IEC PAS 62508:2007

(Main)Guidance on human factors engineering for system life cycle applications

Guidance on human factors engineering for system life cycle applications

This PAS describes the process on human factors (HF) influencing system dependability design and provides HF methods and practices applicable to system life-cycle implementation to achieve dependability performance.

General Information

- Status

- Replaced

- Publication Date

- 24-Jun-2007

- Technical Committee

- TC 56 - Dependability

- Drafting Committee

- WG 3 - TC 56/WG 3

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 29-Jun-2010

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 26-Oct-2025

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

IEC PAS 62508:2007 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Guidance on human factors engineering for system life cycle applications". This standard covers: This PAS describes the process on human factors (HF) influencing system dependability design and provides HF methods and practices applicable to system life-cycle implementation to achieve dependability performance.

This PAS describes the process on human factors (HF) influencing system dependability design and provides HF methods and practices applicable to system life-cycle implementation to achieve dependability performance.

IEC PAS 62508:2007 is classified under the following ICS (International Classification for Standards) categories: 03.100.40 - Research and development; 03.120.01 - Quality in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC PAS 62508:2007 has the following relationships with other standards: It is inter standard links to IEC 62508:2010, IEC 62508:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC PAS 62508:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

PUBLICLY

IEC

AVAILABLE

PAS 62508

SPECIFICATION

First edition

Pre-Standard

2007-06

Guidance on human factors engineering

for system life cycle applications

Reference number

IEC/PAS 62508:2007(E)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

PUBLICLY

IEC

AVAILABLE

PAS 62508

SPECIFICATION

First edition

Pre-Standard

2007-06

Guidance on human factors engineering

for system life cycle applications

PRICE CODE

Commission Electrotechnique Internationale U

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

– 2 – PAS 62508 © IEC:2007(E)

CONTENTS

FOREWORD.4

INTRODUCTION.5

1 Scope.6

2 Normative references .6

3 Terms and definitions .6

4 HF and its influence.7

4.1 Understanding the HF relationships.7

4.2 Human machine comparison .7

4.3 HF engineering process .8

4.4 HF in system life cycle .8

4.5 The importance of HF designs.9

4.6 HF design criteria .10

5 HF activities implementation.11

5.1 HF planning.11

5.2 HF requirements analysis in system definition .11

5.3 HF analysis in system design .12

5.4 Incorporating HF in system requirements .12

5.5 Integrating HF in systems engineering.12

5.6 Outsourcing projects and related HF issues .13

5.7 HF assessment in system operation/maintenance .14

6 HF methods.14

6.1 Classification of HF methods .14

6.2 Applications of HF methods.15

Annex A (informative) HF engineering process concerning task analyses for human-

system interactions.17

A.1 HF engineering process for system application scenarios .17

A.2 HF engineering process for application environment.17

A.3 HF engineering process for requirements analysis.17

A.4 HF engineering process for functional analysis.17

A.5 HF engineering process for function allocation .18

A.6 HF engineering process for tasks design and analysis.18

A.7 HF engineering process for human interface.18

A.8 HF engineering process for requirements reviews .18

Annex B (Informative) Summary of HF design influence and impact on system

dependability.19

B.1 Automation .19

B.2 Design for maintenance.19

B.3 Computer-human interface .20

B.4 Incorporation of displays, controls and alarm functions.20

B.5 Incorporation of input devices.21

PAS 62508 © IEC:2007(E) – 3 –

B.6 Environment .21

B.7 Safety.21

B.8 Security.21

Annex C (Informative) Summary of methods for HF analysis, design and development

and test and evaluation .22

C.1 HF analysis methods .22

C.2 HF methods for design and development.24

C.3 HF methods for test and evaluation .25

C.4 Summary of application areas for HF methods.26

Bibliography.27

Figure 1 – Human factors influence in the system life cycle process .9

Table C.1 – Summary of application areas for HF methods .26

– 4 – PAS 62508 © IEC:2007(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

GUIDANCE ON HUMAN FACTORS ENGINEERING

FOR SYSTEM LIFE CYCLE APPLICATIONS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

A PAS is a technical specification not fulfilling the requirements for a standard but made

available to the public.

IEC-PAS 62508 has been processed by technical committee 56: Dependability.

