IEC 60749-18:2019

(Main)Semiconductor devices - Mechanical and climatic test methods - Part 18: Ionizing radiation (total dose)

Semiconductor devices - Mechanical and climatic test methods - Part 18: Ionizing radiation (total dose)

IEC 60749-18:2019 provides a test procedure for defining requirements for testing packaged semiconductor integrated circuits and discrete semiconductor devices for ionizing radiation (total dose) effects from a cobalt-60 (60Co) gamma ray source. Other suitable radiation sources can be used. This document addresses only steady-state irradiations, and is not applicable to pulse type irradiations. It is intended for military- and aerospace-related applications. It is a destructive test. This edition includes the following significant technical changes with respect to the previous edition:

- updates to subclauses to better align the test method with MIL-STD 883J, method 1019, including the use of enhanced low dose rate sensitivity (ELDRS) testing;

- addition of a Bibliography, which includes ASTM standards relevant to this test method.

Dispositifs à semiconducteurs - Méthodes d'essais mécaniques et climatiques - Partie 18: Rayonnements ionisants (dose totale)

L’IEC 60749-18:2019 présente une procédure d’essai permettant de définir les exigences pour soumettre à essai des circuits intégrés à semiconducteurs sous boîtier et des dispositifs discrets à semiconducteurs, concernant les effets des rayonnements ionisants (dose totale) provenant d’une source de rayons gamma au cobalt-60 (60Co). D’autres sources de rayonnements appropriées peuvent être utilisées. Le présent document ne concerne que les irradiations continues et ne s’applique pas aux irradiations pulsées. Il est destiné aux applications des domaines militaire et aérospatial. Il s’agit d’un essai destructif. Cette édition inclut les modifications techniques majeures suivantes par rapport à l’édition précédente:

- mises à jour apportées aux paragraphes afin de mieux aligner la méthode d’essai avec la méthode 1019 du document MIL-STD 883J, comprenant l’utilisation de l’essai de sensibilité accrue au faible débit de dose (ELDRS);

- ajout d’une bibliographie, comprenant les normes ASTM correspondant à la présente méthode d’essai.

General Information

- Status

- Published

- Publication Date

- 09-Apr-2019

- Technical Committee

- TC 47 - Semiconductor devices

- Drafting Committee

- WG 2 - TC 47/WG 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 10-Apr-2019

- Completion Date

- 03-May-2019

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60749-18:2019 - "Semiconductor devices - Mechanical and climatic test methods - Part 18: Ionizing radiation (total dose)" defines test procedures for characterizing packaged semiconductor integrated circuits and discrete devices under ionizing radiation (total dose) exposure. The standard focuses on steady‑state irradiations (not pulse irradiations) using a cobalt‑60 (60Co) gamma‑ray source or other suitable radiation sources. It is primarily intended for military and aerospace applications and is considered a destructive test when applied to parts under evaluation.

Key Topics and Technical Requirements

- Test scope and objectives: Procedures to measure total‑dose ionizing radiation effects and to estimate time‑dependent degradation (TDE) and annealing behavior.

- Four main test types:

- Standard room temperature irradiation

- Elevated‑temperature / cryogenic‑temperature irradiation

- Accelerated annealing test (to simulate low dose‑rate effects)

- Enhanced Low Dose Rate Sensitivity (ELDRS) test for bipolar/BiCMOS linear and mixed‑signal devices

- Radiation source and dosimetry: Use of 60Co gamma rays (or equivalent sources) and detailed dosimetry system requirements to determine delivered dose and dose rate.

- Dose rate considerations: Definitions of different dose‑rate conditions and specific guidance for low dose‑rate testing; ELDRS sensitivity is evaluated for parts intended to operate below 0.5 Gy(Si)/s.

- Test setup and instrumentation: Requirements for test apparatus, irradiation temperature chambers, test circuit boards, cabling, and interconnect/switching systems.

- Electrical measurements and modes: In‑flux (during irradiation), non in‑flux, and remote testing methodologies; guidance on biasing and loading conditions during exposure.

- Post‑irradiation and annealing procedures: Post‑irradiation measurement sequences, extended room‑temperature annealing, and MOS accelerated annealing tests to assess time‑dependent effects.

- Reporting and alignment: Test report content and alignment updates to better match MIL‑STD‑883J Method 1019; bibliography added with relevant ASTM standards.

Applications and Who Uses This Standard

IEC 60749-18:2019 is used by:

- Semiconductor manufacturers performing qualification and lot acceptance testing for radiation hardness

- Aerospace and defense contractors specifying component radiation performance

- Independent test labs executing total‑dose and ELDRS characterization

- Reliability and design engineers assessing radiation‑tolerant electronics for satellites, launch vehicles, and military systems

Practical benefits include standardized procedures for reproducible dose delivery, consistent measurement of degradation and annealing, and criteria for identifying ELDRS‑sensitive lots.

Related Standards (if applicable)

- MIL‑STD‑883J, Method 1019 (alignment for total dose testing and ELDRS guidance)

- ASTM standards referenced in the IEC 60749-18:2019 bibliography for complementary radiation test practices

Keywords: IEC 60749-18:2019, ionizing radiation, total dose, cobalt-60, gamma ray, ELDRS, radiation testing, semiconductor devices, accelerated annealing, MIL‑STD‑883J, aerospace, military.

Buy Documents

IEC 60749-18:2019 RLV - Semiconductor devices - Mechanical and climatic test methods - Part 18: Ionizing radiation (total dose) Released:4/10/2019

IEC 60749-18:2019 - Semiconductor devices - Mechanical and climatic test methods - Part 18: Ionizing radiation (total dose) Released:4/10/2019

Frequently Asked Questions

IEC 60749-18:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Semiconductor devices - Mechanical and climatic test methods - Part 18: Ionizing radiation (total dose)". This standard covers: IEC 60749-18:2019 provides a test procedure for defining requirements for testing packaged semiconductor integrated circuits and discrete semiconductor devices for ionizing radiation (total dose) effects from a cobalt-60 (60Co) gamma ray source. Other suitable radiation sources can be used. This document addresses only steady-state irradiations, and is not applicable to pulse type irradiations. It is intended for military- and aerospace-related applications. It is a destructive test. This edition includes the following significant technical changes with respect to the previous edition: - updates to subclauses to better align the test method with MIL-STD 883J, method 1019, including the use of enhanced low dose rate sensitivity (ELDRS) testing; - addition of a Bibliography, which includes ASTM standards relevant to this test method.

