IEC 60312-1:2010

(Main)Vacuum cleaners for household use - Part 1: Dry vacuum cleaners - Methods for measuring the performance

Vacuum cleaners for household use - Part 1: Dry vacuum cleaners - Methods for measuring the performance

IEC 60312-1:2010(E) applicable for measurements of the performance of dry vacuum cleaners for household use in or under conditions similar to those in households. The purpose of this document is to specify essential performance characteristics of dry vacuum cleaners being of interest to the users and to describe methods for measuring these characteristics. Due to influence of environmental conditions, variations in time, origin of test materials and proficiency of the operator, most of the described test methods will give more reliable results when applied for comparative testing of a number of appliances at the same time, in the same laboratory and by the same operator. This document is not intended for battery-operated vacuum cleaners. For safety requirements, reference is made to IEC 60335-1 and IEC 60335-2-2.

Click here to access to information on suppliers of test materials and details of test equipment. This information is given for the convenience of users of this International Standard and does not constitute an endorsement by IEC of the suppliers named. This information will be continuously updated.

Aspirateurs de poussière à usage domestique - Partie 1: Aspirateurs de poussière - Méthodes de mesure de l’aptitude à la fonction

General Information

- Status

- Replaced

- Publication Date

- 06-Nov-2011

- Technical Committee

- SC 59F - Surface cleaning appliances

- Drafting Committee

- WG 3 - TC 59/SC 59F/WG 3

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 25-Aug-2016

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Buy Documents

IEC 60312-1:2010+AMD1:2011 CSV - Vacuum cleaners for household use - Part 1: Dry vacuum cleaners - Methods for measuring the performance Released:11/7/2011

IEC 60312-1:2010 - Vacuum cleaners for household use - Part 1: Dry vacuum cleaners - Methods for measuring the performance Released:9/23/2010

IEC 60312-1:2010 - Vacuum cleaners for household use - Part 1: Dry vacuum cleaners - Methods for measuring the performance Released:9/23/2010

Frequently Asked Questions

IEC 60312-1:2010 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Vacuum cleaners for household use - Part 1: Dry vacuum cleaners - Methods for measuring the performance". This standard covers: IEC 60312-1:2010(E) applicable for measurements of the performance of dry vacuum cleaners for household use in or under conditions similar to those in households. The purpose of this document is to specify essential performance characteristics of dry vacuum cleaners being of interest to the users and to describe methods for measuring these characteristics. Due to influence of environmental conditions, variations in time, origin of test materials and proficiency of the operator, most of the described test methods will give more reliable results when applied for comparative testing of a number of appliances at the same time, in the same laboratory and by the same operator. This document is not intended for battery-operated vacuum cleaners. For safety requirements, reference is made to IEC 60335-1 and IEC 60335-2-2. Click here to access to information on suppliers of test materials and details of test equipment. This information is given for the convenience of users of this International Standard and does not constitute an endorsement by IEC of the suppliers named. This information will be continuously updated.

IEC 60312-1:2010(E) applicable for measurements of the performance of dry vacuum cleaners for household use in or under conditions similar to those in households. The purpose of this document is to specify essential performance characteristics of dry vacuum cleaners being of interest to the users and to describe methods for measuring these characteristics. Due to influence of environmental conditions, variations in time, origin of test materials and proficiency of the operator, most of the described test methods will give more reliable results when applied for comparative testing of a number of appliances at the same time, in the same laboratory and by the same operator. This document is not intended for battery-operated vacuum cleaners. For safety requirements, reference is made to IEC 60335-1 and IEC 60335-2-2. Click here to access to information on suppliers of test materials and details of test equipment. This information is given for the convenience of users of this International Standard and does not constitute an endorsement by IEC of the suppliers named. This information will be continuously updated.

IEC 60312-1:2010 is classified under the following ICS (International Classification for Standards) categories: 97.080 - Cleaning appliances. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60312-1:2010 has the following relationships with other standards: It is inter standard links to IEC 60312:2007, IEC 62885-2:2016, IEC 60312-1:2010/AMD1:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60312-1:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60312-1 ®

Edition 1.1 2011-11

INTERNATIONAL

STANDARD

colour

inside

Vacuum cleaners for household use –

Part 1: Dry vacuum cleaners – Methods for measuring the performance

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60312-1 ®

Edition 1.1 2011-11

INTERNATIONAL

STANDARD

colour

inside

Vacuum cleaners for household use –

Part 1: Dry vacuum cleaners – Methods for measuring the performance

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

CQ

ICS 97.080 ISBN 978-2-88912-738-2

– 2 – 60312-1 IEC:2010+A1:2011(E)

