EN 771-1:2003

(Main)Specification for masonry units - Part 1: Clay masonry units

Specification for masonry units - Part 1: Clay masonry units

This EN specifies the characteristics and performance requirements for masonry units manufactured from clay for use in masonry construction (e.g. facing and rendered masonry, loadbearing or non-loadbearing masonry structures, including internal linings and partitions, for building and civil engineering). This EN is intended to apply to all fired-clay masonry units used in masonry construction, including those of an overall non-rectangular parallelepiped shape.

Festlegungen für Mauersteine - Teil 1: Mauerziegel

Diese Europäische Norm beschreibt die Eigenschaften von Mauersteinen aus Ton sowie die an sie gestellten Anforderungen für die Verwendung im Mauerwerk (z. B. Sichtmauerwerk und verputztes Mauerwerk, tragendes und nichttragendes Mauerwerk einschließlich innerer Verkleidungen und Trennwände von Bauwerken des Hoch- und Tiefbaus).

Diese Europäische Norm gilt für zwei Gruppen von Mauersteinen aus gebranntem Ton (Mauerziegel):

LD-Ziegel (siehe 3.4 und 5.2), d.h.:

Mauerziegel mit einer Brutto-Trockenrohdichte 1000 kg/m³ zur Verwendung in geschütztem Mauerwerk.

HD-Ziegel (siehe 3.5 und 5.3), d. h.:

a) alle Mauerziegel zur Verwendung in ungeschütztem Mauerwerk;

b) Mauerziegel mit einer Brutto-Trockenrohdichte > 1000 kg/m³ zur Verwendung in geschütztem Mauerwerk.

Diese Europäische Norm gilt ebenfalls für Mauerziegel mit einer nicht allseitig von Rechtecken begrenzten Form.

Darin werden die Produkteigenschaften unter anderem bezüglich Maßabweichungen, Festigkeit und Rohdichte, die nach den entsprechenden, in gesonderten Europäischen Normen enthaltenen Prüfverfahren bestimmt werden, definiert.

Die Konformitätsbewertung der von dieser Europäischen Norm erfassten Produkte wird festgelegt.

Enthalten ist auch die nach dieser Europäischen Norm geforderte Kennzeichnung der Produkte.

Diese Europäische Norm enthält keine genormten Größen für Mauerziegel, keine Sollmaße und keine Winkel für Formziegel.

Diese Europäische Norm gilt nicht für Pflastersteine, Steine für die Auskleidung von Rauchabzügen, geschosshohe Ziegelelemente und Ziegel mit einem Wärmedämmstoff, der auf die Seiten des Steins, die Feuer ausgesetzt sein können, aufgebracht ist. Sie gilt jedoch für Mauerziegel für Schornsteinaußenmauerwerk.

Spécifications pour éléments de maçonnerie - Partie 1: Briques de terre cuite

La présente Norme européenne spécifie les caractéristiques et les exigences de performances pour les briques de terre cuite destinées aux constructions de maçonnerie (par exemple, maçonnerie apparente et enduite, structures en maçonnerie porteuses ou non, y compris les cloisons de distribution et de doublage pour le bâtiment et le génie civil).

La présente Norme européenne est destinée à être appliquée à deux groupes de briques de terre cuite utilisées dans la construction de maçonnerie :

Les briques LD (voir 3.4 et 5.2), à savoir :

les briques de terre cuite d'une masse volumique apparente sèche inférieure ou égale à 1 000 kg/m3 utilisées pour les maçonneries protégées.

Les briques HD (voir 3.5 et 5.3), à savoir :

a) toutes les briques de terre cuite utilisées pour les maçonneries non protégées ;

b) les briques de terre cuite d'une masse volumique apparente sèche supérieure à 1 000 kg/m3 utilisées pour les maçonneries protégées.

La présente Norme européenne porte également sur les briques de terre cuite n'ayant pas une forme générale de parallélépipède rectangle.

Elle définit les performances concernant par exemple les tolérances dimensionnelles, la résistance et la masse volumique, dont le mesurage est effectué selon les méthodes d'essais correspondantes se trouvant dans des normes européennes séparées.

Elle permet d'évaluer la conformité du produit par rapport à la présente Norme européenne.

Elle inclut les prescriptions de marquage des produits qui y sont traités.

La présente Norme européenne ne spécifie pas les formats standards des briques de terre cuite, les dimensions de fabrication courantes, ni les caractéristiques d'angles des briques de terre cuite de forme particulière.

