IEC 60300-3-16:2008

(Main)Dependability management - Part 3-16: Application guide - Guidelines for specification of maintenance support services

Dependability management - Part 3-16: Application guide - Guidelines for specification of maintenance support services

IEC 60300-3-16:2008 describes a framework for the specification of services related to the maintenance support of products, systems and equipment that are carried out during the operation and maintenance phase. The purpose of this standard is to outline, in a generic manner, the development of agreements for maintenance support services as well as guidelines for the management and monitoring of these agreements by both the company and the service provider.

Gestion de la sûreté de fonctionnement - Partie 3-16: Guide d'application - Lignes directrices pour la spécification des services de support de maintenance

La CEI 60300-3-16:2008 décrit un cadre de travail pour la spécification des services liés au support de maintenance des produits, systèmes et équipements qui sont effectués pendant la phase d'utilisation et de maintenance. Le but de cette norme est de souligner, de manière générique, le développement des accords pour les services de support de maintenance, de même que les lignes directrices pour la gestion et le contrôle de ces accords par l'entreprise et le fournisseur de service.

General Information

- Status

- Published

- Publication Date

- 07-Oct-2008

- Technical Committee

- TC 56 - Dependability

- Current Stage

- PPUB - Publication issued

- Start Date

- 08-Oct-2008

- Completion Date

- 15-Oct-2008

Overview

IEC 60300-3-16:2008, titled Dependability management - Part 3-16: Application guide - Guidelines for specification of maintenance support services, is an international standard published by the International Electrotechnical Commission (IEC). This standard provides a structured framework for specifying and managing maintenance support services during the operation and maintenance phase of products, systems, and equipment. It focuses on generic guidelines for developing maintenance agreements and outlines effective management and monitoring practices for both companies and maintenance service providers.

The standard is fundamental for organizations seeking to ensure the dependability and operational continuity of their assets through well-defined maintenance support contracts. It caters to a broad range of users including suppliers, maintenance organizations, and owners or operators-referred to collectively as the “company.”

Key Topics

Maintenance Support Services Specification

IEC 60300-3-16 details how to specify maintenance support services effectively, encompassing services related to:

- Maintenance labour

- Spare parts provision

- Training on maintenance activities

- Repairs and overhauls

- Refurbishment and modifications

The standard distinguishes between limited service agreements and comprehensive long term service agreements (LTSA), emphasizing performance guarantees and the alignment of service levels with operational needs.

Agreement Development and Management

A core element of IEC 60300-3-16 is the creation of clear, mutually agreed maintenance service agreements. These agreements must:

- Define the scope and responsibilities for both company and service provider

- Outline technical, organizational, and commercial arrangements

- Include monitoring processes to track service performance and compliance

The standard also emphasizes the importance of management responsibility and communication channels to sustain effective collaboration and issue resolution throughout the contract lifecycle.

Lifecycle and Obsolescence Considerations

IEC 60300-3-16 encourages integrating maintenance support service planning into the overall lifecycle management of items-from design and development phases through operation and eventual obsolescence. This lifecycle approach helps organizations anticipate maintenance needs and potential challenges, such as spare parts availability or technology updates, thereby sustaining dependability over time.

Applications

IEC 60300-3-16:2008 serves as a practical guide for:

- Manufacturers embedding maintenance support arrangements within warranty and post-sale service frameworks.

- Operators and asset managers seeking to outsource or enhance maintenance service delivery with clearly defined contracts.

- Maintenance service providers looking to establish standardized service agreements focused on performance and reliability.

- Procurement teams tasked with evaluating and selecting maintenance support vendors.

- Quality and dependability professionals aiming to implement consistent maintenance processes for improved equipment availability and safety compliance.

By following this standard, organizations can reduce equipment downtime, optimize maintenance costs, and improve overall operational reliability through structured service agreements.