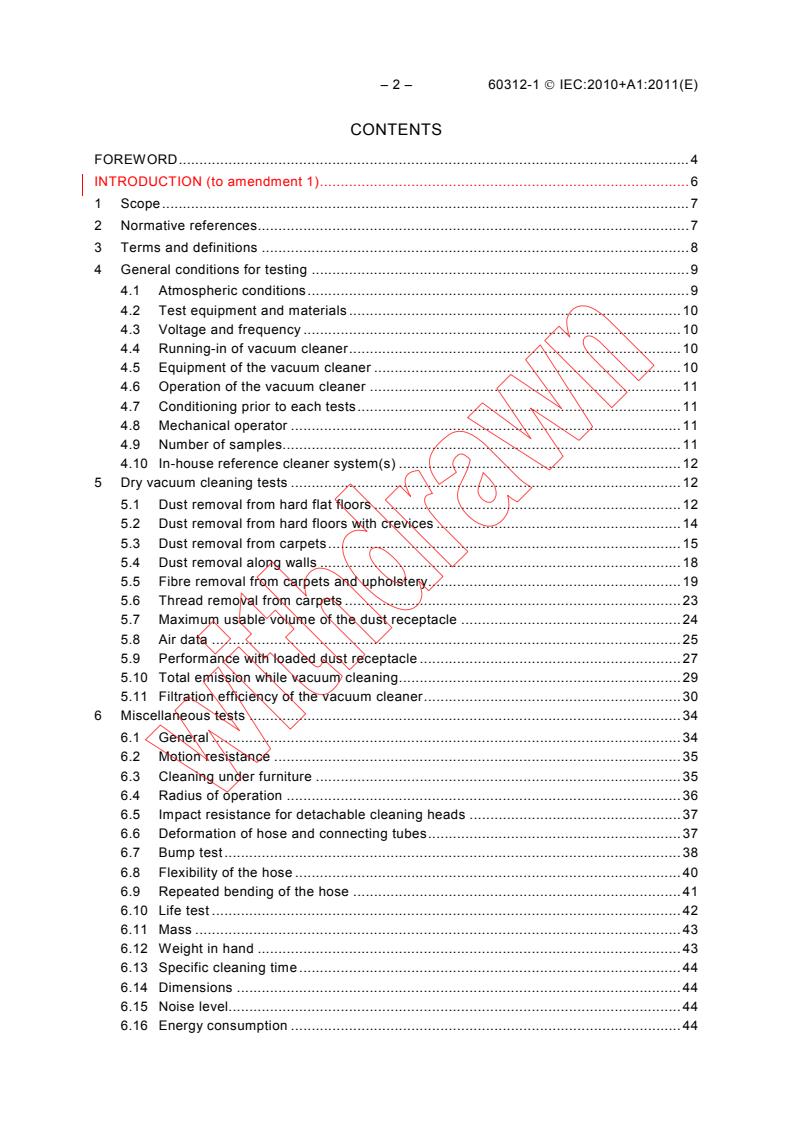

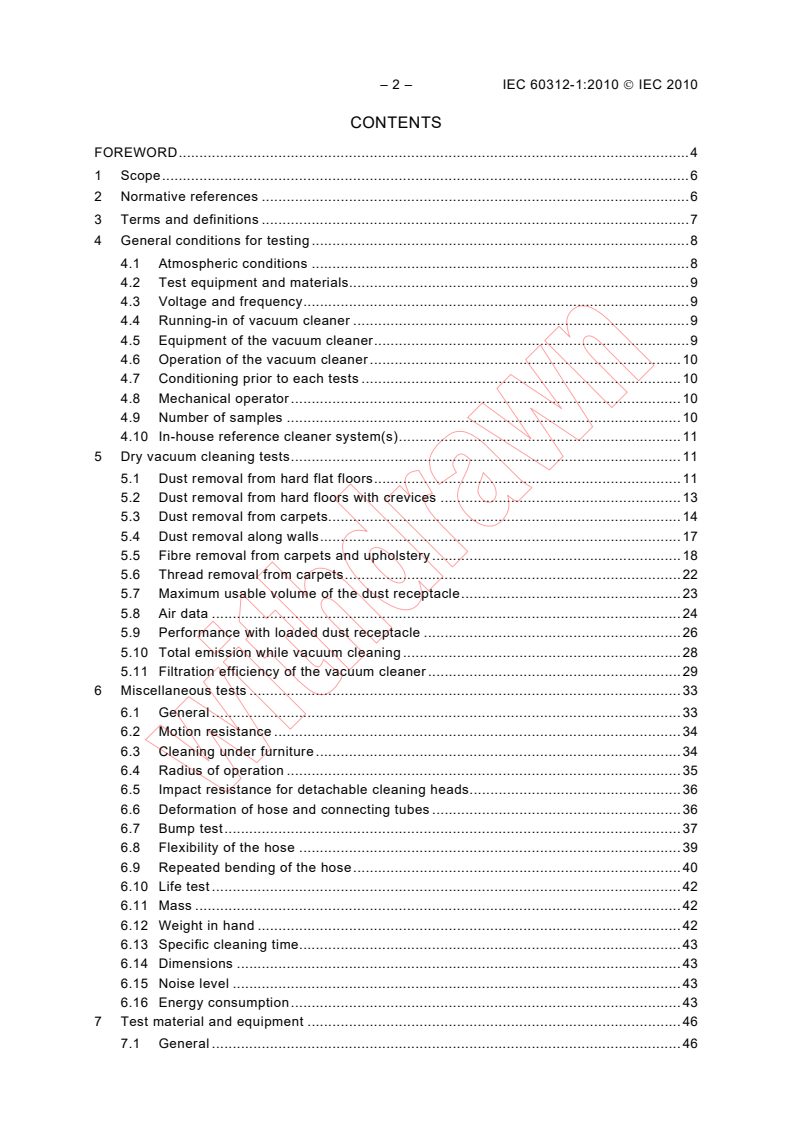

CONTENTS

FOREWORD . 4

INTRODUCTION (to amendment 1) . 6

1 Scope . 7

2 Normative references. 7

3 Terms and definitions . 8

4 General conditions for testing . 9

4.1 Atmospheric conditions . 9

4.2 Test equipment and materials . 10

4.3 Voltage and frequency . 10

4.4 Running-in of vacuum cleaner . 10

4.5 Equipment of the vacuum cleaner . 10

4.6 Operation of the vacuum cleaner . 11

4.7 Conditioning prior to each tests . 11

4.8 Mechanical operator . 11

4.9 Number of samples. 11

4.10 In-house reference cleaner system(s) . 12

5 Dry vacuum cleaning tests . 12

5.1 Dust removal from hard flat floors . 12

5.2 Dust removal from hard floors with crevices . 14

5.3 Dust removal from carpets . 15

5.4 Dust removal along walls . 18

5.5 Fibre removal from carpets and upholstery . 19

5.6 Thread removal from carpets . 23

5.7 Maximum usable volume of the dust receptacle . 24

5.8 Air data . 25

5.9 Performance with loaded dust receptacle . 27

5.10 Total emission while vacuum cleaning . 29

5.11 Filtration efficiency of the vacuum cleaner . 30

6 Miscellaneous tests . 34

6.1 General . 34

6.2 Motion resistance . 35

6.3 Cleaning under furniture . 35

6.4 Radius of operation . 36

6.5 Impact resistance for detachable cleaning heads . 37

6.6 Deformation of hose and connecting tubes . 37

6.7 Bump test . 38

6.8 Flexibility of the hose . 40

6.9 Repeated bending of the hose . 41

6.10 Life test . 42

6.11 Mass . 43

6.12 Weight in hand . 43

6.13 Specific cleaning time . 44

6.14 Dimensions . 44

6.15 Noise level. 44

6.16 Energy consumption . 44

60312-1 IEC:2010+A1:2011(E) – 3 –

7 Test material and equipment . 46

7.1 General . 46

7.2 Material for measurements . 47

7.3 Equipment for measurements . 52

8 Instructions for use . 67

Annex A (informative) Information on materials. 68

Annex B (informative) Information at the point of sale . 69

Annex C (normative) Guidance specification on verified carpets . 70

Bibliography . 72

Figure 1 – Right-angled T . 18

Figure 2 – Determination of cleaning area . 19

Figure 3 – Stencil for distribution of fibres on test carpets . 20

Figure 4 – Zig Zag stroke pattern . 21

Figure 5 – Frame for test cushion . 22

Figure 6 – Stencil for distribution of fibres on upholstery . 22

Figure 7 – Arrangement of threads in the thread removal test . 23

Figure 8 – Stroke length in measurements . 24

Figure 9 – Air data curves . 26

Figure 10 – Connecting tube opening . 27

Figure 11 – Test dust for loading dust receptacle . 28

Figure 12 – Insertion depth . 36

Figure 13 – Position of test object and cross-section for measurement of deformation . 38

Figure 14 – Profile of threshold . 39

Figure 15 – Arrangements for bump test . 39

Figure 16 – Preparation of hoses for testing flexibility . 41

Figure 17 – Equipment for repeated bending of hoses . 42

Figure 18 – Test plate with crevice . 52

Figure 19 – Carpet-beating machine . 53

Figure 20 – Carpet hold-downs and guides . 54

Figure 21 – Dust spreader and roller for embedding dust into carpets . 54

Figure 22 – Alternative A equipment for air data measurements . 55

Figure 23 – Measuring box for alternative A . 56

Figure 24 – Alternative B equipment for air data measurements . 58

Figure 25 – Test hood . 62

Figure 26 – Aerosol channel with sampling probe . 63

Figure 27 – Exhaust channel with sampling probe . 63

Figure 28 – Drum for impact test . 65

Figure 29 – Device for testing deformation of hoses and connecting tubes . 66

Figure 30 – Mechanical operator for the measurement of dust removal from carpets and

of motion resistance . 67

Table 1 – Confidence limits of a Poisson distribution for 95 % - confidence range . 33

Table 2 – Graduation of 8 size classes for particle sizes 0,3 µm – 10 µm . 64

– 4 – 60312-1 IEC:2010+A1:2011(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

VACUUM CLEANERS FOR HOUSEHOLD USE –

Part 1: Dry vacuum cleaners –

Methods for measuring the performance

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of IEC 60312-1 consists of the first edition (2010) [documents

59F/195/FDIS and 59F/199/RVD] and its amendment 1 (2011) [documents 59F/206/CDV

and 59F/207/RVC]. It bears the edition number 1.1.

