EN 16475-6:2020

(Main)Chimneys - Accessories - Part 6: Access components - Requirements and test methods

Chimneys - Accessories - Part 6: Access components - Requirements and test methods

This document specifies the requirements and test methods for access components comprising a frame and a door or doors which provide access to the flue of a chimney for the purpose of inspection or cleaning.

Access components for higher nominal working temperature than 450 °C, positive pressure and wet applications are not covered by this standard.

The document is limited to access components with door opening dimensions with a maximum width of 450 mm and a maximum height of 600 mm.

Products not freely ventilated are excluded from this document.

This document also specifies the requirements for marking, manufacturers’ instruction, product information and information on the AVCP (Assessment and Verification of Constancy of Performance).

Access components already tested together with system chimney products or other chimney components, e.g. flue liners, are not covered by this document.

Abgasanlagen - Zubehörteile - Teil 6: Zugangsbauteile - Anforderungen und Prüfverfahren

Dieses Dokument legt die Anforderungen und Prüfverfahren für Zugangsbauteile mit einem Rahmen und einem Verschluss oder Verschlüssen fest, die dazu dienen, den Abgasweg einer Abgasanlage zur Inspektion oder Reinigung zugänglich zu machen.

Zugangsbauteile für Nennbetriebstemperaturen größer 450 °C, für Überdruck und für feuchte Betriebsweise fallen nicht in den Anwendungsbereich dieser Norm.

Dieses Dokument ist auf Zugangsbauteile mit Öffnungsquerschnitten des Verschlusses von höchstens 450 mm in der Breite und höchstens 600 mm in der Höhe beschränkt.

Nicht frei belüftete Produkte sind von diesem Dokument ausgeschlossen.

Diese Norm legt außerdem die Anforderungen an die Kennzeichnung, Herstelleranweisungen, Produktinformationen und Informationen zur Bewertung und Überprüfung der Leistungsbeständigkeit (en: AVCP) fest.

Zugangsbauteile, die bereits zusammen mit Produkten für System-Abgasanlagen oder mit anderen Bauteilen einer Abgasanlage, z. B. Innenrohre, geprüft worden sind, fallen nicht in den Anwendungsbereich dieses Dokuments.

Conduits de cheminée - Accessoires - Partie 6 : Éléments d'accès - Exigences et méthodes d'essai

Le présent document spécifie les exigences et les méthodes d'essai pour les éléments d'accès comprenant un cadre et une ou plusieurs portes permettant d'accéder au conduit de fumée en vue de son inspection ou de son nettoyage.

Les éléments d'accès pour une température nominale de fonctionnement supérieure à 450 °C, une pression positive et pour des installations en conditions humides ne sont pas traités dans la présente norme.

Le présent document se limite aux éléments d'accès avec une ouverture de porte d'une largeur maximale de 450 mm et d'une hauteur maximale de 600 mm.

Les produits qui ne sont pas ventilés librement sont exclus du présent document.

Le présent document spécifie également les exigences relatives au marquage, aux instructions du fabricant, aux informations produit et aux informations concernant l'EVCP (Évaluation et vérification de la constance des performances).

Les éléments d'accès déjà soumis à essai en même temps que les conduits système ou d'autres composants de conduits de fumée (par exemple, des tubages) ne relèvent pas du domaine d'application du présent document.

Dimovodne naprave - Oprema - 6. del: Čistilne odprtine - Zahteve in preskusne metode

General Information

- Status

- Published

- Publication Date

- 07-Apr-2020

- Withdrawal Date

- 30-Jan-2022

- Technical Committee

- CEN/TC 166 - Chimneys

- Drafting Committee

- CEN/TC 166/WG 1 - General requirements

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 02-Dec-2025

- Completion Date

- 02-Dec-2025

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 16475-6:2020 - published by CEN - specifies requirements and test methods for chimney access components (frames and doors) that provide access to the flue for inspection or cleaning. The standard covers access components intended for dry, negative-pressure chimneys with maximum door opening dimensions of 450 mm width × 600 mm height. It excludes products for nominal working temperatures above 450 °C, positive-pressure or wet applications, products not freely ventilated, and components already tested as part of complete chimney systems or flue liners.