Related Standards

IEC 60300-3-16 is part of the IEC 60300 series on dependability management, complementing several related documents that enhance the maintenance and support framework, including:

- IEC 60300-3-2: Dependability management – Collection of dependability data from the field

- IEC 60300-3-3: Dependability management – Life cycle costing

- IEC 60300-3-10: Dependability management – Maintainability application guide

- IEC 60300-3-12: Dependability management – Integrated logistic support

- IEC 60300-3-14: Dependability management – Maintenance and maintenance support

- IEC 60706-2: Maintainability of equipment – Requirements during design and development

- IEC 62402: Obsolescence management – Application guide

These standards collectively provide best practices for managing the reliability, availability, maintainability, and lifecycle aspects of technical systems.

Keywords: IEC 60300-3-16, maintenance support services, dependability management, maintenance agreements, long term service agreement, operational reliability, maintenance specification, lifecycle maintenance, IEC standards, maintenance contract management, integrated logistic support, asset management.

Frequently Asked Questions

IEC 60300-3-16:2008 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Dependability management - Part 3-16: Application guide - Guidelines for specification of maintenance support services". This standard covers: IEC 60300-3-16:2008 describes a framework for the specification of services related to the maintenance support of products, systems and equipment that are carried out during the operation and maintenance phase. The purpose of this standard is to outline, in a generic manner, the development of agreements for maintenance support services as well as guidelines for the management and monitoring of these agreements by both the company and the service provider.

IEC 60300-3-16:2008 describes a framework for the specification of services related to the maintenance support of products, systems and equipment that are carried out during the operation and maintenance phase. The purpose of this standard is to outline, in a generic manner, the development of agreements for maintenance support services as well as guidelines for the management and monitoring of these agreements by both the company and the service provider.

IEC 60300-3-16:2008 is classified under the following ICS (International Classification for Standards) categories: 03.100.40 - Research and development; 03.120.01 - Quality in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60300-3-16:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60300-3-16

Edition 1.0 2008-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Dependability management –

Part 3-16: Application guide – Guidelines for specification of maintenance

support services

Gestion de la sûreté de fonctionnement –

Partie 3-16: Guide d’application – Lignes directrices pour la spécification des

services de support de maintenance

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60300-3-16

Edition 1.0 2008-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Dependability management –

