EN 1097-6:2013

(Main)Tests for mechanical and physical properties of aggregates - Part 6: Determination of particle density and water absorption

Tests for mechanical and physical properties of aggregates - Part 6: Determination of particle density and water absorption

This European Standard specifies the reference methods used for type testing and in case of dispute, for the determination of particle density and water absorption of normal weight and lightweight aggregates. Other methods may be used for other purposes, such as factory production control, provided that an appropriate working relationship with the reference method has been established. For convenience, some of these other methods are also described in this standard.

The reference methods for normal weight aggregates specified are:

- a wire basket method for aggregate particles retained on the 31,5 mm sieve (Clause 7, except for railway ballast which uses Annex B);

- a pyknometer method for aggregate particles passing the 31,5 mm test sieve and retained on the 4 mm test sieve (Clause 8);

- a pyknometer method for aggregate particles passing the 4 mm test sieve and retained on the 0,063 mm test sieve (Clause 9).

In Clauses 7, 8 and 9, three different particle density parameters (oven-dried particle density, saturated and surface dried particle density and apparent particle density) and water absorption are determined after a soaking period of 24 h. In Annex B, the oven-dried particle density parameter is determined after soaking in water to constant mass.

The wire basket method may be used as an alternative to the pyknometer method for aggregate particles passing the 31, 5 mm test sieve and retained on the 4 mm test sieve. In case of dispute, the pyknometer method described in Clause 8 should be used as the reference method.

NOTE 1 The wire basket method can also be used for single aggregate particles retained on the 63 mm sieve.

NOTE 2 The pyknometer method described in Clause 8 can be used as an alternative for aggregates passing the 4 mm sieve but retained on the 2 mm sieve.

The reference method for lightweight aggregates (Annex C) is a pyknometer method for aggregate particles passing the 31,5 mm test sieve and retained on the 4 mm test sieve. Three different particle density parameters and water absorption are determined after pre-drying and a soaking period of 24 h.

Three other methods for normal weight aggregates can be used to determine the pre-dried particle density:

- a wire basket method for aggregate particles passing the 63 mm test sieve and retained on the 31,5 mm test sieve (A.3);

- a pyknometer method for aggregate particles passing the 31,5 mm test sieve and retained on the 0,063 mm test sieve (A.4);

- a pyknometer method for aggregate particles passing the 31,5 mm test sieve, including the 0/0,063 mm size fraction (Annex G).

NOTE 3 If water absorption is less than about 1,5 %, the apparent particle density can be assessed using the pre-dried particle density method as defined in Annex A.

The quick method in Annex E can be used in factory production control to determine the apparent particle density of lightweight aggregates.

Guidance on the significance and use of the various density and water absorption parameters is given in Annex H.

Prüfverfahren für mechanische und physikalische Eigenschaften von Gesteinskörnungen - Teil 6: Bestimmung der Rohdichte und der Wasseraufnahme

Diese Europäische Norm legt das für die Erstprüfung und in Streitfällen anzuwendende Referenzverfahren für die Bestimmung der Rohdichte und der Wasseraufnahme von normalschweren und leichten Gesteins-körnungen fest. Für andere Zwecke, z. B. die werkseigene Produktionskontrolle, dürfen andere Verfahren angewendet werden, sofern ein ausreichender Zusammenhang zum Referenzverfahren nachgewiesen wurde. Zur Einfachheit sind einige dieser anderen Verfahren ebenfalls in dieser Norm beschrieben.

Die festgelegten Referenzverfahren für normalschwere Gesteinskörnungen sind:

ein Drahtkorbverfahren für Gesteinskörnungen, die vom 31,5 mm Sieb zurückgehalten werden (Abschnitt 7, außer für Eisenbahnschotter, hier Anhang B verwenden);

ein Pyknometer-Verfahren für Gesteinskörnungen, die durch das 31,5 mm Analysensieb hindurchgehen und vom 4 mm Analysensieb zurückgehalten werden (Abschnitt 8);

ein Pyknometer-Verfahren für Gesteinskörnungen, die durch das 4 mm Analysensieb hindurchgehen und vom 0,063 mm Analysensieb zurückgehalten werden (Abschnitt 9).

In den Abschnitten 7, 8 und 9 werden drei verschiedene Parameter der Rohdichte (Rohdichte auf ofen-trockener Basis, Rohdichte auf wassergesättigter und oberflächentrockener Basis und scheinbare Rohdichte) und die Wasseraufnahme nach einer Eintauchzeit von 24 h bestimmt. In Anhang B wird der Parameter der Rohdichte auf ofentrockener Basis nach dem Eintauchen in Wasser bis zur Massenkonstanz bestimmt.

