IEC 62125:2019

(Main)Environmental considerations specific to insulated electrical power and control cables

Environmental considerations specific to insulated electrical power and control cables

IEC 62125:2019 provides methodologies addressing environmental evaluation and communication related to cables in normal use.

It includes an environmental checklist for power cables, the method for life cycle assessment (LCA) and a methodology for conductor size optimization.

The results obtained by applying such methodologies can be used for external communication. Environmental communication can also include other topics, such as material declaration.

General Information

- Status

- Published

- Publication Date

- 15-Sep-2019

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- MT 20 - TC 20/MT 20

- Current Stage

- PPUB - Publication issued

- Start Date

- 16-Sep-2019

- Completion Date

- 04-Oct-2019

Relations

- Effective Date

- 05-Sep-2023

Overview - IEC 62125:2019

IEC 62125:2019 is an international standard from the IEC that defines methodologies for assessing and communicating the environmental performance of insulated electrical power and control cables in normal use. Published in 2019 (Edition 1.0), it supersedes IEC TR 62125:2007 and formalizes approaches for qualitative and quantitative environmental evaluation, conductor-size optimization, and external environmental communication (including material declaration).

Key topics and technical requirements

- Scope: Procedures for environmental evaluation and communication specific to power and control cables in normal use.

- Checklist approach: A qualitative environmental checklist tailored to power cables for screening design, production, use and end-of-life aspects.

- Life Cycle Assessment (LCA): A quantitative LCA methodology covering:

- Goal and scope definition (functional unit, reference flow, system boundary, cut-off criteria)

- Life Cycle Inventory (LCI) data collection, selection and allocation

- Life Cycle Impact Assessment (LCIA) and interpretation

- Use of single environmental indicators where appropriate

- ECSO (Environmental and energy cost-based conductor size optimization):

- Methodology to balance initial cost, energy losses and environmental (CO2) impacts to determine optimum conductor size and operating current ranges

- Includes rules, factors, CO2 evaluation, and calculation procedures with worked examples in annexes

- Environment-related communication:

- Principles for external communication of LCA results and other topics (e.g., material declaration, substance compliance, end-of-life information)

- Supporting material: Informative annexes with a checklist, ECSO example calculations, and an example of environmental communication.

Practical applications

- Use the checklist for early-stage design reviews and to identify environmental risk areas without full LCA.

- Apply the LCA methodology when quantitative, comparable environmental performance data is required for product development, procurement, or compliance reporting.

- Use ECSO to optimize conductor sizing based on life-cycle cost and emissions trade-offs-helpful in projects where energy loss over service life is significant.

- Prepare consistent, auditable environmental communications (e.g., product declarations, environmental product information) that stakeholders and customers can rely on.

Who should use IEC 62125:2019

- Cable manufacturers and designers

- Standards writers and technical committees (IEC TC 20 users)

- Transmission/distribution system operators, specifiers, and procurement teams

- Environmental managers and LCA practitioners working in the electrical cable sector

- Installers and contractors involved in cable selection and lifecycle planning

Related standards and notes

- Supersedes IEC TR 62125:2007 (technical report).

- Document prepared in accordance with ISO/IEC Directives, Part 2.

- Annexes and bibliography provide examples and references to support implementation.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 62125:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Environmental considerations specific to insulated electrical power and control cables". This standard covers: IEC 62125:2019 provides methodologies addressing environmental evaluation and communication related to cables in normal use. It includes an environmental checklist for power cables, the method for life cycle assessment (LCA) and a methodology for conductor size optimization. The results obtained by applying such methodologies can be used for external communication. Environmental communication can also include other topics, such as material declaration.

IEC 62125:2019 provides methodologies addressing environmental evaluation and communication related to cables in normal use. It includes an environmental checklist for power cables, the method for life cycle assessment (LCA) and a methodology for conductor size optimization. The results obtained by applying such methodologies can be used for external communication. Environmental communication can also include other topics, such as material declaration.

