IEC TR 62874:2015

(Main)Guidance on the interpretation of carbon dioxide and 2-furfuraldehyde as markers of paper thermal degradation in insulating mineral oil

Guidance on the interpretation of carbon dioxide and 2-furfuraldehyde as markers of paper thermal degradation in insulating mineral oil

IEC TR 62874:2015 is a Technical Report which provides guidance for the estimation of consumed thermal life of transformers' cellulosic insulators, through the analysis of some compound dissolved in the insulating mineral oil. A comparison between analytical results of 2-furfural (2-FAL) and carbon oxides and their correspondent typical values estimated for different families of equipment gives information on the estimated thermal degradation of papers.

Guide pour l'interprétation du dioxyde de carbone et du 2-furfuraldéhyde comme marqueurs de la dégradation thermique du papier dans de l'huile minérale isolante

L'IEC TR 62874:2015, qui est un rapport technique, est destiné à estimer la vie thermique consommée de l'isolation cellulosique d'un transformateur, grâce à l'analyse de certains composés dissous dans l'huile minérale isolante. Une comparaison entre les résultats d'analyse de 2-furfural (2-FAL) et d oxyde de carbone et de leurs valeurs types correspondantes estimées pour différentes familles d'équipement donne des informations sur la dégradation thermique estimée des papiers.

General Information

- Status

- Published

- Publication Date

- 04-May-2015

- Technical Committee

- TC 10 - Fluids for electrotechnical applications

- Drafting Committee

- WG 33 - TC 10/WG 33

- Current Stage

- PPUB - Publication issued

- Start Date

- 05-May-2015

- Completion Date

- 15-Aug-2015

Overview

IEC TR 62874:2015, published by the International Electrotechnical Commission (IEC), provides comprehensive guidance on interpreting carbon dioxide (CO₂) and 2-furfuraldehyde (2-FAL) as chemical markers for the thermal degradation of paper insulation in transformers. This Technical Report focuses on the evaluation of cellulosic insulator aging in transformers by analyzing compounds dissolved in insulating mineral oil. The report offers valuable methodologies for estimating the consumed thermal life of transformer paper insulation, which is critical for transformer maintenance and reliability.

This standard is essential for electrical engineers, maintenance teams, and asset managers involved in transformer condition monitoring and life assessment. It facilitates more accurate diagnostics by comparing measured 2-FAL and CO₂ concentrations against typical values for various transformer families, helping predict potential insulation failure before catastrophic breakdown occurs.

Key Topics

Thermal Degradation of Paper Insulation

The report explains the processes leading to thermal and mechanical degradation of cellulosic paper used in transformer insulation, emphasizing factors such as temperature, humidity, oxygen content, and operational stresses.Markers of Aging: 2-Furfuraldehyde and Carbon Dioxide

Detailed analysis is provided on how 2-FAL and CO₂ compounds serve as reliable indicators of cellulose aging. The document clarifies how their concentrations in mineral oil correlate with the degree of thermal degradation.Analytical Measurement and Interpretation

IEC TR 62874 outlines recommended monitoring protocols including baseline and supplementary testing to detect soluble and volatile by-products from paper ageing. It also highlights the impact of oil type, condition, and maintenance operations on the accuracy of test results.Typical Values for Different Transformer Families

Reference tables categorize typical 2-FAL and CO₂ concentration values based on transformer types such as generation step-up units (GSU), network transmission, large and industrial distribution units, and low-voltage DC (LVDC) transformers.Estimation and Monitoring Procedure

The report describes a practical approach and flowchart for estimating the thermal degradation rate and remaining paper life, guiding asset managers in planning maintenance and operational decisions effectively.

Applications

Transformer Life Management

IEC TR 62874 helps utilities and industries assess the remaining lifespan of transformers by tracking thermal ageing markers, enabling targeted maintenance and replacement strategies.Condition Monitoring Programs

The standard supports the implementation of condition-based monitoring by recommending test frequencies and interpretation methods for dissolved gas analysis related to cellulose degradation.Asset Optimization and Risk Reduction

By providing early warning signs of paper degradation, this guidance enables operators to reduce the risk of unexpected transformer failure, optimize performance, and improve safety.Oil Analysis Laboratories

Testing facilities gain a benchmark to standardize measurement and reporting of 2-FAL and CO₂ levels, ensuring consistency across international inspections.

Related Standards

IEC 60354 – Guides procedures for determining degree of polymerization (DP) of paper insulation, complementing thermal life estimation through chemical markers.

IEC 60599 – Deals with dissolved gas analysis (DGA) in transformer oil, including methods for detecting gases related to insulation degradation and faults.

IEC 62475 – Addresses measurement of furans in transformer insulating oil, supporting the chemical analysis of paper degradation products.

IEC 60422 – Provides maintenance guidelines for mineral insulating oils in transformers, relevant to oil condition’s effect on paper aging.

Keywords: IEC TR 62874, thermal degradation, transformer insulation, paper aging, 2-furfuraldehyde, carbon dioxide, insulating mineral oil, condition monitoring, transformer life estimation, dissolved gas analysis, insulating oil analysis, asset management, transformer maintenance, electrical standards.

Buy Documents

IEC TR 62874:2015 - Guidance on the interpretation of carbon dioxide and 2-furfuraldehyde as markers of paper thermal degradation in insulating mineral oil/5/2015

IEC TR 62874:2015 - Guidance on the interpretation of carbon dioxide and 2-furfuraldehyde as markers of paper thermal degradation in insulating mineral oil Released:5/5/2015

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC TR 62874:2015 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Guidance on the interpretation of carbon dioxide and 2-furfuraldehyde as markers of paper thermal degradation in insulating mineral oil". This standard covers: IEC TR 62874:2015 is a Technical Report which provides guidance for the estimation of consumed thermal life of transformers' cellulosic insulators, through the analysis of some compound dissolved in the insulating mineral oil. A comparison between analytical results of 2-furfural (2-FAL) and carbon oxides and their correspondent typical values estimated for different families of equipment gives information on the estimated thermal degradation of papers.

