EN 15037-5:2013

(Main)Precast concrete products - Beam-and-block floor systems - Part 5: Lightweight blocks for simple formwork

Precast concrete products - Beam-and-block floor systems - Part 5: Lightweight blocks for simple formwork

This European Standard deals with the requirements and the basic performance criteria for lightweight blocks used as formwork during the construction of the floor system. The blocks are used in conjunction with precast concrete beams in compliance with EN 15037-1, with or without cast-in-situ concrete for the construction of beam-and-block floor systems.

This European Standard does not deal with blocks made in polystyrene, with or without tong, or combined with different materials where polystyrene contributes to more than 50 % of the mechanical resistance of the block. These blocks are covered by EN 15037-4, Precast concrete products — Beam-and-block floor systems Part 4: Expanded polystyrene blocks.

Examples of typology of floor systems are given in Annex B of EN 15037-1:2008.

Betonfertigteile - Balkendecken mit Zwischenbauteilen - Teil 5: Leichte Zwischenbauteile für einfache Schalungen

Diese Europäische Norm legt die Anforderungen an und die grundlegenden Leistungskriterien für Zwischen-bauteile aus Leichtwerkstoffen fest, die bei der Herstellung von Deckensystemen als Schalung verwendet werden. Die Zwischenbauteile werden zusammen mit vorgefertigten Betonbalken nach EN 15037 1 mit oder ohne Ortbeton zur Herstellung von Balkendecken mit Zwischenbauteilen verwendet.

Diese europäische Norm behandelt keine Zwischenbauteile aus Polystyrolhartschaum, mit oder ohne Zange, oder in Kombination mit unterschiedlichen Werkstoffen, bei denen der Anteil von Polystyrolhartschaum an der mechanischen Festigkeit des Zwischenbauteils mehr als 50 % beträgt. Diese Zwischenbauteile sind durch EN 15037 4, Betonfertigteile — Balkendecken mit Zwischenbauteilen — Teil 4: Zwischenbauteile aus Polystyrolhartschaum abgedeckt.

EN 15037 1:2008, Anhang B, enthält Beispiele für die verschiedenen Typen von Deckensystemen.

Produits préfabriqués en béton - Systèmes de planchers à poutrelles et entrevous - Partie 5: Entrevous légers de coffrage simple

La présente Norme européenne spécifie les prescriptions et les critères de performance de base relatifs aux entrevous fabriqués à partir de matériaux légers servant de coffrage pendant la construction du système de plancher. Les entrevous sont utilisés conjointement avec des poutrelles préfabriquées en béton conformes à l’EN 15037-1, avec ou sans béton coulé en place, pour la construction de systèmes de planchers à poutrelles et entrevous.

La présente Norme européenne ne traite pas des entrevous en polystyrène, avec ou sans languette, ou constitués de plusieurs matériaux où le polystyrène contribue pour plus de 50 % à la résistance mécanique de l’entrevous. Ces entrevous sont traités dans l’EN 15037-4, Produits préfabriqués en béton - Systèmes de planchers à poutrelles et entrevous - Partie 4 : Entrevous en polystyrène expansé.

Des exemples de typologie de systèmes de planchers sont donnés dans l’Annexe B de l’EN 15037-1 :2008.

Montažni betonski izdelki - Nosilci za stropne sisteme s polnili - 5. del: Lahki bloki za enostavne opaže

Ta evropski standard obravnava zahteve in osnovna merila učinkovitosti za lahke bloke, ki se uporabljajo kot opaži med izgradnjo talnega sistema. Bloki se uporabljajo v povezavi z montažnimi betonskimi tramovi v skladu s standardom EN 15037-1 z ali brez na gradbišču zmešanega betona za izgradnjo talnih sistemov iz tramov in blokov. Ta evropski standard ne obravnava blokov, izdelanih iz polistirena, z ali brez materiala tong, ali kombiniranih z različnimi materiali, kjer polistiren prispeva več kot 50 % mehanske odpornosti bloka. Te bloke zajema standard EN 15037-4, Montažni betonski izdelki – talni sistemi iz tramov in blokov – del 4: Razširjeni polistirenski bloki. Primeri tipologije talnih sistemov so navedeni v dodatku B standarda EN 15037-1:2008.