IEC 62125:2019 is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 29.060.20 - Cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62125:2019 has the following relationships with other standards: It is inter standard links to IEC TR 62125:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62125:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62125 ®

Edition 1.0 2019-09

INTERNATIONAL

STANDARD

colour

inside

Environmental considerations specific to insulated electrical power and control

cables

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 62125 ®

Edition 1.0 2019-09

INTERNATIONAL

STANDARD

colour

inside

Environmental considerations specific to insulated electrical power and control

cables

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.060.20 ISBN 978-2-8322-7374-6

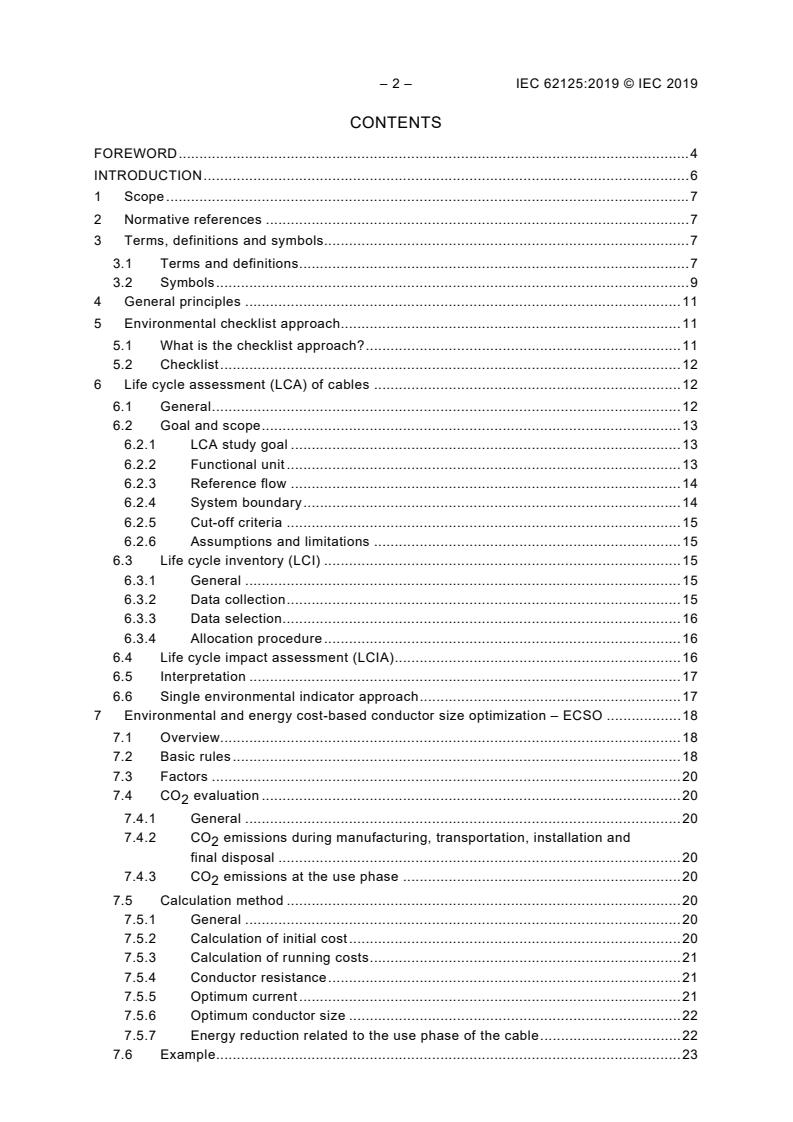

– 2 – IEC 62125:2019 © IEC 2019

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms, definitions and symbols. 7