Key topics and technical requirements

The standard defines product characteristics, test methods and factory assessment requirements, including:

- Mechanical resistance and stability

- Freedom of movement (operation smoothness)

- Impact resistance (e.g., swing ball test)

- Inner door security and closing mechanisms

- Thermal performance

- Reaction to fire and resistance to fire (internal-to-external)

- Thermal resistance and calculation methods (informative)

- Hygiene, health and environmental properties

- Gas tightness classes and test methods

- Condensate resistance

- Corrosion resistance and material selection (stainless steels, cast irons, etc.)

- Dangerous substances requirements

- Materials and operational requirements

- Materials in contact with combustion products

- Handling, angle of opening and space for product information

- Testing & sampling

- Type tests (free movement, swing ball, thermal tests, gas tightness)

- Test assemblies, procedures and test sequence recommendations

- Assessment & conformity

- AVCP (Assessment and Verification of Constancy of Performance)

- Factory Production Control (FPC), sampling plans and surveillance

- Marking and documentation

- Required marking, manufacturer’s instructions and product information

Applications and who uses this standard

EN 16475-6 is used by:

- Manufacturers of chimney access doors and frames to design, test and declare conformity

- Test laboratories performing type tests and gas tightness/thermal assessments

- Certification and regulatory bodies implementing AVCP and FPC requirements

- Specifiers, installers and building engineers selecting compliant access components for dry, negative-pressure chimneys used in residential and commercial installations

Practical uses include verifying durability, safety (fire and gas tightness), corrosion resistance and ensuring correct marking and user instructions for inspection/cleaning openings.

Related standards

This part is one of the EN 16475 series (chimney accessories). Related references include:

- EN 1443 (Chimneys - General requirements)

- EN 1856‑1 / EN 13216‑1 (metal chimney systems / test methods)

- EN 13501‑1 (Reaction to fire) These referenced standards support material, fire and system-level requirements cited by EN 16475-6.

Keywords: EN 16475-6, chimney access components, chimneys, access doors, test methods, requirements, AVCP, FPC, gas tightness, corrosion resistance.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Nonprofit organization that performs technical evaluations of building products.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

BBA (British Board of Agrément)

UK construction product certification.

Sponsored listings

Frequently Asked Questions

EN 16475-6:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Chimneys - Accessories - Part 6: Access components - Requirements and test methods". This standard covers: This document specifies the requirements and test methods for access components comprising a frame and a door or doors which provide access to the flue of a chimney for the purpose of inspection or cleaning. Access components for higher nominal working temperature than 450 °C, positive pressure and wet applications are not covered by this standard. The document is limited to access components with door opening dimensions with a maximum width of 450 mm and a maximum height of 600 mm. Products not freely ventilated are excluded from this document. This document also specifies the requirements for marking, manufacturers’ instruction, product information and information on the AVCP (Assessment and Verification of Constancy of Performance). Access components already tested together with system chimney products or other chimney components, e.g. flue liners, are not covered by this document.

This document specifies the requirements and test methods for access components comprising a frame and a door or doors which provide access to the flue of a chimney for the purpose of inspection or cleaning. Access components for higher nominal working temperature than 450 °C, positive pressure and wet applications are not covered by this standard. The document is limited to access components with door opening dimensions with a maximum width of 450 mm and a maximum height of 600 mm. Products not freely ventilated are excluded from this document. This document also specifies the requirements for marking, manufacturers’ instruction, product information and information on the AVCP (Assessment and Verification of Constancy of Performance). Access components already tested together with system chimney products or other chimney components, e.g. flue liners, are not covered by this document.