IEC 60749-18:2019 provides a test procedure for defining requirements for testing packaged semiconductor integrated circuits and discrete semiconductor devices for ionizing radiation (total dose) effects from a cobalt-60 (60Co) gamma ray source. Other suitable radiation sources can be used. This document addresses only steady-state irradiations, and is not applicable to pulse type irradiations. It is intended for military- and aerospace-related applications. It is a destructive test. This edition includes the following significant technical changes with respect to the previous edition: - updates to subclauses to better align the test method with MIL-STD 883J, method 1019, including the use of enhanced low dose rate sensitivity (ELDRS) testing; - addition of a Bibliography, which includes ASTM standards relevant to this test method.

IEC 60749-18:2019 is classified under the following ICS (International Classification for Standards) categories: 31.080.01 - Semiconductor devices in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60749-18:2019 has the following relationships with other standards: It is inter standard links to IEC 60749-18:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60749-18:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60749-18 ®

Edition 2.0 2019-04

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Semiconductor devices – Mechanical and climatic test methods –

Part 18: Ionizing radiation (total dose)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60749-18 ®

Edition 2.0 2019-04

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Semiconductor devices – Mechanical and climatic test methods –

Part 18: Ionizing radiation (total dose)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.080.01 ISBN 978-2-8322-6832-2

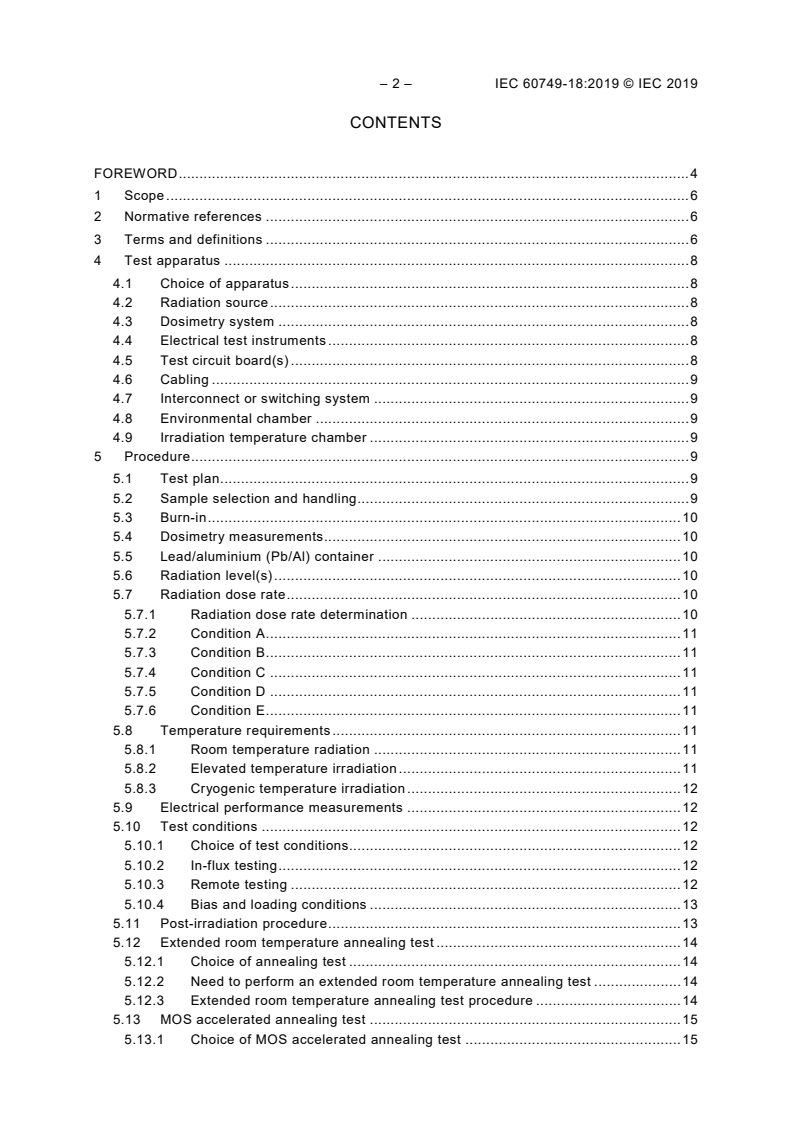

– 2 – IEC 60749-18:2019 RLV © IEC 2019

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Test apparatus . 8

4.1 Choice of apparatus . 8

4.2 Radiation source . 8

4.3 Dosimetry system . 8

4.4 Electrical test instruments . 8

4.5 Test circuit board(s) . 8

4.6 Cabling . 9

4.7 Interconnect or switching system . 9

4.8 Environmental chamber . 9

4.9 Irradiation temperature chamber . 9

5 Procedure . 9

5.1 Test plan . 9

5.2 Sample selection and handling . 9

5.3 Burn-in . 10

5.4 Dosimetry measurements . 10

5.5 Lead/aluminium (Pb/Al) container . 10

5.6 Radiation level(s) . 10

5.7 Radiation dose rate . 10

5.7.1 Radiation dose rate determination . 10

5.7.2 Condition A . 10

5.7.3 Condition B . 11

5.7.4 Condition C . 11

5.7.5 Condition D . 11

5.7.6 Condition E . 11

5.8 Temperature requirements . 11

5.8.1 Room temperature radiation . 11

5.8.2 Elevated temperature irradiation . 12

5.8.3 Cryogenic temperature irradiation . 12

5.9 Electrical performance measurements . 12

5.10 Test conditions . 12

5.10.1 Choice of test conditions. 12

5.10.2 In-flux testing . 12

5.10.3 Remote testing . 13

5.10.4 Bias and loading conditions . 13

5.11 Post-irradiation procedure . 13

5.12 Extended room temperature annealing test . 14

5.12.1 Choice of annealing test . 14

5.12.2 Need to perform an extended room temperature annealing test . 14

5.12.3 Extended room temperature annealing test procedure . 14

5.13 MOS accelerated annealing test . 15

5.13.1 Choice of MOS accelerated annealing test . 15

5.13.2 Need to perform accelerated annealing test . 15

5.13.3 Accelerated annealing test procedure . 16

5.14 Test procedure for bipolar and BiCMOS linear or mixed signal devices with

intended application dose rates less than 0,5 Gy(Si)/s . 16

5.14.1 Need to perform ELDRS testing . 16

5.14.2 Determination of whether a part exhibits ELDRS. 17

5.14.3 Characterization of ELDRS parts to determine the irradiation conditions

for production or lot acceptance testing . 17

5.14.4 Low dose rate or elevated temperature irradiation test for bipolar or

BiCMOS linear or mixed-signal devices . 18

5.15 Test report . 18

6 Summary . 18

Bibliography . 22

Figure 1 – Flow diagram for ionizing radiation test procedure for MOS and digital

bipolar devices. 20

Figure 2 – Flow diagram for ionizing radiation test procedure for bipolar (or BiCMOS)

linear or mixed-signal devices . 21

– 4 – IEC 60749-18:2019 RLV © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SEMICONDUCTOR DEVICES –

MECHANICAL AND CLIMATIC TEST METHODS –

Part 18: Ionizing radiation (total dose)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 60749-18 has been prepared by IEC technical committee 47:

Semiconductor devices.

