IEC 60502-4:2010

(Main)Power cables with extruded insulation and their accessories for rated voltages from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) - Part 4: Test requirements on accessories for cables with rated voltages from 6 kV (Um = 7,2 kV) up to 30 kV (Um = 36 kV)

Power cables with extruded insulation and their accessories for rated voltages from 1 kV (U<sub>m</sub> = 1,2 kV) up to 30 kV (U<sub>m</sub> = 36 kV) - Part 4: Test requirements on accessories for cables with rated voltages from 6 kV (U<sub>m</sub> = 7,2 kV) up to 30 kV (U<sub>m</sub> = 36 kV)

IEC 60502-4:2010 specifies the test requirements for type testing of accessories for power cables with rated voltages from 3,6/6 (7,2) kV up to 18/30 (36) kV, complying with IEC 60502-2. Accessories for special applications, such as aerial cables, submarine or ship cables or hazardous situations (explosive environments, fire-resistant cables or seismic conditions), are not included. It is not necessary to repeat these tests, once successfully completed, unless changes are made in the materials, design or manufacturing process which might affect the performance characteristics. Test methods are included in IEC 61442. Significant technical changes with respect to the previous edition are as follows:

a) the range of approval has been revised;

b) a water immersion test requirement for outdoor terminations has been introduced;

c) examination of accessories at the end of the test sequence is to be recorded in a test report for information only;

d) both the a.c. and d.c. test are to be carried out;

e) the heating cycle test has been added to Table 11.

Câbles d'énergie à isolant extrudé et leurs accessoires pour des tensions assignées de 1 kV (U<sub>m</sub> = 1,2 kV) à 30 kV (U<sub>m</sub> = 36 kV) - Partie 4: Exigences d'essai pour accessoires de câbles de tensions assignées de 6 kV (U<sub>m</sub> = 7,2 kV) à 30 kV (U<sub>m</sub> = 36 kV)

La CEI 60502-4:2010 définit les exigences d'essais de type des accessoires de câbles d'énergie de tensions assignées de 3,6/6 (7,2) kV à 18/30 (36) kV conformes à la CEI 60502-2. Les accessoires pour des applications spéciales telles que les câbles aériens, sous-marins ou de bord ou les situations à risque (environnements explosifs, câbles résistant au feu, ou conditions séismiques) ne sont pas couverts par cette norme. Il n'est pas nécessaire de répéter ces essais lorsqu'ils ont été effectués avec succès, sauf si des changements interviennent dans les matériaux, la constitution ou le procédé de fabrication, susceptibles d'affecter les caractéristiques de fonctionnement. Les méthodes d'essais figurent dans la CEI 61442. Cette troisième édition annule et remplace la deuxième édition, publiée en 2005, et constitue une révision technique. Les changements significatifs par rapport à l'édition précédente sont les suivants:

a) le domaine d'application a été révisé;

b) un essai d'immersion dans l'eau a été introduit pour les extrémités externes;

c) l'examen des accessoires à la fin de la séquence d'essai est à enregistrer dans le rapport d'essai pour information seulement;

d) les deux essais de tenue diélectrique en courant alternative et courant continue sont à affectuer;

e) l'essai de cycles thermiques a été ajouté au Tableau 11.

General Information

- Status

- Published

- Publication Date

- 14-Dec-2010

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- WG 16 - TC 20/WG 16

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 15-Nov-2023

- Completion Date

- 31-May-2021

Relations

- Effective Date

- 10-Feb-2026

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60502-4:2010 is an international standard developed by the International Electrotechnical Commission (IEC) that specifies test requirements for accessories used with power cables featuring extruded insulation. These accessories are designed for cables with rated voltages from 6 kV (Um = 7.2 kV) up to 30 kV (Um = 36 kV). This part of IEC 60502 complements IEC 60502-2, which covers the cable specifications themselves.

The standard outlines rigorous type testing protocols to ensure that cable accessories such as terminations, joints, connectors, and stop ends meet the necessary safety and performance criteria. The testing covers electrical, mechanical, and environmental factors to confirm reliability under operating conditions.

Notably, IEC 60502-4 excludes accessories for special applications like aerial cables, submarine cables, ship cables, and hazardous environments such as explosive atmospheres or seismic zones.

Key Topics

Scope and Purpose

- Defines type test requirements for cable accessories compatible with extruded insulated power cables rated 6 kV to 30 kV.

- Ensures that accessories comply with performance characteristics without needing repeated testing unless design or material modifications occur.

Test Methods and Sequences

- Test methods align with IEC 61442, which provides detailed procedures for power cable accessory testing.

- Includes tests for both alternating current (a.c.) and direct current (d.c.) electrical stress.

- Introduces a water immersion test for outdoor terminations to verify environmental resistance.

- Incorporates a heating cycle test to assess thermal endurance.

- Test sequences prescribe inspections of accessories at the end of testing, with results documented for informational purposes.

Range of Approval

- Establishes allowable conductor cross-sectional areas and insulation types for accessory testing approval.

- Defines conditions under which tests may be extended to different cable configurations or insulating materials.

- Specifies that once an accessory passes full testing, retesting is only needed if changes affect performance.

Documentation and Compliance

- Requires detailed test setup, results recording, and reporting to assure transparency.

- Products certified to IEC 60502-4 demonstrate international compliance, supporting market acceptance.

- Does not invalidate existing national approvals but may require additional assessment for equivalency.

