IEC 61892-4:2007

(Main)Mobile and fixed offshore units - Electrical installations - Part 4: Cables

Mobile and fixed offshore units - Electrical installations - Part 4: Cables

This part of IEC 61892 specifies requirements for the choice and installation of electrical cables intended for fixed electrical systems in mobile and fixed offshore units, including pumping or "pigging" stations, compressor stations and exposed location single buoy moorings, used in the offshore petroleum industry for drilling, production, processing and for storage purposes.

General Information

- Status

- Published

- Publication Date

- 04-Jun-2007

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 09-Apr-2019

- Completion Date

- 13-Feb-2026

Relations

- Revised

IEC 61892-4:2019 - Mobile and fixed offshore units - Electrical installations - Part 4: Cables - Effective Date

- 05-Sep-2023

Overview

IEC 61892-4:2007 - Mobile and fixed offshore units: Electrical installations - Part 4: Cables specifies requirements for the selection and installation of electrical cables used in fixed electrical systems on mobile and fixed offshore units. It covers cables for drilling, production, processing and storage facilities in the offshore petroleum industry, including pumping ("pigging") stations, compressor stations and exposed single buoy moorings. The standard focuses on cables subject to vibration in fixed systems (not repeatedly flexed cables) and excludes optical fibre, subsea/umbilical, downhole pump and data/telecommunication/RF cables.

Key Topics

- Cable types and voltage ratings: Guidance on appropriate power, control and instrumentation cable types and rated voltages for offshore use.

- Conductor cross-sections & current-carrying capacities: Rules for sizing conductors, reference tables and tables for continuous service, plus earth continuity sizing.

- Correction factors: Adjustments for ambient air temperature, short‑time duty, grouping of cables and intermittent service.

- Thermal and short-circuit performance: Requirements for short‑circuit withstand capability and time‑related thermal behavior (time constant concepts and related figures).

- Voltage drop & parallel cables: Considerations for acceptable voltage drop and parallel conductor arrangements.

- Separation & screening: Requirements for circuit separation, core screens/shields and earth/earthing conductor sizing.

- Materials and mechanical protection: Guidance on insulation, sheathing materials, metallic braid armour and bending radii for different voltage classes.

- Fire performance and tests: Fire‑related provisions including fire stops, jet‑fire test for hydrocarbon fires and drilling fluid exposure tests (Annexes B–D).

- Supporting tables and annexes: Extensive tabulated current‑carrying capacities, correction factors and installation methods (Annex A and multiple tables/figures).

Applications

IEC 61892-4 is used to:

- Select and size electrical cables for offshore platforms, FPSOs, mobile rigs and buoy moorings.

- Specify cable materials and mechanical protection compatible with marine and hydrocarbon environments.

- Verify thermal, short-circuit and fire performance during design reviews and procurement.

- Provide installation rules for contractors, asset owners and inspection bodies to ensure compliance with offshore electrical safety practices.

Typical users include offshore electrical designers, marine cable manufacturers and suppliers, installation contractors, classification societies, safety/asset managers and regulatory authorities.

Related standards

- IEC 61892 series (other parts for electrical installations on offshore units)

- IEC 60092 series (shipboard and offshore cable construction and materials) - e.g., IEC 60092-350, -351, -353, -354, -359, -376

- IEC 60228 (conductors) and IEC 60331 (circuit integrity/fire tests)

Keywords: IEC 61892-4:2007, offshore cable standards, electrical cable installation, current-carrying capacity, fire performance, offshore power cables.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Sponsored listings

Frequently Asked Questions

IEC 61892-4:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Mobile and fixed offshore units - Electrical installations - Part 4: Cables". This standard covers: This part of IEC 61892 specifies requirements for the choice and installation of electrical cables intended for fixed electrical systems in mobile and fixed offshore units, including pumping or "pigging" stations, compressor stations and exposed location single buoy moorings, used in the offshore petroleum industry for drilling, production, processing and for storage purposes.

This part of IEC 61892 specifies requirements for the choice and installation of electrical cables intended for fixed electrical systems in mobile and fixed offshore units, including pumping or "pigging" stations, compressor stations and exposed location single buoy moorings, used in the offshore petroleum industry for drilling, production, processing and for storage purposes.