3.1 Terms and definitions . 7

3.2 Symbols . 9

4 General principles . 11

5 Environmental checklist approach. 11

5.1 What is the checklist approach? . 11

5.2 Checklist . 12

6 Life cycle assessment (LCA) of cables . 12

6.1 General . 12

6.2 Goal and scope . 13

6.2.1 LCA study goal . 13

6.2.2 Functional unit . 13

6.2.3 Reference flow . 14

6.2.4 System boundary . 14

6.2.5 Cut-off criteria . 15

6.2.6 Assumptions and limitations . 15

6.3 Life cycle inventory (LCI) . 15

6.3.1 General . 15

6.3.2 Data collection . 15

6.3.3 Data selection. 16

6.3.4 Allocation procedure . 16

6.4 Life cycle impact assessment (LCIA) . 16

6.5 Interpretation . 17

6.6 Single environmental indicator approach . 17

7 Environmental and energy cost-based conductor size optimization – ECSO . 18

7.1 Overview. 18

7.2 Basic rules . 18

7.3 Factors . 20

7.4 CO evaluation . 20

7.4.1 General . 20

7.4.2 CO emissions during manufacturing, transportation, installation and

final disposal . 20

7.4.3 CO emissions at the use phase . 20

7.5 Calculation method . 20

7.5.1 General . 20

7.5.2 Calculation of initial cost . 20

7.5.3 Calculation of running costs . 21

7.5.4 Conductor resistance . 21

7.5.5 Optimum current . 21

7.5.6 Optimum conductor size . 22

7.5.7 Energy reduction related to the use phase of the cable . 22

7.6 Example. 23

8 Environment-related communication . 24

8.1 General . 24

8.2 General principles . 24

8.3 Composition and compliancy to legislation on substances . 25

8.4 Life cycle assessment . 25

8.5 End of life . 25

Annex A (informative) Checklist for the checklist approach . 26

A.1 Preliminary considerations . 26

A.2 Design considerations . 26

A.3 Production considerations . 26

A.4 Considerations for use and end of life phase . 27

Annex B (informative) Example for ECSO . 28

B.1 General . 28

B.2 Cable data . 28

B.3 Calculation condition . 28

B.4 Initial cost . 29

B.4.1 Initial investment . 29

B.4.2 Conversion of CO emissions during material/cable production, removal,

transportation and disposal to cost . 29

B.4.3 Initial cost (sum) . 29

B.4.4 Conductor resistance . 30

B.5 Calculation of running costs . 30

B.5.1 Costs for Joule losses during anticipated life time . 30

B.5.2 Costs for CO emission during anticipated life time . 30

B.6 Life cycle cost . 31

B.7 Optimum current . 31

B.8 Efficiency . 32

B.8.1 Calculation of energy efficiency . 32

B.9 Life cycle cost versus service life . 33

Annex C (informative) Example of environmental communication . 34

Bibliography . 35

Figure 1 – Life cycle phases . 13

Figure 2 – Life cycle costs for conductor size for a certain current . 19

Figure 3 – Optimum current range for minimizing life cycle cost . 19

Table B.1 – Life cycle cost versus service life . 33

Table B.2 – Life cycle cost versus service life, relative to 3C 70 mm . 33

– 4 – IEC 62125:2019 © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ENVIRONMENTAL CONSIDERATIONS SPECIFIC TO

INSULATED ELECTRICAL POWER AND CONTROL CABLES

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62125 has been prepared by IEC technical committee 20: Electric

cables.

This first edition cancels and replaces IEC TR 62125, published in 2007. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to

IEC TR 62125:2007:

a) development of the document from TR to international standard;

b) inclusion of a methodology for LCA;

c) inclusion of a methodology for conductor size optimization.

The text of this standard is based on the following documents:

FDIS Report on voting

20/1876/FDIS 20/1881/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 62125:2019 © IEC 2019

INTRODUCTION

The cable sector has, for many years, considered the impact of electric cables on the

environment with respect to their operating conditions. Transmission system operators,

distribution system operators, manufacturers, installers/contractors, users and authorities

have considerably increased their requirements to take into account the environmental impact

of electric cables.

IEC TC 20 regularly reviews its approach to the incorporation of environmental aspects into

standards for electric cables and their components. Environmental considerations should be

included in both design and redesign work with respect to the raw materials used, energy

consumption, emissions and generation of waste during production, end of life recycling or

disposal, and in-service performance.

