IEC 62878-1-1:2015

(Main)Device embedded substrate - Part 1-1: Generic specification - Test methods

Device embedded substrate - Part 1-1: Generic specification - Test methods

IEC 62878-1-1:2015 specifies the test methods of passive and active device embedded substrates. The basic test methods of printed wiring substrate materials and substrates themselves are specified in IEC 61189-3. This part of IEC 62878 is applicable to device embedded substrates fabricated by use of organic base material, which include for example active or passive devices, discrete components formed in the fabrication process of electronic wiring board, and sheet formed components.

Substrat avec appareil(s) intégré(s) - Partie 1-1: Spécification générique - Méthodes d'essai

L'IEC 62878-1-1:2015 spécifie les méthodes d'essai pour les substrats avec appareils actifs et passifs intégrés. Les méthodes d'essai fondamentales pour les matériaux de substrats de câblage imprimé et pour les substrats eux-mêmes sont spécifiées dans l'IEC 61189-3. La présente partie de l'IEC 62878 est applicable aux substrats avec appareil(s) intégré(s) fabriqués à partir de matériaux de base organiques, y compris par exemple les appareils actifs ou passifs, les composants discrets formés lors du processus de fabrication d'une carte de câblage électronique, ainsi que les composants de feuilles minces.

General Information

- Status

- Published

- Publication Date

- 19-May-2015

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 6 - TC 91/WG 6

- Current Stage

- PPUB - Publication issued

- Start Date

- 20-May-2015

- Completion Date

- 15-Jun-2015

Overview

IEC 62878-1-1:2015, titled Device Embedded Substrate – Part 1-1: Generic Specification – Test Methods, is an international standard developed by the International Electrotechnical Commission (IEC). It specifies test methods specifically for device embedded substrates made using organic base materials. These substrates can include embedded passive and active devices, discrete components formed during the fabrication process of electronic wiring boards, and sheet-formed components.

This standard complements the basic test methods for printed wiring substrate materials found in IEC 61189-3 and focuses on ensuring the performance, reliability, and quality of device embedded substrates through detailed testing requirements.

Key Topics

The standard covers a wide range of test methods categorized into several main areas:

Visual Inspection and Micro-sectioning

- Methods for examining the substrate structure, including conductor integrity, land dimensions, and detection of residues.

Electrical Tests

- Includes conductor resistance, through-hole and build-up via integrity, withstanding current and voltage tests, insulation resistance, and conduction/insulation verification.

Mechanical Tests

- Tests for pulling strength of conductors, through-holes (plated and unplated), land pattern pads, and adhesion tests for plated foil, solder resist, and symbol marking.

Environmental Tests

- Assess substrate resistance to thermal shock, high temperature immersion, humidity, and migration to simulate real-world operating conditions.

Shipping Inspection

- Guidelines for electrical and visual inspection after transport to ensure substrate integrity is maintained.

The document uses detailed measurement techniques, diagrams, and tables to define test conditions, expected characteristics, and evaluation criteria.

Applications

IEC 62878-1-1:2015 is crucial for industries involved in:

Electronic Manufacturing

Ensuring quality control and reliability of device embedded substrates used in advanced electronics like smartphones, IoT devices, and automotive electronics.Printed Circuit Board (PCB) Fabrication

Guiding testing of embedded components to meet stringent requirements for multilayer substrates and build-up boards with embedded devices.Quality Assurance and R&D

Providing standardized testing protocols to validate new materials, fabrication methods, and device embedding techniques.Supply Chain Management

Supporting inspection and test processes for reliable shipping and handling of substrates, minimizing defects and failures in downstream assembly.

By defining industry-recognized test methods, this standard facilitates interoperability, compliance with safety and performance benchmarks, and accelerates innovation in embedded electronics.

Related Standards

IEC 62878-1-1:2015 is closely linked to the following standards:

- IEC 61189-3 – Basic test methods of printed wiring substrate materials and substrates.

- IEC 62878 Series – Covers various parts detailing device embedded substrates and their specifications.

- Other IEC Standards on PCB Materials and Processes – Including environmental testing, mechanical testing, and electrical reliability related to electronic substrates.

Compliance with IEC 62878-1-1 supports adherence to comprehensive international electrotechnical requirements enhancing global trade and quality assurance in electronic components manufacturing.