IEC 61892-4:2007 is classified under the following ICS (International Classification for Standards) categories: 47.020.60 - Electrical equipment of ships and of marine structures. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61892-4:2007 has the following relationships with other standards: It is inter standard links to IEC 61892-4:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61892-4:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 61892-4

First edition

2007-06

Mobile and fixed offshore units –

Electrical installations –

Part 4:

Cables

Reference number

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 61892-4

First edition

2007-06

Mobile and fixed offshore units –

Electrical installations –

Part 4:

Cables

PRICE CODE

Commission Electrotechnique Internationale X

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

– 2 – 61892-4 © IEC:2007(E)

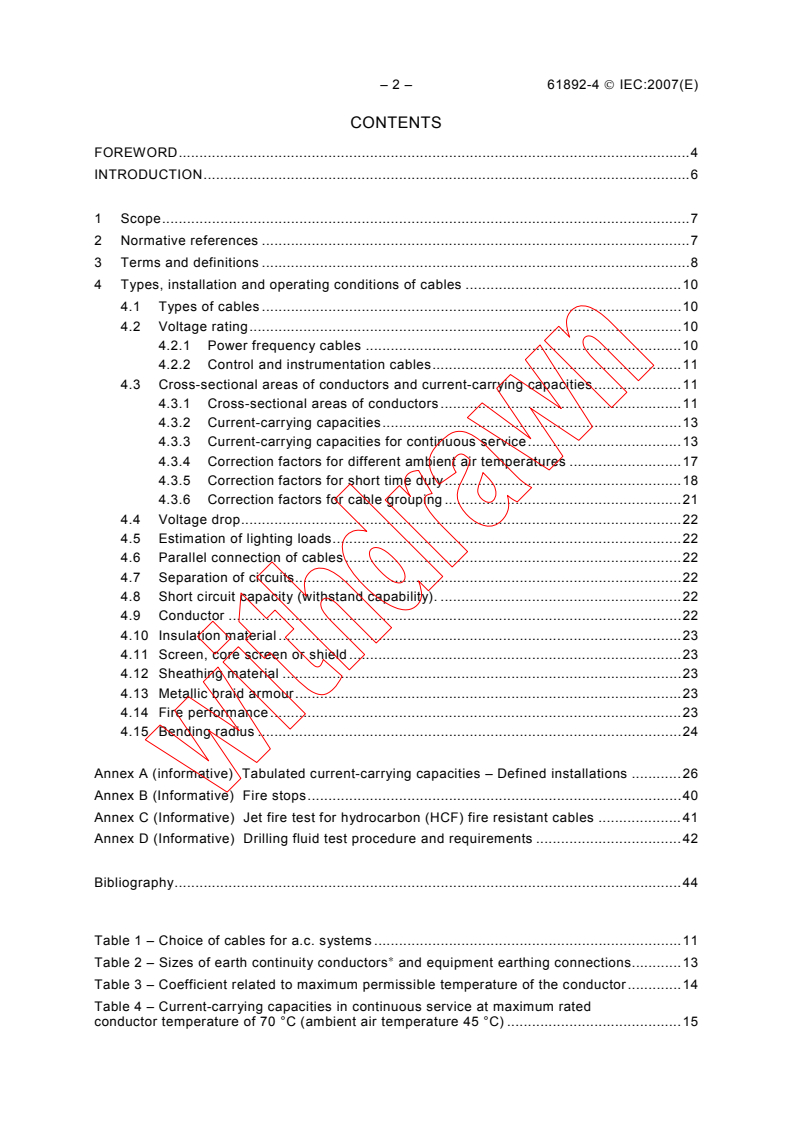

CONTENTS

FOREWORD.4

INTRODUCTION.6

1 Scope.7

2 Normative references .7

3 Terms and definitions .8

4 Types, installation and operating conditions of cables .10

4.1 Types of cables .10

4.2 Voltage rating.10

4.2.1 Power frequency cables .10

4.2.2 Control and instrumentation cables.11

4.3 Cross-sectional areas of conductors and current-carrying capacities .11

4.3.1 Cross-sectional areas of conductors .11

4.3.2 Current-carrying capacities.13

4.3.3 Current-carrying capacities for continuous service.13

4.3.4 Correction factors for different ambient air temperatures .17

4.3.5 Correction factors for short time duty.18

4.3.6 Correction factors for cable grouping .21

4.4 Voltage drop.22

4.5 Estimation of lighting loads.22

4.6 Parallel connection of cables.22

4.7 Separation of circuits.22

4.8 Short circuit capacity (withstand capability). .22

4.9 Conductor .22

4.10 Insulation material.23

4.11 Screen, core screen or shield .23

4.12 Sheathing material .23

4.13 Metallic braid armour.23

4.14 Fire performance.23

4.15 Bending radius .24

Annex A (informative) Tabulated current-carrying capacities – Defined installations .26

Annex B (Informative) Fire stops.40

Annex C (Informative) Jet fire test for hydrocarbon (HCF) fire resistant cables .41

Annex D (Informative) Drilling fluid test procedure and requirements .42

Bibliography.

