IEC 60811-410:2012

(Main)Electric and optical fibre cables - Test methods for non-metallic materials - Part 410: Miscellaneous tests - Test method for copper-catalyzed oxidative degradation of polyolefin insulated conductors

Electric and optical fibre cables - Test methods for non-metallic materials - Part 410: Miscellaneous tests - Test method for copper-catalyzed oxidative degradation of polyolefin insulated conductors

IEC 60811-410:2012 gives the procedure for copper-catalyzed oxidative degradation of a polyolefin, which is typically used for insulation in communication cables. IEC 60811-410:2012 cancels and replaces Annex B of IEC 60811-4-2:2004, which is withdrawn. Full details of the replacements are shown in Annex A of IEC 60811-100:2012. There are no specific technical changes with respect to the previous edition, but see the Foreword to IEC 60811-100:2012.

This publication is to be read in conjunction with IEC 60811-100:2012.

Câbles électriques et à fibres optiques - Méthodes d'essai pour les matériaux non-métalliques - Partie 410: Essais divers - Méthode d'essai pour la mesure de la dégradation par oxydation catalytique par le cuivre des conducteurs isolés aux polyoléfines

La CEI 60811-410:2012 décrit la procédure de mesure de la dégradation par oxydation catalytique, par le cuivre, d'une polyoléfine, généralement utilisée pour l'isolation des câbles de communication. La CEI 60811-410:2012 annule et remplace l'Annexe B de la CEI 60811-4-2:2004, qui est supprimée. L'ensemble des informations relatives aux remplacements figure dans l'Annexe A de la CEI 60811-100:2012. Aucune modification technique n'a été effectuée par rapport à l'édition précédente; voir cependant l'avant-propos de la CEI 60811-100:2012.

Cette publication doit être lue conjointement avec la CEI 60811-100:2012.

Alarm systems - Part 1: General requirements - Section Three: Environmental testing

General Information

- Status

- Published

- Publication Date

- 11-Mar-2012

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- WG 17 - TC 20/WG 17

- Current Stage

- PPUB - Publication issued

- Start Date

- 12-Mar-2012

- Completion Date

- 31-Mar-2012

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60811-410:2012 - Electric and optical fibre cables: Test methods for non-metallic materials - Part 410 - specifies a laboratory test method for copper‑catalyzed oxidative degradation of polyolefin insulated conductors. The procedure targets polyolefin insulation commonly used in communication cables and defines how to reproduce and assess copper‑accelerated oxidative aging in a controlled way. This publication cancels and replaces Annex B of IEC 60811‑4‑2:2004 (withdrawn) and is intended to be read in conjunction with IEC 60811‑100:2012.

Key topics and requirements

- Scope and purpose: Defines the objective and applicability of the copper‑catalyzed oxidative degradation test for polyolefin insulated conductors.

- Test procedure: Provides a standardized method to expose polyolefin insulation to conditions that reveal copper‑catalyzed oxidative effects (sample handling and controlled exposure procedures are included).

- Sample preparation and conditioning: Specifies how specimens should be prepared and conditioned prior to testing to ensure reproducibility (see IEC 60811‑100:2012 for general test principles).

- Observation and evaluation: Covers how to assess degradation outcomes and document results for comparison and quality decisions.

- Traceability and reporting: Requires clear reporting of test conditions, specimen details, and results so data can be used for material qualification or failure analysis.

(Note: IEC 60811‑410:2012 should be used with IEC 60811‑100:2012 for full procedural detail and normative references.)

Applications and who uses it

IEC 60811‑410:2012 is most relevant to:

- Cable manufacturers performing material qualification and production quality control.

- Independent test laboratories and certification bodies conducting standardized aging tests.

- R&D teams evaluating new polyolefin formulations or additives for resistance to copper‑catalyzed oxidation.

- Procurement, engineering and reliability departments needing objective data for supplier acceptance criteria.

- Failure analysis experts assessing insulation degradation in field returns or warranty investigations.

Practical uses include assessing long‑term stability, comparing formulations, setting acceptance limits, and supporting design choices for communication and signal cables where copper conductors and polyolefin insulation are in contact.

Related standards

- IEC 60811 series - Test methods for non‑metallic materials of electric and optical fibre cables

- IEC 60811‑100:2012 - General information on test procedures (to be read with Part 410)

- IEC 60811‑4‑2:2004 - (Annex B withdrawn; replaced by IEC 60811‑410:2012)

Keywords: IEC 60811‑410:2012, copper‑catalyzed oxidative degradation, polyolefin insulated conductors, cable insulation test, communication cables, IEC 60811 test methods.

IEC 60811-410:2012 - Electric and optical fibre cables - Test methods for non-metallic materials - Part 410: Miscellaneous tests - Test method for copper-catalyzed oxidative degradation of polyolefin insulated conductors

IEC 60811-410:2012+AMD1:2017 CSV - Electric and optical fibre cables - Test methods for non-metallic materials - Part 410: Miscellaneous tests - Test method for copper-catalyzed oxidative degradation of polyolefin insulated conductors Released:21. 07. 2017

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

NSF International

Global independent organization facilitating standards development and certification.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 60811-410:2012 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electric and optical fibre cables - Test methods for non-metallic materials - Part 410: Miscellaneous tests - Test method for copper-catalyzed oxidative degradation of polyolefin insulated conductors". This standard covers: IEC 60811-410:2012 gives the procedure for copper-catalyzed oxidative degradation of a polyolefin, which is typically used for insulation in communication cables. IEC 60811-410:2012 cancels and replaces Annex B of IEC 60811-4-2:2004, which is withdrawn. Full details of the replacements are shown in Annex A of IEC 60811-100:2012. There are no specific technical changes with respect to the previous edition, but see the Foreword to IEC 60811-100:2012. This publication is to be read in conjunction with IEC 60811-100:2012.

IEC 60811-410:2012 gives the procedure for copper-catalyzed oxidative degradation of a polyolefin, which is typically used for insulation in communication cables. IEC 60811-410:2012 cancels and replaces Annex B of IEC 60811-4-2:2004, which is withdrawn. Full details of the replacements are shown in Annex A of IEC 60811-100:2012. There are no specific technical changes with respect to the previous edition, but see the Foreword to IEC 60811-100:2012. This publication is to be read in conjunction with IEC 60811-100:2012.