Keywords: IEC 62878-1-1, device embedded substrate, test methods, passive devices, active devices, printed wiring board, substrate materials, electrical testing, mechanical testing, environmental testing, quality assurance, PCB fabrication, electronic manufacturing standards.

Frequently Asked Questions

IEC 62878-1-1:2015 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Device embedded substrate - Part 1-1: Generic specification - Test methods". This standard covers: IEC 62878-1-1:2015 specifies the test methods of passive and active device embedded substrates. The basic test methods of printed wiring substrate materials and substrates themselves are specified in IEC 61189-3. This part of IEC 62878 is applicable to device embedded substrates fabricated by use of organic base material, which include for example active or passive devices, discrete components formed in the fabrication process of electronic wiring board, and sheet formed components.

IEC 62878-1-1:2015 specifies the test methods of passive and active device embedded substrates. The basic test methods of printed wiring substrate materials and substrates themselves are specified in IEC 61189-3. This part of IEC 62878 is applicable to device embedded substrates fabricated by use of organic base material, which include for example active or passive devices, discrete components formed in the fabrication process of electronic wiring board, and sheet formed components.

IEC 62878-1-1:2015 is classified under the following ICS (International Classification for Standards) categories: 31.180 - Printed circuits and boards; 31.190 - Electronic component assemblies. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62878-1-1:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62878-1-1 ®

Edition 1.0 2015-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Device embedded substrate –

Part 1-1: Generic specification – Test methods

Substrat avec appareil(s) intégré(s) –

Partie 1-1: Spécification générique – Méthodes d'essai

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 15

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 60 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

15 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 60 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 62878-1-1 ®

Edition 1.0 2015-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Device embedded substrate –

Part 1-1: Generic specification – Test methods

Substrat avec appareil(s) intégré(s) –

Partie 1-1: Spécification générique – Méthodes d'essai

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.180; 31.190 ISBN 978-2-8322-2674-2