Applications

IEC 60502-4:2010 is essential for manufacturers, testing laboratories, utilities, and engineers involved in specifying, producing, and approving power cable accessories designed for medium-voltage networks. Practical uses include:

- Design verification and type approval of cable terminations, joints, connectors, and stop ends rated for 6 kV to 30 kV systems.

- Ensuring compatibility and reliable performance of accessories used in industrial, commercial, and utility power distribution networks.

- Facilitating international trade and regulatory acceptance through adherence to recognized testing standards.

- Supporting quality assurance and safety management by providing measurable criteria for accessory durability and behavior under operational stresses.

This standard serves as a benchmark for testing power cable accessories to confirm they withstand mechanical, electrical, and environmental stresses encountered during installation and service life.

Related Standards

- IEC 60502-2:2005 – Covers the general specifications for power cables with extruded insulation for the same voltage range.

- IEC 61442:2005 – Details test methods for accessories used with power cables rated from 6 kV up to 30 kV.

- IEC 60183 – Guide for selecting high-voltage cables.

- IEC 61238-1 – Specifies requirements and test methods for compression and mechanical connectors used on power cables up to 30 kV.

- Other IEC 60502 Parts – Encompass cables and accessories for voltages below 6 kV and related systems.

By ensuring comprehensive testing of cable accessories under the IEC 60502-4 framework, stakeholders can achieve enhanced safety, reliability, and interoperability in medium-voltage power distribution infrastructures.

Keywords: IEC 60502-4, power cable accessories, extruded insulation, type testing, rated voltage 6 kV to 30 kV, medium-voltage cables, cable terminations, cable joints, cable connectors, IEC standards, electrical accessory testing, cable accessory certification, power distribution network safety.

Buy Documents

IEC 60502-4:2010 - Power cables with extruded insulation and their accessories for rated voltages from 1 kV (U<sub>m</sub> = 1,2 kV) up to 30 kV (U<sub>m</sub> = 36 kV) - Part 4: Test requirements on accessories for cables with rated voltages from 6 kV (U<sub>m</sub> = 7,2 kV) up to 30 kV (U<sub>m</sub> = 36 kV)

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60502-4:2010 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Power cables with extruded insulation and their accessories for rated voltages from 1 kV (U<sub>m</sub> = 1,2 kV) up to 30 kV (U<sub>m</sub> = 36 kV) - Part 4: Test requirements on accessories for cables with rated voltages from 6 kV (U<sub>m</sub> = 7,2 kV) up to 30 kV (U<sub>m</sub> = 36 kV)". This standard covers: IEC 60502-4:2010 specifies the test requirements for type testing of accessories for power cables with rated voltages from 3,6/6 (7,2) kV up to 18/30 (36) kV, complying with IEC 60502-2. Accessories for special applications, such as aerial cables, submarine or ship cables or hazardous situations (explosive environments, fire-resistant cables or seismic conditions), are not included. It is not necessary to repeat these tests, once successfully completed, unless changes are made in the materials, design or manufacturing process which might affect the performance characteristics. Test methods are included in IEC 61442. Significant technical changes with respect to the previous edition are as follows: a) the range of approval has been revised; b) a water immersion test requirement for outdoor terminations has been introduced; c) examination of accessories at the end of the test sequence is to be recorded in a test report for information only; d) both the a.c. and d.c. test are to be carried out; e) the heating cycle test has been added to Table 11.

IEC 60502-4:2010 specifies the test requirements for type testing of accessories for power cables with rated voltages from 3,6/6 (7,2) kV up to 18/30 (36) kV, complying with IEC 60502-2. Accessories for special applications, such as aerial cables, submarine or ship cables or hazardous situations (explosive environments, fire-resistant cables or seismic conditions), are not included. It is not necessary to repeat these tests, once successfully completed, unless changes are made in the materials, design or manufacturing process which might affect the performance characteristics. Test methods are included in IEC 61442. Significant technical changes with respect to the previous edition are as follows: a) the range of approval has been revised; b) a water immersion test requirement for outdoor terminations has been introduced; c) examination of accessories at the end of the test sequence is to be recorded in a test report for information only; d) both the a.c. and d.c. test are to be carried out; e) the heating cycle test has been added to Table 11.

IEC 60502-4:2010 is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 29.060.20 - Cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60502-4:2010 has the following relationships with other standards: It is inter standard links to EN IEC 62613-1:2018, IEC 60502-4:2005, IEC 60502-4:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60502-4:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60502-4 ®

Edition 3.0 2010-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Power cables with extruded insulation and their accessories for rated voltages

from 1 kV (U = 1,2 kV) up to 30 kV (U = 36 kV) –

m m

Part 4: Test requirements on accessories for cables with rated voltages from

6 kV (U = 7,2 kV) up to 30 kV (U = 36 kV)

m m

Câbles d'énergie à isolant extrudé et leurs accessoires pour des tensions

assignées de 1 kV (U = 1,2 kV) à 30 kV (U = 36 kV) –

m m

Partie 4: Exigences d'essai pour accessoires de câbles de tensions assignées

de 6 kV (U = 7,2 kV) à 30 kV (U = 36 kV)

m m

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

§ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

§ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

§ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

§ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

§ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

§ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

§ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

§ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60502-4 ®

Edition 3.0 2010-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Power cables with extruded insulation and their accessories for rated voltages

from 1 kV (U = 1,2 kV) up to 30 kV (U = 36 kV) –

m m

Part 4: Test requirements on accessories for cables with rated voltages from

6 kV (U = 7,2 kV) up to 30 kV (U = 36 kV)