La présente Norme européenne ne couvre pas les prescriptions relatives aux éléments de pavage, conduits intérieurs de fumées, panneaux hauteur d'étage et briques de terre cuite dont les faces susceptibles d'être exposée au feu sont revêtues d'un enduit contenant un isolant th

Specifikacija za zidake – 1. del: Opečni zidaki

General Information

- Status

- Withdrawn

- Publication Date

- 15-Apr-2003

- Withdrawal Date

- 03-May-2011

- Technical Committee

- CEN/TC 125 - Masonry

- Drafting Committee

- CEN/TC 125/WG 1 - Masonry units

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 04-May-2011

- Completion Date

- 04-May-2011

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 08-Jun-2022

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 771-1:2003 is a standard published by the European Committee for Standardization (CEN). Its full title is "Specification for masonry units - Part 1: Clay masonry units". This standard covers: This EN specifies the characteristics and performance requirements for masonry units manufactured from clay for use in masonry construction (e.g. facing and rendered masonry, loadbearing or non-loadbearing masonry structures, including internal linings and partitions, for building and civil engineering). This EN is intended to apply to all fired-clay masonry units used in masonry construction, including those of an overall non-rectangular parallelepiped shape.

This EN specifies the characteristics and performance requirements for masonry units manufactured from clay for use in masonry construction (e.g. facing and rendered masonry, loadbearing or non-loadbearing masonry structures, including internal linings and partitions, for building and civil engineering). This EN is intended to apply to all fired-clay masonry units used in masonry construction, including those of an overall non-rectangular parallelepiped shape.

EN 771-1:2003 is classified under the following ICS (International Classification for Standards) categories: 91.100.25 - Terracotta building products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 771-1:2003 has the following relationships with other standards: It is inter standard links to EN 771-1:2011, EN 15037-3:2009+A1:2011, EN 771-1:2003/A1:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 771-1:2003 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/116. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 771-1:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Specification for masonry units - Part 1: Clay masonry unitsSpécifications pour éléments de maçonnerie - Partie 1: Briques de terre cuiteFestlegungen für Mauersteine - Teil 1: MauerziegelTa slovenski standard je istoveten z:EN 771-1:2003SIST EN 771-1:2004en91.100.25ICS:SLOVENSKI

STANDARDSIST EN 771-1:200401-januar-2004

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 771-1April 2003ICS 91.100.25English versionSpecification for masonry units - Part 1: Clay masonry unitsSpécifications pour éléments de maçonnerie - Partie 1:Briques de terre cuiteFestlegungen für Mauersteine - Teil 1: MauerziegelThis European Standard was approved by CEN on 2 October 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovakia, Spain, Sweden, Switzerland and UnitedKingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2003 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 771-1:2003 E

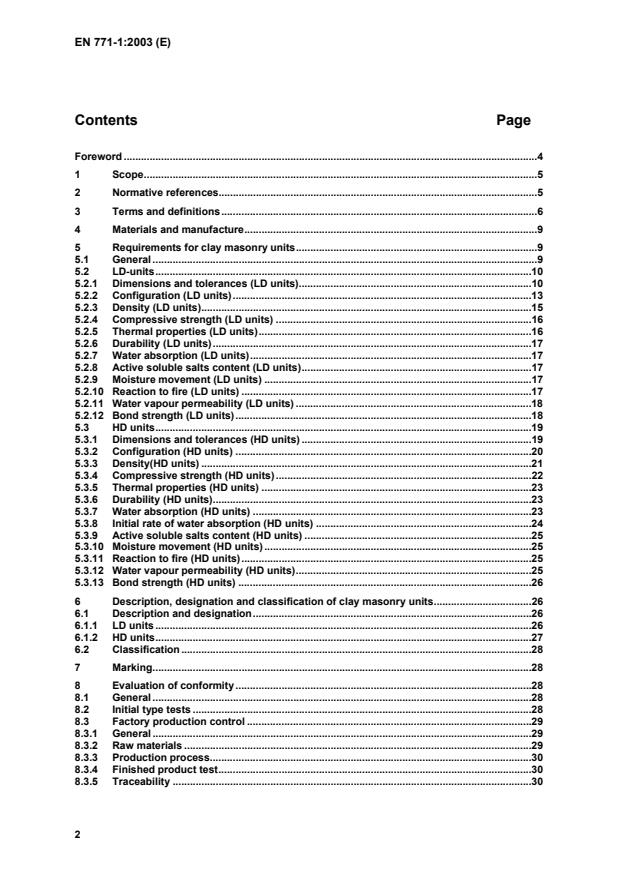

Sampling for initial type testing and for independent testing ofconsignments.31A.1General.31A.2Sampling procedure.31A.2.1Random sampling.31A.2.2Representative sampling.31A.2.3Dividing the sample.32A.2.4Number of units required for testing.32Annex B (informative)

Additional information.35B.1The use of clay masonry units.35B.2Durability.36B.3Freeze/thaw resistance.36B.3.1General.36B.3.2Masonry subjected to severe exposure.37B.3.3Masonry subjected to moderate exposure.37B.3.4Masonry subjected to passive exposure.37B.4Sulfate action on mortars and plasters.37B.5Efflorescence and staining.38B.6General guidance on the appearance of facing clay masonry units.38Annex C (normative)

Determination of water absorption.39Annex ZA (informative)

