IEC 63012:2019

(Main)Insulating liquids - Unused modified or blended esters for electrotechnical applications

Insulating liquids - Unused modified or blended esters for electrotechnical applications

IEC 63012:2019 defines requirements for the characterization of unused modified esters or blends of unused esters used as insulating liquids for electrotechnical applications. It does not cover liquids that contain any proportion of used liquids. The liquids covered by this document are intended mainly for transformer applications.

Unused modified/synthetized esters are derived from a natural or synthetic base, or are blends of both. This document covers a variety of ester liquids not covered by other standards specific to natural esters (IEC 62770) or synthetic esters (IEC 61099). As it addresses various categories of liquids, this document also covers a wide range of values for certain performance characteristics. An important property is viscosity, which can affect the design and cooling performance of electrical equipment. A categorization is defined based on the kinematic viscosity of the different liquids. The category of low viscosity ester liquids is established.

Isolants liquides - Esters neufs modifiés ou mélangés pour applications électrotechniques

L'IEC 63012:2019 définit les exigences relatives à la caractérisation des esters neufs modifiés ou des mélanges d'esters neufs, utilisés comme isolants liquides pour des applications électrotechniques. Il ne couvre pas les liquides contenant une proportion quelconque de liquides usagés. Les liquides couverts par le présent document sont principalement destinés aux applications dans des transformateurs. Les esters neufs synthétiques/modifiés sont dérivés d'une base naturelle ou synthétique, ou sont des mélanges des deux. Le présent document couvre une variété de liquides à base d'esters non couverts par d'autres normes spécifiques aux esters naturels (IEC 62770) ou aux esters synthétiques (IEC 61099). Traitant d'une grande variété de liquides, le présent document couvre également une large plage de valeurs pour certaines caractéristiques de performance. La viscosité est une propriété importante qui peut influencer la conception et les performances de refroidissement du matériel électrique. Une classification est définie sur la base de la viscosité cinématique des différents liquides. La catégorie des liquides à base d'esters à faible viscosité est donc établie.

General Information

- Status

- Published

- Publication Date

- 08-May-2019

- Technical Committee

- TC 10 - Fluids for electrotechnical applications

- Drafting Committee

- PT 63012 - TC 10/PT 63012

- Current Stage

- PPUB - Publication issued

- Start Date

- 09-May-2019

- Completion Date

- 31-May-2019

Overview

IEC 63012:2019 is an international standard developed by the International Electrotechnical Commission (IEC) focusing on unused modified or blended esters used as insulating liquids for electrotechnical applications. This standard specifically addresses esters that are chemically modified, synthesized, or blended from natural and synthetic bases. It excludes liquids that contain any used or previously applied liquids. The primary application targeted by this standard is transformer insulation and cooling.

With the evolution of insulating liquids beyond traditional mineral oils and pure natural or synthetic esters, IEC 63012:2019 fills a crucial gap by defining characterization requirements for newly developed ester blends that do not fit existing standards such as IEC 62770 (natural esters) or IEC 61099 (synthetic esters). These innovative insulating liquids offer enhanced performance features such as improved viscosity profiles, higher flash points, and potential environmental benefits.

Key Topics

Scope and Classification: The standard covers unused, modified, or blended ester insulating liquids excluding any that are recycled or previously used. It defines classifications based on kinematic viscosity to aid in equipment design and cooling considerations, including the introduction of a low viscosity ester category.

Physical and Chemical Properties: The document specifies test methods and minimum requirements for critical properties including:

- Appearance, color, viscosity, lubricity

- Thermal conductivity, thermal expansion, and specific heat capacity

- Pour point and water content/saturation

- Density and interfacial tension

- AC and impulse breakdown voltage, partial discharge inception voltage

- Dielectric dissipation factor, relative permittivity, DC resistivity

- Electrostatic charging tendency

- Acidity, additive content, and corrosive sulfur compounds

- Methanol content and oxidation stability

Performance Characteristics: IEC 63012 defines minimum performance requirements ensuring the modified esters meet the demands of electrotechnical applications, particularly to maintain electrical insulation integrity and thermal management under operational conditions.

Health, Safety, and Environmental Considerations: The standard highlights safety aspects such as flash and fire points, absence of polychlorinated biphenyls (PCBs), biodegradability, environmental toxicity, and proper disposal practices. It encourages sustainable and safe use of these next-generation insulating liquids.