m m

Câbles d'énergie à isolant extrudé et leurs accessoires pour des tensions

assignées de 1 kV (U = 1,2 kV) à 30 kV (U = 36 kV) –

m m

Partie 4: Exigences d'essai pour accessoires de câbles de tensions assignées

de 6 kV (U = 7,2 kV) à 30 kV (U = 36 kV)

m m

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

V

CODE PRIX

ICS 29.060.20 ISBN 978-2-88912-294-3

– 2 – 60502-4 ã IEC:2010

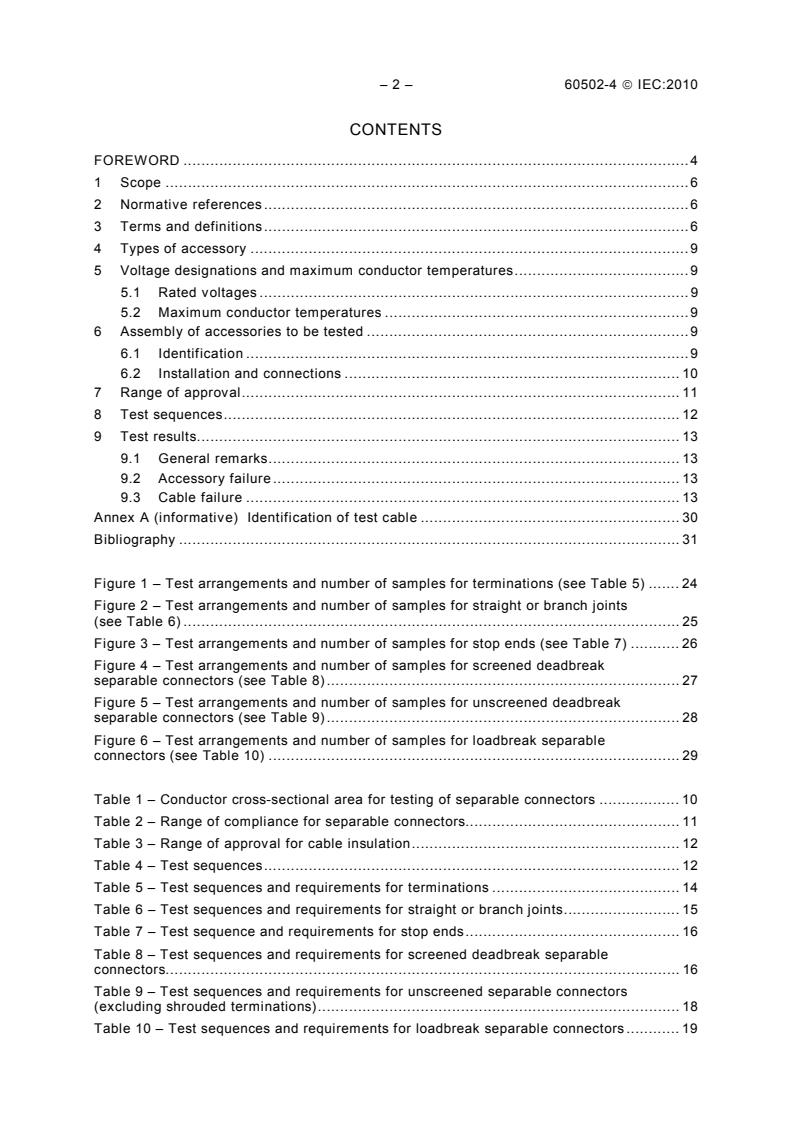

CONTENTS

FOREW ORD . 4

1 Scope . 6

2 Normativ e references . 6

3 Terms and definitions . 6

4 Types of accessory . 9

5 Voltage designations and maximum conductor temperatures . 9

5.1 Rated voltages . 9

5.2 Maximum conductor temperatures . 9

6 Assembly of accessories to be tested . 9

6.1 Identif ication . 9

6.2 Installation and connections . 10

7 Range of approval . 11

8 Test sequences . 12

9 Test results. 13

9.1 General remarks . 13

9.2 Accessory failure . 13

9.3 Cable failure . 13

Annex A (informative) Identification of test cable . 30

Bibliography . 31

Figure 1 – Test arrangements and number of samples for terminations (see Table 5) . 24

Figure 2 – Test arrangements and number of samples for straight or branch joints

(see Table 6) . 25

Figure 3 – Test arrangements and number of samples for stop ends (see Table 7) . 26

Figure 4 – Test arrangements and number of samples for screened deadbreak

separable connectors (see Table 8) . 27

Figure 5 – Test arrangements and number of samples for unscreened deadbreak

separable connectors (see Table 9) . 28

Figure 6 – Test arrangements and number of samples for loadbreak separable

connectors (see Table 10) . 29

Table 1 – Conductor cross-sectional area for testing of separable connectors . 10

Table 2 – Range of compliance for separable connectors. 11

Table 3 – Range of approval for cable insulation . 12

Table 4 – Test sequences . 12

Table 5 – Test sequences and requirements for terminations . 14

Table 6 – Test sequences and requirements for straight or branch joints . 15

Table 7 – Test sequence and requirements for stop ends . 16

Table 8 – Test sequences and requirements for screened deadbreak separable

connectors. 16

Table 9 – Test sequences and requirements for unscreened separable connectors

(excluding shrouded terminations) . 18

Table 10 – Test sequences and requirements for loadbreak separable connectors . 19

60502-4 ã IEC:2010 – 3 –

Table 11 – Additional tests for smaller and/or larger conductor cross-sectional areas