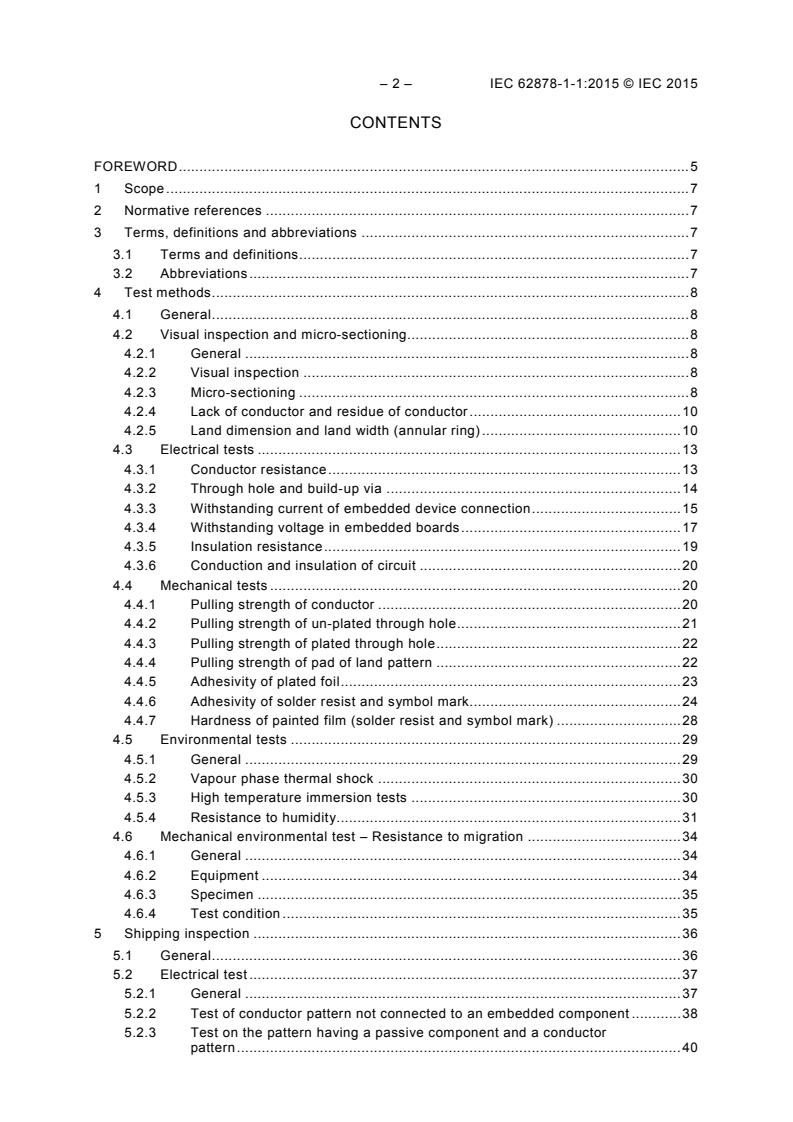

– 2 – IEC 62878-1-1:2015 © IEC 2015

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Normative references . 7

3 Terms, definitions and abbreviations . 7

3.1 Terms and definitions . 7

3.2 Abbreviations . 7

4 Test methods . 8

4.1 General . 8

4.2 Visual inspection and micro-sectioning. 8

4.2.1 General . 8

4.2.2 Visual inspection . 8

4.2.3 Micro-sectioning . 8

4.2.4 Lack of conductor and residue of conductor . 10

4.2.5 Land dimension and land width (annular ring) . 10

4.3 Electrical tests . 13

4.3.1 Conductor resistance . 13

4.3.2 Through hole and build-up via . 14

4.3.3 Withstanding current of embedded device connection . 15

4.3.4 Withstanding voltage in embedded boards . 17

4.3.5 Insulation resistance . 19

4.3.6 Conduction and insulation of circuit . 20

4.4 Mechanical tests . 20

4.4.1 Pulling strength of conductor . 20

4.4.2 Pulling strength of un-plated through hole . 21

4.4.3 Pulling strength of plated through hole . 22

4.4.4 Pulling strength of pad of land pattern . 22

4.4.5 Adhesivity of plated foil . 23

4.4.6 Adhesivity of solder resist and symbol mark. 24

4.4.7 Hardness of painted film (solder resist and symbol mark) . 28

4.5 Environmental tests . 29

4.5.1 General . 29

4.5.2 Vapour phase thermal shock . 30

4.5.3 High temperature immersion tests . 30

4.5.4 Resistance to humidity . 31

4.6 Mechanical environmental test – Resistance to migration . 34

4.6.1 General . 34

4.6.2 Equipment . 34

4.6.3 Specimen . 35

4.6.4 Test condition . 35

5 Shipping inspection . 36

5.1 General . 36

5.2 Electrical test . 37

5.2.1 General . 37

5.2.2 Test of conductor pattern not connected to an embedded component . 38

5.2.3 Test on the pattern having a passive component and a conductor

pattern . 40

5.2.4 Test of a circuit having both active component(s) and a conductor

pattern . 43

5.2.5 Test of a circuit having connections of both individual passive

component(s) and conductor pattern . 46

5.2.6 Test of a circuit having an embedded component which cannot be

checked from the surface and a conductor pattern . 47

5.3 Internal transparent test . 47

5.4 Visual test . 47

Annex A (informative) Related test methods . 49

Bibliography . 52

Figure 1 – Measuring items of the micro-sectioned through hole structure . 9

Figure 2 – Measuring items of the micro-sectioned device embedded board with build-

up structure . 9

Figure 3 – Measurement of land dimension . 11

Figure 4 – Build-up land measurement . 12

Figure 5 – Conductor resistance measurement . 14

Figure 6 – Relationship between current, conductor width and thickness and

temperature rise . 17

Figure 7 – Adhesivity of plated film . 24

Figure 8 – Single cutting tool . 25

Figure 9 – Cutter knife . 25

Figure 10 – Multiple blade cutter . 26

Figure 11 – Equal-distance spacer with guide . 26

Figure 12 – Cutting using a single cutting tool or a cutting knife . 27

Figure 13 – Cross-cut test . 28

Figure 14 – Coated film hardness test . 29

Figure 15 – Temperature and humidity cycles . 33

Figure 16 – Device embedded board for shipping inspection . 36

Figure 17 – Typical circuit construction of device embedded board . 37

Figure 18 – Examples of evaluation levels of electrical test . 39

Figure 19 – Circuit construction not connected to embedded component . 39

Figure 20 – Circuit construction which is capable of independent check . 40

Figure 21 – Circuit construction for parallel connection of passive components . 42

Figure 22 – Circuit construction for series connection of passive components . 43

