IEC 60695-9-2:2021

(Main)Fire hazard testing - Part 9-2: Surface spread of flame - Summary and relevance of test methods

Fire hazard testing - Part 9-2: Surface spread of flame - Summary and relevance of test methods

IEC 60695-9-2:2021 presents a summary of published test methods that are used to determine the surface spread of flame of electrotechnical products or materials from which they are formed.

It represents the current state of the art of the test methods and, where available, includes special observations on their relevance and use.

The list of test methods is not to be considered exhaustive, and test methods that were not developed by the IEC are not to be considered as endorsed by the IEC unless this is specifically stated.

This summary cannot be used in place of published standards which are the only valid reference documents.

This basic safety publication is intended for use by technical committees in the preparation of standards in accordance with the principles laid down in IEC Guide 104 and

ISO/IEC Guide 51.

One of the responsibilities of a technical committee is, wherever applicable, to make use of basic safety publications in the preparation of its publications. The requirements, test methods or test conditions of this basic safety publication will not apply unless specifically referred to or included in the relevant publications.

This International Standard is to be used in conjunction with IEC 60695-1.

This second edition cancels and replaces the first edition of IEC 60695-9-2 published in 2014. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a) Updated introduction

b) Updated normative references

c) Updated terms and definitions

d) New Subclauses 4.1 and 4.2

e) Reference to fire stages as defined in ISO 19706 (Table 1)

f) New sub-division of tests into the following subclauses:

4.3 Small-scale fire tests

4.4 Medium and intermediate-scale fire tests

4.5 Intermediate and large-scale fire tests for cables

4.6 Real-scale fire tests for cables

g) Updated text in parts of Clause 4

h) Addition of the following test methods:

IEC TS 60695-11-21

IEC 60684-2:2011, Clause 26

ISO 3582

ISO 9772

ISO 9773

ISO 12992

ISO 21367

i) New Clause 5 and Table 4 giving an overview of test methods

j) Deletion of all the Annexes

k) Updated bibliography

Essais relatifs aux risques du feu - Partie 9-2: Propagation des flammes en surface - Résumé et pertinence des méthodes d'essai

IEC 60695-9-2:2021 propose un résumé des méthodes d'essai publiées utilisées pour déterminer la propagation de flamme en surface des produits électrotechniques ou des matériaux dont ils sont constitués.

Elle représente l'état actuel de l'art des méthodes d'essai et, le cas échéant, elle comprend des observations particulières sur leur pertinence et leur utilisation.

La liste des méthodes d’essai ne doit pas être considérée comme exhaustive, et les méthodes d'essai qui n'ont pas été élaborées par l’IEC ne doivent pas être considérées comme étant entérinées par l’IEC, sauf si cela est spécifiquement stipulé.

Ce résumé ne peut pas se substituer aux normes publiées, qui sont les seuls documents de référence valables.

Cette publication fondamentale de sécurité est destinée à être utilisée par les comités d’études pour l’établissement de leurs normes, conformément aux principes exposés dans le Guide IEC 104 et dans le Guide ISO/IEC 51.

L'une des responsabilités d'un comité d'études consiste, le cas échéant, à utiliser les publications fondamentales de sécurité dans le cadre de l'élaboration de ses publications. Les exigences, les méthodes d'essai ou les conditions d'essai indiquées dans la présente publication fondamentale de sécurité ne s'appliquent que si elles sont référencées ou incluses dans les publications appropriées.

Cette Norme internationale doit être utilisée conjointement avec l’IEC 60695-9-1.

Cette deuxième édition annule et remplace la première édition de l’IEC 60695-9-2 parue en 2014. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) Mise à jour de l’introduction

b) Mise à jour des références normatives

c) Mise à jour des termes et définitions

d) Nouveaux Paragraphes 4.1 et 4.2

e) Référence aux stades d’incendie tels qu'ils sont définis dans l’ISO 19706 (Tableau 1)

f) Nouvelle répartition des essais dans les paragraphes suivants:

4.3 Essais au feu à petite échelle

4.4 Essais au feu à échelles moyenne et intermédiaire

4.5 Essais au feu à échelle intermédiaire et à grande échelle pour les câbles

4.6 Essais au feu en grandeur réelle pour les câbles

g) Mise à jour du texte de certaines parties de l’Article 4

h) Ajout des méthodes d'essai suivantes:

IEC TS 60695-11-21

IEC 60684-2:2011, Article 26

ISO 3582

ISO 9772

ISO 9773

ISO 12992

ISO 21367

i) Nouvel Article 5 et nouveau Tableau 4 qui donnent une vue générale des méthodes d'essai

j) Suppression de toutes les Annexes

k) Mise à jour de la bibliographie

General Information

- Status

- Published

- Publication Date

- 24-Aug-2021

- Technical Committee

- TC 89 - Fire hazard testing

- Drafting Committee

- WG 11 - TC 89/WG 11

- Current Stage

- PPUB - Publication issued

- Start Date

- 25-Aug-2021

- Completion Date

- 12-Aug-2021

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60695-9-2:2021 is an international standard published by the International Electrotechnical Commission (IEC) that provides a comprehensive summary of test methods used to assess the surface spread of flame of electrotechnical products and their constituent materials. This standard represents the current state of the art in flame spread testing and offers insights into the relevance and proper application of various test methodologies.

The primary objective of IEC 60695-9-2:2021 is to support technical committees in preparing product standards related to fire safety by delivering a consolidated reference of fire hazard testing methods specifically focused on surface flame spread. It is intended to be used alongside IEC 60695-1, enhancing the safety evaluation of electrical and electronic equipment by ensuring fire risks are minimized.

This revision replaces the 2014 edition, incorporating significant technical updates, new test method references, and enhanced terminology aligned with international practices such as ISO 19706.