(see 7.1) . 20

Table 12 – Additional tests for different types of cable insulation semiconducting

screen and approval from round to shaped conductors (not applicable to stop ends,

see 7.1 and 7.3) . 21

Table 13 – Summary of tests . 22

Table 14 – Summary of test voltages and requirements (see Clause 9) . 23

– 4 – 60502-4 ã IEC:2010

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

POWER CABLES WITH EXTRUDED INSULATION AND THEIR ACCESSORIES

FOR RATED VOLTAGES FROM 1 kV (U = 1,2 kV) UP TO 30 kV (U = 36 kV) –

m m

Part 4: Test requirements on accessories for cables with rated voltages

from 6 kV (U = 7,2 kV) up to 30 kV (U = 36 kV)

m m

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and in

addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity assessment services

and, in some areas, access to IEC marks of conformity. IEC is not responsible for any services carried out by independent

certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60502-4 has been prepared by IEC technical committee 20:

Electric cables.

This third edition cancels and replaces the second edition, published in 2005, and

constitutes a technical revision.

Significant technical changes with respect to the previous edition are as follows:

a) the range of approval has been revised;

b) a water immersion test requirement for outdoor terminations has been introduced;

c) examination of accessories at the end of the test sequence is to be recorded in a test

report for information only;

d) both the a.c. and d.c. test are to be carried out;

60502-4 ã IEC:2010 – 5 –

e) the heating cycle test has been added to Table 11.

The text of this standard is based on the following documents:

FDIS Report on voting

20/1181/FDIS 20/1208/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

IEC 60502 consists of the following parts, under the general title Power cables with

extruded insulation and their accessories for rated voltages from 1 kV (U = 1,2 kV) up to

m

30 kV (U = 36 kV):

m

Part 1: Cables for rated voltages of 1 kV (U = 1,2 kV) and 3 kV (U = 3,6 kV);

m m

Part 2: Cables for rated voltages from 6 kV (U = 7,2 kV) up to 30 kV (U = 36 kV);

m m

Part 3: Reserved;

Part 4: Test requirements on accessories for cables with rated voltages from 6 kV

(Um = 7,2 kV) up to 30 kV (Um = 36 kV).

The committee has decided that the contents of this amendment and the base publication

will remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 60502-4 ã IEC:2010

POWER CABLES WITH EXTRUDED INSULATION AND THEIR ACCESSORIES

FOR RATED VOLTAGES FROM 1 kV (U = 1,2 kV) UP TO 30 kV (U = 36 kV) –

m m

Part 4: Test requirements on accessories for cables with rated voltages

from 6 kV (U = 7,2 kV) up to 30 kV (U = 36 kV)

m m

1 Scope

This part of IEC 60502 specifies the test requirements for type testing of accessories for

power cables with rated voltages from 3,6/6 (7,2) kV up to 18/30 (36) kV, complying with

IEC 60502-2.

Accessories for special applications, such as aerial cables, submarine or ship cables or

hazardous situations (explosive environments, fire-resistant cables or seismic conditions),

are not included.

It is not necessary to repeat these tests, once successfully completed, unless changes are

made in the materials, design or manufacturing process which might affect the performance

characteristics.

Test methods are included in IEC 61442.

NOTE This standard does not invalidate existing approvals of products achieved on the basis of national standards

and specifications and/or the demonstration of satisfactory service performance. However, products approved

according to such national standards or specifications cannot directly claim approval to this IEC standard. It may be

possible, subject to agreement between supplier and purchaser, and/or the relevant conformity assessment body, to

demonstrate that conformity to the earlier standard can be used to claim conformity to this standard, provided an

assessment is made of any additional type testing that may need to be carried out. Any such additional testing that is

part of a sequence of testing cannot be done separately.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest

edition of the referenced document (including amendments) applies.

IEC 60183, Guide to the selection of high-voltage cables

IEC 60502-2:2005, Power cables with extruded insulation and their accessories for rated

voltages from 1 kV (U = 1,2 kV) up to 30 kV (U = 36 kV) – Part 2: Cables for rated

m m

voltages from 6 kV (U = 7,2 kV) up to 30 kV (U = 36 kV)

m m

IEC 61238-1, Compression and mechanical connectors for power cables for rated voltages

up to 30 kV (Um = 36 kV) – Part 1: Test methods and requirements

IEC 61442:2005, Test methods for accessories for power cables with rated voltages from

6 kV (U = 7,2 kV) up to 30 kV (U = 36 kV)

m m

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

60502-4 ã IEC:2010 – 7 –

3.1

connector

metallic device to connect cable conductors together

[IEC 60050-461:2008, 461-17-03] [1]

3.2

termination

device fitted to the end of a cable to ensure electrical connection with other parts of the

system and to maintain the insulation up to the point of connection

[IEC 60050-461:2008, 461-10-01]

3.3

indoor termination

termination intended for use where it is not exposed to either solar radiation or weathering

3.4

outdoor termination

termination intended for use where it is exposed to either solar radiation or weathering or

both

3.5

terminal box

air- or compound-filled box fully enclosing a termination

[IEC 60050-461:2008, 461-10-03, modified]

3.6

shrouded termination

indoor termination with additional insulation at the bushing connection and used in an air-

filled terminal box

3.7

straight joint

accessory making a connection between two cables to form a continuous circuit

[IEC 60050-461:2008, 461-11-01]

3.8

branch joint

accessory making a connection of a branch cable to a main cable

[IEC 60050-461:2008, 461-11-17]

3.9

transition joint

straight or branch joint making a connection between cables having different types of

insulation

[IEC 60050-461:2008, 461-11-04, modified]

3.10

stop end

accessory providing a means of insulating the unconnected end of an energized cable

___________

References in square brackets refer to the Bibliography.