Part 3-16: Application guide – Guidelines for specification of maintenance

support services

Gestion de la sûreté de fonctionnement –

Partie 3-16: Guide d’application – Lignes directrices pour la spécification des

services de support de maintenance

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

T

CODE PRIX

ICS 03.100.40; 03.120.01 ISBN 978-2-88910-100-9

– 2 – 60300-3-16 © IEC:2008

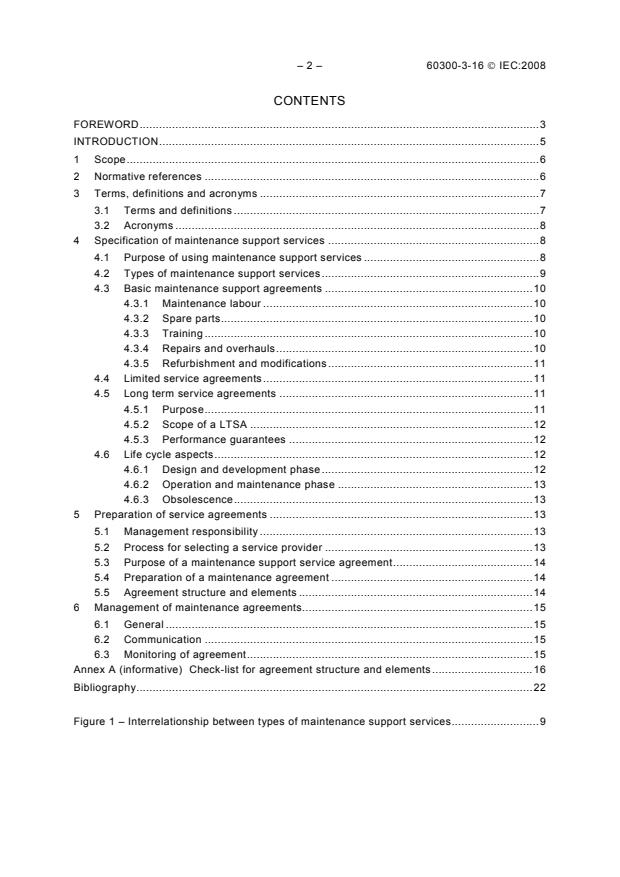

CONTENTS

FOREWORD.3

INTRODUCTION.5

1 Scope.6

2 Normative references .6

3 Terms, definitions and acronyms .7

3.1 Terms and definitions .7

3.2 Acronyms .8

4 Specification of maintenance support services .8

4.1 Purpose of using maintenance support services .8

4.2 Types of maintenance support services.9

4.3 Basic maintenance support agreements .10

4.3.1 Maintenance labour .10

4.3.2 Spare parts.10

4.3.3 Training .10

4.3.4 Repairs and overhauls.10

4.3.5 Refurbishment and modifications .11

4.4 Limited service agreements.11

4.5 Long term service agreements .11

4.5.1 Purpose.11

4.5.2 Scope of a LTSA .12

4.5.3 Performance guarantees .12

4.6 Life cycle aspects.12

4.6.1 Design and development phase.12

4.6.2 Operation and maintenance phase .13

4.6.3 Obsolescence.13

5 Preparation of service agreements .13

5.1 Management responsibility .13

5.2 Process for selecting a service provider .13

5.3 Purpose of a maintenance support service agreement.14

5.4 Preparation of a maintenance agreement .14

5.5 Agreement structure and elements .14

6 Management of maintenance agreements.15

6.1 General .15

6.2 Communication .15

6.3 Monitoring of agreement.15

Annex A (informative) Check-list for agreement structure and elements.16

Bibliography.22

Figure 1 – Interrelationship between types of maintenance support services.

60300-3-16 © IEC:2008 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

DEPENDABILITY MANAGEMENT –

Part 3-16: Application guide –

Guidelines for specification of maintenance support services

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60300-3-16 has been prepared by IEC technical committee 56:

Dependability.

The text of this standard is based on the following documents:

FDIS Report on voting

56/1271/FDIS 56/1290/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 60300 series, under the general title Dependability management

can be found on the IEC website.

– 4 – 60300-3-16 © IEC:2008

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

60300-3-16 © IEC:2008 – 5 –

INTRODUCTION

The use of maintenance agreements is now a common means of providing maintenance

support services to owners and operators of products, systems and equipment. These

services may be included in the initial design and development phase but they may also be

considered and implemented during the operation and maintenance phase.

Specification of maintenance support services requires not only the preparation of an

agreement but also management and monitoring of services during its implementation.

Agreements may be informal arrangements between the two parties or they may entail a

formal contract. Maintenance support services can range in scope from simple ones that

might entail repair of a specific type of item to long term, inclusive arrangements with

guarantees based on a relevant measure of performance.

The agreement must address responsibilities of both the service provider and the company

(and possibly the responsibilities of any warrantee service provided, if another company is

involved) with respect to scope and level of services, technical arrangements, organizational

arrangements, commercial aspects, legal obligations and contractual requirements. This

standard deals only with the service aspects of the agreement and not with legal or

contractual requirements.

– 6 – 60300-3-16 © IEC:2008

DEPENDABILITY MANAGEMENT –

Part 3-16: Application guide –

Guidelines for specification of maintenance support services

1 Scope

This part of IEC 60300 describes a framework for the specification of services related to the

maintenance support of products, systems and equipment that are carried out during the

operation and maintenance phase. The purpose of this standard is to outline, in a generic

manner, the development of agreements for maintenance support services as well as

guidelines for the management and monitoring of these agreements by both the company and

the service provider.

This standard is intended for use by a wide range of suppliers, maintenance support

organizations and users and can be applied to all items. For consistency in this standard, the

user, operator and owner are referred to as the company and the organization or vendor

providing the maintenance support service is called the service provider.

This standard is applicable to items, which include all types of products, equipment and

systems (hardware and software). Most of these require a certain level of maintenance to

ensure that their required functionality, dependability, capability, economic, safety and

regulatory requirements are achieved.

