EN 45510-2-5:2002

(Main)Guide for procurement of power station equipment - Part 2-5: Electrical equipment - Motors

Guide for procurement of power station equipment - Part 2-5: Electrical equipment - Motors

This standard gives guidance on writing the technical specification for the procurement of motors for use in electricity generating stations (power stations). This Guide for procurement is not applicable to equipment for use in the nuclear reactor plant area of nuclear power stations. Other possible applications of such equipment have not been considered in the preparation of this Guide. This Guide covers motors within installations primarily concerned with the generation of electrical power. However, as a complete electrical drive system is not defined in this Guide, attention is drawn to the possible additional electrical and mechanical stresses to which the motor may be subjected e.g. by a static AC converter/inverter. Reference should be made to IEC 60034-17. The equipment covered by this Guide is defined by its function rather than design type. Therefore, the guidance to the specification is stated in performance terms rather than being specified by a detailed description of the equipment to be supplied. This Guide indicates to potential purchasers how their specification should be prepared so that: - the equipment type and capacity interfaces correctly with other elements of the systems; - predicted performance is achieved; - ancillary equipment is properly sized; - reliability, availability and safety requirements are achieved; - proper consideration is given to the evaluation process and the quality measures to be applied. This Guide does not determine the type of specification (e.g. detailed, performance, functional) or the extent of supply for any given contract which is normally decided on the basis of the purchaser’s project strategy. It does not cover: - any commercial, contractual or legal issues which are normally in separate parts of an enquiry; - any allocation of responsibilities which are determined by the contract. This Guide does not prescribe the arrangement of the documents in the enquiry.

Leitfaden für die Beschaffung von Ausrüstungen für Kraftwerke - Teil 2-5: Elektrische Ausrüstung - Motoren

Guide pour l'acquisition d'équipements destinés aux centrales de production d'électricité Partie 2-5: Equipements électriques - Moteurs

Guide for procurement of power station equipment - Part 2-5: Electrical equipment - Motors

General Information

- Status

- Published

- Publication Date

- 20-Aug-2002

- Withdrawal Date

- 31-Mar-2004

- Technical Committee

- CEN/CLC/JTC 2 - Power Engineering

- Drafting Committee

- IEC/TC 2 - IEC_TC_2

- Parallel Committee

- CENCLC/TC 2 - CENCLC_TC_2

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 04-Jun-2018

- Completion Date

- 04-Jun-2018

Relations

- Effective Date

- 13-May-2010

- Effective Date

- 10-Feb-2026

- Effective Date

- 03-Feb-2026

- Effective Date

- 03-Feb-2026

- Effective Date

- 03-Feb-2026

- Effective Date

- 03-Feb-2026

- Refers

EN IEC 60034-23:2019 - Rotating electrical machines - Part 23: Repair, overhaul and reclamation - Effective Date

- 03-Feb-2026

- Effective Date

- 03-Feb-2026

- Effective Date

- 03-Feb-2026

- Effective Date

- 03-Feb-2026

- Effective Date

- 03-Feb-2026

- Effective Date

- 03-Feb-2026

- Effective Date

- 03-Feb-2026

- Effective Date

- 03-Feb-2026

- Effective Date

- 03-Feb-2026

Overview

EN 45510-2-5:2002 - Guide for procurement of power station equipment, Part 2-5: Electrical equipment - Motors (CLC) is a procurement guide that helps purchasers prepare technical specifications for motors used in electricity generating stations (power stations). The standard is performance-focused: it defines equipment by function rather than by detailed design, and it is intended for installations primarily concerned with electrical power generation. It does not apply to equipment used in the nuclear reactor plant area and does not address commercial, contractual or environmental issues.

Key topics

This guide organizes the core technical and procurement topics that should appear in a motor specification for power stations. Major areas covered include:

- Scope and application: defines where the guide applies and exclusions (nuclear reactor plant area).

- Project and site information: project description, purchaser roles, site location and interfaces.

- Extent of supply and terminal points: clarifies what the vendor supplies and connection points.

- Operational requirements: operating environment, duty cycles, start/stop regimes, abnormal conditions and operating hours.

- Performance requirements: duty, expected performance, margins, availability and redundancy levels.

- Design and fabrication: performance-based design guidance, materials, safety and interchangeability considerations.

- Maintenance and life expectancy: planned maintenance, spare parts strategy, lifting and access requirements.

- Testing and verification: works tests, installation and commissioning tests, functional and performance tests.

- Documentation and evaluation: tender and contract documentation, technical documentation, evaluation criteria and quality measures.