EN 16475-6:2020 is classified under the following ICS (International Classification for Standards) categories: 91.060.40 - Chimneys, shafts, ducts. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16475-6:2020 has the following relationships with other standards: It is inter standard links to EN 196-1:1994, EN 13063-1:2005+A1:2007, EN 1857:2010, EN 1561:2023, EN 13501-1:2018, EN 10088-1:2023, EN 13216-1:2019, EN 1443:2019, EN 1563:2018, EN 1856-1:2009, EN 10131:2006, EN 14297:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16475-6:2020 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/105. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16475-6:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-junij-2020

Dimovodne naprave - Oprema - 6. del: Čistilne odprtine - Zahteve in preskusne

metode

Chimneys - Accessories - Part 6: Access components - Requirements and test methods

Abgasanlagen - Zubehörteile - Teil 6: Zugangsbauteile - Anforderungen und

Prüfverfahren

Conduits de cheminée - Accessoires - Partie 6 : Éléments d'accès - Exigences et

méthodes d'essai

Ta slovenski standard je istoveten z: EN 16475-6:2020

ICS:

91.060.40 Dimniki, jaški, kanali Chimneys, shafts, ducts

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 16475-6

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2020

EUROPÄISCHE NORM

ICS 91.060.40

English Version

Chimneys - Accessories - Part 6: Access components -

Requirements and test methods

Conduits de cheminée - Accessoires - Partie 6 : Abgasanlagen - Zubehörteile - Teil 6: Zugangsbauteile -

Éléments d'accès - Exigences et méthodes d'essai Anforderungen und Prüfverfahren

This European Standard was approved by CEN on 25 December 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 16475-6:2020 E

worldwide for CEN national Members.