NOTE For consistency, this standard will use the term “item” as defined in 3.1.4, except where the context

requires otherwise.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60300-3-2, Dependability management – Part 3-2: Application guide – Collection of

dependability data from the field

IEC 60300-3-3, Dependability management – Part 3-3: Application guide – Life cycle costing

IEC 60300-3-10, Dependability management – Part 3-10: Application guide – Maintainability

IEC 60300-3-12, Dependability management – Part 3-12: Application guide – Integrated

logistic support

IEC 60300-3-14, Dependability management – Part 3-14: Application guide – Maintenance

and maintenance support

IEC 60706-2, Maintainability of equipment – Part 2: Maintainability requirements and studies

during the design and development phase

IEC 62402, Obsolescence management – Application guide

60300-3-16 © IEC:2008 – 7 –

3 Terms, definitions and acronyms

For the purposes of this document, the following terms, definitions and acronyms apply.

3.1 Terms and definitions

3.1.1

company

recipient of a maintenance support service provided by the maintenance support service

provider

3.1.2

corrective maintenance

maintenance carried out after fault recognition and intended to put an item into a state in

which it can perform a required function

NOTE In French, the term “dépannage” sometimes implies a provisional restoration.

[IEV 191-07-08:1990]

3.1.3

integrated logistic support

ILS

management method by which all the logistic support services required by a customer can be

brought together in a structured way and in harmony with a product

3.1.4

item

entity

any part, component, device, subsystem, functional unit, equipment or system that can be

individually considered

NOTE 1 An item may consist of hardware, software or both, and may also, in particular cases, include people.

NOTE 2 In French the term “entité” is preferred to the term “dispositif” due to its more general meaning. The term

“dispositif” is also the common equivalent to the English term “device”.

NOTE 3 In French the term “individu” is used mainly in statistics.

NOTE 4 A number of items, e.g. a population of items or a sample, may itself be considered as an item.

NOTE 5 A software item may be source code, object code, job control code, control code or a collection of these

items.

[IEV 191-01-01:1990, modified]

3.1.5

maintenance

combination of all technical and administrative actions, including supervision actions,

intended to retain an item in, or restore it to, a state in which it can perform a required

function

[IEV 191-07-01:1990]

3.1.6

maintenance action

maintenance task

sequence of elementary maintenance activities carried out for a given purpose

NOTE Examples are fault diagnosis, fault localization, function check-out, or combinations thereof.

[IEV 191-07-18:1990]

– 8 – 60300-3-16 © IEC:2008

3.1.7

maintenance concept

interrelationship between the maintenance echelons, the indenture levels and the levels of

maintenance to be applied for the maintenance of an item

3.1.8

maintenance policy

general approach to the provision of maintenance and maintenance support based on the

objectives and policies of owners, users and customers

3.1.9

maintenance support

resources required to maintain an item, under a given maintenance concept and guided by a

maintenance policy

NOTE Resources include human resources, support equipment, materials and spare parts, maintenance facilities,

documentation, information and maintenance information systems.

3.1.10

preventive maintenance

maintenance carried out at predetermined intervals or according to prescribed criteria and

intended to reduce the probability of failure or the degradation of the functioning of an item

NOTE 1 Preventive maintenance includes condition-based tasks that consist of condition monitoring, inspection

and functional testing.

NOTE 2 Predetermined intervals apply to repair or replacement that are carried out at specific intervals such as

elapsed time, operating hours, distance, number of cycles or other relevant measures.

[IEV 191-07-07:1990, modified]

3.1.11

service provider

party (e.g. internal or external organization, manufacturer, etc.) that has agreed to undertake

responsibility for providing a given maintenance support service and obtaining, when specified,

supplies in accordance with an agreement

NOTE This may include the provision of a consultancy service.

3.2 Acronyms

ILS integrated logistic support

LTSA long term service agreement

SLA service level agreement

RCM reliability centred maintenance

4 Specification of maintenance support services

4.1 Purpose of using maintenance support services

Many organizations and users of products, systems and equipment may require the

assistance of internal or external service providers for maintenance support during the

operation and maintenance phase of the life cycle. Many of these services involve an

agreement that details the services being provided and how they are to be managed,

monitored and controlled.