Das Drahtkorbverfahren kann als Alternative zum Pyknometer-Verfahren für Gesteinskörnungen angewendet werden, die durch das 31,5 mm Analysensieb hindurchgehen und vom 4 mm Analysensieb zurückgehalten werden. Im Streitfall sollte das in Abschnitt 8 festgelegte Pyknometer-Verfahren als Referenzverfahren angewendet werden.

ANMERKUNG 1 Das Drahtkorbverfahren kann auch für einzelne Gesteinskörner angewendet werden, die von einem 63 mm Sieb zurückgehalten werden.

ANMERKUNG 2 Das in Abschnitt 8 beschriebene Pyknometer-Verfahren kann als eine Alternative für Gesteins-körnungen angewendet werden, die durch das 4 mm Sieb hindurchgehen, aber vom 2 mm Sieb zurückgehalten werden.

Das Referenzverfahren für leichte Gesteinskörnungen (Anhang C) ist ein Pyknometer-Verfahren für Gesteinskörnungen, die durch das 31,5 mm Analysensieb hindurchgehen und vom 4 mm Analysensieb zurückgehalten werden. Drei verschiedene Parameter der Rohdichte und die Wasseraufnahme nach Vor-trocknung und einer Eintauchzeit von 24 h werden bestimmt.

Zur Bestimmung der Trockenrohdichte von normalschweren Gesteinskörnungen können auch drei andere Verfahren angewendet werden:

ein Drahtkorbverfahren für Gesteinskörnungen, die durch das 63 mm Analysensieb hindurchgehen und vom 31,5 mm Analysensieb zurückgehalten werden (A.3);

ein Pyknometer-Verfahren für Gesteinskörnungen, die durch das 31,5 mm Analysensieb hindurchgehen und vom 0,063 mm Analysensieb zurückgehalten werden (A.4);

ein Pyknometer-Verfahren für Gesteinskörnungen, die durch das 31,5 mm Analysensieb hindurchgehen, einschließlich der Kornklasse 0/0,063 mm (Anhang G).

ANMERKUNG 3 Wenn die Wasseraufnahme geringer als etwa 1,5 % ist, kann die scheinbare Rohdichte durch Verwendung des Verfahrens der Trockenrohdichte, wie in Anhang A definiert, abgeschätzt werden.

Das Schnellverfahren in Anhang E kann in der werkseigenen Produktionskontrolle zur Bestimmung der scheinbaren Rohdichte von leichten Gesteinskörnungen angewendet werden.

Die Erläuterungen zur Bedeutung und Anwendung der verschiedenen Parameter der Dichte und der Wasseraufnahme sind in Anhang H angegeben.

Essais pour déterminer les caractéristiques mécaniques et physiques des granulats - Partie 6 : Détermination de la masse volumique réelle et du coefficient d'absorption d'eau

La présente Norme européenne spécifie les méthodes de référence utilisées pour les essais de type initiaux et en cas de contestation pour la détermination de la masse volumique et du coefficient d'absorption d'eau de granulats courants et légers. D'autres méthodes peuvent être utilisées à d'autres fins, telles que la maîtrise de la production des granulats, dans la mesure où les résultats qu’elles délivrent peuvent être reliés à ceux obtenus avec la méthode de référence. Certaines de ces autres méthodes sont également décrites dans la présente Norme à des fins pratiques.

Les méthodes de référence pour des granulats courants spécifiées sont :

a) la méthode du panier en treillis pour les granulats refusés au tamis de 31,5 mm (article 7 ou Annexe B) ;

b) la méthode au pycnomètre pour les granulats passant au tamis de 31,5 mm et refusés au tamis de 4 mm (Article 8) ;

c) la méthode au pycnomètre pour les granulats passant au tamis de 4 mm et refusés au tamis de 0,063 mm (Article 9).

Dans les Articles 7, 8 et 9, trois paramètres de masse volumique différents (masse volumique après séchage à l’étuve, saturée surface sèche et absolue) et le coefficient d’absorption d’eau sont déterminés après immersion pendant 24 heures. Dans l’Annexe B, le paramètre de masse volumique après séchage à l’étuve est déterminé après immersion dans l’eau jusqu’à masse constante.

NOTE 1 La méthode du panier en treillis peut remplacer la méthode au pycnomètre pour les granulats passant au tamis de 31,5 mm et refusés au tamis de 4 mm. En cas de contestation, il convient d’utiliser la méthode au pycnomètre décrite dans l’article 8 en tant que méthode de référence.