IEC TR 62874:2015 is a Technical Report which provides guidance for the estimation of consumed thermal life of transformers' cellulosic insulators, through the analysis of some compound dissolved in the insulating mineral oil. A comparison between analytical results of 2-furfural (2-FAL) and carbon oxides and their correspondent typical values estimated for different families of equipment gives information on the estimated thermal degradation of papers.

IEC TR 62874:2015 is classified under the following ICS (International Classification for Standards) categories: 29.040.10 - Insulating oils. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 62874:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TR 62874 ®

Edition 1.0 2015-05

TECHNICAL

REPORT

Guidance on the interpretation of carbon dioxide and 2-furfuraldehyde as

markers of paper thermal degradation in insulating mineral oil

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 15

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 60 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC TR 62874 ®

Edition 1.0 2015-05

TECHNICAL

REPORT

Guidance on the interpretation of carbon dioxide and 2-furfuraldehyde as

markers of paper thermal degradation in insulating mineral oil

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.040.10 ISBN 978-2-8322-2661-2

– 2 – IEC TR 62874:2015 © IEC 2015

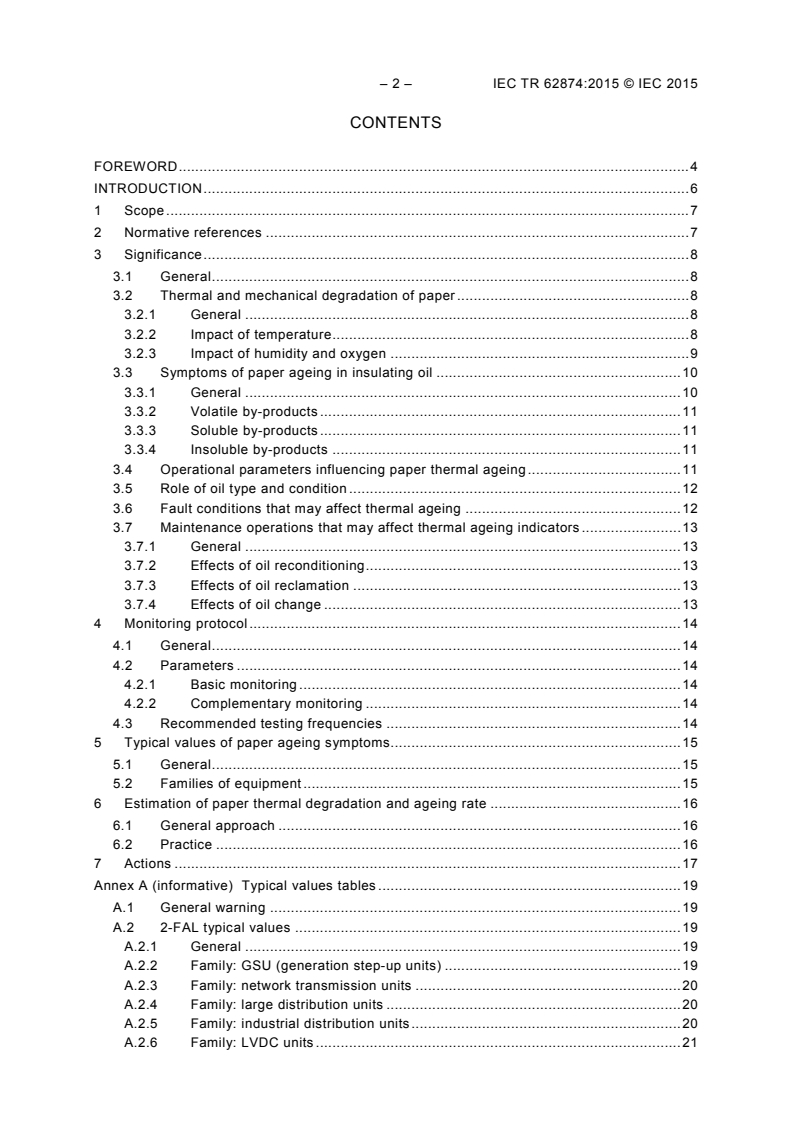

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Significance . 8

3.1 General . 8

3.2 Thermal and mechanical degradation of paper . 8

3.2.1 General . 8

3.2.2 Impact of temperature . 8

3.2.3 Impact of humidity and oxygen . 9

3.3 Symptoms of paper ageing in insulating oil . 10

3.3.1 General . 10

3.3.2 Volatile by-products . 11

3.3.3 Soluble by-products . 11

3.3.4 Insoluble by-products . 11

3.4 Operational parameters influencing paper thermal ageing . 11

3.5 Role of oil type and condition . 12

3.6 Fault conditions that may affect thermal ageing . 12

3.7 Maintenance operations that may affect thermal ageing indicators . 13

3.7.1 General . 13

3.7.2 Effects of oil reconditioning . 13

3.7.3 Effects of oil reclamation . 13

3.7.4 Effects of oil change . 13

4 Monitoring protocol . 14

4.1 General . 14

4.2 Parameters . 14

4.2.1 Basic monitoring . 14

4.2.2 Complementary monitoring . 14

4.3 Recommended testing frequencies . 14

5 Typical values of paper ageing symptoms . 15

5.1 General . 15

5.2 Families of equipment . 15

6 Estimation of paper thermal degradation and ageing rate . 16

6.1 General approach . 16

6.2 Practice . 16

7 Actions . 17

Annex A (informative) Typical values tables . 19

A.1 General warning . 19

A.2 2-FAL typical values . 19

A.2.1 General . 19

A.2.2 Family: GSU (generation step-up units) . 19

A.2.3 Family: network transmission units . 20

A.2.4 Family: large distribution units . 20

A.2.5 Family: industrial distribution units . 20

A.2.6 Family: LVDC units . 21

A.3 Carbon dioxide typical values. 21

A.3.1 General . 21

A.3.2 Family: GSU (generation step-up units) . 21

A.3.3 Family: network transmission units . 21

A.3.4 Family: large distribution units . 22

A.3.5 Family: industrial distribution units . 22

A.3.6 Family: LVDC units . 22

Bibliography . 23

Figure 1 – Schematic diagram showing rate of ageing k, depending on different ageing

mechanisms . 9

Figure 2 – Relationship between mechanical properties of insulating paper and paper

degree of polymerization (DP) [5]. . 10

Figure 3 – Example of flow-chart for the estimation of paper degradation conditions . 17