This second edition cancels and replaces the first edition published in 2002. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) updates to subclauses to better align the test method with MIL-STD 883J, method 1019,

including the use of enhanced low dose rate sensitivity (ELDRS) testing;

b) addition of a Bibliography, which includes ASTM standards relevant to this test method.

The text of this International Standard is based on the following documents:

FDIS Report on voting

47/2539/FDIS 47/2554/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60749 series, published under the general title Semiconductor

devices – Mechanical and climatic test methods, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

– 6 – IEC 60749-18:2019 RLV © IEC 2019

SEMICONDUCTOR DEVICES –

MECHANICAL AND CLIMATIC TEST METHODS –

Part 18: Ionizing radiation (total dose)

1 Scope

This part of IEC 60749 provides a test procedure for defining requirements for testing

packaged semiconductor integrated circuits and discrete semiconductor devices for ionizing

radiation (total dose) effects from a cobalt-60 ( Co) gamma ray source. Other suitable

radiation sources can be used.

This standard provides an accelerated annealing test for estimating low dose rate ionizing

radiation effects on devices. This annealing test is important for low dose rate or certain other

applications in which devices may exhibit significant time-dependent effects.

There are four tests presented in this procedure:

a) a standard room temperature irradiation test;

b) an irradiation at elevated temperature/cryogenic temperature test;

c) an accelerated annealing test;

d) an enhanced low dose rate sensitivity (ELDRS) test.

The accelerated annealing test estimates how dose rate ionizing radiation effects on devices

is important for low dose rate or certain other applications in which devices can exhibit

significant time-dependent effects. The ELDRS test determines if devices with bipolar linear

components exhibit sensitivity to enhanced radiation-induced damage at low dose rates.

This document addresses only steady-state irradiations, and is not applicable to pulse type

irradiations.

It is intended for military- and aerospace-related applications.

This document may can produce severe degradation of the electrical properties of irradiated

devices and thus should be is considered a destructive test.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

ionizing radiation effects, pl

changes in the electrical parameters of a device or integrated circuit resulting from radiation-

induced charge

Note 1 to entry: These are also referred to as total dose effects.

3.2

in-flux test

electrical measurements made on devices during irradiation exposure

3.3

internal dose pattern

logic condition of all elements within a logic circuit during radiation exposure

3.4

non in-flux test

electrical measurements made on devices at any time other than during irradiation

3.5

remote test

electrical measurements made on devices that are physically removed from the radiation

location

3.6

time-dependent effect

TDE

significant degradation in electrical parameters caused by the growth or annealing, or both, of

radiation-induced trapped charge after irradiation

Note 1 to entry: Similar effects also take place during irradiation.

Note 2 to entry: This note applies to the French language only.

3.7

accelerated annealing test

procedure utilizing elevated temperature to accelerate time-dependent effects

3.8

enhanced low dose rate sensitivity

ELDRS

part that shows enhanced radiation-induced damage at dose rates below 0,5 Gy(Si)/s

Note 1 to entry: This note applies to the French language only.

3.9

overtest

factor that is applied to the specification dose to determine the test dose level that the

samples have to pass to be acceptable at the specification level

Note 1 to entry: An overtest factor of 1,5 means that the parts should be tested at 1,5 times the specification dose.

3.10

parameter delta design margin

PDDM

design margin that is applied to the radiation-induced change in an electrical parameter

Note 1 to entry: For a PDDM of 2 the change in a parameter at a specified dose from the pre-irradiation value is

multiplied by two and added to the pre-irradiation value to see if the sample exceeds the post-irradiation parameter

limit. For example, if the pre-irradiation value of base current I is 30 nA and the post-irradiation value at 200 Gy(Si)

b

– 8 – IEC 60749-18:2019 RLV © IEC 2019

is 70 nA (change in I is 40 nA), then for a PDDM of 2 the post-irradiation value would be 110 nA

b

(30 nA + 2 x 40 nA). If the allowable post-irradiation limit is 100 nA, the part would fail.

4 Test apparatus

4.1 Choice of apparatus

The apparatus shall consist of the radiation source, electrical test instrumentation, test circuit

board(s), cabling, interconnect board or switching system, an appropriate dosimetry

measurement system, and an environmental chamber (if required for time-dependent effects

measurements). Adequate precautions shall be observed to obtain an electrical measurement

system with sufficient insulation, ample shielding, satisfactory grounding, and suitable low

noise characteristics.

4.2 Radiation source

The radiation source used in the test shall be the uniform field of a Co gamma ray source.

Uniformity of the radiation field in the volume where devices are irradiated shall be within ±10 %

as measured by the dosimetry system, unless otherwise specified. The intensity of the gamma

Co source shall be known with an uncertainty of no more than ±5 %. Field

ray field of the

uniformity and intensity can be affected by changes in the location of the device with respect

to the radiation source and the presence of radiation absorption and scattering materials.

4.3 Dosimetry system

An appropriate dosimetry system shall be provided that is capable of carrying out the

measurements called for in 5.3 (see Bibliography).

4.4 Electrical test instruments

All instrumentation used for electrical measurements shall have the stability, accuracy, and

resolution required for accurate measurement of the electrical parameters. Any

instrumentation required to operate in a radiation environment shall be appropriately shielded.

4.5 Test circuit board(s)

Devices to be irradiated shall either be mounted on or connected to circuit boards together

with any associated circuitry necessary for device biasing during irradiation or for in situ

measurements. Unless otherwise specified, all device input terminals and any others

which may can affect the radiation response shall be electrically connected during irradiation,

i.e. not left floating.

The geometry and materials of the completed board shall allow uniform irradiation of the

devices under test. Good design and construction practices shall be used to prevent

oscillations, minimize leakage currents, prevent electrical damage and obtain accurate

measurements. Only sockets that are radiation resistant and do not exhibit significant

leakages (relative to the devices under test) shall be used to mount devices and associated

circuitry to the test board(s).

