IEC 60702-1:2002

(Main)Mineral insulated cables and their terminations with a rated voltage not exceeding 750 V - Part 1: Cables

Mineral insulated cables and their terminations with a rated voltage not exceeding 750 V - Part 1: Cables

Applies to mineral insulated general wiring cables with copper or copper alloy sheath and copper conductors and with rated voltages of 500 V and 750 V. Provision is made for a corrosion-resistant extruded outer covering over the copper sheath, when required. This outer covering is not specified for the purpose of electrical insulation of the metal sheath. Requirements for terminations for use with these cables are specified in IEC 60702-2. The purpose of this standard is to specify mineral insulated cables that are safe and reliable when properly used, to state the manufacturing requirements and characteristics to achieve this, and to specify methods for checking conformity with those requirements.

Câbles à isolant minéral et leurs terminaisons de tension assignée ne dépassant pas 750 V - Partie 1: Câbles

S'applique aux câbles à isolant minéral pour usage général, ayant une gaine en cuivre ou en alliage de cuivre et des âmes conductrices en cuivre, de tensions assignées 500 V et 750 V. Elle précise les dispositions qui s'appliquent au revêtement externe en matériau extrudé résistant à la corrosion recouvrant la gaine en cuivre, lorsque cela est exigé. Ce revêtement externe n'est pas destiné à assurer l'isolation électrique de la gaine métallique. Les exigences pour les terminaisons à utiliser avec ces câbles sont spécifiées dans la CEI 60702-2. L'objet de la présente norme est de déterminer les règles auxquelles doivent répondre les câbles à isolant minéral afin qu'ils soient sûrs et fiables lorsqu'ils sont correctement utilisés, de fixer dans ce but leurs caractéristiques et les prescriptions relatives à leur fabrication, et de préciser les méthodes pour la vérification de la conformité à ces prescriptions.

General Information

- Status

- Published

- Publication Date

- 14-Jan-2015

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- WG 17 - TC 20/WG 17

- Current Stage

- PPUB - Publication issued

- Start Date

- 14-Feb-2002

- Completion Date

- 31-Mar-2002

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60702-1:2002 is an international standard developed by the International Electrotechnical Commission (IEC) that specifies requirements for mineral insulated cables with rated voltages not exceeding 750 V. These cables feature copper or copper alloy sheaths and copper conductors and are designed primarily for general wiring applications. The standard also allows for an optional corrosion-resistant extruded outer covering to enhance durability, although this covering is not intended to provide electrical insulation.

The purpose of IEC 60702-1 is to ensure that mineral insulated cables are safe, reliable, and manufactured according to strict quality and construction criteria. It defines manufacturing processes, physical and electrical characteristics, testing methods, and conformity verification to meet international performance expectations.

Key Topics

- Voltage Ratings: The standard applies to two voltage grades-500 V for light duty cables and 750 V for heavy duty cables.

- Conductor and Sheath Materials: Conductors must be copper, while the metallic sheath is made from copper or copper alloy to ensure conductivity and mechanical protection.

- Insulation: The mineral insulation, typically magnesium oxide, provides excellent thermal and electrical insulation and is resistant to fire and mechanical damage.

- Optional Outer Covering: A corrosion-resistant extruded covering can be applied over the copper sheath when necessary; this covering is not part of the electrical insulation system.

- Dimensions and Mechanical Properties: Detailed specifications include sheath thickness, diameter, ovality, and bending and flattening tests to guarantee cable robustness.

- Marking and Identification: Cables must be clearly marked for easy identification, including rated voltage and other relevant details.

- Testing Methods: The standard specifies routine, sample, and type tests such as conductor resistance, insulation resistance, spark tests, flame retardance, smoke emission, and fire resistance tests to ensure quality and safety compliance.

Applications

IEC 60702-1 mineral insulated cables are widely used in applications where high mechanical strength, fire resistance, and durability are critical, including:

- Building Wiring: Ideal for fire-resistant wiring in residential, commercial, and industrial buildings.

- Safety Circuits: Suitable for emergency systems, fire alarms, and safety-related electrical installations requiring reliable operation under adverse conditions.

- Industrial Environments: Applicable in harsh industrial settings where exposure to corrosive agents, moisture, or mechanical impact is common.

- Critical Installations: Used in nuclear power plants, tunnels, hospitals, and transport infrastructure, where cable reliability and safety are paramount.

Related Standards

- IEC 60702-2: Specifies requirements for terminations used with mineral insulated cables covered under IEC 60702-1.

- IEC 60228: Defines standard conductors for electrical cables, including copper conductors used in mineral insulated cables.

- IEC 60332: Covers tests on electric and optical fiber cables under fire conditions, which complement fire resistance provisions in IEC 60702-1.

- IEC 61034: Addresses measurement of smoke density during cable fire testing, relevant to smoke emission tests for mineral insulated cables.

- ISO/IEC Directives Part 3: Governs the drafting principles for international standards, ensuring consistent and harmonized documentation.

Keywords: IEC 60702-1, mineral insulated cables, rated voltage 750 V, copper sheath, copper conductor, mineral insulation, fire-resistant cables, corrosion-resistant covering, electrical safety standards, cable testing, wiring cables, IEC standards.

Buy Documents

IEC 60702-1:2002 - Mineral insulated cables and their terminations with a rated voltage not exceeding 750 V - Part 1: Cables Released:2/14/2002

IEC 60702-1:2002+AMD1:2015 CSV - Mineral insulated cables and their terminations with a rated voltage not exceeding 750 V - Part 1: Cables Released:1/15/2015

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60702-1:2002 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Mineral insulated cables and their terminations with a rated voltage not exceeding 750 V - Part 1: Cables". This standard covers: Applies to mineral insulated general wiring cables with copper or copper alloy sheath and copper conductors and with rated voltages of 500 V and 750 V. Provision is made for a corrosion-resistant extruded outer covering over the copper sheath, when required. This outer covering is not specified for the purpose of electrical insulation of the metal sheath. Requirements for terminations for use with these cables are specified in IEC 60702-2. The purpose of this standard is to specify mineral insulated cables that are safe and reliable when properly used, to state the manufacturing requirements and characteristics to achieve this, and to specify methods for checking conformity with those requirements.

Applies to mineral insulated general wiring cables with copper or copper alloy sheath and copper conductors and with rated voltages of 500 V and 750 V. Provision is made for a corrosion-resistant extruded outer covering over the copper sheath, when required. This outer covering is not specified for the purpose of electrical insulation of the metal sheath. Requirements for terminations for use with these cables are specified in IEC 60702-2. The purpose of this standard is to specify mineral insulated cables that are safe and reliable when properly used, to state the manufacturing requirements and characteristics to achieve this, and to specify methods for checking conformity with those requirements.

IEC 60702-1:2002 is classified under the following ICS (International Classification for Standards) categories: 29.060.20 - Cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60702-1:2002 has the following relationships with other standards: It is inter standard links to IEC 60702-1:2002/AMD1:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60702-1:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

NORME CEI

INTERNATIONALE IEC

60702-1

INTERNATIONAL

Troisième édition

STANDARD

Third edition

2002-02

Câbles à isolant minéral et leurs terminaisons

de tension assignée ne dépassant pas 750 V –

Partie 1:

Câbles

Mineral insulated cables and their terminations

with a rated voltage not exceeding 750 V –

Part 1:

Cables

Numéro de référence

Reference number

CEI/IEC 60702-1:2002

Numérotation des publications Publication numbering

Depuis le 1er janvier 1997, les publications de la CEI As from 1 January 1997 all IEC publications are

sont numérotées à partir de 60000. Ainsi, la CEI 34-1 issued with a designation in the 60000 series. For

devient la CEI 60034-1. example, IEC 34-1 is now referred to as IEC 60034-1.