Some of these services are short-term and limited in their scope of application. Other services

continue for a longer time period and may involve guarantees of performance related to

customer requirements. The latter necessitate a more complicated agreement and ongoing

management and monitoring between the parties.

60300-3-16 © IEC:2008 – 9 –

The reasons for obtaining maintenance support services may include:

– to optimize availability;

– to reduce costs or achieve cost stability;

– a lack of available expertise and resources by customer or user;

– low frequency of maintenance activities;

– lower costs due to economies of scale that can be achieved by a service provider;

– higher level of expertise available from equipment manufacturers and third parties.

4.2 Types of maintenance support services

Externally provided maintenance support services can be divided into three major categories:

– basic maintenance support agreements;

– limited service agreements;

– long term service agreements (LTSA).

The interrelationship between these types of services is illustrated in Figure 1.

Long term

service agreements

Limited service agreements

Basic maintenance support agreements

Refurbishment

Maintenance Spare Training Repairs and

labor parts overhauls and modifications

IEC 1566/08

Figure 1 – Interrelationship between types of maintenance support services

Typically, the lowest level of maintenance support service is provided on the basis of a

specific need, normally for a specific type or manufacturer of hardware and software.

Manufacturers traditionally provide these basic services to support their off-the-shelf

products. Limited service agreements and LTSAs are generally applicable to major

equipment, systems or facilities. They consist of many of the service components at the

– 10 – 60300-3-16 © IEC:2008

lowest level but in addition, include performance guarantees and a specifically tailored

agreement.

4.3 Basic maintenance support agreements

4.3.1 Maintenance labour

External service providers may supply maintenance staff who have specified skills to carry out

preventive or corrective maintenance tasks. These skills also include work-related activities

such as safety and environmental procedures. A single expert or a larger number of workers

may be provided along with the necessary supervision.

Maintenance staff will have maintenance-related skills and qualifications that might include:

– basic labour skills;

– trades qualifications such as millwright, mechanic, electrical or instrumentation with

certification as required;

– operation of special tools and support equipment;

– equipment-specific knowledge (hardware and software);

– manufacturer-specific knowledge; and

– other specialized knowledge, training and experience.

4.3.2 Spare parts

Spare parts and other materials needed for maintenance are available not only from the

original equipment manufacturer but often also from other sources. The specifications and

quality of the spare parts and materials are determined by the original equipment

manufacturer and also based on their operational environment and use. Ensuring that this

quality is met is a shared responsibility between the manufacturer of the spare parts and the

company unless transferred by contract to the service provider.

4.3.3 Training

Many manufacturers of more complex items will offer training on operation and maintenance

of their equipment. This training may be held at the manufacturer or facilities operated by the

company. The use of specialized tools and support equipment may be a major focus of the

training.

4.3.4 Repairs and overhauls

A very common maintenance support service is the repair or overhaul of item. The item may

undergo a repair by replacement only of a failed component. An overhaul is done with the

intent of restoring it to virtually new condition or upgrading the item. Some type of warranty

may be included in the agreement to protect the company against the consequences of

premature failures caused by the overhaul or repair.

For smaller items, the process is straightforward and the repaired item may not be returned to

the original company. It may instead become part of an exchange program.

With a major piece of equipment, the scope of the repair tasks may depend on its condition

which can only be determined after disassembly.

The repairs or overhauls are normally carried out in a special repair shop fully staffed and

equipped to complete them in the most efficient manner possible with strict quality processes.

However, for large items that are difficult to transport, the work may be done on site.

60300-3-16 © IEC:2008 – 11 –

4.3.5 Refurbishment and modifications

Refurbishment usually applies to major items and may involve improvements in functionality

such as output and efficiency. Modifications may be implemented which are not necessarily

related to maintenance needs. Refurbishment may be performed close to the normal end of

an item’s life to extend it for a longer time period.

