EN 15857:2010

(Main)Non-destructive testing - Acoustic emission - Testing of fibre-reinforced polymers - Specific methodology and general evaluation criteria

Non-destructive testing - Acoustic emission - Testing of fibre-reinforced polymers - Specific methodology and general evaluation criteria

This European Standard describes the general principles of acoustic emission (AE) testing of materials, components and structures made of FRP with the aim of:

- materials characterisation;

- proof testing/manufacturing quality control;

- retesting/in-service inspection;

- health monitoring.

When AE testing is used to assess the integrity of FRP materials, components or structures or identify critical zones of high damage accumulation or damage growth under load this standard further describes the specific methodology (e.g. suitable instrumentation, typical sensor arrangements, location procedures, etc.).

It also describes available, generally applicable evaluation criteria for AE testing of FRP and outlines procedures for establishing such evaluation criteria in case they are lacking.

NOTE The structural significance of the AE may not in all cases definitely be assessed based on AE evaluation criteria only but may require further inspection and assessment (e.g. with other non-destructive test methods or fracture mechanics calculations).

This standard also recommends formats for the presentation of AE test data that allow the application of qualitative and quantitative evaluation criteria, both on-line during testing and by post test analysis, and that simplify comparison of AE test results obtained from different test sites and organisations.

Zerstörungsfreie Prüfung - Schallemissionsprüfung - Prüfung von faserverstärkten Polymeren - Spezifische Vorgehensweise und allgemeine Bewertungskriterien

In dieser Europäischen Norm werden die allgemeinen Grundlagen für die Schallemissionsprüfung (AT) von Werkstoffen, Bauteilen und Konstruktionen aus faserverstärkten Polymeren (FVP) mit dem Ziel beschrieben, ⎯ eine Charakterisierung der Werkstoffe; ⎯ eine Abnahmeprüfung/Prüfung der Fertigungsqualität; ⎯ eine wiederkehrende Prüfung/Inspektion während des Betriebs; ⎯ eine Überwachung der Schadensfreiheit durchzuführen. Wenn die AT zur Bewertung der Integrität von Werkstoffen, Bauteilen oder Konstruktionen aus FVP oder zur Identifizierung kritischer Bereiche angewendet wird, in denen eine hohe Schadensakkumulation oder eine Ausbreitung der Schäden unter Last zu verzeichnen ist, legt diese Norm auch die spezifische Vorgehens-weise fest (z. B. die geeignete Instrumentierung, die übliche Anordnung der Sensoren, die Ortungsverfahren usw.). Diese Norm gibt ferner die verfügbaren und allgemein anwendbaren Bewertungskriterien für die AT von FVP an und, sie legt für den Fall, dass keine Bewertungskriterien verfügbar sind, Verfahren zum Festlegen geeigneter Kriterien fest. ANMERKUNG Die strukturelle Signifikanz der Schallemission kann nicht in allen Fällen zweifelsfrei — nur basierend auf den Schallemissionsbewertungskriterien — beurteilt werden, sondern es können weitere Inspektionen und Bewertungen erforderlich sein (z. B. andere zerstörungsfreie Prüfverfahren oder bruchmechanische Berechnungen). In dieser Norm werden auch Grafikformate zur Präsentation der bei der AT gewonnenen Daten empfohlen, die sowohl online während der Prüfung als auch nach Auswertung der Prüfung die Anwendung qualitativer und quantitativer Bewertungskriterien ermöglichen und dadurch einen Vergleich von Schallemissionsprüf-ergebnissen vereinfachen, die an unterschiedlichen Prüfstandorten und von unterschiedlichen Prüf-organisationen ermittelt wurden.

Essais non destructifs - Émission acoustique - Essai des polymères renforcés par des fibres - Méthodologie spécifique et critères d'évaluation généraux

La présente Norme européenne décrit les principes généraux du contrôle par émission acoustique (EA) des

matériaux, composants et structures en PRF dans le but de réaliser :

- la caractérisation des matériaux ;

- des essais de résistance/un contrôle qualité de la production ;

- des contre-essais/une inspection en service ;

- une surveillance de l’intégrité.

Lorsque le contrôle par émission acoustique sert à évaluer l’intégrité de matériaux, composants ou structures

PRF, ou à identifier les zones critiques présentant une forte accumulation de défauts ou une forte croissance

de défauts sous charge, la présente norme décrit en outre la méthodologie spécifique à adopter (par exemple,

les instruments adaptés, des dispositions de capteurs type, les modes opératoires de localisation, etc.).