Editions consolidées Consolidated editions

Les versions consolidées de certaines publications de la The IEC is now publishing consolidated versions of its

CEI incorporant les amendements sont disponibles. Par publications. For example, edition numbers 1.0, 1.1

exemple, les numéros d’édition 1.0, 1.1 et 1.2 indiquent and 1.2 refer, respectively, to the base publication,

respectivement la publication de base, la publication de the base publication incorporating amendment 1 and

base incorporant l’amendement 1, et la publication de the base publication incorporating amendments 1

base incorporant les amendements 1 et 2. and 2.

Informations supplémentaires Further information on IEC publications

sur les publications de la CEI

Le contenu technique des publications de la CEI est The technical content of IEC publications is kept

constamment revu par la CEI afin qu'il reflète l'état under constant review by the IEC, thus ensuring that

actuel de la technique. Des renseignements relatifs à the content reflects current technology. Information

cette publication, y compris sa validité, sont dispo- relating to this publication, including its validity, is

nibles dans le Catalogue des publications de la CEI available in the IEC Catalogue of publications

(voir ci-dessous) en plus des nouvelles éditions, (see below) in addition to new editions, amendments

amendements et corrigenda. Des informations sur les and corrigenda. Information on the subjects under

sujets à l’étude et l’avancement des travaux entrepris consideration and work in progress undertaken by the

par le comité d’études qui a élaboré cette publication, technical committee which has prepared this

ainsi que la liste des publications parues, sont publication, as well as the list of publications issued,

également disponibles par l’intermédiaire de: is also available from the following:

• Site web de la CEI (www.iec.ch) • IEC Web Site (www.iec.ch)

• Catalogue des publications de la CEI • Catalogue of IEC publications

Le catalogue en ligne sur le site web de la CEI The on-line catalogue on the IEC web site

(www.iec.ch/catlg-f.htm) vous permet de faire des (www.iec.ch/catlg-e.htm) enables you to search

recherches en utilisant de nombreux critères, by a variety of criteria including text searches,

comprenant des recherches textuelles, par comité technical committees and date of publication. On-

d’études ou date de publication. Des informations line information is also available on recently

en ligne sont également disponibles sur les issued publications, withdrawn and replaced

nouvelles publications, les publications rempla- publications, as well as corrigenda.

cées ou retirées, ainsi que sur les corrigenda.

• IEC Just Published

• IEC Just Published

Ce résumé des dernières publications parues

This summary of recently issued publications

(www.iec.ch/JP.htm) est aussi disponible par

(www.iec.ch/JP.htm) is also available by email.

courrier électronique. Veuillez prendre contact

Please contact the Customer Service Centre (see

avec le Service client (voir ci-dessous) pour plus

below) for further information.

d’informations.

• Service clients

• Customer Service Centre

Si vous avez des questions au sujet de cette

If you have any questions regarding this

publication ou avez besoin de renseignements

publication or need further assistance, please

supplémentaires, prenez contact avec le Service

contact the Customer Service Centre:

clients:

Email: custserv@iec.ch

Email: custserv@iec.ch

Tél: +41 22 919 02 11

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

Fax: +41 22 919 03 00

.

NORME CEI

INTERNATIONALE IEC

60702-1

INTERNATIONAL

Troisième édition

STANDARD

Third edition

2002-02

Câbles à isolant minéral et leurs terminaisons

de tension assignée ne dépassant pas 750 V –

Partie 1:

Câbles

Mineral insulated cables and their terminations

with a rated voltage not exceeding 750 V –

Part 1:

Cables

IEC 2002 Droits de reproduction réservés Copyright - all rights reserved

Aucune partie de cette publication ne peut être reproduite ni No part of this publication may be reproduced or utilized in any

utilisée sous quelque forme que ce soit et par aucun procédé, form or by any means, electronic or mechanical, including

électronique ou mécanique, y compris la photocopie et les photocopying and microfilm, without permission in writing from

microfilms, sans l'accord écrit de l'éditeur. the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