The technical content is therefore identical to the base edition and its amendment and

has been prepared for user convenience. A vertical line in the margin shows where the

base publication has been modified by amendment 1. Additions and deletions are

displayed in red, with deletions being struck through.

60312-1 IEC:2010+A1:2011(E) – 5 –

International Standard IEC 60312-1 has been prepared by subcommittee 59F: Floor treatment

appliances, of IEC technical committee 59: Performance of household and similar electrical

appliances.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 60312 series, under the general title Vacuum cleaners for

household use, can be found on the IEC website.

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

– 6 – 60312-1 IEC:2010+A1:2011(E)

INTRODUCTION

(to amendment 1)

The following changes to IEC 60312-1 concern Subclauses 5.5 and 5.9 and the related

specifications in Subclauses 7.2.2 and 7.2.6.

The reason for this is due to the tightening of the specification to the cotton linters used in the

test dust. In order to reproduce the airflow restricting conditions expected during the

development of this test it is necessary to use more test dust when Condition 3 is used as a

stopping point. Further, it provides a specification for the cellulose dust.

In addition to this an updated specification of the cushion slip material is available.

60312-1 IEC:2010+A1:2011(E) – 7 –

VACUUM CLEANERS FOR HOUSEHOLD USE –

Part 1: Dry vacuum cleaners –

Methods for measuring the performance

1 Scope

This International Standard is applicable for measurements of the performance of dry vacuum

cleaners for household use in or under conditions similar to those in households.

The purpose of this standard is to specify essential performance characteristics of dry vacuum

cleaners being of interest to the users and to describe methods for measuring these

characteristics.

NOTE 1 Due to influence of environmental conditions, variations in time, origin of test materials and proficiency of

the operator, most of the described test methods will give more reliable results when applied for comparative

testing of a number of appliances at the same time, in the same laboratory and by the same operator.

NOTE 2 This standard is not intended for battery-operated vacuum cleaners.

For safety requirements, reference is made to IEC 60335-1 and IEC 60335-2-2.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60688, Electrical measuring transducers for converting a.c. electrical quantities to

analogue or digital signals

IEC 60704-1, Household and similar electrical appliances − Test code for the determination of

airborne acoustical noise − Part 1: General requirements

IEC 60704-2-1, Household and similar electrical appliances − Test code for the determination

of airborne acoustical noise − Part 2-1: Particular requirements for vacuum cleaners

ISO 554, Standard atmospheres for conditioning and/or testing – Specifications

ISO 679, Methods of testing cements − Determination of strength

ISO 1763, Carpets − Determination of number of tufts and/or loops per unit length and per unit

area

ISO 1765, Machine-made textile floor coverings − Determination of thickness

ISO 1766, Textile floor coverings − Determination of thickness of pile above the substrate

ISO 2424, Textile floor coverings – Vocabulary

ISO 2439, Flexible cellular polymeric materials – Determination of hardness (indentation

technique)

– 8 – 60312-1 IEC:2010+A1:2011(E)

ISO 3386-1, Polymeric materials, cellular flexible – Determination of stress-strain

characteristics in compression – Part 1: Low-density materials

ISO 5167-1, Measurement of fluid flow by means of pressure differential devices inserted in

circular cross-section conduits running full – Part 1: General principles and requirements

ISO 8543, Textile floor coverings – Methods for determination of mass

ISO 12103-1, Road vehicles – Test dust for filter evaluation – Part 1: Arizona test dust

3 Terms and definitions

For the purpose of this document, the following definitions apply:

3.1

dry vacuum cleaner

electrically operated appliance that removes dry material (e. g. dust, fibre, threads) from the

surface to be cleaned by an airflow created by a vacuum developed within the unit, the

removed material being separated in the appliance and the cleaned suction air being returned

to the ambient

3.2

upright cleaner

self-standing and floor-supported vacuum cleaner with the cleaning head forming an integral

part of or permanently connected to the cleaner housing, the cleaning head normally being

provided with an agitation device to assist dirt removal and the complete cleaner housing being

moved over the surface to be cleaned by means of an attached handle

3.3

cleaning head

plain nozzle or a brush attached to a connecting tube, or a power nozzle, separate or part of

the cleaner housing, and that part of a vacuum cleaner which is applied to a surface to be

cleaned

3.4

active nozzle

cleaning head provided with a driven agitation device to assist dirt removal

NOTE The agitation device may be driven by an incorporated electric motor (motorized nozzle), an incorporated

turbine powered by the air flow (air-turbine nozzle) or an incorporated friction or gear mechanism actuated by

moving the cleaning head over the surface to be cleaned (mechanical nozzle)

3.5

passive nozzle

cleaning head without any driven agitation devices

3.6

self-propelled cleaning head

cleaning head provided with a propulsion mechanism

3.7

cleaning head width

B

the external maximum width of the cleaning head in metres

60312-1 IEC:2010+A1:2011(E) – 9 –

3.8

active depth of the cleaning head

distance from the front edge of the cleaning head to its rear edge or a line 10 mm behind the

rear edge of the suction opening on the underside of the cleaning head, whichever is the

shortest

3.9

cleaning cycle

the sequence of five double strokes to be carried out at a specified stroke speed over the test

area according to the appropriate stroke pattern

3.10

stroke pattern

arrangement of the forward and return strokes on the surface to be cleaned

3.11

parallel pattern

stroke pattern where the forward and the return strokes are congruent and are carried out in

the direction of the carpet pile (direction of manufacture) unless otherwise specified

3.12

stroke speed

speed of the cleaning head, moved as uniformly as possible, during a forward or a return

stroke

3.13

stroke length

distance between the two parallel lines defining the limits of a stroke pattern

3.14

double stroke

one forward and one backward movement of the cleaning head performed in a parallel pattern

3.15

forward stroke

forward movement of a stroke pattern

NOTE On test carpets, forward strokes are carried out in the direction of the carpet pile (direction of

manufacturing).

3.16

return stroke

backward movement of a stroke pattern

4 General conditions for testing

4.1 Atmospheric conditions

Unless otherwise specified, the test procedures and measurements shall be carried out under

the following conditions (in accordance with ISO 554):

Standard atmosphere 23/50

Temperature: (23 ± 2) °C

Relative humidity: (50 ± 5) %

Air pressure: 86 kPa to 106 kPa

– 10 – 60312-1 IEC:2010+A1:2011(E)

NOTE Temperature and humidity conditions within the specified ranges are required for good repeatability and

reproducibility. Care should be taken to avoid changes during a test.

For test procedures and measurements which may be carried out at other than standard

atmospheric conditions, the ambient temperature shall be maintained at (23 ± 5) °C.

4.2 Test equipment and materials

To minimize the influence of electrostatic phenomena, measurements on carpets shall be

carried out on a flat floor consisting of a smooth untreated pine plywood or equivalent panel,

at least 15 mm thick and of a size appropriate for the test.

Equipment and materials for measurements (devices, test carpets, test dust etc.) to be used in

a test shall, prior to the test, be kept hanging free or laying flat for at least 16 h at standard

atmospheric conditions according to 4.1.

NOTE It is recommended that carpets that are already being used should be stored unbeaten at standard

atmospheric conditions according to 4.1. When not in use they should be preferably hanging free, or may be lying

flat, pile upwards and uncovered but not rolled.

