IEC 60811-401:2012

(Main)Electric and optical fibre cables - Test methods for non-metallic materials - Part 401: Miscellaneous tests - Thermal ageing methods - Ageing in an air oven

Electric and optical fibre cables - Test methods for non-metallic materials - Part 401: Miscellaneous tests - Thermal ageing methods - Ageing in an air oven

IEC 60811-401:2012 specifies the procedure for ageing in an air oven, which typically applies to crosslinked and thermoplastic compounds used for insulating and sheathing materials. IEC 60811-401:2012 cancels and replaces 8.1 and 8.4 of IEC 60811-1-2:1985, which is withdrawn. Full details of the replacements are shown in Annex A of IEC 60811-100:2012. There are no specific technical changes with respect to the previous edition, but see the Foreword to IEC 60811-100:2012.

This publication is to be read in conjunction with IEC 60811-100:2012.

Câbles électriques et à fibres optiques - Méthodes d'essai pour les matériaux non-métalliques - Partie 401: Essais divers - Méthodes de vieillissement thermique - Vieillissement en étuve à air

La CEI 60811-401:2012 décrit la méthode de vieillissement en étuve à air, généralement applicable aux mélanges réticulés et thermoplastiques utilisés pour les matériaux d'isolation et de gainage. La CEI 60811-401 :2012 annule et remplace 8.1 et 8.4 de la CEI 60811-1-2:1985, qui est supprimée. L'ensemble des informations relatives aux remplacements figure dans l'Annexe A de la CEI 60811-100:2012. Aucune modification technique n'a été effectuée par rapport à l'édition précédente; voir cependant l'avant-propos de la CEI 60811-100:2012.

Cette publication doit être lue conjointement avec la CEI 60811-100:2012.

General Information

- Status

- Published

- Publication Date

- 11-Mar-2012

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- WG 17 - TC 20/WG 17

- Current Stage

- PPUB - Publication issued

- Start Date

- 12-Mar-2012

- Completion Date

- 31-Mar-2012

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

IEC 60811-401:2012 - Thermal Ageing Methods for Cable Insulating and Sheathing Materials

Overview

IEC 60811-401:2012, titled Electric and optical fibre cables - Test methods for non-metallic materials - Part 401: Miscellaneous tests - Thermal ageing methods - Ageing in an air oven, is an international standard published by the International Electrotechnical Commission (IEC). This standard specifies the procedure for conducting thermal ageing tests by exposing non-metallic cable materials, typically crosslinked and thermoplastic compounds used in insulation and sheathing, to elevated temperatures in an air oven.

This standardized ageing method is essential for evaluating the durability and long-term performance of cable materials under thermal stress. It is designed to be used in conjunction with IEC 60811-100, which outlines general test methods for non-metallic materials used in electric and optical fibre cables.

Key Topics

Test Scope:

Application to crosslinked and thermoplastic insulating and sheathing compounds used in electric and optical fibre cables.Ageing Procedure:

Controlled exposure of prepared specimen samples to elevated temperature in a circulated air oven to simulate long-term thermal ageing.Mechanical Properties Evaluation:

Assessment of changes in mechanical characteristics, such as flexibility and tensile properties, post-ageing.Bending Tests:

Specific tests on cable core samples after thermal ageing to determine bending resistance and mechanical integrity.Sample Preparation and Handling:

Guidelines for preparing test specimens including handling challenges for specimens containing copper or metal-coated conductors.Air Flow Control:

Normative annexes describe methods for measuring and regulating air flow within ovens to ensure consistent and reproducible ageing conditions.Reporting Requirements:

Detailed structure for documenting test conditions, procedures, and results to ensure transparency and repeatability.

Applications

IEC 60811-401 is widely used by manufacturers, testing laboratories, and quality assurance teams in the cable industry to:

Assess Thermal Stability:

Evaluate how insulating and sheathing materials perform after prolonged exposure to heat, ensuring reliability in service environments.Material Qualification:

Support certification and compliance processes by providing reproducible thermal ageing data for new or existing cable formulations.Product Development:

Guide the development of materials with enhanced thermal resistance properties tailored for specific operational conditions.Quality Control:

Monitor batch-to-batch consistency in manufacturing by verifying that materials maintain their mechanical integrity after thermal exposure.Failure Analysis:

Investigate causes of thermal degradation in installed cables to inform maintenance and replacement schedules.

Related Standards

IEC 60811-401 should be used in conjunction with the following standards to ensure comprehensive testing and evaluation of cable materials:

IEC 60811-100: General test methods for non-metallic materials used in electric and optical fibre cables.

IEC 60811-409: Loss of mass test for thermoplastic insulations and sheaths.

IEC 60811-501: Mechanical tests for determining properties of insulating and sheathing compounds.

IEC 60811-504: Bending tests at low temperature for insulation and sheath materials.

IEC 60228: Conductors of insulated cables, which complements the ageing study by addressing conductor properties.

Practical Value

By following the IEC 60811-401:2012 standard, stakeholders achieve:

Reliable Assessment of Cable Longevity:

Simulate and predict how cable insulation and sheaths will withstand thermal ageing in operational environments.International Consistency:

Enables harmonized testing and benchmarking across global manufacturers and testing bodies, supporting trade and regulatory compliance.Optimized Cable Design:

Data obtained from thermal ageing informs material selection and construction techniques to enhance cable lifespan and safety.Reduced Field Failures:

Early identification of material vulnerabilities under heat exposure reduces costly in-service failures and downtime.

Keywords: IEC 60811-401, thermal ageing test, electric cables, optical fibre cables, non-metallic materials, cable insulation testing, cable sheathing, air oven ageing, crosslinked compounds, thermoplastic compounds, mechanical property testing, bending test, cable material durability, international cable standards.

Buy Documents

IEC 60811-401:2012 - Electric and optical fibre cables - Test methods for non-metallic materials - Part 401: Miscellaneous tests - Thermal ageing methods - Ageing in an air oven Released:3/12/2012

IEC 60811-401:2012+AMD1:2017 CSV - Electric and optical fibre cables - Test methods for non-metallic materials - Part 401: Miscellaneous tests - Thermal ageing methods - Ageing in an air oven Released:7/21/2017

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

TL 9000 QuEST Forum

Telecommunications quality management system.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 60811-401:2012 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electric and optical fibre cables - Test methods for non-metallic materials - Part 401: Miscellaneous tests - Thermal ageing methods - Ageing in an air oven". This standard covers: IEC 60811-401:2012 specifies the procedure for ageing in an air oven, which typically applies to crosslinked and thermoplastic compounds used for insulating and sheathing materials. IEC 60811-401:2012 cancels and replaces 8.1 and 8.4 of IEC 60811-1-2:1985, which is withdrawn. Full details of the replacements are shown in Annex A of IEC 60811-100:2012. There are no specific technical changes with respect to the previous edition, but see the Foreword to IEC 60811-100:2012. This publication is to be read in conjunction with IEC 60811-100:2012.