The text of this PAS is based on the This PAS was approved for

following document: publication by the P-members of the

committee concerned as indicated in

the following document:

Draft PAS Report on voting

56/1163/PAS 56/1184/RVN

Following publication of this PAS, which is a pre-standard publication, the technical committee

or subcommittee concerned will transform it into an International Standard.

This PAS shall remain valid for an initial maximum period of three years starting from

2007-06. The validity may be extended for a single three-year period, following which it shall

be revised to become another type of normative document or shall be withdrawn.

PAS 62508 © IEC:2007(E) – 5 –

INTRODUCTION

This PAS provides technical information on human factors (HF) for engineering and

implementation of systems. It fills the urgent need for an HF standard currently not available

among the ISO or IEC standards.

HF is one of the key system elements that have significant influence on the system design to

achieve dependability performance and service quality. This PAS provides guidance and

criteria to facilitate the incorporation of HF requirements in system development and

operation. It permits practical HF applications and design trade-offs with other key system

hardware and software elements for cost-effective implementation. The technical contents of

this PAS are based on human engineering standards and guidelines established by the FAA

and NASA. Technical approaches and HF methods are adopted from industry best practices

suitable for systems engineering applications.

The HF and human reliability knowledge base covers a broad scope of technical and scientific

work. This PAS focuses on the engineering aspects for HF applications in the system life-

cycle process. It does not address the human reliability issues involving the study of human

anatomy, anthropometry, biomechanics, physiology, and psychology affecting system design

and operation with human interactions.

– 6 – PAS 62508 © IEC:2007(E)

GUIDANCE ON HUMAN FACTORS ENGINEERING

FOR SYSTEM LIFE CYCLE APPLICATIONS

1 Scope

This PAS describes the process on human factors (HF) influencing system dependability

design and provides HF methods and practices applicable to system life-cycle implementation

to achieve dependability performance.

2 Normative references

The following referenced documents are applicable to this document. For dated references,

only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

IEC 60300-1, Dependability management – Part 1: Dependability management systems

IEC 60300-2, Dependability management – Part 2: Guidelines for dependability management

IEC 60300-3-15, Dependability management – Part 3-15: Guidance to engineering of system

dependability

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

human factors (HF)

knowledge on human abilities, limitations, and other human characteristics that are relevant to

the design and application of products affecting human-system performance

3.2

human factors engineering

application of human factors knowledge to the design of tools, machines, systems, tasks,

jobs, and environment for safe, comfortable, and effective human use

3.3

human reliability

study of human performance in terms of probability that a person will correctly perform some

system-required activity during a given time period (if time is a limiting factor) without

performing any extraneous activity that can degrade the system

NOTE The application of human reliability knowledge is often referred to as human reliability engineering, human

engineering, or human system engineering. It is sometimes used interchangeably as human factors engineering

and the scope of application may vary for each application.

3.4

ergonomics

study of scientific information concerning humans to the design of objects, systems and

environment for human use incorporating elements from many subjects including human

anatomy, physiology, and psychology in the design

NOTE Ergonomics is sometimes used interchangeably as human factors engineering. There are minor differences

in approach.

———————

To be published.

PAS 62508 © IEC:2007(E) – 7 –

4 HF and its influence

4.1 Understanding the HF relationships

The term “HF” is mainly used in North America. The term “ergonomics” is used in Europe and

other parts of the world. HF involves working to make the environment function natural to

human use. Ergonomics is matching the task and product to the human user. Ergonomics and

HF engineering are often used interchangeably in the work environment. Both describe the

interaction between the human user and the task demands, and the human-machine

relationships. The difference between them is that ergonomics focuses on how the task

affects the user, and HF engineering emphasizes the design to reduce the potential of human

error in system operation. It is the HF engineering aspects influencing dependability

performance that needs to be addressed in system dependability standards.

The relationship of HF to system is that humans are often deployed and used in system

functions. The linkage of HF to dependability is that human functions affect the influencing

characteristics of reliability, maintainability and maintenance support in system performance.

Human reliability is related to the field of HF engineering. It refers to the study of reliability of

humans in various fields such as information processing, manufacturing, transportation,

medicine and service operation. Human performance can be affected by many factors such as

age, circadian rhythms, state of mind, physical health, attitude, emotions, propensity for

certain common mistakes such as errors and cognitive biases.