- Standards and legislation: referenced international and European standards and applicable regulations.

The guide also draws attention to possible additional stresses (for example, when motors are driven by static AC converters/inverters) and references IEC 60034-17 for converter-fed motors.

Applications and users

Who benefits from using EN 45510-2-5:2002:

- Procurement teams and specification writers drafting technical tenders for power station motors

- Electrical and design engineers ensuring motor capacity and interfaces match systems

- Vendors and manufacturers preparing compliant offers and test programs

- Project managers, commissioning and maintenance planners aligning availability, redundancy and lifecycle planning

- Consultants advising on performance-based specification and acceptance testing

Practical applications include specifying motors for auxiliaries, drive systems and other power-station electrical installations where predictable performance, safety, availability and maintainability are required.

Related standards

- EN 45510 series (Common clauses and other equipment parts)

- IEC 60034-17 (motors fed from converters/inverters)

- EN ISO 9001 / EN ISO 9002 (quality systems)

- EN 45510-2-7 (Switchgear and controlgear)

- EN 45510-2-9 (Cabling systems)

Keywords: EN 45510-2-5:2002, motors procurement, power station equipment, technical specification, IEC 60034-17, CLC, electrical equipment, procurement guide.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

EN 45510-2-5:2002 is a standard published by CLC. Its full title is "Guide for procurement of power station equipment - Part 2-5: Electrical equipment - Motors". This standard covers: This standard gives guidance on writing the technical specification for the procurement of motors for use in electricity generating stations (power stations). This Guide for procurement is not applicable to equipment for use in the nuclear reactor plant area of nuclear power stations. Other possible applications of such equipment have not been considered in the preparation of this Guide. This Guide covers motors within installations primarily concerned with the generation of electrical power. However, as a complete electrical drive system is not defined in this Guide, attention is drawn to the possible additional electrical and mechanical stresses to which the motor may be subjected e.g. by a static AC converter/inverter. Reference should be made to IEC 60034-17. The equipment covered by this Guide is defined by its function rather than design type. Therefore, the guidance to the specification is stated in performance terms rather than being specified by a detailed description of the equipment to be supplied. This Guide indicates to potential purchasers how their specification should be prepared so that: - the equipment type and capacity interfaces correctly with other elements of the systems; - predicted performance is achieved; - ancillary equipment is properly sized; - reliability, availability and safety requirements are achieved; - proper consideration is given to the evaluation process and the quality measures to be applied. This Guide does not determine the type of specification (e.g. detailed, performance, functional) or the extent of supply for any given contract which is normally decided on the basis of the purchaser’s project strategy. It does not cover: - any commercial, contractual or legal issues which are normally in separate parts of an enquiry; - any allocation of responsibilities which are determined by the contract. This Guide does not prescribe the arrangement of the documents in the enquiry.

This standard gives guidance on writing the technical specification for the procurement of motors for use in electricity generating stations (power stations). This Guide for procurement is not applicable to equipment for use in the nuclear reactor plant area of nuclear power stations. Other possible applications of such equipment have not been considered in the preparation of this Guide. This Guide covers motors within installations primarily concerned with the generation of electrical power. However, as a complete electrical drive system is not defined in this Guide, attention is drawn to the possible additional electrical and mechanical stresses to which the motor may be subjected e.g. by a static AC converter/inverter. Reference should be made to IEC 60034-17. The equipment covered by this Guide is defined by its function rather than design type. Therefore, the guidance to the specification is stated in performance terms rather than being specified by a detailed description of the equipment to be supplied. This Guide indicates to potential purchasers how their specification should be prepared so that: - the equipment type and capacity interfaces correctly with other elements of the systems; - predicted performance is achieved; - ancillary equipment is properly sized; - reliability, availability and safety requirements are achieved; - proper consideration is given to the evaluation process and the quality measures to be applied. This Guide does not determine the type of specification (e.g. detailed, performance, functional) or the extent of supply for any given contract which is normally decided on the basis of the purchaser’s project strategy. It does not cover: - any commercial, contractual or legal issues which are normally in separate parts of an enquiry; - any allocation of responsibilities which are determined by the contract. This Guide does not prescribe the arrangement of the documents in the enquiry.