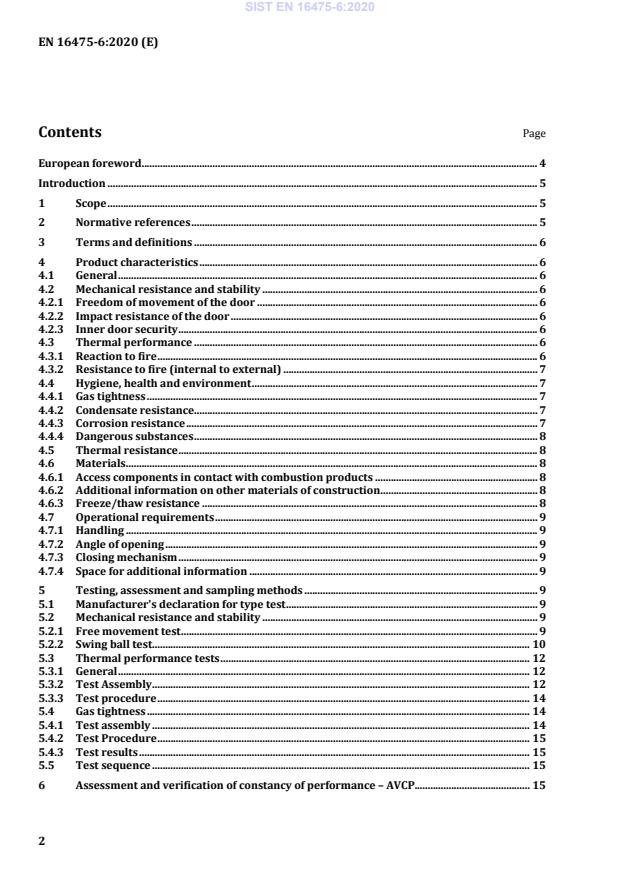

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Product characteristics . 6

4.1 General . 6

4.2 Mechanical resistance and stability . 6

4.2.1 Freedom of movement of the door . 6

4.2.2 Impact resistance of the door . 6

4.2.3 Inner door security . 6

4.3 Thermal performance . 6

4.3.1 Reaction to fire . 6

4.3.2 Resistance to fire (internal to external) . 7

4.4 Hygiene, health and environment . 7

4.4.1 Gas tightness . 7

4.4.2 Condensate resistance . 7

4.4.3 Corrosion resistance . 7

4.4.4 Dangerous substances . 8

4.5 Thermal resistance . 8

4.6 Materials . 8

4.6.1 Access components in contact with combustion products . 8

4.6.2 Additional information on other materials of construction . 8

4.6.3 Freeze/thaw resistance . 8

4.7 Operational requirements . 9

4.7.1 Handling . 9

4.7.2 Angle of opening . 9

4.7.3 Closing mechanism . 9

4.7.4 Space for additional information . 9

5 Testing, assessment and sampling methods . 9

5.1 Manufacturer's declaration for type test . 9

5.2 Mechanical resistance and stability . 9

5.2.1 Free movement test . 9

5.2.2 Swing ball test . 10

5.3 Thermal performance tests . 12

5.3.1 General . 12

5.3.2 Test Assembly . 12

5.3.3 Test procedure . 14

5.4 Gas tightness . 14

5.4.1 Test assembly . 14

5.4.2 Test Procedure . 15

5.4.3 Test results . 15

5.5 Test sequence . 15

6 Assessment and verification of constancy of performance – AVCP. 15

6.1 General . 15

6.2 Type testing . 16

6.2.1 General . 16

6.2.2 Test samples, testing and compliance criteria . 16

6.2.3 Test reports . 17

6.2.4 Shared other party results . 17

6.2.5 Cascading determination of the product type results . 18

6.3 Factory production control (FPC) . 19

6.3.1 General . 19

6.3.2 Requirements . 20

6.3.3 Product specific requirements . 22

6.3.4 Initial inspection of factory and of FPC . 22

6.3.5 Continuous surveillance of FPC . 23

6.3.6 Procedure for modifications . 23

6.3.7 One-off components, pre-production products (e.g. prototypes) and components

produced in very low quantity . 23

7 Classification and designation . 24

7.1 General . 24

7.2 Temperature classes and test temperature . 25

7.3 Gas tightness class . 25

7.4 Condensate resistance class . 25

7.5 Corrosion resistance. 25

7.6 Soot fire resistance and distance to combustible material . 25

8 Marking, labelling and packaging . 25

8.1 Access component . 25

8.2 Packaging . 26

8.3 Product information – Manufacturer’s instructions . 26

Annex A (normative) Choice of size for type test and sampling . 27

Annex B (normative) Sampling for factory productions control . 28

B.1 Sampling plans . 28

B.2 Inspection levels and procedures . 28

Annex C (normative) Factory production control . 30

C.1 General . 30

C.2 Materials, including coatings . 30

C.3 Seals and sealants . 30

C.4 Manufacturing checks . 30

Annex D (informative) Recommended test sequence . 31

Annex E (informative) Calculation of thermal resistance . 32

Bibliography . 33

European foreword

This document (EN 16475-6:2020) has been prepared by Technical Committee CEN/TC 166

“Chimneys”, the secretariat of which is held by ASI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by October 2020, and conflicting national standards shall

be withdrawn at the latest by January 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document is a part of the EN 16475 standards series, Chimneys – Accessories:

— Part 1: Chimney silencers - Requirements and test methods [FprEN 16475-1];

— Part 2: Chimney fans - Requirements and test methods;

— Part 3: Draught regulators, standstill opening devices and combined secondary air devices -

Requirements and test methods;

— Part 4: Flue dampers - Requirements and test methods [prEN 16475-4];

— Part 6: Access components - Requirements and test methods (this document);

— Part 7: Rain caps - Requirements and test methods.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

The main purpose of access components is to provide access to the flue of dry, negative pressure

chimneys, e.g. to be inspected or cleaned.

1 Scope

This document specifies the requirements and test methods for access components comprising a frame

and a door or doors which provide access to the flue of a chimney for the purpose of inspection or

cleaning.