Table A.1 – 2-FAL typical values for GSU transformers, filled with uninhibited mineral

oil (based on a population of 1 860 units) . 19

Table A.2 – 2-FAL typical values for GSU transformers, filled with inhibited mineral oil

(based on a population of 176 units) . 19

Table A.3 – 2-FAL typical values for network transmission transformers, filled with

uninhibited mineral oil (based on a population of 2 845 units) . 20

Table A.4 – 2-FAL typical values for large distribution transformers, with open

breathing conservator, filled with uninhibited mineral oil (based on a population of

7 107 units) . 20

Table A.5 – 2-FAL typical values for large distribution transformers, with sealed

conservator, filled with uninhibited mineral oil (based on a population of 288 units) . 20

Table A.6 – 2-FAL typical values for industrial distribution transformers, filled with

uninhibited mineral oil (based on a population of 3 885 units) . 20

Table A.7 – 2-FAL typical values for LVDC transformers, filled with uninhibited mineral

oil (based on a population of 360 units) . 21

Table A.8 – CO typical values for GSU and excitation transformers, filled with

uninhibited mineral oil (based on a population of 1 098 units) . 21

Table A.9 – CO typical values for network transmission transformers, filled with

uninhibited mineral oil (based on a population of 435 units) . 21

Table A.10 – CO typical values for large distribution transformers, filled with

uninhibited mineral oil (based on a population of 7 291 units) . 22

Table A.11 – CO typical values for industrial distribution transformers, filled with

uninhibited mineral oil (based on a population of 4 556 units) . 22

Table A.12 – CO typical values for LVDC transformers, filled with uninhibited mineral

oil (based on a population of 273 units) . 22

– 4 – IEC TR 62874:2015 © IEC 2015

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

GUIDANCE ON THE INTERPRETATION OF CARBON DIOXIDE

AND 2-FURFURALDEHYDE AS MARKERS OF PAPER THERMAL

DEGRADATION IN INSULATING MINERAL OIL

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a Technical Report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC TR 62874, which is a Technical Report, has been prepared by IEC technical committee

10: Fluids for electrotechnical applications.

The text of this standard is based on the following documents:

Enquiry draft Report on voting

10/903/DTR 10/917A/RVC

Full information on the voting for the approval of this Technical Report can be found in the

report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – IEC TR 62874:2015 © IEC 2015

INTRODUCTION

The cellulosic solid insulation of transformers and other electrical apparatus is subject to

thermal degradation during their operational lifetime. This results in a progressive loss of

paper’s mechanical properties, such as tensile strength, which are related to the duration of

the technical life of the equipment [3,4] .

During its thermal degradation process (also called “ageing” in this Technical Report),

cellulose forms several by-products, some of which may be detected by means of insulating

oil’s chemical analysis [1,2]. The concentration and rate of increase of those by-products can

be used as a tool to estimate the progress of paper thermal degradation in transformers and

other electrical apparata in service.

For this reason, IEC technical committee 10 has prepared this Technical Report for the

monitoring of insulating oil parameters related to cellulose ageing and the interpretation of

results, as a guidance to the thermal degradation evaluation of insulating paper.

This Technical Report is based on the evaluation of cellulose ageing by-products content in

insulating oil, and their rate of formation during the life of the oil-immersed electrical

equipment. Statistical reference values reported in Annex A of this Technical Report are

based on data collected by TC10. The final report of CIGRE WG D1.01.TF13 [7] was taken as

a source of information concerning mechanisms and parameters influencing the formation of

furanic compounds.

NOTE Methods for the estimation of actual degree of polymerization (DP) values of paper, which are widely

available in literature, were not applied within this Technical Report. This is due to the fact that a number of

different models have been developed and reported, and they often lead to different results. Moreover, the

applicability of those models has not been sufficiently proven by comparison with field experience to be included

into an IEC standard.

Health and safety

This Technical Report does not purport to address all the safety problems associated with its

use. It is the responsibility of the user of the Technical Report to establish appropriate health

and safety practices and determine the applicability of regulatory limitations prior to use.

The mineral oils which are the subject of this Technical Report should be handled with due

regard to personal safety and hygiene. Direct contact with eyes may cause slight irritation. In

the case of eye contact, irrigation with copious quantities of clean running water should be

carried out and medical advice sought.

Some of the tests specified in this Technical Report involve the use of processes that could

lead to a hazardous situation. Attention is drawn to the relevant standard for guidance.

Environment

This Technical Report involves mineral oils, chemicals and used sample containers. The

disposal of these items should be carried out in accordance with current national legislation

with regard to the impact on the environment. Every precaution should be taken to prevent the

release into the environment of mineral oil.

___________

Figures in square brackets refer to the Bibliography

GUIDANCE ON THE INTERPRETATION OF CARBON DIOXIDE

AND 2-FURFURALDEHYDE AS MARKERS OF PAPER THERMAL

DEGRADATION IN INSULATING MINERAL OIL

1 Scope

IEC TR 62874, which is a Technical Report provides guidance for the estimation of consumed

thermal life of transformers' cellulosic insulators, through the analysis of some compound

dissolved in the insulating mineral oil. A comparison between analytical results of 2-furfural

(2-FAL) and carbon oxides and their correspondent typical values estimated for different

families of equipment gives information on the estimated thermal degradation of papers.

The ageing rate of insulating papers can be evaluated, in short time ranges (e.g. 1 year), by

regularly monitoring 2-FAL and carbon oxides content in the oil and by comparing them to

typical rates of increase.

A statistical approach for the estimation of paper thermal degradation, and the evaluation of

ageing rate is given.

Typical values for concentrations and rates of increase of the parameters related to paper

ageing were extrapolated from a statistical database collected, and are reported in Annex A.

They may be used as a rough guide, but they should not be considered as threshold values.