Elle décrit également les critères d’évaluation généralement applicables qui sont disponibles pour le contrôle

par émission acoustique des PRF et mentionne les modes opératoires pour établir ces critères s’ils n’existent

pas.

NOTE Il est possible que l’importance structurelle de l’EA ne puisse pas être évaluée de manière définitive dans tous

les cas à l’aide de critères d’évaluation EA uniquement, mais qu’elle requière une inspection et une évaluation

supplémentaires (par exemple, par d’autres méthodes d’essais non destructifs ou par des calculs de mécanique de la

rupture).

La présente norme recommande également des formats pour la présentation des données du contrôle par

émission acoustique permettant l’application de critères d’évaluation qualitatifs et quantitatifs, à la fois en ligne

pendant l’essai et par une analyse après essai, et simplifiant la comparaison des résultats du contrôle par

émission acoustique obtenus sur des sites et par des organismes d’essai différents.

Neporušitveno preskušanje - Akustična emisija - Preskušanje z vlakni ojačenih polimerov - Metodologija in splošna ocenjevalna merila

Ta evropski standard opisuje splošna načela preskušanja materialov, komponent in konstrukcij, narejenih iz FRP, z akustično emisijo (AE) in za: - karakterizacijo materialov; - dokazno preskušanje/nadzor kakovosti proizvodnje; ponovno preskušanje/nadzor med obratovanjem; spremljanje zdravja. Kadar se uporabi preskušanje AE za ocenjevanje neoporečnosti materialov FRP, komponent ali konstrukcij ali prepoznavanje kritičnih območij, kjer se zbira velike škoda ali pa narašča pod bremenom, ta standard nadalje opisuje določeno metodologijo (npr. primerno merilno opremo, tipične razvrstitve senzorjev, lokacijskih postopkov itd.). Prav tako opisuje razpoložljiva, na splošno uporabna ocenjevalna merila za preskušanje FRP z AE in očrta postopke za vzpostavitev takih ocenjevalnih meril, če manjkajo. Ta standard prav tako priporoča formate za prestavitev podatkov preskusa z AE, ki omogočajo uporabo kvalitativnih in kvantitativnih ocenjevalnih meril, neposredno med preskušanjem in z analizo po preskušanju, in da se poenostavi primerjava rezultatov preskusa z AE, pridobljenih iz različnih krajev preskušanja in od različnih organizacij.

General Information

- Status

- Published

- Publication Date

- 12-Jan-2010

- Withdrawal Date

- 30-Jul-2010

- Technical Committee

- CEN/TC 138 - Non-destructive testing

- Drafting Committee

- CEN/TC 138/WG 7 - Acoustic emission testing

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 29-Sep-2024

- Completion Date

- 09-Feb-2026

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 15857:2010 - "Non-destructive testing - Acoustic emission - Testing of fibre-reinforced polymers" - is a CEN European Standard that defines a specific methodology and general evaluation criteria for acoustic emission (AE) testing of fibre‑reinforced polymers (FRP). The standard covers AE use for materials characterisation, proof testing and manufacturing quality control, retesting/in‑service inspection, and structural health monitoring of FRP materials, components and structures.

Key topics and technical requirements

EN 15857:2010 focuses on AE‑specific practice for composites and includes practical guidance on:

- AE source mechanisms typical for FRP (matrix cracking, fibre/matrix debonding, fibre pull‑out, fibre breakage, delamination and micro‑fracture).

- Wave propagation and attenuation issues in FRP (anisotropy, fibre orientation, matrix viscoelastic effects, temperature dependence) that affect AE signals.

- Instrumentation and monitoring guidelines, including sensor selection, location/spacing, coupling/mounting, detection thresholds and waveform storage for post‑analysis.

- Source location procedures and recommended approaches for planar and zone location of AE events.

- Testing methodology for specimens, components and full structures: test preparation, load profiles, written test instructions, stop criteria and evaluation criteria.

- Evaluation criteria: outlines generally applicable, empirical and procedural approaches and describes how to establish criteria where none exist.

- Data presentation and documentation: recommended standard formats for AE test data that support qualitative and quantitative evaluation, on‑line monitoring and post‑test comparison.

