EN 15037-3:2009+A1:2011

(Main)Precast concrete products - Beam-and-block floor systems - Part 3: Clay blocks

Precast concrete products - Beam-and-block floor systems - Part 3: Clay blocks

This European Standard deals with the requirements and the basic performance criteria for blocks made in clay, used in conjunction with precast concrete beams in compliance with EN 15037-1, with or without cast-in-situ concrete for the construction of beam-and-block floor and roof systems.

Examples of typology of floor and roof systems are given in Annex B of EN 15037-1:2008.

Betonfertigteile - Balkendecken mit Zwischenbauteilen - Teil 3: Keramische Zwischenbauteile

Diese Europäische Norm legt die Anforderungen und die grundlegenden Leistungskriterien für keramische

Zwischenbauteile fest, die zusammen mit vorgefertigten Betonbalken nach EN 15037-1 mit oder ohne

Ortbeton zur Herstellung von Balkendecken mit Zwischenbauteilen sowie von Dachsystemen verwendet

werden.

EN 15037-1:2008, Anhang B enthält eine Übersicht über die verschiedenen Typen von Decken- und

Dachsystemen.

Produits préfabriqués en béton - Systèmes de planchers à poutrelles et entrevous - Partie 3: Entrevous en terre cuite

La présente Norme européenne spécifie les prescriptions et les critères de performance de base des entrevous fabriqués en terre cuite, utilisés conjointement avec des poutrelles préfabriquées en béton conformes à l’EN 15037-1, avec ou sans béton coulé en place, pour la construction de systèmes de planchers et de toitures à poutrelles et entrevous.

Des exemples de typologie de systèmes de planchers et de toitures sont donnés dans l’Annexe B de l’EN 15037-1:2008.

Montažni betonski izdelki - Stropni sistemi iz nosilcev in polnil - 3. del: Keramična polnila

Ta evropski standard obravnava zahteve in osnovna merila za zmogljivost za keramična polnila, ki se uporabljajo v povezavi z montažnimi betonskimi nosilci v skladu z EN 15037-1, z ulivanjem betona in-situ za gradnjo talnih in stropnih sistemov iz nosilcev in polnil ali brez njega.

Primeri tipologije talnih in stropnih sistemov so podani v dodatku A EN 15037-1:2008.

General Information

- Status

- Published

- Publication Date

- 22-Feb-2011

- Withdrawal Date

- 29-Apr-2012

- Technical Committee

- CEN/TC 229 - Precast concrete products

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 23-Feb-2011

- Completion Date

- 23-Feb-2011

- Directive

- Harmonized Standard305/2011 - Regulation (eu) No 305/2011 of the European Parliament and of the Council of 9 march 2011 laying down harmonised conditions for the marketing of construction products and repealing council directive 89/106/eecOJ Ref: C 259, C 259, C 259, C 259, C 259, C 259, C 259, C OJ Date: 08-Aug-2014

Not Harmonized89/106/EEC - Construction productsOJ Ref: C 246, C 246, C 246, C 246, C 246, C 246, C 246, C OJ Date: 24-Aug-2011

Relations

- Merged From

EN 15037-3:2009 - Precast concrete products - Beam-and-block floor systems - Part 3: Clay blocks - Effective Date

- 19-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 15037-1:2008 - Precast concrete products - Beam-and-block floor systems - Part 1: Beams - Effective Date

- 28-Jan-2026

Overview

EN 15037-3:2009+A1:2011 is the CEN European Standard that defines requirements and basic performance criteria for clay blocks used in beam-and-block floor and roof systems together with precast concrete beams (see EN 15037-1). The standard covers material, production and finished-product requirements, relevant test methods, conformity assessment and CE marking rules for clay blocks intended for structural or non‑structural use in beam-and-block systems.

Keywords: EN 15037-3, clay blocks, beam-and-block floor systems, precast concrete, CEN, CE marking, conformity

Key topics and technical requirements

- Scope and product types: Defines low non‑resisting (LNR/NR), semi‑resisting (SR) and resisting clay blocks and their intended roles in floor/roof systems.

- Material and production: Requirements for raw clay materials and factory production control (FPC) to ensure consistent block quality.