Compatibility and Retrofill Guidance: Annex A provides informative guidelines on the miscibility and compatibility of modified ester liquids with other insulating fluids, which is critical for transformer retrofilling operations and maintenance.

Applications

IEC 63012:2019 is highly relevant for:

- Power Transformers: Ensuring reliable electrical insulation and efficient heat dissipation by selecting ester blends with the appropriate viscosity and dielectric properties.

- Electrical Equipment Insulation: Supporting the development and validation of new insulating liquids that improve equipment longevity, fire safety, and environmental impact.

- Insulating Liquid Manufacturers: Offering a benchmark for characterization and quality control of innovative ester-based liquids.

- Equipment Design Engineers: Providing parameters needed to optimize transformer cooling system design based on fluid viscosity and thermal properties.

- Environmental and Safety Compliance: Assisting users in evaluating the sustainability and safety profile of insulating liquids, critical in modern power systems aiming for low environmental footprints.

Related Standards

- IEC 62770: Specifies requirements for natural esters used as insulating liquids.

- IEC 61099: Governs properties of synthetic esters for electrical apparatus insulation.

- IEC 60296: Standard for unused mineral insulating oils in electrical equipment.

- IEC 61198: Covers electrical insulating liquids for transformer service.

- ISO/IEC Directives Part 2: Provides framework and best practices used during the preparation of IEC standards.

By integrating IEC 63012 with existing standards, manufacturers and users can comprehensively assess the suitability of various insulating liquids for demanding electrotechnical applications.

Keywords: IEC 63012, insulating liquids, modified esters, blended esters, transformer insulating liquids, electrical insulation, ester dielectric fluids, kinematic viscosity, electrotechnical applications, transformer cooling fluids, transformer insulation standards, synthetic esters, natural esters, electrical insulating fluids, environmental safety, electrical equipment insulation.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 63012:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Insulating liquids - Unused modified or blended esters for electrotechnical applications". This standard covers: IEC 63012:2019 defines requirements for the characterization of unused modified esters or blends of unused esters used as insulating liquids for electrotechnical applications. It does not cover liquids that contain any proportion of used liquids. The liquids covered by this document are intended mainly for transformer applications. Unused modified/synthetized esters are derived from a natural or synthetic base, or are blends of both. This document covers a variety of ester liquids not covered by other standards specific to natural esters (IEC 62770) or synthetic esters (IEC 61099). As it addresses various categories of liquids, this document also covers a wide range of values for certain performance characteristics. An important property is viscosity, which can affect the design and cooling performance of electrical equipment. A categorization is defined based on the kinematic viscosity of the different liquids. The category of low viscosity ester liquids is established.

IEC 63012:2019 defines requirements for the characterization of unused modified esters or blends of unused esters used as insulating liquids for electrotechnical applications. It does not cover liquids that contain any proportion of used liquids. The liquids covered by this document are intended mainly for transformer applications. Unused modified/synthetized esters are derived from a natural or synthetic base, or are blends of both. This document covers a variety of ester liquids not covered by other standards specific to natural esters (IEC 62770) or synthetic esters (IEC 61099). As it addresses various categories of liquids, this document also covers a wide range of values for certain performance characteristics. An important property is viscosity, which can affect the design and cooling performance of electrical equipment. A categorization is defined based on the kinematic viscosity of the different liquids. The category of low viscosity ester liquids is established.

IEC 63012:2019 is classified under the following ICS (International Classification for Standards) categories: 29.040.10 - Insulating oils. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 63012:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 63012 ®

Edition 1.0 2019-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Insulating liquids – Unused modified or blended esters for electrotechnical

applications

Isolants liquides – Esters neufs modifiés ou mélangés pour applications

électrotechniques

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 63012 ®

Edition 1.0 2019-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Insulating liquids – Unused modified or blended esters for electrotechnical

applications

Isolants liquides – Esters neufs modifiés ou mélangés pour applications

électrotechniques

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.040.10 ISBN 978-2-8322-6894-0