Figure 23 – Circuit construction of embedded diode . 44

Figure 24 – Circuit construction of transistor circuit . 44

Figure 25 – Circuit construction of a conductor pattern with embedded IC and LSI . 45

Figure 26 – Circuit construction composed of a passive component and an active

component . 46

Figure 27 – Circuit construction of embedded components having no connection

terminal on the surface . 47

Table 1 – Test items, characteristics and observations of micro-sectioned specimens . 9

Table 2 – Test method for coplanarity around the land pattern . 12

Table 3 – Characteristics and test methods for conductor resistance . 15

– 4 – IEC 62878-1-1:2015 © IEC 2015

Table 4 – Withstanding current and test methods . 16

Table 5 – Withstanding voltage and test methods . 18

Table 6 – Criteria and test methods for insulation resistance . 20

Table 7 – Characteristics and test method of pulling strength of conductor . 21

Table 8 – Dimensions of land, hole and conductor . 22

Table 9 – Characteristics and test methods of pulling strength of plated through hole . 22

Table 10 – Specification and test method of pad pulling strength of land pattern . 23

Table 11 – High and low temperature characteristics and tests . 30

Table 12 – Thermal shock characteristics and test methods . 30

Table 13 – Thermal shock (high temperature immersion test) . 31

Table 14 – Measuring environment . 31

Table 15 – Thermal shock (high temperature immersion tests) . 31

Table 16 – Resistance to humidity characteristics and test methods . 34

Table 17 – Resistance to migration characteristics and test methods . 35

Table 18 – Applicable items of shipping inspection . 37

Table A.1 – Related test methods . 49

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

DEVICE EMBEDDED SUBSTRATE –

Part 1-1: Generic specification – Test methods

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62878-1-1 has been prepared by IEC technical committee 91:

Electronics assembly technology.

The text of this standard is based on the following documents:

FDIS Report on voting

91/1248/FDIS 91/1260/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

A list of all parts in the IEC 62878, published under the general title Device embedded

substrate, can be found on the IEC website.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 6 – IEC 62878-1-1:2015 © IEC 2015

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

DEVICE EMBEDDED SUBSTRATE –

Part 1-1: Generic specification – Test methods

1 Scope

This part of IEC 62878 specifies the test methods of passive and active device embedded

substrates. The basic test methods of printed wiring substrate materials and substrates

themselves are specified in IEC 61189-3.

This part of IEC 62878 is applicable to device embedded substrates fabricated by use of

organic base material, which include for example active or passive devices, discrete

components formed in the fabrication process of electronic wiring board, and sheet formed

components.

The IEC 62878 series neither applies to the re-distribution layer (RDL) nor to the electronic

modules defined as an M-type business model in IEC 62421.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068-2-1, Environmental testing – Part 2-1: Tests – Test A: Cold

IEC 60068-2-2, Environmental testing – Part 2-2: Tests – Test B: Dry heat

IEC 60194, Printed board design, manufacture and assembly – Terms and definitions

IEC 61189-3, Test methods for electrical materials, printed boards and other interconnection

structures and assemblies – Part 3: Test methods for interconnection structures (printed

boards)

IEC TS 62878-2-4:2015, Device embedded substrate – Part 2-4 – Guidelines – Test element

groups (TEG)

3 Terms, definitions and abbreviations

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60194 apply.

3.2 Abbreviations

AABUS as agreed between user and supplier

AOI automated optical inspection

LSI large scale integration

– 8 – IEC 62878-1-1:2015 © IEC 2015

4 Test methods

4.1 General

This clause is given for guidance only. The test shall be carried out at the standard air

conditions (or simply stated as standard environment):

Temperature Relative humidity Atmospheric pressure

15°C to 35°C 25 % to 75 % 86 kPa to 106 kPa

4.2 Visual inspection and micro-sectioning

4.2.1 General

Visual inspection and micro-sectioning of multi-layer printed wiring boards are specified in

4.2.2 and 4.2.3.

4.2.2 Visual inspection

Visual inspection consists of checking the appearance, finish, and pattern of specimens using

the naked eye or a magnifying glass in reference to its individual specification. The test result

shall be as agreed between user and supplier (hereafter referred as AABUS).