IEC 60811-401:2012 specifies the procedure for ageing in an air oven, which typically applies to crosslinked and thermoplastic compounds used for insulating and sheathing materials. IEC 60811-401:2012 cancels and replaces 8.1 and 8.4 of IEC 60811-1-2:1985, which is withdrawn. Full details of the replacements are shown in Annex A of IEC 60811-100:2012. There are no specific technical changes with respect to the previous edition, but see the Foreword to IEC 60811-100:2012. This publication is to be read in conjunction with IEC 60811-100:2012.

IEC 60811-401:2012 is classified under the following ICS (International Classification for Standards) categories: 29.035.01 - Insulating materials in general; 29.060.20 - Cables; 33.060.30 - Radio relay and fixed satellite communications systems. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60811-401:2012 has the following relationships with other standards: It is inter standard links to IEC 60811-1-2:1985/AMD2:2000, IEC 60811-1-2:1985, IEC 60811-401:2012/AMD1:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60811-401:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60811-401 ®

Edition 1.0 2012-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric and optical fibre cables – Test methods for non-metallic materials –

Part 401: Miscellaneous tests – Thermal ageing methods – Ageing in an air oven

Câbles électriques et à fibres optiques – Méthodes d’essai pour les matériaux

non-métalliques –

Partie 401: Essais divers – Méthodes de vieillissement thermique –

Vieillissement en étuve à air

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 60811-401 ®

Edition 1.0 2012-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric and optical fibre cables – Test methods for non-metallic materials –

Part 401: Miscellaneous tests – Thermal ageing methods – Ageing in an air oven

Câbles électriques et à fibres optiques – Méthodes d’essai pour les matériaux

non-métalliques –

Partie 401: Essais divers – Méthodes de vieillissement thermique –

Vieillissement en étuve à air

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX R

ICS 29.035.01; 29.060.20 ISBN 978-2-88912-961-4

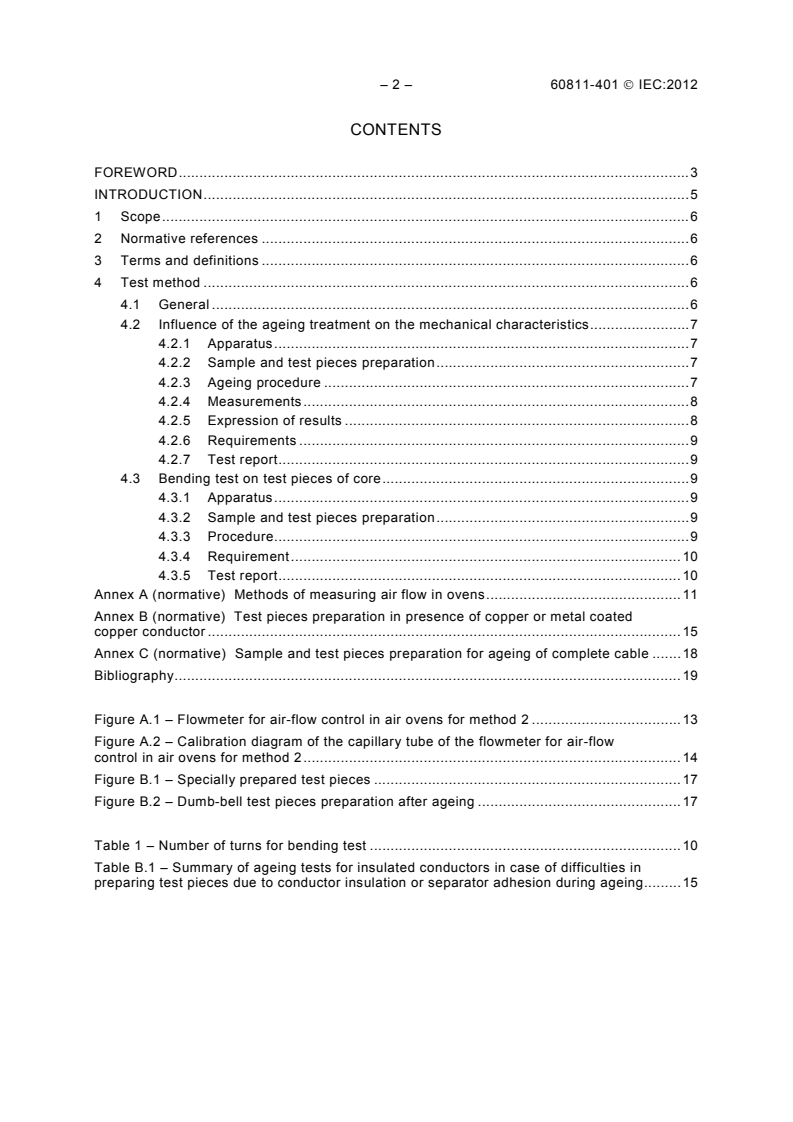

– 2 – 60811-401 IEC:2012

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Test method . 6

4.1 General . 6

4.2 Influence of the ageing treatment on the mechanical characteristics . 7

4.2.1 Apparatus . 7

4.2.2 Sample and test pieces preparation . 7

4.2.3 Ageing procedure . 7

4.2.4 Measurements . 8

4.2.5 Expression of results . 8

4.2.6 Requirements . 9

4.2.7 Test report . 9

4.3 Bending test on test pieces of core . 9

4.3.1 Apparatus . 9

4.3.2 Sample and test pieces preparation . 9

4.3.3 Procedure . 9

4.3.4 Requirement . 10

4.3.5 Test report . 10

Annex A (normative) Methods of measuring air flow in ovens . 11

Annex B (normative) Test pieces preparation in presence of copper or metal coated

copper conductor . 15

Annex C (normative) Sample and test pieces preparation for ageing of complete cable . 18

Bibliography . 19

Figure A.1 – Flowmeter for air-flow control in air ovens for method 2 . 13

Figure A.2 – Calibration diagram of the capillary tube of the flowmeter for air-flow

control in air ovens for method 2 . 14

Figure B.1 – Specially prepared test pieces . 17

Figure B.2 – Dumb-bell test pieces preparation after ageing . 17

Table 1 – Number of turns for bending test . 10

Table B.1 – Summary of ageing tests for insulated conductors in case of difficulties in

preparing test pieces due to conductor insulation or separator adhesion during ageing . 15

60811-401 IEC:2012 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC AND OPTICAL FIBRE CABLES –

TEST METHODS FOR NON-METALLIC MATERIALS –

Part 401: Miscellaneous tests –

Thermal ageing methods – Ageing in an air oven

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60811-401 has been prepared by IEC technical committee 20:

Electric cables.