EN 45510-2-5:2002 is classified under the following ICS (International Classification for Standards) categories: 27.100 - Power stations in general; 29.160.30 - Motors. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 45510-2-5:2002 has the following relationships with other standards: It is inter standard links to EN 50441-1:2006, EN ISO 9001:2015, EN IEC 60034-2-2:2024, EN 60034-8:2007/A1:2014, EN 60034-18-21:2013, EN 60034-22:2009, EN IEC 60034-23:2019, EN IEC 60034-2-3:2024, EN IEC 60072-1:2022, EN 60034-30:2009, EN 60034-7:1993/A1:2001, EN 60034-29:2008, EN 60034-26:2006, EN 60034-28:2007, EN IEC 60034-15:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 45510-2-5:2002 is associated with the following European legislation: EU Directives/Regulations: 93/38/EEC; Standardization Mandates: BC/CLC/92-04/1, M/BC/CEN/92/10. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 45510-2-5:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Guide for procurement of power station equipment - Part 2-5: Electrical equipment - MotorsLeitfaden für die Beschaffung von Ausrüstungen für Kraftwerke -- Teil 2-5: Elektrische Ausrüstung - MotorenGuide pour l'acquisition d'équipements destinés aux centrales de production d'électricité -- Partie 2-5: Equipements électriques - MoteursGuide for procurement of power station equipment -- Part 2-5: Electrical equipment - Motors29.160.30MotorjiMotors27.100Elektrarne na splošnoPower stations in generalICS:Ta slovenski standard je istoveten z:EN 45510-2-5:2002SIST EN 45510-2-5:2003en01-december-2003SIST EN 45510-2-5:2003SLOVENSKI

STANDARD

EUROPEAN STANDARDEN 45510-2-5NORME EUROPÉENNEEUROPÄISCHE NORMAugust 2002

CEN Management Centre:CENELEC Central Secretariat:rue de Stassart, 36

B-1050 Brusselsrue de Stassart, 35

B-1050 Brussels©

2002 CEN/CENELEC -All rights of exploitation in any form and by any means reservedworldwide for CEN national members and for CENELEC members.Ref. No. EN 45510-2-5:2002 EICS 27.100; 29.160.30English versionGuide for procurement of power station equipmentPart 2-5: Electrical equipment -MotorsGuide pour l'acquisition d'équipementsdestinés aux centrales de productiond'électricitéPartie 2-5: Equipements électriques -MoteursLeitfaden für die Beschaffung vonAusrüstungen für KraftwerkeTeil 2-5: Elektrische Ausrüstung -MotorenThis European Standard was approved by CEN and CENELEC on 2001-03-06.CEN and CENELEC members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate theconditions for giving this European Standard the status of a national standard without any alteration. Up-to-date listsand bibliographical references concerning such national standards may be obtained on application to the CENEELECCentral Secretariat or to any CEN or CENELEC member.This European Standard exists in three official versions (English, French, German). A version in any other languagemade by translation under the responsibility of a CEN or CENELEC member into its own language and notified to theCENELEC Central Secretariat has the same status as the official versions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France,Germany, Greece, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden,Switzerland and United Kingdom.CENELEC members are the national electrotechnical committees of Austria, Belgium, Czech Republic, Denmark,Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway,Portugal, Slovakia, Spain, Sweden, Switzerland and United Kingdom.SIST EN 45510-2-5:2003