The broader issues concerning the study of human reliability are directly linked to the possible

adverse consequences of human errors or oversights, especially when the human is engaged

in a crucial part of a complex system for safety, security or mission critical applications

involving human machine and human system interactions. HF engineering utilizes the human

reliability knowledge base for application in user-centric and error-tolerant designs by

adapting appropriate technologies to enhance human-system operation.

4.2 Human machine comparison

The following presents an overview of human versus machine abilities for comparison.

Although rapid advances in technologies have significantly increased the machine abilities,

this overview presents a classical observation that remains valid in the HF field.

Humans surpass machines in

• ability to detect small amount of visual and acoustic energy;

• ability to perceive patterns of light or sound;

• ability to improvise and use flexible procedures;

• ability to store very large amounts of information for long periods and to recall relevant

facts at the appropriate time;

• ability to reason inductively;

• ability to exercise judgement.

Machines surpass humans in

• ability to respond quickly to control signals and to apply great force smoothly and

precisely;

• ability to perform repetitive and routine tasks;

• ability to store information briefly and then to erase it completely;

• ability to reason deductively, including computational ability;

• ability to handle highly complex operations;

– 8 – PAS 62508 © IEC:2007(E)

• ability to do many different things at once.

The major differences between humans and machines are as follows.

• Machines can be modified, redesigned, and retrofit whereas humans cannot. Humans are

born with innate, genetically determined differences that are shaped by the environment.

Innate aptitudes or abilities are developed through education and training.

• Machines can be manufactured to be identical to provide exact output and duplicate

precise operation. Humans are not identical and vary across all sensory, cognitive,

physical and performance characteristics. Specific aspects of human performance can be

made more equal through education and training.

4.3 HF engineering process

HF engineering involves the process of engineering the human into systems. The inclusion of

humans in systems has the advantage of the human’s intuitive reaction, flexibility to adapt to

situations, and the capability of performing many functions and tasks. However, human has

limitations in cognitive and physical capabilities for task performance. The inherent qualities in

the human element as a system attribute can be exploited for design trade-offs with

interacting hardware and software elements contributing in a holistic manner to enhance

system performance. The aim is to maximize the overall system capabilities in performance

operation.

Involvement of HF engineering at early design stages has extensive influence to maximizing

the return on investments and optimizing the system capabilities in performance operation.

The critical impact areas for HF engineering participation in system design and operation

include

• early identification of critical system functions that are considered suitable and

advantageous for human interaction by analysis of system operating scenario;

• user-oriented task designs for timing and operating task sequence through HF engineering

activity in system decomposition and functional analysis for ease and expediency in

human-machine operation;

• consideration of human capabilities and limitations when making function allocation

decisions for cost-effective application and training needs;

• integrating the human requirements into the system design process for optimizing the

system performance compatibility of human-machine interface and interoperability;

• the process of engineering human into systems includes task analyses of the systems

engineering process and the HF engineering process. The relevant tasks, decisions, and

information common between the two processes can be used as basis to identify areas of

interactions between the human and the system.

Annex A provides additional information on the HF engineering process concerning task

analyses for human system interactions.