This Part 401 of IEC 60811 cancels and replaces 8.1 and 8.4 of IEC 60811-1-2:1985, which is

withdrawn. Full details of the replacements are shown in Annex A of IEC 60811-100:2012.

There are no specific technical changes with respect to the previous edition, but see the

Foreword to IEC 60811-100:2012.

– 4 – 60811-401 IEC:2012

The text of this standard is based on the following documents:

FDIS Report on voting

20/1285/FDIS 20/1334/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This part of IEC 60811 shall be used in conjunction with IEC 60811-100.

A list of all the parts in the IEC 60811 series, published under the general title Electric and

optical fibre cables – Test methods for non-metallic materials, can be found on the IEC

website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

60811-401 IEC:2012 – 5 –

INTRODUCTION

The IEC 60811 series specifies the test methods to be used for testing non-metallic materials

of all types of cables. These test methods are intended to be referenced in standards for

cable construction and for cable materials.

NOTE 1 Non-metallic materials are typically used for insulating, sheathing, bedding, filling or taping within cables.

NOTE 2 These test methods are accepted as basic and fundamental and have been developed and used over

many years principally for the materials in all energy cables. They have also been widely accepted and used for

other cables, in particular optical fibre cables, communication and control cables and cables for ships and offshore

applications.

– 6 – 60811-401 IEC:2012

ELECTRIC AND OPTICAL FIBRE CABLES –

TEST METHODS FOR NON-METALLIC MATERIALS –

Part 401: Miscellaneous tests –

Thermal ageing methods – Ageing in an air oven

1 Scope

This Part 401 of IEC 60811 specifies the procedure for ageing in an air oven, which typically

applies to crosslinked and thermoplastic compounds used for insulating and sheathing

materials.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60228, Conductors of insulated cables

IEC 60811-100:2012, Electric and optical fibre cables – Test methods for non-metallic

materials – Part 100: General

IEC 60811-409, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 409: Miscellaneous tests – Loss of mass test for thermoplastic insulations and sheaths

IEC 60811-501, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 501: Mechanical tests – Tests for determining the mechanical properties of insulating and

sheathing compounds

IEC 60811-504, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 504: Mechanical tests – Bending tests at low temperature for insulation and sheaths

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60811-100 apply.

4 Test method

4.1 General

This part of IEC 60811 shall be used in conjunction with IEC 60811-100.

Unless otherwise specified, tests shall be carried out at room temperature.

An ageing treatment in an air oven may be required by the relevant cable standard:

a) for prepared test pieces of insulating or sheathing material only (see 4.2.3.2);

b) for prepared test pieces of cores (conductor and insulation) (see 4.2.3.2 and 4.2.3.3 if

necessary);

60811-401 IEC:2012 – 7 –

c) for test pieces of completed cable (see 4.2.3.4);

d) for the loss of mass test (see IEC 60811-409).

The ageing test a) or b) and the loss of mass test d) may be combined and carried out on the

same test pieces when the aging time and aging temperature are the same.

In general, mechanical characteristics are measured after treatment, but in some cases, the

conductor and the separator, if any, cannot be removed without damaging the insulation and a

bending test is realized on the circular conductor up to and including 16 mm . Ageing followed

by the bending test is considered the acceptance procedure in case of dispute.

4.2 Influence of the ageing treatment on the mechanical characteristics

4.2.1 Apparatus

The ageing treatment is realized in an oven with natural air flow or air flow by pressure. The

air shall enter the oven in such a way that it flows over the surface of the test pieces and

leaves near the top of the oven. The oven shall have not less than 8 and not more than 20

complete air changes per hour at the specified ageing temperature. Two test methods for

measuring air flow through an oven are given in Annex A.

Unless otherwise specified in the relevant cable specification, a rotating fan inside the oven is

allowed when testing rubber compounds. For all other compounds a fan shall not be used

inside the oven, and in cases of dispute, rubber compounds shall also be tested in an oven

which is designed to operate without a fan rotating inside it.

4.2.2 Sample and test pieces preparation

The sample of the cable, or sheath removed from the cable, or samples of core, cut into

pieces which are sufficiently long, shall be taken, preferably from positions close to that from

which the samples for the tensile tests without ageing are taken in accordance with

IEC 60811-501.

Test pieces, dumb-bell or tubular, are prepared according to IEC 60811-501.

Test pieces can consist of samples of core, cut into pieces which are sufficiently long. If, after

ageing, the conductor and the separator, if any, can be removed without damaging the

insulation, preparation of test pieces shall be carried out according to Annex B (Clause B.2).

For circular conductors up to and including 16 mm and having plain or metal coated wires

and also when a separator around the conductor is included, a bending test is carried out on

the aged test pieces.

4.2.3 Ageing procedure

4.2.3.1 General

This test shall be carried out not less than 16 h after the extrusion or cross-linking, if any, of

the insulating or sheathing compounds. It can be done on tubular or dumb-bell test pieces

prepared according to IEC 60811-501 or insulated cores as described in the present standard.

4.2.3.2 Ageing procedure for test pieces prepared according to IEC 60811-501 and

Clause B.1 and B.2.2 and Annex C of this standard

This procedure shall be used for

– test pieces of insulating material without conductor and of sheathing material, according to

IEC 60811-501,

– test pieces of cores with the original conductor (see Clause B.1),

– tubular test pieces with a reduced conductor (see B.2.2),

– 8 – 60811-401 IEC:2012

– complete cable (see Annex C).

Compounds of obviously different compositions shall not be tested at the same time in the

same oven.

Five test pieces, as specified in IEC 60811-501 shall be suspended vertically and

substantially in the middle of the oven so that each test piece is at least 20 mm from any

other test pieces.

The test pieces shall not occupy more than 2 % of the volume of the oven.

The test pieces shall be kept in the oven at the temperature and for the time specified for the

material in the relevant standard for the type of cable.

As soon as the ageing period is completed, the test pieces shall be removed from the oven

and left at ambient temperature, avoiding direct sunlight, for at least 16 h.