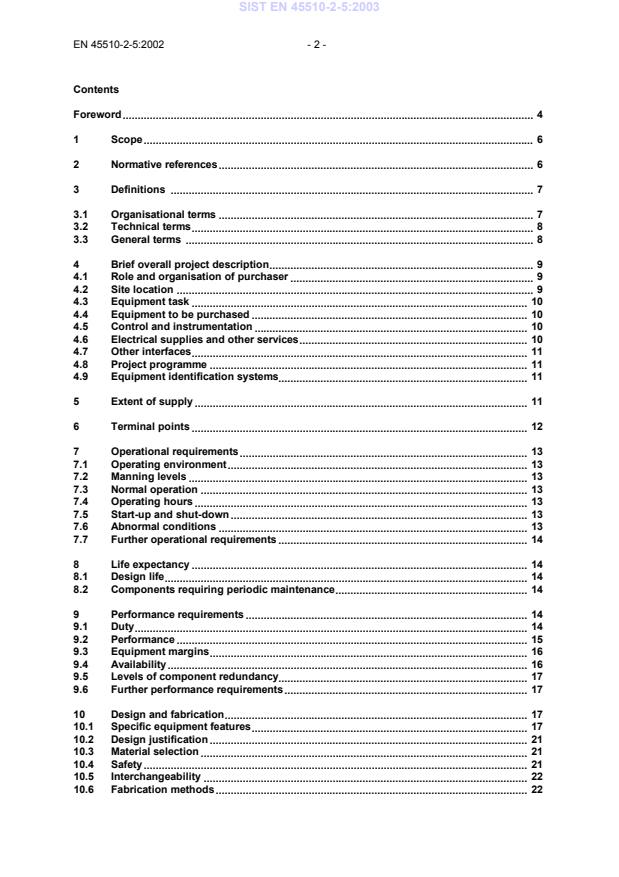

- 3 -EN 45510-2-5:200211Maintenance requirements. 2211.1Planned maintenance. 2211.2Personnel safety. 2211.3Requirements for access. 2311.4Lifting requirements. 2311.5Special tools. 2311.6Test equipment. 2311.7Spare parts strategy. 2311.8Special precautions. 2412Technical documentation requirements. 2412.1Tender documentation. 2412.2Contract documentation. 2413Applicable legislation, regulations, standards and further requirements. 2413.1Legislation and regulations. 2413.2Standards. 2513.3Further requirements. 2514Evaluation criteria. 2514.1General. 2514.2 Technical criteria. 2515Quality measures. 2615.1General. 2615.2Approvals procedure. 2615.3Inspection requirements. 2615.4Non-conformity. 2616Site factors. 2716.1Access. 2716.2Facilities. 2716.3Site specific requirements. 2717Verification of specified performance. 2817.1General. 2817.2Works tests. 2817.3Tests during installation and commissioning. 2817.4Technical conditions for trial run. 2817.5Functional and performance tests. 29Annex A (informative)

Bibliography. 30SIST EN 45510-2-5:2003

- 5 -EN 45510-2-5:2002Part 6-1: Turbine auxiliaries - DeaeratorsPart 6-2: Turbine auxiliaries - Feedwater heatersPart 6-3: Turbine auxiliaries - Condenser plantPart 6-4: Turbine auxiliaries - PumpsPart 6-5: Turbine auxiliaries - Dry cooling systemsPart 6-6: Turbine auxiliaries - Wet and wet/dry cooling towersPart 6-7: Turbine auxiliaries - Moisture separator reheatersPart 6-8: Turbine auxiliaries - CranesPart 6-9: Turbine auxiliaries - Cooling water systemsPart 7-1: Pipework and valves - High pressure piping systemsPart 7-2: Pipework and valves - Boiler and high pressure piping valvesPart 8-1: Control and instrumentationEN 45510-1 contains those clauses common to all the above Guides giving the provisions of a nonequipment specific nature for use in the procurement of power station plant. EN 45510 is theresponsibility of JTFPE. The so called “common clauses”, as appropriate, also appear in italics in thedocuments specific to particular equipment.In this Guide, words in bold type indicate that they have the meaning given in the definitions, clause 3.In this Guide, words and sentences not in italics are specific to this Guide and refer to the particularequipment covered.SIST EN 45510-2-5:2003

Reference should be made to IEC 60034-17.The equipment covered by this Guide is defined by its function rather than design type.

Therefore, theguidance to the specification is stated in performance terms rather than being specified by a detaileddescription of the equipment to be supplied.This Guide indicates to potential purchasers how their specification should be prepared so that:- the equipment type and capacity interfaces correctly with other elements of the systems;- predicted performance is achieved;- ancillary equipment is properly sized;- reliability, availability and safety requirements are achieved;- proper consideration is given to the evaluation process and the quality measures to be

applied.This Guide does not determine the type of specification (e.g. detailed, performance, functional) or theextent of supply for any given contract which is normally decided on the basis of the purchaser’s projectstrategy. It does not cover:- any commercial, contractual or legal issues which are normally in separate parts of an enquiry;- any allocation of responsibilities which are determined by the contract.This Guide does not prescribe the arrangement of the documents in the enquiry.NOTE

As a comprehensive European environmental policy is still under preparation, this Guide does not address the environmentalimplications of the equipment.2 Normative referencesThis Guide for Procurement incorporates by dated or undated reference, provisions from otherpublications. These normative references are cited in the appropriate places in the text and thepublications are listed hereafter. For dated references, subsequent amendments to or revisions of any ofthese publications apply to this Guide only when incorporated in it by amendment or revision. Forundated references, the latest edition of the publication referred to applies.European StandardsEN ISO 9001Quality systems - Model for quality assurance in design, development,production, installation and servicingEN ISO 9002Quality systems - Model for quality assurance in production, installation andservicingEN 45510-2-7Guide for procurement of power station equipment – Part 2-7: Electricalequipment - Switchgear and controlgearEN 45510-2-91)Guide for procurement of power station equipment – Part 2-9: Electricalequipment - Cabling systems