Access components for higher nominal working temperature than 450 °C, positive pressure and wet

applications are not covered by this standard.

The document is limited to access components with door opening dimensions with a maximum width of

450 mm and a maximum height of 600 mm.

Products not freely ventilated are excluded from this document.

This document also specifies the requirements for marking, manufacturers’ instruction, product

information and information on the AVCP (Assessment and Verification of Constancy of Performance).

Access components already tested together with system chimney products or other chimney

components, e.g. flue liners, are not covered by this document.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1443, Chimneys - General requirements

EN 1561, Founding - Grey cast irons

EN 1563, Founding - Spheroidal graphite cast irons

EN 1856-1, Chimneys - Requirements for metal chimneys - Part 1: System chimney products

EN 1857, Chimneys - Components - Concrete flue liners

EN 10088-1, Stainless steels - Part 1: List of stainless steels

EN 10131, Cold rolled uncoated and zinc or zinc-nickel electrolytically coated low carbon and high yield

strength steel flat products for cold forming - Tolerances on dimensions and shape

EN 13063-1, Chimneys - System chimneys with clay/ceramic flue liners – Part 1: Requirements and test

methods for sootfire resistance

EN 13216-1, Chimneys - Test methods for system chimneys - Part 1: General test methods

EN 13501-1, Fire classification of construction products and building elements – Part 1: Classification

using data from reaction to fire tests

EN 14297, Chimneys - Freeze-thaw resistance test method for chimney products

ISO 2859-1, Sampling procedures for inspection by attributes - Part 1: Sampling schemes indexed by

acceptance quality limit (AQL) for lot-by-lot inspection

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 1443, EN 1856-1 and EN 1857,

and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

access component

component comprising a frame and a door or doors installed in the chimney to provide access to the

flue for the purpose of inspection or cleaning

3.2

nominal dimension

dimension of the opening of the access component

4 Product characteristics

4.1 General

The access component shall fulfil the following requirements.

4.2 Mechanical resistance and stability

4.2.1 Freedom of movement of the door

When tested according to 5.2.1 the access component shall be able to move freely when opened and

closed 100 times before and 10 times after the thermal performance tests, and meet the requirement of

4.4.1.

4.2.2 Impact resistance of the door

When tested according to 5.2.2 the access component shall also be able to be opened and closed freely

before and after the thermal tests.

4.2.3 Inner door security

An access component with a separate inner door shall have means for preventing the inner door from

falling into the chimney. This criteria is fulfilled if the inner door is secured, e.g. to the access component

frame by a steel rope, or a bar.

4.3 Thermal performance

4.3.1 Reaction to fire

The reaction to fire for the access component shall be determined in accordance with EN 13501-1.

4.3.2 Resistance to fire (internal to external)

4.3.2.1 General

The minimum distance to combustible shall be declared from the front face of the access component

(distance xx in Figure 2) and to the side of an access component (distance yy in Figure 2) either

measured according to 5.3 or for freely ventilated access components as:

— xx ≥ 400 mm and yy ≥ 200 mm for chimneys designated “G”; or

— xx ≥ 200 mm and yy ≥ 100 mm for chimneys designated “O”; or

— xx ≥ 50 mm and yy ≥ 50 mm for chimneys designated ‘O’ and maximum T160.

The minimum distance to combustible material may be reduced to 50 % of the above values if a

radiation shield creating an air gap, made from non-combustible material, is installed between the

access component and the adjacent combustible materials.

NOTE The minimum distance to combustible materials only takes into account the fire protection and not

e.g. operational requirements.

Freely ventilated means that ventilation of the space around the access component is not enclosed by,

e.g. fitting it in a cupboard.

If tested according to 5.3 the temperature on the combustible material shall not exceed 85 °C during the

heat stress test and shall not exceed 100 °C during the sootfire test.

A multiple layer access component may only be designated G if the outer surface temperature does not

change by more than 10 % when the heat stress test is repeated after the sootfire test.