4.2.3.3 Ageing procedure for test pieces prepared from conductors above 16 mm

The following procedure shall be used when the conductor and the separator, if any, cannot

be removed without damaging the insulation after ageing.

The test pieces prepared as described in B.2.3.1 shall be placed substantially in the middle of

the oven so that each test piece is at least 20 mm from any other test pieces. They shall be

supported at both ends and the insulation shall not contact any object other than the binding

wire. The test pieces shall not occupy more than 2 % of the volume of the oven, and they

shall be kept in the oven at the temperature and for the time specified in the relevant standard

for the type of cable.

As soon as the ageing period is completed, the test pieces shall be removed from the oven,

left at ambient temperature avoiding direct sunlight, for at least 16 h, dumb-bell are prepared

as described in B.2.3.2.

4.2.3.4 Ageing procedure for pieces of complete cable

The three test pieces of cable as described in Clause C.1 shall be suspended vertically and

substantially in the middle of the oven at least 20 mm away from any other piece and shall not

occupy more than 2 % of the volume of the oven.

The test pieces of cable shall be kept in the oven at the temperature and for the time

specified in the relevant standard for the type of cable.

As soon as the specified heating period is completed, the test pieces of cable shall be

removed from the oven and left at ambient temperature, avoiding direct sunlight, for at least

16 h.

4.2.4 Measurements

Determination of the mechanical properties on aged dumb-bell and/or tubular test pieces

obtained directly after ageing or prepared after ageing, according to the case (see B.2.3 or

Clause C.2) shall then be carried out in accordance of IEC 60811-501.

4.2.5 Expression of results

Calculate the tensile strength and the elongation at break, according to the definitions given

in IEC 60811-501.

60811-401 IEC:2012 – 9 –

If required by the standard for the material in the relevant standard for the type of cable, the

values found for the aged test pieces shall be calculated, in terms of variation compared to

the untreated test pieces according to the following formulae:

T − T

E U

V = × 100 (1)

T

T

U

E − E

E U

V = × 100 (2)

E

E

U

where

V variation of the tensile strength in per cent;

T

T tensile strength of aged test piece;

E

T tensile strength of untreated test piece;

U

V variation of the elongation at break in per cent;

E

E elongation at break of aged test piece in per cent;

E

E elongation at break of untreated test piece in per cent.

U

NOTE The untreated specimen is kept at room temperature.

4.2.6 Requirements

The value and the variation between the median value obtained of the test pieces aged and

the median value of the values obtained for the untreated test pieces (see IEC 60811-501)

expressed as a percentage of the latter shall not exceed the percentage specified in the

standard for the material in the relevant standard for the type of cable.

4.2.7 Test report

The test report shall be in accordance with that given in IEC 60811-100.

4.3 Bending test on test pieces of core

4.3.1 Apparatus

Ageing is carried out in an oven as described in 4.2.1.

The bending test apparatus is described in IEC 60811-504.

4.3.2 Sample and test pieces preparation

Two samples of suitable length shall be taken from each core to be tested preferably from

positions close to that from which the samples for the tensile tests without ageing are taken

(see IEC 60811-504).

4.3.3 Procedure

Test pieces are aged according to the procedure described in 4.2.3.3.

As soon as the ageing period is completed, the test pieces shall be removed from the oven

and left at room temperature, avoiding direct sunlight, for at least 16 h.

Each test piece shall then be bent at ambient temperature around a mandrel so as to form a

close helix.

– 10 – 60811-401 IEC:2012

The bending procedure shall be carried out uniformly at a rate of one turn in about 5 s.

The bending tests may be carried out with the apparatus described in IEC 60811-504.

The diameter of the mandrel shall be f times the diameter of the core. The values of f and also

the number of turns are specified as follows.

Table 1 – Number of turns for bending test

Cross-sectional area

Factor

of conductor Number of turns

f

mm

Up to and including 2,5 7

1 ±0,1

4 and 6 6

2 ±0,1

10 and 16 5

4 ±0,1

4.3.4 Requirement

At the end of the bending procedure the test pieces shall be examined while still on the

mandrel. The insulation of both test pieces shall not show any crack when examined with

normal or corrected vision without magnification. Any cracks in the first or the last turn on the

mandrel shall be disregarded.

4.3.5 Test report

The test report shall be in accordance with that given in IEC 60811-100.

60811-401 IEC:2012 – 11 –

Annex A

(normative)

Methods of measuring air flow in ovens

A.1 Method 1 – Indirect or power consumption method

A.1.1 In this method, the additional power required to maintain the oven at a given

temperature with its ports open, over that required to maintain the oven at the same

temperature with its ports closed, is used as a measure of the quantity of air passing through

the oven when the ports are open. The average power (P1 watts) required to maintain the

oven temperature at the specified ageing temperature when the ports are open is determined

over a period of 30 min or longer. The ventilation ports (and, if necessary, the thermometer

aperture) are then closed and the average power (P2 watts) to maintain the same temperature

over a similar period is determined. It is essential that the difference between the oven

temperature and the room temperature should be the same for the two tests to within 0,2 °C.

The room temperature should be measured at a point about 2 m from the oven, approximately

level with its base, and at least 0,6 m from any solid objects.

A.1.2 The amount of air passing through the oven, when the ports are open, is given by the

formulae:

P1− P2

m= (A.1)

C (t − t )

p 2 1

3 600 m

V= (A.2)

d

where

–1 –1

C is the specific heat of air constant pressure (J×g ×K );

p

t is the room temperature, in degrees Celsius;

t is the oven temperature, in degrees Celsius;

P1 – P2 is the difference in power consumption, as defined in A.1.1;

m is the mass of air, in grams per second;

V is the volume of air, in litres per hour;

d is the density of air in the laboratory at the time of test, in grams per litre.

NOTE The density of air at 101,3 kPa (760 mm Hg) and 20 °C is 1,205 g/l.

3 600(P1− P2) 3 590(P1− P2)

Hence: or

V= V=

1,003 d (t − t ) d (t − t)

2 1 2 1

This formula assumes that, when the ports are closed, no air passes through the oven. Therefore, there should

be no leakages; the air-tight door joint should be sealed with adhesive tape and all apertures, including the inlet

port, should be effectively closed.

A.1.3 If the power consumption is measured with a wattmeter, the total length of time, in

seconds, for which the oven heaters are “on” shall be measured with a stop-watch and the

reading of the wattmeter shall be taken once during each "on" period.