– 2 – IEC 63012:2019 © IEC 2019

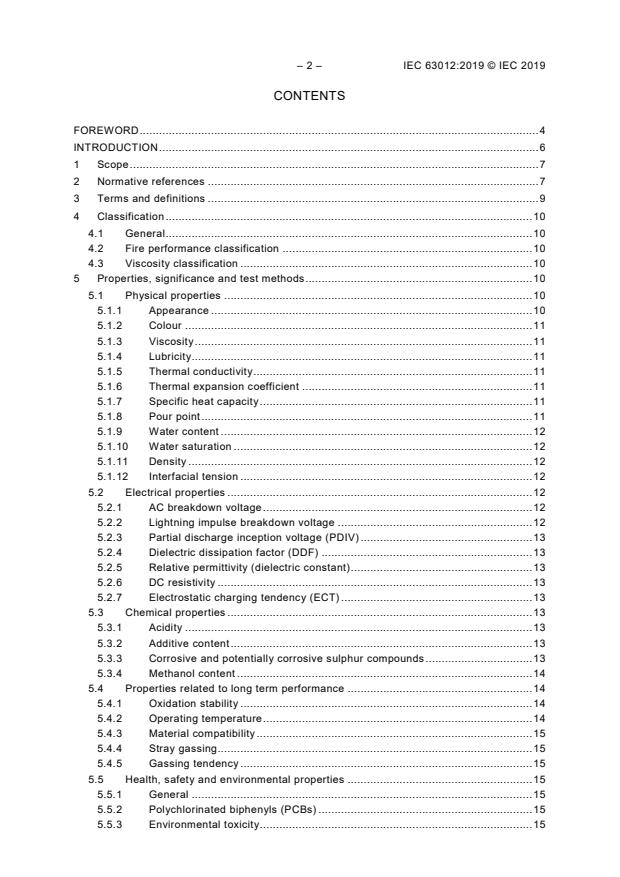

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 9

4 Classification . 10

4.1 General . 10

4.2 Fire performance classification . 10

4.3 Viscosity classification . 10

5 Properties, significance and test methods . 10

5.1 Physical properties . 10

5.1.1 Appearance . 10

5.1.2 Colour . 11

5.1.3 Viscosity . 11

5.1.4 Lubricity . 11

5.1.5 Thermal conductivity . 11

5.1.6 Thermal expansion coefficient . 11

5.1.7 Specific heat capacity . 11

5.1.8 Pour point . 11

5.1.9 Water content . 12

5.1.10 Water saturation . 12

5.1.11 Density . 12

5.1.12 Interfacial tension . 12

5.2 Electrical properties . 12

5.2.1 AC breakdown voltage . 12

5.2.2 Lightning impulse breakdown voltage . 12

5.2.3 Partial discharge inception voltage (PDIV) . 13

5.2.4 Dielectric dissipation factor (DDF) . 13

5.2.5 Relative permittivity (dielectric constant) . 13

5.2.6 DC resistivity . 13

5.2.7 Electrostatic charging tendency (ECT) . 13

5.3 Chemical properties . 13

5.3.1 Acidity . 13

5.3.2 Additive content . 13

5.3.3 Corrosive and potentially corrosive sulphur compounds . 13

5.3.4 Methanol content . 14

5.4 Properties related to long term performance . 14

5.4.1 Oxidation stability . 14

5.4.2 Operating temperature . 14

5.4.3 Material compatibility . 15

5.4.4 Stray gassing . 15

5.4.5 Gassing tendency . 15

5.5 Health, safety and environmental properties . 15

5.5.1 General . 15

5.5.2 Polychlorinated biphenyls (PCBs) . 15

5.5.3 Environmental toxicity . 15

5.5.4 Flash point and fire point . 15

5.5.5 Sustainability . 16

5.5.6 Biodegradation . 16

5.5.7 Disposal . 16

6 Minimum performance requirements . 16

7 Identification and general delivery requirements . 16

Annex A (informative) Miscibility and compatibility of liquids and retrofilling of

transformers . 19

Bibliography . 20

Table 1 – Required performance characteristics of modified or blended esters . 17

Table 2 – Optional performance characteristics of modified or blended esters . 18

– 4 – IEC 63012:2019 © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

INSULATING LIQUIDS – UNUSED MODIFIED OR BLENDED ESTERS

FOR ELECTROTECHNICAL APPLICATIONS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 63012 has been prepared by IEC Technical Committee 10: Fluids

for electrotechnical applications.

The text of this International Standard is based on the following documents:

FDIS Report on voting

10/1078/FDIS 10/1082/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 63012:2019 © IEC 2019

INTRODUCTION

Electrical insulation and heat transfer are essential functions of insulating liquids for

electrotechnical applications. Until recently, these liquids have been normally homogeneous,

selected from different categories, such as most common mineral oils or newer synthetic

esters, natural esters or silicone liquids. The continuous research for improvement of

performance characteristics of equipment drives an interest in exploring benefits from

combinations of liquids. Some known examples of desired improved characteristics include

optimized liquid cost, increased cooling performance, improved flash point, extended

insulation life or reduced environmental impacts.