General Information

- Status

- Published

- Publication Date

- 30-Apr-2013

- Withdrawal Date

- 29-Nov-2013

- Technical Committee

- CEN/TC 229 - Precast concrete products

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 05-Jun-2024

- Completion Date

- 09-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 04-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN ISO 20789:2019 - Anaesthetic and respiratory equipment - Passive humidifiers (ISO 20789:2018) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 15037-5:2013 is a CEN European Standard for lightweight blocks used as simple formwork in beam-and-block floor systems. It specifies requirements, basic performance criteria and test methods for blocks used together with precast concrete beams (see EN 15037-1). The scope covers blocks with no lasting structural function (their mechanical role is limited to formwork during construction) and excludes expanded polystyrene blocks covered by EN 15037-4 where polystyrene contributes to more than 50% of mechanical resistance.

Key topics and requirements

- Materials: Permitted materials include plywood, fibreboards, OSB, polyethylene (PE), polypropylene (PP), cardboard/cellulose, GRP, polymer concrete, metals and combinations. Polystyrene is only allowed when it does not dominate mechanical resistance.

- Production rules: Only approved materials (see the standard) may be used; suitability must be established via relevant European/ISO standards or technical approvals where needed.

- Finished product requirements: Geometrical properties and production tolerances are defined; finished blocks must meet dimensional, weight and functional requirements.

- Test methods: Standardised tests cover measurement of dimensions, determination of weight, mechanical strength (including gravity loading), reaction to fire, thermal conductivity and thermal resistance of the floor system. Annexes detail sampling, test rigs, calibration and compliance criteria.

- Conformity and control: Procedures for initial type testing, factory production control (FPC) and evaluation of conformity are included to support product quality and CE marking.

- Documentation & marking: Requirements for technical documentation, marking and traceability are specified; Annex ZA links provisions to EU construction product regulatory requirements.

Applications and practical value

- Used as temporary formwork in the construction of beam-and-block floors (with or without cast-in-situ topping).

- Helps manufacturers demonstrate consistent product performance for safety, durability, thermal and fire performance.

- Enables specifiers and contractors to select lightweight blocks that comply with harmonised European rules, simplifying procurement across EU markets.

- Provides test protocols for laboratories and third-party assessors performing conformity assessment and CE marking verification.

Who uses this standard

- Precast concrete product manufacturers and lightweight block producers

- Structural and design engineers specifying beam-and-block floor systems

- Contractors and site managers implementing formwork and floor installation

- Testing laboratories, notified bodies and certification authorities

- Building control inspectors and product purchasers seeking compliance evidence

Related standards

- EN 15037-1 (beams for beam-and-block systems)

- EN 15037-4 (expanded polystyrene blocks)

- EN 13369 (common rules for precast concrete products)

- Relevant fire and thermal standards (EN 13501-1, EN 13823, EN 12667, EN ISO 11925-2)

Keywords: EN 15037-5:2013, lightweight blocks, beam-and-block floor systems, precast concrete, simple formwork, mechanical strength, reaction to fire, thermal conductivity, factory production control, CE marking.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 15037-5:2013 is a standard published by the European Committee for Standardization (CEN). Its full title is "Precast concrete products - Beam-and-block floor systems - Part 5: Lightweight blocks for simple formwork". This standard covers: This European Standard deals with the requirements and the basic performance criteria for lightweight blocks used as formwork during the construction of the floor system. The blocks are used in conjunction with precast concrete beams in compliance with EN 15037-1, with or without cast-in-situ concrete for the construction of beam-and-block floor systems. This European Standard does not deal with blocks made in polystyrene, with or without tong, or combined with different materials where polystyrene contributes to more than 50 % of the mechanical resistance of the block. These blocks are covered by EN 15037-4, Precast concrete products — Beam-and-block floor systems Part 4: Expanded polystyrene blocks. Examples of typology of floor systems are given in Annex B of EN 15037-1:2008.

