EN 15050:2007+A1:2012

(Main)Precast concrete products - Bridge elements

Precast concrete products - Bridge elements

This European Standard applies to precast concrete structural elements produced in a factory and used in bridge construction, such as deck elements.Normal weight concrete elements are considered, both reinforced and prestressed; their use can be on road bridges, railway bridges and footbridges.

Deck elements include both single elements from which the deck may be composed (beams, slabs, ribbed or cellular elements) and elements consisting of a segment of the entire deck.

Some examples of elements dealt with are shown in Annex A.

The durability aspects are also considered.

This European Standard makes reference to precast elements produced in a factory or near the construction site in a place protected from adverse weather conditions. It is assumed that if the elements are not manufactured in a factory, the production conditions assure the same level of quality control as in a factory. It is assumed that the production place is protected from rain, sunshine and wind.

Some of the elements are also treated in other European Standards (e.g. beams, slabs). This European Standard deals with the specific aspects related to the use of these elements in bridge construction.

Foundation piles, piers, abutments, barriers, bumpers, guards, arches and" box culverts are out the scope of this European Standard.

Betonfertigteile - Fertigteile für Brücken

Diese Europäische Norm gilt für im Werk hergestellte tragende Betonfertigteile zur Verwendung im Brückenbau, zum Beispiel Bauteile für den Überbau.

Es werden sowohl Stahlbeton- als auch Spannbetonbauteile aus Normalbeton zur Verwendung bei Straßen-, Eisenbahn- und Fußgängerbrücken behandelt.

Überbau Bauteile umfassen sowohl Einzelbauteile, aus denen sich der Überbau zusammensetzen lässt (Träger, Platten, gerippte oder zellenförmige Bauteile), als auch Bauteile, die einzelne Segmente des Überbaus bilden.

Einige Beispiele für Bauteile sind in Anhang A dargestellt.

Die Dauerhaftigkeit wird ebenfalls behandelt.

Diese Europäische Norm bezieht sich auf vorgefertigte Bauteile, die im Werk oder in der Nähe des Einsatzortes an einem wettergeschützten Ort hergestellt werden. Falls die Bauteile nicht im Werk gefertigt werden, müssen die Herstellungsbedingungen dergestalt sein, dass das gleiche Maß an Güteüberwachung wie im Werk sichergestellt ist. Es wird davon ausgegangen, dass der Herstellungsort vor Regen, Sonneneinstrahlung und Wind geschützt ist.

Einige der Bauteile sind auch in weiteren Europäischen Normen behandelt (z. B. Träger, Platten). Diese Europäische Norm behandelt die besonderen Aspekte, die mit der Verwendung dieser Bauteile beim Brückenbau zusammenhängen.

Gründungspfähle, Pfeiler, Widerlager, Rückhaltesysteme, Stoßfänger, Schutzeinrichtungen und Hohlkastenelemente sind nicht Gegenstand dieser Norm.

Produits préfabriqués en béton - Eléments de ponts

La présente Norme européenne s’applique aux éléments structurels préfabriqués en béton fabriqués en usine utilisés dans la construction des ponts, par exemple éléments de tablier et arches préfabriquées.

Les éléments en béton de masse volumique normale, armés ou précontraints, sont considérés ; ils peuvent être utilisés pour des ponts routiers, des ponts-rails et des passerelles.

Les éléments de tablier comprennent à la fois les éléments simples qui composent le tablier (poutres, dalles, éléments nervurés ou cellulaires) et des éléments constitués d’un tronçon de tablier complet.

texte supprimé

L’Annexe A illustre quelques exemples d’éléments traités.

Les aspects de durabilité sont également considérés.

La présente Norme européenne fait référence à des éléments préfabriqués produits en usine ou à proximité du chantier de construction, dans un lieu protégé des conditions météorologiques défavorables. On admet que, si les éléments ne sont pas fabriqués en usine, les conditions de fabrication garantissent le même niveau de contrôle de la qualité qu’en usine. On admet que le site de production est protégé de la pluie, du soleil et du vent.

Certains éléments sont également traités dans d’autres Normes européennes (par exemple poutres, dalles). La présente Norme européenne traite des aspects spécifiques relatifs à l’utilisation de ces éléments dans la construction de ponts.

Les pieux de fondation, les piles, les culées, les parapets, les dispositifs de retenue frontaux, les garde-corps, les arches et les cadres fermés sont hors du domaine d'application de la présente Norme européenne.