All apparatus used repeatedly in radiation fields shall be checked periodically for physical or

electrical degradation. Components which are placed on the test circuit board, other than

devices under test, shall be insensitive to the accumulated radiation or they shall be shielded

from the radiation. Test fixtures shall be made such that materials will not perturb the

uniformity of the radiation field intensity on the devices under test.

Leakage current shall be measured outside the field of radiation. With no devices installed in

the sockets, the test circuit board shall be connected to the test system such that all expected

sources of noise and interference are operative. With the maximum specified bias for the test

device applied, the leakage current between any two terminals shall not exceed 10 % of the

lowest current limit value in the pre-irradiation device specification.

Test circuit boards used to bias devices during accelerated annealing must shall be capable

of withstanding the temperature requirements of the accelerated annealing test and shall be

checked before and after testing for physical and electrical degradation.

4.6 Cabling

Cables connecting the test circuit boards in the radiation field to the test instrumentation shall

be as short as possible. If long cables are necessary, line drivers may can be required. The

cables shall have low capacitance and low leakage to ground, and low leakage between wires.

4.7 Interconnect or switching system

This system shall be located external to outside the radiation environment location, and

provides the interface between the test instrumentation and the devices under test. It is part

of the entire test system and subject to the limitation specified in 4.5 for leakage between

terminals.

4.8 Environmental chamber

The environmental chamber for time-dependent effects testing, if required, shall be capable of

maintaining the selected accelerated annealing temperature within ±5 °C.

4.9 Irradiation temperature chamber

The irradiation temperature chamber, if required for elevated temperature irradiation should

be capable of maintaining a circuit under test at 100 °C ± 5 °C while it is being irradiated. The

chamber should be capable of raising the temperature of the circuit under test from room

temperature to the irradiation temperature within a reasonable time prior to irradiation and

cooling the circuit under test from the irradiation temperature to room temperature in less than

20 min following irradiation. The irradiation bias shall be maintained during the heating and

cooling. The method for raising, maintaining and lowering the temperature of the circuit under

test can be by conduction through a heat sink using heating and cooling fluids, by convection

using forced hot and cool air, or other means that will achieve the proper results. For

cryogenic temperature irradiations, the chamber should be capable of maintaining the test

device/unit at the required cryogenic temperature within ±5 °C (e.g., liquid helium or liquid

nitrogen) while it is being irradiated. The chamber should be capable of maintaining the

cryogenic temperature of the test device/unit during post-irradiation electrical testing.

5 Procedure

5.1 Test plan

The test devices shall be irradiated and subjected to accelerated annealing testing (if required

for time-dependent effects testing) as specified by a test plan. This plan shall specify the

device description, irradiation conditions, device bias conditions, dosimetry system, operating

conditions, measurement parameters and conditions and accelerated annealing test

conditions (if required).

5.2 Sample selection and handling

Only devices that have passed the electrical specifications as defined in the test plan shall be

submitted to radiation testing. Unless otherwise specified, the test samples shall be randomly

selected from the parent population and identically packaged. Each part shall be individually

identifiable to enable pre- and post-irradiation comparison. For device types that are

electrostatic discharge (ESD)-sensitive, proper handling techniques shall be used to prevent

damage to the devices.

– 10 – IEC 60749-18:2019 RLV © IEC 2019

5.3 Burn-in

For some devices, there are differences in the total dose radiation response before and after

burn-in. Unless it has been shown by prior characterization or by design that burn-in has a

negligible effect (parameters remain within post-irradiation specified electrical limits) on the

total dose radiation response, then one of the following functions must shall take place:

a) the manufacturer shall subject the radiation samples to the specified burn-in conditions

prior to conducting total dose radiation testing; or

b) the manufacturer shall develop a correction factor, (which is acceptable to the parties to

the test) taking into account the changes in total dose response resulting from subjecting

the product to burn-in. The correction factor shall then be used to accept the product for

total dose response without subjecting the test samples to burn-in.

5.4 Dosimetry measurements

The radiation field intensity at the location of the device under test shall be determined prior

to testing by dosimetry or by source decay correction calculations, as appropriate, to ensure

conformance to the test level and uniformity requirements.

The dose applied to the device under test shall be determined in one of two ways:

a) by measurement during the irradiation with an appropriate dosimeter; or

Co source intensity in

b) by correcting a previous dosimetry value for the decay of the

the intervening time. Appropriate correction shall be made to convert from the measured

or calculated dose in the dosimeter material to the dose in the device under test.

5.5 Lead/aluminium (Pb/Al) container

Test specimens shall be enclosed in a Pb/Al container to minimize dose enhancement effects

caused by low-energy scattered radiation. A minimum of 1,5 mm of lead (Pb), surrounding an

inner shield of at least 0,7 mm aluminium (Al) is required. This Pb/Al container produces an

approximate charged particle equilibrium for Si and for thermoluminescence dosimetries

(TLDs) such as CaF2. The radiation field intensity shall be measured inside the Pb/Al

container (1) initially, (2) when the source is changed, or (3) when the orientation or

configuration of the source, container or test-fixture is changed. This measurement shall be

performed by placing a dosimeter (e.g. a TLD) in the device-irradiation container at the

approximate test-device position. If it can be demonstrated that low energy scattered radiation

is small enough that it will not cause dosimetry errors due to dose enhancement, the Pb/Al

container may be omitted.

5.6 Radiation level(s)

The test devices shall be irradiated to the dose level(s) specified in the test plan within ±10 %.

If multiple irradiations are required for a set of test devices, then the post-irradiation electrical

parameter measurements shall be performed after each irradiation.

5.7 Radiation dose rate

5.7.1 Radiation dose rate determination

CAUTION: For the application of some bipolar and biCMOS devices to space-level dose rates,

testing at condition A dose rates may not provide worst case results. These are devices that

fail due to reduced transistor gain.

NOTE For those bipolar and biCMOS devices, where the application involves space-level dose rates and the

excess base current has been observed to increase at decreasing dose rates, testing may be accomplished at

the lowest dose rate of interest in accordance with Condition C in order to obtain a conservative estimate of the

device performance.

The radiation dose rate for bipolar and BiCMOS linear or mixed-signal parts used in

applications where the maximum dose rate is below 0,5 Gy(Si)/s shall be determined as

described in 5.14. Parts used in low dose rate applications, unless they have been

demonstrated to not exhibit an ELDRS response shall use condition C, condition D, or

condition E.