Table 1 – Choice of cables for a.c. systems .11

∗

Table 2 – Sizes of earth continuity conductors and equipment earthing connections.13

Table 3 – Coefficient related to maximum permissible temperature of the conductor.14

Table 4 – Current-carrying capacities in continuous service at maximum rated

conductor temperature of 70 °C (ambient air temperature 45 °C) .15

61892-4 © IEC:2007(E) – 3 –

Table 5 – Current-carrying capacities in continuous service at maximum rated

conductor temperature of 90 °C (ambient air temperature 45 °C) .16

Table 6 – Current-carrying capacities in continuous service at maximum rated

conductor temperature of 95 °C (ambient air temperature 45 °C) .17

Table 7 – Correction factor for various ambient air temperatures (reference ambient

temperature of 45 °C) .18

Table 8 – Correction factor for various ambient air temperatures (reference ambient

temperature of 30 °C) .18

Table 9 – Bending radii for cables rated up to 1,8/3 kV .25

Table 10 – Bending radii for cables rated at 3,6/6,0(7,2) kV and above.25

Table A.1 – Current-carrying capacities in amperes – Copper conductor temperature

60 °C and reference ambient air temperature 45 °C .29

Table A.2 – Current-carrying capacities in amperes – Copper conductor temperature

70 °C and reference ambient air temperature 45 °C .30

Table A.3 – Current-carrying capacities in amperes – Copper conductor temperature

85 °C and reference ambient air temperature 45 °C .31

Table A.4 – Current-carrying capacities in amperes – Copper conductor temperature

60 °C and reference ambient air temperature 30 °C .32

Table A.5 – Current-carrying capacities in amperes – Copper conductors temperature

70 °C and reference ambient temperature 30 °C .33

Table A.6 – Current-carrying capacities in amperes – Copper conductors temperature

85 °C and reference ambient temperature 30 °C .34

Table A.7 – Current-carrying capacities in amperes – Copper conductors temperature

90 °C and reference ambient temperature 45 °C .35

Table A.8 – Current-carrying capacities in amperes – Copper conductors temperature

95 °C and reference ambient temperature 45 °C .36

Table A.9 – Correction factors for groups of more than one circuit or of more than one

multi-core cable to be used with current-carrying capacities of Tables A.1 to A.8.37

Table A.10 – Correction factors for group of more than one multi-core cable to be

applied to reference ratings for multi-core cables in free air – Method of installation E

in Tables A.1 to A.8 .38

Table A.11 – Correction factors for groups of more than one circuit of single-core

cables to be applied to reference rating for one circuit of single-core cables in free air

– Method of installation F in Tables A.1 to A.8 .39

Figure 1 – Time constant of cables .19

Figure 2 – Correction factors for half-hour and one-hour service.20

Figure 3 – Correction factor for intermittent service.21

Figure C.1 – International recognized HC fire curve .41

– 4 – 61892-4 © IEC:2007(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MOBILE AND FIXED OFFSHORE UNITS –

ELECTRICAL INSTALLATIONS –

Part 4: Cables

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61892-4 has been prepared by IEC technical committee 18:

Electrical installations of ships and of mobile and fixed offshore units, in cooperation with

SC 18A: Cables and cable installations.

The text of this standard is based on the following documents:

FDIS Report on voting

18/1052/FDIS 18/1058/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

61892-4 © IEC:2007(E) – 5 –

A list of all parts of the IEC 61892 series, published under the general title Mobile and fixed

offshore units – Electrical installations, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – 61892-4 © IEC:2007(E)

INTRODUCTION

IEC 61892 forms a series of International Standards intended to enable safety in the design,

selection, installation, maintenance and use of electrical equipment for the generation,

storage, distribution and utilisation of electrical energy for all purposes in offshore units which

are being used for the purpose of exploration or production of petroleum resources.

This part of IEC 61892 also incorporates and coordinates, as far as possible, existing rules

and forms a code of interpretation, where applicable, of the requirements of the International

Maritime Organisation. It also constitutes a guide for future regulations which may be

prepared and a statement of practice for offshore unit owners, constructors and appropriate

organisations.

This standard is based on equipment and practices which are in current use but it is not

intended in any way to impede development of new or improved techniques.

The ultimate aim has been to produce a set of International standards exclusively for the

offshore petroleum industry.

61892-4 © IEC:2007(E) – 7 –

MOBILE AND FIXED OFFSHORE UNITS –

ELECTRICAL INSTALLATIONS –

Part 4: Cables

1 Scope

This part of IEC 61892 specifies requirements for the choice and installation of electrical

cables intended for fixed electrical systems in mobile and fixed offshore units, including

pumping or “pigging” stations, compressor stations and exposed location single buoy

moorings, used in the offshore petroleum industry for drilling, production, processing and for

storage purposes.

The reference to fixed electrical systems includes those that are subjected to vibration due to

the movement of the unit, e.g. cables installed on a drag chain, and not those that are

intended for repeated flexing. Cables suitable for repeated flexing use are detailed in other

IEC specifications, e.g. IEC 60227 and IEC 60245, and their uses on board offshore units are

restricted to those situations which do not directly involve exposure to a marine environment,

e.g. portable tools, domestic appliances, etc.