1) In preparation.SIST EN 45510-2-5:2003

- 7 -EN 45510-2-5:2002EN 50347General purpose three-phase induction motors having standard dimensionsand outputs - Frame numbers 56 to 315 and flange numbers 65 to 740EN 60034-1Rotating electrical machinery - Part 1: Rating and performances(IEC 60034-1, mod.)EN 60034-2Rotating electrical machines - Part 2: Methods for determining losses andefficiency of rotating electrical machinery from tests (IEC 60034-2 +IEC 60034-2A)EN 60034-5Rotating electrical machines - Part 5: Classification of degrees of protectionprovided by enclosures for rotating machines (IEC 60034-5, mod.)EN 60034-6Rotating electrical machines - Part 6: Methods of cooling rotating machineryIEC 60034-6)EN 60034-9Rotating electrical machines - Part 9: Noise limits (IEC 60034-9)EN 60034-12Rotating electrical machines - Part 12: Starting performances of single-speedthree-phase cage induction motors for up to and including 660 V and 50 Hz(IEC 60034-12, mod.)EN 60034-14Rotating electrical machines - Part 14: Mechanical vibration of certainmachines with shaft heights 56 mm and higher - Measurement, evaluation andlimits of the vibration severity (IEC 60034-14)EN 60034-15Rotating electrical machines - Part 15: Impulse voltage withstand levels ofrotating AC machines with form-wound stator coils (IEC 60034-15)EN 60034-18seriesRotating electrical machines - Part 18: Functional evaluations of insulationsystems (IEC 60034-18 series)Harmonization Documents (HD)HD 53.8Rotating electrical machines - Part 8: Terminal markings and direction ofrotation of rotating machines (IEC 60034-8)HD 566Thermal evaluation and classification of electrical insulation (IEC 60085)HD 637Power installations exceeding a.c. 1 kVInternational StandardsIEC 60034-17Rotating electrical machines - Part 17: Guide for the application of cageinduction motors fed from convertersIEC 60050-191International electrotechnical vocabulary - Chapter 191: Dependability andQuality of ServicesIEC 60050-411International electrotechnical vocabulary - Chapter 411: Rotating machines3DefinitionsFor the purposes of this Guide, the following definitions apply:3.1Organisational terms3.1.1purchaserrecipient of a product and/or a service provided by a supplierSIST EN 45510-2-5:2003

Further definitions of useful organisational terms may be found in EN ISO 8402 (see annex A).3.2 Technical termsThe technical terms applicable to the design, description, construction and performance of electricmotors are defined in IEC 60050-411 and the relevant component standards.3.3 General terms3.3.1equipmentplant, component, system and/or associated service to be provided in response to the enquiry3.3.2conformityfulfilment of specified requirements by a product, process or service3.3.3performanceobligations verified by specified tests3.3.4operating periodtime between planned outages or maintenance periods during which the equipment is in operationand/or does not restrict operational requirements of the power station3.3.5life expectancytime period over which the equipment might be expected to operate with planned maintenance butwithout replacement of a significant component. For example a rotor is a significant componentSIST EN 45510-2-5:2003

- 9 -EN 45510-2-5:20023.3.6design lifeoperating hours of the equipment on which design calculations are based3.3.7acceptabilitycompliance with criteria defined by the purchaser for assessing the suitability of equipment3.3.8equipment marginsallowance for design, fabrication or operating contingency defined in the specification. These areseparate to those normally included by the supplier for his own purposes3.3.9proven equipmentequipment which may be demonstrated to be similar to that offered and has operated for a sufficienttime to have demonstrated performance and availability3.3.10availabilityas defined in IEC 60050-1913.3.11reliabilityas defined in IEC 60050-1913.3.12maintainabilityas defined in IEC 60050-1914Brief overall project description4.1Role and organisation of purchaserThe enquiry should define the purchaser’s role in the project, including whether the purchaser willassume responsibility for the planning and technical coordination of the project, or whether otherorganisations will be appointed to carry out all or part of this function. The enquiry should define allorganisational interfaces and the procedures to be employed for managing the contract and the site.4.2Site locationThe specification should describe the geographical location of the site which may include surveyingpoints, the previous use of the site and any local features such as impact of industrial or military activitiesand planning restrictions.Where applicable, the specification should indicate site datum on specification drawings and specifysite and drawing orientation and define co-ordinate axes (x,y,z) and numbering order to ensureconsistency between suppliers of connected equipment.Where appropriate, the specification should define the permitted ground loading, dimensional and timerestrictions on access routes up to but not including public roads or railways.The specification should identify, where appropriate, the environment of the site in which theequipment will operate. The following factors may normally be included if appropriate:-climatic e.g. atmospheric pressure, annual variation of air and cooling water temperature, relativehumidity, rain fall, icing, snow, wind velocity (normal and maximum), lightning;SIST EN 45510-2-5:2003