This European Standard deals with the requirements and the basic performance criteria for lightweight blocks used as formwork during the construction of the floor system. The blocks are used in conjunction with precast concrete beams in compliance with EN 15037-1, with or without cast-in-situ concrete for the construction of beam-and-block floor systems. This European Standard does not deal with blocks made in polystyrene, with or without tong, or combined with different materials where polystyrene contributes to more than 50 % of the mechanical resistance of the block. These blocks are covered by EN 15037-4, Precast concrete products — Beam-and-block floor systems Part 4: Expanded polystyrene blocks. Examples of typology of floor systems are given in Annex B of EN 15037-1:2008.

EN 15037-5:2013 is classified under the following ICS (International Classification for Standards) categories: 91.100.30 - Concrete and concrete products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15037-5:2013 has the following relationships with other standards: It is inter standard links to EN ISO 11925-2:2026, EN 12390-4:2025, EN ISO 10211:2017, EN 12667:2001, EN ISO 11925-2:2020, EN 15037-1:2008, EN 13823:2010, EN 13501-1:2018, EN 13369:2013, EN ISO 20789:2019, EN ISO 10651-2:2009, EN ISO 5366:2016, EN ISO 7376:2020, EN ISO 10651-5:2021, EN ISO 17510-2:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15037-5:2013 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/100. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15037-5:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Montažni betonski izdelki - Nosilci za stropne sisteme s polnili - 5. del: Lahki bloki za enostavne opažeBetonfertigteile - Balkendecken mit Zwischenbauteilen - Teil 5: Leichte Zwischenbauteile für einfache SchalungenProduits préfabriqués en béton - Systèmes de planchers à poutrelles et entrevous - Partie 5: Entrevous légers de coffrage simplePrecast concrete products - Beam-and-block floor systems - Part 5: Lightweight blocks for simple formwork91.100.30Beton in betonski izdelkiConcrete and concrete products91.060.30Stropi. Tla. StopniceCeilings. Floors. StairsICS:Ta slovenski standard je istoveten z:EN 15037-5:2013SIST EN 15037-5:2013en,fr,de01-september-2013SIST EN 15037-5:2013SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15037-5

May 2013 ICS 91.100.30 English Version

Precast concrete products - Beam-and-block floor systems - Part 5: Lightweight blocks for simple formwork

Produits préfabriqués en béton - Systèmes de planchers à poutrelles et entrevous - Partie 5: Entrevous légers de coffrage simple

Betonfertigteile - Balkendecken mit Zwischenbauteilen - Teil 5: Leichte Zwischenbauteile für einfache Schalungen This European Standard was approved by CEN on 21 January 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15037-5:2013: ESIST EN 15037-5:2013

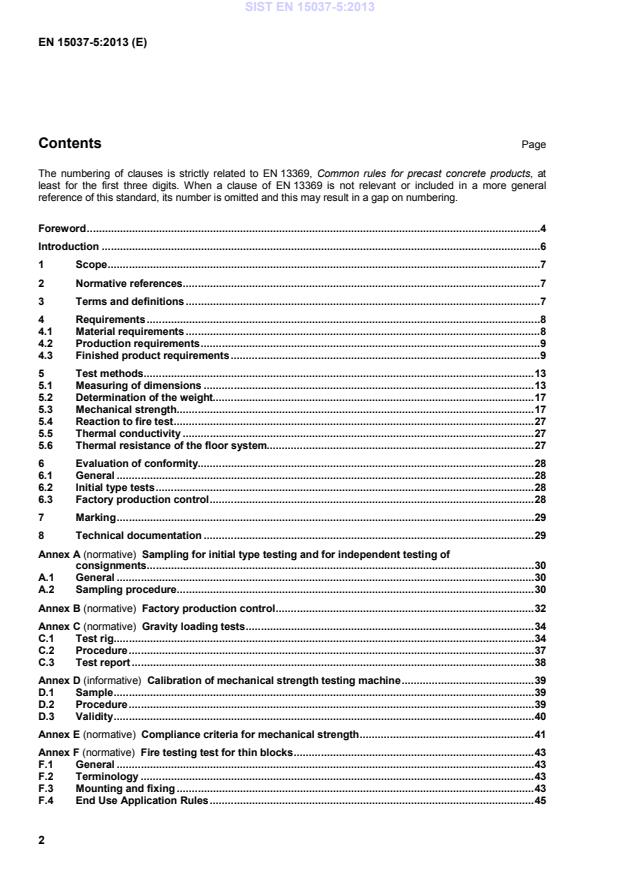

Sampling for initial type testing and for independent testing of consignments . 30 A.1 General . 30 A.2 Sampling procedure . 30 Annex B (normative)