4.3 Voltage and frequency

Unless otherwise stated, measurements shall be carried out at rated voltage with a tolerance of

±1 % and, if applicable, at rated frequency.

Vacuum cleaners designed for d.c. only shall be operated at d.c. Vacuum cleaners designed

for both a.c. and d.c. shall be operated at a.c. Vacuum cleaners not marked with rated

frequency shall be operated at either 50 Hz or 60 Hz, as is common in the country of use.

For vacuum cleaners with a rated voltage range, measurements shall be carried out at the

mean value of the voltage range if the difference between the limits of the range does not

exceed 10 % of the mean value. If the difference exceeds 10 % of the mean value,

measurements shall be carried out both at the upper and lower limits of the voltage range.

If the rated voltage differs from the nominal system voltage of the country concerned,

measurements carried out at rated voltage may give test results misleading for the consumer,

and additional measurements may be required. If the test voltage differs from the rated

voltage, this shall be reported.

4.4 Running-in of vacuum cleaner

Prior to the first test on a new vacuum cleaner it shall be kept running with unrestricted air flow

for at least 2 h to ensure adequate running-in. For active nozzles, the agitation device shall be

running but not in contact with the floor.

Prior to conducting any series of tests, the age, condition, and history of the product shall be

recorded.

4.5 Equipment of the vacuum cleaner

If the vacuum cleaner is designed to be used with disposable dust receptacles, it shall, prior to

each measurement, be equipped with a new dust receptacle of the type recommended or

supplied by the manufacturer of the vacuum cleaner.

If the vacuum cleaner is provided with a reusable dust receptacle (as the sole original dust

receptacle or as an enclosure for disposable dust receptacles), the dust receptacle and any

additional filters removable without the aid of tools shall, prior to each measurement, be

cleaned according to manufacturer’s instructions until its weight is within 1 % or 2 g of its

original weight whichever is the lower.

60312-1 IEC:2010+A1:2011(E) – 11 –

Some reusable receptacles consist of a rigid container and an integral filter. In this case the

container and the filter are considered to be the receptacle and should be treated as if they

were a single component.

Vacuum cleaners equipped with separation devices, being part of the appliance, used to

separate the dust from the airflow and/or having additional filters to be changed or cleaned by

the user, without the use of tools, the weight of such specific devices shall be taken into

account for dust removal ability.

Vacuum cleaners with disposable or reusable dust receptacles may have secondary filtration

stage devices which do not collect meaningful dust in removal ability tests but which do impact

on filtration and life tests. Replacement and/or maintenance of such devices shall be in

accordance with relevant sections and carried out according to manufacturer’s instructions.

4.6 Operation of the vacuum cleaner

The vacuum cleaner and its attachments shall be used and adjusted in accordance with the

manufacturer's instructions for normal operation for the test to be carried out. Height

adjustment controls for the cleaning head shall be set as appropriate for the surface to be

cleaned and the position noted. Any electrical controls shall be set for maximum continuous air

flow and, unless the manufacturer's instruction states otherwise, any manually operated air by-

pass openings for reduction of the suction power shall be closed, and if open, it shall be

reported. Any safety-related device shall be allowed to operate.

The tube grip of cleaners with suction hose or the handle of other cleaners shall be held as for

normal operation at a height of (800 ± 50) mm above the test floor.

During measurements where the agitation device of an active nozzle is not used as in normal

operation, the agitation device shall be running but not in contact with any surface.

4.7 Conditioning prior to each tests

If the vacuum cleaner is unused and de-energized for more than 1 h, then the vacuum cleaner

and attachments to be used shall be kept running for at least 10 min under the provisions given

in 4.4 to allow them to stabilise.

4.8 Mechanical operator

In order to achieve reliable results, certain measurements require the cleaning head to be

moved at uniform speed over the test area and without exerting an additional force pressing

the cleaning head against the test surface.

It is recommended to simulate the handling of the vacuum cleaner by using a mechanical

operator such as described in 7.3.12. The tube grip of cleaners with suction hose or the handle

of other cleaners shall then be attached to the linear drive so that its centre pivots at a height

of (800 ± 50) mm above the test surface. For nozzles without pivoting connectors, it shall be

ensured that the bottom of the cleaning head be made parallel with the test surface by

adjusting the handle height within the tolerances. If this is not possible, the length of a

telescopic tube may be adjusted. Any adjustment shall be reported.

The linear drive may be motorized or operated by hand. The method of operation shall be

reported.

4.9 Number of samples

All measurements of performance shall be carried out on the same sample(s) of the vacuum

cleaner with its attachments, if any.

– 12 – 60312-1 IEC:2010+A1:2011(E)

NOTE For increased confidence in the test results, it is recommended that a minimum of three samples of a

vacuum cleaner should be tested.

Tests carried out to simulate stresses a vacuum cleaner may be exposed to during normal use,

possibly causing impairment of the cleaner’s performance, may require additional samples of

replaceable parts. Such tests shall be carried out at the end of the test programme.

4.10 In-house reference cleaner system(s)

NOTE 1 The reference cleaner referred to in this standard is a product designated within a laboratory for internal

comparison and should not be used for inter-laboratory comparisons

Test carpets used in a laboratory for the determination of dust removal ability will, over time,

change from their original conditions, for instance due to wearing or gradual filling with dust. It

is therefore required that in-house reference cleaner system(s) be used to regularly check the

carpet conditions as a verification of the test results obtained and being recorded.

NOTE 2 Due to the fact that pick-up ability may differ between carpets used for active or passive nozzles, the

result from tests between active and passive nozzles may not be compared.

Test carpets designated for testing of passive nozzles shall only be cleaned with a passive

nozzle on the face. Test carpets designated for testing active nozzles shall only be cleaned

with an active nozzle on the face.

5 Dry vacuum cleaning tests

5.1 Dust removal from hard flat floors

5.1.1 Test equipment

A floor test plate in accordance with 7.3.1 shall be used.

5.1.2 Test area and stroke length

The length of the test area is (700 ± 5) mm. The width of the test area is equal to the cleaning

head width (see 3.7).

A length of at least 200 mm shall be added before the beginning of the test area and at least

300 mm after the end of the test area in order to allow acceleration and deceleration of the

cleaning head.

Thus, the stroke length is at least 1200 mm for the given test length of 700 mm. The centreline

of the front edge of the cleaning head is aligned to the centre line of the beginning of the

acceleration area at the commencement of the stroke allowing the distance of 200 mm to be

used for acceleration. The cleaning head shall reach the end of the stroke when the rear edge

of the active depth of the cleaning head is at least 200 mm past the end of the test area, thus

allowing a suitable distance for deceleration. The reverse stroke is carried out in the same

manner until the front edge of the cleaning head is once again lined up with the beginning of

the acceleration length in front of the test area.

The active depth of the cleaning head shall move at uniform stroke speed 0,50 m/s ± 0,02 m/s

and in a straight line over the test area.

For optimum control of the double stroke movement it is recommended that an

electromechanical operator (see 4.8) be used.

___________

This test is under review and may be substituted by a debris pick-up test from hard floor.

60312-1 IEC:2010+A1:2011(E) – 13 –

Two hold-downs in accordance with 7.3.4 serve the purpose of acting as guides to keep the

cleaning head in a straight line as it is moved over the test area and to ensure an undisturbed

flow.

Vacuum cleaners equipped with a self drive device shall be operated at the prescribed stroke

speed of 0,5 m/s ± 0,02 m/s if possible. Otherwise, the stroke speed will be determined by the

vacuum cleaner.