4.2.3 Micro-sectioning

Micro-sectioning is to check the state, appearance, and dimensions according to individual

specifications of the plated through hole, the via in the build-up layer, the conductor, the

interlayer distance, the conductor distance, and the connections to the embedded device. The

specimen is mounted in epoxy or polyester resin and the specimen is cross-sectioned and

polished for observation. The evaluation of the results shall be AABUS. The equipment,

material, specimen and test are specified in a) to d).

a) Equipment

An industrial microscope capable of measuring plated film thicknesses with an accuracy of

0,001 mm.

b) Material

Materials used in this test are releasing agent, moulding resin, polishing cloth or paper

(#180, #400, #1 000, etc.) with the option to use polishing materials (alumina or chromium

oxide).

c) Specimen

A specimen is cut from the product to an appropriate size sufficient for observation and

mounted in moulding resin. The cut surface is then polished with polishing cloth/paper

starting from coarse to fine using a rotating felt surface and the above mentioned polishing

material. The polishing face shall be within an angle of 85° to 95° to the layer to be

observed. The diameter of the plated film of the through hole and of the vias in the build-

up layer observed by micro-sectioning shall be no less than 90 % of the previously

observed hole diameter. Etch the specimen if the boundary of the plating needs to be

clarified after polishing.

d) Test

The test consists of observing the items specified in the individual specifications by means

of a microscope of specified magnification. Figure 1 illustrates the test items for the

through hole to check the micro-sectioned faces, and Figure 2 for the build-up structure

and embedded devices. Table 1 gives the characteristics and observation items of the test.

E

B

A

F

C

G

C

D

H

I

I J

IEC

Key

A Conductor width F Conductor plated film thickness

B Conductor gap G Thickness of copper foil

C Insulation layer thickness H Conductor thickness

D Hole diameter I Boundary of plated film

E Plated film thickness of through hole J Internal circuit

Figure 1 – Measuring items of the micro-sectioned through hole structure

A

B

IEC

Key

A Distance between conductor and embedded device

B Device embedding layer

Figure 2 – Measuring items of the micro-sectioned device

embedded board with build-up structure

Table 1 – Test items, characteristics and observations

of micro-sectioned specimens

No Test item Characteristics and observation

– Upper conductor width

Conductor width

1 – Lower conductor width

(inner layer , outer layer)

– Etch factor

2 Conductor gap (inner layer, outer layer) – Minimum conductor gap

– Minimum insulation layer/minimum conductor gap

– Delamination

3 Insulation layer thickness/conductor gap

– Measling

– Crazing

– Hole diameter

4 Hole diameter and land width

– Land width

– 10 – IEC 62878-1-1:2015 © IEC 2015

No Test item Characteristics and observation

– Plated film thickness of the through hole

– Plated film thickness of the via in the build-up layer

(conformal via)

5 Plated film thickness of the through hole

– Corner crack

– Barrel crack

– Foil crack

6 Film thickness of the plated conductor – Film thickness of the plated conductor

7 Copper foil thickness – Copper foil thickness

– Total conductor thickness(copper foil and film thickness

8 Conductor thickness

of the plated conductor)

Distance between conductor and

9 – Distance between conductor and embedded device

embedded device

– Thickness of the device embedding layer

– Delamination

10 Thickness of the device embedding layer

– Measling

– Crazing

4.2.4 Lack of conductor and residue of conductor

In order to measure lack and residue of conductor, a) and b) apply:

a) Equipment

An industrial microscope with an accuracy of at least 0,001 mm.

b) Measurement

Measure the lack of conductor and residue of the conductor in the vertical and horizontal

directions at the insulating area.

4.2.5 Land dimension and land width (annular ring)

4.2.5.1 Component insertion land and through hole land

In order to measure component insertion land and through hole land, a) and b) apply:

a) Equipment

An industrial microscope with an accuracy of at least 0,001 mm.

b) Measurement

1) Measure the land dimension d to d as illustrated in Figure 3.

1 4

2) Measure the left outer land width w to w as illustrated in Figure 3 by micro-sectioning

1 4

of the distance between the hall edge and not including the plated film and land edge

to better than 0,001 mm.

d

d

w

w

B

A

w

A

C

d

d

w

w

B

A

w

A 6

IEC

a) Non-plated hole b) Plated hole

Key

A Non-plated hole

B Plated hole

C Via in the build-up layer with the form of conformal via

d to d Maximum dimension of land

1 4

w to w Width of lands in outer layer

1 4

w , w Width of lands in inter layer

5 6

Figure 3 – Measurement of land dimension

4.2.5.2 Via (including interstitial via hole and via in the build-up layer)

In order to measure the via, a) and b) apply:

a) Equipment

Industrial microscope with an accuracy of at least 0,001 mm.

b) Measurement

1) Measure the land dimension d to d as illustrated in Figure 4.