Currently, international standards exist for specifically defined liquid categories (mineral oils,

synthetic esters, natural esters, silicone liquids). None of them cover chemically modified

natural ester liquids or blends of various esters. Moreover, the existing standards do not

cover synthetic esters whose characteristics may go beyond the limits defined in IEC 61099.

Some modified esters or their blends are already available as commercial products by liquid

suppliers. Examples are:

• Palm fatty acid ester with low viscosity of 5 mm /s at 40 °C and with flash point of 176 °C.

• Blend of triglycerides (50 %) and monoesters (50 %) with low viscosity of 17 mm /s at

40 °C and with flash point of 200 °C.

The number of sources for ester liquids or their blends is expected to grow over the coming

years. Such liquids need to be characterized to confirm suitability for the intended application

by the user. Performance characteristics of blends should not be solely assumed from

performance characteristics of their individual components. This document is to provide

minimum requirements on characterization of new compositions.

WARNING

This document sets performance criteria for unused modified/synthetized or blended esters

earmarked for electrical applications. This document does not purport to address all the safety

problems associated with their use. It is the responsibility of the user of this document to

establish appropriate health and safety practices and determine the applicability of regulatory

limitation prior to use.

Performance of some of the tests mentioned in this document could lead to a hazardous

situation. Attention is drawn to the relevant standard test method for guidance.

The disposal of liquids, chemicals and sample containers mentioned in this document should

be carried out in accordance with current local and national legislation with regards to the

impact on the environment. Every precaution should be taken to prevent the release of the

liquid into the environment.

INSULATING LIQUIDS – UNUSED MODIFIED OR BLENDED ESTERS

FOR ELECTROTECHNICAL APPLICATIONS

1 Scope

This document defines requirements for the characterization of unused modified esters or

blends of unused esters used as insulating liquids for electrotechnical applications. It does not

cover liquids that contain any proportion of used liquids.

The liquids covered by this document are intended mainly for transformer applications.

Unused modified/synthetized esters are derived from a natural or synthetic base, or are

blends of both. This document covers a variety of ester liquids not covered by other standards

specific to natural esters (IEC 62770) or synthetic esters (IEC 61099).

As it addresses various categories of liquids, this document also covers a wide range of

values for certain performance characteristics. An important property is viscosity, which can

affect the design and cooling performance of electrical equipment. A categorization is defined

based on the kinematic viscosity of the different liquids. The category of low viscosity ester

liquids is established.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60156, Insulating liquids – Determination of the breakdown voltage at power frequency –

Test method

IEC 60247, Insulating liquids – Measurement of relative permittivity, dielectric dissipation

factor (tan δ) and d.c. resistivity

IEC 60666, Detection and determination of specified additives in mineral insulating oils

IEC 60628, Gassing of insulating liquids under electrical stress and ionization

IEC 60814, Insulating liquids – Oil-impregnated paper and pressboard – Determination of

water by automatic coulometric Karl Fischer titration

IEC 60897, Methods for the determination of the lightning impulse breakdown voltage of

insulating liquids

IEC 61099:2010, Insulating liquids – Specifications for unused synthetic organic esters for

electrical purposes

IEC 61125, Insulating liquids – Test methods for oxidation stability – Test method for

evaluating the oxidation stability of insulating liquids in the delivered state

IEC TR 61294, Insulating liquids – Determination of the partial discharge inception voltage

(PDIV) – Test procedure

– 8 – IEC 63012:2019 © IEC 2019

IEC 61619, Insulating liquids – Contamination by polychlorinated biphenyls (PCBs) – Method

of determination by capillary column gas chromatography

IEC 61620, Insulating liquids – Determination of the dielectric dissipation factor by

measurement of the conductance and capacitance – Test method

IEC 62021-3, Insulating liquids – Determination of acidity – Part 3: Test methods for non-

mineral insulating oils

IEC 62535, Insulating liquids – Test method for detection of potentially corrosive sulphur in

used and unused insulating oil

IEC 62697-1, Test method for quantitative determination of corrosive sulfur compounds in

unused and used insulating liquids – Part 1: Test method for quantitative determination of

dibenzyldisulfide (DBDS)