– 8 – 60502-4 ã IEC:2010

[IEC 60050-461:2008, 461-10-07, modified]

3.11

separable connector

fully insulated termination permitting the connection and the disconnection of a cable to

other equipment

3.12

screened separable connector

separable connector which has a fully screened external surface

3.13

unscreened separable connector

separable connector which does not have an external screen

3.14

plug-in type separable connector

separable connector in which the electrical contact is made by a sliding device

3.15

bolted-type separable connector

separable connector in which the electrical contact is made by a bolted device

3.16

deadbreak connector

separable connector designed to be connected and disconnected on de-energized circuits

only

3.17

loadbreak connector

separable connector designed to be connected and disconnected on energized circuits

3.18

range-taking accessory

accessory designed to take more than one cross-section of cable

3.19

tracking

irreversible degradation by formation of paths, which are conductive even under dry

conditions, starting and developing on the surface of an insulating material and which may

occur on surfaces in contact with air and also on the interfaces between different insulating

materials

3.20

erosion

irreversible and non-conducting degradation of the surface of the insulator that occurs by

loss of material, and which may be uniform, localized or tree shaped

NOTE Shallow surface traces, commonly tree-shaped, may occur on terminations, after partial flashover. These

traces are acceptable as long as they are non-conductive. When they are conductive they are classed as tracking.

3.21

metallic housing

metal enclosure in intimate contact with the outer screen of a separable connector and

having at least the same current carrying capacity to earth as the metallic screen of the

cable with which the separable connector is to be used

60502-4 ã IEC:2010 – 9 –

4 Types of accessory

The accessories covered by this standard are listed below:

– indoor and outdoor terminations of all designs, including terminal boxes;

– straight joints, branch joints and stop ends of all designs, suitable for use underground

or in air;

– screened or unscreened plug-in type or bolted type separable connectors.

NOTE Transition joints connecting cables with extruded insulation to paper-insulated cables are not included in the

scope of this standard. The requirements for these accessories are dealt with in IEC 60055 [2].

5 Voltage designations and maximum conductor temperatures

5.1 Rated voltages

The rated voltages U /U (U ) of accessories considered in this standard are given in 4.1 of

0 m

IEC 60502-2:2005.

For a given application, the rated voltage of an accessory shall be consistent with that of

the cable, and shall be suitable for the operating condition of the system in which they are

used, in accordance with the recommendations of IEC 60183.

5.2 Maximum conductor temperatures

The accessories shall be suitable for use on cables having the conductor temperatures

specified in 4.2 of IEC 60502-2:2005 for normal operation.

The maximum conductor temperatures of the cables under short-circuit conditions are given

in Table 3 of IEC 60502-2:2005.

6 Assembly of accessories to be tested

6.1 Identification

6.1.1 Cables used for testing shall comply with IEC 60502-2 and shall be of the same

rated voltage as the accessories to be tested.

Constructional details of the cables shall be identified (refer to Annex A).

6.1.2 Connectors used within the accessories shall be correctly identified with respect to

– assembly technique,

– tooling, dies and necessary setting,

– preparation of contact surfaces, if applicable,

– type, reference number and any other identification of the connector,

– details of the type test approval,

– the standard with which they comply (i.e. IEC 61238-1).

6.1.3 Accessories to be tested shall be correctly identified with respect to

– name of manufacturer.

– type, designation, manufacturing date or code.

– minimum and maximum cable cross-sections, material and shape of cable conductor.

– 10 – 60502-4 ã IEC:2010

– minimum and maximum cable insulation diameters,

– rated voltage (see 5.1),

– installation instructions (reference and date),

– inside dimensions or type of terminal box if applicable.

6.2 Installation and connections

6.2.1 Unless otherwise specified, the conductor cross-sectional area shall be as follows:

2 2 2

a) for terminations, joints and stop ends: 120 mm or 150 mm or 185 mm ;

b) for separable connectors: each rating shall be tested as indicated in Table 1, using

either aluminium or copper conductors.

Table 1 – Conductor cross-sectional area for testing of separable connectors

Conductor cross-sectional area

Rating

mm

A Cu Al

200/250 50 70

400 95 150

600/630 185 300

800 300 400

1 250 500 630

NOTE 1 The current value should be sufficient to achieve the specified conductor

temperature (see 9.1 of IEC 61442:2005).

NOTE 2 The use of these conductor cross-sectional areas may lead to overheating

of the bushing while achieving the required conductor temperature. Under these

circumstances, it is permissible to use a conductor cross-sectional area one size

smaller. If a bushing failure occurs, the test should be declared void (see 9.2 of this

standard).

6.2.2 Accessories shall be assembled in the manner specified by the manufacturer's

instructions, with the grade and quantity of materials supplied, including lubricants, if any.

6.2.3 Accessories shall be dry and clean, but neither the cables nor the accessories shall

be subjected to any form of conditioning which might modify the electrical or thermal or

mechanical performance of the test assemblies.

NOTE Contact with chemicals, e.g. transformer oil, may affect the properties of the accessory and should be

avoided.

6.2.4 Unless otherwise specified, separable connectors shall be connected to their mating

bushing.

6.2.5 Where terminations or separable connectors are to be tested, the connection

between either lugs or bushings shall have the same electrical cross-sectional area as that

of the cable conductor.

