1) . 95

Table 11 – Clearances for insulation co-ordination (from IEC 60664-1:2007, Table F.2). 96

Table 12 – Minimum creepage distances for basic insulation . 100

Table 13 – Minimum creepage distances for functional insulation . 101

Table 14 – Electrical/electronic component fault modes . 107

Table 15 – Minimum insulation resistance . 114

Table 16 – Insulation or disconnection test voltages . 115

Table 17 – Maximum heating temperatures . 119

Table 18 – Electrical conditions for the overvoltage and endurance tests . 125

Table 19 – Electrical conditions for the overload tests of 19.7 and 19.10 . 127

Table 20 – Electrical conditions for the endurance tests of 19.8, 19.9, 19.11, 19.12 and

19.13 . 128

Table 21 – Pull-cord force test values . 136

Table 22 – Pull and torque values . 138

Table 23 – Emission limit for residential electromagnetic environment . 143

Table 24 – Emission limit for industrial electromagnetic environment . 144

Table 25 – The applicable EMC test in relation to the class of control function and type

of Action . 146

Table 26 – Immunity test requirements for residential electromagnetic environments . 148

Table 27 – Immunity test requirements for industrial electromagnetic environment . 150

Table 28 – Performance criteria . 152

Table 29 – Maximum winding temperature (for test of mechanical blocked output

conditions) . 155

Table B.1 – Value of X . 175

Table C.1 – Inherent control or equivalent protective control . 179

Table C.2 – Cases where protective control is necessary and control is provided by

surge arresters having a ratio of clamping voltage to rated voltage not smaller than

that specified by IEC 60099-1 . 180

Table E.1 – Typical usage. 182

Table H.1 – Additional items to Table 1 . 197

a

Table H.2 – Acceptable measures to address fault/errors . 200

Table H.3 – Examples of techniques/measures for semi-formal methods . 207

Table H.4 – Examples of techniques/measures for software architecture specification . 207

Table H.5 – Examples of techniques/measures for module design specification . 208

Table H.6 – Examples of techniques/measures for design and coding standards . 208

Table H.7 – Examples of techniques/measures for software module testing . 209

Table H.8 – Examples of techniques/measures for software integration testing . 210

Table H.9 – Examples of techniques/measures for software safety validation . 210

Table H.10 – Combinations of analytical measures during hardware development . 212

Table H.11 – Examples of defences against unauthorised access and transmission

failure modes . 213

Table H.12 – Applicable test levels in addition to Clause 25. 222

Table H.13 – Voltage dips, short interruptions and voltage variations . 223

Table H.14 – Test values for voltage variations . 224

Table H.15 – Test voltages for test level 2 (depending on the installation class

conditions) . 226

Table H.16 – Test level for electrical fast transient burst test . 227

Table H.17 – Test levels for conducted disturbances on mains and I/O lines . 229

Table H.18 – Test level for immunity to radiated electromagnetic fields . 230

Table H.19 – Increased test level for radiated immunity . 230

Table H.20 – Test level for supply frequency variations . 231

Table H.21 – Test level for continuous fields . 232

Table I.1 – Electrical transient conduction immunity in accordance with ISO 7637-2 . 234

Table I.2 – Electrical transient conduction immunity in accordance with ISO 7637-3 . 235

Table J.1 – Maximum current . 238

Table J.2 – Normal operating conditions . 239

Table J.3 – Samples for the test (clause reference) . 240

Table J.4 – Electrical and thermal ratings of a thermistor . 241

Table J.5 – Additional items to Table 1 . 242

Table J.6 – Sequence of calibration and conditioning tests for PTC thermistors . 244

Table J.7 – Classes for PTC sensing thermistors . 245

Table J.8 – Sequence of calibration and conditioning tests for NTC thermistors . 246

Table J.9 – Classes for NTC sensing thermistors . 246

Table J.10 – Number of cycles for endurance test . 250

Table J.11 – Ageing test temperature . 250

Table J.12 – Number of cycles for endurance test . 251

Table L.1 – Environmental cycling conditions . 254

Table M.1 – IEC 60664-3 test levels or conditions . 256

Table O.1 – Example A – Using Annex O guidance for applying Clause 11 . 265

Table O.2 – Example B – Using Annex O guidance for applying Clause 11 . 265

Table Q.1 – Additional aging parameters for windings . 270

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

Automatic electrical controls -

Part 2-11: Particular requirements for energy regulators

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt wi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...