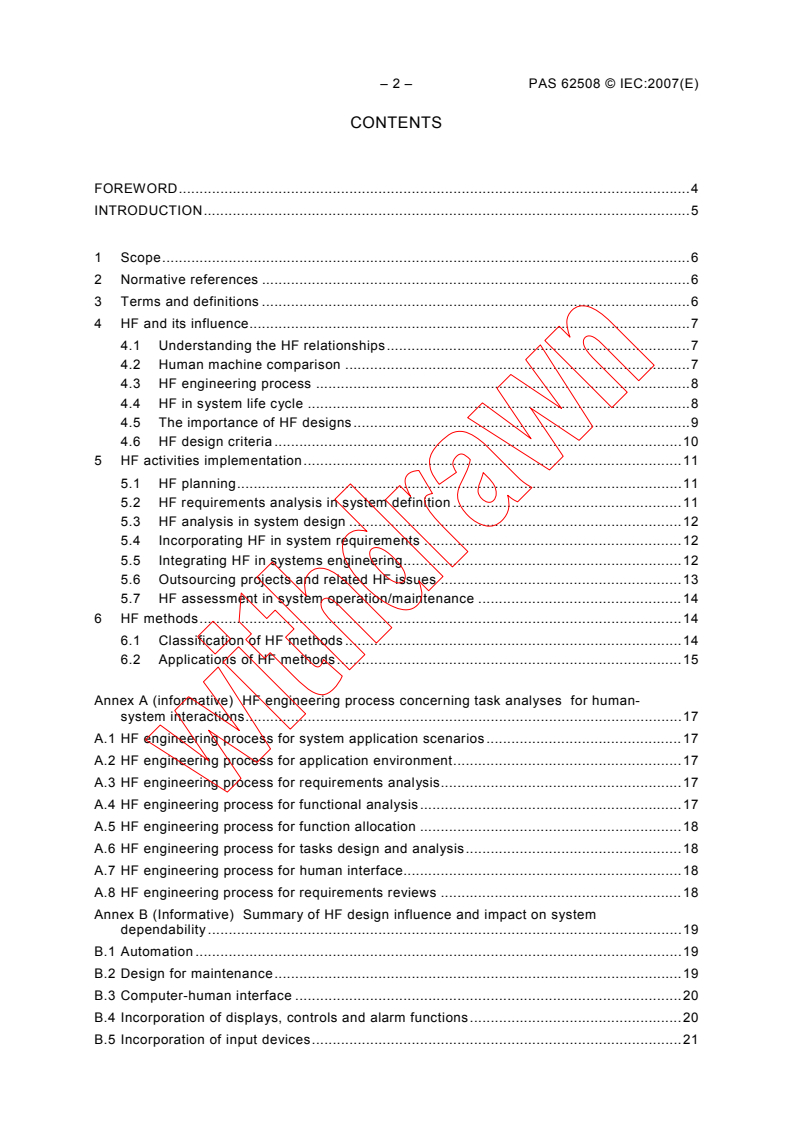

4.4 HF in system life cycle

HF as a technical discipline is closely associated with systems engineering and system life-

cycle process. The system life cycle concept adopted from IEC 60300-3-15 is shown in Figure

1 to identify the key HF influence in the system life cycle. The system life-cycle stages are

briefly described as follows.

The concept/definition stage is to identify the market needs, define/identify the operational

use environment/timeline, define preliminary system requirements and confirm feasible design

solutions by producing technical specifications for the system design.

The design/development stage is to plan and execute selected engineering design solutions

for realization of system functions.

PAS 62508 © IEC:2007(E) – 9 –

Realization/implementation stage is to execute make-buy decisions for acquisition and

deployment of subsystem elements.

The operation/maintenance stage is used to deploy the system for delivery of service and to

support system operational capability by means of maintenance.

The enhancement stage is to improve system performance with added features to meet

growing user demands on the system.

The retirement/decommissioning stage is to end the existence of the system entity.

Retirement/

Decommission

Enhancement

Concept/

Definition

Design/

Operation/Maintenance

Development

•HF issues

Realization/

related to

Implementation

disposals,

recycling, and

•Define HF

reuse

objectives

•Operation/

•Analyze HF

maintenance

requirements

•Skills training

records

•Health and safety

•Allocate HF •Corrective/ •Review in-service

awareness

functions HF performance

preventive actions

•Implement fault

•HF design for •Incidents •Process

management procedures

usability and improvements

reporting

•Regulatory compliance

compatibility •HF error analysis

Figure 1 – Human factors influence in the system life-cycle process

4.5 The importance of HF designs

The HF activities complement the dependability projects and work programmes. Dependability

is the ability of a system to perform as and when required to meet specific objectives.

Dependability describes the availability performance of a system influenced by its

performance characteristics of reliability, maintainability and maintenance support. The

principles of dependability management are presented in IEC 60300-1. The applications of

dependability management techniques are described in IEC 60300-2.

HF activities have significant impact on system dependability design and performance

operation. The HF issues when identified and applied early in the system life-cycle design

process would

• increase productivity, improve performance, and gain greater user satisfaction;

• reduce errors in design and operation;

• simplify system operation and maintenance procedures;

• reduce time in user support;

• reduce the need for special skills training;

• reduce risks of serious accidents;

– 10 – PAS 62508 © IEC:2007(E)

• result in cost avoidance and optimize life-cycle costs.

4.6 HF design criteria

The premise for HF design and operation related to safety, security or mission critical

application of complex systems is to avoid catastrophic impact and negative consequences.

HF standardization facilitates system integration, enhances interoperability of system

elements, and improves serviceability and overall dependability performance.