- Personnel qualification expectations (see EN 473 for certification guidance).

- Limitations and caveats: AE results may require corroboration by other NDT methods or fracture mechanics assessment to determine structural significance.

Applications and who uses it

EN 15857:2010 is relevant to practitioners and organizations involved with FRP in safety‑critical and structural roles, including:

- NDT engineers and acoustic emission specialists

- Manufacturers performing proof testing and production quality control of FRP components (e.g., pressure vessels, gas cylinders)

- Asset owners/operators in aerospace, automotive, civil engineering, pipelines and storage tanks conducting in‑service inspection and health monitoring

- Certification bodies, test laboratories and research groups developing AE evaluation criteria or advanced AE analysis (modal AE, pattern recognition)

Practical benefits include improved detection of damage accumulation and damage growth, standardized reporting formats for AE results, and guidance to reduce ambiguity when applying AE to anisotropic composite materials.

Related standards

- EN 13554 - AE general principles

- EN 13477 series - AE equipment characterisation

- EN 14584 / EN 15495 - AE examination/planar and zone location (metallic pressure equipment)

- EN 473 - Qualification and certification of NDT personnel

Keywords: EN 15857:2010, acoustic emission, AE testing, fibre‑reinforced polymers, FRP, non‑destructive testing, NDT, health monitoring, proof testing, sensor arrangements, evaluation criteria.

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

EN 15857:2010 is a standard published by the European Committee for Standardization (CEN). Its full title is "Non-destructive testing - Acoustic emission - Testing of fibre-reinforced polymers - Specific methodology and general evaluation criteria". This standard covers: This European Standard describes the general principles of acoustic emission (AE) testing of materials, components and structures made of FRP with the aim of: - materials characterisation; - proof testing/manufacturing quality control; - retesting/in-service inspection; - health monitoring. When AE testing is used to assess the integrity of FRP materials, components or structures or identify critical zones of high damage accumulation or damage growth under load this standard further describes the specific methodology (e.g. suitable instrumentation, typical sensor arrangements, location procedures, etc.). It also describes available, generally applicable evaluation criteria for AE testing of FRP and outlines procedures for establishing such evaluation criteria in case they are lacking. NOTE The structural significance of the AE may not in all cases definitely be assessed based on AE evaluation criteria only but may require further inspection and assessment (e.g. with other non-destructive test methods or fracture mechanics calculations). This standard also recommends formats for the presentation of AE test data that allow the application of qualitative and quantitative evaluation criteria, both on-line during testing and by post test analysis, and that simplify comparison of AE test results obtained from different test sites and organisations.

This European Standard describes the general principles of acoustic emission (AE) testing of materials, components and structures made of FRP with the aim of: - materials characterisation; - proof testing/manufacturing quality control; - retesting/in-service inspection; - health monitoring. When AE testing is used to assess the integrity of FRP materials, components or structures or identify critical zones of high damage accumulation or damage growth under load this standard further describes the specific methodology (e.g. suitable instrumentation, typical sensor arrangements, location procedures, etc.). It also describes available, generally applicable evaluation criteria for AE testing of FRP and outlines procedures for establishing such evaluation criteria in case they are lacking. NOTE The structural significance of the AE may not in all cases definitely be assessed based on AE evaluation criteria only but may require further inspection and assessment (e.g. with other non-destructive test methods or fracture mechanics calculations). This standard also recommends formats for the presentation of AE test data that allow the application of qualitative and quantitative evaluation criteria, both on-line during testing and by post test analysis, and that simplify comparison of AE test results obtained from different test sites and organisations.

EN 15857:2010 is classified under the following ICS (International Classification for Standards) categories: 19.100 - Non-destructive testing. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15857:2010 has the following relationships with other standards: It is inter standard links to EN 1330-9:2009, EN 13477-2:2021, EN 13477-1:2001, EN 13554:2011, EN 15495:2007, EN 1330-1:1998, EN 1330-2:1998, EN 14584:2013, EN ISO 9712:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15857:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Zerstörungsfreie Prüfung - Schallemissionsprüfung - Prüfung von faserverstärkten Polymeren - Spezifische Methodologie und allgemeine BewertungskriterienEssais non destructifs - Émission acoustique - Essai des polymères renforcés par des fibres - Méthodologie spécifique et critères d'évaluation générauxNon-destructive testing - Acoustic emission - Testing of fibre-reinforced polymers - Specific methodology and general evaluation criteria19.100Neporušitveno preskušanjeNon-destructive testingICS:Ta slovenski standard je istoveten z:EN 15857:2010SIST EN 15857:2011en,fr,de01-februar-2011SIST EN 15857:2011SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15857