The following types and applications of cables are not included:

• optical fibre cables;

• sub-sea and umbilical cables;

• cables supplying downhole pumps;

• data, telecommunication and radio frequency cables.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

1)

IEC 60038:1983, IEC standard voltages

Amendment 1 (1994)

Amendment 2 (1997)

IEC 60092-350:2001, Electrical installations in ships – Part 350: Shipboard power cables -

General construction and test requirements

IEC 60092-351, Electrical installations in ships – Part 351: Insulating materials for shipboard

and offshore units, power, control, instrumentation, telecommunication and data cables

IEC 60092-353, Electrical installations in ships – Part 353: Single and multicore non-radial

field power cables with extruded solid insulation for rated voltages 1 kV and 3 kV

IEC 60092-354, Electrical installations in ships – Part 354: Single and three-core power

cables with extruded solid insulation for rated voltages 6 kV (U =7,2 kV); up to 30 kV

m

=36 kV)

(U

m

___________

1)

There exists a consolidated edition 6.2 (2002) including IEC 60038:1983 and its Amendments 1 and 2.

– 8 – 61892-4 © IEC:2007(E)

IEC 60092-359, Electrical installations in ships – Part 359: Sheathing materials for shipboard

power and telecommunication cables

IEC 60092-376, Electrical installations in ships – Part 376: Cables for control and

instrumentation circuits 150/250 V (300 V)

IEC 60228:2004, Conductors of insulated cables

IEC 60331-21:1999, Tests for electric cables under fire conditions – Circuit integrity – Part 21:

Procedures and requirements – Cables of rated voltage up to and including 0,6/1,0 kV

IEC 60331-31:2002, Tests for electric cables under fire conditions – Circuit integrity – Part 31:

Procedures and requirements for fire with shock – Cables of rated voltage up to and including

0,6/1 kV

IEC 60332-1-2:2004, Tests on electric and optical fibre cables under fire conditions – Part 1-

2: Test for vertical flame propagation for a single insulated wire or cable – Procedure for 1 kW

pre-mixed flame

IEC 60332-3-22:2000, Tests on electric cables under fire conditions – Part 3-22: Test for

vertical flame spread of vertically-mounted bunched wires or cables – Category A

IEC 60754-1:1994, Test on gases evolved during combustion of materials from cables –

Part 1: Determination of the amount of halogen acid gas

IEC 60754-2:1991, Test on gases evolved during combustion of electric cables – Part 2:

Determination of degree of acidity of gases evolved during the combustion of materials taken

from electric cables by measuring pH and conductivity

Amendment 1 (1997)

IEC 61034-2:2005, Measurement of smoke density of cables burning under defined conditions

– Part 2: Test procedure and requirements

IEC 61892-1:2001, Mobile and fixed offshore units – Electrical installations – Part 1: General

requirements and conditions

IEC 61892-2, Mobile and fixed offshore units – Electrical installations – Part 2: System design

IEC 61892-6, Mobile and fixed offshore units – Electrical installations – Part 6: Installation

3 Terms and definitions

3.1

appropriate authority

governmental body and/or classification society with whose rules an offshore unit is required

to comply

3.2

braid armour

covering formed from braided metal wires used to protect the cable from external mechanical

effects

3.3

braid

covering made of plaited metallic or non-metallic material

61892-4 © IEC:2007(E) – 9 –

3.4

core insulated conductor

assembly comprising a conductor and its own insulation (and screens, if any)

3.5

core screen

electric screen of non-metallic and/or metallic materials covering the insulation

3.6

insulated cable

an assembly consisting of:

– one or more cores,

– their individual covering(s) (if any)

– assembly protection (if any)

– protective coverings (if any)

NOTE Additional uninsulated conductor(s) may be included in the cable.

3.7

conductor screen

non-metallic conducting layer applied between the conductor and insulation to equalise the

electrical stress between these components. It may also provide smooth surfaces as the

boundaries of the insulation and assist in the elimination of spaces at these boundaries

3.8

inner sheath

inner jacket (North America) non-metallic extruded sheath applied under a metallic sheath,

reinforcement, or armour

NOTE

It must be extruded.

It can be used to fill the interstices.

It must be a material listed in IEC 60092-359.

It has a defined nominal thickness (value).

3.9

outer sheath

jacket (North America)

non-metallic extruded sheath applied over a metallic sheath, reinforcement, or armour It must

.

be extruded

NOTE 1

It can be used to fill the interstices.

It must be a material listed in IEC 60092-359.

It has a defined nominal thickness (value).

NOTE 2 The term sheath is only used for metallic coverings in North America, where the term jacket is used for

non-metallic coverings.