The HF design criteria are based on the following.

a) Fitness for use

• Make system durable, reliable and applicable for its intended use.

• Allocate functions appropriately.

• Test with users.

b) Simplicity

• Design for simplicity.

• Minimize training.

• Make functions obvious.

c) Consistency

• Make design consistent.

• Be consistent with user experience with real life objects and similar system.

d) Standardization

• Standardize hardware and software.

• Maintain identical interfaces for identical functions.

• Make controls, displays, markings, coding, labelling, and arrangement uniform.

• Make appearance distinctive.

• Standardize terminology, look, and feel.

• Make functionally similar equipment interchangeable.

e) Safety

• Incorporate safety factors.

• Provide fail-safe design.

• Make system error resistant and tolerant.

• Warning of potentially unsafe actions.

• Provide emergency procedures.

f) User-centred perspective

• Provide timely and informative feedback.

• Use familiar terms and images.

• Design within user abilities.

• Maximize human performance.

• Minimize training requirements.

• Facilitate transfer of skills.

• Accommodate physical diversity.

g) Maintenance support

• Provide logistic support where needed.

PAS 62508 © IEC:2007(E) – 11 –

• Design for common tools.

• Make system easy to maintain and accessible.

Annex B summarizes the HF design influence and impact on system dependability.

5 HF activities implementation

5.1 HF planning

A HF plan is essential to establish a strategy for managing HF effort to support system

development and operation. The objective is to address HF issues to improve total system

performance and reduce developmental and life-cycle costs. This is achieved by optimizing

human performance when the system is operated and maintained in the application

environment. The planning approach should consider

• identifying the target system of interest and application environment;

• identifying legacy issues of existing system in enhancement projects;

• focusing on the tasks with human involvement in the system life cycle;

• early identification and resolution of human performance issues;

• assigning HF specialists responsible for activities coordination;

• determining the human capabilities and limitations for appropriate task designs;

• establishing a strategy for task implementation involving human interactions;

• project tailoring for system integration;

• incorporation of assurance provisions and review process.

An HF plan should be developed in early concept/definition stage of the system life cycle to

maximize its effectiveness to influence system definition and framework development. The HF

plan should be part of the system overall plan.

5.2 HF requirements analysis in system definition

HF requirements definition is needed for application scenario and mission analysis of the

system of interest. This activity gathers essential information to develop system requirements,

prepare cost-benefit and risk analyses, and develop plans, specifications, and statement of

work. The HF requirements analysis provides the necessary information and relevant data to

• determine HF issues in system application and operating scenario;

• integrate HF principles into the system context;

• tailor the project to HF content in the system;

• establish HF plan and strategy.

The objective is to achieve a human-centred, error-resistant and tolerant system framework

that is suitable and usable for effective system operation. HF requirements should address

• human-system interfaces influencing user performance efficiency and effectiveness;

• system architecture design affecting the human-system interactions;

• interoperability of system elements consisting of hardware, software and humans;

• system application environment impacting human resources and requirements.

The HF requirements analysis should be conducted in conjunction with the HF plan during the

concept/definition stage of the system life cycle. This facilitates the tailoring process working

to meet specific project needs in system definition. The project tailoring process is described

in IEC 60300-2.

– 12 – PAS 62508 © IEC:2007(E)

5.3 HF analysis in system design

HF analysis in system design is conducted during the design/development stage of the

system life cycle. The objective is to ensure that

• human system capabilities and limitations are properly reflected in the system

requirements;

• human system performance characteristics are providing relevant information to identify

design options and alternatives;

• human system performance risks and cost impacts are appropriately addressed.

The HF analysis approach should consider

• human performance such as human capabilities and limitations, workload, function

allocation, hardware and software design, decision aids, environmental constraints, and

team versus individual performance;

• training needs such as duration of training, training effectiveness, skills retraining, training

devices and facilities, and embedded training;

• staffing requirements such as staffing levels, team composition, and organizational

structure;

• personnel selection such as minimum skill levels, special skills, competency and

experience;

• health and safety issues such as hazardous materials and conditions, system and

equipment design for safe operation, operational and procedural constraints, biomedical

influences, protective equipment, and warnings and alarms requirements.

5.4 Incorporating HF in system requirements

The purpose of incorporating HF in system requirements is to

• provide HF inputs to development of system specifications;

• include HF requirements in quality assurance process;

• include HF requirements for outsourcing and subcontracting;

• establish HF procedures for system operation and maintenance.