CODE PRIX

S

PRICE CODE

Commission Electrotechnique Internationale

International Electrotechnical Commission

Международная Электротехническая Комиссия

Pour prix, voir catalogue en vigueur

For price, see current catalogue

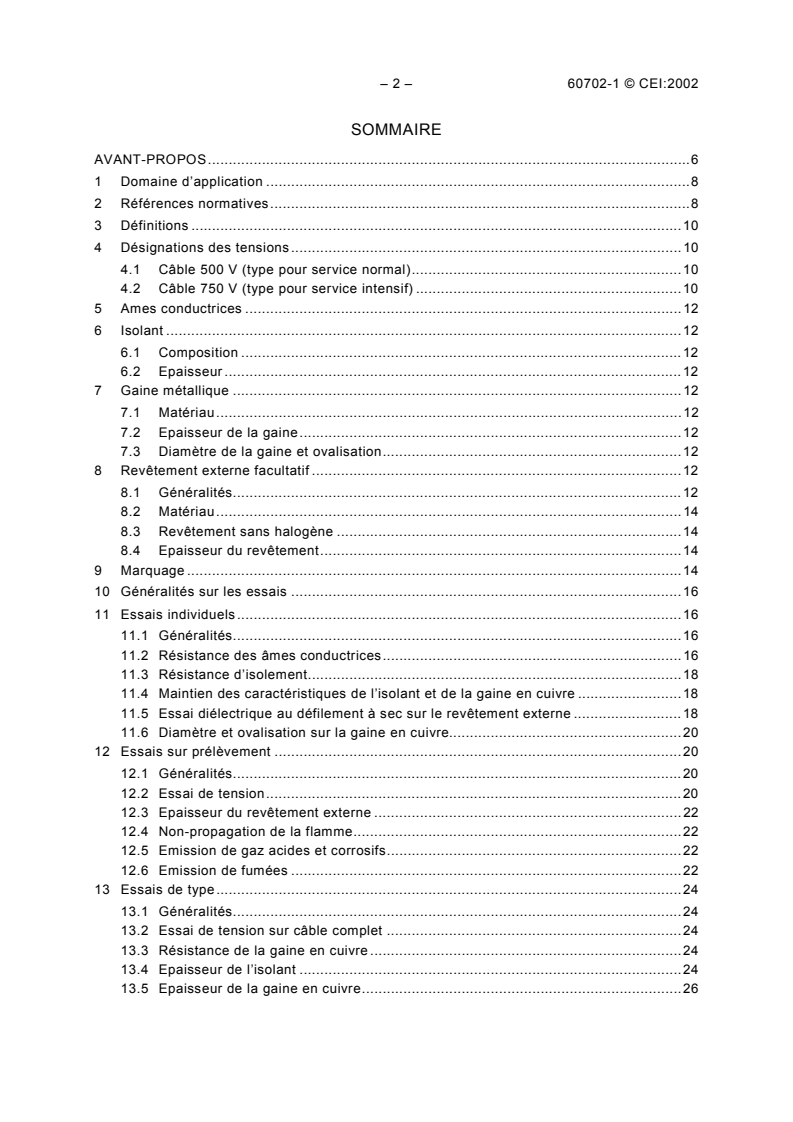

– 2 – 60702-1 © CEI:2002

SOMMAIRE

AVANT-PROPOS.6

1 Domaine d’application .8

2 Références normatives.8

3 Définitions .10

4 Désignations des tensions.10

4.1 Câble 500 V (type pour service normal).10

4.2 Câble 750 V (type pour service intensif) .10

5 Ames conductrices .12

6 Isolant .12

6.1 Composition .12

6.2 Epaisseur .12

7 Gaine métallique .12

7.1 Matériau.12

7.2 Epaisseur de la gaine.12

7.3 Diamètre de la gaine et ovalisation.12

8 Revêtement externe facultatif .12

8.1 Généralités.12

8.2 Matériau.14

8.3 Revêtement sans halogène .14

8.4 Epaisseur du revêtement.14

9 Marquage .14

10 Généralités sur les essais .16

11 Essais individuels.16

11.1 Généralités.16

11.2 Résistance des âmes conductrices.16

11.3 Résistance d’isolement.18

11.4 Maintien des caractéristiques de l’isolant et de la gaine en cuivre .18

11.5 Essai diélectrique au défilement à sec sur le revêtement externe .18

11.6 Diamètre et ovalisation sur la gaine en cuivre.20

12 Essais sur prélèvement .20

12.1 Généralités.20

12.2 Essai de tension.20

12.3 Epaisseur du revêtement externe .22

12.4 Non-propagation de la flamme.22

12.5 Emission de gaz acides et corrosifs.22

12.6 Emission de fumées .22

13 Essais de type.24

13.1 Généralités.24

13.2 Essai de tension sur câble complet .24

13.3 Résistance de la gaine en cuivre .24

13.4 Epaisseur de l’isolant .24

13.5 Epaisseur de la gaine en cuivre.26

60702-1 © IEC:2002 – 3 –

CONTENTS

FOREWORD.7

1 Scope.9

2 Normative references .9

3 Definitions .11

4 Voltage designations .11

4.1 500 V cable (light duty grade).11

4.2 750 V cable (heavy duty grade) .11

5 Conductors.13

6 Insulation .13

6.1 Composition .13

6.2 Thickness.13

7 Metallic sheath .13

7.1 Material .13

7.2 Sheath thickness .13

7.3 Sheath diameter and ovality .13

8 Optional outer covering .13

8.1 General .13

8.2 Material .15

8.3 Halogen-free covering .15

8.4 Thickness of covering.15

9 Marking .15

10 General notes on tests .17

11 Routine tests .17

11.1 General .17

11.2 Conductor resistance.17

11.3 Insulation resistance .19

11.4 Integrity of insulation and copper sheath .19

11.5 Spark test on outer covering.19

11.6 Diameter and ovality over copper sheath.21

12 Sample tests .21

12.1 General .21

12.2 Voltage test.21

12.3 Thickness of outer covering.23

12.4 Flame retardance .23

12.5 Emission of acidic and corrosive gases .23

12.6 Smoke emission .23

13 Type tests .25

13.1 General .25

13.2 Voltage test on completed cable.25

13.3 Resistance of copper sheath .25

13.4 Thickness of insulation .25

13.5 Thickness of copper sheath.27

– 4 – 60702-1 © CEI:2002

13.6 Essai de pliage.26

13.7 Essai d’aplatissement.34

13.8 Résistance au feu.36

14 Câble à isolant minéral de 500 V (service normal) .36

14.1 Désignation .36

14.2 Tension assignée .36

14.3 Construction.36

14.4 Dimensions .36

14.5 Prescriptions .38

15 Câbles à isolant minéral de 750 V (service intensif).38

15.1 Désignation .38

15.2 Tension assignée .38

15.3 Construction.40

15.4 Dimensions .40

15.5 Prescriptions .44

60702-1 © IEC:2002 – 5 –

13.6 Bending test .27

13.7 Flattening test .35

13.8 Fire resistance .37

14 500 V mineral insulated cable (light duty grade) .37

14.1 Code designation .37

14.2 Rated voltage.37

14.3 Construction.37

14.4 Dimensions .37

14.5 Requirements.39

15 750 V mineral insulated cable (heavy duty grade).39

15.1 Code designation .39

15.2 Rated voltage.39

15.3 Construction.41

15.4 Dimensions .41

15.5 Requirements.45

– 6 – 60702-1 © CEI:2002

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

CÂBLES À ISOLANT MINÉRAL ET LEURS TERMINAISONS

DE TENSION ASSIGNÉE NE DÉPASSANT PAS 750 V –

Partie 1: Câbles

AVANT-PROPOS

1) La CEI (Commission Électrotechnique Internationale) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI, entre autres activités, publie des Normes

internationales. Leur élaboration est confiée à des comités d'études, aux travaux desquels tout Comité national

intéressé par le sujet traité peut participer. Les organisations internationales, gouvernementales et non

gouvernementales, en liaison avec la CEI, participent également aux travaux. La CEI collabore étroitement

avec l'Organisation Internationale de Normalisation (ISO), selon des conditions fixées par accord entre les

deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux intéressés

sont représentés dans chaque comité d’études.

3) Les documents produits se présentent sous la forme de recommandations internationales. Ils sont publiés

comme normes, spécifications techniques, rapports techniques ou guides et agréés comme tels par les

Comités nationaux.

4) Dans le but d'encourager l'unification internationale, les Comités nationaux de la CEI s'engagent à appliquer de

façon transparente, dans toute la mesure possible, les Normes internationales de la CEI dans leurs normes

nationales et régionales. Toute divergence entre la norme de la CEI et la norme nationale ou régionale

correspondante doit être indiquée en termes clairs dans cette dernière.

5) La CEI n’a fixé aucune procédure concernant le marquage comme indication d’approbation et sa responsabilité

n’est pas engagée quand un matériel est déclaré conforme à l’une de ses normes.

6) L’attention est attirée sur le fait que certains des éléments de la présente Norme internationale peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 60702-1 a été établie par le comité d'études 20 de la CEI:

Câbles électriques.

Cette troisième édition de la CEI 60702-1 annule et remplace la deuxième édition publiée en

1988 et son amendement 1 publié en 1992, et constitue une révision technique.

Le texte de cette norme est issu des documents suivants:

FDIS Rapport de vote

20/490/FDIS 20/510/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote ayant

abouti à l'approbation de cette norme.

Cette publication a été rédigée selon les Directives ISO/CEI, Partie 3.

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant 2012.

A cette date, la publication sera

• reconduite;

• supprimée;

• remplacée par une édition révisée, ou

• amendée.

60702-1 © IEC:2002 – 7 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MINERAL INSULATED CABLES AND THEIR TERMINATIONS

WITH A RATED VOLTAGE NOT EXCEEDING 750 V –

Part 1: Cables

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International

Organization for Standardization (ISO) in accordance with conditions determined by agreement between the

two organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60702-1 has been prepared by IEC technical committee 20:

Electric cables.

This third edition of IEC 60702-1 cancels and replaces the second edition of IEC 60702-1

published in 1988 and its amendment 1 published in 1992, and constitutes a technical

revision.

The text of this standard is based on the following documents:

FDIS Report on voting

20/490/FDIS 20/510/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 3.