January 2010 ICS 19.100 English Version

Non-destructive testing - Acoustic emission - Testing of fibre-reinforced polymers - Specific methodology and general evaluation criteria

Essais non destructifs - Émission acoustique - Essai des polymères renforcés par des fibres - Méthodologie spécifique et critères d'évaluation généraux

Zerstörungsfreie Prüfung - Schallemissionsprüfung - Prüfung von faserverstärkten Polymeren - Spezifische Vorgehensweise und allgemeine Bewertungskriterien This European Standard was approved by CEN on 4 December 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15857:2010: ESIST EN 15857:2011

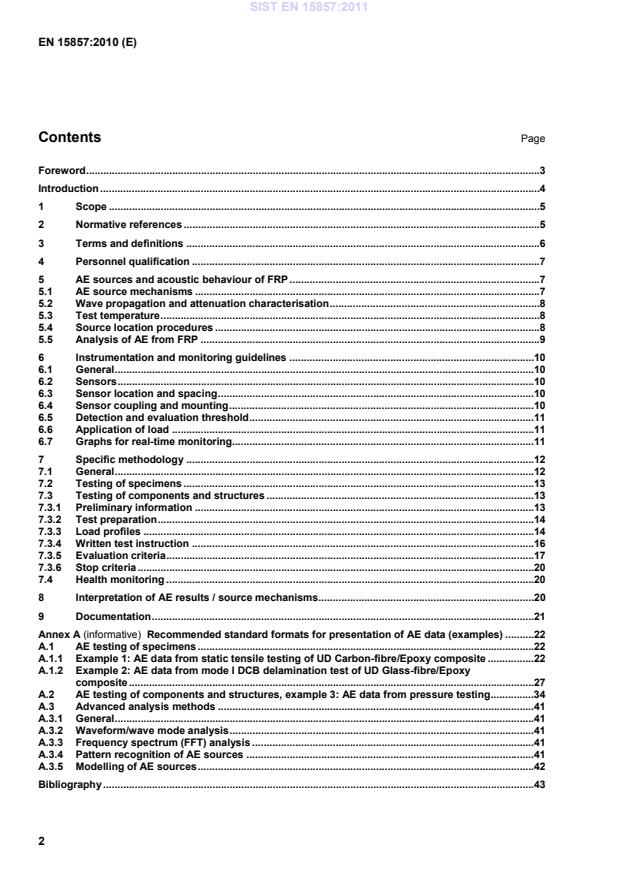

Recommended standard formats for presentation of AE data (examples) .22A.1AE testing of specimens .22A.1.1Example 1: AE data from static tensile testing of UD Carbon-fibre/Epoxy composite .22A.1.2Example 2: AE data from mode I DCB delamination test of UD Glass-fibre/Epoxy composite .27A.2AE testing of components and structures, example 3: AE data from pressure testing.34A.3Advanced analysis methods .41A.3.1General .41A.3.2Waveform/wave mode analysis .41A.3.3Frequency spectrum (FFT) analysis .41A.3.4Pattern recognition of AE sources .41A.3.5Modelling of AE sources .42Bibliography .43 SIST EN 15857:2011