Key Topics

Scope and Purpose

IEC 60695-9-2:2021 presents a detailed summary of various published test methods to evaluate the extent and rate of surface flame spread on materials used in electrotechnical products. It highlights the practical importance of these tests in assessing fire hazards, aiming to reduce fire risk through material and product design.Classification of Test Methods

The document organizes flame spread tests into four major categories:- Small-scale fire tests (e.g., IEC 60695-11-10, IEC 60684-2:2011 Clause 26, ISO 3582)

- Medium and intermediate-scale fire tests (e.g., ISO 5658-2, ISO 21367)

- Intermediate and large-scale fire tests for cables (e.g., IEC 60332 series)

- Real-scale fire tests for cables (e.g., UL 1666, EN 50289-4-11)

Fire Stages and Physical Fire Model

The standard references ISO 19706 to describe fire stages, clarifying how flame spread contributes to fire development from ignition through flashover to full development. This aligns the test methods with realistic fire scenarios.Updated References and Methods

Inclusion of new test standards such as IEC TS 60695-11-21 and ISO 12992 ensures the summary covers the latest methodologies. The removal of annexes focuses attention on direct normative references and practical testing guidelines.Relevance to Electrotechnical Product Safety

The standard stresses the importance of considering surface flame spread during design and material selection to prevent or contain fires even under reasonably foreseeable failure or misuse scenarios.

Applications

Fire Hazard Assessment in Product Design

Engineers and product developers utilize IEC 60695-9-2:2021 to select appropriate flame spread test methods when designing electrical and electronic devices. This aids in minimizing fire risks through material choices and construction practices.Standardization of Safety Tests

Technical committees across the globe leverage this standard for harmonizing fire safety testing requirements in electrotechnical product standards, ensuring consistent evaluation criteria are applied.Cable Flame Spread Evaluation

Given the specific risks associated with cables in fire propagation, the standard provides extensive guidance on large-scale and real-scale testing methods to better understand cable behavior in fire.Regulatory Compliance and Certification

Manufacturers aiming to meet regional and international fire safety regulations and certifications often refer to IEC 60695-9-2:2021 as a foundational resource for testing protocols related to flame spread.Risk Mitigation in Electrical Installations

This standard supports safety assessments that help reduce the likelihood of fire escalation within electrical installations found in buildings, transportation, and industrial environments.

Related Standards

IEC 60695-1 Series – Provides general principles and guidance on fire hazard testing for electrotechnical products. IEC 60695-9-2 is designed to be used in conjunction with this series.

IEC 60695-11 Series – Details specific test methods such as the horizontal and vertical flame tests at various power levels (50 W, 500 W).

ISO 19706 – Defines the characteristics of fire stages, supporting the interpretation of flame spread behavior in real fire conditions.

IEC 60684-2:2011 – Specifies test procedures for flexible insulating sleeving including flame propagation tests relevant for small-scale evaluations.

ISO 5658 Series – Covers medium-scale fire tests assessing lateral flame spread on building and transport products.

UL 1666 – A recognized real-scale fire test standard evaluating vertical flame propagation of cables installed in shafts.

EN 50289-4-11 – Focuses on horizontal flame spread testing for cables.

ISO 3582, ISO 9772, ISO 9773, ISO 12992, ISO 21367 – International standards covering various fire testing methods on plastics and polymeric materials relevant to flame spread characteristics.

Keywords:

IEC 60695-9-2, surface spread of flame, fire hazard testing, electrotechnical products, flame spread test methods, flame propagation, fire safety standards, cable fire tests, small-scale fire tests, medium-scale fire tests, real-scale fire tests, electrical fire risk, electrotechnical safety, IEC standards, fire stages, ISO 19706.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

NSF International

Global independent organization facilitating standards development and certification.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 60695-9-2:2021 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Fire hazard testing - Part 9-2: Surface spread of flame - Summary and relevance of test methods". This standard covers: IEC 60695-9-2:2021 presents a summary of published test methods that are used to determine the surface spread of flame of electrotechnical products or materials from which they are formed. It represents the current state of the art of the test methods and, where available, includes special observations on their relevance and use. The list of test methods is not to be considered exhaustive, and test methods that were not developed by the IEC are not to be considered as endorsed by the IEC unless this is specifically stated. This summary cannot be used in place of published standards which are the only valid reference documents. This basic safety publication is intended for use by technical committees in the preparation of standards in accordance with the principles laid down in IEC Guide 104 and ISO/IEC Guide 51. One of the responsibilities of a technical committee is, wherever applicable, to make use of basic safety publications in the preparation of its publications. The requirements, test methods or test conditions of this basic safety publication will not apply unless specifically referred to or included in the relevant publications. This International Standard is to be used in conjunction with IEC 60695-1. This second edition cancels and replaces the first edition of IEC 60695-9-2 published in 2014. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) Updated introduction b) Updated normative references c) Updated terms and definitions d) New Subclauses 4.1 and 4.2 e) Reference to fire stages as defined in ISO 19706 (Table 1) f) New sub-division of tests into the following subclauses: 4.3 Small-scale fire tests 4.4 Medium and intermediate-scale fire tests 4.5 Intermediate and large-scale fire tests for cables 4.6 Real-scale fire tests for cables g) Updated text in parts of Clause 4 h) Addition of the following test methods: IEC TS 60695-11-21 IEC 60684-2:2011, Clause 26 ISO 3582 ISO 9772 ISO 9773 ISO 12992 ISO 21367 i) New Clause 5 and Table 4 giving an overview of test methods j) Deletion of all the Annexes k) Updated bibliography