Montažni betonski izdelki - Elementi za mostove

Ta evropski standard se uporablja za montažne betonske strukturne elemente, ki so izdelani v tovarni in se uporabljajo pri gradnji mostov, kot so elementi prekladne konstrukcije. Zajeti so betonski elementi običajne teže, armirani in prednapeti; uporabljajo se lahko na cestnih mostovih, železniških mostovih in brveh. Elementi prekladne konstrukcije zajemajo posamezne elemente, iz katerih je lahko sestavljena prekladna konstrukcija (tramovi, plošče, rebrasti ali celični elementi), ter elemente iz segmenta celotne prekladne konstrukcije. !besedilo črtano. Nekateri primeri obravnavanih elementov so prikazani v dodatku A. Upoštevani so tudi vidiki trajnosti. Ta evropski standard se sklicuje na montažne elemente, izdelane v tovarni ali v bližini gradbišča na mestu, zaščitenem pred neugodnimi vremenskimi razmerami. Če elementi niso izdelani v tovarni, se predpostavlja, da pogoji proizvodnje zagotavljajo enako raven nadzora kakovosti kot v tovarni. Predpostavlja se, da je mesto proizvodnje zaščiteno pred dežjem, soncem in vetrom. Nekateri elementi so zajeti tudi v drugih evropskih standardih (npr. tramovi, plošče). Ta evropski standard obravnava specifične vidike v zvezi z uporabo teh elementov pri gradnji mostov.

General Information

- Status

- Published

- Publication Date

- 13-Mar-2012

- Withdrawal Date

- 29-Sep-2012

- Technical Committee

- CEN/TC 229 - Precast concrete products

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 14-Mar-2012

- Completion Date

- 14-Mar-2012

- Directive

- Harmonized Standard305/2011 - Regulation (eu) No 305/2011 of the European Parliament and of the Council of 9 march 2011 laying down harmonised conditions for the marketing of construction products and repealing council directive 89/106/eecOJ Ref: C 259, C 259, C 259, C 259, C 259, C 259, C 259, C OJ Date: 08-Aug-2014

Not Harmonized89/106/EEC - Construction productsOJ Ref: C 176, C 176, C 176, C 176, C 176, C 176, C 176, C OJ Date: 19-Jun-2012

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 18-Jan-2012

- Effective Date

- 28-Jan-2026

- Refers

EN 1992-1-2:2023 - Eurocode 2 - Design of concrete structures - Part 1-2: Structural fire design - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 15050:2007+A1:2012 - "Precast concrete products - Bridge elements" is a CEN European Standard that specifies requirements for factory-produced precast concrete structural elements used in bridge construction. It covers normal-weight concrete elements, both reinforced and prestressed, intended for road bridges, railway bridges and footbridges. Deck elements addressed include single components (beams, slabs, ribbed or cellular elements) and segments of an entire deck. Durability, production conditions (factory or protected site) and quality control are integral parts of the standard. Several bridge-related elements (piles, piers, abutments, arches, box culverts, barriers, guards) are explicitly out of scope.

Key Topics and Requirements

- Scope & Definitions: Applies to precast bridge elements produced in a factory or in a production place protected from adverse weather; assumes factory-level quality control.

- Material Requirements: Conformity with concrete material standards (references include EN 206-1 via EN 13369).

- Production Requirements: Factory production control, handling of prestressing, and measures to ensure consistent quality.

- Finished Product Requirements:

- Geometrical properties and dimensional tolerances

- Surface characteristics

- Mechanical resistance (strength and structural performance)

- Durability requirements for exposure conditions

- Resistance to fire, acoustic and thermal properties where relevant

- Test Methods & Inspection: Procedures for testing concrete, measuring dimensions and surface characteristics, and finished-product inspection (see normative test clauses and Annex J).

- Conformity & CE marking: Evaluation of conformity, technical documentation, marking and labelling; Annex ZA links the standard to the EU Construction Products Directive and CE marking procedures.

- Informative Annexes: Typologies (Annex A), decks formed by beams and slabs (B), use of plates (C), continuity and segmental decks (G), ambient conditions (H), and more - providing practical guidance for bridge-specific configurations.

Applications and Who Uses It

- Typical applications: bridge deck elements, precast beams, slabs, segmental decks and ribbed elements for road, rail and pedestrian bridges.

- Primary users:

- Precast manufacturers and factory quality managers implementing production control

- Bridge designers and structural engineers applying Eurocodes and specifying precast components

- Contractors and erectors responsible for installation and handling of precast bridge elements

- Certification bodies and authorities assessing conformity and CE marking documentation

- The standard supports design compatibility with Eurocodes (EN 1992 series) and assists in achieving durable, factory-controlled precast bridge components.