4.4 Limited service agreements

It may be advantageous for a company to establish an agreement with a service provider or

equipment manufacturer that entails a more comprehensive set of maintenance support

services. These agreements may include a combination of the basic services listed in 4.3.

The time period and level of service should be defined accordingly. The time period of the

agreement is normally relatively short, e.g. on a yearly basis. The agreement may also be

restricted to providing agreed upon services to only a portion of the item.

Limited service agreements may include services such as:

– maintenance labour to assist with a major maintenance activity such as a facility

shutdown;

– provision of maintenance staff for regular preventive and corrective maintenance actions

for a specified time period;

– single sourcing of spare parts where the supplier guarantees a certain availability,

response time and pricing;

– provision of repair and overhaul services for certain items for a specified time period;

– training of staff;

– condition monitoring of items;

– a program to refurbish and modify items;

– development of maintenance policy and concept;

– preparation or review of maintenance tasks using a method such as RCM.

The performance of the agreement is verified by the measurement of a quality indicator

appropriate for the service provided. Normally a limited warranty is provided for the services

provided, work being done or parts that have been supplied.

4.5 Long term service agreements

4.5.1 Purpose

Long term service agreements consist of a comprehensive set of maintenance support

services for a longer time period with performance guarantees that relate to the major function

of the item. A LTSA is often provided by a supplier or manufacturer of major items at a facility.

It may also include in its scope all of the other items at that facility, known as balance of

plant.

LTSAs assure comprehensive item coverage with predictable costs so that a company can

better forecast annual budgeting requirements and minimize the variability of life cycle costs

(see IEC 60300-3-3). All or most costs are covered and item risk related to maintenance is

removed or reduced. One disadvantage may be that the costs may be higher than a company

could potentially achieve by performing its own maintenance activities and assuming its own

risk.

Another major reason for a LTSA is the expertise that an original item manufacturer has in its

design or that a service provider may have obtained through extensive experience with a

certain type of item. There is also the benefit of economy of scale if the services are supplied

to a large number of item users.

– 12 – 60300-3-16 © IEC:2008

A LTSA may be referred to as a service level agreement (SLA) and the performance

guarantees may be defined in terms of Quality of Services (QoS) indicators which may be

qualitative and/or quantitative.

4.5.2 Scope of a LTSA

The scope of a LTSA is comprehensive and long term, typically a period of 3-10 years and

even longer in some circumstances. It may include

– maintenance management services consisting of development of maintenance policy and

concept, planning and scheduling of maintenance actions, managing of spare parts

inventory and management of maintenance data using a computerized maintenance

management system;

– provision of maintenance staff for regular preventive and corrective maintenance actions

possibly by dedicated staff located at the facility;

– supply of all spare parts and materials;

– repair and overhaul services for specified items;

– training of staff;

– condition monitoring of items;

– refurbishment and modification of items;

– regular reporting of services supplied and item performance achieved;

– obsolescence management.

4.5.3 Performance guarantees

The performance and success of the LTSA is measured by means of a guarantee that is

related to the major function of the item to the company. Service or QoS “guarantees” to

specific performance levels are becoming more predominant. Guarantees may consist of a

dependability measure such as availability or a performance measure such as power output or

energy delivered. A performance target may be set with an incentive if a higher threshold is

exceeded. If the performance does not meet the target, a financial penalty may be charged

against the service provider.

The method used to measure performance has to be clearly defined and carefully monitored.

As well, the extent of liability by the service provider has to be defined. For example,

business-related losses are generally excluded from performance guarantees.

4.6 Life cycle aspects

4.6.1 Design and development phase

The evaluation of maintainability during the design phase (see IEC 60300-3-10 and

IEC 60706-2) may include the possibility or necessity for the use of external service providers

to supply either limited maintenance support services or a more comprehensive LTSA to the

company. Trade-offs can then be considered and the most effective solution for

maintainability and maintenance support can then be implemented in the design.

Implementation of a service agreement may be possible only when the user of the item is

known. The company has three options:

– provision of all of the maintenance by the company;

– giving part of the maintenance to a service provider;

– entrusting all of the maintenance to a service provider.