plant, a modification to an existing powergenerating plant or replacement equipment.Where appropriate, the specification should define the function and the known limitations, if any, in theequipment connected to that which is being supplied so that the equipment may avoid imposingadverse conditions or the supplier may suggest modifications to connected equipment which wouldensure satisfactory operation.4.4Equipment to be purchasedThe specification may define the equipment type or arrangement to be purchased.For example, the purchaser may specify: synchronous or asynchronous (induction) motor.The specification may state any preferences with regard to the extent of the supply.

For example, thePurchaser may wish to include an integral or separate bearing lubricating system.The specification may state requirements for the type of enclosure selected, particularly if the motor isto be installed in a hazardous area.The specification may also define preferences for equipment types (or give information) regardingcompatibility with existing equipment, if required.The specification should define the intended methods or local practice for maintenance, inspection andoperation.The specification should define requirements with regard to the general appearance of the equipment(e.g. dimensions, shape or colour) to meet local planning requirements or specific criteria, where suchrequirements exist.NOTE

Attention is drawn to European, national and/or local legislation which may place restrictions in this area.4.5Control and instrumentationThe specification should define the general requirements for the control and instrumentation system, thelevel of operator intervention allowed or required, integration with other control systems, localised controlloops, commonality and redundancy.NOTE

Guidance on the procurement of control and instrumentation systems for power stations, including advice on interfaces, can befound in EN 45510-8-1.4.6 Electrical supplies and other servicesThe specification should define the electrical supplies available for the operation of the equipment, theirvoltages and frequencies, with their range of variation, phases available and, where appropriate, theacceptable values of maximum load (kW) and short circuit level at each voltage level and the harmoniccontent. Requirements for terminals and terminal boxes should be stated; these should be to arecognised European or international standard.SIST EN 45510-2-5:2003

- 11 -EN 45510-2-5:2002The specification should define the type and capacity of other services for the operation of theequipment such as service fluids.4.7 Other interfacesThe specification should define the interfaces with existing ancillary or new ancillary equipment to besupplied under separate contracts which interact directly with the equipment.For example, protection, metering, cabling, auxiliary electrical systems, civil works, cranage, ortemporary systems.4.8Project programmeThe specification should describe the overall programme and timescale in which the project is to becarried out.

This may include the principal dates associated with tendering, placement of orders, accessto site, start and completion of installation, commissioning, take-over and final acceptance.4.9Equipment identification systemsThe specification may specify the equipment identification system for use during the operating life of theplant.

If applicable to the project, a recognised European or international system should be used.5Extent of supplyThe specification should define the extent of supply of all the equipment.This may include the motor(s) with its main and auxiliary terminal boxes (if applicable), earth terminal,anti-condensation heaters, temperature detectors and/or other condition monitoring devices (ifapplicable).For synchronous motors, integral field excitation systems should be included, but if a separate excitationpackage is required it should be clearly stated.For machines with oil lubricated plain bearings, the specification should state if the oil supply is to be:-self contained (if technically possible),-provided from a separately mounted oil conditioning unit, or-provided from a source outside the scope of supply. In this case, the specification should state theoil grade, temperature, viscosity and available flow rate which may be subject to agreement.The extent of supply may also include spare parts, installation and maintenance manuals, test reports,other specified documentation, transportation, installation and commissioning. The shaft coupling isnormally outside the scope of the motor manufacturers supply.If the motor is to be subjected to external thrust loading, the specification should define whether aspecial thrust bearing is to be included.Unless otherwise specified or agreed the supplier should provide first fillings of all fluids to be used inthe equipment.Consideration should also be given to the Guide for Procurement on Switchgear prEN 45510-2-7 where,for example, a motor control centre or AC distribution switchgear, is required, or to the Guide forProcurement on Cabling Systems prEN 45510-2-9 where, for example, local cabling is required.SIST EN 45510-2-5:2003

For example, this mayinclude a requirement for cooperation between the purchaser and supplier.