Factory production control . 32 Annex C (normative)

Gravity loading tests . 34 C.1 Test rig . 34 C.2 Procedure . 37 C.3 Test report . 38 Annex D (informative)

Calibration of mechanical strength testing machine . 39 D.1 Sample . 39 D.2 Procedure . 39 D.3 Validity . 40 Annex E (normative)

Compliance criteria for mechanical strength . 41 Annex F (normative)

Fire testing test for thin blocks . 43 F.1 General . 43 F.2 Terminology . 43 F.3 Mounting and fixing . 43 F.4 End Use Application Rules . 45 SIST EN 15037-5:2013

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive . 48 ZA.1 Scope and relevant characteristics . 48 ZA.2 Procedure for attestation of conformity of lightweight blocks for beam-and-block floor systems. 49 ZA.3 CE marking and labelling . 55 Bibliography . 58

Note 1 to entry: Its only mechanical function is that of formwork during the construction of the floor system. Note 2 to entry: This block is mentioned in the present standard as lightweight block. See Figure 1. SIST EN 15037-5:2013

Figure 1 — Examples of lightweight blocks 3.2 cut block lightweight block, the form of which is obtained by cutting 3.3 moulded block lightweight block formed by moulding, either by injection of the material in a mould (injected blocks), or by pressing of the material in a mould (pressed block) 3.4 thin block lightweight block formed as a vault made of one or several layers of material 3.5 thick block lightweight block constituted by one or several materials, which forms a filled product 3.6 family group of products for which the test results for one or more characteristics from any one product within the family are valid for all other products within the family Note 1 to entry: The definition of the family takes into account at least a same material and a similar shape and geometry. 3.7 batch quantity of lightweight blocks defined by either a same reference of raw material, or similar parameters and conditions of manufacturing, or manufactured during the same day of production (or 24 h in case of continuous production), without exceeding a length of 10 000 m 4 Requirements 4.1 Material requirements Only materials with established suitability shall be used. Lightweight block may be manufactured from: SIST EN 15037-5:2013

Key 1 block width l 6 width of the support nib ln (when relevant) 2 block height h for blocks with a rebate or end plates for beams 7 height of the support nib hn 3 height above beam support h1 8 rebate width lr (when relevant) 4 chamfer width lc 9 rebate height hr (when relevant) 5 chamfer height hc 10 minimal thickness em for thin blocks Figure 2 — Dimensions of the lightweight block Table 1 – Dimensional tolerances Dimensions Tolerance 1 — width of the block l ± 5 mm 2 — height of the block h for blocks with rebate or end plates [- 3 mm ; + 7 mm] 3 — height above beam support h1 ± 5 mm

length of the block L (see Figure 6) ± Max [0,6 % ; 5 mm] ≤ 12 mm 4 — width of the chamfer lc ± 10 mm 5 — height of the chamfer hc ± 5 mm 6 — width of the support nib in upper part ln (when relevant) ± 3 mm 7 — height of the support nib hn [- 2 mm ; + 4 mm] 8 — width of the rebate lr (when relevant) ± 3 mm 9 — height of the rebate hr (when relevant) ± 3 mm 10 — minimal thickness em a for thin blocks [- em/10 ; + 2 mm] a Applicable on the vault and the wall(s) of the block, outside the zones where the mechanical contribution is negligible. Lower tolerances may be declared by the manufacturer.

4.3.1.1.2 Straightness Straightness shall be verified according to 5.1.2. The tolerances are: ± 1/250th of the block length in the vertical plane; SIST EN 15037-5:2013

EN 15037-1:2008 may be used (airborne and impact sound insulation). 4.3.6 Thermal properties When relevant, the λ90,90 value (thermal conductivity) and the R value (thermal resistance) and the U value (thermal transmittance) of the specified floor shall be declared. The thermal conductivity (λ90,90) shall be measured in accordance with 5.5. For the calculation of the thermal resistance of the floor (R value / U value), the non-rounded λ value may be used. A method is given in 5.6. Another method may be used, provided that the results are equivalent. If the thermal properties are calculated, the calculation assumptions for thermal resistance of floor which are given in Annex F of EN 15037-4:2010 should be used. SIST EN 15037-5:2013