Related Standards

- EN 13369 (Common rules for precast products) - referenced for shared requirements

- EN 206-1 (Concrete specification and conformity) - material performance reference

- Relevant product standards within CEN/TC 229 (e.g., hollow core slabs, ribbed elements) and Eurocodes for structural design

Keywords: EN 15050:2007+A1:2012, precast concrete bridge elements, bridge deck elements, prestressed concrete, reinforced concrete, durability, CE marking, Eurocodes.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 15050:2007+A1:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Precast concrete products - Bridge elements". This standard covers: This European Standard applies to precast concrete structural elements produced in a factory and used in bridge construction, such as deck elements.Normal weight concrete elements are considered, both reinforced and prestressed; their use can be on road bridges, railway bridges and footbridges. Deck elements include both single elements from which the deck may be composed (beams, slabs, ribbed or cellular elements) and elements consisting of a segment of the entire deck. Some examples of elements dealt with are shown in Annex A. The durability aspects are also considered. This European Standard makes reference to precast elements produced in a factory or near the construction site in a place protected from adverse weather conditions. It is assumed that if the elements are not manufactured in a factory, the production conditions assure the same level of quality control as in a factory. It is assumed that the production place is protected from rain, sunshine and wind. Some of the elements are also treated in other European Standards (e.g. beams, slabs). This European Standard deals with the specific aspects related to the use of these elements in bridge construction. Foundation piles, piers, abutments, barriers, bumpers, guards, arches and" box culverts are out the scope of this European Standard.

This European Standard applies to precast concrete structural elements produced in a factory and used in bridge construction, such as deck elements.Normal weight concrete elements are considered, both reinforced and prestressed; their use can be on road bridges, railway bridges and footbridges. Deck elements include both single elements from which the deck may be composed (beams, slabs, ribbed or cellular elements) and elements consisting of a segment of the entire deck. Some examples of elements dealt with are shown in Annex A. The durability aspects are also considered. This European Standard makes reference to precast elements produced in a factory or near the construction site in a place protected from adverse weather conditions. It is assumed that if the elements are not manufactured in a factory, the production conditions assure the same level of quality control as in a factory. It is assumed that the production place is protected from rain, sunshine and wind. Some of the elements are also treated in other European Standards (e.g. beams, slabs). This European Standard deals with the specific aspects related to the use of these elements in bridge construction. Foundation piles, piers, abutments, barriers, bumpers, guards, arches and" box culverts are out the scope of this European Standard.

EN 15050:2007+A1:2012 is classified under the following ICS (International Classification for Standards) categories: 91.100.30 - Concrete and concrete products; 93.040 - Bridge construction. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15050:2007+A1:2012 has the following relationships with other standards: It is inter standard links to EN 15050:2007, EN 15050:2007/FprA1, EN 1992-1-1:2004, EN 1992-1-2:2023, EN 13369:2004, EN 1992-2:2005, EN 206:2013+A2:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15050:2007+A1:2012 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/100. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15050:2007+A1:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Montažni betonski izdelki - Elementi za mostoveBetonfertigteile - Fertigteile für BrückenProduits préfabriqués en béton - Eléments de pontsPrecast concrete products - Bridge elements93.040Gradnja mostovBridge construction91.100.30Beton in betonski izdelkiConcrete and concrete productsICS:Ta slovenski standard je istoveten z:EN 15050:2007+A1:2012SIST EN 15050:2007+A1:2012en,fr,de01-junij-2012SIST EN 15050:2007+A1:2012SLOVENSKI