This document supersedes IEC TR 62125 published 2007, which intended to give assistance

to writers of standards within IEC Technical Committee 20, to take into account the relevant

environmental aspects that are specific to electric cables in normal use.

This document is addressed to writers of standards, manufacturers and users of power cables

to provide guidance when evaluating:

– the qualitative environmental impact (checklist approach), or

– the quantitative environmental impact (LCA approach), and

– the environmental and energy cost-based conductor size optimization (ECSO).

ENVIRONMENTAL CONSIDERATIONS SPECIFIC TO

INSULATED ELECTRICAL POWER AND CONTROL CABLES

1 Scope

This document provides methodologies addressing environmental evaluation and

communication related to cables in normal use.

It includes an environmental checklist for power cables, the method for life cycle assessment

(LCA) and a methodology for conductor size optimization.

The results obtained by applying such methodologies can be used for external communication.

Environmental communication can also include other topics, such as material declaration.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60287-3-2:2012, Electric cables – Calculation of the current rating – Part 3-2: Sections on

operating conditions – Economic optimization of power cable size

ISO 14040:2006, Environmental management – Life cycle assessment – Principles and

framework

ISO 14044:2006, Environmental management – Life cycle assessment – Requirements and

guidelines

3 Terms, definitions and symbols

3.1 Terms and definitions

3.1.1

life cycle assessment

LCA

compilation and evaluation of the inputs, outputs and the potential environmental impacts of a

product system throughout its life cycle

[SOURCE: ISO 14040:2006, 3.2]

3.1.2

life cycle inventory

LCI

phase of life cycle assessment involving the compilation and quantification of inputs and

outputs for a product throughout its life cycle

[SOURCE: ISO 14040:2006, 3.3]

– 8 – IEC 62125:2019 © IEC 2019

3.1.3

life cycle impact assessment

LCIA

phase of life cycle assessment aimed at understanding and evaluating the magnitude and

significance of the potential environmental impacts for a product system throughout the life

cycle of the product

[SOURCE: ISO 14040:2006, 3.4]

3.1.4

life cycle thinking

LCT

consideration of all relevant environmental aspects during the entire lifecycle of products

[SOURCE: IEC 62430:2009, 3.11]

3.1.5

reference flow

measure of the outputs from processes in a given product system required to fulfil the function

expressed by the functional unit

[SOURCE: ISO 14040:2006, 3.29]

3.1.6

functional unit

quantified performance of a product system for use as a reference unit

[SOURCE: ISO 14040:2006, 3.20]

3.1.7

environment

surroundings in which a product or system exists, including air, water, land, natural resources,

flora, fauna, humans and their interrelation

Note 1 to entry: "Environment" in this document means ecological environment. It does not refer to surrounding

factors influencing the cable (such as humidity or temperature), nor to the business environment.

[SOURCE: IEC Guide 109:2012, 3.3, modified – Note 1 to entry has been added.]

3.1.8

life cycle

consecutive and interlinked stages of a product system, from raw material acquisition or

generation from natural resources to final disposal

[SOURCE: ISO 14040:2006, 3.1]

3.1.9

environmental impact of a product

change to the environment, whether adverse or beneficial, wholly or partially resulting from

the life cycle of a product

3.1.10

unit process

smallest element considered in the life cycle inventory analysis for which input and output

data are quantified

[SOURCE: ISO 14040:2006, 3.34]

3.2 Symbols

temperature coefficient of conductor resistance at

α 1/K

20 °C (for copper: 0,003 93, for aluminium: 0,004 03)

θ maximum rated conductor operating temperature °C

θ ambient average temperature °C

a

θ mean operating conductor temperature °C

m

temperature rise of conductor Δθ = (θ − 20 °C)