IEC 60811-410:2012 is classified under the following ICS (International Classification for Standards) categories: 13.320 - Alarm and warning systems; 29.035.01 - Insulating materials in general; 29.060.20 - Cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60811-410:2012 has the following relationships with other standards: It is inter standard links to IEC 60811-4-2:2004, IEC 60811-410:2012/AMD1:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60811-410:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-1995

Alarm systems - Part 1: General requirements - Section Three: Environmental

testing

Alarm systems. Part 1: General requirements. Section Three: Environmental testing

Systèmes d'alarme. Première partie: Prescriptions générales. Section trois: Essais

climatiques et mécaniques

Ta slovenski standard je istoveten z: IEC 60839-1-3

ICS:

13.320 Alarmni in opozorilni sistemi Alarm and warning systems

19.040 Preskušanje v zvezi z Environmental testing

okoljem

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

NORME CEI

INTERNATIONALE IEC

839-1-3

INTERNATIONAL

Première édition

STAN DARD

First edition

Systèmes d'alarme

Première partie:

Prescriptions générales

Section trois — Essais climatiques et mécaniques

Alarm systems

Part 1:

General requirements

Section three — Environmental testing

© CEI 1988 Droits de reproduction réservés — Copyright - all rights reserved

Aucune partie de cette publication ne peut âtre reproduite ni No part of this publication may be reproduced or utilized

utilisée sous quelque forme que ce soit et par aucun procédé, in any form or by any means, electronic or mechanical,

électronique ou mécanique, y compris la photocopie et les including photocopying and microfilm, without permission

microfilms, sans l'accord écrit de l'éditeur. in writing from the publisher

Bureau central de la Commission Electrotechnique Internationale 3, rue de Varembé Genève Suisse

CODE PRIX

Commission Electrotechnique Internationale

X

PRICE CODE

International Electrotechnical Commission

IEC

McHf,gyHapoaHae 3rleKTpoTeXH114ecKaR HOMHCCHfi

Pour prix, voir catalogue en vigueur

•

For price, see current catalogue

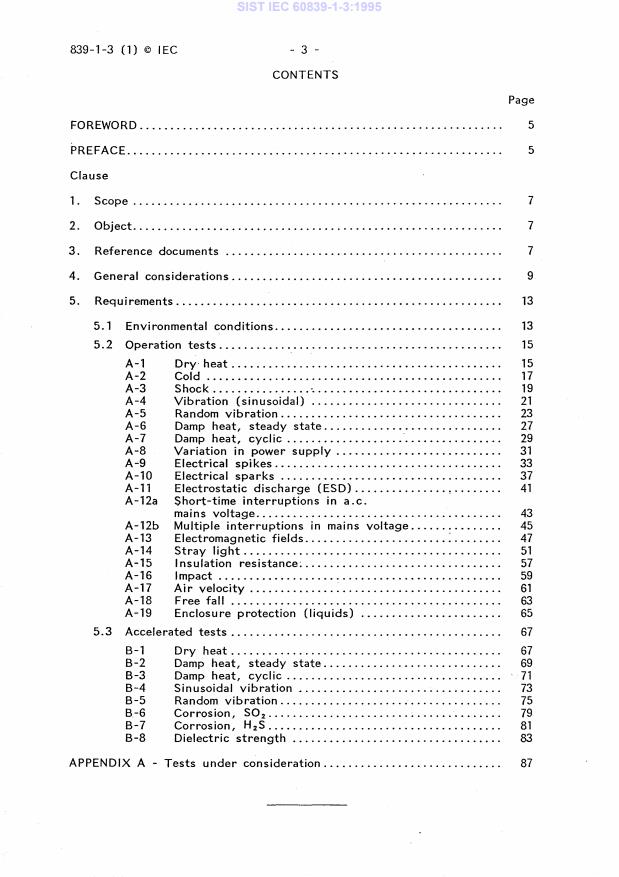

839-1-3(1)©IEC - 3 -

CONTENTS

Page

FOREWORD 5

PREFACE

Clause

1. Scope 7

2. Object 7

3. Reference documents 7

4. General considerations 9.

5. Requirements 13

5.1 Environmental conditions 13

5.2 Operation tests 15

A-1 Dry heat 15

A-2 Cold 17

A-3 Shock 19

A-4 Vibration (sinusoidal) 21

A-5 Random vibration 23

A-6 Damp heat, steady state 27

A-7 Damp heat, cyclic 29

A-8 Variation in power supply 31

A-9 Electrical spikes 33

A-10 Electrical sparks 37

A-11 Electrostatic discharge (ESD) 41

A-12a Short-time interruptions in a.c.

mains voltage 43

A-12b Multiple interruptions in mains voltage 45

A-13 Electromagnetic fields 47

A-14 Stray light 51

A-15 Insulation resistance 57

A-16 Impact 59

A-17 Air velocity 61

A-18 Free fall 63

A-19 Enclosure protection (liquids) 65

5.3 Accelerated tests 67

B-1 Dry heat 67

B-2 Damp heat, steady state 69

B-3 Damp heat, cyclic 71

B-4 Sinusoidal vibration 73

B-5 Random vibration 75

2 B-6 Corrosion, SO 79

2 S B-7 Corrosion, H 81

B-8 Dielectric strength 83

APPENDIX A - Tests under consideration 87

839-1-3 (1) ©

IEC

INTERNATIONAL ELECTROTECHNICAL COMMISSION

ALARM SYSTEMS

Part 1: General requirements

Section Three - Environmental testing

FOREWORD

The formal decisions or agreements of the IEC on technical matters, prepared by Technical

1)

Committees on which all the National Committees having a special interest therein are

represented, express, as nearly as possible, an international consensus of opinion on the

subjects dealt with.

They have the form of recommendations for international use and they are accepted by the

2)

National Committees in that sense.

In order to promote international unification, the IEC expresses the wish that all

3)

National Committees should adopt the text of the IEC recommendation for their national

rules in so far as national conditions will permit. Any divergence between the IEC recom-

mendation and the corresponding national rules should, as far as possible, be clearly

indicated in the latter.

PREFACE

This standard has been prepared by IEC Technical Committee No. 79:

Alarm systems.

The text of this standard is based on the following documents:

Report on Voting

Six Months' Rule

79(C0)9 79(CO)11

Full information on the voting for the approval of this standard can be

found in the Voting Report indicated in the above table.