For human performance influencing the system design and application, the system

specifications and operation and maintenance procedures should consider

• staffing constraints;

• system operator and maintainer skills;

• training requirements;

• level of comprehension of the end users.

Incorporation of HF requirements in system specifications should be completed during the

design/development stage of the system life cycle.

5.5 Integrating HF in systems engineering

The purpose of integrating HF in systems engineering is to

• develop or enhance human-system interface;

• achieve human performance design objective and effectiveness in system operation and

maintenance support;

• establish system operating scenario;

• optimize utilization of personnel resources, skills, training, and costs;

PAS 62508 © IEC:2007(E) – 13 –

• address resource allocation for automation and for task simplification;

• incorporate HF needs in system enhancement and retirement, equipment assembly and

disassembly, and disposal of parts.

Integrating HF in systems engineering is done throughout the system life cycle, especially

during the design/development, realization/implementation and operation/maintenance

stages, where HF has the most influence on systems engineering tasks related to design

enhancements, safety features, automation impacts, human-system performance trade-offs,

ease of use, and workload.

Specific systems engineering activities related to HF include

• systems engineering planning and incorporation of HF requirements to identify critical

issues for technical resolution;

• development of system design configuration based on functional analysis and function

allocation contributed by human elements, and HF task design trade-offs with hardware

and software system functions;

• task analysis to determine the information flow and processing requirements by operators,

maintainers, and end users to accomplish the system performance objectives;

• test and evaluation of system functions involving human interactions to determine

operational effectiveness and conformance to established HF requirements and system

performance criteria.

5.6 Outsourcing projects and related HF issues

The HF requirements should be incorporated in system specifications and procurement

documents. This is crucial for the system to achieve its objectives for coherent design and

consistent performance involving proper function allocation and interactions of hardware,

software and human elements in system design and operation. The outsourcing of

subsystems development requiring human operation is common in today’s complex system

development and enhancement projects. Incorporation of commercial-off-the-shelf (COTS)

products as system functions often has cost benefits. System support services are frequently

used for contract maintenance. The success factors are dependent on the collaborative

efforts of the acquirers and suppliers, the system integrators and service providers through

application of supply-chain management and quality assurance processes. Since HF involves

multi-disciplinary actions, technical experts are sometimes required to deal with resolution of

critical HF issues related to outsourcing and procurement needs.

Outsourcing HF projects should consider

• human system interface requirements to achieve the level of human performance during

system operation and maintenance;

• maximizing the economical demands on utilization of available human resources, skills,

and training;

• staffing implications of the human resources required, job classification, skill levels, and

experience needed for the projects;

• evaluation for design automation trade-off with human operation in terms of applicability,

efficiency and cost implications;

• potential system safety and health hazards areas involving human-system interactions;

• quality assurance provisions for procurement contracts.

Outsourcing projects should be identified during concept/definition stage of the system life

cycle. The procurement contracts should be well established at the completion of the

design/development stage. This would permit time for subcontractor evaluation, multiple

sourcing of preferred suppliers, and COTS product assessment for incorporation as system

functions to facilitate the system integration process.

– 14 – PAS 62508 © IEC:2007(E)

5.7 HF assessment in system operation/maintenance

HF assessment in system operation/maintenance is to ensure that HF considerations are

adequately integrated into the system for effective performance operation. The assessment is

conducted during the operation/maintenance stage of the system life cycle. The assessment

is achieved by system testing and performance verification. This is to produce evidence of

conformance to HF requirements in an application environment. The HF assessment process

should

• measure human performance in critical tasks;

• determine efficiency and effectiveness of human intervention;

• maintain HF test records and assessment data as basis for evaluation and improvement.

Human performance testing of COTS products should take advantage of available information

from the product manufacturers, records of warranty returns, previous commercial testing, and

product use experience.

The HF assessment results should be analyzed to support recommendations in design

changes where appropriate, provide rationale for human performance improvements, or

implement training solutions. The HF information flow should include sharing with Integrated

logistics support (ILS) programmes where applicable. ILS is a disciplined approach to

integrate support considerations into design, to acquire the necessary initial support for the

system, and to identify life-cycle support requirements. The HF programme provides the

human resource and performance dimension for logistics support requirements and functions.