Δθ °C

m

µ loss load factor, see IEC 60853-1 –

cu/km

cost for ancillary materials and installation materials

C

af

(like conduits)

cu/km

cable cost including transportation

C

C

initial cost of the cable being considered cu/km

C

I

cu/km

cost for CO emission during mining, manufacturing,

C

I(CO )

transportation, installation and final disposal for a

certain conductor size

C initial cost of the next smaller standard size of cu/km

I1

conductor

cost for CO emission during mining, manufacturing, cu/km

C

I1(CO )

transportation, installation and final disposal for the

next smaller size of conductor

C initial cost of the next larger standard size of cu/km

I2

conductor

cost for CO emission during mining, manufacturing, cu/km

C 2

I2(CO )

disposal for the

transportation, installation and final

next larger size of conductor

C present value of the cost of joule losses during N cu/km

J

years

present value of the costs for CO emission during cu/km

C

J(CO )

anticipated life time due to Joule losses

cable installation (including laying, removal and cu/km

C

L

disposal) cost

life cycle cost cu/km

C

T

life cycle cost for the next smaller size of conductor cu/km

C

T1

life cycle costs for the next larger size of conductor cu/km

C

T2

arbitrary currency unit

cu

CO emission of the cable of conventional size per CO -kg/year

E

2 2

CONV

year during use phase

– 10 – IEC 62125:2019 © IEC 2019

CO emission of the cable of optimum size per year CO -kg/year

E

2 2

OPTI

during use phase

F auxiliary quantity defined by Formula (8) cu/W

load factor

f

power factor (= cos φ, φ being the phase angle

f

between voltage and current)

maximum load current A

I

max

upper limit of I A

I

max

upper

lower limit of I A

I

max

lower

CO emissions during mining, manufacturing, CO -kg/km

I

2 2

Z

transportation, installation and final disposal

CO emission for generation of unit power to be CO -kg/kWh

K

2 2

adjusted to the national situation

k Coefficient based on wiring system, e.g. 3 phase-3

w

wire kw = √3, for DC cables kw = 1

cable length km

L

coefficient for converting CO emissions to cost CO -cu/kg

M

2 2

to be adjusted to the national situation

service life, a synonym (anticipated life time) year

N

N number of loaded phase conductors –

p

P cost of one kilowatt-hour at relevant voltage level cu/kWh

R conductor resistance of conductor per length

Ω/km

(considered to be a constant value at an average

operating temperature)

R conductor resistance per length of the next smaller

Ω/km

standard conductor size

R conductor resistance per length of the next larger

Ω/km

standard conductor size

conductor resistance at 20 °C per length, (ohm/km)

Ω/km

R

AC resistance per length of the cable with

Ω/km

R

conv

conventional size for AC system and DC resistance

per length of the cable with conventional size for DC

system

AC resistance per length of the cable with optimum

Ω/km

R

opti

size for AC system and DC resistance per length of

the cable with optimum size for DC system

S cross-sectional area of a cable conductor

mm

S cross-sectional area of the next smaller standard

mm

conductor size

S cross-sectional area of the next larger standard

mm

conductor size

U system voltage V

W amount of power consumption per year kWh/year

distribution losses with the cable of conventional size kWh/year

W

conv

distribution losses of the cable with optimum size kWh/year

W

opti

annual operating days days

Y

4 General principles

The environmental impact of an electric cable shall be considered throughout all life cycle

phases: from design till end of life. This is called the concept of life cycle thinking.

There are various tools for the environmental evaluation of the products, for example:

– a checklist approach, which is a qualitative consideration of the environmental aspects

related to the life cycle steps of the product, i.e. use of the checklist in accordance with

Clause 5 and Annex A, that is based on IEC Guide 109 and specifically focused on power

cables;

– life cycle assessment (LCA), which is a scientific tool providing a quantitative evaluation of

the environmental impact occuring during the whole life cycle of the product, i.e. use of

the life cycle assessment in accordance with Clause 6 for assessment of the

environmental impacts of a product.

The use of LCA methodology is recommended, as it provides quantified and detailed

information on product environmental impact. Nevertheless, considering the knowledge and

resources required to perform LCA studies, the checklist might be acceptable, for instance if

certain aspects are considered without determining the complete environmental impact. This

choice has to be made depending on objectives and knowledge and resources available.