4.3.2.2 Heat stress

The access component shall be tested to the designated nominal working temperature in accordance

with 5.3.3.2 and the requirements of 4.2 and 4.4 shall be met.

4.3.2.3 Sootfire

The access component designated sootfire resistant shall be tested in accordance with 5.3.3.3 and the

requirements of 4.2 and 4.4 shall be met.

4.4 Hygiene, health and environment

4.4.1 Gas tightness

When an access component is tested according to the test method described in 5.4 both before and after

-1. −1

the thermal performance tests, the leakage rate shall not be greater than 1,5 l·s m of joint length at a

test pressure of 40 Pa and shall be measured on the largest door size in a manufacturer’s range suitable

for a chimney of 200 mm diameter or equivalent area.

NOTE The parameter N1 or N of the chimney is not changed by the installation of such an access component.

4.4.2 Condensate resistance

Access components to this standard shall be designated ‘Dry’.

4.4.3 Corrosion resistance

Access components having materials to this standard (see 4.6.1) shall be designated with the corrosion

class 3 in accordance with EN 1443.

4.4.4 Dangerous substances

National regulations on dangerous substances may require verification and declaration on release, and

sometimes content, when construction products covered by this standard are placed on those markets.

In the absence of European harmonized test methods, verification and declaration on release/content

should be done taking into account national provisions in the place of use.

NOTE An informative database covering European and national provisions on dangerous substances is

available at the Construction website on EUROPA accessed through:

http://ec.europa.eu/enterprise/construction/cpd-ds/.

4.5 Thermal resistance

The outer door of the access component shall have a minimum thermal resistance of 0,05 m · K/W.

This is deemed to be fulfilled for concrete with a wall thickness of 60 mm and for metal with insulation

(of maximum thermal conductivity of 0,1 W/(mK) of at least 10 mm thickness.

The thermal resistance of an access component may be calculated using the method in Annex E.

4.6 Materials

4.6.1 Access components in contact with combustion products

The part of the access component, multi-layer or not, in contact with the products of combustion shall

have a minimum material specification of one of the following:

a) cast iron to EN 1561 or EN 1563: minimum thickness 4 mm;

b) zinc coated mild steels to EN 10131: minimum thickness 1,25 mm;

c) stainless steel: minimum material number according to EN 10088-1 of 1.4301 or higher number ,

minimum thickness 0,6 mm;

d) concrete: minimum density 1 700 kg/m , thickness shall be selected to correspond to a maximum

overall weight of 6,5 kg;

e) clay as specified in EN 13063-1.

4.6.2 Additional information on other materials of construction

Other materials used in access components shall not show any deformation, permanent or temporary,

when the relevant material of the access component is tested in accordance with 5.3 that will affect the

performance of the access component.

4.6.3 Freeze/thaw resistance

Access components of metal construction are deemed to be freeze/thaw resistant.

Access components of concrete material are deemed to be freeze/thaw resistant when they satisfied the

requirements in accordance with EN 14297.

A stainless material type of a higher number means any steel according to the material list of EN 1856-2.

4.7 Operational requirements

4.7.1 Handling

An access component shall have a facility to handle the openable part.

The access component shall have no sharp edges that can cause injury when handled, or damage

cleaning or inspection tools.

4.7.2 Angle of opening

A hinged door shall open at least to an angle of 140°, or be removable.

4.7.3 Closing mechanism

A door shall have the operating part of the closing mechanism consisting of either:

— a square spigot of (7 ± 0,1) mm x (7 ± 0,1) mm cross-section, with a length of at least 6,5 mm

operating a latch mechanism;

— in a 18 mm diameter circular recess, at least 6,5 mm deep;

— a lever operating a latch mechanism;

— close under its own weight e.g. for concrete access doors, by fitting into a recess.

4.7.4 Space for additional information

If it is required, the door of the access component shall have a space of 80 mm x 170 mm for additional

information to be added in particular where an access component needs additional information, e.g. in

terms of which chimney it serves in a property in a multiple apartment block.