IEC 62770, Fluids for electrotechnical applications – Unused natural esters for transformers

and similar electrical equipment

IEC 62961, Insulating liquids – Test methods for the determination of interfacial tension of

insulating liquids – Determination with the ring method

ISO 2049, Petroleum products – Determination of colour (ASTM scale)

ISO 2211, Liquid chemical products – Measurement of colour in Hazen units (platinum-cobalt

scale)

ISO 2592, Petroleum and related products – Determination of flash and fire points –

Cleveland open cup method

ISO 2719, Determination of flash point – Pensky-Martens closed cup method

ISO 3016, Petroleum products – Determination of pour point

ISO 3104, Petroleum products – Transparent and opaque liquids – Determination of kinematic

viscosity and calculation of dynamic viscosity

ISO 3675, Crude petroleum and liquid petroleum products – Laboratory determination of

density – Hydrometer method

ISO 12185, Crude petroleum and petroleum products – Determination of density – Oscillating

U-tube method

EN 14210, Surface active agents – Determination of interfacial tension of solutions of surface

active agents by the stirrup or ring method

ASTM D1275, Standard test method for corrosive sulphur in electrical insulating liquids

ASTM D1903, Standard practice for determining the coefficient of thermal expansion of

electrical insulating liquids of petroleum origin, and askarels

ASTM D3300, Standard test method for dielectric breakdown voltage of insulating oils of

petroleum origin under impulse conditions

ASTM D4172, Standard test method for wear preventive characteristics of lubricating fluid

(four-ball method)

ASTM D7150, Standard test method for the determination of gassing characteristics of

insulating liquids under thermal stress

ASTM D7896, Standard test method for thermal conductivity, thermal diffusivity and

volumetric heat capacity of engine coolants and related fluids by transient hot wire liquid

thermal conductivity method

ASTM E1269, Standard test method for determining specific heat capacity by differential

scanning calorimetry

DIN 51350-1, Testing of lubricants – Testing in the four-ball tester – Part 1: General working

principles

DIN 51350-2, Testing of lubricants – Testing in the four-ball tester – Part 2: Determination of

welding load of liquid lubricants

DIN 51350-3, Testing of lubricants – Testing in the four-ball tester – Part 3: Determination of

wearing characteristics of liquid lubricants

OECD 301-B, OECD Guidelines for the testing of chemicals – Section 3: Environmental fate

and behaviour – 301 Ready biodegradability – 301 B: CO Evolution test

OECD 301-C, OECD Guidelines for the testing of chemicals – Section 3: Environmental fate

and behaviour – 301 Ready biodegradability – 301 C: Modified MITI test

OECD 301-F, OECD Guidelines for the testing of chemicals – Section 3: Environmental fate

and behaviour – 301 Ready biodegradability – 301 F: Manometric respirometry test

U.S. Environmental Protection Agency, EPA 712-C-98-076, US EPA OPPTS Series 835: Fate,

transport and transformation test guidelines – Group C: Laboratory biological transformation

test guidelines – 835.3110 Ready biodegradability

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp/ui

3.1

unused insulating liquid

liquid as delivered by the supplier which has not been used in, or been in contact with

electrical equipment or other equipment not required for its manufacture, storage or transport

3.2

ester insulating liquid

insulating liquid consisting of fatty acid esters

Note 1 to entry: Fatty acid esters are commonly prepared from the reaction of alcohols and carboxylic acids or

found naturally in vegetable oils and fats.

3.3

modified ester insulating liquid

ester insulating liquid which has been made/synthesized or altered by chemical reaction

– 10 – IEC 63012:2019 © IEC 2019

Note 1 to entry: The chemical reaction could come about by means of organic chemistry processes, or

biochemical processes including enzymatic reactions.

Note 2 to entry: Modified ester insulating liquids can, for example, be composed of triglycerides, polyol esters,

fatty acid monoesters, fatty acid diesters or combinations thereof.

3.4

blended ester insulating liquid

homogeneous combination of unused natural, synthetic and/or modified esters that are

miscible

Note 1 to entry: The natural esters in this definition are those defined in IEC 62770, synthetic esters in this

definition are those defined in IEC 61099.

3.5

additive

chemical substance which is deliberately added to an insulating liquid in small proportion in

order to improve certain characteristics

4 Classification

4.1 General

As it addresses various compositions of insulating liquids, this document also covers a range

of values for certain performance characteristics when these are compared to other

recognized liquids with precisely defined performance characteristics. Therefore, the following

categorizations are established.

4.2 Fire performance classification

The insulating liquids are classified for fire performance according to IEC 61039.