IEC 60695-9-2:2021 presents a summary of published test methods that are used to determine the surface spread of flame of electrotechnical products or materials from which they are formed. It represents the current state of the art of the test methods and, where available, includes special observations on their relevance and use. The list of test methods is not to be considered exhaustive, and test methods that were not developed by the IEC are not to be considered as endorsed by the IEC unless this is specifically stated. This summary cannot be used in place of published standards which are the only valid reference documents. This basic safety publication is intended for use by technical committees in the preparation of standards in accordance with the principles laid down in IEC Guide 104 and ISO/IEC Guide 51. One of the responsibilities of a technical committee is, wherever applicable, to make use of basic safety publications in the preparation of its publications. The requirements, test methods or test conditions of this basic safety publication will not apply unless specifically referred to or included in the relevant publications. This International Standard is to be used in conjunction with IEC 60695-1. This second edition cancels and replaces the first edition of IEC 60695-9-2 published in 2014. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) Updated introduction b) Updated normative references c) Updated terms and definitions d) New Subclauses 4.1 and 4.2 e) Reference to fire stages as defined in ISO 19706 (Table 1) f) New sub-division of tests into the following subclauses: 4.3 Small-scale fire tests 4.4 Medium and intermediate-scale fire tests 4.5 Intermediate and large-scale fire tests for cables 4.6 Real-scale fire tests for cables g) Updated text in parts of Clause 4 h) Addition of the following test methods: IEC TS 60695-11-21 IEC 60684-2:2011, Clause 26 ISO 3582 ISO 9772 ISO 9773 ISO 12992 ISO 21367 i) New Clause 5 and Table 4 giving an overview of test methods j) Deletion of all the Annexes k) Updated bibliography

IEC 60695-9-2:2021 is classified under the following ICS (International Classification for Standards) categories: 13.220.40 - Ignitability and burning behaviour of materials and products; 29.020 - Electrical engineering in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60695-9-2:2021 has the following relationships with other standards: It is inter standard links to IEC TS 60695-9-2:2005, IEC 60695-9-2:2014, IEC TS 60695-9-2:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60695-9-2:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60695-9-2 ®

Edition 2.0 2021-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

HORIZONTAL PUBLICATION

PUBLICATION HORIZONTALE

Fire hazard testing –

Part 9-2: Surface spread of flame – Summary and relevance of test methods

Essais relatifs aux risques du feu –

Partie 9-2: Propagation des flammes en surface – Résumé et pertinence

des méthodes d'essai

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC online collection - oc.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur adapté à vos besoins.

les projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au

Restez informé sur les nouvelles publications IEC. Just

monde, avec plus de 22 000 articles terminologiques en

Published détaille les nouvelles publications parues.

anglais et en français, ainsi que les termes équivalents dans

Disponible en ligne et une fois par mois par email.

16 langues additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 60695-9-2 ®

Edition 2.0 2021-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

HORIZONTAL PUBLICATION

PUBLICATION HORIZONTALE

Fire hazard testing –

Part 9-2: Surface spread of flame – Summary and relevance of test methods

Essais relatifs aux risques du feu –

Partie 9-2: Propagation des flammes en surface – Résumé et pertinence

des méthodes d'essai

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 13.220.40; 29.020 ISBN 978-2-8322-9997-5

– 2 – IEC 60695-9-2:2021 © IEC 2021

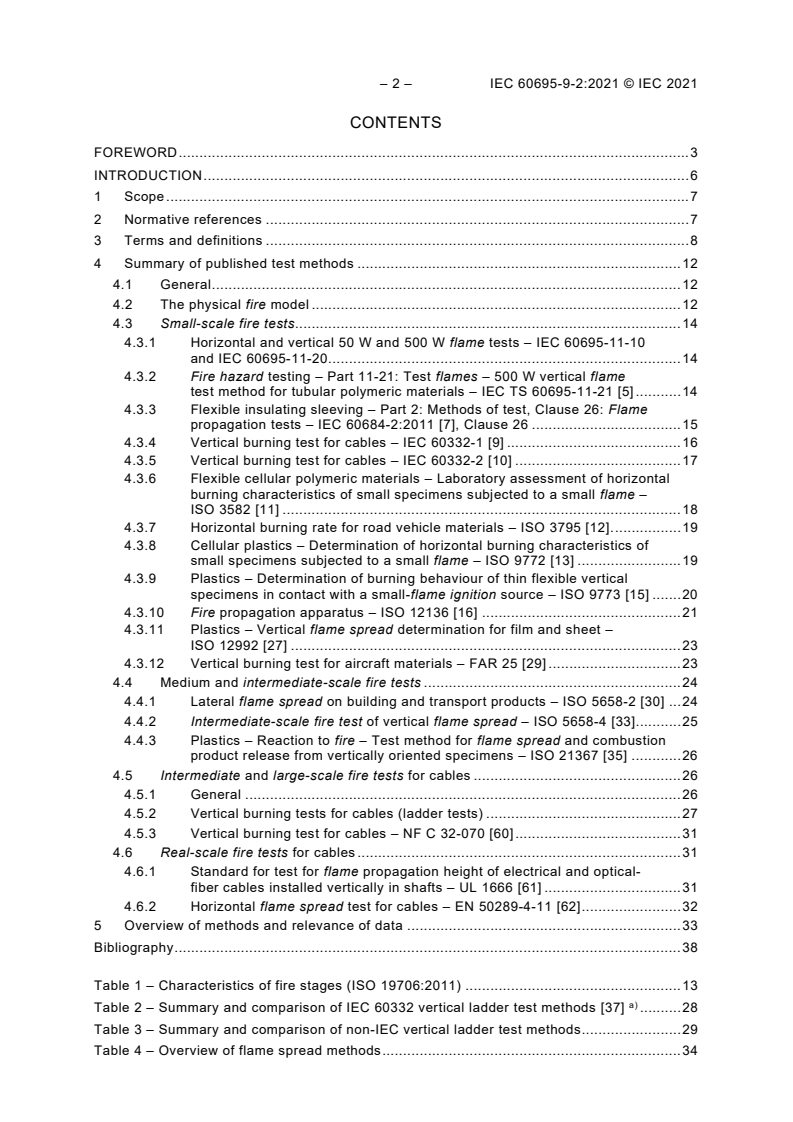

CONTENTS

FOREWORD . 3

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Summary of published test methods . 12