NOTE 2 La méthode du panier en treillis peut également être utilisée pour les grains isolés refusés au tamis de 63 mm.

NOTE 3 La méthode au pycnomètre décrite à l’article 8 peut également être utilisée pour les granulats passant au tamis de 4 mm, mais refusés au tamis de 2 mm.

(...)

Preskusi mehanskih in fizikalnih lastnosti agregatov - 6. del: Določevanje prostorninske mase zrn in vpijanja vode

Ta evropski standard določa referenčne metode, ki se uporabljajo za tipsko preskušanje in v primeru spora za določevanje prostorninske mase zrn in vpijanja vode agregatov z običajno težo in lahkih agregatov. Za druge namene, na primer za kontrolo proizvodnje v obratu, se lahko uporabijo druge metode, če obstaja primerna delovna povezava z referenčno metodo. Za lažjo uporabo so v tem standardu opisane tudi nekatere druge metode. Referenčne metode, določene za agregate z običajno težo, so: – metoda z žično košaro za zrna agregatov, ki ostanejo na situ 31,5 mm (točka 7, razen za grede železniških prog, ki uporabljajo dodatek B); – metoda s piknometrom za zrna agregatov, ki gredo skozi preskusno sito 31,5 mm in ostanejo na preskusnem situ 4 mm (točka 8); – metoda s piknometrom za zrna agregatov, ki gredo skozi preskusno sito 4 mm in ostanejo na preskusnem situ 0,063 mm (točka 9). V točkah 7, 8 in 9 so določeni trije različni parametri prostorninske mase zrn (prostorninska masa sušenih zrn, prostorninska masa zrn z nasičeno suho površino in dejanska prostorninska masa zrn) in vpijanje vode po 24-urnem namakanju. V dodatku B je določen parameter prostorninske mase sušenih zrn po namakanju v vodi do stalne mase. Metoda z žično košaro se lahko uporablja namesto metode s piknometrom za zrna agregatov, ki gredo skozi preskusno sito 31,5 mm in ostanejo na preskusnem situ 4 mm. V primeru spora se kot referenčna metoda uporabi metoda s piknometrom, opisana v točki 8. Referenčna metoda za lahke agregate (dodatek C) je metoda s piknometrom za zrna agregatov, ki gredo skozi preskusno sito 31,5 mm in ostanejo na preskusnem situ 4 mm. Trije različni parametri prostorninske mase zrn in vpijanje vode so določeni po predhodnem sušenju in 24-urnem namakanju. Za določevanje prostorninske mase predhodno sušenih zrn agregatov z običajno težo se lahko uporabijo tri druge metode: – metoda z žično košaro za zrna agregatov, ki gredo skozi preskusno sito 63 mm in ostanejo na preskusnem situ 31,5 mm (A.3); – metoda s piknometrom za zrna agregatov, ki gredo skozi preskusno sito 31,5 mm in ostanejo na preskusnem situ 0,063 mm (A.4); – metoda s piknometrom za zrna agregatov, ki gredo skozi preskusno sito 31,5 mm, vključno z deležem velikosti 0/0,063 mm (dodatek G). Hitra metoda v dodatku E se lahko uporabi pri kontroli proizvodnje v obratu za določevanje dejanske prostorninske mase zrn lahkih agregatov. Napotki o pomembnosti in uporabi različnih parametrov prostorninske mase in vpijanja vode so podani v dodatku H.