3.10

electrostatic screen

electrostatic shield (North America)

surrounding earthed metallic layer to confine the electric field within the cable cores, pair(s),

triples(s), or quad(s), and to protect the pair(s), triad(s), or quad(s) from external influence

– 10 – 61892-4 © IEC:2007(E)

4 Types, installation and operating conditions of cables

4.1 Types of cables

Cables constructed in accordance with IEC 60092-350, IEC 60092-353, IEC 60092-354 and

IEC 60092-376 are recommended for use on mobile and fixed offshore units.

4.2 Voltage rating

4.2.1 Power frequency cables

The maximum rated voltage (U) considered in this standard for power frequency cables is

30 kV.

In the voltage designation of cables U / U / (U )

0 m :

– U is the rated power frequency voltage between conductor and earth or metallic screen

for which the cable is designed;

– U is the rated power frequency voltage between conductors for which the cable is

designed;

– U is the maximum value of the highest system voltage which may be sustained under

m

normal operating conditions at anytime and at any point in the system. It excludes

transient voltage conditions and rapid disconnection of loads.

U is chosen to be equal to or greater than the highest voltage of the three-phase system.

m

Where cables are permitted for use on circuits where the nominal system voltage exceeds the

rated voltage of the cables, the nominal system voltage shall not exceed the highest system

voltage (U ) of the cable.

m

Careful consideration shall be given to cables subjected to voltage surges associated with

highly inductive circuits to ensure that they are of a suitable voltage rating.

The choice of standard cables of appropriate voltage designations for particular systems

depends upon the system voltage and the system earthing arrangements

The rated voltage of any cable shall not be lower than the nominal voltage of the circuit for

which it is used. To facilitate the choice of the cable, the values of U recommended for cables

to be used in three-phase systems are listed in Table 1 in which systems are divided into the

following three categories.

• Category A

This category comprises those systems in which any phase conductor that comes in contact

with earth or an earth conductor is automatically disconnected from the system.

• Category B

This category comprises those systems that, under fault conditions are operated for a short

time, not exceeding 8 h on any occasion, with one phase earthed.

For example, for a 13,8 kV system of Category A or B, the cable should have a rated voltage

not less than 8,7/15 kV.

NOTE In a system where an earth fault is not automatically and promptly eliminated, the increased stresses on

the insulation of cables during the earth fault are likely to affect the life of the cables to a certain degree. If the

system is expected to be operated fairly often with a sustained earth fault, it may be preferable to use cables

suitable for Category C. In any case, for classification as Category B the expected total duration of earth faults in

any year should not exceed 125 h.

• Category C

61892-4 © IEC:2007(E) – 11 –

This category comprises all systems that do not fall into Categories A and B.

The nominal system voltages from 3,3 kV to 30 kV shown in Table 1 are generally in

accordance with Series 1 in IEC 60038. For nominal system voltages intermediate between

these standard voltages and also between 0,6/1 kV and 1,8/3,3 kV, the cables should be

selected with a rated voltage not less than the next higher standard value. For example: a first

earth fault with one phase earthed causes a √3 higher voltage between the phases and earth

during the fault. If the duration of this earth fault exceeds the times given for Category B, then

according to Table 1, for a 17,5 kV system, the cable is to have a rated voltage not less than

12/20 kV.

A d.c. voltage to earth of up to a maximum of 1,5 times the a.c. U voltage may be used.

However consideration should be given to the peak value when determining the voltage of

d.c. systems derived from rectifiers, bearing in mind that smoothing does not modify the peak

value when the semiconductors are operating on an open circuit.

Table 1 – Choice of cables for a.c. systems

System Minimum rated voltage

System voltage

category of cable U /U

o

Maximum

Unscreened

Single-core or

Nominal voltage U

sustained

screened

voltage, U

m

kV kV kV kV

up to 0,25 0,30 A, B or C 0,15 / 0,25 −

1 1,2 A, B or C 0,6 / 1,0 0,6 /1,0

3 3,6 A or B 1,8 / 3,0 1,8 / 3,0

3 3,6 C 3,6 / 6,0

6 7,2 A or B 3,6 / 6,0

6 7,2 C 6,0 / 10

10 12 A or B 6,0 / 10

10 12 C 8,7 / 15

15 17,5 A or B 8,7 / 15

15 17,5 C 12 /20

20 24 A or B 12 / 20

20 24 C 18 / 30

30 36 A or B 18 / 30

4.2.2 Control and instrumentation cables

The typical rated voltage (U) for control and instrumentation cables considered in this

standard is 250 V.

In some instances for conductor sizes 1 mm and larger, or when circuits are to be supplied

from a low impedance source, 0,6/1 kV rated cables shall be used as control or

instrumentation cables.