It is already being used for load test monitoring (increasing test safety) and for proof-testing, periodic inspection and periodic or continuous, real-time monitoring (health monitoring) of pressure vessels, storage tanks and other safety-relevant FRP structures. AE testing shows potential where established non-destructive test methods (e.g. ultrasonic or water-jacket tests) are not applicable (e.g. "thick" carbon-fibre reinforced gas cylinders used for the storage and transport of compressed natural gas (CNG), gaseous hydrogen, etc.). The general principles outlined in EN 13554 apply (as stated) to all classes of materials but the document in fact emphasises applications to metal components (see Clause 6 "Applications of the acoustic emission method"). However, the properties of FRP relevant to AE testing are distinctly different from those of metals. FRP structures are inherently inhomogeneous and show a certain degree of anisotropic behaviour, depending on fibre orientation and stacking sequence of plies, respectively. Material composition and properties, and geometry affect wave propagation, e.g. mode, velocity, dispersion, and attenuation, and hence the AE signals recorded by the sensors. Composites with a distinct viscoelastic polymer matrix (e.g. thermoplastics) possess a comparatively high acoustic wave attenuation which is dependent on wave propagation parallel or perpendicular to direction of fibre orientation, plate-wave mode, frequency and temperature dependent relaxation behaviour. Therefore, successful AE testing of FRP materials, components and structures requires a specific methodology (e.g. storage of complete waveforms, specific sensors and sensor arrays, specific threshold settings, suitable loading patterns, improved data analysis, etc.), different from that applied to metals. Most evaluation criteria for AE tests on FRP components and structures to date are either empirical (derived from comparative tests on a limited number of specimens) or else classified (proprietary, unpublished data banks). The time and effort to establish qualified evaluation criteria for specific AE test applications may be too costly to make it worthwhile. Generally applicable evaluation criteria for a class of materials – FRP – will help to pave the way for the development of new applications. There are recent developments in AE testing, e.g. "modal AE" (wave and wave mode analysis in time and frequency domain) and "pattern recognition analysis".

In particular, feature extraction and pattern recognition techniques seem promising for achieving, among others, improved source location and damage mechanism discrimination in materials that show complex wave propagation behaviour and signals originating from multiple mechanisms acting simultaneously, such as FRP. SIST EN 15857:2011

FRP polymer matrix composite with one or more fibre orientations with respect to some reference direction NOTE Those are usually continuous fibre laminates. Typical as-fabricated geometries of continuous fibres include uniaxial, cross-ply and angle-ply laminates or woven fabrics. FRP are also made from discontinuous fibres such as short-fibre, long-fibre or random mat reinforcement. 3.5 delamination intra- or inter-laminar fracture (crack propagation) in composite materials under different modes of loading NOTE Delamination mostly occurs between the fibre layers by separation of laminate layers with the weakest bonding or the highest stresses under static or repeated cyclic stresses (fatigue), impact, etc. Delamination involves a large number of micro-fractures and secondary effects such as rubbing between fracture surfaces. It develops inside of the composite, without being noticeable on the surface and it is often connected with significant loss of mechanical stiffness and strength. 3.6 micro-fracture (of composites) occurrence of local failure mechanisms on a microscopic level, such as matrix failure (crazing, cracking), fibre/matrix interface failure (debonding) or fibre pull-out as well as fibre failure (breakage, buckling) NOTE It is caused by local overstress of the composite. Accumulation of micro-failures leads to macro-failure and determines ultimate strength and life-time. SIST EN 15857:2011

For certain types of construction widely distributed AE sources from matrix or interfacial micro-failure mechanisms under given conditions commonly represent a "normal" behaviour. This particularly appears during the first loading of a newly manufactured FRP structure, where the composite strain for detection of first significant acoustic emission is in the range of 0,1 % to 0,3 %. High stiffness optimised composites may shift the onset of first significant acoustic emission towards comparatively high stresses due to the low matrix strain in the composite.

In the case of high strength composites acoustic emission from first fibre breakage, beside of other sources, is normally observed at stress levels of about 40 % to 60 % of the ultimate composite strength. A "normal" behaviour of FRP structures is also characterised by the occurrence of different regions with alternating higher and lower AE activity particularly at higher stress levels due to redistribution of local stress.

In the case of a serious discontinuity or other severe stress concentration, that influence the failure behaviour of FRP structures, AE activity will concentrate at the affected area, thereby providing a method of detection. Conversely, discontinuities in areas of the component that remain unstressed as a result of the test and discontinuities that are structurally insignificant will not generate abnormal acoustic emission. SIST EN 15857:2011

5.3 Test temperature The mechanical (stiffness, strength) and acoustical (wave velocity, attenuation) behaviour of FRP structures and, hence, their AE activity and AE wave characteristic (waveforms, spectra) strongly changes if the test temperature approaches transition temperature ranges of the matrix, such as the ductile-brittle transition (β-relaxation of semi-crystalline matrices) or the glass-rubber transition (α-relaxation of amorphous matrices). Therefore the test temperature shall be considered for data evaluation and interpretation of AE test results as well as in the loading procedure. 5.4 Source location procedures Accurate source location in FRP structures is difficult. Due to the high attenuation in composite materials the AE hits only the nearest sensor in most practical monitoring situations on structures. For this reason, zone location is usually the main source of location information. The use of zone location however does not prevent linear or planar location of AE sources that has sufficient energy to hit several sensors to allow location by time arrival differences. Linear or planar location is a useful supplement, predominantly for the location of higher energy emissions. Great care shall be taken with both methods where timing information is used for location since the velocity of sound and attenuation will usually change with the direction of propagation in FRP. An additional caution when using location methods on FRP shall be taken because of the very high emission rates (hit overlapping).