4.1 General . 12

4.2 The physical fire model . 12

4.3 Small-scale fire tests. 14

4.3.1 Horizontal and vertical 50 W and 500 W flame tests – IEC 60695-11-10

and IEC 60695-11-20 . 14

4.3.2 Fire hazard testing – Part 11-21: Test flames – 500 W vertical flame

test method for tubular polymeric materials – IEC TS 60695-11-21 [5] . 14

4.3.3 Flexible insulating sleeving – Part 2: Methods of test, Clause 26: Flame

propagation tests – IEC 60684-2:2011 [7], Clause 26 . 15

4.3.4 Vertical burning test for cables – IEC 60332-1 [9] . 16

4.3.5 Vertical burning test for cables – IEC 60332-2 [10] . 17

4.3.6 Flexible cellular polymeric materials – Laboratory assessment of horizontal

burning characteristics of small specimens subjected to a small flame –

ISO 3582 [11] . 18

4.3.7 Horizontal burning rate for road vehicle materials – ISO 3795 [12]. . 19

4.3.8 Cellular plastics – Determination of horizontal burning characteristics of

small specimens subjected to a small flame – ISO 9772 [13] . 19

4.3.9 Plastics – Determination of burning behaviour of thin flexible vertical

specimens in contact with a small-flame ignition source – ISO 9773 [15] . 20

4.3.10 Fire propagation apparatus – ISO 12136 [16] . 21

4.3.11 Plastics – Vertical flame spread determination for film and sheet –

ISO 12992 [27] . 23

4.3.12 Vertical burning test for aircraft materials – FAR 25 [29] . 23

4.4 Medium and intermediate-scale fire tests . 24

4.4.1 Lateral flame spread on building and transport products – ISO 5658-2 [30] . 24

4.4.2 Intermediate-scale fire test of vertical flame spread – ISO 5658-4 [33]. 25

4.4.3 Plastics – Reaction to fire – Test method for flame spread and combustion

product release from vertically oriented specimens – ISO 21367 [35] . 26

4.5 Intermediate and large-scale fire tests for cables . 26

4.5.1 General . 26

4.5.2 Vertical burning tests for cables (ladder tests) . 27

4.5.3 Vertical burning test for cables – NF C 32-070 [60] . 31

4.6 Real-scale fire tests for cables . 31

4.6.1 Standard for test for flame propagation height of electrical and optical-

fiber cables installed vertically in shafts – UL 1666 [61] . 31

4.6.2 Horizontal flame spread test for cables – EN 50289-4-11 [62] . 32

5 Overview of methods and relevance of data . 33

Bibliography . 38

Table 1 – Characteristics of fire stages (ISO 19706:2011) . 13

a)

Table 2 – Summary and comparison of IEC 60332 vertical ladder test methods [37] . 28

Table 3 – Summary and comparison of non-IEC vertical ladder test methods . 29

Table 4 – Overview of flame spread methods . 34

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FIRE HAZARD TESTING –

Part 9-2: Surface spread of flame –

Summary and relevance of test methods

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60695-9-2 has been prepared by IEC technical committee 89: Fire

hazard testing.

It has the status of a basic safety publication in accordance with IEC Guide 104.

This second edition cancels and replaces the first edition of IEC 60695-9-2 published in 2014.

This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Updated introduction

b) Updated normative references

c) Updated terms and definitions

d) New Subclauses 4.1 and 4.2

– 4 – IEC 60695-9-2:2021 © IEC 2021

e) Reference to fire stages as defined in ISO 19706 (Table 1)

f) New sub-division of tests into the following subclauses:

4.3 Small-scale fire tests

4.4 Medium and intermediate-scale fire tests

4.5 Intermediate and large-scale fire tests for cables

4.6 Real-scale fire tests for cables

g) Updated text in parts of Clause 4

h) Addition of the following test methods:

IEC TS 60695-11-21

IEC 60684-2:2011, Clause 26

ISO 3582

ISO 9772

ISO 9773

ISO 12992

ISO 21367

i) New Clause 5 and Table 4 giving an overview of test methods

j) Deletion of all the Annexes

k) Updated bibliography

The text of this International Standard is based on the following documents:

Draft Report on voting

89/1469/CDV 89/1505/RVC

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement,

available at www.iec.ch/members_experts/refdocs. The main document types developed by

IEC are described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 60695 series, published under the general title Fire hazard testing,

can be found on the IEC website.

This International Standard is to be used in conjunction with IEC 60695-1.

In this standard, the following print types are used:

terms referred to in Clause 3: in italic type.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 60695-9-2:2021 © IEC 2021

INTRODUCTION

In the design of an electrotechnical product, the risk of fire and the potential hazards

associated with fire need to be considered. In this respect the objective of component, circuit

and equipment design, as well as the choice of materials, is to reduce the risk of fire to a

tolerable level even in the event of reasonably foreseeable (mis)use, malfunction or failure.

IEC 60695-1-10, IEC 60695-1-11 [1] , and IEC 60695-1-12 [2] provide guidance on how this is

to be accomplished.

Fires involving electrotechnical products can also be initiated from external non-electrical

sources. Considerations of this nature are dealt with in an overall fire hazard assessment.