This Technical Report is only applicable to transformers and reactors filled with insulating

mineral oils and insulated with Kraft paper. The approaches and procedures specified should

be taken as a practical guidance to investigate the thermal degradation of cellulosic

insulation, and not as an algorithm to calculate the actual degree of polymerization (DP) of

papers.

The paper thermal life evaluation protocol described in this Technical Report applies to

mineral oil impregnated transformers and reactors, insulated with Kraft paper. Any equipment

filled with insulating liquids other than mineral oil (i.e. esters, silicones) or insulated with solid

materials other than Kraft paper (i.e. TUP – thermally upgraded Kraft paper, synthetic

polymers) is outside of the scope of this Technical Report.

This Technical Report is applicable to equipment that has been submitted to a regular

monitoring practice during the service, and for which maintenance and fault history is known.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

None.

– 8 – IEC TR 62874:2015 © IEC 2015

3 Significance

3.1 General

This Technical Report describes a statistical approach to paper thermal life evaluation. This

means that all typical values are obtained from populations of transformers belonging to the

same family for technical characteristics and application (see Annex A).

The approach used to collect statistical data, described in 6.1, can be applied by utilities or

owners having a large population of units, to calculate individual reference values related to a

specific family of transformers or reactors. This is very important because different population

of transformers (i.e. operating in different climates or under different operational conditions)

may have different typical values.

NOTE For an extensive survey on furanic compounds as markers for diagnosis of paper insulation degradation,

see CIGRE Brochure 494/2012 [7].

3.2 Thermal and mechanical degradation of paper

3.2.1 General

There are main factors: design and materials, contaminants in the insulation system and

operational conditions, that will determine the ageing of a transformer [1,2]. For the solid

insulation – paper and pressboard – it means a combination of mechanical and dielectric

performance, which are interlinked and synergetic. For a transformer, in the context of

thermal ageing, it is the mechanical strength of the paper that matters. The ageing of paper

results in a decreased mechanical strength and is assumed to reduce the ability of the

transformer to withstand short circuit stress. This, however, has not been statistically

demonstrated, yet.

Tensile strength, elongation and folding strength all decay with time, and more quickly at

higher temperatures.

The mechanical performance of cellulosic insulation is given in terms of tensile index or

degree of polymerization (DP), which are strongly influenced by ageing. The DP value is an

average value of chain lengths of the cellulose molecules given as a number of glucose rings

in a cellulose chain. It is measured through measurement of the viscosity of a paper solution,

according to IEC 60450 [8].

It is more convenient to perform DP than tensile index, because of the limited amount of

paper accessible for tests; therefore it is widely used for the evaluation of the cellulosic

ageing status.

There are three main processes of degradation:

– hydrolysis;

– oxidation;

– pyrolysis.

3.2.2 Impact of temperature

Temperature affects the rate of degradation. This fact is reflected in IEC 60076-7 [3] and

IEEE Std C57.91 [4] transformer loading guides.

IEC 60076-7 [3] suggests in accordance with Montsinger that the life of a transformer can be

described according to Equation (1):

−p×θ

e

Life duration = (1)

where:

p is a constant (a value of 6 is suggested in the range 80 °C to 140 °C)

θ is the temperature in degrees Celsius.

This is a simplified version of Arrhenius law used in IEEE Std C57.91 [4].

Since a precise end-of-line criterion for a transformer is not really available, IEEE and IEC

standards use an approach where ageing rate is considered. This is the inverse of lifetime –

in Montsinger form:

p×θ

×e (2)

Rate of ageing = constant

The constant in Equation (2) is dependent on many parameters, e.g. original quality of

cellulosic products as well as environmental parameters (moisture content and oxygen in the

system). A graphical representation of these influences is shown in Figure 1.

Pyrolysis

Mixed mechanism –

non linear plot

Hydrolysis

Oxidation

1/T

IEC

Figure 1 – Schematic diagram showing rate of ageing k,

depending on different ageing mechanisms

3.2.3 Impact of humidity and oxygen

Humidity and oxygen ingress (oxidation) have an important impact on the ageing of Kraft

paper. This means not only that the mechanical strength of paper rapidly decreases under

ingress of moisture and air, but practically causes an increasing contamination of the

combined liquid-solid insulation under these conditions. It is a consequence of the

degradation products formed from oil and paper leading to a further degradation.

During the ageing of the combined cellulosic and oil insulation many by-products are formed –

carbon oxides, water, acids, sludge and furanic compounds. Many of these degradation

products, e.g. furanic compounds, are soluble in oil and stable enough to be used as

diagnostic markers. Furanics are formed by dehydration reactions following hydrolysis of the

cellulose and hemicellulose as well as by oxidative pyrolysis of cellulose. Their analytical

determination is well known and reliable (see IEC 61198 [12]).

In a transformer all these processes – hydrolysis, oxidation and pyrolysis – act

simultaneously, resulting in a non-linear mechanism (see Figure 1). Which process will

dominate depends on the temperature and the operational parameters. In fact the application

of one activation energy, although often practiced, is very difficult because of the complexity

of the degradation processes.

Ln k

– 10 – IEC TR 62874:2015 © IEC 2015

3.3 Symptoms of paper ageing in insulating oil

3.3.1 General

The ageing of paper can be detected by direct investigation on the paper or by the

measurement of by-products dissolved in the oil.

Cellulose degradation mainly affects the mechanical properties (tensile strength, elongation,

burst strength, double fold strength, etc.) of paper (see Figure 2), but a direct measure of

those parameters requires the sampling of a large amount of paper, which is normally

impossible during the operational lifetime of a transformer. However, the relationship between

the mechanical indexes and the degree of polymerization (DP) is well known. Degradation of

paper does not significantly affect its resistance to the compression forces mostly and

continuously applied to transformer windings through clamping.

0,5

Severe ageing

Moderate ageing

0 0,5 1

Relative degree of polymerisation

IEC

Figure 2 – Relationship be

...