The average of the wattage readings multiplied by the total time registered by the stop-watch

and divided by the duration of the test, in seconds, is taken as the power, in watts, required to

maintain a constant temperature.

– 12 – 60811-401 IEC:2012

A.1.4 If a watt-hour or kilowatt-hour meter is used, the reading of the total energy

consumption registered by the meter shall be divided by the duration of the test, measured as

a fraction of an hour. If a household kilowatt-hour meter is used, the dial units are too large to

enable a sufficient accuracy to be obtained over a reasonably short test, and the rotating disc

with which these meters are provided shall be used therefore as the power consumption

indicator. The meter shall be put into operation until the index mark on the disc is opposite the

centre of the window; it shall then be disconnected until the start of the test.

To reduce the possible error, the period of test shall be long enough to permit 100 revolutions

of the disc and the test shall preferably be ended when the mark on the disc is visible. If,

however, the mark is out of sight at the end of the test, an estimated fraction of a revolution

shall be added. The test shall be started and stopped at corresponding points on the "on-off"

heating cycle (e.g., at the moment when the heaters are switched on by the thermostat).

A.2 Method 2 – Direct and continuous method

A.2.1 Description of the equipment

Starting from the high-pressure air source, i.e. from a pipe system or air cylinders:

A.2.1.1 Air pressure regulator

A device to reduce the air pressure from the many atmospheres of the supply mains to the

quite low-pressure values needed for supplying the oven. It is equipped with an adjustable

valve which permits a constant pressure downstream.

A.2.1.2 Flowmeter

An instrument with which the rate of air flow can be measured. It is illustrated by Figure A.1,

and operates on a manometric principle, with:

a) A calibrated capillary tube, with an internal calibrated diameter of about 2 mm and a

calibrated length of about 70 mm. Figure A.2 shows a typical calibration diagram which

permits the control of air flow up to 500 l/h or 600 l/h.

b) A manometric tube with a double graduation of pressure difference ranging between

0 mm and ±300 mm of water. Distilled water is the manometric liquid.

A.2.1.3 Air oven

An air oven to be operated when carefully sealed, including sealing round the inlet tube,

which should preferably enter the oven through the bottom. The outflow hole, which should be

at the top of the oven, is the only port to be open.

NOTE The following two features facilitate the reliability of the method and the equipment:

– the flowmeter described above can be considered as fully reliable, easy to manufacture and to calibrate, as

well as suitable for the range of air rates involved here;

– as shown by tests the adoption of a slightly “forced” ventilation does not alter, in practice, the uniformity of the

temperature at the various points in the ovens.

60811-401 IEC:2012 – 13 –

IEC 256/12

Figure A.1 – Flowmeter for air-flow control in air ovens for method 2

– 14 – 60811-401 IEC:2012

IEC 257/12

Key

P pressure differences, millimetres of water

A air flow in litres per hour

NOTE Capillary tube, diameter: d = 2 mm; length: l = 70 mm.

Figure A.2 – Calibration diagram of the capillary tube of the flowmeter

for air-flow control in air ovens for method 2

60811-401 IEC:2012 – 15 –

Annex B

(normative)

Test pieces preparation in presence of copper

or metal coated copper conductor

B.1 Test pieces preparation of cores with the original conductor

When the conductor and the separator, if any, can be removed without damaging the

insulation after ageing, the procedure shall be as follows: samples of core, cut into pieces

which are sufficiently long, shall be taken, preferably from positions close to that from which

the samples for the tensile tests without ageing are taken in accordance with IEC 60811-501.

They shall then be aged as described in 4.2.3.2, after which the conductor shall be removed

and the cross-sectional area of the test pieces shall be determined according to

IEC 60811-501.

B.2 Test pieces preparation in case of adhesion of conductor insulation or

separator after ageing

B.2.1 General

When it is not possible to remove the conductor or the separator, if any, after the ageing

procedure without damaging the insulation, the appropriate preparation and test method shall

be applied as given in Table B.1.

Table B.1 – Summary of ageing tests for insulated conductors in case of

difficulties in preparing test pieces due to conductor insulation or

separator adhesion during ageing

Class of copper conductor

Test method

and conductor form acc. to IEC 60228

Class 1: plain copper See B.2.2.1 or, if this method also gives rise to adhesion

problems, see 4.3.

Ageing followed by the bending test is considered the acceptance

procedure in case of dispute

Class 1: metal coated or with a separator See 4.3

around the conductor

Class 2: circular conductors up to and See 4.3

including 16 mm and having plain or metal

coated wires and with or without separator

as appropriate

Class 2: conductors above 16 mm , circular See 4.2.3.3

or shaped, and having plain or metal-coated

wires

Classes 5 and 6: conductors up to and See B.2.2.2 or if this method also gives rise to adhesion problems

including 16 mm having plain or metal- see 4.3.

coated wires and with or without separator

Ageing followed by the bending test is considered the acceptance

as appropriate

procedure in case of dispute

Classes 5 and 6: conductors above 16mm See 4.2.3.3

having plain or metal-coated wires

NOTE In the case of the bending test (4.3), ageing conditions may be different from those requiring the

determination of tensile properties (Clause B.1 and B.2.2); see the relevant cable standard.

– 16 – 60811-401 IEC:2012

B.2.2 Tubular test pieces preparation with a reduced conductor

B.2.2.1 Solid plain conductor with reduced diameter

After preparation of five tubular test pieces in accordance with IEC 60811-501 a piece of solid

plain conductor, having a diameter reduced by up to 10 % shall be reinserted. This shall be

achieved by stretching the original conductor or by using a conductor having the required

smaller diameter.

These tubular test pieces shall then be aged as described in 4.2.3.2 after which the reduced

conductor shall be removed and the cross-sectional area of the tubular test pieces shall be

determined according to IEC 60811-501.

B.2.2.2 Class 5 and class 6 conductor with a reduced number of wires

The preparation of five tubular test pieces shall be carried out in accordance with IEC 60811-

501. For this purpose, either approximately 30 % of the wires forming the conductor may be

removed from the insulation or approximately 70 % of the wires may be reinserted into the

tubular test piece.

These tubular test pieces shall then be aged as described in 4.2.3.2 after which the reduced

conductor shall be removed and the cross-sectional area of the tubular test pieces shall be

determined according to IEC 60811-501.

B.2.3 Test pieces preparation for conductors above 16 mm

B.2.3.1 Sampling and preparation of test pieces for ageing

Three test pieces each about 200 mm long shall be taken from each core to be tested,

preferably from positions close to that from which the samples for the tensile tests without

ageing are taken (see IEC 60811-501).