4.3 Viscosity classification

Viscosity influences heat transfer and therefore the temperature rise of the equipment. The

lower the viscosity, the easier the liquid circulates leading to improved heat transfer.

Viscosity of natural esters and some synthetic esters is usually higher than that of mineral oil.

This requires special considerations at the equipment design stage and may affect

performance of equipment at low temperatures, too. Adjustment of modified or blended ester

composition allows for tailoring the viscosity and other properties to fit the equipment design

requirements.

Based on the viscosity, the liquids are classified as in Table 1. The category V1 refers to

esters of low viscosity, similar to mineral oils. The category V2 refers to esters of higher

viscosity than V1, but still lower than typical synthetic or natural esters. The category V3

refers to modified or blended esters that do not show low viscosity characteristics.

NOTE At the stage of development of this document, there are no commercial modified or blended esters with

viscosity category V3. This category makes provision for future technical developments.

5 Properties, significance and test methods

5.1 Physical properties

5.1.1 Appearance

A visual inspection of unused modified or blended esters (with light transmitted through

approximately 10 cm thickness of the liquid at ambient temperature) shall not indicate the

presence of visible contaminants, free water or suspended matter.

5.1.2 Colour

If required, colour shall be measured according to ISO 2211 (Hazen scale) or ISO 2049

(ASTM scale).

5.1.3 Viscosity

Kinematic viscosity shall be measured according to ISO 3104 and reported at 40 °C. The user

can request viscosity values in the range of temperatures 0 °C to 100 °C (with at least three

points: 0 °C, 40 °C and 100 °C).

NOTE Another suitable method for viscosity measurement is given in ASTM D7042.

It is beneficial to have the value of viscosity at temperatures below 0 °C to understand the

behaviour of the liquid in temperatures near the pour point, for example at −20 °C.

NOTE Viscosity at very low temperatures can be measured according to IEC 61868.

At low temperatures, the resulting higher viscosity of liquid is a critical factor for the cold start

of transformers with natural liquid circulation (no forced circulation and therefore possible

overheating at the hot spots) and negatively influences the speed of moving parts, such as in

power circuit breakers, switchgear, on-load tap changer mechanisms, pumps and regulators.

Lowest cold start energizing temperature (LCSET) requirements should be agreed upon

between supplier and purchaser.

5.1.4 Lubricity

If liquid is to be used in equipment with moving parts, for example switching equipment, tap

changers, the lubricity shall be measured. The test method shall be that given in ASTM D4172

or DIN 51350 (parts 1 through 3). In the case of ASTM D4172, the test parameters shall be:

load 392 N, rotation speed 1 200 r/min temperature 75 °C, duration 60 min.

5.1.5 Thermal conductivity

Thermal conductivity shall be measured in accordance with ASTM D7896 and the value shall

be given by the manufacturer.

NOTE Users can request that the thermal conductivity be measured at a range of temperatures, e.g. 0 °C to

100 °C (at least three points), for calculating the thermal performance of the equipment in different conditions.

5.1.6 Thermal expansion coefficient

Thermal expansion coefficient shall be measured in accordance with ASTM D1903 and the

value shall be reported by the manufacturer.

NOTE Users can request that the thermal expansion coefficient be measured at a range of temperatures, e.g.

0 °C to 100 °C (at least three points), for calculating the thermal performance of the equipment in different

conditions.

5.1.7 Specific heat capacity

Specific heat shall be measured in accordance with ASTM E1269 and the value shall be given

by the manufacturer.

NOTE Users can request that the specific heat capacity be measured at a range of temperatures, e.g. 0 °C to

100 °C (at least three points), for calculating the thermal performance of the equipment in different conditions.

5.1.8 Pour point

Pour point of insulating liquid is the lowest temperature at which the liquid is just sufficiently

fluid to flow at test conditions. Pour point shall be measured in accordance with ISO 3016.

Table 1 gives the requirement for a maximum pour point of −25 °C acceptable for modified or

blended esters. A lower value may be required by end users based on regional ambient

– 12 – IEC 63012:2019 © IEC 2019

conditions. It is recommended that the pour point should be minimum 10 K below the lowest

cold start energizing temperature (LCSET). LCSET requirements should be agreed upon

between supplier and purchaser.

Crystallization behaviour of modified or blended esters depends on time and temperature.

Crystals should not be present in the liquid at application temperature; precautions shall be

taken if liquid temperature inside the electrical device is lower than 0 °C. Below this

temperature, the thermal, mechanical and dielectric behaviour of the device with modified or

blended esters can be adversely affected.