- Finished product properties:

- Geometrical properties: dimensions, nib width/depth, top flange thickness, flatness and straightness.

- Surface characteristics: tolerances and surface finish relevant to installation and bonding with concrete topping.

- Mechanical resistance: tests for concentrated load resistance, bending strength, longitudinal compression and transverse strength for resisting and semi‑resisting blocks.

- Durability: resistance to environmental conditions relevant to long-term performance.

- Fire, thermal and acoustic properties: reaction/resistance to fire, thermal design values and acoustic performance (airborne/impact).

- Test methods: Detailed procedures for measuring dimensions, void content, density, moisture expansion and mechanical tests.

- Conformity & marking: Initial type testing, factory production control, inspection schemes (Annex B) and CE marking information (Annex ZA) aligned with the Construction Products Directive.

Applications and users

EN 15037-3 is intended for:

- Precast clay-block manufacturers implementing factory production control and preparing technical documentation for CE marking.

- Structural and design engineers specifying beam-and-block floor and roof systems using clay blocks in compliance with Eurocodes (EN 1992 series) and EN 15037 family.

- Contractors and installers selecting appropriate block types (NR, SR, resisting) for construction sequences and cast-in-situ topping requirements.

- Testing laboratories and conformity assessors performing initial type tests and batch inspections.

Practical uses include specification, procurement and quality assurance of clay block components for residential and commercial floor/roof systems, ensuring compatibility with precast beams and compliance with EU requirements.

Related standards

- EN 15037-1, EN 15037-2, EN 15037-4, prEN 15037-5 (beam-and-block system parts)

- EN 13369 (common rules for precast concrete products)

- EN 1992 (Eurocode 2 design references), EN 206-1, EN 13670

- Test references: EN 771-1, EN 772 series, EN 1745, EN 12390-4, EN 13501-1, EN ISO 717 series

This standard helps align product performance, testing and CE marking for clay blocks within the precast beam-and-block system supply chain.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 15037-3:2009+A1:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Precast concrete products - Beam-and-block floor systems - Part 3: Clay blocks". This standard covers: This European Standard deals with the requirements and the basic performance criteria for blocks made in clay, used in conjunction with precast concrete beams in compliance with EN 15037-1, with or without cast-in-situ concrete for the construction of beam-and-block floor and roof systems. Examples of typology of floor and roof systems are given in Annex B of EN 15037-1:2008.

This European Standard deals with the requirements and the basic performance criteria for blocks made in clay, used in conjunction with precast concrete beams in compliance with EN 15037-1, with or without cast-in-situ concrete for the construction of beam-and-block floor and roof systems. Examples of typology of floor and roof systems are given in Annex B of EN 15037-1:2008.

EN 15037-3:2009+A1:2011 is classified under the following ICS (International Classification for Standards) categories: 91.100.30 - Concrete and concrete products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15037-3:2009+A1:2011 has the following relationships with other standards: It is inter standard links to EN 15037-3:2009, EN ISO 10140-5:2021, EN 772-19:2000, EN 771-1:2003, EN ISO 717-2:2020, EN ISO 10140-3:2021, EN 772-9:1998, EN 12390-4:2000, EN ISO 717-1:2020, EN 1745:2020, EN 772-3:1998, EN 13501-1:2018, EN 13369:2004, EN ISO 16119-5:2023, EN 15037-1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15037-3:2009+A1:2011 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/100. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15037-3:2009+A1:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.SROQLODBetonfertigteile - Balkendecken mit Zwischenbauteilen - Teil 3: Keramische ZwischenbauteileProduits préfabriqués en béton - Systèmes de planchers à poutrelles et entrevous - Partie 3: Entrevous en terre cuitePrecast concrete products - Beam-and-block floor systems - Part 3: Clay blocks91.100.30Beton in betonski izdelkiConcrete and concrete products91.060.30Stropi. Tla. StopniceCeilings. Floors. StairsICS:Ta slovenski standard je istoveten z:EN 15037-3:2009+A1:2011SIST EN 15037-3:2009+A1:2011en,fr,de01-maj-2011SIST EN 15037-3:2009+A1:2011SLOVENSKI

STANDARDSIST EN 15037-3:20091DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15037-3:2009+A1