5 Testing, assessment and sampling methods

5.1 Manufacturer's declaration for type test

The manufacturer shall provide the relevant information in Clause 8 and, in addition, shall declare, for

the access component:

a) drawings including declared nominal dimensions,

b) Material types for the component parts, and their minimum thicknesses,

c) weight of product,

d) method of fixing.

5.2 Mechanical resistance and stability

5.2.1 Free movement test

5.2.1.1 Test assembly

Mount the access component on the test assembly of 5.2.2.1 according to the manufacturer’s

instructions.

5.2.1.2 Test procedure

Check if a hinged door opens to a minimum angle of 140°.

Subject the access component to the gas tightness test of 5.4.

Open and close the access component door 100 times.

Record whether the door opens and closes freely and record whether the hinged door opens to a

minimum angle of 140°.Subject the access component to the thermal test of 5.3 appropriate to the

access component designation.

Open and close the access component door 10 times.

Record whether the door opens and closes freely and record whether the hinged door opens to a

minimum angle of 140°.

Subject the access component to the gas tightness test of 5.4.

5.2.1.3 Test Results

Record whether the access component door opens and closes freely, and the leakage from the gas

tightness test.

5.2.2 Swing ball test

5.2.2.1 Test assembly

Construct a test assembly according to Figure 1 with the access component installed according to the

manufacturer’s instructions, using gypsum for easy dismantling.

Construct a pendulum with a steel ball of (14,85 ± 0,05) kg attached to a 1,7 m long rope and the pivot

−0

point 200 mm from the access component, all with a tolerance of %.

+5

Dimensions in millimetres

Key

1 access component

2 pivot point

3 opening section

4 insulation layer

5 outer wall

6 pendulum

7 weight (14,85 ± 0,05) kg

8 support frame

Figure 1 — Example of free movement and swing ball test arrangement

5.2.2.2 Test procedure

+25

Move the ball away from the test assembly by (435 ) mm. Release the ball to strike the access

component firstly at the top, then in the middle and again at the bottom.

Check that the access component still opens and closes freely.

5.2.2.3 Test results

Record any deterioration of the free movement of the access component.

5.3 Thermal performance tests

5.3.1 General

For thermal testing assemble the access component according to Figure 2.

5.3.2 Test Assembly

5.3.2.1 General

Construct a test assembly according to Figure 2 with the access component installed on a ‘section of

chimney according to the manufacturer’s instructions. Attach a hot gas connecting pipe (see 5.3.2.2),

and a hot gas generator (see 5.3.2.3) to the box.

Dimensions in millimetres

Key

1 access door 5 hot gas exhaust hood

2 hot gas generator xx front distance to combustible material

3 hot gas connecting pipe yy side distance to combustible material

4 hot gas measurement position D inner diameter of the hot gas connecting pipe

Figure 2 — Example of test arrangement for thermal performance tests

5.3.2.2 Hot gas connecting pipe

The hot gas connecting pipe shall be in accordance with EN 13216-1.

5.3.2.3 Hot gas generator

The hot gas generator shall be in accordance with EN 13216-1.

5.3.2.4 Measuring parameters

The measurement parameters for the hot gas shall be in accordance with EN 13216-1.

Measure the temperature of the test assembly at the point(s) opposite the horizontal and vertical centre

line of the access component, using thermocouples with accuracy according to EN 13216-1 for surface

temperature measurements.

5.3.3 Test procedure

5.3.3.1 General

The mechanical resistance and stability tests of 5.2.1 and 5.2.2 and the gas tightness test of 5.4 shall be

performed before the thermal tests.

For a product designated “G” undertake both the heat stress test and the sootfire test and then repeat

the mechanical resistance and stability test of 5.2.1 and 5.2.2, and the gas tightness test of 5.4.