NOTE For the evaluation of crystallization, a method is described in IEC 61099:2010, Annex A. The cloud point,

an indication of crystallization, can be measured according to the methods given in ISO 3015 or AOCS Cc 6-25.

5.1.9 Water content

The water content of modified or blended esters affects their dielectric properties. Water

content shall be measured in accordance with IEC 60814.

5.1.10 Water saturation

Water saturation is defined as a maximum amount of water that can be dissolved in the

insulating liquid at a specific temperature. If required, water saturation should be measured

and the value should be given by the manufacturer for a range of temperatures (e.g. 20 °C

to 100 °C). The test method shall be reported with test results.

NOTE For information refer to CIGRE Brochure 349 and CIGRE Brochure 741.

5.1.11 Density

Density of modified or blended esters shall be measured in accordance with ISO 12185 and

reported at 20 °C (reference method), but ISO 3675 is also acceptable. The test method shall

be reported.

NOTE 1 Another suitable method for density measurement is given in ASTM D7042.

NOTE 2 Users can request that the density be measured at a range of temperatures, e.g. 0 °C to 100 °C (at least

three points), for calculating the thermal performance of the equipment in different conditions.

5.1.12 Interfacial tension

The interfacial tension between insulating liquids and water provides a means of detecting

soluble polar contaminants and products of degradation. If requested, the following standards

shall be used for the determination of interfacial tension: IEC 62961 or EN 14210.

5.2 Electrical properties

5.2.1 AC breakdown voltage

Breakdown voltage of unused modified or blended esters shall be measured in accordance

with IEC 60156, which was developed for mineral oils. However, due to the high viscosity of

some modified or blended esters, the set-up time before application of the voltage and resting

time between voltage applications shall be extended as suggested in IEC 60156.

5.2.2 Lightning impulse breakdown voltage

If required, for characterization of the lightning impulse breakdown voltage of the liquid,

IEC 60897 shall be used. Alternatively, ASTM D3300 can be used. Similarly to the AC

breakdown voltage and due to the higher viscosity of some modified or blended esters, the

set-up time before application of the voltage and resting time between voltage applications

shall be extended as suggested in IEC 60156. The test method shall be reported.

5.2.3 Partial discharge inception voltage (PDIV)

If required, for the characterization of the PDIV of the liquid, IEC TR 61294 shall be used.

5.2.4 Dielectric dissipation factor (DDF)

DDF is a measure of dielectric losses caused by the liquid. A high DDF can indicate

contamination of the liquid with moisture, particles or soluble polar contaminants or poor

manufacturing quality. DDF shall be measured in accordance with IEC 60247 or IEC 61620 at

90 °C. The test method shall be reported. In case of dispute, IEC 60247 at 90 °C shall be

used.

NOTE Users can require that the DDF be measured at other temperatures.

5.2.5 Relative permittivity (dielectric constant)

Relative permittivity (dielectric constant) is the ratio of the amount of electric energy stored in

the liquid at an applied voltage, relative to that stored in a vacuum. It shall be measured in

accordance with IEC 60247 at 90 °C, and reported.

5.2.6 DC resistivity

If required, the DC resisitivity shall be measured in accordance with IEC 60247.

5.2.7 Electrostatic charging tendency (ECT)

The ECT of liquid is an important property for certain designs of transformers which have

liquid pumping rates that can give rise to the build-up of electrostatic charge. This charge can

result in energy discharge causing transformer failure.

A method to measure ECT is proposed by CIGRE Technical Brochure 170.

5.3 Chemical properties

5.3.1 Acidity

Acidity shall be measured in accordance with IEC 62021-3.

NOTE The acidity of unused ester liquids is typically higher than that of mineral oils.

5.3.2 Additive content

Additives include antioxidants, pour point depressants, electrostatic charging tendency

depressants, metal passivators or deactivators, antifoam agents, refining process improvers,

etc. The antioxidant additive slows down the oxidation of ester liquids and, in turn, the

formation of gels and acidity. One such antioxidant is phenolic 2,6-di-tert-butyl-p-cresol

(DBPC), also known as butylated hydroxytoluene (BHT), but others are also used. Detection

and measurement of defined antioxidant and other additives shall be in accordance with

IEC 60666 or other appropriate methods. Appropriate methods are normally those which have

published precision data where repeatability, reproducibility and limit of detection are known.