February 2011 ICS 91.100.30 Supersedes EN 15037-3:2009English Version

Precast concrete products - Beam-and-block floor systems - Part 3: Clay blocks

Produits préfabriqués en béton - Systèmes de planchers à poutrelles et entrevous - Partie 3: Entrevous en terre cuite Betonfertigteile - Balkendecken mit Zwischenbauteilen - Teil 3: Keramische Zwischenbauteile This European Standard was approved by CEN on 25 January 2009 and includes Amendment 1 approved by CEN on 10 January 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15037-3:2009+A1:2011: ESIST EN 15037-3:2009+A1:2011

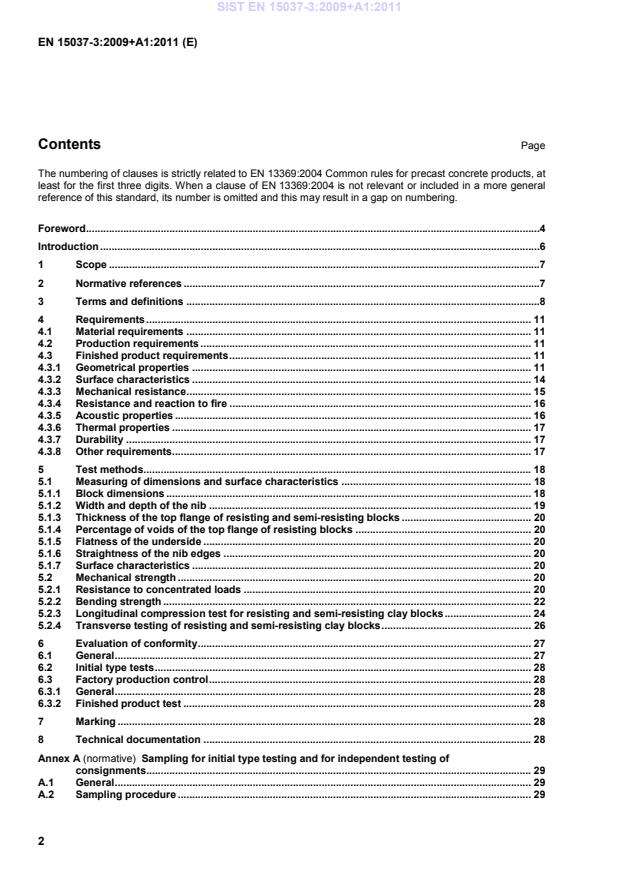

Sampling for initial type testing and for independent testing of consignments . 29A.1 General . 29A.2 Sampling procedure . 29SIST EN 15037-3:2009+A1:2011

Inspection schemes for clay blocks . 31Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive . 33ZA.1 Scope and relevant characteristics . 33ZA.2 Procedure for attestation of conformity of clay blocks for beam-and-block floor systems . 35ZA.2.1 System of attestation of conformity . 35ZA.2.2 EC Certificate and Declaration of conformity . 35ZA.3 CE marking and labelling. 36ZA.3.1 General . 36ZA.3.2 Simplified label . 37ZA.3.3 Information to be provided with the CE marking . 38Bibliography . 40 SIST EN 15037-3:2009+A1:2011

Figure 1 — Examples of semi-resisting clay blocks 3.3 resisting block block with the same functions as semi-resisting blocks but whose top flange can, under certain conditions, play a role as compression slab in the final floor system (designated RR)

Figure 2 — Example of resisting clay blocks 3.4 nib shape given to the block so that it will bear on the beam 3.5 longitudinal block block where the axis of the perforations are parallel to the beam SIST EN 15037-3:2009+A1:2011

Key 1 web 6 depth of the nib 2 overall length 7 overall width 3 flange (top part of the block) 8 overall height 4 height to nib 9 direction of the beam 5 width of the nib

Figure 3 — Example of a longitudinal block NOTE The flange in the top part of the block may be partially opened. 3.6 transverse block block where the axis of the perforations are perpendicular to the beam NOTE An example of a transverse block is given in Figure 4. SIST EN 15037-3:2009+A1:2011

Key 1 web 6 depth of the nib 2 overall length 7 overall width 3 flange (top part of the block) 8 overall height 4 height to nib 9 direction of the beam 5 width of the nib

Figure 4 — Example of a transverse block NOTE The flange may be partially opened. 3.7 !!!!open block or open clay shell"""" !low non-resisting or non-resisting block" or semi-resisting block without top flange NOTE An example of an open block is given in Figure 5.