839-1-3 (1) © IEC -7-

ALARM SYSTEMS

Part One: General Requirements

Section Three - Environmental testing

1. Scope

This standard specifies environmental test methods to be used for

testing system components of an alarm system.

This standard does not preclude the use of other environmental

exposures having special characteristics suitable for the evaluation of

special environmental conditions.

Requirements, performance criteria, test schedules, etc., are not

covered by this standard, but are to be given in the specific

standards for the particular alarm systems and/or components.

This standard shall be used in conjunction with the following IEC

publications.

Publications:

839-1-1: Alarm systems, Part 1: General requirements. Sec-

tion One - General. (Under consideration.)

801-1 (1984): Electromagnetic compatibility for industrial-process

measurement and control equipment, Part 1: General

introduction.

2. Object

The object of this standard is to provide a standard range of tests

to determine the suitability of components and equipment for use,

storage and transportation under various environmental conditions.

3.

Reference documents

Publications:

68: Basic environmental testing procedures.

68-1 (1982) : Part 1: General and guidance.

529 (1976) : Classification of degrees of protection provided by

enclosures.

654: Operating conditions for industrial-process measurement

and control equipment.

839-1-3 (1) © IEC - 9 -

721: Classification of environmental conditions.

801-2 (1984): Electromagnetic compatibility for industrial-process

measurement and control equipment, Part 2: Electrostatic

discharge requirements.

801-3 (1984): Part 3: Radiated electromagnetic field requirements.

4. General considerations

4.1 This standard contains a selection of environmental test methods

taken from other standards including IEC Publication 68.

4.2 The selected test methods have been found suitable for testing

components of an alarm system and have the necessary reproducibility

and severities suitable for this field of application.

For general guidance on environmental testing, reference should be

made to IEC Publication 68-1.

For specific guidance on the various environmental test methods used

in this standard, reference should be made to the description of the

relevant test.

4.3 Classification of tests

This standard specifies a range of test methods with a number of

test severities in order to cover the need for relevant tests for each

system component.

The aim of each test is characterized by allocation of the test to one

of the following two test classes:

a)

Class A - Operation tests

The object of a test in Class A is:

i)

to demonstrate the ability of the specimen to operate correctly

under the influence of the normal service environment and/or

ii)

to demonstrate the immunity of the specimen to false alarm

under the influence of a particular service environment.

The test specimen is exposed to an environment corresponding in

its effects to the normal service environment.

b) Class B - Accelerated tests

The object of a test in Class B is to demonstrate the ability of the

specimen to survive under the influence of an artificial environ-

ment more severe than the normal service environment.

The test specimen is subjected to exposures, which are intention-

ally more severe that the service environment, in order to give

information about the long-term stability.

839-1-3 (1) © IEC - 11 -

The specimen shall be switched off during all Test B exposures.

See Appendix B of IEC Publication 68-1.

4.4 Identification of tests

References in other parts of the standard to a specific environmental

test in this part of the standard shall be identified as follows:

Example: lEC 839-1-3/ A - 1/1

This part

Test class, for example A: Operation tests

Test serial number

Test severity, for example 1: 40 °C/2 h

Reference "A-1/1" in this example identifies the relevant test

method and severity in Test A-1 (see Sub-clause 5.2) .

A higher severity number does not necessarily mean a more severe

test.

4.5 Recommendations for basic requirements

(to be incorporated in the specific standards)

Severity

Test Method

Indoor Outdoor

a) Operation tests

A- 1 3 5

Dry heat

6 7

A- 2 Cold

1 1

A- 3 Shock

2 2

A- 4 Vibration (sinusoidal)

A- 5 Random vibration - -

2 2

A- 6 Damp heat, steady state

1 2

A- 7 Damp heat, cyclic

A- 8 Variation in power supply See Test A-8

A- 9 Electrical spikes 6

A-10 Electrical sparks 1 1

A-11 Electrostatic discharge (ESD) 4 4

A-12a Short-time interruptions in a.c.

mains voltage 4 4

A-13 Electromagnetic fields 4 4

A-14

Stray light - -

A-15 1 1

Insulation resistance

1 1

A-16 Impact

A-17 Air velocity - -

A-18 Free fall 3 3

A-19 Enclosure protection (liquids) - -

b) Accelerated tests

B-1 Dry heat - 5

1 1

B-2 Damp heat, steady state

1 2

B-3 Damp heat, cyclic

2 2

B-4 Sinusoidal vibration

2 2

B-5 Random vibration

B-6 Corrosion, SO2 6

-

.B-7 Corrosion, H2S -

1 1

B-8 Dielectric strength

839-1-3 (1) © IEC - 13 -

5. Requirements

5.1 Environmental' conditions

Equipment for use in hostile environments such as cold stores,

plating shops or corrosive atmospheres shall be to an appropriate

specification or be provided with special protection to take account of

the particular hazards.

Where high levels of interference from other equipment or external

sources such as lightning or power supply transients are likely,

special care shall be taken in the design and installation of the alarm

equipment to reduce the possibility of interference signals affecting the

normal operation of the system.

For other details refer to the specific rules for the devices and to

the test mentioned in this,standard.

839-1-3 (1) © IEC - 15 -

5.2 Operation tests

Test:

A-1

Test method:

Dry heat.

Reference to standard: IEC Publication 68-2 -2, fourth edition (1974),

Part 2: Tests - Test Bd: Dry heat, for heat-

dissipating specimen with gradual change of

temperature.

Object of the test: To determine the suitability of components,

equipment and other articles for operation

under conditions of high temperature.

Background information concerning the dry

heat test is given in IEC Publication 68-3-1,

first edition (1974), Part 3: Background

information. Section One - Cold and dry heat

tests.

Test procedure in brief: The test consists of exposure to the specified

high temperature under "free air" conditions

for the time specified. The time shall be

long enough for the specimen to achieve tempe-

rature stability.

Special preconditioning may be specified. The

rate of change of temperature shall not exceed

1 °C/min.

The humidity content of the test atmosphere

shall not exceed 20 g/m3.

Detail specification:

For full test details, reference should be made

to the IEC publication stated above and the

detail specification of this test in the relevant

part of the standard.

Test severities: The following severities can be specified:

Severity 1 2 3 4 5 6 7 8 9

Temperature (°C) 40 55 40 55 70

Duration (h) ** 2 2 16 16 2 2

* To be given in the specific standards for the particular alarm systems

and/or components.