Close coordination between the HF and ILS programs will reduce data redundancies and

result in more effective use and sharing of information.

6 HF methods

6.1 Classification of HF methods

HF methods are classified as follows.

a) HF analysis methods

HF analysis methods are used to define system concepts, describe application/mission

scenarios, determine functional requirements, and assign tasks for appropriate skills

allocation. The various analyses provide a means for identifying HF-related goals, objectives,

critical design issues, and further evaluation needs to meet system performance requirements

involving human interactions.

b) HF methods for design and development

HF methods for design and development are used to incorporate all necessary HF design

criteria into the human system interface design. The human system interface includes system

hardware, software, procedures, work environments, and facilities associated with the system

functions requiring human interactions. The process is to convert the results of the HF

analysis activities into HF training and skill level design criteria for HF project development

and implementation.

c) HF methods for test and evaluation

HF methods for test and evaluation are used to verify human system interface and procedures

to ensure that the system can be operated, maintained, supported, and controlled in its

intended operating environment by the users. These methods facilitate identification of critical

HF issues in operation and maintenance for problem resolution and process improvement.

Annex C provides a summary of practical methods for HF analysis, evaluation and

assessment.

PAS 62508 © IEC:2007(E) – 15 –

6.2 Applications of HF methods

The HF methods for general analysis, evaluation and assessment applications are based on

systems engineering techniques. They should be used in conjunction with other engineering

methods and technical disciplines in system design and implementation. The HF methods

listed in Annex C facilitate the accomplishments of one or more of the following tasks.

1) Application/mission effectiveness criteria.

2) Detailed design requirements.

3) Concepts formulation ideas.

4) Personnel requirements information.

5) Operational procedures development.

6) Training system development.

7) Maintenance system development.

8) System operational evaluation.

9) Additional HF analysis.

Other application areas related to implementation of HF activities include

a) HF planning

• project management;

• cost-benefits and risk analysis;

• decision-making process.

b) Human-system performance assessment

• situation assessment;

• function allocation;

• cognitive assessment.

c) modelling and simulation

• human performance modelling;

• information flow analysis and simulation;

• human-machine integrated design and analysis system.

d) human computer interaction

• human computer mock-up;

• diagnostic evaluation;

• cognitive walkthrough;

• usability inspection.

e) knowledge elicitation

• cognitive task analysis;

• interview, questionnaire, and observation.

f) physical ergonomics

• empirical models;

• standards.

g) safety

• accident investigation;

• human error;

– 16 – PAS 62508 © IEC:2007(E)

• human reliability;

• risk assessment.

HF tools are mostly developed for specific applications. They often incorporate experienced

database and custom design criteria in dedicated computerized systems. These HF tools are

upgraded or changed to meet specific application needs which become difficult for generic

application purposes. They are referenced in various literatures and not included in this PAS.

PAS 62508 © IEC:2007(E) – 17 –

Annex A

(Informative)

HF engineering process concerning task analyses

for human system interactions

A.1 HF engineering process for system application scenarios

System inputs HF engineering outputs

• System scenarios • Estimate of staffing requirements

• Mission profiles and timelines • Verification of workload and task

assignments

• Concept of system operations

• Evaluation of skills and training

• Technology limitations

requirements

• Regulatory constraints

• Identification of potential problem areas

• Legacy issues related to operation and maintenance

A.2 HF engineering process for application environment

System inputs HF engineering outputs

• Natural environmental conditions • Effects of predicted natural

(weather, topology, time of day) environmental conditions

• Induced environmental conditions • Design constraints reflecting the natural

(lighting, noise, vibration, induced heat) environmental conditions

• Strategies to mitigate environmental

impact on users

A.3 HF engineering process for requirements analysis

System inputs HF engineering outputs

• Source requirements and application • Users’ knowledge, skills and abilities to

constraints perform tasks

• Human capabilities and limitations • Human performance requirements in

terms of time for task completion and

• System capabilities and limitations

competency required

• HF engineering design requirements to

support operators and maintainers

• Knowledge and experience database

establishment

A.4 HF engineering process for functional analysis

System inputs HF engineering outputs

• Mission analysis • Functional flow diagrams

• Activity analysis • Functional architecture

• Requirements analysis • Critical functions identification

• Decision actions

• Design characteristics to support users

– 18 – P

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...