4.3 Cross-sectional areas of conductors and current-carrying capacities

4.3.1 Cross-sectional areas of conductors

The cross-sectional area of each conductor shall be selected to be large enough to comply

with the following conditions:

– 12 – 61892-4 © IEC:2007(E)

a) The highest load to be carried by the cable shall be calculated from the load demands and

diversity factors given in IEC 61892-2.

b) The “corrected current rating” calculated by applying the appropriate correction factors to

the “current rating for continuous services” shall not be lower than the highest current

likely to be carried by the cable. The correction factors to be applied are those given in

4.3.4, 4.3.5 and 4.3.6.

c) The voltage drop in the circuit shall not exceed the limits specified by the appropriate

authority for the circuits concerned - further guidance is given in 4.4.

d) The cross-sectional area of the conductor shall be able to accommodate the mechanical

and thermal effects of a short circuit current (see 4.8) and the effect upon voltage drop of

motor-starting currents (see 4.4, Note 3).

e) The nominal cross-section of the earth conductor shall comply with Table 2. One of the

alternative methods of determining the cross-sectional area of each earthing conductor is

that based upon the rating of the fuse or circuit protection device installed to protect the

circuit. If this method is used the nominal cross-sectional area finally selected shall be the

higher of any cross-sectional area determined by each of the methods.

NOTE The tables incorporated in this standard for the current ratings give only average values; these are not

exactly applicable to all cable constructions and all installation conditions existing in practice. They are

nevertheless recommended for general application, considering that the errors (a few degrees Celsius in the

estimated operating temperature) are of little importance against the advantages of having a single international

standard for the evaluation of the current ratings. In particular cases, however, a more precise evaluation is

permitted, based on experimental or calculated data acceptable to all interested parties

61892-4 © IEC:2007(E) – 13 –

a

Table 2 – Sizes of earth continuity conductors and equipment earthing connections

Cross-section Q of

associated

current-carrying Minimum cross-section of

Arrangement of earth conductor

conductor (One earth conductor

phase or pole)

mm

1 i) Insulated earth conductor in cable for fixed Q ≤ 16 Q

installation.

ii) Copper braid of cable for fixed installation

according to subclause 8.2 of IEC 60092-350.

50% of the current-carrying

iii) Separate, insulated earth conductor for fixed

Q > 16 conductor, but not less than

installation in pipes in dry accommodation spaces,

16 mm

when carried in the same pipe as the supply cable.

iv) Separate, insulated earth conductor when installed

inside enclosures or behind covers or panels,

including earth conductor for hinged doors.

2 Uninsulated earth conductor in cable for fixed Q ≤ 2,5 1 mm

installation, being laid under the cable's armour or

2,5 < Q ≤ 6 1,5 mm

copper braid and in metal-to-metal contact with this.

Q > 6 Not permitted

3 Separately installed earth conductor for fixed Q < 2,5 Same as current-carrying

installation other than specified in 1 iii) and 1 iv). conductor subject to min.

1,5 mm for stranded earthing

connection or 2,5 mm for

unstranded earthing

connection

2,5 < Q ≤ 120 50 % of current-carrying

conductor, but not less than

4 mm

Q > 120 70 mm

4 Insulated earth conductor in flexible cable. Q ≤ 16 Same as current-carrying

conductor

Q > 16 50 % of current-carrying

conductor, but minimum

16 mm

NOTE Refer also to 4.3.1 for method based on rating of fuses.

a

The term protective conductor is accepted as an alternative term for the earth continuity conductor.

4.3.2 Current-carrying capacities

The procedure for cable selection employs rating factors to adjust the current-carrying

capacities for different ambient temperature, short time duty, for the mutual heating effects of

grouping with other cables, and methods of installation. Guidance on the use of these factors

is given below.

4.3.3 Current-carrying capacities for continuous service

Continuous service for a cable shall be considered, for the purpose of this standard, as a

current-carrying service with constant load having a duration longer than three times the

thermal time constant of the cable, i.e., longer than the critical duration (see Figure 1).

– 14 – 61892-4 © IEC:2007(E)

The current to be carried by any conductor for sustained periods during normal operation shall

be such that the appropriate conductor temperature limit is not exceeded.

These current-carrying capacities are derived from those as documented in

IEC 60092-352:1997.

Current ratings currently available from various approval authorities for use in the general

case for continuous service are shown in Tables 4 through 6 and are recommended as being

applicable to both unarmoured and armoured cables laid in free air as a group of six bunched

together.

These ratings may be considered applicable, without correction factors, for cables bunched

together on cable trays, in cable conduits, pipes or trunking, unless more than six cables,

which may be expected to operate simultaneously at their full rated capacity, are laid close

together in a cable bunch in such a way that there is an absence of free air circulation around

them. In this case a correction factor of 0,85 should be applied.

NOTE Cables are said to be bunched when two or more are contained within a single conduit, trunking or duct, or

if not enclosed, are not separated from each other.