** After temperature stability is reached.

839-1-3 (1) © IEC - 17 -

Test: A-2

Test method: Cold.

Reference to standard: IEC Publication 68-2-1, fourth edition (1974),

Part 2: Tests - Test Ad: Cold for heat-

dissipating specimen with gradual change of

temperature.

Object of the test: To determine the suitability of components,

equipment and other articles for operation

under conditions of low temperature.

Background information concerning the cold

test is given in IEC Publication 68-3-1, first

edition (1974), Part 3: Background inform-

ation. Section One - Cold and dry heat tests.

Test procedure in brief: The test consists of exposure to the specified

low temperature under "free air" conditions for

the time specified. The time shall be long

enough for the specimen to achieve tempera-

ture stability.

Special preconditioning may be specified. The

rate of change of temperature shall not exceed

1 °C/min to avoid temperature shock.

Detail specification: For full test details, reference should be made

to the IEC publication stated above and the

detail specification of this test in the relevant

part of the standard.

Test severities: The following severities can be specified:

Severity

1 2 3 4 5 6 7 8 9 10

Temperature (°C) +5 +5 0 -10 -25

0 -10 -25 -40 -40

Duration (h) * 2 16 2 16 2 16 2 16 16

* After temperature stability is reached.

839-1-3(1)©IEC -19-

Test: A-3

Test method: Shock.

IEC Publication 68-2-27, second edition (1972),

Reference to standard:

Part 2: Tests - Test Ea: Shock.

Object of the test: To determine the suitability of components,

equipment and other articles for operation

under conditions of mechanical shock.

Test procedure in brief: The test consists of exposure to a number of

shocks with a fixed peak acceleration and time

duration.

The shock pulse has a half-sine time response.

The specimen shall, in turn, be subjected to

shocks in both directions of each of three

mutually perpendicular axes. The specimen

shall be mounted on a stiff fixture by its

normal mounting means. The specimen shall be

switched on during the test.

Detail specification: For full test details, reference should be made

to the IEC publication stated above, and the

detail specification of this test in the relevant

part of the standard.

Test severities: The following severities can be specified:

Severity 1 2

Shock impulse Half sine Half sine

Level (m.s- Z ) 500 1 000

(g) (50) (100)

Duration (ms)

11 6

Number of shocks 3 3

per direction

Number of directions 6 6

839-1-3 (1) © IEC - 21 -

Test: A-4

Test method: Vibration (sinusoidal).

Reference to standard:

IEC Publication 68-2-6, fifth edition (1982),

Part 2: Tests - Test Fc and guidance: Vibra-

tion (sinusoidal) .

Object of the test: To determine the suitability of components,

equipment and other articles for use and

operation under conditions of vibration.

Test procedure in brief: The test consists of exposure to the vibration

level for a time long enough for testing the

various functions of the specimen during the

exposure. The specimen shall, in turn, be

tested in three mutually perpendicular axes

mounted on a rigid fixture by its normal

mounting means. The specimen shall be

switched on during the test.

The equipment shall normally be mounted so

that the gravitational force acts in the same

direction as it would in normal use. Where the

effect of gravitational force is not important,

the equipment may be mounted in any attitude.

Detail specification:

For full test details, reference should be made

to the IEC . publication stated above, and the

detail specification of this test in the relevant

part of the standard.

Test severities: The following severities can be specified:

Severity 1 2 3 4

Frequency (Hz) 10 to 55 10 to 55 10 to 150 10 to 150

Level (m.s-2) 0.981 9.81 0.981 9.81

(g) (0.1) (1) (0.1) (1)

Number of axes

3 3 3 3

Number of sweep cycles One sweep cycle in each functional mode

per axis

as defined in the specific standards for

alarm systems and/or components

839-1-3(1)©IEC -23-

Test: A-5

Test method: Random vibration.

Reference to standard: IEC Publication 68-2-34, first edition (1973),

Part 2: Tests - Test Fd: Random vibration

wide band. General requirements, and IEC

Publication 68-2-35, first edition (1973),

Part 2: Tests - Test Fda: Random vibration

wide band - Reproducibility high.

Object of the test:.

To determine the suitability of components,

equipment and other articles for use and

operation under conditions of vibration.

Test procedure in brief:

The test consists of exposure to the vibration

level for a time long enough for testing the

various functions of the specimen during the

exposure. The specimen shall, in turn, be

tested in three mutually perpendicular axes

mounted on a rigid fixture by its normal

mounting means. The specimen shall be

switched on during the test.

The equipment shall normally be mounted so

that the gravitational force acts in the same

direction as it would in normal use. Where the

effect of gravitational force is not important,

the equipment may be mounted in any attitude.

Detail specification: For full test details, reference should be made

to the IEC publication stated above and the

detail specification of this test in the relevant

part of the standard.

839-1-3 (1) ©

IEC - 25 -

Test severities: The following severities can be specified:

Severity

1 2

Total frequency range (Hz)

10 to 150 10 to 150

Total rms level

(m. s- 2 ) 1.6 16

(g) (0.16) (1.6)

ASD level, 10 Hz to 20 Hz (mes -3) 0.048 4.8

(g 2/Hz) (0.0005) (0.05)

ASD level, 20 Hz to 150 Hz (dB/octave) -3 -3

Number of axes

3 3

Duration per axis

Minimum 2 min in each

functional mode as

defined in the specific

standards for alarm

systems and/or

components

839-1-3 (1) © IEC

- 27 -

Test:

A-6

Test method:

Damp heat, steady state.

Reference to standard:

IEC Publication 68-2-3, third edition (1969),

Part 2: Tests - Test Ca: Damp heat, steady

state (modified procedure).

Object of the test:

To determine the suitability of components,

equipment and other articles for use and

storage under conditions of high relative

humidity, where the absorption of humidity

mainly takes place by diffusion.

Further background information concerning

damp heat tests is given in

IEC Publica-

tion 68-2-28, second edition (1980) :

Guidance

for damp heat test.

Test procedure in brief: The test consists of exposure to a constant

temperature of 30 °C and a constant relative

humidity of 93% for a certain fixed time defined

by the severity class in question. The hand-

ling of the specimen shall be such that no

condensation of water occurs on the specimen.

Special recovery conditions before final mea-

surements can be specified.