1 4

2) It is not necessary to measure the land dimension w to w as shown in Figure 4

1 4

unless there is a problem with the electrical connection. The measurement can be

carried out upon agreement between user and supplier and by means of micro-

sectioning to better than 0,001 mm of the maximum dimension.

– 12 – IEC 62878-1-1:2015 © IEC 2015

d d

1 3

w

w

1 3

d

d

A

w

w

2 4

IEC

a) Conformal via b) Filled via

Key

A Insulation layer

d to d Maximum land dimension

1 4

w to w

Land edge width

1 4

Figure 4 – Build-up land measurement

4.2.5.3 Coplanarity

4.2.5.3.1 Bend

In order to measure the bend, a) and b) apply.

a) Equipment

A gap gauge or a height gauge with an accuracy of 0,1 mm or better shall be used.

b) Measurement

Place a device embedded board on a precision plate with the protruded side up and then

measure the maximum gap between the base and specimen to an accuracy of 0,1 mm to

find the bend.

4.2.5.3.2 Twist

In order to measure the twist, a) and b) apply

a) Equipment

A gap gauge or a height gauge with an accuracy of 0,1 mm or better shall be used.

b) Measurement

Place a device embedded board on a precision plate with the protruded side up with three

corners of the specimen touched to the plate and measure the distance between the plate

and the untouched corner of the specimen to an accuracy of 0,1 mm.

4.2.5.3.3 Test method

Table 2 gives the test method for coplanarity around the land pattern.

Table 2 – Test method for coplanarity around the land pattern

Item Criteria Test method

Effect on embedded device AABUS Use TEG in-place of an embedded device

A test for terminal connections of embedded devices is under

consideration.

4.3 Electrical tests

4.3.1 Conductor resistance

In order to check conductor resistance, a) to d) apply:

a) Equipment

Voltage drop method (four-terminal method) or equivalent. The measuring signal (voltage

or current) shall be DC or AC.

b) Specimen

The specimen is the specified section of the test pattern or the complex test pattern of a

device embedded board illustrated in IEC TS 62878-2-4:2015, Figures 1 to 27.

c) Pre-treatment

Pre-treatment shall be either 1) or 2), depending on the individual specifications.

1) Leave a specimen in the standard environment for 24 h ± 4 h.

2) Leave a specimen in a bath of 85 °C ± 2 °C for 4 h and then in the standard

environment for 24 h ± 4 h.

d) Test

The measurement shall be carried out as illustrated in Figure 5 to an accuracy of ± 5 %.

Ensure that effects of probe contacting and heating due to measuring current are avoided.

The specimen includes the connection between an embedded device and terminals, a

conductor including through hole and a via in the build-up layer.

– 14 – IEC 62878-1-1:2015 © IEC 2015

A B

A

B

IEC

B

A

IEC

a) Conductor resistance measurement b) Through hole resistance measurement

B A

A

B

IEC

A

B

IEC

c) Resistance measurement of via in the d) Resistance measurement of via in the inner

build-up layer conductor layer

A

B

D

C

IEC

e) Resistance measurement for connection

of embedded device

Key

A Current terminal C TEG

B Voltage terminal D Connection actually used

Figure 5 – Conductor resistance measurement

4.3.2 Through hole and build-up via

In order to check through hole and build-up via, a) to d) apply:

a) Equipment

The equipment shall be in accordance with 4.3.1 a).

b) Specimen

Specimen is the specified section of the test pattern or of the complex test pattern of a

device embedded board illustrated in Figures 1 to 27 of IEC TS 62878-2-4:2015.

c) Pre-treatment

Pre-treatment shall be in accordance with 4.3.1 c).

d) Test

Measurement shall be made as illustrated in Figure 5 to an accuracy of ± 5 % with an

effort to avoid effects of probe contacting and heating due to measuring current.

Table 3 gives the characteristics and test method for conductor resistance.

Table 3 – Characteristics and test methods for conductor resistance

Item Characteristics Test method

Connection to embedded device/Pad AABUS As indicated in 4.3.2, plated through hole and via in

connection/Via connection the build-up layer. Use TEG for embedded device.