General Information

- Status

- Withdrawn

- Publication Date

- 02-Jul-2013

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 154 - Aggregates

- Drafting Committee

- CEN/TC 154/SC 6 - Test methods

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 23-Feb-2022

- Completion Date

- 09-Feb-2026

Relations

- Effective Date

- 10-Jul-2013

- Effective Date

- 10-Jul-2013

- Effective Date

- 23-Mar-2009

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 13108-4:2016 - Bituminous mixtures - Material specifications - Part 4: Hot Rolled Asphalt - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 13108-5:2016 - Bituminous mixtures - Material specifications - Part 5: Stone Mastic Asphalt - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 1097-6:2013 is a standard published by the European Committee for Standardization (CEN). Its full title is "Tests for mechanical and physical properties of aggregates - Part 6: Determination of particle density and water absorption". This standard covers: This European Standard specifies the reference methods used for type testing and in case of dispute, for the determination of particle density and water absorption of normal weight and lightweight aggregates. Other methods may be used for other purposes, such as factory production control, provided that an appropriate working relationship with the reference method has been established. For convenience, some of these other methods are also described in this standard. The reference methods for normal weight aggregates specified are: - a wire basket method for aggregate particles retained on the 31,5 mm sieve (Clause 7, except for railway ballast which uses Annex B); - a pyknometer method for aggregate particles passing the 31,5 mm test sieve and retained on the 4 mm test sieve (Clause 8); - a pyknometer method for aggregate particles passing the 4 mm test sieve and retained on the 0,063 mm test sieve (Clause 9). In Clauses 7, 8 and 9, three different particle density parameters (oven-dried particle density, saturated and surface dried particle density and apparent particle density) and water absorption are determined after a soaking period of 24 h. In Annex B, the oven-dried particle density parameter is determined after soaking in water to constant mass. The wire basket method may be used as an alternative to the pyknometer method for aggregate particles passing the 31, 5 mm test sieve and retained on the 4 mm test sieve. In case of dispute, the pyknometer method described in Clause 8 should be used as the reference method. NOTE 1 The wire basket method can also be used for single aggregate particles retained on the 63 mm sieve. NOTE 2 The pyknometer method described in Clause 8 can be used as an alternative for aggregates passing the 4 mm sieve but retained on the 2 mm sieve. The reference method for lightweight aggregates (Annex C) is a pyknometer method for aggregate particles passing the 31,5 mm test sieve and retained on the 4 mm test sieve. Three different particle density parameters and water absorption are determined after pre-drying and a soaking period of 24 h. Three other methods for normal weight aggregates can be used to determine the pre-dried particle density: - a wire basket method for aggregate particles passing the 63 mm test sieve and retained on the 31,5 mm test sieve (A.3); - a pyknometer method for aggregate particles passing the 31,5 mm test sieve and retained on the 0,063 mm test sieve (A.4); - a pyknometer method for aggregate particles passing the 31,5 mm test sieve, including the 0/0,063 mm size fraction (Annex G). NOTE 3 If water absorption is less than about 1,5 %, the apparent particle density can be assessed using the pre-dried particle density method as defined in Annex A. The quick method in Annex E can be used in factory production control to determine the apparent particle density of lightweight aggregates. Guidance on the significance and use of the various density and water absorption parameters is given in Annex H.

This European Standard specifies the reference methods used for type testing and in case of dispute, for the determination of particle density and water absorption of normal weight and lightweight aggregates. Other methods may be used for other purposes, such as factory production control, provided that an appropriate working relationship with the reference method has been established. For convenience, some of these other methods are also described in this standard. The reference methods for normal weight aggregates specified are: - a wire basket method for aggregate particles retained on the 31,5 mm sieve (Clause 7, except for railway ballast which uses Annex B); - a pyknometer method for aggregate particles passing the 31,5 mm test sieve and retained on the 4 mm test sieve (Clause 8); - a pyknometer method for aggregate particles passing the 4 mm test sieve and retained on the 0,063 mm test sieve (Clause 9). In Clauses 7, 8 and 9, three different particle density parameters (oven-dried particle density, saturated and surface dried particle density and apparent particle density) and water absorption are determined after a soaking period of 24 h. In Annex B, the oven-dried particle density parameter is determined after soaking in water to constant mass. The wire basket method may be used as an alternative to the pyknometer method for aggregate particles passing the 31, 5 mm test sieve and retained on the 4 mm test sieve. In case of dispute, the pyknometer method described in Clause 8 should be used as the reference method. NOTE 1 The wire basket method can also be used for single aggregate particles retained on the 63 mm sieve. NOTE 2 The pyknometer method described in Clause 8 can be used as an alternative for aggregates passing the 4 mm sieve but retained on the 2 mm sieve. The reference method for lightweight aggregates (Annex C) is a pyknometer method for aggregate particles passing the 31,5 mm test sieve and retained on the 4 mm test sieve. Three different particle density parameters and water absorption are determined after pre-drying and a soaking period of 24 h. Three other methods for normal weight aggregates can be used to determine the pre-dried particle density: - a wire basket method for aggregate particles passing the 63 mm test sieve and retained on the 31,5 mm test sieve (A.3); - a pyknometer method for aggregate particles passing the 31,5 mm test sieve and retained on the 0,063 mm test sieve (A.4); - a pyknometer method for aggregate particles passing the 31,5 mm test sieve, including the 0/0,063 mm size fraction (Annex G). NOTE 3 If water absorption is less than about 1,5 %, the apparent particle density can be assessed using the pre-dried particle density method as defined in Annex A. The quick method in Annex E can be used in factory production control to determine the apparent particle density of lightweight aggregates. Guidance on the significance and use of the various density and water absorption parameters is given in Annex H.