6.2.6 For unscreened separable connectors, the minimum phase-to-phase and phase-to-

earth clearances, recommended by the manufacturer, shall be tested.

6.2.7 Where branch joints are to be tested, only the main cable shall carry the heating

current.

60502-4 ã IEC:2010 – 11 –

6.2.8 The main details regarding test mounting, especially supporting devices, shall be

recorded.

6.2.9 Test arrangements and number of samples are detailed in Figures 1 to 5.

7 Range of approval

7.1 For terminations, joints and stop ends, compliance for one type of accessory for the

range of cable conductor cross-sections from 95 mm² to 300 mm² shall be obtained by

successfully completing all the appropriate tests of Tables 5 to 7 on one of the cross-

sections specified in 6.2.1.

For separable connectors, compliance for one type of accessory for the range of cable

conductor cross-sections given in Table 2 shall be obtained by successfully completing all

the appropriate tests of Table 8 to 10 on the cross-section specified in Table 1 in 6.2.1 b).

Extension of the range of compliance for the same type of accessory to larger or smaller

cable conductor cross-sections shall be obtained by successfully completing the additional

test sequence in Table 11, on the appropriate larger or smaller cross-section.

For extension of compliance of separable connectors to larger cable conductor cross-

sections, the test current shall be limited to the rating of the mating bushing.

Table 2 – Range of compliance for separable connectors

Cable conductor cross-sectional area

Rating of separable

Range of compliance

connector

mm

A Min. Max.

200/250 25 95

400 95 240

600/630 95 300

800 150 400

1 250 240 630

7.2 Approval is independent of the cable conductor material: tests may therefore be

carried out using cables with either aluminium or copper conductors.

7.3 Tests performed on accessories installed on cables having shaped conductors shall be

deemed to cover the same type of accessory when used on cables having circular

conductors; however, the converse does not apply.

In order to achieve extension of approval from round to sector-shaped conductors,

additional tests shall be performed according to Table 12. Stop ends shall be tested as in

Table 7 using half the number of samples in Figure 3.

7.4 Approval is dependent on the cable insulation tested as detailed in Table 3.

– 12 – 60502-4 ã IEC:2010

Table 3 – Range of approval for cable insulation

Insulation of test cable Range of approval

XLPE XLPE, EPR, HEPR and PVC

EPR or HEPR EPR, HEPR and PVC

PVC PVC

7.5 The additional tests specified in Table 12 shall be carried out to achieve extension of

approval for different types of cable insulation semiconducting screens. Stop ends shall be

tested as in Table 7 using half the number of samples in Figure 3.

7.6 Approval obtained by testing on a non longitudinally water-blocked type of cable shall

be extended to a cable with means of longitudinal water-blocking in the metallic screen area

but otherwise of the same design. The converse shall not apply.

7.7 Tests performed on three-core accessories shall be deemed to cover single-core

accessories of the same design. The converse shall not apply.

7.8 Compliance of an accessory tested for a specified U shall extend to operation of the

accessory at a lower U provided that the radial electrical stress at the insulation screen of

the cable of lower U is not greater than that of the test cable.

In addition, for separable connectors, the screen fault current initiation test shall be carried

out at the lowest U for which compliance is required.

8 Test sequences

The tests applicable to accessories shall be carried out in the sequences listed in the tables

and figures mentioned in Table 4.

Table 4 – Test sequences

Accessories Table Figure

Terminations 5 1

Straight or branch joints 6 2

Stop ends 7 3

Screened deadbreak separable connectors 8 4

Unscreened deadbreak separable connectors 9 5

a a

Loadbreak separable connectors 10 6

Additional tests for smallest and largest conductor cross-sectional areas 11 –

Additional tests for different types of cable insulations screen and

approval from round to shaped conductors 12 –

NOTE In Tables 5 to 9, the symbols have the meaning given in IEC 61442, i.e:

I short-circuit current (r.m.s. value) in the metallic screen;

sc

I short-circuit current (initial peak value) in the conductor;

d

q maximum permissible short-circuit temperature of the cable conductor.

sc

a

Under consideration.

Tests on terminations and joints may be combined, provided the sequences and

requirements are the same.

60502-4 ã IEC:2010 – 13 –

A summary of the tests required is given in Table 13. The test voltages and requirements

are summarized in Table 14.

9 Test results

9.1 General remarks

All test samples, tested as indicated in Clause 7 and Tables 5 to 12, shall meet the

requirements for all test sequences.

If any of the test samples do not meet the requirements, they shall be dismantled, inspected

to determine if 9.2 or 9.3 applies and the result of the inspection recorded.

The examination at the end of a test sequence is for information only, but the results shall

be recorded in the test report.

9.2 Accessory failure

If an accessory fails to meet the requirements due to either installation or test procedure

errors, the test shall be declared void without discrediting the accessories.

The complete test sequence shall be repeated on a new set of samples.

If there is no evidence of such error, the type of accessory is not approved.

9.3 Cable failure

If a cable fails beyond any part of an accessory, the tests shall be declared void without

discrediting the accessories. Tests may be repeated using new accessories (start testing

from the beginning of the test sequence) or alternatively by repair of the cable (continue

testing from the point of break).