In the case of sector-shaped cores, a strip of not less than 10 mm width shall be cut out of the

insulation at the sector back along the conductor axis and separated from the conductor.

Subsequently, this strip shall be applied again in the same place and fastened with suitable

wire in the middle of the test piece and at about 20 mm from each end in such a way that the

strip is again well in contact with the conductor; see Figure B.1 below.

60811-401 IEC:2012 – 17 –

IEC 258/12

Key

1 binding wire (aluminium or zinc-coated steel)

Figure B.1 – Specially prepared test pieces

For cores with circular conductors, a similar procedure shall be applied, where, for smaller

sizes (for example, 25 mm ), up to half the insulation can be separated.

B.2.3.2 Dumb-bell tests pieces preparation after ageing

Aged test pieces are dismantled and dumb-bell test pieces, two from each test pieces, shall

then be prepared in accordance with IEC 60811-501, the cross-sectional area being

determined in accordance with IEC 60811-501, as shown in the Figure B.2 below.

IEC 259/12

Figure B.2 – Dumb-bell test pieces preparation after ageing

– 18 – 60811-401 IEC:2012

Annex C

(normative)

Sample and test pieces preparation for ageing of complete cable

C.1 Sampling and preparation of test pieces for ageing

Three test pieces of complete cable about 200 mm long shall be taken, preferably from

positions close to that from which the samples for the tensile tests without ageing (see

IEC 60811-501) are taken.

C.2 Dumb-bell or tubular tests pieces preparation after ageing

The aged three test pieces of cable shall be dismantled. Two dumb-bell or tubular test pieces

shall be prepared from the insulation of each core (up to a maximum of three cores) and from

the sheath of each piece of cable, as specified in IEC 60811-501 so that there are six test

pieces from each core and from the sheath.

If the test pieces need to be cut or ground to reduce their thickness to not more than 2 mm,

this operation shall be effected, so far as possible, on the side which was not facing a

material of different type in the complete cable. If ridges need to be cut or ground on the side

which was facing the different type of material, the material removed on that side shall be the

minimum compatible with adequate smoothing.

60811-401 IEC:2012 – 19 –

Bibliography

IEC 60811-1-2:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section Two – Thermal ageing methods

(withdrawn)

______________

– 20 – 60811-401 CEI:2012

SOMMAIRE

AVANT-PROPOS . 21

INTRODUCTION . 23

1 Domaine d’application . 24

2 Références normatives . 24

3 Termes et définitions . 24

4 Méthode d’essai . 24

4.1 Généralités. 24

4.2 Influence du traitement de vieillissement sur les caractéristiques mécaniques . 25

4.2.1 Appareillage . 25

4.2.2 Echantillons et préparation des éprouvettes . 25

4.2.3 Méthode de vieillissement . 25

4.2.4 Mesures . 27

4.2.5 Expression du résultat . 27

4.2.6 Exigences . 27

4.2.7 Rapport d’essai . 27

4.3 Essai d’enroulement sur des éprouvettes de conducteur . 27

4.3.1 Appareillage . 27

4.3.2 Echantillons et préparation des éprouvettes . 27

4.3.3 Mode opératoire . 28

4.3.4 Exigence . 28

4.3.5 Rapport d’essai . 28

Annexe A (normative) Méthodes de mesure du débit d’air dans les étuves . 29

Annexe B (normative) Préparation des éprouvettes en présence d’âmes en cuivre nu

ou avec revêtement métallique . 33

Annexe C (normative) Préparation des échantillons et des éprouvettes pour le

vieillissement d’un câble complet . 36

Bibliographie . 37

Figure A.1 – Débitmètre pour le contrôle du débit d’air dans les étuves par la méthode 2 . 31

Figure A.2 – Diagramme d’étalonnage du tube capillaire du débitmètre pour le contrôle

du débit d’air dans les étuves par la méthode 2 . 32

Figure B.1 – Eprouvettes spécialement préparées . 35

Figure B.2 – Préparation des éprouvettes en forme d’haltère après vieillissement . 35

Tableau 1 – Nombre de tours pour l’essai d’enroulement . 28

Tableau B.1 – Résumé des essais de vieillissement des âmes isolées en cas de

difficultés rencontrées dans la préparation des éprouvettes, en raison d'une adhérence

de l’enveloppe isolante ou du séparateur pendant le vieillissement . 33

60811-401 CEI:2012 – 21 –

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

CÂBLES ÉLECTRIQUES ET À FIBRES OPTIQUES –

MÉTHODES D’ESSAI POUR LES MATÉRIAUX NON-MÉTALLIQUES –

Partie 401: Essais divers –

Méthodes de vieillissement thermique –

Vieillissement en étuve à air

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet

...

IEC 60811-401 ®

Edition 1.1 2017-07

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Electric and optical fibre cables – Test methods for non-metallic materials –

Part 401: Miscellaneous tests – Thermal ageing methods – Ageing in an air oven

Câbles électriques et à fibres optiques – Méthodes d’essai pour les matériaux

non-métalliques –

Partie 401: Essais divers – Méthodes de vieillissement thermique –

Vieillissement en étuve à air

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC

65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte,

et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les

publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées.

antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Restez informé sur les nouvelles publications IEC. Just Service Clients - webstore.iec.ch/csc

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60811-401 ®

Edition 1.1 2017-07

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Electric and optical fibre cables – Test methods for non-metallic materials –

Part 401: Miscellaneous tests – Thermal ageing methods – Ageing in an air oven

Câbles électriques et à fibres optiques – Méthodes d’essai pour les matériaux

non-métalliques –

Partie 401: Essais divers – Méthodes de vieillissement thermique –

Vieillissement en étuve à air

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.035.01; 29.060.20 ISBN 978-2-8322-4652-8