The function, chemical nature and concentrations of additives shall be declared.

The total concentration of additives shall be less than a weight fraction of 5 %.

5.3.3 Corrosive and potentially corrosive sulphur compounds

Corrosive and potentially corrosive compounds are detected by placing copper in contact with

insulating liquid under standardized conditions (IEC 62535 or ASTM D1275). Known corrosive

– 14 – IEC 63012:2019 © IEC 2019

or potentially corrosive sulphur compounds such as dibenzyl disulphide (DBDS) shall not be

present above the detection limit (IEC 62697-1).

Under the influence of heat, sulphur containing molecules may decompose and react with

metal surfaces to form metal sulphide layers. Switching equipment often features silver-plated

contacts, which are very sensitive to reactions with certain sulphur compounds. The contact

resistance may increase or silver-sulphide layers may flake off, promoting flashovers. The test

method in DIN 51353 is an appropriate method to detect reactions of corrosive sulphur with

silver.

NOTE 1 Corrosive sulphur compounds are not naturally present in ester liquids in general. The test, however, can

verify that additives are non-corrosive and that cross-contamination with potentially corrosive liquids has not

occurred.

NOTE 2 Another suitable method to assess potential corrosivity is described in IEC TR 62697-2.

5.3.4 Methanol content

The standard test method for measuring methanol content (IEC 63025 series ) is at the

development stage.

5.4 Properties related to long term performance

5.4.1 Oxidation stability

For the evaluation of oxidation stability performance, IEC 61125 shall be used. The resistance

to oxidation is evaluated based on the amount of sludge, total acidity and dielectric dissipation

factor or from the time it takes to develop a given amount of volatile acidity (induction period).

Additionally, for modified or blended esters the viscosity change during the oxidation stability

test shall be measured.

For liquids intended for use in sealed systems, IEC 61125 shall be used with 48 h test

duration, and minimum performance requirement limits are based on IEC 62770. If requested,

the amount of sludge shall be reported.

For liquids intended for use in free breathing systems or other applications, IEC 61125 shall

be used with 164 h test duration, and minimum performance requirement limits are based on

IEC 61099. If requested, the DDF and viscosity change shall be reported.

NOTE Oxidation stability according to IEC 61125 at 500 h is an optional extra stability test. No performance limits

are defined in this document.

5.4.2 Operating temperature

IEC 60076-14 provides guidance on the maximum acceptable temperatures for operation of

ester liquids. Those are based on typical K-class natural esters and synthetic esters in

accordance with IEC 62770 and IEC 61099, respectively. While the temperature performance

of the modified or blended esters could be expected to be better than that of mineral oil due to

the nature of ester liquids, guidance on applicable temperatures in IEC 60076-14 may not

apply to the liquids under the scope of this document. Individual evaluation of liquid

performance shall be made to establish acceptable limits for the operating temperature.

Currently, there are no standard IEC methods for this evaluation. As a minimum, the side-by-

side comparison of liquid performance at selected temperatures shall be made against the

natural or synthetic esters according to IEC 62770 or IEC 61099, respectively.

___________

The IEC 63025 series is under consideration. Stage at the time of publication, IEC ACD 63025-1:2019 and

IEC ACD 63025-2:2019.

5.4.3 Material compatibility

Compatibility of the dielectric liquid with materials it may come into contact with shall be

determined under the standard operating conditions of the application. This refers to the list of

materials, operating temperatures range, free breathing versus sealed system, etc.

There is no current ISO or IEC test method for material compatibility evaluation. However,

there are references for material compatibility, such as ASTM D471, ASTM D4289,

ASTM D3455. They could be used as guides for defining the compatibility test procedures.

NOTE See also Annex A.

5.4.4 Stray gassing

Gases such as hydrogen, ethane and carbon oxides can be generated from ester-based

liquids under normal operating conditions in the absence of thermal or electrical fault. These

gases are referred to as 'stray gases'. If requested, stray gassing characteristics of liquids

shall be determined in accordance with ASTM D7150.

NOTE A new test method is under development and will be included in the next edition of IEC 60296, under

preparation.

5.4.5 Gassing tendency

By definition, the gassing tendency is the ability of the liquid to absorb or evolve gases

(hydrogen only) under electrical corona or partial discharge. The measurement shall be made

in accordance with method A in IEC 60628.

5.5 Health, safety and environmental properties

5.5.1 General

These are the properties that are related to safe handling of modified or blended e

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...