IEC TR 62874 ®

Edition 1.0 2015-05

TECHNICAL

REPORT

RAPPORT

TECHNIQUE

Guidance on the interpretation of carbon dioxide and 2-furfuraldehyde as

markers of paper thermal degradation in insulating mineral oil

Guide pour l’interprétation du dioxyde de carbone et du 2-furfuraldéhyde

comme marqueurs de la dégradation thermique du papier dans de l’huile

minérale isolante

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 15

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

65 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC TR 62874 ®

Edition 1.0 2015-05

TECHNICAL

REPORT

RAPPORT

TECHNIQUE

Guidance on the interpretation of carbon dioxide and 2-furfuraldehyde as

markers of paper thermal degradation in insulating mineral oil

Guide pour l’interprétation du dioxyde de carbone et du 2-furfuraldéhyde

comme marqueurs de la dégradation thermique du papier dans de l’huile

minérale isolante

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.040.10 ISBN 978-2-8322-3085-5

– 2 – IEC TR 62874:2015 © IEC 2015

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Significance . 8

3.1 General . 8

3.2 Thermal and mechanical degradation of paper . 8

3.2.1 General . 8

3.2.2 Impact of temperature . 8

3.2.3 Impact of humidity and oxygen . 9

3.3 Symptoms of paper ageing in insulating oil . 10

3.3.1 General . 10

3.3.2 Volatile by-products . 11

3.3.3 Soluble by-products . 11

3.3.4 Insoluble by-products . 11

3.4 Operational parameters influencing paper thermal ageing . 11

3.5 Role of oil type and condition . 12

3.6 Fault conditions that may affect thermal ageing . 12

3.7 Maintenance operations that may affect thermal ageing indicators . 13

3.7.1 General . 13

3.7.2 Effects of oil reconditioning . 13

3.7.3 Effects of oil reclamation . 13

3.7.4 Effects of oil change . 13

4 Monitoring protocol . 14

4.1 General . 14

4.2 Parameters . 14

4.2.1 Basic monitoring . 14

4.2.2 Complementary monitoring . 14

4.3 Recommended testing frequencies . 14

5 Typical values of paper ageing symptoms . 15

5.1 General . 15

5.2 Families of equipment . 15

6 Estimation of paper thermal degradation and ageing rate . 16

6.1 General approach . 16

6.2 Practice . 16

7 Actions . 17

Annex A (informative) Typical values tables . 19

A.1 General warning . 19

A.2 2-FAL typical values . 19

A.2.1 General . 19

A.2.2 Family: GSU (generation step-up units) . 19

A.2.3 Family: network transmission units . 20

A.2.4 Family: large distribution units . 20

A.2.5 Family: industrial distribution units . 20

A.2.6 Family: LVDC units . 21

A.3 Carbon dioxide typical values. 21

A.3.1 General . 21

A.3.2 Family: GSU (generation step-up units) . 21

A.3.3 Family: network transmission units . 21

A.3.4 Family: large distribution units . 22

A.3.5 Family: industrial distribution units . 22

A.3.6 Family: LVDC units . 22

Bibliography . 23

Figure 1 – Schematic diagram showing rate of ageing k, depending on different ageing

mechanisms . 9

Figure 2 – Relationship between mechanical properties of insulating paper and paper

degree of polymerization (DP) [5] . 10

Figure 3 – Example of flow-chart for the estimation of paper degradation conditions . 17

Table A.1 – 2-FAL typical values for GSU transformers, filled with uninhibited mineral

oil (based on a population of 1 860 units) . 19

Table A.2 – 2-FAL typical values for GSU transformers, filled with inhibited mineral oil

(based on a population of 176 units) . 19

Table A.3 – 2-FAL typical values for network transmission transformers, filled with

uninhibited mineral oil (based on a population of 2 845 units) . 20

Table A.4 – 2-FAL typical values for large distribution transformers, with open

breathing conservator, filled with uninhibited mineral oil (based on a population of

7 107 units) . 20

Table A.5 – 2-FAL typical values for large distribution transformers, with sealed

conservator, filled with uninhibited mineral oil (based on a population of 288 units) . 20

Table A.6 – 2-FAL typical values for industrial distribution transformers, filled with

uninhibited mineral oil (based on a population of 3 885 units) . 20

Table A.7 – 2-FAL typical values for LVDC transformers, filled with uninhibited mineral

oil (based on a population of 360 units) . 21

Table A.8 – CO typical values for GSU and excitation transformers, filled with

uninhibited mineral oil (based on a population of 1 098 units) . 21

Table A.9 – CO typical values for network transmission transformers, filled with

uninhibited mineral oil (based on a population of 435 units) . 21

Table A.10 – CO typical values for large distribution transformers, filled with

uninhibited mineral oil (based on a population of 7 291 units) . 22

Table A.11 – CO typical values for industrial distribution transformers, filled with

uninhibited mineral oil (based on a population of 4 556 units) . 22

Table A.12 – CO typical values for LVDC transformers, filled with uninhibited mineral

oil (based on a population of 273 units) . 22

– 4 – IEC TR 62874:2015 © IEC 2015

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

GUIDANCE ON THE INTERPRETATION OF CARBON DIOXIDE

AND 2-FURFURALDEHYDE AS MARKERS OF PAPER THERMAL

DEGRADATION IN INSULATING MINERAL OIL

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a Technical Report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC TR 62874, which is a Technical Report, has been prepared by IEC technical committee

10: Fluids for electrotechnical applications.

This bilingual version (2016-01) corresponds to the English version, published in 2015-05.

The text of this Technical Report is based on the following documents:

Enquiry draft Report on voting

10/903/DTR 10/917A/RVC

Full information on the voting for the approval of this Technical Report can be found in the

report on voting indicated in the above table.

The French version of this Technical Report has note been voted upon.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC TR 62874:2015 © IEC 2015

INTRODUCTION

The cellulosic solid insulation of transformers and other electrical apparatus is subject to

thermal degradation during their operational lifetime. This results in a progressive loss of

paper’s mechanical properties, such as tensile strength, which are related to the duration of

the technical life of the equipment [3,4] .

During its thermal degradation process (also called “ageing” in this Technical Report),

cellulose forms several by-products, some of which may be detected by means of insulating

oil’s chemical analysis [1,2]. The concentration and rate of increase of those by-products can

be used as a tool to estimate the progress of paper thermal degradation in transformers and

other electrical apparata in service.