STANDARDSIST EN 15050:20071DGRPHãþD

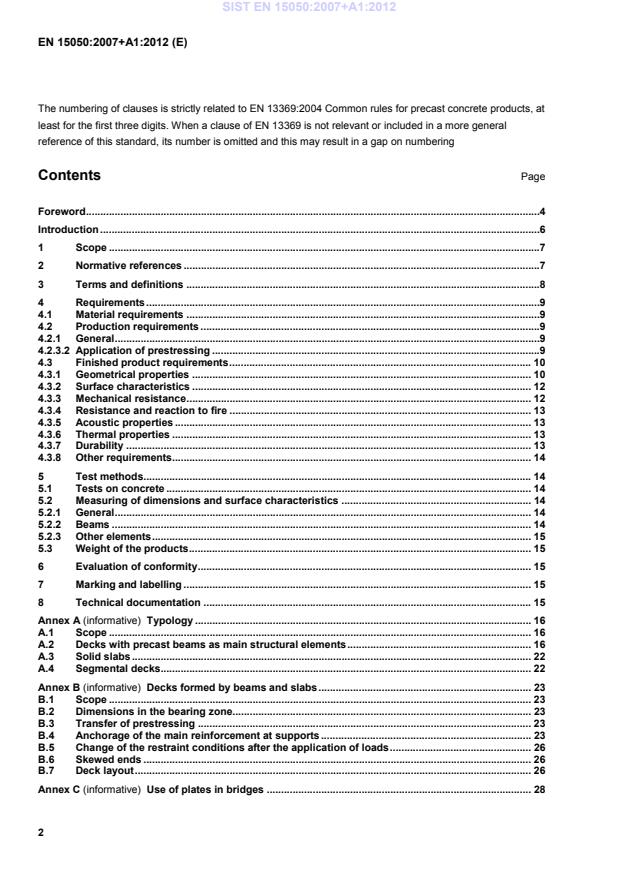

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15050:2007+A1

March 2012 ICS 91.100.30; 93.040 Supersedes EN 15050:2007English Version

Precast concrete products - Bridge elements

Produits préfabriqués en béton - Eléments de ponts

Betonfertigteile - Fertigteile für Brücken This European Standard was approved by CEN on 28 February 2007 and includes Amendment 1 approved by CEN on 23 January 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15050:2007+A1:2012: ESIST EN 15050:2007+A1:2012

Typology . 16A.1 Scope . 16A.2 Decks with precast beams as main structural elements . 16A.3 Solid slabs . 22A.4 Segmental decks. 22Annex B (informative)

Decks formed by beams and slabs . 23B.1 Scope . 23B.2 Dimensions in the bearing zone . 23B.3 Transfer of prestressing . 23B.4 Anchorage of the main reinforcement at supports . 23B.5 Change of the restraint conditions after the application of loads . 26B.6 Skewed ends . 26B.7 Deck layout . 26Annex C (informative)

Use of plates in bridges . 28SIST EN 15050:2007+A1:2012

Continuity of bridge decks . 31D.1 Scope . 31D.2 Continuity of bridge decks . 31D.3 Hogging moments at supports . 31D.4 Long term sagging moments at supports . 31Annex E (informative)

Infilled beams . 37E.1 General . 37E.2 Infilled beams with a thin topping . 37E.3 Infilled beams with a thick topping . 37Annex F (informative)

Precast beams without topping . 39F.1 Scope . 39F.2 Transverse prestressing by post-tensioning . 39F.3 Reinforced joints . 39Annex G (informative)

Precast segmental decks . 41G.1 General . 41G.1.1 Description . 41G.1.2 Joints . 41G.1.3 Keys . 41G.1.4 Post-tensioning . 42G.2 Design . 42G.2.1 Assembly stage . 42G.2.2 Final situation . 42G.2.3 Checking of joints . 43G.2.4 Local transverse bending . 43G.2.5 Discontinuity regions . 43G.3 Production . 44G.4 Building assembly . 44G.4.1 Segment positioning . 44G.4.2 Segment sealing . 44G.4.3 Post-tensioning . 44G.4.4 Closing segment . 44Annex H (informative)

Ambient conditions for bridge elements. 46Annex J (normative)

Finished product inspection . 47Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive . 49ZA.1 Scope and relevant characteristics . 49ZA.2 Procedure for attestation of conformity of precast concrete bridge elements . 50ZA.2.1 System of attestation of conformity . 50ZA.2.2 EC Certificate and Declaration of conformity . 52ZA.3 CE marking and labelling . 52ZA.3.1 General . 52ZA.3.2 Declaration of geometrical data and material properties . 54ZA.3.3 Declaration of product properties . 56ZA.3.4 Declaration of compliance with a given design specification . 58Bibliography . 60SIST EN 15050:2007+A1:2012

The installation of some structural precast concrete products is dealt with by ENV 13670-1: Execution of concrete structures – Part 1: Common rules, which has at the moment the status of a European prestandard. In all countries it can be accompanied by alternatives for national application and it shall not be treated as a European Standard. The programme of standards for structural precast concrete products comprises the following standards, in some cases consisting of several parts: EN 1168, Precast concrete products — Hollow core slabs EN 12794, Precast concrete products — Foundation piles EN 12843, Precast concrete products — Masts and poles EN 13224, Precast concrete products — Ribbed floor elements EN 13225, Precast concrete products — Linear structural elements SIST EN 15050:2007+A1:2012