Detail specification:

For full test details, reference should be made

to the IEC publication stated above and the

detail specification of this test in the relevant

part of the standard.

Test severities:

The following severities can be specified:

Severity

1 2 3 4 5 6 7 8 9

Duration (days) 16 21

839-1-3 (1) © IEC - 29 -

Test:

A-7

Test method:

Damp heat, cyclic.

Reference to standard: IEC Publication 68-2-30, second edition (1980),

Part 2: Tests - Test Db and guidance: Damp

heat, cyclic (12 h + 12-hour cycle).

Object of the test: To determine the suitability of components,

equipment and other articles for operation

under conditions of high relative humidity

when combined with cyclic temperature

changes.

Further background information concerning

damp heat tests is given in IEC Publica-

tion 68-2-28, second edition (1980): Guidance

for damp heat tests.

Test procedure in brief: The test consists of exposure to cyclic

temperature variations between 25 °C and the

appropriate upper temperature, maintaining the

relative humidity above 95% during the tempe-

rature change and low temperature phases,

and at (93 ± 3)% during the upper temperature

phases.

Condensation shall occur on the specimen

during the temperature rise.

Standard stabilizing period before and re-

covery conditions after the cyclic exposure are

specified. Special electrical conditions and

recovery conditions may be specified.

Detail specification: For full test details, reference should be made

to the IEC publication stated above and the

detail specification of this test in the relevant

part of the standard.

Test severities:

The following severities can be specified:

Severity

1 2 3 4 5 6 7 8 9

Upper temperature (°C)

40 40 55 55

Duration (cycles)

2 6 2 6

839-1-3 (1) © IEC - 31 -

Test: A-8

Test method: Variation in power supply.

Reference to standard: No reference to international standards can be

given at the moment.

Object of the test: To determine the suitability of alarm system

components for operation under conditions of

varying mains supply.

Test procedure in brief: The test consists of exposure at standard

atmospheric conditions for testing to the

specified power supply condition for a period

long enough to obtain temperature stability and

to perform the required measurements.

Detail specification: For full test details, reference should be made

to the detail specification of this test in the

relevant part of the standard.

Test severities:

The following severities can be specified:

Severity

1 2

Supply voltage (Vnom) +1O% To manufacturer's

-15% specification

Duration Until temperature stability is reached

and measurements are performed

839-1-3 (1) o IEC - 33 -

Test: A-9

Test method: Electrical spikes.

Reference to standard: IEC Publication 801-4: Electromagnetic

compatibility for industrial-process measu re-

ment and control equipment, Part 4: Electrical

fast transient requirements (in preparation)

and Part 5: Surge voltage immunity require-

ments (under consideration) .

Object of the test: To determine the suitability of equipment and

sub-units to function under conditions where

electrical spikes are superimposed on the mains

voltage or induced on signal lines.

Test procedure in brief: The test consists of exposure to double

exponential waveform transient voltages. Below

500 V the transients shall have rise times of

10 ns and decay times in the interval 0.1 ps to

1 ps. Above 500 V the transients shall have

rise times of 35 ns and decay times in the

interval 1 ps to 3 ps. The decay time is the

interval between the half amplitude points of

the transient.

Note.- The decay time intervals are given for

the possibility of using available

generators, but the decay time used

should be specified in the test report.

The transient generator shall have an output

impedance of 50 Q. Transients shall be coupled

to the test object using both common mode and

differential mode interference. At least 10

positive and 10 negative transients shall be

applied in each mode.

Insertion of blocking filters in the cables to

the specimen may be necessary to prevent the

transient energy being dissipated in the mains

or other interconnected units.

Detail specification: For full test details, reference is made to the

lEC publication stated above and the detailed

specification of this test in the relevant part

of the standard.

839-1-3 (1) © IEC 35 - -

Test severities: The following severities can be specified:

(all figures are open-circuit values)

Severity

1 2 3 4 5 6 7 8

Amplitude (V) 50 100 200 500 1 000 1 500 2 000 3 750

(peak value)

Decay time (Ns) 0.1 0.1 1 1 1 1

0.1 0.1

to 1 to 1 to 3 to 3 to 3 to 3

to 1 to 1

839-1-3 (1) co -37-

Test: A-10

Test method: Electrical sparks.

Reference to standard: No reference to international standards can be

given at the moment.

Object of the test: To determine the suitability of equipment and

sub-units to function under conditions where

electrical transients in the form of a pulse

train (repetitive spikes) are superimposed on

the mains voltage.

Test procedure in brief: The test consists of exposure to a pulse train

of repetitive transient voltages (see

Figure A-10). The test pulse is generated by

switching off a 300 H coil supplied with a d.c.

voltage between 110 V and 220 V. The test

pulse has a frequency spectrum up to

100 MHz. The test pulse shall be coupled to

the test object through a 0.1 nF capacitor.

The test signal shall be superimposed on the

mains both as common mode and differential

mode interference. At least 60 pulse trains

shall be applied in each mode.

A low-pass filter is inserted to prevent the

transient energy being dissipated in the mains

impedance.

Amplitude

Duration

ow-

916/87

Fig. A-10. - Waveform of test signal.

Detail specification: For full test details, reference should be made

to the detail specification of this test in the

relevant part of the standard.

839-1-3 (1) © IEC - 39 -

Test severities: The following severities can be specified:

(all figures are open-circuit values)

Severity 1 2 3

Amplitude (kV) approx.

(peak value) 4

Duration (ms) approx. 1

839-1-3 (1) © IEC

- 41 -

Test: A-11

Test method: Electrostatic discharge (ESD) .

Reference to standard: IEC Publication 801-2, first edition (1984):

Electromagnetic compatibility for industrial-

process measurement and control equipment,

Part 2: Electrostatic discharge requirements.

Object of the test: To evaluate the performance of equipment and

sub-units when subjected to electrostatic

discharges.

Test procedure in brief: A capacitor of 150 pF shall be charged by a

suitable d.c. voltage source. The capacitor is

then discharged through the specimen by

connecting one terminal to earth (chassis) and

the other via 150 St to surfaces which are

normally accessible to the operator. At least

10 discharges shall be applied.

The time interval between successive dis-

charges shall be greater than 1 s.

Test specimens without an earth terminal shall

be placed on a ground plane which projects

beyond the specimen by at least 0.1 m on all

sides. The earth connection to the capacitor

shall be as short as possible.