For this reason, IEC technical committee 10 has prepared this Technical Report for the

monitoring of insulating oil parameters related to cellulose ageing and the interpretation of

results, as a guidance to the thermal degradation evaluation of insulating paper.

This Technical Report is based on the evaluation of cellulose ageing by-products content in

insulating oil, and their rate of formation during the life of the oil-immersed electrical

equipment. Statistical reference values reported in Annex A of this Technical Report are

based on data collected by TC10. The final report of CIGRE WG D1.01.TF13 [7] was taken as

a source of information concerning mechanisms and parameters influencing the formation of

furanic compounds.

NOTE Methods for the estimation of actual degree of polymerization (DP) values of paper, which are widely

available in literature, were not applied within this Technical Report. This is due to the fact that a number of

different models have been developed and reported, and they often lead to different results. Moreover, the

applicability of those models has not been sufficiently proven by comparison with field experience to be included

into an IEC standard.

Health and safety

This Technical Report does not purport to address all the safety problems associated with its

use. It is the responsibility of the user of the Technical Report to establish appropriate health

and safety practices and determine the applicability of regulatory limitations prior to use.

The mineral oils which are the subject of this Technical Report should be handled with due

regard to personal safety and hygiene. Direct contact with eyes may cause slight irritation. In

the case of eye contact, irrigation with copious quantities of clean running water should be

carried out and medical advice sought.

Some of the tests specified in this Technical Report involve the use of processes that could

lead to a hazardous situation. Attention is drawn to the relevant standard for guidance.

Environment

This Technical Report involves mineral oils, chemicals and used sample containers. The

disposal of these items should be carried out in accordance with current national legislation

with regard to the impact on the environment. Every precaution should be taken to prevent the

release into the environment of mineral oil.

___________

Figures in square brackets refer to the Bibliography.

GUIDANCE ON THE INTERPRETATION OF CARBON DIOXIDE

AND 2-FURFURALDEHYDE AS MARKERS OF PAPER THERMAL

DEGRADATION IN INSULATING MINERAL OIL

1 Scope

IEC TR 62874, which is a Technical Report, provides guidance for the estimation of

consumed thermal life of transformers' cellulosic insulators, through the analysis of some

compound dissolved in the insulating mineral oil. A comparison between analytical results of

2-furfural (2-FAL) and carbon oxides and their correspondent typical values estimated for

different families of equipment gives information on the estimated thermal degradation of

papers.

The ageing rate of insulating papers can be evaluated, in short time ranges (e.g. 1 year), by

regularly monitoring 2-FAL and carbon oxides content in the oil and by comparing them to

typical rates of increase.

A statistical approach for the estimation of paper thermal degradation, and the evaluation of

ageing rate is given.

Typical values for concentrations and rates of increase of the parameters related to paper

ageing were extrapolated from a statistical database collected, and are reported in Annex A.

They may be used as a rough guide, but they should not be considered as threshold values.

This Technical Report is only applicable to transformers and reactors filled with insulating

mineral oils and insulated with Kraft paper. The approaches and procedures specified should

be taken as a practical guidance to investigate the thermal degradation of cellulosic

insulation, and not as an algorithm to calculate the actual degree of polymerization (DP) of

papers.

The paper thermal life evaluation protocol described in this Technical Report applies to

mineral oil impregnated transformers and reactors, insulated with Kraft paper. Any equipment

filled with insulating liquids other than mineral oil (i.e. esters, silicones) or insulated with solid

materials other than Kraft paper (i.e. TUP – thermally upgraded Kraft paper, synthetic

polymers) is outside of the scope of this Technical Report.

This Technical Report is applicable to equipment that has been submitted to a regular

monitoring practice during the service, and for which maintenance and fault history is known.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

None.

– 8 – IEC TR 62874:2015 © IEC 2015

3 Significance

3.1 General

This Technical Report describes a statistical approach to paper thermal life evaluation. This

means that all typical values are obtained from populations of transformers belonging to the

same family for technical characteristics and application (see Annex A).

The approach used to collect statistical data, described in 6.1, can be applied by utilities or

owners having a large population of units, to calculate individual reference values related to a

specific family of transformers or reactors. This is very important because different population

of transformers (i.e. operating in different climates or under different operational conditions)

may have different typical values.

NOTE For an extensive survey on furanic compounds as markers for diagnosis of paper insulation degradation,

see CIGRE Brochure 494/2012 [7].

3.2 Thermal and mechanical degradation of paper

3.2.1 General

There are main factors: design and materials, contaminants in the insulation system and

operational conditions, that will determine the ageing of a transformer [1,2]. For the solid

insulation – paper and pressboard – it means a combination of mechanical and dielectric

performance, which are interlinked and synergetic. For a transformer, in the context of

thermal ageing, it is the mechanical strength of the paper that matters. The ageing of paper

results in a decreased mechanical strength and is assumed to reduce the ability of the

transformer to withstand short circuit stress. This, however, has not been statistically

demonstrated, yet.

Tensile strength, elongation and folding strength all decay with time, and more quickly at

higher temperatures.

The mechanical performance of cellulosic insulation is given in terms of tensile index or

degree of polymerization (DP), which are strongly influenced by ageing. The DP value is an

average value of chain lengths of the cellulose molecules given as a number of glucose rings

in a cellulose chain. It is measured through measurement of the viscosity of a paper solution,

according to IEC 60450 [8].

It is more convenient to perform DP than tensile index, because of the limited amount of

paper accessible for tests; therefore it is widely used for the evaluation of the cellulosic

ageing status.

There are three main processes of degradation:

– hydrolysis;

– oxidation;

– pyrolysis.

3.2.2 Impact of temperature

Temperature affects the rate of degradation. This fact is reflected in IEC 60076-7 [3] and

IEEE Std C57.91 [4] transformer loading guides.

IEC 60076-7 [3] suggests in accordance with Montsinger that the life of a transformer can be

described according to Equation (1):

−p×θ

Life duration = e (1)

where:

p is a constant (a value of 6 is suggested in the range 80 °C to 140 °C)

θ is the temperature in degrees Celsius.