EN 1097-6:2013 is classified under the following ICS (International Classification for Standards) categories: 91.100.15 - Mineral materials and products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1097-6:2013 has the following relationships with other standards: It is inter standard links to EN 1097-6:2000/A1:2005, EN 1097-6:2000/AC:2002, EN 1097-6:2000, EN 1097-6:2022, EN 932-5:2012, EN 932-1:1996, EN 933-2:2020, EN 13108-2:2016, EN 206:2013+A1:2016, EN 13108-4:2016, EN 13108-9:2016, EN 13108-5:2016, CEN/TS 15427-2-3:2021, EN 206:2013, EN 13108-3:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1097-6:2013 is associated with the following European legislation: Standardization Mandates: M/125. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1097-6:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.ORþHYDQMHPrüfverfahren für mechanische und physikalische Eigenschaften von Gesteinskörnungen - Teil 6: Bestimmung der Rohdichte und der WasseraufnahmeEssais pour déterminer les caractéristiques mécaniques et physiques des granulats - Partie 6 : Détermination de la masse volumique réelle et du coefficient d'absorption d'eauTests for mechanical and physical properties of aggregates - Part 6: Determination of particle density and water absorption91.100.15Mineralni materiali in izdelkiMineral materials and productsICS:Ta slovenski standard je istoveten z:EN 1097-6:2013SIST EN 1097-6:2013en,fr,de01-oktober-2013SIST EN 1097-6:2013SLOVENSKI

STANDARDSIST EN 1097-6:2002/AC:2004SIST EN 1097-6:2002/A1:2005SIST EN 1097-6:20021DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1097-6

July 2013 ICS 91.100.15 Supersedes EN 1097-6:2000English Version

Tests for mechanical and physical properties of aggregates - Part 6: Determination of particle density and water absorption

Essais pour déterminer les caractéristiques mécaniques et physiques des granulats - Partie 6 : Détermination de la masse volumique réelle et du coefficient d'absorption d'eau Prüfverfahren für mechanische und physikalische Eigenschaften von Gesteinskörnungen - Teil 6: Bestimmung der Rohdichte und der Wasseraufnahme This European Standard was approved by CEN on 8 May 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1097-6:2013: ESIST EN 1097-6:2013