The committee has decided that the contents of this publication will remain unchanged until

2012. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 8 – 60702-1 © CEI:2002

CÂBLES À ISOLANT MINÉRAL ET LEURS TERMINAISONS

DE TENSION ASSIGNÉE NE DÉPASSANT PAS 750 V –

Partie 1: Câbles

1 Domaine d’application

La présente norme s’applique aux câbles à isolant minéral pour usage général, ayant une

gaine en cuivre ou en alliage de cuivre et des âmes conductrices en cuivre, de tensions

assignées 500 V et 750 V. Elle précise les dispositions qui s’appliquent au revêtement

externe en matériau extrudé résistant à la corrosion recouvrant la gaine en cuivre, lorsque

cela est exigé. Ce revêtement externe n’est pas destiné à assurer l’isolation électrique de la

gaine métallique.

Les exigences pour les terminaisons à utiliser avec ces câbles sont spécifiées dans la

CEI 60702-2.

L’objet de la présente norme est de déterminer les règles auxquelles doivent répondre les

câbles à isolant minéral afin qu’ils soient sûrs et fiables lorsqu’ils sont correctement utilisés,

de fixer dans ce but leurs caractéristiques et les prescriptions relatives à leur fabrication, et

de préciser les méthodes pour la vérification de la conformité à ces prescriptions.

2 Références normatives

Les documents de référence suivants sont indispensables pour l'application du présent

document. Pour les références datées, seule l'édition citée s'applique. Pour les références

non datées, la dernière édition du document de référence s'applique (y compris les éventuels

amendements).

CEI 60227-1:1993, Conducteurs et câbles isolés au polychlorure de vinyle, de tension

nominale au plus égale à 450/750 V – Partie 1: Prescriptions générales

CEI 60228:1978, Âmes des câbles isolés

CEI 60331-21:1999, Essais de câbles électriques soumis au feu – Intégrité des circuits –

Partie 21: Procédures et prescriptions – Câbles de tension assignée jusque et y compris

0,6/1,0 kV

CEI 60332-1:1993, Essais des câbles électriques soumis au feu – Partie 1: Essais sur un

conducteur ou câble isolé vertical

CEI 60702-2:2002, Câbles à isolant minéral et leurs terminaisons de tension assignée ne

dépassant pas 750 V – Partie 2: Terminaisons

CEI 60754-2:1991, Essai sur les gaz émis lors de la combustion des câbles électriques –

Partie 2: Détermination de l’acidité des gaz émis lors de la combustion d’un matériau prélevé

sur un câble par mesurage du pH et de la conductivité

CEI 60811-1-1:1993, Méthodes d’essai communes pour les matériaux d’isolation et de

gainage des câbles électriques et des câbles optiques – Partie 1: Méthodes d’application

générale – Section 1: Mesure des épaisseurs et des dimensions extérieures – Détermination

des propriétés mécaniques

60702-1 © IEC:2002 – 9 –

MINERAL INSULATED CABLES AND THEIR TERMINATIONS

WITH A RATED VOLTAGE NOT EXCEEDING 750 V –

Part 1: Cables

1 Scope

This standard applies to mineral insulated general wiring cables with copper or copper alloy

sheath and copper conductors and with rated voltages of 500 V and 750 V. Provision is made

for a corrosion-resistant extruded outer covering over the copper sheath, when required. This

outer covering is not specified for the purpose of electrical insulation of the metal sheath.

Requirements for terminations for use with these cables are specified in IEC 60702-2.

The purpose of this standard is to specify mineral insulated cables that are safe and reliable

when properly used, to state the manufacturing requirements and characteristics to achieve

this, and to specify methods for checking conformity with those requirements.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60227-1:1993, Polyvinyl chloride insulated cables of rated voltages up to and including

450/750 V – Part 1: General requirements

IEC 60228:1978, Conductors of insulated cables

IEC 60331-21:1999, Tests for electric cables under fire conditions – Circuit integrity – Part 21:

Procedures and requirements – Cables of rated voltage up to and including 0,6/1,0 kV

IEC 60332-1:1993, Tests on electric cables under fire conditions – Part 1: Test on a single

vertical insulated wire or cable

IEC 60702-2:2002, Mineral insulated cables and their terminations with a rated voltage not

exceeding 750 V – Part 2: Terminations

IEC 60754-2:1991, Test on gases evolved during combustion of electric cables – Part 2:

Determination of degree of acidity of gases evolved during the combustion of materials taken

from electric cables by measuring pH and conductivity

IEC 60811-1-1:1993, Common test methods for insulating and sheathing materials of electric

cables and optical cables – Part 1: Methods for general application – Section 1: Measurement

of thickness and overall dimensions – Tests for determining the mechanical properties

– 10 – 60702-1 © CEI:2002

CEI 60811-1-4:1985, Méthodes d’essais communes pour les matériaux d’isolation et de

gainage des câbles électriques – Partie 1: Méthodes d’application générale – Section 4:

Essais à basse température

CEI 60811-3-1:1985, Méthodes d’essais communes pour les matériaux d’isolation et de

gainage des câbles électriques – Partie 3: Méthodes spécifiques pour les mélanges PVC –

Section 1: Essai de pression à température élevée – Essais de résistance à la fissuration

CEI 61034-2:1997, Mesure de la densité de fumées dégagées par des câbles brûlant dans

des conditions définies – Partie 2: Procédure d’essai et prescriptions

3 Définitions

Pour les besoins de la présente partie de la CEI 60702, les définitions suivantes s’appliquent.

3.1

valeur nominale

valeur par laquelle on désigne une grandeur et qui est fréquemment utilisée dans les

tableaux. De manière générale, dans la présente norme, les valeurs nominales donnent des

valeurs qui doivent être vérifiées par des mesures en tenant compte de tolérances spécifiées

3.2

essais individuels (symbole R)

essais réalisés par le fabricant sur chaque longueur de câble fabriquée pour vérifier que

l’ensemble de chaque longueur satisfait aux prescriptions spécifiées

3.3

essais sur prélèvement (symbole S)

essais réalisés par le fabricant sur des échantillons de câbles complets ou des éléments

provenant d’un câble complet, à une fréquence prévue, de manière à vérifier que le produit

fini satisfait aux exigences spécifiées

3.4

essais de type (symbole T)

essais réalisés avant la mise sur le marché, sur une base commerciale générale, d’un type de

câble couvert par la présente norme pour démontrer que les caractéristiques de performances

sont satisfaisantes pour répondre à l’application prévue. Ces essais sont tels qu’après leur

réalisation il n’est pas nécessaire de les répéter, à moins que des modifications aient été

effectuées sur les matériaux du câble, la conception ou le procédé de fabrication pouvant

modifier les caractéristiques de performances

4 Désignations des tensions

Les tensions assignées des câbles traités dans la présente norme sont les suivantes.

4.1 Câble 500 V (type pour service normal)

Pour utilisation lorsque la tension entre âmes conductrices et gaine et entre âmes

conductrices ne dépasse pas 500 V en valeur efficace ou 500 V en courant continu.

4.2 Câble 750 V (type pour service intensif)

Pour utilisation lorsque la tension entre âmes conductrices et gaine et entre âmes

conductrices ne dépasse pas 750 V en valeur efficace ou 750 V en courant continu.

60702-1 © IEC:2002 – 11 –

IEC 60811-1-4:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section 4: Tests at low temperature

IEC 60811-3-1:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 3: Methods specific to PVC compounds – Section 1: Pressure test at high

temperature – Tests for resistance to cracking

IEC 61034-2:1997, Measurement of smoke density of cables burning under defined conditions

– Part 2: Test procedure and requirements

3 Definitions

For the purpose of this part of IEC 60702, the following definitions apply.