5.1.3 Removal of remaining dust

The hard surface shall be dry cleaned so that no dust remains prior to any subsequent test.

5.1.4 Distribution of test dust

Test dust, Type 1 in accordance with 7.2.2.1, shall be distributed with a mean coverage of 50

g/m per square metre as uniformly as possible over the test area.

The amount of test dust to be used is calculated from the formula B × 0,7 m × 50 g/m , where

B is the cleaning head width in meters and the length of the test area is 0,7 m.

5.1.5 Preconditioning of dust receptacle

In order to minimize the effects of humidity, the dust receptacle shall be preconditioned as

follows.

The vacuum cleaner under test is equipped with a clean dust receptacle and allowed to run

with an unimpeded air flow with the nozzle clear of the surface for 2 min or until input power

has stabilised.

After the preconditioning, the dust receptacle and any filters removable without tools are

removed from the cleaner to be weighed. The weight shall be noted and the items are

replaced.

NOTE Since the cleaner air flow can have an effect on the weight of the dust receptacle during the 2 min

preconditioning, caution should be taken so that the weight of the dust receptacle has stabilised before weighing.

5.1.6 Determination of dust removal ability

Three separate measurements, each comprising one double stroke, shall be carried out. After

the double stroke, the cleaning head shall be lifted at least 50 mm clear of the surface before

the vacuum cleaner is switched off. The dust receptacle shall not be removed before the motor

has completely stopped.

Once the cleaner has completely stopped, the receptacle is carefully removed and reweighed.

Due to effects of possible static charge build-up during the time the vacuum cleaner is picking

up dust, it is necessary to ensure that the receptacle has completely stabilised prior to

recording the weight.

The dust removal ability is calculated as the ratio of the weight increase of the dust receptacle

during the double stroke to the weight of the test dust distributed on the test area. The mean

value for 3 measurements is calculated as follows:

K (3) = (K + K + K ) 3

B B1 B2 B3

– 14 – 60312-1 IEC:2010+A1:2011(E)

where K = 100 × (m − m ) m

Bi DRf DRe D

and

K (i ) is the mean dust removal for i measurements in per cent;

B

K is the dust removal for measurement i in per cent;

Bi

m is the weight of the dust distributed on the test area in grams;

D

m (i ) is the weight of the preconditioned dust receptacle in grams;

DRe

is the weight of the dust receptacle after cleaning in grams.

m (i )

DRf

When the mean value is lower than 90 %: should the range of measurements be greater than 3

percentage units, two additional measurements are carried out and the mean value of all the

measurements should be given as the result.

When the mean value is equal or higher than 90 %: should the range of the measurements be

greater than 0,3 × (100 % − mean value), two additional measurements are carried out and the

mean value of all the measurements should be given as the result.

In both cases, consideration should be given to the control of repeatability within the laboratory

and the design or manufacture of the cleaner or cleaning head in order to ascertain whether

any factors not previously observed may affect the repeatability adversely.

5.2 Dust removal from hard floors with crevices

5.2.1 Test equipment

The surface, in accordance with 7.3.2, consists of a wooden test plate incorporating a

removable insert with a crevice, the angle between the crevice and the direction of strokes

being 45°.

The test plate may be fitted to the test rig according to 7.3.12 or, if being used for testing by

hand, is placed upon the floor.

Two hold-downs in accordance with 7.3.4 serve the purpose of acting as guides to keep the

cleaning head in a straight line as it is moved over the test area. The guides should have a

distance of 10 mm from the surface to ensure an undisturbed flow.

5.2.2 Distribution of test dust

The insert is weighed and its crevice thereafter filled with mineral dust, in accordance with

7.2.2.1. After levelling the surface of the dust with a rubber scraper, the insert is again weighed

and carefully replaced in the test plate, avoiding shaking.

5.2.3 Determination of dust removal ability

During a measurement, the cleaning head is passed over the crevice by performing double

strokes in a parallel pattern at a stroke speed of (0,50 ± 0,02) m/s, keeping the cleaning head

to the centre of the test plate. The quantity of dust removed from the crevice after five double

strokes is determined as the difference in weight of the insert before and after cleanings, both

values being recorded.

The dust removal ability, in per cent, is calculated according to the following formula as the

ratio of the quantity of dust removed to the quantity of dust in that part of the crevice which is

determined by the cleaning head width (see 3.2.5) and accounting for the oblique angle of 45°:

m − m

L

L r

°

k = cos 45 × 100

cr

m

B

L

60312-1 IEC:2010+A1:2011(E) – 15 –

where

k is the dust removal ability, in per cent;

cr

m is the dust quantity in the crevice before cleaning, in grams;

L

m is the dust quantity remaining in the crevice after cleaning, in grams;

r

L is the length of the crevice, in metres;

B is the cleaning head width, in metres.

Two separate measurements shall be carried out to establish a mean value of the dust removal

ability for five double strokes, k , to be reported separately.

cr5

5.3 Dust removal from carpets

5.3.1 Test carpet

A test carpet, in accordance with 7.2.1, shall be used; the type of carpet selected shall be

recorded. It shall have been prepared in accordance with 7.2.1.4. Due to the significant

influence of humidity on this test, the carpet shall be left in the test environment at standard

atmospheric conditions for at least 16 h before the test is due to commence.

The preferred carpet for comparative testing purposes is the Wilton Carpet (see 7.2.1.3.2). If

additional carpet(s) are desired for testing, the carpet(s) shall be selected from those specified

in Subclause 7.2.1.3.

During measurements the carpet is kept in position on the test floor by the use of carpet hold-

downs (see 7.3.4). The carpet is to be fixed on the test floor at the end where the forward

+10

stroke starts. A force of 60 N shall be applied at the other end of the test carpet to define

−0

the tension on the carpet during testing.

5.3.2 Test area and stroke length

The direction of the stroke on the test area shall be in the direction of the carpet pile. The

length of the test area is 700 mm ± 5 mm. The width of the test area is equal to the cleaning

head width (see 3.7).

A length of at least 200 mm shall be added before the beginning of the test area and at least

300 mm added after the test area in order to allow for acceleration and deceleration of the

cleaning head.

Thus, the stroke length is at least 1200 mm for the given test length of 700 mm. The centreline

of the front edge of the cleaning head is aligned to the centre line of the beginning of the

acceleration area at the commencement of the stroke, allowing the distance of 200 mm to be

used for acceleration. The cleaning head shall reach the end of the stroke when the rear edge

of the active depth of the cleaning head is at least 200 mm past the end of the test area, thus

allowing a suitable distance for deceleration. The reverse stroke is carried out in the same

manner until the front edge of the cleaning head is once again lined up with the beginning of

the acceleration length in front of the test area.

The active depth of the cleaning head shall move at uniform stroke speed 0,50 m/s ± 0,02 m/s

and in a straight line over the test area.

Vacuum cleaners equipped with a self drive device shall be operated at the prescribed stroke

speed of 0,5 m/s ± 0,02 m/s if possible. Otherwise, the stroke speed will be determined by the

vacuum cleaner.

NOTE 1 For optimum control of the double stroke movement it is recommended that an mechanical operator (see

4.8) be used.

– 16 – 60312-1 IEC:2010+A1:2011(E)

NOTE 2 The two carpet hold-downs serve the purpose of holding the test carpet in position during measurement

and of acting as

...