This is a simplified version of Arrhenius law used in IEEE Std C57.91 [4].

Since a precise end-of-line criterion for a transformer is not really available, IEEE and IEC

standards use an approach where ageing rate is considered. This is the inverse of lifetime –

in Montsinger form:

p×θ

×e

Rate of ageing = constant (2)

The constant in Equation (2) is dependent on many parameters, e.g. original quality of

cellulosic products as well as environmental parameters (moisture content and oxygen in the

system). A graphical representation of these influences is shown in Figure 1.

Pyrolysis

Mixed mechanism –

non linear plot

Hydrolysis

Oxidation

1/T

IEC

Figure 1 – Schematic diagram showing rate of ageing k,

depending on different ageing mechanisms

3.2.3 Impact of humidity and oxygen

Humidity and oxygen ingress (oxidation) have an important impact on the ageing of Kraft

paper. This means not only that the mechanical strength of paper rapidly decreases under

ingress of moisture and air, but practically causes an increasing contamination of the

combined liquid-solid insulation under these conditions. It is a consequence of the

degradation products formed from oil and paper leading to a further degradation.

During the ageing of the combined cellulosic and oil insulation many by-products are formed –

carbon oxides, water, acids, sludge and furanic compounds. Many of these degradation

products, e.g. furanic compounds, are soluble in oil and stable enough to be used as

diagnostic markers. Furanics are formed by dehydration reactions following hydrolysis of the

cellulose and hemicellulose as well as by oxidative pyrolysis of cellulose. Their analytical

determination is well known and reliable (see IEC 61198 [12]).

In a transformer all these processes – hydrolysis, oxidation and pyrolysis – act

simultaneously, resulting in a non-linear mechanism (see Figure 1). Which process will

dominate depends on the temperature and the operational parameters. In fact the application

of one activation energy, although often practiced, is very difficult because of the complexity

of the degradation processes.

Ln k

– 10 – IEC TR 62874:2015 © IEC 2015

3.3 Symptoms of paper ageing in insulating oil

3.3.1 General

The ageing of paper can be detected by direct investigation on the paper or by the

measurement of by-products dissolved in the oil.

Cellulose degradation mainly affects the mechanical properties (tensile strength, elongation,

burst strength, double fold strength, etc.) of paper (see Figure 2), but a direct measure of

those parameters requires the sampling of a large amount of paper, which is normally

impossible during the operational lifetime of a transformer. However, the relationship between

the mechanical indexes and the degree of polymerization (DP) is well known. Degradation of

paper does not significantly affect its resistance to the compression forces mostly and

continuously applied to transformer windings through clamping.

0,5

Severe ageing

Moderate ageing

0 0,5 1

Relative degree of polymerisation

IEC

Figure 2 – Relationship between mechanical properties of

insulating paper and paper degree of polymerization (DP) [5]

The DP value is the average number of glycoside rings in the cellulose polymer; in the native

cellulose DP may be as high as or more than 10 000 units but after the purification process

and other treatments the DP value of the electrical Kraft paper decreases to around

1 000 units (typical value: 1 200).

DP is measured in accordance with IEC 60450 [8], through measurement of the specific

viscosity of a very small amount of paper dissolved in cupri-ethylene-diamine (CuED). From

this measurement the intrinsic viscosity of solution is deduced and from this, using the

Martin’s formula, the DP value is easily calculated.

By-products of aged paper may be classified as volatile, soluble and insoluble, and are

dependent on the specific decomposition process: pyrolysis, hydrolysis or oxidation.

Relative value of indicated parameter

3.3.2 Volatile by-products

Carbon oxides (CO and CO ) are the ultimate products of cellulose degradation and are

measured with dissolved gas analysis (DGA) in accordance with IEC 60567 [9]. It must be

taken into account that both CO and CO can be generated from oil oxidation as well.

Water can reach several per cent of the paper weight. Most of the water formed is adsorbed

and retained in the solid insulation of the transformer and only a little part is dissolved in oil.

Of course another contribution to total water is the ingress of moisture from atmosphere.

The detection of water in oil is performed in accordance with IEC 60814 [10].

3.3.3 Soluble by-products

A large number of oil soluble compounds (acids, alcohols, etc.) are generated from paper

degradation. The most commonly used compound for diagnosis is 2-furfural (2-FAL) and its

related compounds:

– 5 hydroxymethyl 2-furfural (5-HMF)

– 2 furfurylalcohol (2-FOL)

– 2 acetylfuran (2-ACF)

– 5 methyl 2-furfural (5-MEF).

The detection of 2-FAL and related compounds in oil is performed in accordance with

IEC 61198 [12].

In the same way as with water, a relevant amount of generated furanic compounds is retained

in the bulk of the paper. The ratio between the concentration of furanic compounds in the

paper and in the oil differs for each single compound, and is affected by temperature.

Increased temperature forces the equilibrium of furanic compounds to a higher concentration

in the oil. Decreased temperature forces the equilibrium of furanic compounds to a higher

concentration in the paper, especially in the case of dry paper.

Paper humidity and type of paper also influence the oil-to-paper concentration ratio of furanic

compounds. A wet paper tends to retain a larger amount of furanic compounds, thus reducing

the oil-to-paper concentration ratio.

Furanic compounds are not highly stable, and may be degraded by oxidation, mostly in oils

with high oxygen content. Decay in the concentration of 2-FAL was observed in transformers

during their operation, due to its inherent instability.

Acid compounds may be formed either by cellulose and/or oil oxidation, and a high acidity

often accompanies other symptoms of paper ageing.

3.3.4 Insoluble by-products

Severe paper ageing can finally lead to the fragmentation of polymeric cellulose, and small

paper fibres can be detached from the paper mass.

The cellulose fibres can be detected as particles present in insulating oil, in accordance with

IEC 60970 [11].

3.4 Operational parameters influencing paper thermal ageing

In addition to transformer hours of service as a key parameter in defining “real age” of paper

insulation in normal working regimes, other operational parameters such as load, type of

cooling and transformer sub-type have a major influence on paper thermal ageing. The nature

of the oil may also be a fundamental parameter for the estimation of paper thermal ageing.