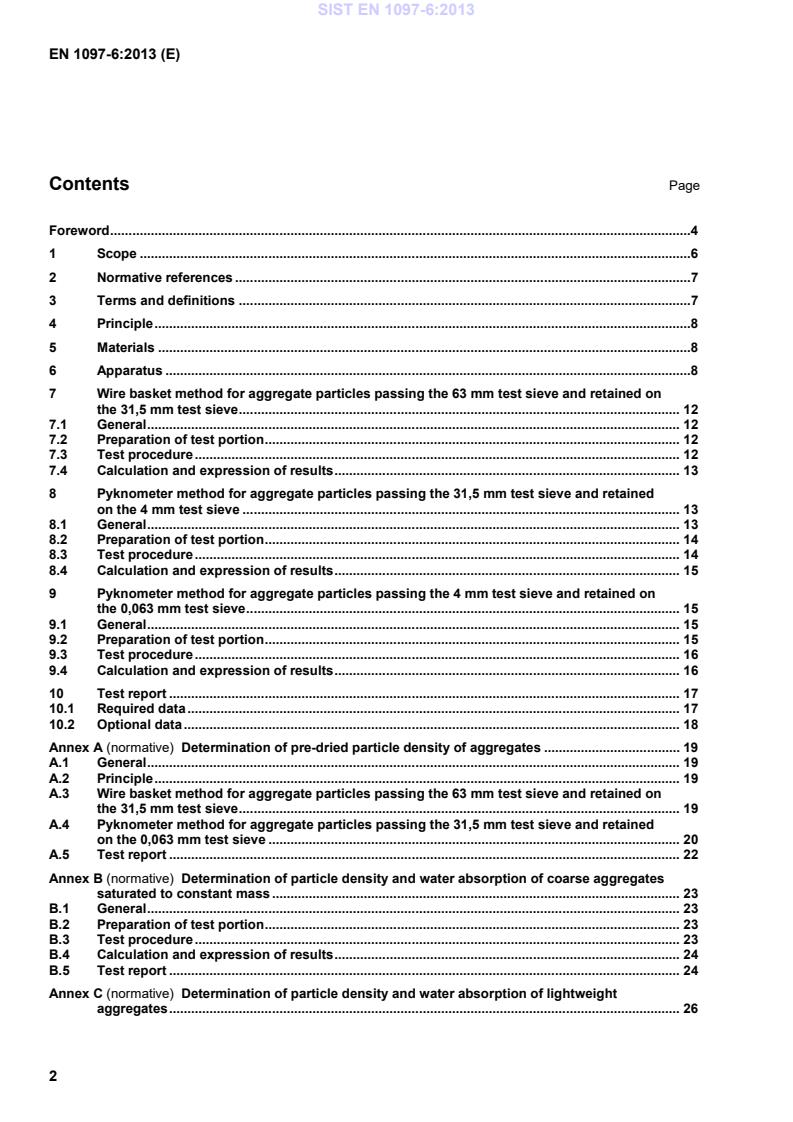

Determination of pre-dried particle density of aggregates . 19 A.1 General . 19 A.2 Principle . 19 A.3 Wire basket method for aggregate particles passing the 63 mm test sieve and retained on the 31,5 mm test sieve . 19 A.4 Pyknometer method for aggregate particles passing the 31,5 mm test sieve and retained on the 0,063 mm test sieve . 20 A.5 Test report . 22 Annex B (normative)

Determination of particle density and water absorption of coarse aggregates saturated to constant mass . 23 B.1 General . 23 B.2 Preparation of test portion . 23 B.3 Test procedure . 23 B.4 Calculation and expression of results . 24 B.5 Test report . 24 Annex C (normative)

Determination of particle density and water absorption of lightweight aggregates . 26 SIST EN 1097-6:2013

Density of water . 30 Annex E (normative)

Quick method for the determination of the apparent particle density of lightweight aggregates using a graduated measuring cylinder and short soaking times . 31 E.1 General . 31 E.2 Preparation of test specimen . 31 E.3 Procedure . 31 E.4 Calculation and expression of results . 31 E.5 Test report . 32 Annex F (informative)

Guidance on the saturated and surface-dried condition of fine aggregates . 33 Annex G (normative)

Determination of the pre-dried particle density of aggregates passing the 31,5 mm test sieve

(including the 0/0,063 mm size fraction) . 35 G.1 General . 35 G.2 Principle . 35 G.3 Preparation of the test portion . 35 G.4 Test procedure . 35 G.5 Calculation and expression of results . 36 G.6 Test report . 37 Annex H (informative)

Guidance on the significance and use of various particle density parameters and water absorption . 38 H.1 General . 38 H.2 Characteristics of the reference methods for normal weight aggregates according to Clauses 7, 8 and 9 and Annex B . 39 H.3 Characteristics of the reference method for lightweight aggregates, specified in Annex C . 40 H.4 Characteristics of the methods for determination of the pre-dried particle density of normal weight aggregates, specified in Annex A and Annex G . 41 H.5 Selection of the appropriate particle density parameter . 41 H.6 Applicability of and test conditions for the various test methods in EN 1097-6 . 42 H.7 Relationships between different particle density parameters (notations according to the main methods, specified in Clauses 7, 8 and 9) . 43 Annex I (informative)

Precision . 44 I.1 Data from National Standards . 44 I.2 Data from cross testing experiments . 45 Annex J (informative)

List of main changes from the previous edition (EN 1097-6:2000) . 47 Bibliography . 49

The quick method in Annex E can be used in factory production control to determine the apparent particle density of lightweight aggregates. Guidance on the significance and use of the various density and water absorption parameters is given in Annex H. SIST EN 1097-6:2013

EN 932-2, Tests for general properties of aggregates — Part 2: Methods for reducing laboratory samples

EN 932-5, Tests for general properties of aggregates — Part 5: Common equipment and calibration EN 933-2, Tests for geometrical properties of aggregates — Part 2: Determination of particle size distribution — Test sieves, nominal size of apertures

3 Terms and definitions For the purposes of this document, the following terms and definitions apply. 3.1 apparent particle density ρa ratio obtained by dividing the oven-dried mass of an aggregate sample by the volume it occupies in water including the volume of any internal sealed voids but excluding the volume of water in any water accessible voids Note 1 to entry: For lightweight aggregates the symbol ρLa is used. 3.2 constant mass mass determined after successive weighings at least 1 h apart not differing by more than 0,1 % Note 1 to entry: In many cases constant mass can be achieved after a test portion has been dried for a pre-determined period in a specified oven at (110 ± 5) °C. Test laboratories can determine the time necessary to achieve constant mass for specific types and sizes of sample dependent upon the drying capacity of the oven used. 3.3 oven-dried particle density ρrd ratio obtained by dividing the oven-dried mass of an aggregate sample by the volume it occupies in water including the volume of any internal sealed voids and the volume of any water accessible voids Note 1 to entry: For lightweight aggregates the symbol ρLrd is used. 3.4 pre-dried particle density ρp ratio obtained by dividing the pre-dried mass of an aggregate sample by the volume it occupies in water including the volume of any internal sealed voids but excluding the volume of water in any water accessible voids Note 1 to entry: Test conditions in terms of pre-drying of the test sample and the shorter immersion period differ from the ones for apparent particle density. Note 2 to entry: Pre-dried particle density is a rapid test. SIST EN 1097-6:2013