A flow diagram for ionizing test procedures for MOS and digital bipolar devices is shown in

Figure 1. A flow diagram for ionizing radiation test procedure for bipolar

(or BiCMOS) linear or mixed-signal devices is shown in Figure 2.

NOTE Devices that contain both MOS and bipolar devices can require qualification to multiple subconditions to

ensure that both ELDRS and traditional MOS effects are evaluated.

5.7.2 Condition A

For condition A (standard condition), the dose rate shall be between 0,5 Gy(Si)/s and

3 Gy(Si)/s for integrated circuits and between 0,5 Gy(Si)/s and 20 Gy(Si)/s for discrete

semi-conductor devices. The dose rates may be different for each radiation dose level in

a series; however, the dose rate shall not vary by more than ±10 % during each irradiation.

5.7.3 Condition B

For condition B, for MOS devices only, if the maximum dose rate is < less than 0,5 Gy(Si)/s in

the intended application, the parties to the test may can agree to perform the test at a dose

rate greater than or equal to the maximum dose rate of the intended application. Unless the

exclusions in 5.13.2 b) are met, the accelerated annealing test of 5.13.3 shall be performed.

5.7.4 Condition C

For condition C, (as an alternative) the test may be performed at the dose rate of the intended

application if this is agreed to by the parties to the test. Where the final user is not known, the

test conditions and results shall be made available in the test report with each purchase order.

5.7.5 Condition D

For condition D, for bipolar or BiCMOS linear or mixed-signal devices only, the parts shall be

irradiated at less than or equal to 0,1 mGy(Si)/s.

5.7.6 Condition E

For condition E, for bipolar or BiCMOS linear or mixed-signal devices only, the parts shall be

irradiated with the accelerated test conditions determined by characterization testing as

discussed in 5.14.3. The accelerated test may include irradiation at an elevated temperature.

5.8 Temperature requirements

5.8.1 Room temperature radiation

Since radiation effects are temperature dependent, devices under test shall be irradiated in an

ambient temperature of 24 °C ± 6 °C as measured at a point in the test chamber in close

proximity to the test fixture. The electrical measurements shall be performed in an ambient

temperature of 25 24 °C ± 5 6 °C. If devices are transported to and from a remote electrical

measurement site, the temperature of the test devices shall not be allowed to increase by

more than 10 °C from the irradiation environment. If any other temperature range is required,

it shall be specified.

Caution: Annealing at ambient temperatures above the irradiation temperature can be

significant, especially for the extended times allowed for the time between irradiations at low

dose rate (condition D). It is important to ensure that the temperature of the parts is

maintained within the above stated requirements to minimize annealing.

– 12 – IEC 60749-18:2019 RLV © IEC 2019

5.8.2 Elevated temperature irradiation

For bipolar or BiCMOS linear or mixed-signal devices irradiated using the condition E

elevated temperature irradiation test, devices under test shall be irradiated in an ambient

temperature determined by characterization testing (see 5.14.3) as measured at a point in the

test chamber in close proximity to the test fixture (see 4.8 for details on raising and lowering

the irradiation temperature).

5.8.3 Cryogenic temperature irradiation

For test devices/units operated in cryogenic temperature applications, the devices/units shall

be irradiated at cryogenic temperature (see 4.8) and maintained at cryogenic temperature for

post exposure characterization testing (see 5.11). The test device/units shall remain at

cryogenic temperature throughout all irradiations and characterization testing until the final

total dose exposure and characterization have been completed.

5.9 Electrical performance measurements

The electrical parameters to be measured and functional tests to be performed shall be

specified in the test plan. As a check on the validity of the measurement system and pre- and

post-irradiation data, at least one control sample shall be measured using the operating

conditions provided in the governing device specifications. For automatic test equipment,

there is no restriction on the test sequence provided that the rise in the device junction

temperature is minimized. For manual measurements, the sequence of parameter

measurements shall be chosen to allow the shortest possible measurement period. When a

series of measurements is made, the tests shall be arranged so that the lowest power

dissipation in the device occurs in the earliest measurements and the power dissipation

increases with subsequent measurements in the sequence.

The pre- and post-irradiation electrical measurements shall be carried out on the same

measurement system and the same sequence of measurements shall be maintained for each

series of electrical measurements of devices in a test sample. Pulse-type measurements of

electrical parameters should be used as appropriate to minimize heating and subsequent

annealing effects. Devices which will be subjected to the accelerated annealing testing (see

5.13) may be given a pre-irradiation burn-in to eliminate burn-in related failures.

5.10 Test conditions

5.10.1 Choice of test conditions

The use of in-flux or non in-flux testing shall be specified in the test plan. (This may can

depend on the intended application for which the data are being obtained.) The use of in-flux

testing may can help to avoid variations introduced by post-irradiation time-dependent effects.

However, errors may can occur for the situation where a device is irradiated in-flux with static

bias, but where the electrical testing conditions require the use of dynamic bias for a

significant fraction of the total irradiation period. Non-in-flux testing generally allows for more

comprehensive electrical testing, but can be misleading if significant post-irradiation time-

dependent effects occur.

5.10.2 In-flux testing

Each test device shall be checked for operation within specifications prior to being irradiated.

After the entire system is in place for the in-flux radiation test, it shall be checked for proper

interconnections, leakage (see 4.5), and noise level. To ensure the proper operation and

stability of the test set-up, a control device with known parameter values shall be measured at

all operational conditions called for in the test plan. This measurement shall be carried out

either before the insertion of test devices or upon completion of the irradiation after removal

of the test devices or both.

5.10.3 Remote testing

Unless otherwise specified, the bias shall be removed and the device leads placed in

conductive foam (or similarly shorted) during transfer from the irradiation source to a remote

tester and back again for further irradiation. This minimizes post-irradiation time-dependent

effects.

5.10.4 Bias and loading conditions

Bias conditions for test devices during irradiation or accelerated annealing shall be within

±10 % of those specified by the test plan. The bias applied to the test devices shall be

selected to produce the greatest radiation-induced damage or the worst-case damage for the

intended application, if known. The bias, loading and internal dose-pattern conditions shall

remain constant throughout a step-wise total ionizing dose exposure and anneal. If any of the

bias, loading or internal dose-pattern conditions are not at the worst-case condition, then a

justification for the conditions used shall be provided in the test plan and test report. While

maximum voltage is often worst case some bipolar linear device parameters (e.g. input bias

current or maximum output load current) exhibit more degradation with 0 V bias. The specified

bias shall be maintained on each device in accordance with the test plan. Bias shall be

checked immediately before and after irradiation. Care shall be taken in selecting the loading

such that the rise in the junction temperature is minimized.