– 14 – 60502-4 ã IEC:2010

Table 5 – Test sequences and requirements for terminations

Test methods Test sequences

a

Tests Requirements

of IEC 61442 (see Figure 1)

1.1 1.2 1.3 1.4 1.5

1 AC and DC voltage AC for 5 min at 4,5 U and d.c. Clauses 4 and 5 x x x

for 15 min at 4 U

b

AC (wet) 1 min at 4 U Clause 4 x

c

2 Partial discharge 10 pC max. at 1,73 U Clause 7 x

d

3 Impulse at q 10 impulses of each polarity Clause 6 x

t

e d

4 Heating cycles in air 9.2 and 9.3 x

60 cycles at q and 2,5 U

t 0

b e d

5 Immersion test 10 cycles at q 9.5 x

t

c

6 Partial discharge 10 pC max. at 1,73 U Clause 7 x

d, f

at q and ambient

t

temperature

h

7 Thermal short-circuit Two short-circuits at I of the Clause 10 x X

sc

g

(screen) cable screen.

No visible deterioration

h

8 Thermal short-circuit Two short-circuits to raise Clause 11 x X

(conductor) conductor to q of the cable.

sc

No visible deterioration

i

9 Dynamic short-circuit One short-circuit at I Clause 12 x

d

No visible deterioration

10 Impulse 10 impulses of each polarity Clause 6 x x x

11 AC voltage 15 min at 2,5 U Clause 4 x x x

j, k

12 Humidity 300 h at 1,25 U , see Table 13 Clause 13 x

b, k

13 Salt fog 1 000 h at 1,25 U , see Table 13 Clause 13 x

l

14 Examination For information only – x x x x x

a

Unless otherwise specified, tests shall be carried out at ambient temperature.

b

For outdoor terminations only.

c

Not required for accessories installed on 3,6/6 (7,2) kV cables having unscreened insulation.

d

q is the maximum cable conductor temperature in normal operation +5 K to 10 K.

t

e

8 h total with ³2 h steady and ³3 h cooling.

f

Measurement is made at the end of the heating period.

g

This test is only required for terminations that are equipped with a connection to, or adaptor for, the metallic screen of

the cable.

h

Thermal short-circuit may be combined with the dynamic short-circuit.

i

Only required for single-core cable accessories designed for initial peak currents i > 80 kA and three-core accessories

p

designed for i > 63 kA . Value of I shall be declared by the manufacturer.

p d

j

For indoor terminations only. Not required for compound-filled terminal boxes. Shrouded terminations shall be tested

in a three-phase condition.

k

Not required for terminations having porcelain insulators.

l

It is advised that the accessory be examined for signs of any of the following:

(i) cracking in the filling media and/or tape or tube components; and/or

(ii) a moisture path across a primary seal; and/or

(iii) corrosion and/or tracking and/or erosion; and/or

(iv) leakage of any insulating material.

60502-4 ã IEC:2010 – 15 –

Table 6 – Test sequences and requirements for straight or branch joints

Test

Test methods

a

Tests Requirements sequences

of IEC 61442

(see Figure 2)

2.1 2.2 2.3

1 AC and DC voltage AC for 5 min at 4,5 U and d.c. for Clauses 4 and 5 x x x

15 min at 4 U

b, c

2 Partial discharge 10 pC max. at 1,73 U Clause 7 x

c, d

3 Impulse at q 10 impulses of each polarity Clause 6 x

t

e c, d

4 Heating cycles in air 9.2 and 9.3 x

30 cycles at q and 2,5 U

t 0

e c, d

5 Heating cycles under 30 cycles at q and 2,5 U , 9.2 and 9.3 x

t 0

water

water height 1 m

b, c

6 Partial discharge at 10 pC max. at 1,73 U Clause 7 x

c,d, f

q and ambient

t

temperature

g

7 Thermal short-circuit Two short-circuits at I of the cable Clause 10 x x

sc

c

(screen) screen.

No visible deterioration

g

8 Thermal short-circuit Two short-circuits to raise conductor Clause 11 x X

c

(conductor)

to q of the cable.

sc

No visible deterioration

9 Dynamic One short-circuit at I . Clause 12 x

d

h

short-circuit No visible deterioration

10 Impulse 10 impulses of each polarity Clause 6 x x x

11 AC voltage 15 min at 2,5 U Clause 4 x x x

i

12 Examination For information only – x x x

a

Unless otherwise specified, tests shall be carried out at ambient temperature.

b

Not required for accessories installed on 3,6/6 (7,2) kV cables having unscreened insulation.

c

For transition joints (extruded insulation to extruded insulation), the testing parameters are those for the lower

rated cable.

d

q is the maximum cable conductor temperature in normal operation +5 K to 10 K.

t

e

8 h total with ³2 h steady and ³3 h cooling.

f

Measurement is made at the end of the heating period.

g

Thermal short-circuit may be combined with the dynamic short-circuit.

h

Only required for single-core cable accessories designed for initial peak currents i >80 kA and three-core

p

accessories designed for i >63 kA. Value of I shall be declared by the manufacturer.

p d

i

It is advised that the accessory is examined for signs of any of the following:

(i) cracking in the filling media and/or tape or tube components; and/or

(ii) a moisture path across a primary seal; and/or

(iii) corrosion and/or tracking and/or erosion; and/or

(iv) leakage of any insulating material.