For products where an integrated logistics support (ILS) approach is applied

(see IEC 60300-3-12), all maintenance and maintenance support activities are completely

60300-3-16 © IEC:2008 – 13 –

planned and provided for prior to the operation and maintenance phase. This often entails the

use of external service providers and the need for service agreements.

4.6.2 Operation and maintenance phase

When existing products are incorporated in complex systems by another manufacturer or

organization and are then supplied to a company, maintenance support is usually established

by the company during the operation and maintenance phase (see IEC 60300-3-14). External

maintenance support services are determined by a company since each one will have

different capabilities for performing maintenance and maintenance support activities and thus

the need and economic viability of external maintenance support services will vary. Other

factors that will influence the use of external services are the availability and accessibility of

those services to a specific company.

4.6.3 Obsolescence

The major reasons for parts obsolescence is the cessation of production capability as well as

diminishing demand. However, the use of service providers may hasten or extend the

obsolescence of items since maintenance support, in their parts consumption, is a major

factor in the ability of a company to successfully operate and maintain items. Obsolescence

may be forced on a company if a service provider ceases to provide maintenance support

services and no alternatives are available. On the other hand, the life of an item may be

extended if a third party service provider is able to continue maintenance support even though

the original manufacturer has ceased support for that item. Please refer to IEC 62402 for

further details on the management of obsolescence.

5 Preparation of service agreements

5.1 Management responsibility

Management has overall responsibility for establishing the maintenance policy for all items,

including the extent to which level of maintenance support services should be outsourced to

external service providers. This policy may change over time as economic factors and the

availability and accessibility of service providers changes.

Management is thus responsible for the preparation, evaluation and monitoring of

maintenance agreements that are put in place.

5.2 Process for selecting a service provider

Prior to a maintenance agreement being agreed upon, a user or operator of items will

normally go through a process of selecting a maintenance service provider. The actual

process used will be guided by company policy for obtaining services. In general, this process

may involve the preparation of a Formal Request for Proposal which documents:

– the specific services being requested;

– the response that is required and possibly a list of questions that need to be answered;

– a draft of the agreement terms that are expected to be part of the final agreement;

– the process and method for selecting the successful bidder;

– where and when the response is to be delivered.

Service providers allowed to bid on an agreement may need to be pre-qualified to establish

basic conditions for an agreement. The Formal Request for Proposal is then sent to the list of

acceptable vendors. Once the bids are received, a selection process is used to decide on the

successful bidder. At this point, a negotiation process may need to be initiated to finalize the

scope, terms and conditions and deal with exceptions. The final agreement can then be

prepared.

– 14 – 60300-3-16 © IEC:2008

5.3 Purpose of a maintenance support service agreement

A maintenance support service agreement is a functional as well as a legal agreement

between a company and a service provider. It defines the services being provided and

clarifies objectives and respective responsibilities. Agreements are usually set up with an

external service provider but may also be made with a service group internal to the company.

Internal agreements may be easier to execute but the same approach should be taken in

order to ensure that both parties will be satisfied with the end result.

The purpose of a maintenance support service agreement is:

– to specify the services being provided and any constraints that may apply;

– to define performance guarantees that are to be met and incentives or penalties that may

apply if the performance guarantee is exceeded or not met, respectively;

– to clearly establish and document contractual responsibilities;

– to define legal and regulatory obligations that have to be met;

– to assist with resolution of conflicts that may arise;

– to make provisions for extra work that may arise such as the incorporation of

modifications requested by the company or suggested by the service provider;

– to enable expected benefits to be realized by both company and service provider.

5.4 Preparation of a maintenance agreement

The preparation of a maintenance agreement consists of the following steps:

– deciding which maintenance support services are desired to be outsourced;

– deciding on the type of maintenance agreement which may be appropriate;

– defining the specific scope of services required;

– setting out performance guarantees and related incentives or penalties;

– determining legal and regulatory obligations that must be met by the service provider and

the owner / operator;

– outlining the commercial terms that will apply.

Each individual agreement should be drafted, and negotiated where appropriate, to take into

account the specific aspects arising from the work required on the items to be maintained, the

parties involved and any applicable laws and regulations.