(which is greater) SIST EN 15050:2007+A1:2012

Figure 1a

Figure 1b Figure 1c

Figure 1d Figure 1 — Basic dimensions and deviations SIST EN 15050:2007+A1:2012

Typology A.1 Scope Some examples of elements dealt with in this European Standard are presented in this annex, even if this annex is not exhaustive. Other types of precast elements can be used in bridge construction. A.2 Decks with precast beams as main structural elements Some types of precast beams used in bridges are sketched in Figure A.1: rectangular beams (Figure A.1a); I or double T beams (Figure A.1b); TT beams (Figure A.1c); T beams with (Figure A.1d) or without base enlargement; inverted T beams (Figure A.1e and f); U beams, V beams (Figure A.1g and h).

Figure A.1 — Some examples of precast beams and related cast in situ concrete The following sub types of decks result: a) precast beams, completed by a cast in situ slab (Figure A.2); b) one or more U beams, completed by cast in situ slab (Figure A.3); c) segmental beams, completed by cast in situ slab (Figure A.4); d) precast T beams completed by cast in situ slab (Figure A.5); e) infilled precast beams (Figure A.6); f) precast box elements without topping (Figure A.7). In types from a) to c) thin floor plates are frequently used as permanent formwork for the cast in situ concrete slab (see B.6).

Key 1 cast in situ slab 2 precast slab (or formwork) Figure A.2 — Precast beams with cast in situ slab

Figure A.3a

Figure A.3b Key 1 in situ slab 2 precast beam Figure A.3 — Single (A.3a) or multiple (A.3b) box girders SIST EN 15050:2007+A1:2012

Figure A.4a

Figure A.4b Key 1 connections 2 cast in situ slab 3 precast beam

Figure A.4 — Segmental beams, cast in situ slab SIST EN 15050:2007+A1:2012

Figure A.5 — Precast beams, cast in situ slab SIST EN 15050:2007+A1:2012

Figure A.6a

Figure A.6b Key 1 transverse reinforcement 2 precast elements Figure A.6 — Infilled precast beams

Figure A.7 — Precast box elements without cast in situ slab SIST EN 15050:2007+A1:2012

Side elevation Cross section Key 1 precast slab 2 cast in situ concrete Figure A.8 — Solid slab A.4 Segmental decks Decks formed by a number of short precast segments having width usually equal to the total width of the deck, connected together by joints transverse perpendicular to the span (Figure A.9).

Figure A.9 — Precast segment !deleted text" SIST EN 15050:2007+A1:2012

Decks formed by beams and slabs B.1 Scope This annex deals with decks having precast beams as the main resistant elements, i.e. types described in A.1 a), b), c) and d). B.2 Dimensions in the bearing zone The suggested minimum dimensions for the bearing zone of precast beams are shown in Figure B.1 (full depth bearings ) and in Figure B.2 (half joints). Such dimensions are to be intended as design specifications and not as acceptance tolerances. Deviations from the above values require special detailing provisions to assure safety against local spalling of concrete. Half joints (Figure B.2) can lead to durability and maintenance problems because of difficulties in inspection and in bearings replacement and should be avoided as far as possible. In case of beams to be placed with a longitudinal gradient greater than 3 %, a cavity should be provided in the underside of the beam to ensure a horizontal bearing surface at the support. In the cavity area the minimum concrete cover should still be guarantied. B.3 Transfer of prestressing 8.10.2 and 8.10.3 of EN 1992-1-1:2004 and 8.10 of EN 1992-2:2005 should apply. When the prestressing tendons are placed outside of the vertical plane of the webs, a horizontal transfer check should be made. This is particularly important for very wide elements such as box and U beams. B.4 Anchorage of the main reinforcement at supports At the end of the beams, enough support length should be provided to verify that the horizontal force, derived from the shear mechanism, is resisted by the tension chord. When the transfer of prestressing is assured by bond (pre-tensioned beams), the part of prestressing effectively anchored can be evaluated according to 8.10.2.2 and 8.10.2.3 of EN 1992-1-1:2004. The effectiveness of tendons placed at a distance from the web edge greater than the thickness of the flange should be verified case by case. If the force provided by the prestressing is insufficient, adequately anchored reinforcing steel should be added. SIST EN 15050:2007+A1:2012

Figure B.1 — Dimensions in the bearing zone SIST EN 15050:2007+A1:2012

Key 1 alternative shape of the beam Figure B.2 — Dimensions in the bearing zone in case of half joints SIST EN 15050:2007+A1:2012

Key

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...