3.1

nominal value

value by which a quantity is designated and which is often used in tables. Usually, in this

standard, nominal values give rise to values to be checked by measurements, taking into

account specified tolerances

3.2

routine tests (symbol R)

tests made by the manufacturer on each manufactured length of cable to check that the whole

of each length meets the specified requirements

3.3

sample tests (symbol S)

tests made by the manufacturer on samples of completed cable, or components from a

completed cable, at a planned frequency, so as to verify that the finished product meets the

specified requirements

3.4

type tests (symbol T)

tests made before supplying, on a general commercial basis, a type of cable covered by this

standard, in order to demonstrate satisfactory performance characteristics to meet the

intended application. These tests are such that, after they have been made, they need not be

repeated unless changes are made in the cable material, design or manufacturing process

which might change the performance characteristics

4 Voltage designations

The rated voltages of the cables considered in this standard are as follows.

4.1 500 V cable (light duty grade)

For use where the voltage between conductors and sheath and between conductors does not

exceed 500 V r.m.s. or 500 V d.c.

4.2 750 V cable (heavy duty grade)

For use where the voltage between conductors and sheath and between conductors does not

exceed 750 V r.m.s. or 750 V d.c.

– 12 – 60702-1 © CEI:2002

5 Ames conductrices

Les âmes conductrices doivent être en cuivre recuit nu et de section approximativement

circulaire. Elles doivent être conformes aux prescriptions données dans la CEI 60228 pour les

âmes de classe 1.

La vérification est effectuée par examen et en mesurant sur chaque couronne complète de

câble en l'état de livraison la résistance de chaque âme conductrice et la longueur du câble.

La résistance mesurée doit être corrigée à 20 °C et pour une longueur de 1 km,

conformément à 11.2.

6 Isolant

6.1 Composition

L’isolant est constitué par une poudre d’un ou de plusieurs minéraux, comprimée pour former

une masse compacte. Les caractéristiques électriques de l’isolant doivent être telles que le

câble terminé satisfasse aux essais prescrits par la présente norme.

6.2 Epaisseur

L’épaisseur nominale de l’isolant entre les âmes conductrices et entre chaque âme conduc-

trice et la gaine doit être conforme aux valeurs des tableaux 7 et 10.

Lorsqu’on réalise les mesures conformément à 13.4, l’épaisseur minimale ne doit pas être

inférieure à 80 % de la valeur nominale moins 0,1 mm.

7 Gaine métallique

7.1 Matériau

La gaine doit être en cuivre recuit nu ou en alliage de cuivre. La résistance de la gaine,

mesurée et corrigée à 20 °C conformément à 13.3, doit être conforme aux valeurs des

tableaux 9 et 12.

7.2 Epaisseur de la gaine

L’épaisseur moyenne de la gaine ne doit pas être inférieure à l’épaisseur nominale spécifiée

aux tableaux 8 et 11. L’épaisseur en un point peut cependant être inférieure à la valeur

nominale, dans la mesure où la différence ne dépasse pas 10 % de la valeur nominale.

La vérification est effectuée par l’essai de 13.5.

7.3 Diamètre de la gaine et ovalisation

Les mesures du diamètre, lorsqu’elles sont réalisées conformément à 11.6, doivent être

égales à ±0,05 mm près à la valeur spécifiée aux tableaux 7 et 10.

8 Revêtement externe facultatif

8.1 Généralités

Lorsque cela est jugé nécessaire en raison d’environnements corrosifs, d’identification du câble

ou d'un critère esthétique, un revêtement externe extrudé peut être utilisé. La mise en œuvre

doit être réalisée de telle manière que le câble soit conforme à l’essai diélectrique au défilement

à sec spécifié en 11.5 et à l’essai de non-propagation de la flamme spécifié en 12.4.

60702-1 © IEC:2002 – 13 –

5 Conductors

Conductors shall consist of plain annealed copper and shall be of approximately circular

cross-section. They shall comply with the requirements given in IEC 60228 for class 1

conductors.

Compliance shall be checked by inspection and by measuring the resistance of each

conductor of each complete coil of completed cable and measuring the length of the cable.

The measured resistance shall be corrected to 20 °C and to a length of 1 km, in accordance

with 11.2.

6 Insulation

6.1 Composition

The insulation shall consist of compressed powdered mineral or minerals which shall form a

compact body. The electrical properties of the insulation shall be such that the completed

cable shall meet the test requirements of this standard.

6.2 Thickness

The nominal thickness of insulation between conductors and between each conductor and the

sheath shall be as given in tables 7 and 10.

When measured in accordance with 13.4, the minimum thickness shall be not less than 80 %

of the nominal value minus 0,1 mm.

7 Metallic sheath

7.1 Material

The sheath shall be of plain annealed copper or copper alloy. The resistance of the sheath,

measured and corrected to 20 °C in accordance with 13.3, shall comply with the values in

tables 9 and 12.

7.2 Sheath thickness

The mean thickness of the sheath shall be not less than the nominal thickness specified in

tables 8 and 11. The thickness at any point may, however, be less than the nominal value,

provided that the difference does not exceed 10 % of the nominal value.

Compliance shall be checked by the test in 13.5.

7.3 Sheath diameter and ovality

When measured in accordance with 11.6, the diameter measurements shall be within ±0,05 mm

of the value specified in tables 7 and 10.

8 Optional outer covering

8.1 General

Where deemed necessary because of corrosive environments, cable identification or aesthetic

appeal, an extruded outer covering may be applied. Application shall be such that the cable

complies with the spark test specified in 11.5 and with the flame retardance test specified in 12.4.

– 14 – 60702-1 © CEI:2002

Ce revêtement peut être de n’importe quelle couleur appropriée pour le pays d’utilisation. Le

matériau doit satisfaire aux prescriptions de 8.2 et 8.3, le cas échéant.

NOTE Après accord entre le fabricant et l’acheteur, il est admis d’appliquer des revêtements externes avec

d’autres matériaux et d’autres épaisseurs.

8.2 Matériau

Le matériau du revêtement externe doit être conforme aux prescriptions suivantes.

8.2.1 Choc à basse température

Lorsque des échantillons de câble avec revêtement externe sont essayés conformément à 8.5

de la CEI 60811-1-4, à une température de (–15 ± 2) °C, ils ne doivent pas se craqueler.

8.2.2 Essai de choc thermique

Lorsque des échantillons de câble avec revêtement externe sont essayés conformément à 9.2

de la CEI 60811-3-1, à une température de (150 ± 3) °C, ils ne doivent pas se craqueler.

8.3 Revêtement sans halogène

Le revêtement sans halogènes doit satisfaire aux prescriptions données en 8.2 et être tels

que le câble complet satisfasse aux essais de performance au feu de 12.4, 12.5 et 12.6.

8.4 Epaisseur du revêtement

Lorsque la mesure est réalisée conformément à 12.3, la valeur moyenne de l’épaisseur du

revêtement externe ne doit pas être inférieure à la valeur nominale donnée au tableau 1.

L’épaisseur en un point peut cependant être inférieure à la valeur nominale, sous réserve que

la différence ne dépasse pas 0,1 mm + 15 % de la valeur nominale spécifiée.