IEC 60312-1 ®

Edition 1.0 2010-09

INTERNATIONAL

STANDARD

Vacuum cleaners for household use –

Part 1: Dry vacuum cleaners – Methods for measuring the performance

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60312-1 ®

Edition 1.0 2010-09

INTERNATIONAL

STANDARD

Vacuum cleaners for household use –

Part 1: Dry vacuum cleaners – Methods for measuring the performance

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

XB

ICS 97.080 ISBN 978-2-88912-179-3

– 2 – 60312-1 © IEC:2010(E)

CONTENTS

FOREWORD.4

1 Scope.6

2 Normative references.6

3 Terms and definitions .7

4 General conditions for testing .8

4.1 Atmospheric conditions.8

4.2 Test equipment and materials .9

4.3 Voltage and frequency .9

4.4 Running-in of vacuum cleaner.9

4.5 Equipment of the vacuum cleaner .9

4.6 Operation of the vacuum cleaner .10

4.7 Conditioning prior to each tests.10

4.8 Mechanical operator .10

4.9 Number of samples.10

4.10 In-house reference cleaner system(s) .11

5 Dry vacuum cleaning tests .11

5.1 Dust removal from hard flat floors .11

5.2 Dust removal from hard floors with crevices .13

5.3 Dust removal from carpets.14

5.4 Dust removal along walls .17

5.5 Fibre removal from carpets and upholstery.18

5.6 Thread removal from carpets .22

5.7 Maximum usable volume of the dust receptacle .23

5.8 Air data .24

5.9 Performance with loaded dust receptacle .26

5.10 Total emission while vacuum cleaning.28

5.11 Filtration efficiency of the vacuum cleaner.28

6 Miscellaneous tests .33

6.1 General .33

6.2 Motion resistance .34

6.3 Cleaning under furniture .34

6.4 Radius of operation .35

6.5 Impact resistance for detachable cleaning heads .36

6.6 Deformation of hose and connecting tubes.36

6.7 Bump test.37

6.8 Flexibility of the hose .39

6.9 Repeated bending of the hose .40

6.10 Life test .41

6.11 Mass .42

6.12 Weight in hand .42

6.13 Specific cleaning time.43

6.14 Dimensions .43

6.15 Noise level.43

6.16 Energy consumption .43

7 Test material and equipment.45

7.1 General .45

60312-1 © IEC:2010(E) – 3 –

7.2 Material for measurements .46

7.3 Equipment for measurements .50

8 Instructions for use .65

Annex A (informative) Information on materials.66

Annex B (informative) Information at the point of sale .67

Annex C (normative) Guidance specification on verified carpets .68

Bibliography .70

Figure 1 – Right-angled T.17

Figure 2 – Determination of cleaning area .18

Figure 3 – Stencil for distribution of fibres on test carpets .19

Figure 4 – Zig Zag stroke pattern .20

Figure 5 – Frame for test cushion.21

Figure 6 – Stencil for distribution of fibres on upholstery .21

Figure 7 – Arrangement of threads in the thread removal test .22

Figure 8 – Stroke length in measurements.23

Figure 9 – Air data curves .25

Figure 10 – Connecting tube opening .26

Figure 11 – Test dust for loading dust receptacle.27

Figure 12 – Insertion depth.35

Figure 13 – Position of test object and cross-section for measurement of deformation .37

Figure 14 – Profile of threshold .38

Figure 15 – Arrangements for bump test.38

Figure 16 – Preparation of hoses for testing flexibility .40

Figure 17 – Equipment for repeated bending of hoses .41

Figure 18 – Test plate with crevice .50

Figure 19 – Carpet-beating machine.51

Figure 20 – Carpet hold-downs and guides .52

Figure 21 – Dust spreader and roller for embedding dust into carpets .52

Figure 22 – Alternative A equipment for air data measurements.53

Figure 23 – Measuring box for alternative A.54

Figure 24 – Alternative B equipment for air data measurements.56

Figure 25 – Test hood .60

Figure 26 – Aerosol channel with sampling probe .61

Figure 27 – Exhaust channel with sampling probe.61

Figure 28 – Drum for impact test .63

Figure 29 – Device for testing deformation of hoses and connecting tubes.64

Figure 30 – Mechanical operator for the measurement of dust removal from carpets and

of motion resistance.65

Table 1 – Confidence limits of a Poisson distribution for 95 % - confidence range .32

Table 2 – Graduation of 8 size classes for particle sizes 0,3 μm – 10 μm .62

– 4 – 60312-1 © IEC:2010(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

VACUUM CLEANERS FOR HOUSEHOLD USE –

Part 1: Dry vacuum cleaners –

Methods for measuring the performance

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60312-1 has been prepared by subcommittee 59F: Floor treatment

appliances, of IEC technical committee 59: Performance of household and similar electrical

appliances.

The text of this standard is based on the following documents:

FDIS Report on voting

59F/195/FDIS 59F/199/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

60312-1 © IEC:2010(E) – 5 –

A list of all the parts in the IEC 60312 series, under the general title Vacuum cleaners for

household use, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until the

stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data related to

the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – 60312-1 © IEC:2010(E)

VACUUM CLEANERS FOR HOUSEHOLD USE –

Part 1: Dry vacuum cleaners –

Methods for measuring the performance

1 Scope

This International Standard is applicable for measurements of the performance of dry vacuum

cleaners for household use in or under conditions similar to those in households.

The purpose of this standard is to specify essential performance characteristics of dry vacuum

cleaners being of interest to the users and to describe methods for measuring these

characteristics.

NOTE 1 Due to influence of environmental conditions, variations in time, origin of test materials and proficiency of

the operator, most of the described test methods will give more reliable results when applied for comparative

testing of a number of appliances at the same time, in the same laboratory and by the same operator.

NOTE 2 This standard is not intended for battery-operated vacuum cleaners.

For safety requirements, reference is made to IEC 60335-1 and IEC 60335-2-2.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60688, Electrical measuring transducers for converting a.c. electrical quantities to

analogue or digital signals

IEC 60704-1, Household and similar electrical appliances − Test code for the determination of

airborne acoustical noise − Part 1: General requirements

IEC 60704-2-1, Household and similar electrical appliances − Test code for the determination

of airborne acoustical noise − Part 2-1: Particular requirements for vacuum cleaners

ISO 554, Standard atmospheres for conditioning and/or testing – Specifications

ISO 679, Methods of testing cements − Determination of strength

ISO 1763, Carpets − Determination of number of tufts and/or loops per unit length and per unit

area

ISO 1765, Machine-made textile floor coverings − Determination of thickness

ISO 1766, Textile floor coverings − Determination of thickness of pile above the substrate

ISO 2424, Textile floor coverings – Vocabulary

ISO 2439, Flexible cellular polymeric materials – Determination of hardness (indentation

technique)

60312-1 © IEC:2010(E) – 7 –

ISO 3386-1, Polymeric materials, cellular flexible – Determination of stress-strain

characteristics in compression – Part 1: Low-density materials

ISO 5167-1, Measurement of fluid flow by means of pressure differential devices inserted in

circular cross-section conduits running full – Part 1: General principles and requirements

ISO 8543, Textile floor coverings – Methods for determination of mass

ISO 12103-1, Road vehicles – Test dust for filter evaluation – Part 1: Arizona test dust

3 Terms and definitions

For the purpose of this document, the following definitions apply:

3.1

dry vacuum cleaner

electrically operated appliance that removes dry material (e. g. dust, fibre, threads) from the

surface to be cleaned by an airflow created by a vacuum developed within the unit, the

removed material being separated in the appliance and the cleaned suction air being returned

to the ambient

3.2

upright cleaner

self-standing and floor-supported vacuum cleaner with the cleaning head forming an integral

part of or permanently connected to the cleaner housing, the cleaning head normally being

provided with an agitation device to assist dirt removal and the complete cleaner housing being

moved over the surface to be cleaned by means of an attached handle

3.3

cleaning head

plain nozzle or a brush attached to a connecting tube, or a power nozzle, separate or part of

the cleaner housing, and that part of a vacuum cleaner which is applied to a surface to be

cleaned

3.4

active nozzle

cleaning head provided with a driven agitation device to assist dirt removal

NOTE The agitation device may be driven by an incorporated electric motor (motorized nozzle), an incorporated

turbine powered by the air flow (air-turbine nozzle) or an incorporated friction or gear mechanism actuated by

moving the cleaning head over the surface to be cleaned (mechanical nozzle)

3.5

passive nozzle

cleaning head without any driven agitation devices

3.6

self-propelled cleaning head

cleaning head provided with a propulsion mechanism

3.7

cleaning head width

B

the external maximum width of the cleaning head in metres

– 8 – 60312-1 © IEC:2010(E)

3.8

active depth of the cleaning head

distance from the front edge of the cleaning head to its rear edge or a line 10 mm behind the

rear edge of the suction opening on the underside of the cleaning head, whichever is the

shortest

3.9

cleaning cycle

the sequence of five double strokes to be carried out at a specified stroke speed over the test

area according to the appropriate stroke pattern

3.10

stroke pattern

arrangement of the forward and return strokes on the surface to be cleaned

3.11

parallel pattern

stroke pattern where the forward and the return strokes are congruent and are carried out in

the direction of the carpet pile (direction of manufacture) unless otherwise specified

3.12

stroke speed

speed of the cleaning head, moved as uniformly as possible, during a forward or a return

stroke

3.13

stroke length

distance between the two parallel lines defining the limits of a stroke pattern

3.14

double stroke

one forward and one backward movement of the cleaning head performed in a parallel pattern

3.15

forward stroke

forward movement of a stroke pattern

NOTE On test carpets, forward strokes are carried out in the direction of the carpet pile (direction of

manufacturing).

3.16

return stroke

backward movement of a stroke pattern

4 General conditions for testing

4.1 Atmospheric conditions

Unless otherwise specified, the test procedures and measurements shall be carried out under

the following conditions (in accordance with ISO 554):

Standard atmosphere 23/50

Temperature: (23 ± 2) °C

Relative humidity: (50 ± 5) %

Air pressure: 86 kPa to 106 kPa

60312-1 © IEC:2010(E) – 9 –

NOTE Temperature and humidity conditions within the specified ranges are required for good repeatability and

reproducibility. Care should be taken to avoid changes during a test.

For test procedures and measurements which may be carried out at other than standard

atmospheric conditions, the ambient temperature shall be maintained at (23 ± 5) °C.

4.2 Test equipment and materials

To minimize the influence of electrostatic phenomena, measurements on carpets shall be

carried out on a flat floor consisting of a smooth untreated pine plywood or equivalent panel,

at least 15 mm thick and of a size appropriate for the test.

Equipment and materials for measurements (devices, test carpets, test dust etc.) to be used in

a test shall, prior to the test, be kept hanging free or laying flat for at least 16 h at standard

atmospheric conditions according to 4.1.

NOTE It is recommended that carpets that are already being used should be stored unbeaten at standard

atmospheric conditions according to 4.1. When not in use they should be preferably hanging free, or may be lying

flat, pile upwards and uncovered but not rolled.

4.3 Voltage and frequency

Unless otherwise stated, measurements shall be carried out at rated voltage with a tolerance of

±1 % and, if applicable, at rated frequency.

Vacuum cleaners designed for d.c. only shall be operated at d.c. Vacuum cleaners designed

for both a.c. and d.c. shall be operated at a.c. Vacuum cleaners not marked with rated

frequency shall be operated at either 50 Hz or 60 Hz, as is common in the country of use.

For vacuum cleaners with a rated voltage range, measurements shall be carried out at the

mean value of the voltage range if the difference between the limits of the range does not

exceed 10 % of the mean value. If the difference exceeds 10 % of the mean value,

measurements shall be carried out both at the upper and lower limits of the voltage range.

If the rated voltage differs from the nominal system voltage of the country concerned,

measurements carried out at rated voltage may give test results misleading for the consumer,

and additional measurements may be required. If the test voltage differs from the rated

voltage, this shall be reported.

4.4 Running-in of vacuum cleaner

Prior to the first test on a new vacuum cleaner it shall be kept running with unrestricted air flow

for at least 2 h to ensure adequate running-in. For active nozzles, the agitation device shall be

running but not in contact with the floor.

Prior to conducting any series of tests, the age, condition, and history of the product shall be

recorded.

4.5 Equipment of the vacuum cleaner

If the vacuum cleaner is designed to be used with disposable dust receptacles, it shall, prior to

each measurement, be equipped with a new dust receptacle of the type recommended or

supplied by the manufacturer of the vacuum cleaner.

If the vacuum cleaner is provided with a reusable dust receptacle (as the sole original dust

receptacle or as an enclosure for disposable dust receptacles), the dust receptacle and any

additional filters removable without the aid of tools shall, prior to each measurement, be

cleaned according to manufacturer’s instructions until its weight is within 1 % or 2 g of its

original weight whichever is the lower.

– 10 – 60312-1 © IEC:2010(E)

Some reusable receptacles consist of a rigid container and an integral filter. In this case the

container and the filter are considered to be the receptacle and should be treated as if they

were a single component.

Vacuum cleaners equipped with separation devices, being part of the appliance, used to

separate the dust from the airflow and/or having additional filters to be changed or cleaned by

the user, without the use of tools, the weight of such specific devices shall be taken into

account for dust removal ability.

Vacuum cleaners with disposable or reusable dust receptacles may have secondary filtration

stage devices which do not collect meaningful dust in removal ability tests but which do impact

on filtration and life tests. Replacement and/or maintenance of such devices shall be in

accordance with relevant sections and carried out according to manufacturer’s instructions.

4.6 Operation of the vacuum cleaner

The vacuum cleaner and its attachments shall be used and adjusted in accordance with the

manufacturer's instructions for normal operation for the test to be carried out. Height

adjustment controls for the cleaning head shall be set as appropriate for the surface to be

cleaned and the position noted. Any electrical controls shall be set for maximum continuous air

flow and, unless the manufacturer's instruction states otherwise, any manually operated air by-

pass openings for reduction of the suction power shall be closed, and if open, it shall be

reported. Any safety-related device shall be allowed to operate.

The tube grip of cleaners with suction hose or the handle of other cleaners shall be held as for

normal operation at a height of (800 ± 50) mm above the test floor.

During measurements where the agitation device of an active nozzle is not used as in normal

operation, the agitation device shall be running but not in contact with any surface.

4.7 Conditioning prior to each tests

If the vacuum cleaner is unused and de-energized for more than 1 h, then the vacuum cleaner

and attachments to be used shall be kept running for at least 10 min under the provisions given

in 4.4 to allow them to stabilise.

4.8 Mechanical operator

In order to achieve reliable results, certain measurements require the cleaning head to be

moved at uniform speed over the test area and without exerting an additional force pressing

the cleaning head against the test surface.