These ratings have been calculated using the basis given below for an ambient temperature

of 45°C and a conductor temperature that is assumed to be equal to the maximum rated

temperature of the insulation and continuously maintained. The cable constructions are based

on the various insulating materials given in 60092-351 together with any type of sheathing

material given in 60092-359.

The basis for the calculation of the ratings in Tables 4 to 6 is as follows:

The current ratings I, in amperes, have been calculated for each nominal cross-sectional area

A, in square millimetres, with the formula:

0,625

I = α A

where α is a coefficient related to the maximum permissible service temperature of the

conductor as follows:

Table 3 – Coefficient related to maximum permissible temperature of the conductor

Maximum permissible temperature of the 70 °C 90 °C 95 °C

conductor

≥ 2,5 mm² 12 17 18

Values of α for nominal

cross-sectional area

<2,5 mm² 11,5 18 20

For two-, three- and four-conductor cables, the current ratings given in Table 3 should be

multiplied by the following (approximate) correction factors:

0,85 for two core cables,

0,70 for three- and four-core cables.

The ambient temperature of 45 °C, on which the current ratings in Tables 4 through 6 are

based, is considered as a standard value for the ambient air temperature, generally applicable

for any kind of offshore unit in any climate.

When, however, fixed offshore units are installed in locations where the ambient temperature

is known to be permanently lower than 45 °C, it is permitted to increase the current ratings

from those in the tables - but in no case shall the ambient temperature be considered to be

lower than 25 °C.

61892-4 © IEC:2007(E) – 15 –

When, on the other hand, it is to be expected that the air temperature around the cables could

be higher than 45 °C (for instance, when a cable is wholly or partly installed in spaces or

compartments where heat is produced or higher cable temperatures could be reached due to

heat transfer), the current ratings from the Tables 4 through 6 shall be reduced.

The correction factors for these different ambient air temperatures are given in Table 7 or 8.

The selection of the method applicable to any particular installation is the responsibility of the

appropriate approval authority or governing regulation. An optional alternative method is given

in Appendix A (Informative) when utilized under Engineering Supervision.

Table 4 – Current-carrying capacities in continuous service at maximum rated

conductor temperature of 70 °C (ambient air temperature 45 °C)

Rated conductor

70 °C

temperature

Nominal cross-sectional

Single-core 2-core 3- or 4-core

area

(mm²) (A) (A) (A)

1 12 10 8

1,5 15 13 10

2,5 20 18 15

4 29 24 20

6 37 31 26

10 51 43 35

16 68 58 48

25 90 76 63

35 111 94 78

50 138 118 97

70 171 145 120

95 207 176 145

120 239 203 167

150 275 234 192

185 313 266 219

240 369 313 258

300 424 360 297

400 508 431 355

500 583 496 408

630 674 573 472

– 16 – 61892-4 © IEC:2007(E)

Table 5 – Current-carrying capacities in continuous service at maximum rated

conductor temperature of 90 °C (ambient air temperature 45 °C)

Conductor temperature 90 °C

Nominal cross-sectional

Single-core 2-core 3- or 4-core

area

(mm²) (A) (A) (A)

1 18 15 13

1,5 23 20 16

2,5 30 26 21

4 40 34 28

6 52 44 36

10 72 61 50

16 96 82 67

25 127 108 89

35 157 133 110

50 196 167 137

70 242 206 169

95 293 249 205

120 339 288 237

150 389 331 273

185 444 377 311

240 522 444 366

300 601 511 420

400 719 611 503

500 827 703 579

630 955 812 669

61892-4 © IEC:2007(E) – 17 –

Table 6 – Current-carrying capacities in continuous service at maximum rated

conductor temperature of 95 °C (ambient air temperature 45 °C)

Conductor temperature 95 °C

Nominal cross-sectional 3- or 4-

Single-core 2-core

area core

(mm²) (A) (A) (A)

1 20 17 14

1,5 26 22 18

2,5 32 27 22

4 43 36 30

6 55 47 39

10 76 65 53

16 102 87 71

25 135 114 94

35 166 141 116

50 208 176 145

70 256 218 179

95 310 263 217

120 359 305 251

150 412 351 289

185 470 400 329

240 553 470 387

300 636 541 445

400 761 647 533

500 875 744 613

630 1011 860 708

4.3.4 Correction factors for different ambient air temperatures

The ambient temperature is the temperature of the surrounding medium when the cable(s) or

insulated conductor(s) under consideration are not loaded.

The current-carrying capacity tabulated in this subclause and in Annex A assumes the

following reference ambient temperatures for insulated conductors and cables in air,

irrespective of the method of installation:

• 45 °C for standard situations, generally applicable for any kind of unit and in any climate;

• 30 °C for particular situations, applicable for mobile and fixed offshore units for particular

uses for which the ambient temperature is known to be permanently lower or equal to

30 °C.