Figure 5 — Example of open block 3.8 gross dry density mass per unit gross volume after drying to constant mass 3.9 complementary block block of shorter length, width or height designed to aid the construction of floors having dimensions which are not multiples of the dimensions of blocks SIST EN 15037-3:2009+A1:2011

2,5 % of the declared value. NOTE Lower range may be declared by the manufacturer. 4.3.1.3 Minimum dimensions 4.3.1.3.1 General The dimensions shall be verified according to 5.1.1. The effective width (minimum bearing width for support on precast beams) of clay block nib shall be greater than: minimum dimensions Class N1: 15 mm; minimum dimensions Class N2: 20 mm; minimum dimensions Class N3: 25 mm. 4.3.1.3.2 Top flange of resisting blocks The top flange of clay resisting blocks shall be at least: top flange Class TF1: 30 mm thick !deleted text"; top flange Class TF2: 50 mm thick. !The minimum thickness of the horizontal web, the shell of top flange given in Figure 6 and the percentage and dimensions of voids in the top flange shall be declared by the manufacturer." When relevant to the uses also the actual thickness of the top flange shall be declared. SIST EN 15037-3:2009+A1:2011

!Minimum dimensions in millimetres" !

" !!!!Key 1 ≥ 30 (class TF1) or 50 (class TF2)" Figure 6 — Minimum thickness of top flange of resisting blocks (hatched surface) NOTE The clay blocks may have grooves on both sides and on the top and bottom shells. 4.3.1.4 Nominal configuration of blocks The nominal values for the shape shown on Figure 7 shall be declared.

Key 1 width (l) 5 width of the nib 2 height (h) 6 depth of the nib 3 length (L) 7 horizontal part of the slope 4 height to nib

Figure 7 — Nominal dimensions declared for blocks When relevant to the uses for which the blocks are put on the market the following shall also be declared: SIST EN 15037-3:2009+A1:2011

a) section b) block with single recess Figure 8 — Example of clay block with single recess

a) section b) block with double recess Figure 9 — Example of clay block with double recesses 4.3.2 Surface characteristics Blocks shall not have cracks or spalling which may be detrimental to their mechanical performance. For test method see 5.1.7. SIST EN 15037-3:2009+A1:2011

!EN ISO 10140-3". It shall be expressed in the third octave bands 100 Hz to 3 150 Hz and as a single number quantity with spectrum adaptation terms according to EN ISO 717-1. The impact sound insulation of a product shall be estimated by calculation or measured according to

!EN ISO 10140-5". It shall be expressed in the third octave bands 100 Hz to 3 150 Hz and as a single number quantity with spectrum adaptation terms according to EN ISO 717-2. When sound insulation values are estimated by calculation, details of the calculation models and the input data shall be provided. Complementary information may be found in the relevant standards. Estimates by calculation may be performed according to EN 12354-1:2000, Annex B and EN 12354-2:2000, Annex B. SIST EN 15037-3:2009+A1:2011

Figure 10 — Measurement of width b) Length Take the two measurements as shown in Figure 11. SIST EN 15037-3:2009+A1:2011

Figure 11 — Measurement of length c) Height Take the two measurements as shown in Figure 12.

Figure 12 — Measurement of height 5.1.1.3 Interpretation of results Calculate the length, width and height for the sample as the mean of the values of the individual specimens. All !results" shall comply with the requirements of 4.3.1, and the values declared by the manufacturer, within the tolerances given in 4.3.1.2.1. NOTE Measurements shown in Figures 10 to 12 may refer to different nominal values. 5.1.1.4 Test report !All the measured dimensions and the calculated dimensions such as length, width and height of the sample shall be recorded." 5.1.2 Width and depth of the nib Place the block on a level horizontal surface (the flatness shall be controlled). Take two measurements: one in the middle of each side. Repeat the operation to measure depth. For blocks with asymmetric nib, take two measurements on each side. SIST EN 15037-3:2009+A1:2011