Tableau 1 – Epaisseur du revêtement

1)

Diamètre sur gaine en cuivre

Epaisseur nominale

mm

du revêtement

mm

Supérieur à Inférieur ou égal à

– 7 0,65

7 15 0,75

15 20 1,00

20 – 1,25

1)

Comme indiqué aux tableaux 7 et 10.

9 Marquage

Tous les câbles doivent porter un marquage avec la tension assignée et un moyen d’identi-

fication du fabricant. Le marquage doit être conforme aux prescriptions de la CEI 60227-1 à

l'exception des câbles sans revêtement externe, pour lesquels les informations peuvent être

portées sur une étiquette attachée à chaque longueur de câble.

60702-1 © IEC:2002 – 15 –

The covering may be of any colour appropriate for the country of use. The material shall meet

the requirements of 8.2 and 8.3, as appropriate.

NOTE By agreement between the manufacturer and purchaser, outer coverings of alternative materials and

thicknesses may be applied.

8.2 Material

The material of the outer covering shall comply with the following requirements.

8.2.1 Low temperature impact

When samples of cable with outer covering are tested in accordance with 8.5 of IEC 60811-1-4,

at a temperature of (–15 ± 2) °C, the samples shall not crack.

8.2.2 Heat shock test

When samples of cable with outer covering are tested in accordance with 9.2 of IEC 60811-3-1,

at a temperature of (150 ± 3) °C, the samples shall not crack.

8.3 Halogen-free covering

Halogen-free covering shall meet the requirements given in 8.2, and be such that the

completed cable will meet the fire performance tests of 12.4, 12.5 and 12.6.

8.4 Thickness of covering

When measured in accordance with 12.3, the mean value of the thickness of the outer

covering shall be not less than the nominal value given in table 1. The thickness at any point

may, however, be less than the nominal value, provided that the difference does not exceed

0,1 mm + 15 % of the specified nominal value.

Table 1 – Thickness of covering

1)

Diameter over copper sheath

Nominal thickness

mm

of covering

mm

Above Up to and including

– 7 0,65

7 15 0,75

15 20 1,00

20 – 1,25

1)

As given in tables 7 and 10.

9 Marking

Every cable shall be identified with the rated voltage and a means of identifying the

manufacturer. Marking shall comply with the requirements of IEC 60227-1 except that, for

cables without an outer covering, the information may be marked on a label attached to each

length of cable.

– 16 – 60702-1 © CEI:2002

Tableau 2 – Liste des essais

1)

Essai Article

Catégorie

Résistance des âmes 5 R

Isolant:

Résistance de l’isolant 11.3 R

Epaisseur 13.4 T

Gaine en cuivre:

Rés

...

IEC 60702-1 ®

Edition 3.1 2015-01

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Mineral insulated cables and their terminations with a rated voltage not

exceeding 750 V –

Part 1: Cables

Câbles à isolant minéral et leurs terminaisons de tension assignée ne dépassant

pas 750 V –

Partie 1: Câbles

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 15

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 60 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

15 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC Plus de 60 000 entrées terminologiques électrotechniques, en

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60702-1 ®

Edition 3.1 2015-01

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Mineral insulated cables and their terminations with a rated voltage not

exceeding 750 V –

Part 1: Cables

Câbles à isolant minéral et leurs terminaisons de tension assignée ne

dépassant pas 750 V –

Partie 1: Câbles

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.060.20 ISBN 978-2-8322-2203-4

IEC 60702-1 ®

Edition 3.1 2015-01

CONSOLIDATED VERSION

REDLINE VERSION

VERSION REDLINE

colour

inside

Mineral insulated cables and their terminations with a rated voltage not

exceeding 750 V –

Part 1: Cables

Câbles à isolant minéral et leurs terminaisons de tension assignée ne dépassant

pas 750 V –

Partie 1: Câbles

– 2 – IEC 60702-1:2002

+AMD1:2015 © IEC 2015

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Definitions . 7

4 Voltage designations . 8

4.1 500 V cable (light duty grade) . 8

4.2 750 V cable (heavy duty grade) . 8

5 Conductors . 8

6 Insulation . 8

6.1 Composition . 8

6.2 Thickness . 8

7 Metallic sheath . 8

7.1 Material . 8

7.2 Sheath thickness . 9

7.3 Sheath diameter and ovality . 9

8 Optional outer covering . 9

8.1 General . 9

8.2 Material . 9

8.3 Halogen-free covering . 9

8.4 Thickness of covering . 9

9 Marking . 10

10 General notes on tests . 10

11 Routine tests . 11

11.1 General . 11

11.2 Conductor resistance . 11

11.3 Insulation resistance . 11

11.4 Integrity of insulation and copper sheath . 11

11.5 Spark test on outer covering . 11

11.6 Diameter and ovality over copper sheath . 12

12 Sample tests . 12

12.1 General . 12

12.2 Voltage test . 12

12.3 Thickness of outer covering . 13

12.4 Flame retardance . 13

12.5 Emission of acidic and corrosive gases . 13

12.6 Smoke emission . 13

13 Type tests . 14

13.1 General . 14

13.2 Voltage test on completed cable . 14

13.3 Resistance of copper sheath . 14

13.4 Thickness of insulation . 14

13.5 Thickness of copper sheath . 15

13.6 Bending test . 15

13.7 Flattening test . 18

13.8 Fire resistance . 19

+AMD1:2015 © IEC 2015

14 500 V mineral insulated cable (light duty grade) . 19

14.1 Code designation . 19

14.2 Rated voltage . 19

14.3 Construction . 19

14.4 Dimensions . 19

14.5 Requirements . 20

15 750 V mineral insulated cable (heavy duty grade) . 20

15.1 Code designation . 20

15.2 Rated voltage . 20

15.3 Construction . 21

15.4 Dimensions . 21

15.5 Requirements . 23

Bibliography . 24

– 4 – IEC 60702-1:2002

+AMD1:2015 © IEC 2015

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MINERAL INSULATED CABLES AND THEIR TERMINATIONS

WITH A RATED VOLTAGE NOT EXCEEDING 750 V –

Part 1: Cables

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been prepared

for user convenience.

IEC 60702-1 edition 3.1 contains the third edition (2002-02) [documents 20/490/FDIS and 20/510/

RVD] and its amendment 1 (2015-01) [documents 20/1528/FDIS and 20/1556/RVD].

In this Redline version, a vertical line in the margin shows where the technical content is

modified by amendment 1. Additions and deletions are displayed in red, with deletions being

struck through. A separate Final version with all changes accepted is available in this

publication.

+AMD1:2015 © IEC 2015

International Standard IEC 60702-1 has been prepared by IEC technical committee 20:

Electric cables.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 3.

The committee has decided that the contents of the base publication and its amendment will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

– 6 – IEC 60702-1:2002

+AMD1:2015 © IEC 2015

MINERAL INSULATED CABLES AND THEIR TERMINATIONS

WITH A RATED VOLTAGE NOT EXCEEDING 750 V –

Part 1: Cables

1 Scope

This standard applies to mineral insulated general wiring cables with copper or copper alloy

sheath and copper conductors and with rated voltages of 500 V and 750 V. Provision is made

for a corrosion-resistant extruded outer covering over the copper sheath, when required. This

outer covering is not specified for the purpose of electrical insulation of the metal sheath.

Requirements for terminations for use with these cables are specified in IEC 60702-2.