IEC 60811-401 ®

Edition 1.1 2017-07

CONSOLIDATED VERSION

REDLINE VERSION

VERSION REDLINE

colour

inside

Electric and optical fibre cables – Test methods for non-metallic materials –

Part 401: Miscellaneous tests – Thermal ageing methods – Ageing in an air oven

Câbles électriques et à fibres optiques – Méthodes d’essai pour les matériaux

non-métalliques –

Partie 401: Essais divers – Méthodes de vieillissement thermique –

Vieillissement en étuve à air

– 2 – IEC 60811-401:2012+AMD1:2017 CSV

IEC 2017

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Test method . 6

4.1 General . 6

4.2 Influence of the ageing treatment on the mechanical characteristics . 7

4.2.1 Apparatus . 7

4.2.2 Sample and test pieces preparation . 7

4.2.3 Ageing procedure . 7

4.2.4 Measurements . 8

4.2.5 Expression of results . 8

4.2.6 Requirements . 9

4.2.7 Test report . 9

4.3 Bending test on test pieces of core . 9

4.3.1 Apparatus . 9

4.3.2 Sample and test pieces preparation . 9

4.3.3 Procedure . 9

4.3.4 Requirement . 10

4.3.5 Test report . 10

Annex A (normative) Methods of measuring air flow in ovens . 11

Annex B (normative) Test pieces preparation in presence of copper or metal coated

copper conductor . 15

Annex C (normative) Sample and test pieces preparation for ageing of complete cable . 18

Bibliography . 19

Figure A.1 – Flowmeter for air-flow control in air ovens for method 2 . 13

Figure A.2 – Calibration diagram of the capillary tube of the flowmeter for air-flow

control in air ovens for method 2 . 14

Figure B.1 – Specially prepared test pieces . 17

Figure B.2 – Dumb-bell test pieces preparation after ageing . 17

Table 1 – Number of turns for bending test . 10

Table B.1 – Summary of ageing tests for insulated conductors in case of difficulties in

preparing test pieces due to conductor insulation or separator adhesion during ageing . 15

IEC 2017

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC AND OPTICAL FIBRE CABLES –

TEST METHODS FOR NON-METALLIC MATERIALS –

Part 401: Miscellaneous tests –

Thermal ageing methods – Ageing in an air oven

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been prepared

for user convenience.

IEC 60811-401 edition 1.1 contains the first edition (2012-03) [documents 20/1285/FDIS and

20/1334/RVD] and its amendment 1 (2017-07) [documents 20/1733/FDIS and 20/1738/RVD].

In this Redline version, a vertical line in the margin shows where the technical content is

modified by amendment 1. Additions are in green text, deletions are in strikethrough red text. A

separate Final version with all changes accepted is available in this publication.

– 4 – IEC 60811-401:2012+AMD1:2017 CSV

IEC 2017

International Standard IEC 60811-401 has been prepared by IEC technical committee 20:

Electric cables.

There are no specific technical changes with respect to the previous edition, but see

the Foreword to IEC 60811-100:2012.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This part of IEC 60811 shall be used in conjunction with IEC 60811-100.

A list of all the parts in the IEC 60811 series, published under the general title Electric and

optical fibre cables – Test methods for non-metallic materials, can be found on the IEC

website.

The committee has decided that the contents of the base publication and its amendment will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date,

the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

IEC 2017

INTRODUCTION

The IEC 60811 series specifies the test methods to be used for testing non-metallic materials

of all types of cables. These test methods are intended to be referenced in standards for

cable construction and for cable materials.

NOTE 1 Non-metallic materials are typically used for insulating, sheathing, bedding, filling or taping within cables.

NOTE 2 These test methods are accepted as basic and fundamental and have been developed and used over

many years principally for the materials in all energy cables. They have also been widely accepted and used for

other cables, in particular optical fibre cables, communication and control cables and cables for ships and offshore

applications.

– 6 – IEC 60811-401:2012+AMD1:2017 CSV

IEC 2017

ELECTRIC AND OPTICAL FIBRE CABLES –

TEST METHODS FOR NON-METALLIC MATERIALS –

Part 401: Miscellaneous tests –

Thermal ageing methods – Ageing in an air oven

1 Scope

This Part 401 of IEC 60811 specifies the procedure for ageing in an air oven, which typically

applies to crosslinked and thermoplastic compounds used for insulating and sheathing

materials.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60228, Conductors of insulated cables

IEC 60811-100:2012, Electric and optical fibre cables – Test methods for non-metallic

materials – Part 100: General

IEC 60811-409, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 409: Miscellaneous tests – Loss of mass test for thermoplastic insulations and sheaths

IEC 60811-501, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 501: Mechanical tests – Tests for determining the mechanical properties of insulating and

sheathing compounds

IEC 60811-504, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 504: Mechanical tests – Bending tests at low temperature for insulation and sheaths

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60811-100 apply.

4 Test method

4.1 General

This part of IEC 60811 shall be used in conjunction with IEC 60811-100.

Unless otherwise specified, tests shall be carried out at room temperature.

An ageing treatment in an air oven may be required by the relevant cable standard:

a) for prepared test pieces of insulating or sheathing material only (see 4.2.3.2);

b) for prepared test pieces of cores (conductor and insulation) (see 4.2.3.2 and 4.2.3.3 if

necessary);

IEC 2017

c) for test pieces of completed cable (see 4.2.3.4);

d) for the loss of mass test (see IEC 60811-409).

The ageing test a) or b) and the loss of mass test d) may be combined and carried out on the

same test pieces when the aging time and aging temperature are the same.

In general, mechanical characteristics are measured after treatment, but in some cases, the

conductor and the separator, if any, cannot be removed without damaging the insulation and a

bending test is realized on the circular conductor up to and including 16 mm . Ageing followed

by the bending test is considered the acceptance procedure in case of dispute.

4.2 Influence of the ageing treatment on the mechanical characteristics

4.2.1 Apparatus

The ageing treatment is realized in an oven with natural air flow or air flow by pressure. The

air shall enter the oven in such a way that it flows over the surface of the test pieces and

leaves near the top of the oven. The oven shall have not less than 8 and not more than 20

complete air changes per hour at the specified ageing temperature. Two test methods for

measuring air flow through an oven are given in Annex A.

Unless otherwise specified in the relevant cable specification, a rotating fan inside the oven is

allowed when testing rubber compounds. For all other compounds a fan shall not be used

inside the oven, and in cases of dispute, rubber compounds shall also be tested in an oven

which is designed to operate without a fan rotating inside it.

4.2.2 Sample and test pieces preparation

The sample of the cable, or sheath removed from the cable, or samples of core, cut into

pieces which are sufficiently long, shall be taken, preferably from positions close to that from

which the samples for the tensile tests without ageing are taken in accordance with

IEC 60811-501.

Test pieces, dumb-bell or tubular, are prepared according to IEC 60811-501.

Test pieces can consist of samples of core, cut into pieces which are sufficiently long. If, after

ageing, the conductor and the separator, if any, cannot be removed without damaging the

insulation, preparation of test pieces shall be carried out according to Annex B (Clause B.2).