Choose the pyknometer to suit the size of the test specimen. It is recommended that the test specimen occupies about half of the pyknometer volume. NOTE An example of a suitable pyknometer is shown in Figure 1.

Key 1 glass funnel 2 mark 3 ground section to fit the wide-neck flat bottom flask 4 wide-neck flat bottom flask Figure 1 — Example of pyknometer 6.6 Special apparatus for the determination of particle density and water absorption of coarse aggregates saturated to constant mass (Annex B). 6.6.1 Container, of similar capacity to the wire basket specified in 6.2.1 for storage of the sample in water. SIST EN 1097-6:2013

Figure 2 — Steel plunger with perforated plate 6.9 Special apparatus for the determination of the pre-dried particle density of aggregate passing the 31,5 mm test sieve (including the 0/0,063 mm size fraction) (Annex G). 6.9.1 Vacuum system, with a manometer or vacuum gauge, capable of evacuating air from the pyknometer to give a residual pressure of 4 kPa or less. SIST EN 1097-6:2013

7.3 Test procedure Place the prepared test portion in the wire basket and immerse it in the tank containing water at a temperature of (22 ± 3) °C, with a cover of at least 50 mm of water above the top of the basket. Immediately after immersion, remove the entrapped air from the prepared test portion by lifting the basket about 25 mm above the base of the tank and letting it drop 25 times at about once per second. Leave the basket and aggregate to remain completely immersed in the water at (22 ± 3) °C for a period of (24 ± 0,5) h. Shake the basket and test portion and weigh them in water at a temperature of (22 ± 3) °C, M2. Record the temperature of the water when M2 was determined. If it is necessary for the test portion to be transferred to a different tank for weighing, shake the basket and test portion 25 times as before in the new tank before weighing M2. Remove the basket and aggregate from the water and leave them to drain for a few minutes. Gently empty the aggregate from the basket on to one of the dry cloths. Return the empty basket to the water, shake it 25 times and weigh it in water, M3. Gently surface-dry the aggregate and transfer the aggregate to a second dry soft absorbent cloth when the first will remove no further moisture. Spread the aggregate out not more than one stone deep on the second sheet, and leave it exposed to the atmosphere away from direct sunlight or any other source of heat until all visible films of water are removed, but the aggregate still has a damp appearance. Weigh the aggregate, M1. SIST EN 1097-6:2013

)(3244waMMMM−−=ρρ (1) oven-dried particle density )(3214wrdMMMM−−=ρρ (2) saturated and surface-dried particle density )(3211wssdMMMM−−=ρρ (3) and the water absorption after immersion for 24 h, WA24, in accordance with the following formula: 44124)(100MMMWA−×= (4) where ρw

is the density of water at the temperature recorded when M2 was determined, in megagrams per cubic metre (see Annex D); M1 is the mass of the saturated and surface-dried aggregate in the air, in grams; M2 is the apparent mass in water of the basket containing the sample of saturated aggregate, in grams; M3 is the apparent mass in water of the empty basket, in grams; M4 is the mass of the oven-dried test portion in air, in grams. Express the values of particle density to the nearest 0,01 Mg/m3 and the water absorption to the nearest 0,1 %. NOTE 1 The calculations can be checked using the following formula: )/1(ardwrdssdρρρρ−+= (5) NOTE 2 An indication of precision is given in Annex I. 8 Pyknometer method for aggregate particles passing the 31,5 mm test sieve and retained on the 4 mm test sieve 8.1 General The pyknometer method specified in this clause shall be used on aggregate particles passing the 31,5 mm test sieve and retained on the 4 mm test sieve. SIST EN 1097-6:2013

8.3 Test procedure Immerse the prepared test portion in water at (22 ± 3) °C in the pyknometer and remove entrapped air by gently rolling and jolting the pyknometer in a tipped position. Stand the pyknometer in the water bath and keep the test portion at a temperature of (22 ± 3) °C for (24 ± 0,5) h. At the end of the soaking period, take the pyknometer from the water bath and remove any remaining entrapped air by gentle rolling and jolting. Entrapped air may also be removed by applying a vacuum.