5.11 Post-irradiation procedure

Unless otherwise specified, the following time intervals shall be observed:

a) The time from the end of an irradiation to the start of electrical measurements shall be a

maximum of 1 h for condition A. For conditions B, C, D and E, the time from the end of an

irradiation to the start of electrical measurements may be equal to 10 % of the incremental

irradiation time up to (but not exceeding) 72 h if this time is greater than 1 h, otherwise it

shall be a maximum of 1 h. As an option for remote electrical testing, for conditions A, B,

C, D and E, parts may be packed in dry ice until the start of electrical testing, but only if

packed within 15 min after the completion of irradiation. While in dry ice, the part leads

shall be shorted, the parts shall be verifiably maintained at a maximum temperature of

−60 °C, and the time from completion of irradiation until the start of electrical testing may

not exceed 72 h. The electrical testing shall be conducted after the parts have been

restored to room temperature but within 30 min after the parts are removed from the dry

ice. Electrical testing shall be as specified in 5.8.1. The times at room temperature and

the times and temperature for the dry ice procedure may be different if demonstrated by a

characterization test as described in 5.11 c) below.

b) The time to perform the electrical measurements and to return the device for a

subsequent irradiation, if any, shall be within 2 h of the end of the prior irradiation for

condition A. For conditions B, C, D and E, the time to perform the electrical measurements

and to return the device for a subsequent irradiation, if any, may be equal to 20 % of the

incremental irradiation time up to (but not exceeding) 120 h if this time is greater than 2 h,

otherwise it shall be a maximum of 2 h. As an option for continued additional irradiation

when parts are electrically tested at a remote location, for conditions A, B, C, D and E

parts may be packed in dry ice until the start of irradiation, but only if packed within

15 min after the completion of electrical testing. While in the dry ice, the part leads shall

be shorted, the parts shall be verifiably maintained at a maximum temperature of −60 °C,

and the time from completion of electrical testing until the start of irradiation may not

exceed 72 h. The radiation exposure shall begin after the parts have been restored to

room temperature but within 30 min after the parts are removed from the dry ice. The

times at room temperature and the times and temperature for the dry ice procedure may

be different if demonstrated by a characterization test as described in 5.11 c) below.

c) If the dry ice test method is used, the characterization test shall be performed on

annealing at the particular technology node of study to demonstrate that the annealing will

be less than 10 % for all critical parameters compared to room temperature data taken

within 1 h after irradiation. Other times and temperatures than those listed in 5.11 a) and

5.11 b) may be considered as part of the characterization test. However, the time for

electrical measurements following irradiation shall not exceed 72 h and the time between

– 14 – IEC 60749-18:2019 RLV © IEC 2019

successive irradiations shall not exceed 120 h. For example, if the manufacturer’s cold

temperature specification limit is higher than −60 °C this higher temperature may be

allowed. For another example, if the parts show very little annealing at room temperature

following condition A irradiation, the 1-h and 2-h limits could be increased. For any

exceptions to the times and temperatures in 5.11 a) and 5.11 b) it shall be demonstrated

that the annealing under these different conditions is within 10 % for all critical parameters

compared to room temperature data taken within 1 h after irradiation, or the appropriate

time limit for the irradiation test condition, if greater than 1 h. The characterization test

results shall be included with the test report as specified in 5.15.

To minimize time-dependent effects, these intervals shall be as short as possible. The

sequence of parameter measurements shall be maintained constant throughout the

tests series.

5.12 Extended room temperature annealing test

5.12.1 Choice of annealing test

The tests of 5.2 to 5.11 are known to be overly conservative for some devices in a very low

dose rate environment (e.g. dose rates characteristic of space missions). The extended room

temperature annealing test provides an estimate of the performance of a device in a very low

dose rate environment even though the testing is performed at a relatively high dose rate

(e.g. 0,5 Gy

...

IEC 60749-18 ®

Edition 2.0 2019-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Semiconductor devices – Mechanical and climatic test methods –

Part 18: Ionizing radiation (total dose)

Dispositifs à semiconducteurs – Méthodes d’essais mécaniques et climatiques –

Partie 18: Rayonnements ionisants (dose totale)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 60749-18 ®

Edition 2.0 2019-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Semiconductor devices – Mechanical and climatic test methods –

Part 18: Ionizing radiation (total dose)

Dispositifs à semiconducteurs – Méthodes d’essais mécaniques et climatiques –

Partie 18: Rayonnements ionisants (dose totale)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.080.01 ISBN 978-2-8322-6755-4

– 2 – IEC 60749-18:2019 © IEC 2019

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Test apparatus . 8

4.1 Choice of apparatus . 8

4.2 Radiation source . 8

4.3 Dosimetry system . 8

4.4 Electrical test instruments . 8

4.5 Test circuit board(s) . 8

4.6 Cabling . 9

4.7 Interconnect or switching system . 9

4.8 Environmental chamber . 9

4.9 Irradiation temperature chamber . 9

5 Procedure . 9

5.1 Test plan . 9

5.2 Sample selection and handling . 9

5.3 Burn-in . 10

5.4 Dosimetry measurements . 10

5.5 Lead/aluminium (Pb/Al) container . 10

5.6 Radiation level(s) . 10

5.7 Radiation dose rate . 10

5.7.1 Radiation dose rate determination . 10

5.7.2 Condition A . 11

5.7.3 Condition B . 11

5.7.4 Condition C . 11

5.7.5 Condition D . 11

5.7.6 Condition E . 11

5.8 Temperature requirements . 11

5.8.1 Room temperature radiation . 11

5.8.2 Elevated temperature irradiation . 11

5.8.3 Cryogenic temperature irradiation . 12

5.9 Electrical performance measurements . 12

5.10 Test conditions . 12

5.10.1 Choice of test conditions. 12

5.10.2 In-flux testing . 12

5.10.3 Remote testing . 12

5.10.4 Bias and loading conditions . 13

5.11 Post-irradiation procedure . 13

5.12 Extended room temperature annealing test . 14

5.12.1 Choice of annealing test . 14

5.12.2 Need to perform an extended room temperature annealing test . 14

5.12.3 Extended room temperature annealing test procedure . 14

5.13 MOS accelerated annealing test . 15

5.13.1 Choice of MOS accelerated annealing test . 15

5.13.2 Need to perform accelerated annealing test . 15

5.13.3 Accelerated annealing test procedure . 16

5.14 Test procedure for bipolar and BiCMOS linear or mixed signal devices with

intended application dose rates less than 0,5 Gy(Si)/s . 16

5.14.1 Need to perform ELDRS testing . 16

5.14.2 Determination of whether a part exhibits ELDRS. 17

5.14.3 Characterization of ELDRS parts to determine the irradiation conditions

for production or lot acceptance testing . 17

5.14.4 Low dose rate or elevated temperature irradiation test for bipolar or

BiCMOS linear or mixed-signal devices . 18

5.15 Test report . 18

6 Summary . 18

Bibliography . 21

Figure 1 – Flow diagram for ionizing radiation test procedure for MOS and digital

bipolar devices. 19

Figure 2 – Flow diagram for ionizing radiation test procedure for bipolar (or BiCMOS)

linear or mixed-signal devices . 20

– 4 – IEC 60749-18:2019 © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SEMICONDUCTOR DEVICES –