National regulations on dangerous substances may require verification and declaration on release, and sometimes content, when construction products covered by this standard are placed on those markets. In the absence of European harmonised test methods, verification and declaration on release/content should be done taking into account national provisions in the place of use. NOTE An informative database covering European and national provisions on dangerous substances is available at the Construction web site on EUROPA accessed through: http://ec.europa.eu/enterprise/construction/cpd-ds/

5 Test methods 5.1 Measuring of dimensions 5.1.1 Block dimensions 5.1.1.1 General The following dimensions shall be checked with a measurement device having an accuracy of 1/5 or better of the tolerance to be checked. For irregular or ribbed surfaces, the measurement points shall be consistent with the definition of the relevant dimensions in the manufacturer documentation, except the thickness of the vault "em" to the nearest 0,1 mm. 5.1.1.2 Procedure a) Block width l Measure the width of each end section as shown in Figure 3 (the larger width).

Figure 3 — Measurement of the width of the block Calculate the width for the block as the mean of the two measurements values. The dimensions shall comply with the requirements of 4.3.1, and the values declared by the manufacturer, within the tolerances given in 4.3.1.1.1. b) Block height h (for blocks with a rebate or end plates for beams) Measure the height h of each end section as shown in Figure 4 approximately at its mid-width. SIST EN 15037-5:2013

Figure 4 — Measurement of the height of the block Calculate the height for the block as the mean of the two measurements values. The dimensions shall comply with the requirements of 4.3.1, and the values declared by the manufacturer, within the tolerances given in 4.3.1.1.1. c) Height above beam support h1 Measure the height above beam support of each end section as shown in Figure 5.

Figure 5 — Measurement of the height above beam support Calculate the height above beam support for the block as the mean of the two measurement values. The dimensions shall comply with the requirements of 4.3.1, and the values declared by the manufacturer, within the tolerances given in 4.3.1.1.1. d) Block length L Measure the length of each side as shown in Figure 6.

Figure 6 — Measurement of the length of the block Calculate the length for the block as the mean of the two measurements values. The dimensions shall comply with the requirements of 4.3.1, and the values declared by the manufacturer, within the tolerances given in 4.3.1.1.1. e) Width lc and height hc of the chamfer Measure the width and the height of each chamfer in the vicinity of each end section as shown in Figure 7. SIST EN 15037-5:2013

Figure 7 — Measurement of the width and the height of the chamfer The tolerance defined in 4.3.1.1.1 applies to each measurement result (four measurements results for width, four measurements results for height). f) Width ln and height hn of the support nib Measure the width and the height of each support nib (when relevant) in the vicinity of each end section as shown in Figure 8.

Figure 8 — Measurement of the width and the height of the support nib The tolerance defined in 4.3.1.1.1 applies to each measurement result (four measurements results for width, four measurements results for height). SIST EN 15037-5:2013

Figure 9 — Measurement of the width and the height of the rebate

The tolerance defined in 4.3.1.1.1 applies to each measurement result (four measurements results for width, four measurements results for height). h) Thickness em When relevant, measure the minimum thickness of the vault and the wall(s) at the edge of the product or if necessary in a cut section of the product. The tolerance defined in 4.3.1.1.1 applies to each measurement results. 5.1.1.3 Test report All individual measurements and the calculated values of each specimen shall be recorded. 5.1.2 Straightness Measure the straightness of the edge of each nib to the nearest 0,5 mm over their entire length, in the two directions specified in Figure 10. The bow is the maximum distance between the edge and a reference straight line (ruler, stretched wire, etc.). When relevant, the measurement in the vertical plane shall be obtained with a pressure on the top of the lightweight block which does not exceed more than 50 Newtons per meter of block length.