Bearing in mind the above sensor separation and positioning should be set appropriately taking into account: a) Sensor frequency range SIST EN 15857:2011

b) Modal AE; waveform analysis; wavelets; frequency spectra Analysis of the AE waveforms may provide useful information on the source mechanism and the propagation path, however this is a specialist task requiring experience with the materials under study and is not considered "routine" practice. Waveform analysis is usually done post test and requires the ability to store time signals, either depending on the AE activity or by a continuous streaming. c) Real-time analysis Real-time analysis of the detected acoustic emission and the application of defined criteria is normal practice, and essential whenever the monitoring is required to feedback for the safe progressive application of load. Real-time graphs shall provide all AE and other parameters that are necessary to make a decision about the need to stop the test, if necessary. SIST EN 15857:2011

The detection threshold shall be set to avoid excessive data from "normal" behaviour of certain laminate types. High rates of micro-failure lead to a high AE activity in practice during the first loading of new (unstressed) structures. The definition of AE hits (and calculation of hit rates) from burst signals does not work under such conditions of an apparently continuous acoustic emission as a consequence of high AE activity and low detection threshold. For this case appropriate actions should be scheduled. For example, waveform streaming, increasing threshold (makes determination of arrival times more inaccurate and decline location performance!) or using higher threshold channels in parallel or analysis of continuous signal parameters. Extraneous noise caused by the loading process, e.g. pump noise or leakage from servo-hydraulic test machine or pressure equipment, rubbing between grips and test specimen etc. shall be suppressed prior to the test. If this is not possible, correctly identified noise signals may be removed from data during post analysis using data filter or location procedures. 6.6 Application of load The application of load depends on the aim of the test, the test object, the pressurisation fluid when applicable and operation safety requirements. The loading profile shall define the maximum test load, loading rate, level and duration of load holds and if necessary unloading/reloading steps to determine the Felicity ratio. In cases where the test load is not sufficiently higher than the previous maximum in-service load, a longer period off-load prior to the test may be required. The application of load shall specify the load level for starting the AE data acquisition. Loading rate shall consider the inherent high AE activity of FRP and potential for hit overlapping leading to continuous emission. The loading rate and times for hold periods shall be adapted for each application. Care shall be taken with very low strain rates and very long hold periods which can lead to creep (relaxation) effects. 6.7 Graphs for real-time monitoring Real-time monitoring should comprise the following steps:

a) evaluating AE activity, e.g. the rate or cumulative number of selected AE hits or located events and noting their correlation with time or applied load;

c) AE source location. Graphs for real-time observation and analysis of the AE behaviour depend on the type of application. During real-time monitoring the number of graphs shall be minimised. Particularly location plots need much computing time and resource. To ensure a fast data acquisition and analysis only graphs essential to recognise the stop criteria should be activated.

Types of real-time monitoring graphs which can be chosen are: d) External parameter vs. Time; e) AE burst signal parameters vs. time or external parameter for each channel: 1) hit rate; 2) burst signal peak amplitude; 3) burst signal energy; 4) cumulative hits; 5) cumulative burst energy; f) Event location based AE parameter: 1) location graph (zone, linear or planar location); 2) located events (first hit) or energy analysis of AE events or clusters; 3) cumulative first hits vs. channels; 4) cumulative located events vs. time or external parameter for each channel; g) Time based AE parameter (RMS, ASL or time driven cumulative AE energy); monitoring of time driven AE parameter can prevent a loss of information if the AE activity is too high and/or the measuring system cannot separate hits; h) Waveform and spectral power of AE signals. Examples of typical graphs containing test results are given in Annex A. 7 Specific methodology 7.1 General There are differences and specific problems with testing of small specimens or large components and structures. Account shall be taken of the dispersion and attenuation effects in FRP as described in 5.2. SIST EN 15857:2011