MECHANICAL AND CLIMATIC TEST METHODS –

Part 18: Ionizing radiation (total dose)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60749-18 has been prepared by IEC technical committee 47:

Semiconductor devices.

This second edition cancels and replaces the first edition published in 2002. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) updates to subclauses to better align the test method with MIL-STD 883J, method 1019,

including the use of enhanced low dose rate sensitivity (ELDRS) testing;

b) addition of a Bibliography, which includes ASTM standards relevant to this test method.

The text of this International Standard is based on the following documents:

FDIS Report on voting

47/2539/FDIS 47/2554/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60749 series, published under the general title Semiconductor

devices – Mechanical and climatic test methods, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 60749-18:2019 © IEC 2019

SEMICONDUCTOR DEVICES –

MECHANICAL AND CLIMATIC TEST METHODS –

Part 18: Ionizing radiation (total dose)

1 Scope

This part of IEC 60749 provides a test procedure for defining requirements for testing

packaged semiconductor integrated circuits and discrete semiconductor devices for ionizing

radiation (total dose) effects from a cobalt-60 ( Co) gamma ray source. Other suitable

radiation sources can be used.

There are four tests presented in this procedure:

a) a standard room temperature irradiation test;

b) an irradiation at elevated temperature/cryogenic temperature test;

c) an accelerated annealing test;

d) an enhanced low dose rate sensitivity (ELDRS) test.

The accelerated annealing test estimates how dose rate ionizing radiation effects on devices

is important for low dose rate or certain other applications in which devices can exhibit

significant time-dependent effects. The ELDRS test determines if devices with bipolar linear

components exhibit sensitivity to enhanced radiation-induced damage at low dose rates.

This document addresses only steady-state irradiations, and is not applicable to pulse type

irradiations.

It is intended for military- and aerospace-related applications.

This document can produce severe degradation of the electrical properties of irradiated

devices and thus is considered a destructive test.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

ionizing radiation effects, pl

changes in the electrical parameters of a device or integrated circuit resulting from radiation-

induced charge

Note 1 to entry: These are also referred to as total dose effects.

3.2

in-flux test

electrical measurements made on devices during irradiation exposure

3.3

internal dose pattern

logic condition of all elements within a logic circuit during radiation exposure

3.4

non in-flux test

electrical measurements made on devices at any time other than during irradiation

3.5

remote test

electrical measurements made on devices that are physically removed from the radiation

location

3.6

time-dependent effect

TDE

significant degradation in electrical parameters caused by the growth or annealing, or both, of

radiation-induced trapped charge after irradiation

Note 1 to entry: Similar effects also take place during irradiation.

Note 2 to entry: This note applies to the French language only.

3.7

accelerated annealing test

procedure utilizing elevated temperature to accelerate time-dependent effects

3.8

enhanced low dose rate sensitivity

ELDRS

part that shows enhanced radiation-induced damage at dose rates below 0,5 Gy(Si)/s

Note 1 to entry: This note applies to the French language only.

3.9

overtest

factor that is applied to the specification dose to determine the test dose level that the

samples have to pass to be acceptable at the specification level

Note 1 to entry: An overtest factor of 1,5 means that the parts should be tested at 1,5 times the specification dose.

3.10

parameter delta design margin

PDDM

design margin that is applied to the radiation-induced change in an electrical parameter

Note 1 to entry: For a PDDM of 2 the change in a parameter at a specified dose from the pre-irradiation value is

multiplied by two and added to the pre-irradiation value to see if the sample exceeds the post-irradiation parameter

limit. For example, if the pre-irradiation value of base current I is 30 nA and the post-irradiation value at 200 Gy(Si)

b

is 70 nA (change in I is 40 nA), then for a PDDM of 2 the post-irradiation value would be 110 nA

b

(30 nA + 2 x 40 nA). If the allowable post-irradiation limit is 100 nA, the part would fail.

– 8 – IEC 60749-18:2019 © IEC 2019

4 Test apparatus

4.1 Choice of apparatus

The apparatus shall consist of the radiation source, electrical test instrumentation, test circuit

board(s), cabling, interconnect board or switching system, an appropriate dosimetry

measurement system, and an environmental chamber (if required for time-dependent effects

measurements). Adequate precautions shall be observed to obtain an electrical measurement

system with sufficient insulation, ample shielding, satisfactory grounding, and suitable low

noise characteristics.

4.2 Radiation source

The radiation source used in the test shall be the uniform field of a Co gamma ray source.

Uniformity of the radiation field in the volume where devices are irradiated shall be within ±10 %

as measured by the dosimetry system, unless otherwise specified. The intensity of the gamma

ray field of the Co source shall be known with an uncertainty of no more than ±5 %. Field

uniformity and intensity can be affected by changes in the location of the device with respect

to the radiation source and the presence of radiation absorption and scattering materials.

4.3 Dosimetry system

An appropriate dosimetry system shall be provided that is capable of carrying out the

measurements called for in 5.3 (see Bibliography).

4.4 Electrical test instruments

All instrumentation used for electrical measurements shall have the stability, accuracy, and

resolution required for accurate measurement of the electrical parameters. Any

instrumentation required to operate in a radiation environment shall be appropriately shielded.

4.5 Test circuit board(s)

Devices to be irradiated shall either be mounted on or connected to circuit boards together

with any associated circuitry necessary for device biasing during irradiation or for in situ

measurements. Unless otherwise specified, all device input terminals and any others

which can affect the radiation response shall be electrically connected during irradiation,

i.e. not left floating.

The geometry and materials of the completed board shall allow uniform irradiation of the

devices under test. Good design and construction practices shall be used to prevent

oscillations, minimize leakage currents, prevent electrical damage and obtain accurate

measurements. Only sockets that are radiation resistant and do not exhibit significant

leakages (relative to the devices under test) shall be used to mount devices and associated

circuitry to the test board(s).