The purpose of this standard is to specify mineral insulated cables that are safe and reliable

when properly used, to state the manufacturing requirements and characteristics to achieve

this, and to specify methods for checking conformity with those requirements.

2 Normative references

The following referenced documents, in whole or in part, are normatively referenced in this

document and are indispensable for the its application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the

referenced document (including any amendments) applies.

IEC 60227-1:1993, Polyvinyl chloride insulated cables of rated voltages up to and including

450/750 V – Part 1: General requirements

IEC 60228:1978, Conductors of insulated cables

IEC 60331-21:1999, Tests for electric cables under fire conditions – Circuit integrity – Part 21:

Procedures and requirements – Cables of rated voltage up to and including 0,6/1,0 kV

IEC 60332-1:1993, Tests on electric cables under fire conditions – Part 1: Test on a single

vertical insulated wire or cable

IEC 60702-2:2002, Mineral insulated cables and their terminations with a rated voltage not

exceeding 750 V – Part 2: Terminations

IEC 60331-1, Tests for electric cables under fire conditions – Circuit integrity – Part 1: Test

method for fire with shock at a temperature of at least 830 °C for cables of rated voltage up to

and including 0,6/1,0 kV and with an overall diameter exceeding 20 mm

IEC 60331-2, Tests for electric cables under fire conditions – Circuit integrity – Part 2: Test

method for fire with shock at a temperature of at least 830 °C for cables of rated voltage up to

and including 0,6/1,0 kV and with an overall diameter not exceeding 20 mm

IEC 60332-1-2, Tests on electric and optical fibre cables under fire conditions – Part 1-2: Test

for vertical flame propagation for a single insulated wire or cable – Procedure for 1 kW pre-

mixed flame

+AMD1:2015 © IEC 2015

IEC 60754-2:1991, Test on gases evolved during combustion of electric materials from cables

– Part 2: Determination of degree of acidity of gases evolved during the combustion of

materials taken from electric cables by measuring pH (by pH measurement) and conductivity

IEC 60811-1-1:1993, Common test methods for insulating and sheathing materials of electric

cables and optical cables – Part 1: Methods for general application – Section 1: Measurement

of thickness and overall dimensions – Tests for determining the mechanical properties

IEC 60811-1-4:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section 4: Tests at low temperature

IEC 60811-3-1:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 3: Methods specific to PVC compounds – Section 1: Pressure test at high

temperature – Tests for resistance to cracking

IEC 60811-202, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 202: General tests – Measurement of thickness of non-metallic sheath

IEC 60811-506, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 506: Mechanical tests – Impact test at low temperature for insulations and sheaths

IEC 60811-509, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 509: Mechanical tests – Test for resistance of insulations and sheaths to cracking (heat

shock test)

IEC 61034-2:1997, Measurement of smoke density of cables burning under defined conditions

– Part 2: Test procedure and requirements

3 Definitions

For the purpose of this part of IEC 60702, the following definitions apply.

3.1

nominal value

value by which a quantity is designated and which is often used in tables

Note 1 to entry: Usually, in this standard, nominal values give rise to values to be checked by measurements,

taking into account specified tolerances.

3.2

routine tests (symbol R)

tests made by the manufacturer on each manufactured length of cable to check that the whole

of each length meets the specified requirements

3.3

sample tests (symbol S)

tests made by the manufacturer on samples of completed cable, or components from a

completed cable, at a planned frequency, so as to verify that the finished product meets the

specified requirements

3.4

type tests (symbol T)

T

tests made before supplying, on a general commercial basis, a type of cable covered by this

standard, in order to demonstrate satisfactory performance characteristics to meet the

intended application

– 8 – IEC 60702-1:2002

+AMD1:2015 © IEC 2015

Note 1 to entry: These Type tests are such that, after they have been made, they need not be repeated unless

changes are made in the cable material, design or manufacturing process which might change the performance

characteristics.

4 Voltage designations

The rated voltages of the cables considered in this standard are as follows.

4.1 500 V cable (light duty grade)

For use where the voltage between conductors and sheath and between conductors does not

exceed 500 V r.m.s. or 500 V d.c.

4.2 750 V cable (heavy duty grade)

For use where the voltage between conductors and sheath and between conductors does not

exceed 750 V r.m.s. or 750 V d.c.

5 Conductors

Conductors shall consist of plain annealed copper and shall be of approximately circular

cross-section. They shall comply with the requirements given in IEC 60228 for class 1

conductors.

Compliance shall be checked by inspection and by measuring the resistance of each

conductor of each complete coil of completed cable and measuring the length of the cable.

The measured resistance shall be corrected to 20 °C and to a length of 1 km, in accordance

with 11.2.

6 Insulation

6.1 Composition

The insulation shall consist of compressed powdered mineral or minerals which shall form a

compact body. The electrical properties of the insulation shall be such that the completed

cable shall meet the test requirements of this standard.

6.2 Thickness

The nominal thickness of insulation between conductors and between each conductor and the

sheath shall be as given in tables 7 and 10.

When measured in accordance with 13.4, the minimum thickness shall be not less than 80 %

of the nominal value minus 0,1 mm.

7 Metallic sheath

7.1 Material

The sheath shall be of plain annealed copper or copper alloy. The resistance of the sheath,

measured and corrected to 20 °C in accordance with 13.3, shall comply with the values in

tables 9 and 12.

+AMD1:2015 © IEC 2015

7.2 Sheath thickness

The mean thickness of the sheath shall be not less than the nominal thickness specified in

tables 8 and 11. The thickness at any point may, however, be less than the nominal value,

provided that the difference does not exceed 10 % of the nominal value.

Compliance shall be checked by the test in 13.5.

7.3 Sheath diameter and ovality

When measured in accordance with 11.6, the diameter measurements shall be within ±0,05 mm

of the value specified in tables 7 and 10.

8 Optional outer covering

8.1 General

Where deemed necessary because of corrosive environments, cable identification or aesthetic

appeal, an extruded outer covering may be applied. Application shall be such that the cable

complies with the spark test specified in 11.5 and with the flame retardance test specified in 12.4.

The covering may be of any colour appropriate for the country of use. The material shall meet

the requirements of 8.2 and 8.3, as appropriate.

NOTE By agreement between the manufacturer and purchaser, outer coverings of alternative materials and

thicknesses may be applied.

8.2 Material

The material of the outer covering shall comply with the following requirements.

8.2.1 Low temperature impact

When samples of cable with outer covering are tested in accordance with 8.5 of IEC 60811-1-4

IEC 60811-506, at a temperature of (–15 ± 2) °C, the samples shall not crack.

8.2.2 Heat shock test

When samples of cable with outer covering are tested in accordance with 9.2 of IEC 60811-3-1

IEC 60811-509, at a temperature of (150 ± 3) °C, the samples shall not crack.

8.3 Halogen-free covering

Halogen-free covering shall meet the requirements given in 8.2, and be such that the

completed cable will meet the fire performance tests of 12.4, 12.5 and 12.6.

8.4 Thickness of covering

When measured in accordance with 12.3, the mean value of the thickness of the outer

covering shall be not less than the nominal value given in table 1. The thickness at any point

may, however, be less than the nominal value, provided that the difference does not exceed

0,1 mm + 15 % of the specified nominal value.

– 10 – IEC 60702-1:2002

+AMD1:2015 © IEC 2015

Table 1 – Thickness of covering

1)

Diameter over copper sheath

Nominal thickness

mm

of covering

mm

Above Up to and including

– 7 0,65

7 15 0,75

15 20 1,00

20 – 1,25

1)

As given in tables 7 and 10.