Figure 13 — Measurement of thickness of the top flange 5.1.4 Percentage of voids of the top flange of resisting blocks The measurements shall be done according to EN 772-3 or EN 772-9. 5.1.5 Flatness of the underside When required, the general flatness of the underside is to be tested, preferably using a gauging rod, this being placed at successive pairs of points at the ends of the underside. It shall be measured to an accuracy of 0,5 mm. The deviation is given by the difference between the maximum and the minimum distances between the gauging rod and the underside. 5.1.6 Straightness of the nib edges When required, the straightness of each of the nib edges is to be checked, preferably using a gauging rod, this being placed at the ends of the nibs, first in the horizontal plane and then in the vertical plane. It shall be measured to an accuracy of 0.5 mm. The deviation is given by the difference between the maximum and the minimum distances between the gauging rod and the edge. 5.1.7 Surface characteristics The surface appearance of blocks shall be inspected visually. Defects likely to be detrimental to their mechanical performance shall be rejected. 5.2 Mechanical strength 5.2.1 Resistance to concentrated loads 5.2.1.1 General The test method given in the next paragraph shall apply to determine the characteristic resistance to concentrated loads of clay blocks. SIST EN 15037-3:2009+A1:2011

Key 1 fixed support 2 load P 3 adjustable support Figure 14 — Concentrated load test on clay blocks 5.2.1.4 Interpretation of test results The characteristic resistance to concentrated loads, PRk, shall be verified in accordance with the procedure described in Table 3. The declared value for PRk may be greater than the minimum value of characteristic failure load defined in Table 1 for the type of block concerned. SIST EN 15037-3:2009+A1:2011

Key 1 central line load 2 hinged support Figure 15 — Test arrangement for determining the failure load 5.2.2.3 Evaluation Single values shall be given to the nearest 0,05 kN. 5.2.2.4 Test report The test report shall contain the following information: manufacturing plant; type of blocks (LNR, NR, SR or RR); date of manufacture or some other code; laboratory and person in charge of testing; date and place of testing; test method; failure load value of the samples; a statement that the tests were carried out in compliance with this European Standard. SIST EN 15037-3:2009+A1:2011

Figure 16 — Longitudinal compression test on clay resisting or semi-resisting blocks Before the test, the upper and lower faces of the test piece shall be made parallel. They shall have no unevenness in excess of 0,5 mm. To ensure a uniform load distribution over the block, either a spreader plate (cardboard, PTFE etc.) or corrective action (mortar or sulphur capping, grinding etc.) should be used. The load, Q, is applied as shown in Figure 17 and is increased gradually up to failure of the specimen. The loading rate shall not be greater than 2 MPa/s. SIST EN 15037-3:2009+A1:2011

Key 1 rigid plate for uniform spreading of load 3 test piece 2 spreader plate, if necessary 4 test machine bed Figure 17 — Longitudinal compression test - method for applying load The failure load, QR, shall be recorded. The results from the resistance to concentrated loads tests may be used to determine the longitudinal compressive strength after correlation by means of laboratory tests (at least 35). 5.2.3.3 Interpretation of test results The characteristic longitudinal compressive !stress", fbk, shall be verified in accordance with the procedure described in Table 4. The longitudinal compressive !stress" of the samples is determined by dividing the failure load, QR, by the nominal loaded surface area, and is expressed to the nearest 0,1 MPa. The loaded surface area of the specimen, S, is the hatched area in Figure 16. Table 4 — Conformity criteria for determining !!!!the characteristic longitudinal compression stress"""" of clay blocks Production Number of blocks "n" criterion 1 criterion 2 bnf (MPa) fbi (MPa) At start 3 ≥ fbk + 4 ≥ fbk − 4 during production ≥ 15 ≥ fbk + 1,48 σ ≥ fbk − 4 where ! n is the number of blocks; bnf is the average stress of all blocks over the moving period considered, in MPa; SIST EN 15037-3:2009+A1:2011

Key 1 specimen 3 square steel plate 2 supports 4 movable bearer (to prevent torsion) Figure 18 — Principle of transve

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...