5.5 Agreement structure and elements

The following standard elements and a template are provided to simplify preparation of

maintenance agreements. An agreement will typically have these major elements:

– general section with descriptive information on the nature of the agreement and its

objectives;

– scope of services agreed upon;

– technical arrangements related to the performance of duties;

– organizational arrangements;

– commercial aspects;

– legal obligations by both parties;

– contractual requirements.

Since legal obligations and contractual requirements will vary with the jurisdictions where the

items are located, they will not be described in this standard.

60300-3-16 © IEC:2008 – 15 –

A standard check-list for use when drafting maintenance agreements is provided in Annex A.

It is intended as a working tool and offers typical headings which are not exhaustive and

which parties may or may not include, exclude, modify and adapt to their own contractual

relationship. It is not binding for the parties to use any part of this template and not all

elements will be applicable to every agreement.

6 Management of maintenance agreements

6.1 General

Maintenance agreements need to be managed and monitored to ensure that objectives of the

company are met and payment to the service provider can be made. If performance

guarantees are involved, documentation of results and actual performance is crucial to

minimize disputes. In particular, a LTSA requires considerable attention because of the long

term nature of the agreement. A company may wish to prepare and approve a management

plan to cover the use of maintenance agreements to ensure they are consistent with company

objectives and policies.

6.2 Communication

Clear lines of communication are essential to efficient execution of maintenance activities.

Specific positions, names and contact information need to be up-to-date at all times. Where

possible, the type of communication desired (face-to-face meeting, phone, email, written

report, etc.) should be identified in the agreement or specifically agreed upon later.

Activities that involve communication between company and service provider include items

such as:

– provision of necessary information by the company to the service provider with respect to

operating procedures, location of items, operating and maintenance history, etc. and

changes to this information as it occurs;

– approval by company for initiation of specific activities covered by the agreement;

– agreement on scheduling of activities and management of changes or delays to timing;

– submission of technical documentation by the service provider to the company on work

performed or services rendered;

– verification of services rendered and actual performance for purpose of payment;

– communication between parties on issues and disagreements.

6.3 Monitoring of agreement

Both the service provider and the company have responsibilities for monitoring the status of

the agreement to verify that the terms of the agreement are being met. Included in these

responsibilities are:

– verification of work performed and services provided;

– accurate measurement of performance used for guarantees;

– compliance with health, safety and environmental requirements;

– maintaining confidentiality of information;

– resolution of issues and disagreements;

– adequate documentation of technical records;

– official reporting between service provider and company;

– ensuring qualifications and competence of personnel supplied by the service provider;

– verification of compliance with company operating practices and procedures.

Guidelines on the collection of dependability data are provided in IEC 60300-3-2.

– 16 – 60300-3-16 © IEC:2008

Annex A

(informative)

Check-list for agreement structure and elements

A.1 General

These elements cover general aspects of the agreement.

ELEMENTS PURPOSE PROPOSED CONTENT

1 General

1.1 Title General heading used for the Short description of the agreement such as

agreement “Maintenance support services agreement for

preventive maintenance of large electric

motors”

1.2 Parties Identification of parties involved Names, addresses and contact information for

in the agreement both parties

1.3 Description General description of the nature

of the agreement

1.4 Objective Statement of the objective that This describes the intent of both parties and

the company is trying to achieve. the objectives they are trying to achieve. It may

Stating the general intention of include a general statement of the level of

the parties and the purposes of performance expected and guarantees that are

the agreement may be especially required

important for long-term

agreements when changing

conditions may make adjustments

to the agreement necessary

1.5 Definitions In the area of maintenance many Technical, legal and commercial terms should

terms are often used with be defined. Where possible, national or

different or ambiguous meanings. international standards should be used and

Therefore, terms should be referenced instead of narrow company

defined in a way that is common definitions

to the parties

A.2 Scope of services

This describes the specific services that are to be provided by the service provider.

ELEMENTS PURPOSE PROPOSED CONTENT

2 Scope of services

2.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...