– 12 – IEC TR 62874:2015 © IEC 2015

The high-load of a transformer, implying elevated operating temperatures, promotes the paper

thermal degradation process, observed with some types of transformers that are often

overloaded (shunt reactors, HVDC, generator step-up (GSU) in thermal power plants (TPP),

high voltage inter-tie transmission transformers).

The type of cooling, in terms of cooling media (water or air) and type of flow applied (forced or

natural convection), affects efficiency of heat removal, thus influencing the rate of paper

thermal degradation. The most efficient cooling can be achieved by applying water as coolant

in forced oil flow.

For example, it was observed in most cases that the degree of paper degradation with GSU

transformers in hydro power plants (HPP) is lower than with thermal power plant GSU units,

having a similar service duration. These findings are correlated to different types of cooling

(OFWF versus ONAF and OFAF), hours of service and loading history of HPP and TPP units

[6].

Among different transformer sub-types, air-breathing transformers are subjected to more

intensive paper degradation than sealed ones, due to higher oxygen and moisture content.

Elevated concentrations of oxygen and water accelerate the paper degradation process.

Since the paper degradation process is temperature driven, every environmental and

operational condition that may affect the temperature can also modify the degradation rate of

the solid insulation. An elevated environmental temperature or a high loading can thus

increase the rate of paper degradation, resulting in a sudden increase of 2-FAL, CO , CO and

other by-products.

3.5 Role of oil type and condition

Oil type may affect the ageing rate of paper. Inhibited oils show a lower tendency to form

acidity, and the oxidation process is slackened; the effect of oxygen in the paper oxidation

process is reduced.

Transformers impregnated with inhibited oil may show a lower content of 2-FAL if compared

with units insulated with an uninhibited oil, even if showing the same degree of polymerization

(DP) of the paper.

The effect of passivators (triazole derivates) in the ageing of celluloses is still not well

defined. By definition, metal passivators may induce a lower rate of the oil degradation

process by deactivating the copper catalyst in oxidation processes, therefore slowing down

the paper degradation process, but influence of metal passivators on 2-FAL concentration in

the oil may not be straightforward. Some laboratory studies have shown that papers

impregnated with oils to which a passivator has been added, may have a lower tendency to

form furanic compounds; this may lead to optimistic estimation of ageing in presence of

triazolic passivators.

The ageing condition of the oil may also affect the partition of furanic compounds between

solid and liquid insulation; acidic oils may result in an increased 2-FAL concentration in oil,

due to its augmented capability to extract polar compounds from the paper.

3.6 Fault conditions that may affect thermal ageing

In transformers where the degradation mechanism may be either thermal or electrical, the rate

of paper degradation may increase rapidly as a consequence of significant temperature rise.

High energy thermal and electrical faults involving excessive currents circulating through the

insulation and large current follow-through lead to extensive destruction and carbonization of

paper.

In presence of local thermal degradation due to a fault, the estimation of the paper’s

consumed thermal life may become very difficult, since the extension of the paper volume

involved is unknown, and temperature may have strong variations even over a short time.

Investigations on the presence of thermal faults through DGA should always accompany

thermal life evaluation, to avoid misleading conclusions.

High energy electrical faults (discharges of high energy) usually involve a very small volume

of paper, so that the contribution to the detected concentration of furanic compounds is

negligible. In case of discharges with paper involved, a sharp increase of carbon oxides is

observed, rather than an noticeable increase of 2-FAL. The formation of cellulose by-product

has not been found to be related to partial discharges.

3.7 Maintenance operations that may affect thermal ageing indicators

3.7.1 General

Maintenance operations on the oil may affect (partially or totally) parameters used as

indicators of cellulose thermal ageing (see 3.3). Their effects should be taken into account

during the estimation of the total 2-FAL concentration, and in evaluating the rate of increase

of the thermal ageing indicators.

3.7.2 Effects of oil reconditioning

Oil reconditioning may reduce 2-FAL concentration in oil, depending on the duration/efficiency

of the treatment.

Oil reconditioning normally does not significantly affect 2-FAL, gas and moisture

concentration in cellulose. On-line degassing or long-term reconditioning may reduce moisture

in paper.

The equilibrium of 2-FAL distribution between oil and paper is restored in a time depending on

temperature, cooling and oil circulation.

Dissolved gases and water dissolved in oil are mostly removed by vacuum degassing.

In the 6 months following a reconditioning, the rates of increase of 2-FAL, dissolved gases

and moisture should not be considered as an indicator of increased ageing rate, the

equilibrium being forced thermodynamically through the increase of concentration in the oil.

3.7.3 Effects of oil reclamation

Reclaiming the oil has major effects on the concentration of 2-FAL. Furanic compounds are

polar and they are almost completely removed by fuller’s earth and other adsorbing media.

After an oil reclamation the trend of furanic compounds should be carefully recorded (with

frequent sampling) to monitor the increase of 2-FAL, taking into account new equilibrium

conditions.

NOTE For effects of reclamation on dissolved gases and moisture see 3.7.2

3.7.4 Effects of oil change

Oil change has major effects on the concentration of 2-FAL, as well. All the by-products

dissolved in the oil are removed. Nevertheless, after an oil change a new equilibrium between

solid and liquid insulation is dependent on temperature, cooling and oil circulation.

After an oil replacement the trend of furanic compounds should be carefully recorded (with

frequent sampling) to monitor the increase of 2-FAL, taking into account new equilibrium

conditions.

NOTE For effects of oil change on dissolved gases and moisture see 3.7.2

– 14 – IEC TR 62874:2015 © IEC 2015

4 Monitoring protocol

4.1 General

A regular monitoring of parameters related to thermal ageing of cellulose is strictly required

for the estimation of paper ageing condition and its rate of thermal degradation. No evaluation

should be done and no action should be taken on the basis of a single determination.

Evaluation based on a few samples close to the end of the operational lifetime will not lead to

reliable conclusions; the approach for the estimation of paper thermal degradation repo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...