Key 1 measurement direction in the horizontal plane 2 measurement direction in the vertical plane Figure 10 — Measurement of straightness The tolerance defined in 4.3.1.1.2 applies to each of the four measurements results. SIST EN 15037-5:2013

Key 1 test piece 2 moulded block 3 cut or moulded block Figure 11 — Longitudinal block restraining device 2) it is possible to use a lateral block restraining device, if the manufacturer specifies in the technical documentation that lateral tightening of the beams is necessary: i) a load of 30 N/m ± 5 N/m is applied to the moving support by a reliable, manageable and traceable means; SIST EN 15037-5:2013

The loading plate may be mounted on a balls plate to reduce the effect of horizontal strength (Figure 13) determined in 5.3.3. Dimensions in millimetres

Key 1 position of the ball join Figure 12 — Rigid loading plate SIST EN 15037-5:2013

c) Balls plate d) Suspension axis Key 1 connection to the load cell 6 connection of the ball join to the rigid loading plate 2 hardened surface of the plates 7 transversal displacement ≥ 25 mm 3 balls Ø8 mm and cage thrust assembly

4 suspension axis

5 washer interdependent with the lower plate

Figure 13 — Example of balls plate The cage thrust assembly for balls shall have a diameter of minimum 80 mm. Just before the application of the load, the axis of the load cell shall be lined up with the axis of the ball join. SIST EN 15037-5:2013

If l2 ≤ 100 mm, l1 = 150 mm and if l2 > 100 mm, l1 = (l2 + 50) mm Key 1 fixed support 5 longitudinal axis of the loading plate 2 adjustable support 6 point of load application 3 loading plate 7 end view 4 distance between supports D 8 plan view Figure 14 — Plate in a longitudinal position on the block SIST EN 15037-5:2013

If l2 ≤ 50 mm, l1 = 150 mm and if l2 > 50 mm, l1 = (l2 + 100) mm. It is admitted that the loading plate can go beyond the top of the block by its larger side. Key 1 fixed support 5 transversal axis of the loading plate

2 adjustable support 6 point of load application 3 loading plate 7 end view 4 distance between supports D 8 plan view Figure 15 — Plate in a transverse position on the block SIST EN 15037-5:2013

Key 1 test specimen 2 support Figure 16 — Adjustment of support lines for block without rebate or end plates It is possible to install an angle on each support to simulate the rib of the beam. In that case, the space between the edge of the block and the angle shall be equal to 0,5 mm (see Figure 17). SIST EN 15037-5:2013

Key 1 test specimen 2 angle 3 support Figure 17 — Adjustment of support lines with angles for block without rebate or end plates If the blocks have rebates or end plates are used to position the lightweight block on the beams, the distance D between the two supports is equal to: D = d + 1 mm (1) where D is the distance between the two supports, in millimetres; d is the block width between rebates or end plates, in millimetres. The position shall be adjusted as follows: measure the width d of the bottom part of the block, adjust the support lines to the measured value increased by 1 mm (Figure 18). SIST EN 15037-5:2013

Key 1 test specimen 2 support Figure 18 — Adjustment of support lines for block with rebates or end plates 5.3.5.2 Positioning the rigid loading plate on the lightweight block In accordance with 5.3.4.2. 5.3.5.3 Loading In accordance with 5.3.4.3. 5.3.5.4 Expression of results In accordance with 5.3.4.4. 5.3.6 Interpretation of tests results The characteristic resistance to concentrated load PRk, in accordance with 4.3.3.7, shall be verified in accordance with the procedure described in Table 3. Annex E shall be used for the assessment of conformity. Table 3 — Conformity criteria for determining the characteristic resistance to concentrated load of lightweight blocks Production Number of blocks "n" criterion 1 criterion 2 nP(kN) Pi (kN) at start 5 ≥ 1,2 PRk ≥ 0,8 PRk during production ≥ 15 ≥ PRk + 1,48 σ ≥ 0,8 PRk where n is the number of individual results; nP is the average strength of the n individual results obtained: SIST EN 15037-5:2013

1) For thick blocks, EN 13823 shall apply. 2) For thin blocks, Annex F shall apply. 5.5 Thermal conductivity When relevant, EN 12667 shall apply. 5.6 Thermal resistance of the floor system When relevant, the thermal resistance of floor systems is determined by calculation. The method used shall meet the requirements of EN ISO 10211. The thermal resistance is determined from the thermal conductivity of the lightweight expressed for a mean temperature of 10 °C. SIST EN 15037-5:2013

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...