All apparatus used repeatedly in radiation fields shall be checked periodically for physical or

electrical degradation. Components which are placed on the test circuit board, other than

devices under test, shall be insensitive to the accumulated radiation or they shall be shielded

from the radiation. Test fixtures shall be made such that materials will not perturb the

uniformity of the radiation field intensity on the devices under test.

Leakage current shall be measured outside the field of radiation. With no devices installed in

the sockets, the test circuit board shall be connected to the test system such that all expected

sources of noise and interference are operative. With the maximum specified bias for the test

device applied, the leakage current between any two terminals shall not exceed 10 % of the

lowest current limit value in the pre-irradiation device specification.

Test circuit boards used to bias devices during accelerated annealing shall be capable of

withstanding the temperature requirements of the accelerated annealing test and shall be

checked before and after testing for physical and electrical degradation.

4.6 Cabling

Cables connecting the test circuit boards in the radiation field to the test instrumentation shall

be as short as possible. If long cables are necessary, line drivers can be required. The cables

shall have low capacitance and low leakage to ground, and low leakage between wires.

4.7 Interconnect or switching system

This system shall be located outside the radiation environment location, and provides the

interface between the test instrumentation and the devices under test. It is part of the entire

test system and subject to the limitation specified in 4.5 for leakage between terminals.

4.8 Environmental chamber

The environmental chamber for time-dependent effects testing, if required, shall be capable of

maintaining the selected accelerated annealing temperature within ±5 °C.

4.9 Irradiation temperature chamber

The irradiation temperature chamber, if required for elevated temperature irradiation should

be capable of maintaining a circuit under test at 100 °C ± 5 °C while it is being irradiated. The

chamber should be capable of raising the temperature of the circuit under test from room

temperature to the irradiation temperature within a reasonable time prior to irradiation and

cooling the circuit under test from the irradiation temperature to room temperature in less than

20 min following irradiation. The irradiation bias shall be maintained during the heating and

cooling. The method for raising, maintaining and lowering the temperature of the circuit under

test can be by conduction through a heat sink using heating and cooling fluids, by convection

using forced hot and cool air, or other means that will achieve the proper results. For

cryogenic temperature irradiations, the chamber should be capable of maintaining the test

device/unit at the required cryogenic temperature within ±5 °C (e.g., liquid helium or liquid

nitrogen) while it is being irradiated. The chamber should be capable of maintaining the

cryogenic temperature of the test device/unit during post-irradiation electrical testing.

5 Procedure

5.1 Test plan

The test devices shall be irradiated and subjected to accelerated annealing testing (if required

for time-dependent effects testing) as specified by a test plan. This plan shall specify the

device description, irradiation conditions, device bias conditions, dosimetry system, operating

conditions, measurement parameters and conditions and accelerated annealing test

conditions (if required).

5.2 Sample selection and handling

Only devices that have passed the electrical specifications as defined in the test plan shall be

submitted to radiation testing. Unless otherwise specified, the test samples shall be randomly

selected from the parent population and identically packaged. Each part shall be individually

identifiable to enable pre- and post-irradiation comparison. For device types that are

electrostatic discharge (ESD)-sensitive, proper handling techniques shall be used to prevent

damage to the devices.

– 10 – IEC 60749-18:2019 © IEC 2019

5.3 Burn-in

For some devices, there are differences in the total dose radiation response before and after

burn-in. Unless it has been shown by prior characterization or by design that burn-in has a

negligible effect (parameters remain within post-irradiation specified electrical limits) on the

total dose radiation response, then one of the following functions shall take place:

a) the manufacturer shall subject the radiation samples to the specified burn-in conditions

prior to conducting total dose radiation testing; or

b) the manufacturer shall develop a correction factor, (which is acceptable to the parties to

the test) taking into account the changes in total dose response resulting from subjecting

the product to burn-in. The correction factor shall then be used to accept the product for

total dose response without subjecting the test samples to burn-in.

5.4 Dosimetry measurements

The radiation field intensity at the location of the device under test shall be determined prior

to testing by dosimetry or by source decay correction calculations, as appropriate, to ensure

conformance to the test level and uniformity requirements.

The dose applied to the device under test shall be determined in one of two ways:

a) by measurement during the irradiation with an appropriate dosimeter; or

Co source intensity in

b) by correcting a previous dosimetry value for the decay of the

the intervening time. Appropriate correction shall be made to convert from the measured

or calculated dose in the dosimeter material to the dose in the device under test.

5.5 Lead/aluminium (Pb/Al) container

Test specimens shall be enclosed in a Pb/Al container to minimize dose enhancement effects

caused by low-energy scattered radiation. A minimum of 1,5 mm of lead (Pb), surrounding an

inner shield of at least 0,7 mm aluminium (Al) is required. This Pb/Al container produces an

approximate charged particle equilibrium for Si and for thermoluminescence dosimetries

(TLDs) such as CaF2. The radiation field intensity shall be measured inside the Pb/Al

container (1) initially, (2) when the source is changed, or (3) when the orientation or

configuration of the source, container or test-fixture is changed. This measurement shall be

performed by placing a dosimeter (e.g. a TLD) in the device-irradiation container at the

approximate test-device position. If it can be demonstrated that low energy scattered radiation

is small enough that it will not cause dosimetry errors due to dose enhancement, the Pb/Al

container may be omitted.

5.6 Radiation level(s)

The test devices shall be irradiated to the dose level(s) specified in the test plan within ±10 %.

If multiple irradiations are required for a set of test devices, then the post-irradiation electrical

parameter measurements shall be performed after each irradiation.

5.7 Radiation dose rate

5.7.1 Radiation dose rate determination

The radiation dose rate for bipolar and BiCMOS linear or mixed-signal parts used in

applications where the maximum dose rate is below 0,5 Gy(Si)/s shall be determined as

described in 5.14. Parts used in low dose rate applications, unless they have been

demonstrated to not exhibit an ELDRS response shall use condition C, condition D, or

condition E.

A flow diagram for ionizing test procedures for MOS and digital bipolar devices is shown in

Figure 1. A flow diagram for ionizing radiation test procedure for bipolar

(or BiCMOS) linear or mixed-signal devices is shown in Figure 2.

NOTE Devices that contain both MOS and bipolar devices can require qualification to multiple subconditions to

ensure that both ELDRS and traditional MOS effects are evaluated.

5.7.2 Condition A