Apart from life cycle thinking, other approaches can be used, such as:

– ECSO, a tool (described in Clause 7) to evaluate and optimize the conductor size by

combining environmental and energy costs. ECSO is the optimization of the conductor

size so that the sum of the total costs and the conversion costs of CO emissions

throughout the life phases (defined in 6.2.4) of the cable is minimized.

Environmental improvement shall be balanced against other factors, such as product function,

performance, health and safety, cost, marketability and quality, legal and regulatory

requirements and other standards.

5 Environmental checklist approach

5.1 What is the checklist approach?

The checklist approach is a simple method without quantification of the complete

environmental impact. It is a working aid to evaluate the cable design and the cable choice for

a certain application so as to find environmentally related aspects that may require

consideration. The lists in 5.2 and Annex A address key factors that have an impact on the

environment.

– 12 – IEC 62125:2019 © IEC 2019

It should be noted that considerations of the points in 5.2 and Annex A do not always lead to

reduction of the adverse environmental impact of the product throughout its lifetime: any

decision to improve one environmental indicator can impact negatively another indicator. A

possible way to confirm and quantify the environmental improvement is the use of the LCA

methodology described in Clause 6.

5.2 Checklist

The following list, which is in accordance with IEC Guide 109:2012, Annex A, addresses key

factors that may have an impact on the environment. Determine whether cable design and

cable choice for the application consider the following aspects:

– material conservation:

• minimal material content in the product;

• minimal material content in the packaging;

• minimal number of different materials;

• maximum separability of different materials;

• maximum recyclability of used materials;

• reusability of product parts and components;

• reusability and upgradability of the product as a whole;

• possibility of using recycled materials;

• possibility of using refurbished product parts and components;

• minimal size of product;

• minimal mass of product.

– energy conservation:

• minimal energy consumption during the product's manufacture and operation;

• power management, e.g. automatic switch to standby mode.

– pollution prevention:

• avoidance of hazardous substances;

• avoidance of substance emissions into the environment (air, water, soil);

• avoidance of other releases, e.g. radiation, noise, dust.

– avoidance of waste:

• modularity allowing multiple use of components (e.g. common chargers for different

applications).

This list is not exhaustive; more items could be added for specific reasons. Not every item on

the list will apply to every situation. Some more specific guidance related to electric cables is

given in Annex A.

6 Life cycle assessment (LCA) of cables

6.1 General

As recommended by IEC Guide 109, the basis of the assessment of product-related

environmental impact is life cycle thinking. The environmental impact of a product needs to be

evaluated by taking into account its whole life cycle, and by evaluating various environmental

indicators. LCA is a tool covering all life cycle stages (cradle to grave).

Figure 1 illustrates the elements in an LCA. An LCA shall be carried out in accordance with

the methodology of life cycle assessment (LCA) specified in ISO 14040 and ISO 14044.

Some basic steps to conduct this life cycle assessment of power cables are described in 6.2

to 6.6.

It has to be noted that an environmental optimum may not coincide with the economical

optimum. LCA has to be seen as an evaluation tool to quantify the environmental impact and

is not related to economic aspects. Regarding economic consideration, other methodologies

can be applied, such as environmental life cycle cost (monetary expression, i.e. monetization

of environmental indicators) or ECSO (see Clause 7), which combine environmental and

economic aspects.

Figure 1 – Life cycle phases

6.2 Goal and scope

6.2.1 LCA study goal

The goal and scope of the LCA study should be clearly defined and be consistent with the

intended application of the LCA.

The following items shall be unambiguously stated:

– the intended application;

– the decision context (reason for carrying out the study);

– the intended audience, i.e. to whom the results of the study are intended to be

communicated.

6.2.2 Functional unit

The functional unit defines the quantification of the identified functions (performance

characteristics) of the product being considered. The purpose of the functional unit is to

provide a reference to which the inputs and outputs are related. This reference is necessary

to ensure comparability of LCA results.

– 14 – IEC 62125:2019 © IEC 2019

The functional unit shall mention:

– the main function delivered to the user;

– the quantified level of performance to be achieved by the main function.