Where the ambient temperature in the intended location of the insulated conductors or cables

differs from the reference ambient temperature, the appropriate correction factors specified in

Table 7 and Table 8 shall be applied to the values of current-carrying capacity set out in this

subclause and in Annex A.

NOTE The air temperature around the cables can be higher than 45 °C when, for instance, a cable is wholly or

partly installed in spaces or compartments where heat is produced or due to heat transfer.

– 18 – 61892-4 © IEC:2007(E)

Table 7 – Correction factor for various ambient air temperatures

(reference ambient temperature of 45 °C)

Maximum

conductor Correction factors for ambient air temperatures

temperature

°C 25 °C 30 °C 35 °C 40 °C 45 °C 50 °C 55 °C 60 °C 65 °C 70 °C 75 °C 80 °C 85 °C

70 1,32 1,25 1,18 1,10 1,00 0,89 0,77 0,63 - - - - -

90 1,20 1,15 1,10 1,05 1,00 0,94 0,88 0,82 0,74 0,67 0,58 0,47 -

95 1,18 1,14 1,10 1,05 1,00 0,95 0,89 0,84 0,77 0,71 0,63 0,55 0,45

Table 8 – Correction factor for various ambient air temperatures

(reference ambient temperature of 30 °C)

Maximum

conductor Correction factors for ambient air temperatures

temperature

°C 20 °C 25 °C 30 °C 35 °C 40 °C 45 °C 50 °C 55 °C 60 °C 65 °C 70 °C 75 °C 80 °C 85 °C

70 1,12 1,06 1,00 0,94 0,87 0,79 0,71 0,61 0,50 - - - - -

90 1,08 1,04 1,00 0,96 0,91 0,87 0,82 0,76 0,71 0,65 0,58 0,50 0,41 -

95 1,07 1,04 1,00 0,96 0,92 0,88 0,83 0,78 0,73 0,68 0,62 0,55 0,48 0.39

4.3.5 Correction factors for short time duty

If a cable is intended to supply a motor or equipment operating for periods of half an hour or

one hour, its current rating, as given by the relevant table (see 4.3.3 and Annex A), may be

increased using the relevant correction factors given by Figure 2. These correction factors are

applicable only if the intermediate periods of rests are longer than the critical duration (which

is equal to three times the time constant of the cable), given in Figure 1 as a function of the

cable diameter.

NOTE 1 The correction factors given in Figure 2 are approximate and depend mainly upon the diameter of the

cable. In general, the half-an-hour service is applicable to mooring winches. The half-an-hour rating might not be

adequate for automatic tensioning mooring winches.

NOTE 2 For cables supplying a single motor or other equipment intended to operate in an intermittent service, as

is generally the case for engine room cranes and similar devices, the current ratings as given by Annexes A and B

may be increased by applying the correction factor given by Figure 3.

NOTE 3 The correction factor given in Figure 3 has been roughly calculated for periods of 10 min, of which 4 min

are with a constant load and 6 min without load.

61892-4 © IEC:2007(E) – 19 –

Critical duration = 3 T

1,35

T = 0,245 x d

11,5 2 2,5 3 3,5 4 5 6 7 8 9 10 15 20 25 30 35 40 50 60 70 90 100

d = overall diameter of the cable (mm)

IEC 938/97

Figure 1 – Time constant of cables

T = time constant (min.)

– 20 – 61892-4 © IEC:2007(E)

2,2

1,12

Correction factor =

2,1

t

s

1 - exp -

T

For T, see Figure 2

2,0

1,9

1,8

1,7

1,6

1,5

1,4

1,3

t = 30´

s

1,2

t = 60´

s

1,1

1,0

0 10 20 3040 50 60 70 8090

Overall diameter of the cable (mm)

IEC 937/97

t = service time

s

Figure 2 – Correction factors for half-hour and one-hour service

Correction factor(s)

61892-4 © IEC:2007(E) – 21 –

1,7

1,6

1,5

1,4

-

1 - exp

T

Correction factor =

1,3

1 - exp -

T

1,3

1,2

1,1

0 10 20 3040 5060 70 80 90

Overall diameter of the cable (mm)

IEC 939/97

Intermittence period = 10 min Intermittence ratio = 40 %

Figure 3 – Correction factor for intermittent service

4.3.6 Correction factors for cable grouping

In the case of a group of insulated conductors or cables the current-carrying capacities

tabulated are subjected to the group correction factors given in 4.3.3 or the tables of Annex A.

The group reduction factors are applicable to groups of insulated conductors or cables having

the same maximum operating temperature.

For groups containing cables or insulated conductors having different maximum operating

temperatures, the current-carrying capacity of all the cables or insulated conductors in the

group shall be based on the lowest maximum operating temperature of any cable in the group

together with the appropriate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...