Alternatively, thespecification may define the technical information on equipment characteristics to be provided by thesupplier and the programme for its delivery.If the purchaser wishes to have a contract for electrical systems, electrical equipment, cables, etc.separate from the equipment supply contract, the specification may require the supplier to provideinformation on all the necessary interfaces (electrical loads, shaft heights, motor speeds and direction ofrotation, terminal boxes, etc.). Provision may need to be made in the contract for cooperation betweenpurchaser and supplier for system(s) to be developed or the specification may define the technicalinformation to be provided by the supplier and the programme for its delivery.Similar provisions may be made for other services, etc.The extent of supply may include training, technical and layout studies, requirements for cooperation withthe purchaser and/or other suppliers and information on necessary interfaces, if any.The specification should define the requirements with regard to weather protection, the surface finish(e.g. painting), thermal insulation, noise insulation or cladding, etc.The specification may require that all parts of the equipment should be protected at all stages ofdelivery, storage and installation. Subsequent to final manufacture all equipment items should beprotected against deterioration due to corrosion.The specification may also define exclusions, for example civil works such as buildings, foundations,structures and equipment obtained separately by the purchaser.The specification may indicate the acceptability of alternative offers being included in the tender.6Terminal pointsThe specification should define the main process input and output terminal points such that the functionand performance of the equipment and its major components, e.g. as defined in the extent of supply,may be demonstrated to meet the requirements of the purchaser.The specification should define the motor supply boundaries which should normally include but extendno further than: the shaft end(s), with tongued and grooved or oil-pressure joint, as appropriate; the main and auxiliary terminal boxes (including handing); the mounting feet for horizontal foot mounted motors; the flange(s) or skirt(s) for vertical shaft motors (some small horizontal shaft motors may be flangemounted); the pipe flanges for input and output of cooling water and lubricating oil as appropriate; foundation plate (if required) together with mounting materials; mounting and alignment plates and auxiliaries; coupling and coupling guard; lifting devices, including position and type; connections to cooling and lubrication sources.SIST EN 45510-2-5:2003

- 13 -EN 45510-2-5:2002The specification should also define terminal points for existing or proposed services, support structuresor civil works. These may, for example, include ancillary services, control and instrumentation system,heating and ventilation systems, cranage, general access arrangements and fire fighting systems.It may be necessary for design and analytical work to extend beyond the physical terminal points. Thespecification should define such requirements, if any.7Operational requirements7.1 Operating environmentThe specification should describe the operating environment in which the equipment will be required tofunction. Factors such as temperature, humidity, extent of weather protection, dust, vibration andelectromagnetic environment (this may include both emission and immunity requirements) should beincluded for both normal and abnormal conditions by reference to the EN 60034 series of standards. Thetype of installation, whether indoor or outdoor, should be stated.The specification should also state the policy in the following operational areas:-risks e.g. loss of electrical supplies, loss of cooling systems, dust or water ingress, explosions orovervoltage surges;-obligations e.g. noise limits;-restrictions e.g. waste disposal, oil spillage.7.2Manning levelsThe specification should define the power station manning levels where they may influence theequipment supply.7.3 Normal operationThe specification should define in broad terms the expected normal operation of the power station andof the equipment.7.4 Operating hoursThe specification should define the total life time required of the power station and the equipment (e.g.hours) and the required operating period of the equipment.7.5 Start-up and shut-downThe specification should identify specific duties of the driven plant where these could influence theselection of motors (e.g. base load, peak load, start up/shut down requirements, standby, etc.).Refer also to 8.1.The specification should define the expected changeover strategy where standby equipment orbypasses are provided.7.6Abnormal conditionsThe specification should provide information on the known abnormal conditions to which the equipmentmight be subjected. The supplier should take these into account in the design or selection ofcomponents/materials.The specification should identify where motor operating modes may be linked to fast transfer of supplysystems and advise of any special requirements for the motors under such conditions.SIST EN 45510-2-5:2003

GeneralThis should be a specific period which takes into account the anticipated operating regime andrecommended maintenance and will broadly equate to the stated operating hours (see 7.4).The specification should define the design life of components which may be subject to periodicreplacement.The supplier should define limitations on equipment life, if any, and these should be included in thetender evaluation process.8.1.2

Number of start-up and shut-down cyclesThe specification should include an estimate of the number of cycles to which the equipment will besubjected.The specification should state the number of starts required per year of the motor, the normaldistribution and any special starting distribution(s) which may occur during commissioning periods.8.1.3

Equipment for monitoring remaining lifeThe specification may request proposals for monitoring the remaining life of components which aresubject to fatigue, wear, erosion and/or corrosion.