For example, for a standard functional unit of power cables:

– "To transmit energy expressed for x A over a distance of y km during n years at a b % use

rate, in accordance with the relevant standards." or

– "To transmit energy of x kWh over a distance of y km during n years at a b % use rate, in

accordance with the relevant standards."

NOTE Use rate represents the operating time per year and can be expressed as

– the % of annual operating days (in %);

– the number of operating hours per year (in hours);

– the number of operating days per year (in days).

Other functional units can be defined depending on the goal of the LCA and the intended

application.

6.2.3 Reference flow

Each functional unit corresponds to a reference flow. This reference flow describes all the

needed flows to fulfil the functional unit and includes at least a reference power cable.

The reference flow shall include:

– the quantification of the reference product and its mass (kg), used to fulfil the functional

unit;

– the additional materials not found in the reference product that include waste and

discarded materials generated at each life cycle stage (manufacturing process, cutting,

installation, etc.);

– elements, flows and processes required to distribute, install, use (maintenance, repairs,

replacements…) remove, dismantle and treat the reference product.

6.2.4 System boundary

The system boundary describes the unit processes that are included in the LCA. Concerning

power cables, the main impacting life phases are known to be the manufacturing (of the raw

materials) and the use phases of the cables.

The life phases include:

– the manufacturing phase with:

• raw material extraction and processing, transport of raw materials to the cable

manufacturer;

• cable manufacturing;

– the transportation phase with the transportation of the power cable from the

manufacturer to the installation place;

– the installation phase including processes, components and energy accounted for the

installation phase. Owing to the wide range of possible installation of these products, it

may be decided to exclude the installation phase from the life cycle assessment's

perimeter;

– the use phase with the energy consumption related to cables losses and other impacts, if

any. The impact of the use phase will clearly describe the scenario used, such as cable

lifetime, cable load factor, conductor resistivity and current load of the conductor;

– the end of life phase, including cable removal and transportation, as well as end-of-life

treatment (grinding, separation, landfill, recycling, energy recovery, etc.).

The LCA has to be composed by all the life cycle steps. The LCA methodology could be used

in some cases and for some reasons (for example, if it is required by a customer) to analyze

just some phases, for instance "cradle to gate" analysis that only takes into consideration raw

materials and cable manufacturing. This approach does not result in an LCA as such.

6.2.5 Cut-off criteria

Criteria for the exclusion of inputs and outputs shall not be applied to hide data. Any

application of the criteria for the exclusion of inputs and outputs shall be documented. The

cut-off criteria depend on the goal and scope definition and the boundary setting. Various cut-

off criteria may be used to decide inputs and outputs to be included in the assessment, such

as weight, energy and environmental influence. The total of neglected input flows (for

example, raw materials to manufacture the cable) shall be clearly identified. Moreover,

particular care should be taken to include material and energy flows known to have the

potential to cause significant emissions into air, water and soil in relation to the environmental

indicators of this document.

As an example, the following cut-off criteria can be applied:

– the mass of intermediate flows not taken into account shall be less than or equal to 5 % of

the mass of the elements of the reference product corresponding to the functional unit;

– the energy flows not taken into account shall be less than or equal to 5 % of the total use

of primary energy during the life cycle of the reference product corresponding to the

functional unit.

6.2.6 Assumptions and limitations

Every assumption made – if necessary because of, for example, lack of data impossible to

retrieve – should be clearly specified.

6.3 Life cycle inventory (LCI)

6.3.1 General

The life cycle inventory includes the collection of input data about resources, products or

energy entering into the process, as well as output data about product, material or energy

flow that leaves a process.

6.3.2 Data collection

The data to be included in the LCA study shall be obtained for each process included in the

system boundary. For each unit process within the system boundaries, inputs and outputs

related to the reference flow shall be collected including:

– consumption of materials, energy, water;

– emissions to air, water, soil;

– waste from the processes analysed.