For circular conductors up to and including 16 mm and having plain or metal coated wires

and also when a separator around the conductor is included, a bending test is carried out on

the aged test pieces.

4.2.3 Ageing procedure

4.2.3.1 General

This test shall be carried out not less than 16 h after the extrusion or cross-linking, if any, of

the insulating or sheathing compounds. It can be done on tubular or dumb-bell test pieces

prepared according to IEC 60811-501 or insulated cores as described in the present standard.

4.2.3.2 Ageing procedure for test pieces prepared according to IEC 60811-501 and

Clause B.1 and B.2.2 and Annex C of this standard

This procedure shall be used for

– test pieces of insulating material without conductor and of sheathing material, according to

IEC 60811-501,

– test pieces of cores with the original conductor (see Clause B.1),

– tubular test pieces with a reduced conductor (see B.2.2),

– 8 – IEC 60811-401:2012+AMD1:2017 CSV

IEC 2017

– complete cable (see Annex C).

Compounds of obviously different compositions shall not be tested at the same time in the

same oven.

Five test pieces, as specified in IEC 60811-501 shall be suspended vertically and

substantially in the middle of the oven so that each test piece is at least 20 mm from any

other test pieces.

The test pieces shall not occupy more than 2 % of the volume of the oven.

The test pieces shall be kept in the oven at the temperature and for the time specified for the

material in the relevant standard for the type of cable.

As soon as the ageing period is completed, the test pieces shall be removed from the oven

and left at ambient room temperature, avoiding direct sunlight, for at least 16 h.

4.2.3.3 Ageing procedure for test pieces prepared from conductors above 16 mm

The following procedure shall be used when the conductor and the separator, if any, cannot

be removed without damaging the insulation after ageing.

The test pieces prepared as described in B.2.3.1 shall be placed substantially in the middle of

the oven so that each test piece is at least 20 mm from any other test pieces. They shall be

supported at both ends and the insulation shall not contact any object other than the binding

wire. The test pieces shall not occupy more than 2 % of the volume of the oven, and they

shall be kept in the oven at the temperature and for the time specified in the relevant standard

for the type of cable.

As soon as the ageing period is completed, the test pieces shall be removed from the oven,

left at ambient room temperature avoiding direct sunlight, for at least 16 h, dumb-bell are

prepared as described in B.2.3.2.

4.2.3.4 Ageing procedure for pieces of complete cable

The three test pieces of cable as described in Clause C.1 shall be suspended vertically and

substantially in the middle of the oven at least 20 mm away from any other piece and shall not

occupy more than 2 % of the volume of the oven.

The test pieces of cable shall be kept in the oven at the temperature and for the time

specified in the relevant standard for the type of cable.

As soon as the specified heating period is completed, the test pieces of cable shall be

removed from the oven and left at ambient room temperature, avoiding direct sunlight, for at

least 16 h.

4.2.4 Measurements

Determination of the mechanical properties on aged dumb-bell and/or tubular test pieces

obtained directly after ageing or prepared after ageing, according to the case (see B.2.3 or

Clause C.2) shall then be carried out in accordance of IEC 60811-501.

4.2.5 Expression of results

Calculate the tensile strength and the elongation at break, according to the definitions given

in IEC 60811-501.

IEC 2017

If required by the standard for the material in the relevant standard for the type of cable, the

values found for the aged test pieces shall be calculated, in terms of variation compared to

the untreated test pieces according to the following formulae:

T − T

E U

V = × 100 (1)

T

T

U

E − E

E U

V = × 100 (2)

E

E

U

where

V variation of the tensile strength in per cent;

T

T tensile strength of aged test piece;

E

T tensile strength of untreated test piece;

U

V variation of the elongation at break in per cent;

E

E elongation at break of aged test piece in per cent;

E

E elongation at break of untreated test piece in per cent.

U

NOTE The untreated specimen is kept at room temperature.

4.2.6 Requirements

The value and the variation between the median value obtained of the test pieces aged and

the median value of the values obtained for the untreated test pieces (see IEC 60811-501)

expressed as a percentage of the latter shall not exceed the percentage specified in the

standard for the material in the relevant standard for the type of cable.

4.2.7 Test report

The test report shall be in accordance with that given in IEC 60811-100.

4.3 Bending test on test pieces of core

4.3.1 Apparatus

Ageing is carried out in an oven as described in 4.2.1.

The bending test apparatus is described in IEC 60811-504.

4.3.2 Sample and test pieces preparation

Two samples of suitable length shall be taken from each core to be tested preferably from

positions close to that from which the samples for the tensile tests without ageing are taken

(see IEC 60811-504).

4.3.3 Procedure

Test pieces are aged according to the procedure described in 4.2.3.3.

As soon as the ageing period is completed, the test pieces shall be removed from the oven

and left at room temperature, avoiding direct sunlight, for at least 16 h.

Each test piece shall then be bent at ambient room temperature around a mandrel so as to

form a close helix.

– 10 – IEC 60811-401:2012+AMD1:2017 CSV

IEC 2017

The bending procedure shall be carried out uniformly at a rate of one turn in about 5 s.

The bending tests may be carried out with the apparatus described in IEC 60811-504.

The diameter of the mandrel shall be f times the diameter of the core. The values of f and also

the number of turns are specified as follows.

Table 1 – Number of turns for bending test

Cross-sectional area

Factor

of conductor Number of turns

f

mm

Up to and including 2,5 7

1 ±0,1

4 and 6 6

2 ±0,1

10 and 16 5

4 ±0,1

4.3.4 Requirement

At the end of the bending procedure the test pieces shall be examined while still on the

mandrel. The insulation of both test pieces shall not show any crack when examined with

normal or corrected vision without magnification. Any cracks in the first or the last turn on the

mandrel shall be disregarded.

4.3.5 Test report

The test report shall be in accordance with that given in IEC 60811-100.

IEC 2017

Annex A

(normative)

Methods of measuring air flow in ovens

A.1 Method 1 – Indirect or power consumption method

A.1.1 In this method, the additional power required to maintain the oven at a given

temperature with its ports open, over that required to maintain the oven at the same

temperature with its ports closed, is used as a measure of the quantity of air passing through

the oven when the ports are open. The average power (P1 watts) required to maintain the

oven temperature at the specified ageing temperature when the ports are open is determined

over a period of 30 min or longer. The ventilation ports (and, if necessary, the thermometer

aperture) are then closed and the average power (P2 watts) to maintain the same temperature

over a similar period is determined. It is essential that the difference between the oven

temperature and the room temperature should be the same for the two tests to within 0,2 °C.