In some cases specific requirements may be stated.For example: recording of the cumulative number of motor starts, incorporation of means to monitor motor circuits, (e.g. motor management schemes, protectionrelays with communications facility).8.2Components requiring periodic maintenanceThe specification should request the supplier to provide a schedule of components which requireperiodic maintenance or replacement. This should include the frequency of these operations. Thisschedule should include estimates of maintenance man-hours and cost of components. The suppliershould identify those maintenance replacement operations which require shut-down of the process morefrequently than the planned maintenance shut-downs.9Performance requirements9.1DutyThe specification should define the performance targets for the equipment at defined operating pointsand at other defined conditions. These may include efficiency and margins at full load operation andavailability. The specification may also define the flexibility requirements over the full range ofoperating conditions.SIST EN 45510-2-5:2003

- 15 -EN 45510-2-5:2002The specification should define the type of duty which the motor(s) has to perform in accordance withEN 60034-1.

This should be a statement of the load(s) to which the machine is subjected, including ifapplicable, starting, electric braking, no-load, rest and de-energised periods, including durations andsequence.The specification should state the required performance of the motor during and following specifiedsupply variations such as short time interruption, voltage unbalance or reduction, harmonics etc., wherethese are not in accordance with EN 60034-1.9.2Performance9.2.1

GeneralThe specification may define the operating points and other defined conditions at which the equipmentperformance requirements are to be demonstrated immediately after commissioning and/or at otherpoints in the life of the equipment.The specification should state the requirements for the performance of the motor during starting,operation at rated or partial loads under specified conditions.

The specification should also provideinformation on the type and characteristics of the driven machine (eg. torque/speed profile, moment ofinertia, etc.).9.2.2

Starting conditionsThe specification should provide information on: Frequency of starting: number of successive starts required under the specified conditions of load, torque, inertia andsupply, acceptable interval between starting sequences. Minimum voltage during starting: minimum value of voltage at the motor terminals during starting. Starting characteristics of cage induction and synchronous motors: method of starting, maximum permitted starting current and/or kVA, locked rotor and starting torque. Restart from any speed: assumptions to be applied to the voltage levels and times applicable, following a systemdisturbance resulting in a temporary loss of supply for a defined period, maximum permitted reacceleration time.Attention is drawn to EN 60034-1 and to EN 60034-12 for machines with a rated supply voltage of 690volts or less.9.2.3

Rated load conditionsMotors should operate within the supply variations identified in 9.1 without prejudicial overheating.The specification should state the time period for operating at rated frequency and load with a definedreduction in voltage.

The supplier should state the resulting heating in conformity with EN 60034-1 andevaluate the reliability.SIST EN 45510-2-5:2003

In theabsence of a specific request, the summation of losses method should be assumed.9.2.4

Thermal performanceThe specification should specify the minimum thermal class of insulation (e.g. Class B or F) and statethe permitted temperature rise of the windings.

The temperature rises should be selected anddetermined with reference to EN 60034-1.The specification may also require temperature rises lower than those corresponding to the selectedthermal class (eg. Class B temperature rise with Class F insulation system).In those applications where the motor temperature may be appreciably affected by conducted or radiatedheat, the conditions should be stated in the specification and appropriate temperature rises agreed withthe supplier.9.2.5

Mechanical performance Vibration levels: the permitted limits of vibration severity and method of measurement should be as detailed inEN 60034-14 unless otherwise stated. Acoustic performance: the specification should state the permitted acoustic performance of the motor.

In the absenceof specific information, the levels and method of measurement contained in EN 60034-9 should beassumed. Insulation performance: the specification should indicate the value of the maximum reference voltage Um to be used inthe choice of insulation levels in accordance with EN 60034-1; the specification should state the required time limits of motor operation with one phasegrounded either as a maximum continuous period or a cumulative period during motor lifetime.In the absence of specific insulation performance information, the recommendations of HD 566,EN 60034-1 and EN 60034-18 should be assumed.The specification may stipulate a higher test voltage than that specified in EN 60034-15.NOTE

Performance tests are sometimes conducted off site and may be carried out at

conditions different from the operating point.The results may require scaling according to agreed rules.9.3Equipment marginsThe specification should identify required equipment margins.In the absence of specific information, the schedule of tolerances on quantities involved in the rating ofelectrical machines to EN 60034-1 should be assumed.9.4AvailabilityThe specification may specify availability requirements. In order to demonstrate conformity with theserequirements, the specification may request the supplier to use data on availability, reliability andmaintainability to carry out an analysis to show that the target availability will be met.SIST EN 45510-2-5:2003

- 17 -EN 45510-2-5:20029.5Levels of component redundancyThe specification may defi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...