Clauses of this European standard addressing the provisions ofthe EU Construction Products Directive.40

handling the masonry unit3.19shellperipheral material between a perforation and the surface of a masonry unit3.20websolid material between the perforations in a masonry unit3.21declared valuevalue that a manufacturer is confident in achieving, bearing in mind the precision of test and thevariability of the manufacturing process3.22mean compressive strength of masonry unitsarithmetic mean of the compressive strengths of masonry units3.23normalised compressive strengthcompressive strength of masonry units converted to the air dry compressive strength of an equivalent100 mm wide ´ 100 mm high masonry unitNOTESee the procedure given in Annex A of EN 772-1: 20003.24damp proof course unitclay masonry unit which when laid in two courses with broken bond in a strong cementitious mortar,will resist rising damp in masonry3.25high precision clay masonry unitclay masonry unit with small dimensional tolerance especially in unit height3.26vertically perforated or hollow clay masonry unitclay masonry unit with one or more formed voids that pass completely through a masonry unit per-pendicular to the bed face3.27horizontally perforated or hollow clay masonry unitclay masonry unit with one or more formed voids that pass completely through a masonry unit parallelto the bed face3.28clay masonry unit for concrete or mortar infillclay masonry unit with special perforation suitable for concrete or mortar infill

Length2

Width3

Height4

Bed5

Face6

HeaderNOTEThis relates to the normal use of the masonry unit in the wall.Figure 1 — Dimensions and surfacesThe manufacturer shall also declare which of the tolerance categories for mean values in 5.2.1.2 theclay masonry units fulfil.When relevant to the uses for which the unit is put on the market, the manufacturer shall declarewhich of the range categories in 5.2.1.2 a given consignment of the clay masonry units fulfils.NOTE 2This additional declaration may be made for example in relation to:¾ the achievement of the required accuracy (planarity, bonds and thin layer joints) of the masonry;¾ the use of detailed project drawings to achieve these requirements.

mm or 3 mm whichever is the greaterT1+:± 0,40 dimension) size(work

mm or 3 mm for length and width whichever is thegreater and± 0,05 dimension) size(work

mm or 1 mm for the height whichever is the greaterT2:± 0,25 dimension) size(work

mm or 2 mm whichever is the greaterT2+:± 0,25 dimension) size(work

mm or 2 mm for length and width whichever is thegreater and± 0,05 dimension) size(work

mm or 1 mm for the height whichever is the greateror Tm:a deviation in mm declared by the manufacturer (may be wider or closer than theother categories).RangeWhen declared and the clay masonry units are sampled from a consignment in accordance withannex A and tested in accordance with EN 772-16 using the measurement procedure stated belowthe maximum range for any given dimension (i.e. the difference between the largest and smallestdetermined dimensions on individual units) to be found within the test sample shall be within thedeclared one of the three categories indicated below, where the value shall be rounded to whole mm:

CategoryMaximum rangeR1:0,6 dimension) size(work

mmR1+:0,6 dimension) size(work

mm for length and width and1,0 mm for the heightR2:0,3 dimension) size(work

mmR2+:0,3 dimension) size(work

mm for length and width and1,0 mm for the heightor Rm:a range in mm declared by the manufacturer (may be wider or closer than theother categories)

mm or 3 mm whichever is the greaterT2:± 0,25 dimension) size(work

mm or 2 mm whichever is the greaterOr Tm:a deviation in mm declared by the manufacturer (may be wider or closer than theother categories).RangeWhen declared and the clay masonry units are sampled from a consignment in accordance withannex A and tested in accordance with EN 772-16 using the measurement procedure stated belowthe maximum range for any given dimension (i.e. the difference between the largest and smallestdetermined dimensions on individual units) to be found within the test sample shall be within thedeclared one of the three categories indicated below, where the value shall be rounded to whole mm:CategoryMaximum rangeR1:0,6 dimension) size(work

mm

mmOr Rm:a range in mm declared by the manufacturer (may be wider or closer than theother categories)NOTEFor some types of facing masonry where different production batches are mixed to achieve an overallconsistent appearance, the category Rm may be satisfactory.Measurement procedureThe following measurement procedure shall be used:¾ when at least two of the work dimensions of the unit are not greater than 250 mm, 125 mm and100 mm for length, width and height respectively procedure b as described in EN 772-16:2000shall be followed using a calliper with overlapping jaws with the jaws aligning with the dotted linesin Fig. 1 b) of EN 772-16:2000 with the exception for the measurement of the height which isdetermined as the average of two measurements, where the second measurement is transverseto the dotted line at the middle of the unit. The width of the jaws shall be not less than 5 and notgreater than 10 mm.¾ for all other units procedure a as described in EN 772-16:2000 shall be followed.5.3.2 Configuration (HD units)a. Solid unitb. Frogged unitc. Vertically perforated unitd. Vertically perforated unite. Vertically perforated unitFigure 3 — Examples of HD unitsThe shape of a clay masonry unit and the directions and percentage of voids shall be declared by themanufacturer.The total volume of frogs shall not exceed 20% of the overall volume of the unit,i.e. length ´ width ´ height.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...