Overfill the pyknometer by adding water and place the cover on top without trapping air in the vessel. Then dry the pyknometer on the outside and weigh it, M2. Record the temperature of the water. Remove the aggregate from the water and leave to drain for a few minutes. Refill the pyknometer with water and place the cover in position as before. Then dry the pyknometer on the outside and weigh it, M3. Record the temperature of the water. The difference in the temperature of the water in the pyknometer during the M2 and M3 weighings shall not exceed 2 °C. Instead of measuring the pyknometer volume at each test it can be pre-calibrated. In that case the pyknometer should be tempered in a thermostatic bath to the calibration temperature ± 0,5 °C. Transfer the drained test portion onto one of the dry cloths. Gently surface-dry the aggregate placed upon it and transfer the aggregate to a second absorbent cloth when the first will remove no further moisture. Spread the aggregate out not more than one aggregate particle deep on the second sheet, and leave it exposed to the atmosphere away from direct sunlight or any other source of heat until all visible films of water are removed, but the aggregate still has a damp appearance. Transfer the saturated and surface-dried test portion to a tray and weigh the aggregate, M1. Dry the aggregate in a ventilated oven at a temperature of (110 ± 5) °C until it has reached a constant mass. Let it cool to ambient temperature and weigh, M4. Record all masses to an accuracy of 0,1 % of the mass of the test portion M4 or better. SIST EN 1097-6:2013

)(3244waMMMM−−=ρρ (6) oven-dried particle density )(3214wrdMMMM−−=ρρ (7) saturated and surface-dried particle density )(3211wssdMMMM−−=ρρ (8) and the water absorption after immersion for 24 h, WA24, from the following formula: 44124)(100MMMWA−×= (9) where ρw

is the density of water at the test temperature, in megagrams per cubic metre (Annex D); M1 is the mass of the saturated and surface-dried aggregate in the air, in grams; M2 is the mass of the pyknometer containing the sample of saturated aggregate and water, in grams; M3 is the mass of the pyknometer filled with water only, in grams; M4 is the mass of the oven-dried test portion in air, in grams. Express the values of particle density to the nearest 0,01 Mg/m3 and the water absorption to the nearest 0,1 %. NOTE 1 The calculations can be checked using the following formula: −+=ardwrdssd1ρρρρρ (10) NOTE 2 An indication of precision is given in Annex I. 9 Pyknometer method for aggregate particles passing the 4 mm test sieve and retained on the 0,063 mm test sieve 9.1 General The pyknometer method specified in this clause shall be used on aggregate particles passing the 4 mm test sieve and retained on the 0,063 mm test sieve. 9.2 Preparation of test portion Sampling of the aggregate shall be in accordance with EN 932-1 and reduction shall be in accordance with EN 932-2. Wash the sample on a 4 mm and a 0,063 mm sieve to remove finer particles. Discard particles retained on the 4 mm sieve. SIST EN 1097-6:2013

)(3244waMMMM−−=ρρ (11) oven-dried particle density )(3214wrdMMMM−−= (12) SIST EN 1097-6:2013

is the density of water at the test temperature, in megagrams per cubic metre (see Annex D); M1 is the mass of the saturated and surface-dried aggregate in the air, in grams; M2 is the mass of the pyknometer containing the sample of saturated aggregate and water, in grams; M3 is the mass of the pyknometer filled with water only, in grams; M4 is the mass of the oven-dried test portion in air, in grams. Express the values of particle density to the nearest 0,01 Mg/m3 and the water absorption to the nearest 0,1 %. NOTE 1 The calculations can be checked using the following formula: −+=ardwrdssd1ρρρρρ (15) NOTE 2 An indication of precision is given in Annex I. 10 Test report 10.1 Required data The test report shall include the following information: a) reference to this European Standard; b) identification of the test sample, including identification of the source and date of sampling; c) sample reception date if different from sampling date; d) identification of the laboratory; e) size fraction of the aggregate and, if tested as a number of fractions, the percentage of each size fraction; f) the method used to determine the particle density and absorption (Clauses 7, 8 or 9); g) the test results with significant digits (four values for each test); h) deviations from the reference method – if any. SIST EN 1097-6:2013

Determination of pre-dried particle density of aggregates A.1 General This annex specifies methods for the determination of the pre-dried particle density of aggregates with a particle density greater than 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...