The discharge electrode shall approach the

specimen until discharge occurs and shall then

be removed before the next disc

...

IEC 60811-410 ®

Edition 1.0 2012-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric and optical fibre cables – Test methods for non-metallic materials –

Part 410: Miscellaneous tests – Test method for copper-catalyzed oxidative

degradation of polyolefin insulated conductors

Câbles électriques et à fibres optiques – Méthodes d’essai pour les matériaux

non-métalliques –

Partie 410: Essais divers – Méthode d’essai pour la mesure de la dégradation

par oxydation catalytique par le cuivre des conducteurs isolés aux polyoléfines

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 60811-410 ®

Edition 1.0 2012-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric and optical fibre cables – Test methods for non-metallic materials –

Part 410: Miscellaneous tests – Test method for copper-catalyzed oxidative

degradation of polyolefin insulated conductors

Câbles électriques et à fibres optiques – Méthodes d’essai pour les matériaux

non-métalliques –

Partie 410: Essais divers – Méthode d’essai pour la mesure de la dégradation

par oxydation catalytique par le cuivre des conducteurs isolés aux polyoléfines

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX L

ICS 29.035.01; 29.060.20 ISBN 978-2-88912-972-0

– 2 – 60811-410 IEC:2012

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Test method . 6

4.1 General . 6

4.2 Apparatus . 6

4.3 Sample and test pieces preparation. 7

4.4 Test procedure . 7

4.5 Measurements . 8

5 Test report. 8

Annex A (normative) Instrument calibration . 10

Bibliography . 11

Figure 1 – Evaluation of OIT from recorded-time-based thermogram . 9

Figure A.1 – Representative melting endothermic for indium . 10

60811-410 IEC:2012 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC AND OPTICAL FIBRE CABLES –

TEST METHODS FOR NON-METALLIC MATERIALS –

Part 410: Miscellaneous tests –

Test method for copper-catalyzed oxidative degradation

of polyolefin insulated conductors

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60811-410 has been prepared by IEC technical committee 20:

Electric cables.

This Part 410 of IEC 60811 cancels and replaces Annex B of IEC 60811-4-2:2004, which is

withdrawn. Full details of the replacements are shown in Annex A of IEC 60811-100:2012.

There are no specific technical changes with respect to the previous edition, but see the

Foreword to IEC 60811-100:2012.

– 4 – 60811-410 IEC:2012

The text of this standard is based on the following documents:

FDIS Report on voting

20/1294/FDIS 20/1343/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This part of IEC 60811 shall be used in conjunction with IEC 60811-100.

A list of all the parts in the IEC 60811 series, published under the general title Electric and

optical fibre cables – Test methods for non-metallic materials, can be found on the IEC

website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

60811-410 IEC:2012 – 5 –

INTRODUCTION

The IEC 60811 series specifies the test methods to be used for testing non-metallic materials

of all types of cables. These test methods are intended to be referenced in standards for

cable construction and for cable materials.

NOTE 1 Non-metallic materials are typically used for insulating, sheathing, bedding, filling or taping within cables.

NOTE 2 These test methods are accepted as basic and fundamental and have been developed and used over

many years principally for the materials in all energy cables. They have also been widely accepted and used for

other cables, in particular optical fibre cables, communication and control cables and cables for ships and offshore

applications.

– 6 – 60811-410 IEC:2012

ELECTRIC AND OPTICAL FIBRE CABLES –

TEST METHODS FOR NON-METALLIC MATERIALS –

Part 410: Miscellaneous tests –

Test method for copper-catalyzed oxidative degradation

of polyolefin insulated conductors

1 Scope

This Part 410 of IEC 60811 gives the procedure for copper-catalyzed oxidative degradation of

a polyolefin, which is typically used for insulation in communication cables.

Full test conditions, such as temperature, duration, etc. and full test requirements are not

specified in this standard; it is intended that they should be specified by the standard dealing

with the relevant type of cable.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60811-100:2012, Electric and optical fibre cables – Test methods for non-metallic

materials – Part 100: General

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60811-100 apply.

4 Test method

4.1 General

The need for a manufacturer to monitor his cable production to ensure that it has adequate

resistance to oxidation is well established. The Oxidation Induction Time (OIT) test has been

found suitable for monitoring both raw materials and cables for compliance with this

requirement, once suitable materials have been selected. The OIT test is not suitable for the

selection of materials. For this purpose, long-term thermal ageing tests are preferred.

4.2 Apparatus

For the purposes of this test, the different equipment used is as follows:

a) A differential thermal analyser or differential scanning calorimeter, capable of heating at

rates of up to at least (20 ± 1) K/min and maintaining the test temperature isothermally

within 0,2 K and of automatic recording of differences in temperature (or differences in

heat transfer) between the sample and a reference material to the required sensitivity and

precision.

b) A recorder capable of displaying heat flow or temperature difference on the Y-axis, and

time on the X-axis. The time base shall be accurate to ± 1 % and be readable to 0,1 min.

c) A gas-selector switch and regulators for high-purity nitrogen and oxygen.

60811-410 IEC:2012 – 7 –

d) An analytical balance capable of weighing 30 g, and readable and repeatable to ±0,1 mg.

e) Test pieces holders: aluminium holders, each of approximately 6 mm to 7 mm in diameter,

or of similar dimensions as supplied by the manufacturer of the instrument.

4.3 Sample and test pieces preparation

From a sample of the cable, prepare an appropriate number, e.g. four test pieces of different

colours, of approximately 4 mm length containing the core. The test pieces shall be cut from

an insulated core to yield 3 mg to 5 mg of insulating material.

Insert one test piece in an aluminium holder.

4.4 Test procedure

Before carrying out a test series, the instrument shall be calibrated and prepared as described

in Annex A.

Open valves on both the nitrogen and oxygen gas cylinders. Place the gas selector switch to

the nitrogen (N ) position and adjust the flow rate to (50 ± 5) ml/min using a flowmeter.

Place the prepared test piece holder (see 4.3) in the differential thermal analyser and an

empty aluminium holder in the reference position.

NOTE Crimping the test piece with a suitable aluminium or stainless steel screen is optional. It may provide a

better contact with the test piece holder.

Purge with nitrogen for 5 min. Check the flow rate and readjust to (50 ± 5) ml/min if required.

Set signal amplification and recorder sensitivity to the full scale pen deflection associated with

the exothermic reaction and set the temperature base at zero.