The data gathered, whether they are measured, calculated or estimated, shall be used to

quantify the inputs and output flows of a process. If data cannot be collected directly on-site

(primary data), data can be obtained from high-quality and well-recognized databases

(secondary data).

Secondary data shall be identified and consistent with the scope of the study in terms of time-

related, geographic and technologic coverage. The databases used for the LCA shall be

mentioned in the LCA report.

– 16 – IEC 62125:2019 © IEC 2019

NOTE Examples of public database are:

– Ecoinvent database [1] ;

– European Life Cycle Database (ELCD) [2];

– U.S. Life Cycle Inventory Database (USLCI) [3].

6.3.3 Data selection

Specific or average data derived from specific production processes shall be the first choice

as a basis for the LCA study of power cables.

It is recommended that:

– the collected flows should be averaged over a sufficiently long period, preferably over a

year, to even out any seasonal peaks;

– the collected data should be representative of a current scenario in terms of geographic

coverage and technologic coverage. When data are collected from several sites, the data

should be collected from representative sites. The method used to aggregate the multi-site

data (i.e. measurements taken on each site) and the rules applying to the creation of data

sources should be documented in the LCA report.

6.3.4 Allocation procedure

Most industrial processes produce more than the intended product. Normally, more than one

input is needed to produce one product and sometimes products are co-produced with other

products. When dealing with systems involving multiple products, allocation rules need to be

set up to share the inputs and outputs to each product. Several methods are described in

ISO 14044.

To allocate the consumptions of energy, materials, and water and emissions in air, water, soil

and waste, it is necessary to apply a physical allocation rule being representative for the

parameter, which shall be allocated to the functional unit.

The physical parameter of assignment of input and output flows may be for example mass,

surface, or the number of units produced according to what is suitable for the system of

production. Allocation should be considered carefully and should be justified.

6.4 Life cycle impact assessment (LCIA)

It includes the assignment of the LCI results to the selected impact categories and the

potential environmental impacts in each category.

The impact assessment methodology used to carry out the LCA should be clearly described.

The impact assessment is carried out preferentially following the ILCD (International

Reference Life Cycle Data System) recommendations given in the ILCD handbook [4].

Regarding the global warming potential, this can be expressed in two possible ways:

a) by quantifying its impact with the "CO equivalent" units, intended as the "mid-point

category" as potential direct impact to the environment;

b) by quantifying its impact up to the final damage to the "endpoint categories", for example:

damage to human health, environment, resource depletion.

The same two approaches can be followed for any other impact category used to evaluate the

LCA impact of the cable.

___________

Numbers in square brackets refer to the Bibliography.

6.5 Interpretation

The LCA interpretation shall include:

a) an interpretation starting with the identification of significant issues;

b) a description of the completeness (taking into account system boundaries and cut-off

criteria);

c) sensitivity and consistency checks.

The result should be interpreted taking into account the initial aim of the study.

If the aim of the study is the comparison between alternative cables, the results interpretation

should be focused on the differences of the cables, not on their common properties.

Whilst if the aim of the study is the identification of the main impact elements of a cable in

order to improve its environmental design (for example: what is the most impacting raw

material? what is the most impact life cycle step – production, use or other? Etc.), the

conclusions should be structured consequently.

This means that a strong result interpretation implies focusing on the elements relevant for

the product to be analyzed and for the objectives of the LCA.

For this reason, the interpretation is also feedback about the quality of the LCA performed,

since it can make evident the need to review the study before releasing the definitive results,

allowing for possible significant elements to be included in the LCA that could have been

neglected at first.

The interpretation should also be carried out with the purpose of identifying the main

conclusions to communicate in the LCA report.

As a matter of fact, the LCA results (after the "impact assessment" step) are represented by

one or more numbers and charts, indicating how much the cable life cycle impacts on the

environment. Those numbers are often not very clear to non-expert readers. Therefore, they

should be translated into final conclusions by putting them through the "interpretation" step.

Such conclusions – in order to be communicated to the public – should be defined

consistently with the basic aim of the study.

6.6 Single environmental indicator approach

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...