The aim of the IEC 60695 series of standards is to save lives and property by reducing the

number of fires or reducing the consequences of the fire. This can be accomplished by:

• trying to prevent ignition caused by an electrically energised component part and, in the

event of ignition, to confine any resulting fire within the bounds of the enclosure of the

electrotechnical product;

• trying to minimise flame spread beyond the product’s enclosure and to minimise the

harmful effects of fire effluents including heat, smoke, and toxic or corrosive combustion

products.

Fire hazard increases as the burning area increases, leading in some cases to flashover and

a fully developed fire. This is a typical fire scenario in buildings. It is therefore useful to

measure the rate and extent of the surface spread of flame.

This part of IEC 60695-9 describes surface spread of flame test methods in common use to

assess electrotechnical products or materials used in electrotechnical products. It forms part

of the IEC 60695-9 series which gives guidance to product committees wishing to incorporate

test methods for surface spread of flame in product standards.

___________

Numbers in square brackets refer to the bibliography.

FIRE HAZARD TESTING –

Part 9-2: Surface spread of flame –

Summary and relevance of test methods

1 Scope

This part of IEC 60695-9 presents a summary of published test methods that are used to

determine the surface spread of flame of electrotechnical products or materials from which

they are formed.

It represents the current state of the art of the test methods and, where available, includes

special observations on their relevance and use.

The list of test methods is not to be considered exhaustive, and test methods that were not

developed by the IEC are not to be considered as endorsed by the IEC unless this is

specifically stated.

This summary cannot be used in place of published standards which are the only valid

reference documents.

This basic safety publication is intended for use by technical committees in the preparation of

standards in accordance with the principles laid down in IEC Guide 104 and

ISO/IEC Guide 51.

One of the responsibilities of a technical committee is, wherever applicable, to make use of

basic safety publications in the preparation of its publications. The requirements, test

methods or test conditions of this basic safety publication will not apply unless specifically

referred to or included in the relevant publications.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60695-1-10, Fire hazard testing – Part 1-10: Guidance for assessing the fire hazard of

electrotechnical products – General guidelines

IEC 60695-4:2012, Fire hazard testing – Part 4: Terminology concerning fire tests for

electrotechnical products

IEC 60695-9-1, Fire hazard testing – Part 9-1: Surface spread of flame – General guidance

IEC GUIDE 104, The preparation of safety publications and the use of basic safety

publications and group safety publications

ISO/IEC Guide 51, Safety aspects – Guidelines for their inclusion in standards

ISO 13943:2017, Fire Safety – Vocabulary

– 8 – IEC 60695-9-2:2021 © IEC 2021

ISO 19706:2011, Guidelines for assessing the fire threat to people.

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60695-4:2012 and

ISO 13943:2017 (some of which are reproduced below) and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

burned length

maximum extent in a specified direction of the burned area

Note 1 to entry: The typical unit is m.

Note 2 to entry: Compare with the term damaged length (3.5).

[SOURCE: ISO 13943: 2017, definition 3.37]

3.2

char length

length of charred area

Note 1 to entry: Compare with the terms burned length (3.1) and damaged length (3.5).

Note 2 to entry: In some standards, char length is defined by a specific test method.

[SOURCE: ISO 13943: 2017, definition 3.49]

3.3

combustible, noun

item capable of combustion (3.4)

[SOURCE: ISO 13943: 2017, definition 3.53]

3.4

combustion

exothermic reaction of a substance with an oxidizing agent

Note 1 to entry: Combustion generally emits fire effluent accompanied by flames (3.11) and/or glowing.

[SOURCE: ISO 13943: 2017, definition 3.55]

3.5

damaged length

maximum extent in a specified direction of the damaged area

Note 1 to entry: Compare with the terms char length (3.2) and burned length (3.1)

[SOURCE: ISO 13943: 2017, definition 3.73]

3.6

fire

〈general〉 process of combustion (3.4) characterized by the emission of heat and fire effluent

and usually accompanied by smoke, flame (3.11), glowing or a combination thereof

Note 1 to entry: In the English language the term “fire” is used to designate three concepts, two of which relate to

specific types of self-supporting combustion with different meanings. Of these three, two of them are designated

using two different terms in both French and German.

[SOURCE: ISO 13943: 2017, definition 3.114]

3.7

fire

〈controlled〉 self-supporting combustion (3.4) that has been deliberately arranged to provide

useful effects and is limited in its extent in time and space

[SOURCE: ISO 13943: 2017, definition 3.115]

3.8

fire

〈uncontrolled〉 self-supporting combustion (3.4) that has not been deliberately arranged to

provide useful effects and is not limited in its extent in time and space

[SOURCE: ISO 13943: 2017, definition 3.116]

3.9

fire hazard

potential for harm associated with fire (3.8)

Note 1 to entry: Alternatively, fire hazard can be a physical object or condition with a potential for an undesirable

consequence from fire.

[SOURCE: ISO 13943: 2017, definition 3.131]

3.10

fire scenario

qualitative description of the course of a fire (3.8) with respect to time, identifying key events

that characterize the studied fire and differentiate it from other possible fires

Note 1 to entry: It typically defines the ignition (3.18) and fire growth processes, the fully developed fire (3.16)

stage, the fire decay stage, and the environment and systems that impact on the course of the fire.

Note 2 to entry: Unlike deterministic fire analysis, where fire scenarios are individually selected and used as

design fire scenarios, in fire risk assessment, fire scenarios are used as representative fire scenarios within fire

scenario clusters.