Set the heating rate to 20 K/min and start the programmed heating.

Continue heating until the specified test temperature, controlled to ± 1 °C, is reached.

Discontinue programmed heating and equilibrate the test piece to a constant temperature.

Start to record the thermogram. A test temperature of 200 °C has been found appropriate for

polyethylene. To simplify the procedure, it is allowed to omit the programmed pre-heating and

start directly at the test temperature.

Once temperature equilibrium has been established (steady recorder signal), change purge

gas to oxygen, and adjust the flow rate to (50 ±5) ml/min. Mark this point on the recorder. This

change-over point to oxygen purge is considered the zero time of the experiment (T ).

o

Continue the isothermal operation until maximum pen deflection is attained after

commencement of the oxidative exotherm as shown on the recorder (see Figure 1).

In the case of a multi-step exotherm, continue the isothermal operation until maximum pen

deflection occurs.

When the test is completed, turn off the recorder and switch the gas selector back to nitrogen.

Allow the differential thermal analyser to cool to the ambient temperature.

Repeat the entire test on a new test piece, three more times, thus generating a total of four

thermograms. The use of a fresh aluminium reference holder for each test piece is optional.

– 8 – 60811-410 IEC:2012

4.5 Measurements

Extend the recorded base line from time zero to beyond the oxidative exotherm. Extrapolate

the steepest part of the exotherm to intercept the extended baseline (see Figure 1).

The OIT shall be measured from zero to the smallest time interval practical, not exceeding

1 min.

5 Test report

The test report shall be in accordance with that given in IEC 60811-100.

60811-410 IEC:2012 – 9 –

Key

1 5 switch to isothermal operation

∆ power or ∆T

2 time 6 switch to oxygen

...

IEC 60811-410 ®

Edition 1.1 2017-07

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Electric and optical fibre cables – Test methods for non-metallic materials –

Part 410: Miscellaneous tests – Test method for copper-catalyzed oxidative

degradation of polyolefin insulated conductors

Câbles électriques et à fibres optiques – Méthodes d’essai pour les matériaux

non-métalliques –

Partie 410: Essais divers – Méthode d’essai pour la mesure de la dégradation

par oxydation catalytique par le cuivre des conducteurs isolés aux polyoléfines

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC

65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte,

et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les

publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées.

antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Restez informé sur les nouvelles publications IEC. Just Service Clients - webstore.iec.ch/csc

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60811-410 ®

Edition 1.1 2017-07

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Electric and optical fibre cables – Test methods for non-metallic materials –

Part 410: Miscellaneous tests – Test method for copper-catalyzed oxidative

degradation of polyolefin insulated conductors

Câbles électriques et à fibres optiques – Méthodes d’essai pour les matériaux

non-métalliques –

Partie 410: Essais divers – Méthode d’essai pour la mesure de la dégradation

par oxydation catalytique par le cuivre des conducteurs isolés aux polyoléfines

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.035.01; 29.060.20 ISBN 978-2-8322-4653-5

IEC 60811-410 ®

Edition 1.1 2017-07

CONSOLIDATED VERSION

REDLINE VERSION

VERSION REDLINE

colour

inside

Electric and optical fibre cables – Test methods for non-metallic materials –

Part 410: Miscellaneous tests – Test method for copper-catalyzed oxidative

degradation of polyolefin insulated conductors

Câbles électriques et à fibres optiques – Méthodes d’essai pour les matériaux

non-métalliques –

Partie 410: Essais divers – Méthode d’essai pour la mesure de la dégradation

par oxydation catalytique par le cuivre des conducteurs isolés aux polyoléfines

– 2 – IEC 60811-410:2012+AMD1:2017 CSV

IEC 2017

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Test method . 6

4.1 General . 6

4.2 Apparatus . 6

4.3 Sample and test pieces preparation. 7

4.4 Test procedure . 7

4.5 Measurements . 8

5 Test report. 8

Annex A (normative) Instrument calibration . 10

Bibliography . 11

Figure 1 – Evaluation of OIT from recorded-time-based thermogram . 9

Figure A.1 – Representative melting endothermic for indium . 10

IEC 2017

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC AND OPTICAL FIBRE CABLES –

TEST METHODS FOR NON-METALLIC MATERIALS –

Part 410: Miscellaneous tests –

Test method for copper-catalyzed oxidative degradation

of polyolefin insulated conductors

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been prepared

for user convenience.

IEC 60811-410 edition 1.1 contains the first edition (2012-03) [documents 20/1294/FDIS and

20/1343/RVD] and its amendment 1 (2017-07) [documents 20/1734/FDIS and 20/1739/RVD].

In this Redline version, a vertical line in the margin shows where the technical content is

modified by amendment 1. Additions are in green text, deletions are in strikethrough red text. A

separate Final version with all changes accepted is available in this publication.

– 4 – IEC 60811-410:2012+AMD1:2017 CSV

IEC 2017

International Standard IEC 60811-410 has been prepared by IEC technical committee 20:

Electric cables.

There are no specific technical changes with respect to the previous edition, but see

the Foreword to IEC 60811-100:2012.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This part of IEC 60811 shall be used in conjunction with IEC 60811-100.

A list of all the parts in the IEC 60811 series, published under the general title Electric and

optical fibre cables – Test methods for non-metallic materials, can be found on the IEC

website.

The committee has decided that the contents of the base publication and its amendment will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date,

the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

IEC 2017

INTRODUCTION

The IEC 60811 series specifies the test methods to be used for testing non-metallic materials

of all types of cables. These test methods are intended to be referenced in standards for

cable construction and for cable materials.

NOTE 1 Non-metallic materials are typically used for insulating, sheathing, bedding, filling or taping within cables.

NOTE 2 These test methods are accepted as basic and fundamental and have been developed and used over

many years principally for the materials in all energy cables. They have also been widely accepted and used for

other cables, in particular optical fibre cables, communication and control cables and cables for ships and offshore

applications.

– 6 – IEC 60811-410:2012+AMD1:2017 CSV

IEC 2017

ELECTRIC AND OPTICAL FIBRE CABLES –

TEST METHODS FOR NON-METALLIC MATERIALS –

Part 410: Miscellaneous tests –

Test method for copper-catalyzed oxidative degradation

of polyolefin insulated conductors

1 Scope

This Part 410 of IEC 60811 gives the procedure for copper-catalyzed oxidative degradation of

a polyolefin, which is typically used for insulation in communication cables.