– 16 – 60502-4 ã IEC:2010

Table 7 – Test sequence and requirements for stop ends

Test

Test methods

a

Tests Requirements sequence

of IEC 61442

(see Figure 3)

3.1

1 AC and DC voltage AC for 5 min at 4,5 U and d.c. for Clauses 4 and 5 x

15 min at 4 U

b

2 Partial discharge 10 pC max. at 1,73 U Clause 7 x

3 Impulse 10 impulses of each polarity Clause 6 x

4 AC voltage 500 h at 2,5 U Clause 4 x

b

5 Partial discharge 10 pC max. at 1,73 U Clause 7 x

6 Impulse 10 impulses of each polarity Clause 6 x

7 AC voltage 15 min at 2,5 U Clause 4 x

c

8 Examination For information only – x

a

Unless otherwise specified, tests shall be carried out at ambient temperature.

b

Not required for accessories installed on 3,6/6 (7,2) kV cables having unscreened insulation.

c

It is advised that the accessory is examined for signs of any of the following:

(i) cracking in the filling media and/or tape or tube components; and/or

(ii) a moisture path across a primary seal; and/or

(iii) corrosion and/or tracking and/or erosion; and/or

(iv) leakage of any insulating material.

Table 8 – Test sequences and requirements for screened deadbreak separable connectors

Test methods Test sequences

a

Tests Requirements

of IEC 61442 (see Figure 4)

4.1 4.2 4.3 4.4

1 AC and DC voltage AC for 5 min at 4,5 U and d.c. for Clauses 4 and 5 x x x

15 min at 4 U

b

2 Partial discharge 10 pC max. at 1,73 U Clause 7 x

c

3 Impulse at q 10 impulses of each polarity Clause 6 x

t

g

4 Thermal short-circuit Two short-circuits at I of Clause 10 x X

sc

f

(screen) the cable screen.

No visible deterioration

g

5 Thermal short-circuit Two short-circuits to raise Clause 11 x X

(conductor) conductor to q of the cable.

sc

No visible deterioration

6 Dynamic short-circuit One short-circuit at I . Clause 12 x

d

h

No visible deterioration

d c l

7 Heating cycles in air 30 cycles at q and 2,5 U Clause 9 x

t 0

d c l

8 Heating cycles under Clause 9 x

30 cycles at q and 2,5 U

t 0

water

i

9 Disconnect/connect Five times. – x x x

No visible damage to contact

b

10 Partial discharge at 10 pC max. at 1,73 U Clause 7 x

c, e

q and ambient

t

temperature

11 Impulse 10 impulses of each polarity Clause 6 x x x

12 AC voltage 15 min at 2,5 U Clause 4 x x x

60502-4 ã IEC:2010 – 17 –

Test methods Test sequences

a

Tests Requirements

of IEC 61442 (see Figure 4)

13 Operating eye Axial force 1 300 N for 1 min. Clause 19 x

Torque 14 N × m

b

14 Partial discharge 10 pC max. at 1,73 U Clause 7 x

m

15 Examination For information only – x x x x

j

16 Screen resistance Clause 15

Maximum 5 000 W

17 Screen leakage Maximum 0,5 mA at U Clause 16 Tests 16 to 20 are

m

j

carried out on

current

separate samples.

j, k

18 Fault current initiation See notes Clause 17

For tests 16 and 19,

19 Operating force Force <900 N Clause 18

no cable is required.

20 Capacitive test point Capacitance of test point to cable Clause 20

For tests 17, 18 and

conductor:

20, appropriate cable

lengths are to be

C > 1,0 pF

tc

used

Ratio of capacitance of test point

to earth C and capacitance of test

te

point to cable conductor C :

tc

C /C £ 12,0

te tc

a

Unless otherwise specified, tests shall be carried out at ambient temperature.

b

Not required for accessories installed on 3,6/6 (7,2) kV cables having unscreened insulation.

c

q is the maximum cable conductor temperature in normal operation +5 K to 10 K.

t

d

8 h total with ³2 h steady and ³3 h cooling.

e

Measurement is made at the end of the heating period.

f

This test applies only to separable connectors that are equipped with a connection to, or adaptor for, the metallic

screen of the cable.

g

Thermal short-circuit may be combined with the dynamic short-circuit.

h

Only required for single-core cable accessories designed for initial peak currents i > 80 kA and three-core

p

accessories designed for i > 63 kA. Value of I shall be declared by the manufacturer.

p d

i

The test shall be carried out only when the cable is de-energized.

j

The test is required for separable connectors without a metallic housing or with a removable metallic housing. The

metallic housing shall be removed prior to the test. This test is not required for separable connectors which can

only be used in service with the metallic housing in position.

k

For solidly earthed systems, the fault initiation shall occur within 3 s. For unearthed or impedance earthed

systems, the fault current shall flow continuously.

l

Current, see Table 1.

m

It is advised that the accessory is examined for signs of any of the following:

(i) cracking in the filling media and/or tape or tube components; and/or

(ii) a moisture path across a primary seal; and/or

(iii) corrosion and/or tracking and/or erosion; and/or

(iv) leakage of any insulating material.

– 18 – 60502-4 ã IEC:2010

Table 9 – Test sequences and requirements for unscreened separable connectors

(excluding shrouded terminations)

Test methods Test sequences

a

Tests Requirements

of IEC 61442 (see Figure 5)

5.1 5.2 5.3 5.4

1 AC and DC voltage AC for 5 min at 4,5 U and d.c. for Clauses 4 and 5 x x x

15 min at 4 U

b

2 Partial discharge 10 pC max. at 1,73 U Clause 7 x

c

3 Impulse at q 10 impulses of each polarity Clause 6 x

t

g

4 Thermal short-circuit Two short-circuits at I of Clause 10 x x

sc

f

(screen)

the cable screen.

No visible deterioration

g

5 Thermal short-circuit Two short-circuits to raise Clause 11 x X

(conductor)

conductor to q of the cable.

sc

No visible deterioration

6 Dynamic One short-circuit at I . Clause 12 x

d

h

short-circuit

No visibl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...