[SOURCE: ISO 13943: 2017, definition 3.152, modified – Note 1 removed as not relevant]

3.11

flame, noun

zone in which there is rapid, self-sustaining, sub-sonic propagation of combustion (3.4) in a

gaseous medium, usually with emission of light

[SOURCE: ISO 13943: 2017, definition 3.159 – modified by the addition of “zone in which

there is”]

3.12

flame front

boundary of flaming combustion at the surface of a material or propagating through a gaseous

mixture

[SOURCE: ISO 13943: 2017, definition 3.162]

– 10 – IEC 60695-9-2:2021 © IEC 2021

3.13

flame spread

propagation of a flame front (3.12)

[SOURCE: ISO 13943: 2017, definition 3.168]

3.14

flame-spread rate

DEPRECATED: burning rate

DEPRECATED: rate of burning

distance travelled by a flame front (3.12) during its propagation, divided by the time of travel,

under specified conditions

-1

Note 1 to entry: The typical unit is m.s .

[SOURCE: ISO 13943: 2017, definition 3.169]

3.15

flashover

〈stage of fire〉 transition to a state of total surface involvement in a fire (3.8) of combustible

materials within an enclosure

[SOURCE: ISO 13943: 2017, definition 3.184]

3.16

fully developed fire

state of total involvement of combustible materials in a fire (3.6)

[SOURCE: ISO 13943: 2017, definition 3.192]

3.17

heat release rate

DEPRECATED: burning rate

DEPRECATED: rate of burning

rate of thermal energy production generated by combustion (3.4)

Note 1 to entry: The typical unit is W.

[SOURCE: ISO 13943: 2017, definition 3.206]

3.18

ignition

DEPRECATED: sustained ignition

〈general〉 initiation of combustion (3.4)

[SOURCE: ISO 13943: 2017, definition 3.217]

3.19

ignition source

source of energy that initiates combustion (3.4)

[SOURCE: ISO 13943: 2017, definition 3.219]

3.20

intermediate-scale fire test

fire test performed on a test specimen of medium dimensions

Note 1 to entry: A fire test performed on a test specimen for which the maximum dimension is between 1 m and

3 m is usually called an intermediate-scale fire test.

Note 2 to entry: The dimensions in Note 1 to entry usually refer to reaction-to-fire testing and not to fire

resistance testing.

Note 3 to entry: ISO 29903 considers medium dimensions to be those with a maximum dimension between 1 m

and 3 m.

[SOURCE: ISO 13943: 2017, definition 3.233]

3.21

large-scale fire test

fire test that cannot be carried out in a typical laboratory chamber, performed on a test

specimen of large dimensions

Note 1 to entry: A fire test performed on a test specimen of which the maximum dimension is greater than 3 m is

usually called a large-scale fire test.

[SOURCE: ISO 13943: 2017, definition 3.239]

3.22

medium-scale fire test

fire test performed on a test specimen of small-medium size dimensions

Note 1 to entry: A fire test performed on a test specimen of which the maximum dimension is between 0,5 m and

1,0 m is often called a medium-scale fire test.

Note 2 to entry: The dimensions referenced in Note 1 to entry usually refer to reaction-to-fire testing and not to

fire resistance testing, where a maximum dimension of 1 m corresponds to a small-scale test.

[SOURCE: ISO 13943: 2017, definition 3.269]

3.23

pyrolysis

chemical decomposition of a substance by the action of heat

Note 1 to entry: Pyrolysis is often used to refer to a stage of fire (3.6) before flaming combustion has begun.

Note 2 to entry: In fire science, no assumption is made about the presence or absence of oxygen.

[SOURCE: ISO 13943: 2017, definition 3.316]

3.24

real-scale fire test

fire test that simulates a given application, taking into account the real scale, the real way the

item is installed and used, and the environment

Note 1 to entry: Such a fire test normally assumes that the products will be used in accordance with the

conditions laid down by the specifier and/or in accordance with normal practice.

[SOURCE: ISO 13943: 2017, definition 3.325]

3.25

riser cable

cable that runs vertically between floors in a building

Note 1 to entry: This is a term used predominantly in North America

3.26

small-scale fire test

fire test performed on a test specimen of small dimensions

– 12 – IEC 60695-9-2:2021 © IEC 2021

Note 1 to entry: There is no clear upper limit for the dimensions of the test specimen in a small-scale fire test. In

some instances, a fire test performed on a test specimen with a maximum dimension of less than 1 m is called a

small-scale fire test. However, a fire test performed on a test specimen of which the maximum dimension is

between 0,5 m and 1,0 m is often called a medium-scale fire test.

[SOURCE: ISO 13943: 2017, definition 3.346]

3.27

surface spread of flame

flame spread (3.13) away from the source of ignition (3.18) across the surface of a liquid or a

solid

[SOURCE: ISO 13943: 2017, definition 3.378]

4 Summary of published test methods

4.1 General

This summary does not replace published standards, which are the only valid reference

documents.

In cases where fire tests are not yet specified, and need to be developed or altered for the

special purpose of an IEC technical committee, this shall be done in liaison with the relevant

IEC technical committee, as mandated by IEC Guide 104. The test method(s) selected shall

be relevant to the fire scenario of concern. Guidance on the selection and relevance of fire

tests for electrotechnical products is given in IEC 60695-1-10.

General guidance on surface spread of flame tests for electrotechnical products is given in

IEC 60695-9-1.

4.2 The physical fire model

Flame spread is not an inherent property of a material or product, but is critically dependent

on the conditions under which that material or product is burnt. The various factors that affect

flame spread are discussed in IEC 60695-9-1.

It is important to show that the test conditions defined in a standardised test method (the

physical fire model) are relevant to, and replicate the desired stage of a real fire. ISO has

published a general classification of fire stages in ISO 19706:2011, shown in Table 1.