Full test conditions, such as temperature, duration, etc. and full test requirements are not

specified in this standard; it is intended that they should be specified by the standard dealing

with the relevant type of cable.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60811-100:2012, Electric and optical fibre cables – Test methods for non-metallic

materials – Part 100: General

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60811-100 apply.

4 Test method

4.1 General

The need for a manufacturer to monitor his cable production to ensure that it has adequate

resistance to oxidation is well established. Once suitable materials have been selected, the

oxidation induction time (OIT) test has been found suitable for monitoring both raw materials

and cables for compliance with this the oxidative degradation requirement, once suitable

materials have been selected. The OIT test is not suitable for the selection determination of

materials ageing properties. For this purpose, long-term thermal ageing tests are preferred.

4.2 Apparatus

For the purposes of this test, the different equipment used is as follows:

a) A differential thermal analyser or differential scanning calorimeter, capable of heating at

rates of up to at least (20 ± 1) K/min and maintaining the test temperature isothermally

within 0,2 K and of automatic recording of differences in temperature (or differences in

heat transfer) between the sample and a reference material to the required sensitivity and

precision.

b) A recorder capable of displaying heat flow or temperature difference on the Y-axis, and

time on the X-axis. The time base shall be accurate to ± 1 % and be readable to 0,1 min.

© IEC 2017

c) A gas-selector switch and regulators for high-purity nitrogen and oxygen; N , O with

2 2

purity:

• N 5.0 = 99,999 % purity;

• O 4.5 = 99,995 % purity.

d) An analytical balance capable of weighing 30 g 3 mg to 5 mg, and readable and

repeatable to ±0,1 mg ± 1 μg. The mass rounding is in 10 μg.

e) Test pieces holders: aluminium holders, each of approximately 6 mm to 7 mm in diameter,

or of similar dimensions as supplied by the manufacturer of the instrument.

4.3 Sample and test pieces preparation

From a sample of the cable, prepare an appropriate number, e.g. four test pieces of different

colours, of approximately 4 mm length containing the core. The test pieces shall be cut from

an insulated core to yield 3 mg to 5 mg of insulating material.

Insert one test piece in an aluminium holder.

4.4 Test procedure

Before carrying out a test series, the instrument shall be calibrated and prepared as described

in Annex A.

Open valves on both the nitrogen and oxygen gas cylinders. Place the gas selector switch to

the nitrogen (N ) position and adjust the flow rate to (50 ± 5) ml/min using a flowmeter.

Place the prepared test piece holder (see 4.3) in the differential thermal analyser and an

empty aluminium holder in the reference position.

NOTE Crimping the test piece with a suitable aluminium or stainless steel screen is optional. It may provide a

better contact with the test piece holder. If the piece holder is closed, the oxidation cannot be made.

Purge with nitrogen for 5 min. Check the flow rate and readjust to (50 ± 5) ml/min if required.

Set signal amplification and recorder sensitivity to the full scale pen deflection associated with

the exothermic reaction and set the temperature base at zero.

Set the heating rate to 20 K/min and start the programmed heating.

Continue heating until the specified test temperature, controlled to ± 1 °C, is reached.

Discontinue programmed heating and equilibrate the test piece to a constant temperature.

Start to record the thermogram. A test temperature of 200 °C has been found appropriate for

polyethylene. To simplify the procedure, it is allowed to omit the programmed pre-heating and

start directly at the test temperature.

Once temperature equilibrium has been established (steady recorder signal), change purge

gas to oxygen, and adjust the flow rate to (50 ±5) ml/min. Mark this point on the recorder. This

change-over point to oxygen purge is considered the zero time of the experiment (T ).

o

Continue the isothermal operation until maximum pen deflection is attained after

commencement of the oxidative exotherm as shown on the recorder (see Figure 1).

In the case of a multi-step exotherm, continue the isothermal operation until maximum pen

deflection occurs.

When the test is completed, turn off the recorder and switch the gas selector back to nitrogen.

– 8 – IEC 60811-410:2012+AMD1:2017 CSV

IEC 2017

Allow the differential thermal analyser to cool to the ambient temperature.

Repeat the entire test on a new test piece, three more times, thus generating a total of four

thermograms. The use of a fresh aluminium reference holder for each test piece is optional.

4.5 Measurements

Extend the recorded base line from time zero to beyond the oxidative exotherm. Extrapolate

the steepest part of the exotherm to intercept the extended baseline (see Figure 1).

The OIT shall be measured from zero to the smallest time interval practical, not exceeding

1 min.

5 Test report

The test report shall be in accordance with that given in IEC 60811-100.

IEC 2017

Key

1 5 switch to isothermal operation

∆ power or ∆T or ∆enthalpy

2 time 6 switch to oxygen

3 programmed heat (nitrogen) 7 OIT

4 isothermal mode (oxygen)

Figure 1 – Evaluation of OIT from recorded-time-based thermogram

– 10 – IEC 60811-410:2012+AMD1:2017 CSV

IEC 2017

Annex A

(normative)

Instrument calibration

The instruments shall be calibrated as follows:

a) Calibrate the instrument according to the manufacturer's instructions before starting. Use

analytical-grade indium as a temperature reference material.

b) Place analytical-grade indium into an aluminium holder with an aluminium cover. Place

the sample, typically 6 mg, thus prepared, and a reference aluminium holder with cover

into the instrument.

Should it be necessary to clean the sample and the aluminium reference holder and

cover, use petroleum ether or other suitable solvent to remove contaminants.

c) Programme the temperature of the scanner from 145 °C to 165 °C at a rate of 1 K/min,

while recording the thermogram.

d) Calibrate the instrument according to the manufacturer's instructions in order to obtain an

indium first order transition temperature of 156,6 °C. For calibration purposes, the melting

point 156,6 °C is defined as the intersection of the extrapolated peak onset and the

extrapolated baseline (see Figure A.1).

Figure A.1 – Representative melting endothermic for indium

IEC 2017

Bibliography

IEC 60811-4-2:2004, Insulating and sheathing materials of electric and optical cables –

Common test methods – Part 4-2: Methods specific to polyethylene and polypropylene

compounds – Tensile strength and elongation at break after conditioning at elevated

temperature – Wrapping test after conditioning at elevated temperature – Wrapping test after