9 Marking

Every cable shall be identified with the rated voltage and a means of identifying the

manufacturer. Marking shall comply with the requirements of IEC 60227-1 except that, for

cables without an outer covering, the information may be marked on a label attached to each

length of cable.

Table 2 – Schedule of tests

1)

Test Clause

Category

Conductor resistance 5 R

Insulation:

Insulation resistance 11.3 R

Thickness 13.4 T

Copper sheath:

Sheath resistance 13.3 T

Thickness 13.5 T

Integrity of sheath 11.4 R

Diameter and ovality 11.6

R

Outer covering:

Material properties 8.2 S

Thickness 12.3 S

Spark test 11.5 R

Acidic and corrosive gases 12.5 S

Voltage test (1 min) 12.2 S

Voltage test (15 min) 13.2 T

Bending test 13.6 T

Flattening test 13.7 T

Flame retardance test

12.4 S

Smoke emission test 12.6 S

Fire resistance test 13.8 T

1)

R = routine test; S = sample test; T = type test

10 General notes on tests

Unless otherwise specified, tests shall be made at an ambient temperature of (20 ± 15) °C.

+AMD1:2015 © IEC 2015

Unless otherwise specified, the test voltages shall be either a.c. 49 Hz to 61 Hz of

approximately sine-wave form, the ratio peak value/r.m.s. being equal to 2 with a tolerance

of ±7 %, or d.c. at 1,5 times the r.m.s. value.

11 Routine tests

11.1 General

Routine tests are identified in table 2 by the symbol R, as defined in 3.2.

11.2 Conductor resistance

The d.c. resistance of each conductor shall comply with IEC 60228 when measured and

corrected to 20 °C in accordance with that standard.

11.3 Insulation resistance

Each complete coil of completed cable, prior to the application of any outer covering, shall be

totally immersed for at least 1 h in water at a temperature of (15 ± 10) °C. Within 8 h of the

cable being removed from the water, the cable ends shall then be stripped to expose the

conductors and temporarily sealed at each end.

A d.c. voltage of not less than 80 V and not more than the peak voltage corresponding to the

appropriate r.m.s. value specified in 11.4 shall be applied between the conductors and

between conductors and the copper sheath. The insulation resistance shall be measured after

1 min of voltage application or sooner provided that the reading is satisfactory and not

decreasing.

The product of the insulation resistance in megohms and the cable length in kilometres shall

be not less than 1 000 MΩ⋅km, except for cable lengths less than 100 m when the measured

insulation resistance shall be not less than 10 000 MΩ.

11.4 Integrity of insulation and copper sheath

Each complete coil of completed cable, prior to the application of any outer covering, shall be

totally immersed for at least 1 h in water at a temperature of (15 ± 10) °C. Within 8 h of the

cable being removed from the water, the cable ends shall be stripped, to expose the

conductors, and temporarily sealed at each end. The voltages specified below shall be

applied with a minimum rate of rise of voltage of 150 V/s and maintained for at least 60 s

between conductors and between conductors and sheath.

Rated voltage Test voltage

500 V 2,0 kV r.m.s.

750 V 2,5 kV r.m.s.

This test may be combined with that specified in 11.3 provided that a d.c. voltage equal to

1,5 times the value of the appropriate a.c. r.m.s. value is used.

11.5 Spark test on outer covering

The integrity of the outer covering shall be verified by compliance with the following spark test.

An electrode, consisting preferably of a curtain of metallic beads, shall make intimate contact

with the plastic covered surface of the cable.

The speed at which the cable passes through the electrode shall be such that every point is in

contact with the electrode for not less than 0,05 s.

– 12 – IEC 60702-1:2002

+AMD1:2015 © IEC 2015

The test voltage supply to the electrode shall be a.c. at a frequency of 49 Hz to 61 Hz and of

a value given in table 3, the copper sheath of the cable being earthed.

Table 3 – Test voltages

1)

Diameter over copper sheath

Test voltage

mm

r.m.s.

kV

Above Up to and including

– 7 4

7 15 5

15 20 6

20 – 8

1)

As given in tables 7 and 10.

A fault detector shall be so arranged as to maintain its indication even after a fault has passed

out of the electrode.

The minimum sensitivity of the spark testing apparatus shall be such that the detector will

operate when an artificial fault device, consisting of a spark gap in series with a capacitor, is

connected between the electrode and earth. The electrode voltage shall be 6 kV r.m.s. and

the capacitance of the capacitor shall be 350 pF.

The spark gap shall consist of a metal plate moving past a needle point in 0,02 s, and the

distance between them during this time shall be 5,0 mm.

The covered cable shall exhibit no fault when tested with this apparatus.

11.6 Diameter and ovality over copper sheath

The overall diameter of the completed cable (excluding outer covering) shall be checked by

measurement on complete cable samples. The measurements shall be made at two positions,

separated by at least 1 m. At each position, measurements shall be made in two directions

perpendicular to each other, by means of a micrometer with flat anvils or an equivalent

method.

All four measurements shall lie within ±0,05 mm of the value in table 7 or 10 as appropriate.

12 Sample tests

12.1 General

Sample tests are identified in table 2 by the symbol S, as defined in 3.3.

12.2 Voltage test

Prior to the application of any plastic outer covering, a complete coil of completed cable shall

be stripped to expose the conductors, and temporarily sealed at each end.

A voltage of

• 2 000 V r.m.s. for 500 V cables, or

• 2 500 V r.m.s. for 750 V cables

shall then be applied for 1 min each time between

+AMD1:2015 © IEC 2015

a) conductors,

b) each conductor and the copper sheath.

The rate of rise of test voltage shall be not less than 150 V/s.

When required by the purchaser, the same levels of test voltage shall be applied to cables

with a plastic outer covering.

No breakdown shall occur during the test.

12.3 Thickness of outer covering

A sample of the cable covering approximately 250 mm in length shall be taken not less than

300 mm from the end of a coil of cable.

The thickness of the covering shall be measured at three cross-sections, not less than 100 mm

apart, in accordance with 8.2 of IEC 60811-1-1 IEC 60811-202.

The average of all 18 measurements shall be calculated and rounded off to two decimal

places as below, and this shall be taken as the mean value of the thickness of the outer

covering.

If in the calculation the third decimal figure is 5 or more, the second decimal figure shall be

raised to the next number; thus, for example, 1,734 is rounded off to 1,73 and 1,757 to 1,76.

The lowest of all values obtained shall be taken as the minimum thickness of the plastic outer

covering.

The average and minimum thicknesses shall meet the requirements of 8.4.

12.4 Flame retardance

When a cable with an outer covering is tested in accordance with IEC 60332-1-2, the charred

or affected portion shall not reach within 50 mm of the top clamp.

12.5 Emission of acidic and corrosive gases

When samples of halogen-free covering, removed from finished cables, are tested in

accordance with IEC 60754-2, the pH shall not be less than 4,3 and the conductivity shall not

be greater than 10 µS/mm.

12.6 Smoke emission

When samples of finished cables with halogen-free covering are tested in accordance with

IEC 61034-2, the smoke produced shall be such that the light transmittance meets the

requirements in table 4. The sample requirements shall be in accordance with table 4.

– 14 – IEC 60702-1:2002

+AMD1:2015 © IEC 2015

Table 4 – Smoke emission