Table 1 – Characteristics of fire stages (ISO 19706:2011)

Fire stage Heat flux to Max. temperature °C Oxygen volume % Fuel/air

[CO] 100 ×[CO2]

fuel surface equivalence

[CO2] ([CO2] + [CO])

kW/m ratio (plume)

Fuel surface Upper layer Entrained Exhausted

v/v % efficiency

1. Non-flaming

a. self-sustaining

d

n.a. 450 to 800 25 to 85 20 20 0,1 to 1 50 to 90

(smouldering)

b. oxidative pyrolysis from

a b c c

300 to 600 20 20 < 1

externally applied radiation

c. anaerobic pyrolysis from

b c c

100 to 500 0 0 >> 1

externally applied radiation

d e

2. Well-ventilated flaming 0 to 60 350 to 650 50 to 500 ≈ 20 ≈ 20 < 1 < 0,05 > 95

f

3. Under-ventilated flaming

a. small, localized fire,

a

generally in a poorly 0 to 30 300 to 600 50 to 500 15 to 20 5 to 10 > 1 0,2 to 0,4 70 to 80

ventilated compartment

g h i

b. post-flashover fire 50 to 150 350 to 650 > 600 < 15 < 5 > 1 0,1 to 0,4 70 to 90

a The upper limit is lower than for well-ventilated flaming combustion of a given combustible.

b The temperature in the upper layer of the fire room is most likely determined by the source of the externally applied radiation and room geometry.

c There are few data; but for pyrolysis, this ratio is expected to vary widely depending on the material chemistry and the local ventilation and thermal conditions.

d The fire’s oxygen consumption is small compared to that in the room or the inflow, the flame tip is below the hot gas upper layer or the upper layer is not yet significantly

vitiated to increase the CO yield significantly, the flames are not truncated by contact with another object, and the burning rate is controlled by the availability of fuel.

e The ratio may be up to an order of magnitude higher for materials that are fire-resistant. There is no significant increase in this ratio for equivalence ratios up to ≈ 0,75.

Between ≈ 0,75 and 1, some increase in this ratio may occur.

f The fire’s oxygen demand is limited by the ventilation opening(s); the flames extend into the upper layer.

g Assumed to be similar to well-ventilated flaming.

h The plume equivalence ratio has not been measured; the use of a global equivalence ratio is inappropriate.

i Instances of lower ratios have been measured. Generally, these result from secondary combustion outside the room vent.

– 14 – IEC 60695-9-2:2021 © IEC 2021

4.3 Small-scale fire tests

4.3.1 Horizontal and vertical 50 W and 500 W flame tests – IEC 60695-11-10

and IEC 60695-11-20

4.3.1.1 Purpose and principle

IEC 60695-11-10 [3] is a test using a 50 W flame. IEC 60695-11-20 [4] is a test using a 500 W

flame. These tests refer to solid electrical insulating materials and are intended to serve as a

preliminary indication of their behaviour when exposed to an ignition source. The results make

it possible to check the constancy of the characteristics of a material and provide an

indication of the progress in the development of the flame retardancy of insulating materials.

The results also provide a relative comparison and classification of insulating materials.

4.3.1.2 Test specimen

The relatively small test specimen is 125 mm long, 13 mm wide, and up to 13 mm thick.

4.3.1.3 Test method

These tests involve the application of an ignition source to a horizontal or vertical test

specimen and the evaluation of the linear burning rate (HB classification) and the vertical

spread of flame (V classification).

4.3.1.4 Repeatability and reproducibility

Data are available in IEC 60695-11-10:2013, Annexes A and B, and IEC 60695-11-20:2015,

Annex A.

4.3.1.5 Relevance of test data

These test methods are used to evaluate materials. The test methods provide classifications

that may be used for quality assurance, the preselection of component materials of products,

or to verify the required minimum flammability classification of materials used in end products.

The tests are not valid for determining the fire behaviour and fire hazard of complete items of

equipment, since the dimensions of the insulating systems and the design and heat transfer to

adjacent metallic parts, greatly influence the flammability of the electrical insulating materials

being used.

4.3.2 Fire hazard testing – Part 11-21: Test flames – 500 W vertical flame test method

for tubular polymeric materials – IEC TS 60695-11-21 [5]

4.3.2.1 Purpose and principle

This document describes a small-scale laboratory pass/fail procedure which is based on the

comparative burning characteristics of tubular polymeric materials. A flame is applied to test

specimens held in a vertical position, supported by a wire or mandrel. Upon removal of the

test flame, the extinguishing times and the burning characteristics are determined.

4.3.2.2 Test specimen

Test specimens are at least 450 mm long samples of tubular polymeric material.

4.3.2.3 Test method

A burner conforming to IEC 60695-11-3 [6], Method A, is used. This provides a pre-mixed

methane flame of nominal power 500 W.

The test specimen is secured by a wire or mandrel with its longitudinal axis vertical. An

indicator flag is attached to the test specimen with its lower edge (250 ± 2) mm above the

point at which the blue inner cone of the test flame touches the test specimen. A flat

horizontal layer of cotton is placed below the test specimen.

The flame is applied for (15 ± 0,5) s to the side of the test specimen at a point near its lower

edge. It is then removed for (15 ± 0,5) s. The flaming time, t, is noted. This operation is

repeated until the test specimen has been subjected to five applications of the test flame.

Where flaming of the test specimen persists longer than 15 s after the previous application of

the test flame, the test flame is not reapplied until flaming of the test specimen has ceased of

its own accord. The test flame is reapplied as soon as flaming of the test specimen has

ceased.

The test specimen is considered to have passed the test if three criteria apply to all three test

specimens. These are:

a) the test specimen does not flame longer than 60 s following any of five 15 s applications of

the test flame;

b) flaming material from the test specimen does not ignite the cotton pad; and

c) the indicator flag is not more than 25 % damaged, during, between, or after the five

applications of the test flame.

4.3.2.4 Repeatability and reproducibility

No data are given.

4.3.2.5 Relevance of test data

This test method can be used to compare the burning characteristics of tubular polymeric

materials. It can be used to compare the relative performance of materials, to aid in material

selection, for quality control purposes and for quality assurance.