It is recommended to simulate the handling of the vacuum cleaner by using a mechanical

operator such as described in 7.3.12. The tube grip of cleaners with suction hose or the handle

of other cleaners shall then be attached to the linear drive so that its centre pivots at a height

of (800 ± 50) mm above the test surface. For nozzles without pivoting connectors, it shall be

ensured that the bottom of the cleaning head be made parallel with the test surface by

adjusting the handle height within the tolerances. If this is not possible, the length of a

telescopic tube may be adjusted. Any adjustment shall be reported.

The linear drive may be motorized or operated by hand. The method of operation shall be

reported.

4.9 Number of samples

All measurements of performance shall be carried out on the same sample(s) of the vacuum

cleaner with its attachments, if any.

60312-1 © IEC:2010(E) – 11 –

NOTE For increased confidence in the test results, it is recommended that a minimum of three samples of a

vacuum cleaner should be tested.

Tests carried out to simulate stresses a vacuum cleaner may be exposed to during normal use,

possibly causing impairment of the cleaner’s performance, may require additional samples of

replaceable parts. Such tests shall be carried out at the end of the test programme.

4.10 In-house reference cleaner system(s)

NOTE 1 The reference cleaner referred to in this standard is a product designated within a laboratory for internal

comparison and should not be used for inter-laboratory comparisons

Test carpets used in a laboratory for the determination of dust removal ability will, over time,

change from their original conditions, for instance due to wearing or gradual filling with dust. It

is therefore required that in-house reference cleaner system(s) be used to regularly check the

carpet conditions as a verification of the test results obtained and being recorded.

NOTE 2 Due to the fact that pick-up ability may differ between carpets used for active or passive nozzles, the

result from tests between active and passive nozzles may not be compared.

Test carpets designated for testing of passive nozzles shall only be cleaned with a passive

nozzle on the face. Test carpets designated for testing active nozzles shall only be cleaned

with an active nozzle on the face.

5 Dry vacuum cleaning tests

5.1 Dust removal from hard flat floors

5.1.1 Test equipment

A floor test plate in accordance with 7.3.1 shall be used.

5.1.2 Test area and stroke length

The length of the test area is (700 ± 5) mm. The width of the test area is equal to the cleaning

head width (see 3.7).

A length of at least 200 mm shall be added before the beginning of the test area and at least

300 mm after the end of the test area in order to allow acceleration and deceleration of the

cleaning head.

Thus, the stroke length is at least 1200 mm for the given test length of 700 mm. The centreline

of the front edge of the cleaning head is aligned to the centre line of the beginning of the

acceleration area at the commencement of the stroke allowing the distance of 200 mm to be

used for acceleration. The cleaning head shall reach the end of the stroke when the rear edge

of the active depth of the cleaning head is at least 200 mm past the end of the test area, thus

allowing a suitable distance for deceleration. The reverse stroke is carried out in the same

manner until the front edge of the cleaning head is once again lined up with the beginning of

the acceleration length in front of the test area.

The active depth of the cleaning head shall move at uniform stroke speed 0,50 m/s ± 0,02 m/s

and in a straight line over the test area.

For optimum control of the double stroke movement it is recommended that an

electromechanical operator (see 4.8) be used.

___________

This test is under review and may be substituted by a debris pick-up test from hard floor.

– 12 – 60312-1 © IEC:2010(E)

Two hold-downs in accordance with 7.3.4 serve the purpose of acting as guides to keep the

cleaning head in a straight line as it is moved over the test area and to ensure an undisturbed

flow.

Vacuum cleaners equipped with a self drive device shall be operated at the prescribed stroke

speed of 0,5 m/s ± 0,02 m/s if possible. Otherwise, the stroke speed will be determined by the

vacuum cleaner.

5.1.3 Removal of remaining dust

The hard surface shall be dry cleaned so that no dust remains prior to any subsequent test.

5.1.4 Distribution of test dust

Test dust, Type 1 in accordance with 7.2.2.1, shall be distributed with a mean coverage of 50

g/m per square metre as uniformly as possible over the test area.

The amount of test dust to be used is calculated from the formula B × 0,7 m × 50 g/m , where

B is the cleaning head width in meters and the length of the test area is 0,7 m.

5.1.5 Preconditioning of dust receptacle

In order to minimize the effects of humidity, the dust receptacle shall be preconditioned as

follows.

The vacuum cleaner under test is equipped with a clean dust receptacle and allowed to run

with an unimpeded air flow with the nozzle clear of the surface for 2 min or until input power

has stabilised.

After the preconditioning, the dust receptacle and any filters removable without tools are

removed from the cleaner to be weighed. The weight shall be noted and the items are

replaced.

NOTE Since the cleaner air flow can have an effect on the weight of the dust receptacle during the 2 min

preconditioning, caution should be taken so that the weight of the dust receptacle has stabilised before weighing.

5.1.6 Determination of dust removal ability

Three separate measurements, each comprising one double stroke, shall be carried out. After

the double stroke, the cleaning head shall be lifted at least 50 mm clear of the surface before

the vacuum cleaner is switched off. The dust receptacle shall not be removed before the motor

has completely stopped.

Once the cleaner has completely stopped, the receptacle is carefully removed and reweighed.

Due to effects of possible static charge build-up during the time the vacuum cleaner is picking

up dust, it is necessary to ensure that the receptacle has completely stabilised prior to

recording the weight.

The dust removal ability is calculated as the ratio of the weight increase of the dust receptacle

during the double stroke to the weight of the test dust distributed on the test area. The mean

value for 3 measurements is calculated as follows:

K ()3 =(K + K + K ) 3

B B1 B2 B3

where K = 100 ×()m − m m

Bi DRf DRe D

and

K ()i is the mean dust removal for i measurements in per cent;

B

60312-1 © IEC:2010(E) – 13 –

is the dust removal for measurement i in per cent;

K

Bi

m is the weight of the dust distributed on the test area in grams;

D

m ()i is the weight of the preconditioned dust receptacle in grams;

DRe

m ()i is the weight of the dust receptacle after cleaning in grams.

DRf

When the mean value is lower than 90 %: should the range of measurements be greater than 3

percentage units, two additional measurements are carried out and the mean value of all the

measurements should be given as the result.

When the mean value is equal or higher than 90 %: should the range of the measurements be

greater than 0,3 × (100 % − mean value), two additional measurements are carried out and the

mean value of all the measurements should be given as the result.

In both cases, consideration should be given to the control of repeatability within the laboratory

and the design or manufacture of the cleaner or cleaning head in order to ascertain whether

any factors not previously observed may affect the repeatability adversely.

5.2 Dust removal from hard floors with crevices

5.2.1 Test equipment

The surface, in accordance with 7.3.2, consists of a wooden test plate incorporating a

removable insert with a crevice, the angle between the crevice and the direction of strokes

being 45°.

The test plate may be fitted to the test rig according to 7.3.12 or, if being used for testing by

hand, is placed upon the floor.

Two hold-downs in accordance with 7.3.4 serve the purpose of acting as guides to keep the

cleaning head in a straight line as it is moved over the test area. The guides should have a

distance of 10 mm from the surface to ensure an undisturbed flow.

5.2.2 Distribution of test dust

The insert is weighed and its crevice thereafter filled with mineral dust, in accordance with

7.2.2.1. After levelling the surface of the dust with a rubber scraper, the insert is again weighed

and carefully replaced in the test plate, avoiding shaking.

5.2.3 Determination of dust removal ability

During a measurement, the cleaning head is passed over the crevice by performing double