4.3.3 Withstanding current of embedded device connection

In order to measure withstanding current of embedded device connection, a) to d) apply:

a) Equipment

A DC or AC power supply capable of giving the test current specified in Table 4 and an

ammeter. The equipment shall be a DC or AC power supply capable of giving the test

current specified in 4.3.2 a) and an ammeter.

b) Specimen

The specimen shall be the terminals of the TEG and the specified part of the complex test

pattern (Figures 1 to 28 in IEC TS 62878-2-4:2015). A zero ohm jumper resistor is

recommended for the TEG for an embedded device.

c) Pre-treatment

Pre-treatment shall be in accordance with 4.3.1 c).

d) Test

Check any abnormality after supplying a current contact terminal of TEG and pad on the

board with a specified current given its individual specification for 30 s. Test current for a

given hole diameter is given in Table 5.

Table 4 shows the withstanding current characteristics and test methods.

– 16 – IEC 62878-1-1:2015 © IEC 2015

Table 4 – Withstanding current and test methods

Item Characteristics Test method

Conductor Withstanding current As per 4.3.2 withstanding current for through hole and

characteristics shall be AABUS. via in the build-up layers.

The relationship between As per 4.3.3 withstanding current of conductor. Shape

current and conductor width, and dimension of specimen shall be AABUS.

conductor thickness and

temperature rise is shown in

Figure 6.

Through hole and As per 4.3.3 withstanding current of conductor. Shape

via in the build-up and dimension of specimen shall be AABUS.

layer

Embedded device As per 4.3.3 withstanding current of embedding device

connection. Use the TEG for embedded device. Internal

– Pad connection

resistance of the TEG shall be less than 50 mΩ. The test

current shall not exceed the rated current shown below.

– Via connection

Rated current is for steady state loading of 30 s.

The maximum overload current is defined for 2 s.

Type Rated current Maximum overload

70 °C, A current, A

0402 ― ―

0603 0,5 1,0

1005 1,0 2,0

1608 1,0 2,0

2,5

2,5

∆ t = 10 °C

∆ t = 10 °C

1,5

1,5

∆ t = 20 °C

∆ t = 20 °C

1,2

1,2

∆ t = 30 °C

∆ t = 30 °C

1,0

1,0

∆ t = 40 °C

∆ t = 40 °C

0,8

0,8

0,6

0,6

0,5

0,5

∆ t = 50 °C

∆ t = 50 °C

0,4

0,4

∆ t = 75 °C

∆ t = 75 °C

0,3

0,3

∆ t = 100 °C

∆ t = 100 °C

0,2

0,2

0,15

0,15

0,1

0,1

0,2 0,3 0,4 0,6 0,8 1 1,5 2 3 4 5 6 8 10

0,3 0,5 0,7 0,9 1,2 1,5 2 3 4 6 8 10 15

IEC

IEC

a) Conductor thickness is 18 µm b) Conductor thickness is 35 µm

2,5

2,5

∆ t = 10 °C

∆ t = 10 °C

1,5

∆ t = 20 °C

1,5

∆ t = 20 °C

1,2

∆ t = 30 °C

1,2

∆ t = 30 °C

1,0

∆ t = 40 °C 1,0

∆ t = 40 °C

0,8

0,8

0,6

0,6

0,5

0,5

∆ t = 50 °C

0,4

∆ t = 50 °C

0,4

∆ t = 75 °C

0,3 ∆ t = 75 °C

0,3

∆ t = 100 °C

∆ t = 100 °C

0,2

0,2

0,15

0,15

0,1 0,1

0,4 0,8 1,2 2 3 4 6 8 10 15 20

0,6 1 1,5 2 3 4 5 6 8 10 15 20 30

IEC

IEC

c) Conductor thickness is 70 µm d) Conductor thickness is 105 µm

X current (A)

Y conductor width (mm)

Figure 6 – Relationship between current, conductor width

and thickness and temperature rise

4.3.4 Withstanding voltage in embedded boards

4.3.4.1 General

Withstanding voltages of conductor, plated through hole and via in the build-up layers, inner

connection and connection to the embedded device shall be measured according to each

individual specification. This test shall be made only when the test of withstanding voltage is

required.