It is not to be used to compare the burning characteristics of any wire or cable products or

any cable management systems.

4.3.3 Flexible insulating sleeving – Part 2: Methods of test, Clause 26:

Flame propagation tests – IEC 60684-2:2011 [7], Clause 26

4.3.3.1 Purpose and principle

These are three small-scale laboratory procedures of different severities for determining the

burning characteristics of flexible insulating sleeving. Methods A and B are vertical burning

o

tests. Method C tests a sample at 20 from the vertical.

NOTE IEC 60684-3 [8] indicates which tests should be applied to a particular type or grade of sleeving.

4.3.3.2 Method A

4.3.3.2.1 Test specimen

Test specimens are at least 450 mm long. Heat-shrinkable sleeving is recovered before

testing. The bore of the sleeving is not more than 10 mm.

NOTE For heat-shrinkable sleeving, this dimension is the specified recovered bore.

4.3.3.2.2 Test method

Tests are carried out in accordance with IEC TS 60695-11-21:2005 except that the source of

heat is as defined in 26.3 of IEC 60684:2011.

– 16 – IEC 60695-9-2:2021 © IEC 2021

4.3.3.3 Method B

4.3.3.3.1 Test specimen

Test specimens are approximately 660 mm long (recovered in the case of heat-shrinkable

sleeving) and are supported on piano wire 900 mm in length. The sleeving is closed at the top

end to prevent a chimney effect.

4.3.3.3.2 Test method

Tests are carried out in accordance with IEC TS 60695-11-21:2005 except that the source of

heat is as defined in 26.3 of IEC 60684-2:2011.

4.3.3.4 Method C

4.3.3.4.1 Test specimen

Test specimens are approximately 560 mm long (recovered in the case of heat-shrinkable

sleeving) and are supported on piano wire 800 mm in length. The sleeving is closed at the top

end to prevent a chimney effect.

4.3.3.4.2 Test method

The source of heat is as defined in 26.3 of IEC 60684-2:2011. An indicator flag is attached to

the test specimen with its lower edge (250 ± 2) mm away from the point at which the blue

inner cone of the test flame touches the test specimen. There is no cotton layer.

o

The test specimen is supported so as to be 20 from the vertical and the flame is applied at

o

45 to the test specimen. The flame is applied for 15 s to the side of the test specimen at a

point near its lower edge. After-flame time is noted as well as the length of burned specimen.

4.3.3.5 Repeatability and reproducibility

No data are given.

4.3.3.6 Relevance of test data

These test methods are used in order to determine if products meet specifications given

in IEC 60684-3. It can also be used for quality control purposes and for quality assurance.

4.3.4 Vertical burning test for cables – IEC 60332-1 [9]

4.3.4.1 Purpose and principle

This test method specifies a method of testing a single vertical wire or cable or optical cable

under fire conditions. IEC 60332-1-1 defines the apparatus. IEC 60332-1-2 defines the

procedure. The char length of a vertical test specimen, exposed to a 1 kW pre-mixed flame in

a suitable chamber, is measured. The standard includes, in an informative annex,

recommended requirements for compliance for use where these are not given in the cable

product standard. IEC 60332-1-3 is a procedure for determination of flaming

droplets/particles.

The method specified is not suitable for the testing of small single insulated conductors or

cables of less than 0,5 mm total cross-section, because the conductor melts before the test

is completed, or for the testing of small optical fibre cables because the cable is broken

before the test is completed – see 4.1.3.

NOTE The corresponding EN standards are EN 60332-1-1, EN 60332-1-2 and EN 60332-1-3.

4.3.4.2 Test specimen

The test specimen consists of a piece of finished wire or cable 600 mm ± 25 mm long.

4.3.4.3 Test method

The test specimen is held in a vertical position by means of two support arms within a three-

sided metallic screen. A calibrated burner is used to ignite the test specimen. Its flame is

continuously applied for a period of time which is related to the overall diameter of the test

specimen. The damaged length of the test specimen is then noted.

4.3.4.4 Repeatability and reproducibility

No data are known to be available.

4.3.4.5 Relevance of test data

This method is used to determine the extent of vertical burning of a single finished wire or

cable by measuring the char length.

The use of insulated wire or cable, which retards flame propagation and complies with the

requirements of this standard, cannot be assumed by itself to prevent propagation of fire

under all conditions of installation. Two examples of such conditions are:

a) vertical runs of bunched or bundled cables

b) potential ignition sources that would impose a more intense thermal environment than that

provided by the test method.

It is recommended that wherever the risk of propagation is high, special installation

precautions should be taken.

4.3.5 Vertical burning test for cables – IEC 60332-2 [10]

4.3.5.1 Purpose and principle

This test method specifies a method of testing a small insulated wire under fire conditions

when the method specified in vertical burning test IEC 60332-1 is not suitable – see 4.1.2.1.

IEC 60332-2-1 defines the apparatus. IEC 60332-2-2 defines the procedure. The char length

of a vertical test specimen, exposed to a diffusion flame of length 125 mm ± 25 mm in a

draught-free chamber, is measured. The standard includes, in an informative annex,

recommended requirements for compliance for use where these are not given in the cable

product standard.

NOTE The corresponding EN standards are EN 60332-2-1 and EN 60332-2-2.

4.3.5.2 Test specimen

The test specimen consists of a piece of finished copper wire or cable or optical cable,

600 mm ± 25 mm long.

4.3.5.3 Test method

The test specimen is held in a vertical position by means of two support arms within a three-

sided metallic screen. A load of 5 N for each mm of conductor area is attached to the lower

part of the test specimen. A calibrated burner is used to ignite the test specimen. Its flame is

continuously applied for a maximum period of 20 s. The damaged length of the test specimen

is then noted.

--

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...