Prior to the test, the AE Test Organisation shall collect following information: a) explicit statement of the purpose of the test and limitations, if any; b) type and dimensions of test object; c) material (composition and mechanical properties); d) design load, in-service temperature; e) conditions of use or operation; f) history of the object (maximum in-service load, temperature, etc.), if available; g) particular zones to be monitored (damage zones or zones with high stress level) h) test conditions (type and sequence of loading); i) environmental conditions at the test site and safety regulations to be observed; j) potential sources of interference noise (mechanical, electrical, process noise, etc.); k) if applicable, the results of previous examinations; l) type, size and position of identified defects, if available. Interpretation of results shall usually require reference to a relevant experimental data base. For uncommon structural materials, of which the AE response characteristics are unknown, a qualitative analysis shall be made under controlled test conditions using test specimens of the same material, fabricated in the same way and simulating, as near as possible, the original causes of the discontinuity and service stress conditions. SIST EN 15857:2011

Due to the Felicity effect, when the test load is not sufficiently higher than the previous maximum in-service load, the operating conditions for structures that have been stressed previously shall be reduced prior to AE testing. The time for conditioning at reduced load (generally between 12 h for 90 % or more and seven days for 40 % reduction of operating load) should ensure a sufficient stress relaxation and a clear determination of the Felicity ratio. 7.3.3 Load profiles Loading procedure depends on application and aim of AE test. The loading shall be performed with a minimum extraneous noise. Hold periods during loading are a key aspect for evaluation of AE results.

An initial period at starting load is monitored to check the increase of the background noise based on the loading procedure. The strain rate and times for hold periods shall be adapted for each application. Care must be taken with very low strain rates and very long hold periods which can lead to creep effects.

A typical load hold time for composites is about 4 min to 10 min. For determination of the Felicity ratio at specific load levels unload-rest-reload steps shall be designed. The existence of damages is also indicated by friction-based AE sources during unloading. Common loading profile examples are given in Figures 1 and 2.

Key X time Y percent of test load Figure 1 — Load schedule with steps SIST EN 15857:2011

Key X time Y percent of test load Figure 2 — Load schedule with a loading-holding-unloading As examples, load schedules for fibre reinforced tanks, vacuum and pressure vessels are given in Figures 3 to 5. EXAMPLES Fibre reinforced tanks and vessels shall be pressurised with a maximum strain rate of 0,005 % of principal strains per minute. Intermediate load holds at specific load levels shall be 4 min and the final load hold shall be 30 min.

Key X time Y percent of test load Figure 3 — Load schedule for tanks SIST EN 15857:2011

Key X time Y percent of test load Figure 4 — Load schedule for vacuum vessels

Key X time Y percent of test load Figure 5 — Load schedule for pressure vessels 7.3.4 Written test instruction The AE Test Organisation shall provide a written test instruction, which shall include appropriate parts of preliminary information and the following: a) sensor type, frequency and manufacturer; b) method of sensor attachment; SIST EN 15857:2011

Table 1 — Evaluation criteria for AT of FRP Evaluation criteria AE features & information a) Detection of significant AE

Continuous increase of both the hit rate and hit energy from onset or continuation of damage processes. At low stress levels it normally indicates inter-fibre micro-failure, such as matrix cracking, fibre/matrix debonding, etc. During determination of Felicity ratios from severe damage states also fibre breakage and delamination growth can be associated to AE events. b) AE activity and intensity

AE activity and intensity specified by number of hits, ring down counts or signal energy as rate or cumulative function that show, e.g.: – an exponential increase which can be described by a factor α depending on the composite, temperature and strain-rate [Brunner et al. (1995)]: tratetcumulative××××=×=αααekAEekAE

– an increase with a "knee" in the curve which is related to progressive damage due to inter-fibre failure and/or occurrence of new failure mechanisms, e.g. fibre breakage; – values equal to or beyond statistically firmed mean values and standard deviations for "normal" AE behaviour; – an increase during unloading indicating rubbing of damaged areas against each other, e.g. delaminated surfaces. c) AE during load hold Constant or increasing rate of AE activity or AE intensity parameter during hold periods – indicates extensive damage and achievement of unstable damage stages; – is often associated with matrix cracking. d) Burst signal peak amplitude or energy Cumulative distribution of burst

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...