4.3.4.2 Withstanding voltage of inner layers in embedded boards

In order to measure withstanding voltage of inner layer in embedded boards, a) to d) apply:

a) Equipment

The equipment shall be in accordance with 4.3.2.a).

b) Specimen

– 18 – IEC 62878-1-1:2015 © IEC 2015

The specimen shall be manufactured to fit the connection terminal of the TEG in the

device embedding board or the pad of complex test pattern (see Figures 1 to 27 in

IEC TS 62878-2-4:2015). A specimen suffering from mechanical damage, flashover,

sparkover or breakdown shall not be used in further tests.

c) Pre-treatment

Pre-treatment shall be as described in 4.3.1 c).

d) Test

The test shall be as described in 4.3.1 d).

4.3.4.3 Withstanding voltage of embedded device connection

Items a) to d) apply:

a) Equipment

The equipment shall be in accordance with 4.3.1 a).

b) Specimen

The specimen shall be a specified part of the TEG in a device embedding board or

complex test pattern (Figures 1 to 27 of IEC TS 62878-2-4:2015). It is recommended to

use a zero ohm jumper resistor for the TEG. A specimen suffering from mechanical

damage, flush over, spark over or breakdown shall not be used in further tests.

c) Pre-treatment

Pre-treatment shall be as described in 4.3.1 c).

d) Test

The test shall be as described in 4.3.1 d).

Table 5 shows the test methods for withstanding voltage.

Table 5 – Withstanding voltage and test methods

Item Characteristics Test

Interlayer There should be no abnormality As stated in 4.3.4.2, interlayer surge voltage. The test voltage

such as mechanical damage, is given below.

flush-over or insulation

Interlayer distance x Test voltage

damage.

mm V

0,02 ≦ x < 0,05

0,05 ≦ x < 0,08

0,08 ≦ x < 0,20

1 000

0,20 ≦ x

Connection to There should be no abnormality As stated in 4.3.4.3, withstanding voltage for embedded

embedded such as mechanical damage, device.

device flush-over or insulation

Use the TEG for embedded device.

damage.

The internal resistance of the TEG shall be less than 50 mΩ.

Test below the isolation voltage of the TEG.

Isolation voltage

Type (effective value of

V or V )

dc ac

0402 ―

0603 30

1005 100

1608 100

4.3.5 Insulation resistance

4.3.5.1 General

The insulation resistance shall be measured between the terminals of the conductor the

embedded device based on individual specifications.

4.3.5.2 Insulation resistance of the inner layer

In order to measure insulation resistance of the inner layer, a) to d) apply:

a) Equipment

An insulation resistance tester capable of measuring values greater than 10 Ω.

b) Specimen

The specimen shall be a specified part of a device embedding board, test pattern or

complex test pattern (Figures 1 to 27 of IEC TS 62878-2-4:2015) including connection to

embedded device.

c) Pre-treatment

Pre-treatment shall be in accordance with 4.3.4.2 c).

d) Test

Apply a DC voltage of 10 V ± 1 V, 50 V ± 5 V, 100 V ± 10 V or 500 V ± 50 V depending on

the individual specification for 1 min and then measure the insulation resistance while

applying the voltage.

4.3.5.3 Insulation resistance between inner layers

In order to measure insulation resistance between inner layers, a) to d) apply:

a) Equipment

Equipment shall be in accordance with 4.3.1 a).

b) Specimen

The specimen shall be a specified part of a device embedding board, test pattern or a

complex test pattern (Figures 1 to 27 of IEC TS 62878-2-4:2015) including connection to

embedded device.

c) Pre-treatment

Pre-treatment shall be in accordance with 4.3.1 c).

d) Test

The test shall be in accordance with 4.3.1 d).

4.3.5.4 Insulation resistance between embedded terminals

In order to measure insulation resistance between embedded terminals, a) to d) apply:

a) Equipment

The equipment shall be in accordance with 4.3.4.3 a).

b) Specimen

The specimen shall be a specified part of a device embedding board, test pattern or a

complex test pattern (Figures 1 to 27 in IEC TS 62878-2-4:2015) including connection to

embedded device. It is recommended to use a zero ohm jumper resistor for TEG.

c) Pre-treatment

Pre-treatment shall be in accordance with 4.3.1 c).

d) Test

– 20 – IEC 62878-1-1:2015 © IEC 2015

The test shall be in accordance with 4.3.1 d).

Table 6 shows evaluation items of insulation resistance, characteris

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...