5.3.3.2 Test procedure for heat stress test (normal operation)

Undertake the mechanical resistance and stability tests of 5.2.1 and 5.2.2.

Undertake the gas tightness test of 5.4.

With the test assembly temperatures within 10 °C of the test room ambient conditions, generate hot gas

with a temperature and the velocity in accordance with EN 13216-1 appropriate to the product

designation and flue size.

Regulate the rate of rise of the hot gas temperature to achieve the specified gas temperature (Tt) in time

T = (Tt x 60/50) s ± 30 s.

−0

Maintain the flue gas temperature at the specified test temperature at % until equilibrium is

+5

achieved or a maximum time 6 h. Equilibrium is deemed to exist when the average rate of rise of the

temperature on the test chimney or structure does not exceed 2 °C per 30 min.

For access components designated “O”:

Repeat the mechanical resistance and stability tests of 5.2.1 and 5.2.2.

Repeat the gas tightness test of 5.4.

5.3.3.3 Test procedure for sootfire test

With the test assembly temperatures within 10 °C of the test room ambient conditions, generate hot gas

with a temperature of 1 000 °C and the velocity in accordance with EN 13216-1 appropriate to the

product designation and flue size. Regulate the rate of rise of the hot gas temperature to achieve

1 000 °C in (10 ± 1) min. The ambient air temperature shall not vary during test more than 5 K.

+50,0 −0

Maintain the hot gas temperature at (1 000 ) °C for a period of (30 ) min, then turn off the hot

−2 0,0 +1

gas generator.

Repeat the mechanical resistance and stability tests of 5.2.1 and 5.2.2;

Repeat the gas tightness test of 5.4.

5.3.3.4 Test results

Record any instance where the access component does not meet the required function.

Record whether the door moves freely and whether the opening area is reduced.

Record whether the leakage exceeds the value appropriate to the nominal dimension of the access

component.

5.4 Gas tightness

5.4.1 Test assembly

The test assembly is that used for the thermal tests see Figure 3, with the test assembly sealed at one

end, and a fan, pressure meter and volume flow meter to the other end.

Key

1 access component 4 flow meter

2 equipment for closing the outlet 5 fan (air supply)

3 seal/adapter 6 manometer

Figure 3 — Example of a measurement facility for the determination of gas tightness

5.4.2 Test Procedure

Mount the access component in the test assembly of Figure 3 according to the manufacturer’s

instructions. Fix the access component in the closed position.

Deliver ambient air according to EN 13216-1 from the air supply to the flue at a rate necessary to

achieve and maintain the test pressure of 40 Pa with the tolerances according to EN 13216-1.

Measure the flow rate.

5.4.3 Test results

Record the leakage rate.

5.5 Test sequence

Annex D contains a recommended test sequence.

6 Assessment and verification of constancy of performance – AVCP

6.1 General

The compliance of access components with the requirements of this standard and with the

performances declared by the manufacturer in the DoP shall be demonstrated by:

— determination of the product type;

— factory production control by the manufacturer, including product assessment.

The manufacturer shall always retain the overall control and shall have the necessary means to take

responsibility for the conformity of the product with its declared performance(s).

6.2 Type testing

6.2.1 General

All performances related to characteristics included in this standard shall be determined when the

manufacturer intends to declare the respective performances unless the standard gives provisions for

declaring them without performing tests. (e.g. use of previously existing data, CWFT and conventionally

accepted performance).

Assessment previously performed in accordance with the provisions of this standard, may be taken into

account provided that they were made to the same or a more rigorous test method, under the same

AVCP system on the same product or products of similar design, construction and functionality, such

that the results are applicable to the product in question.

— For the purposes of assessment, the manufacturer's products may be grouped into families, where

it is considered that the results for one or more characteristics from any one product within the

family are representative for that same characteristics for all products within that same family.

Products may be grouped in different families for different characteristics.

Reference to the assessment method standards should be made to allow the selection of a suitable

representative sample.

In addition, the determination of the product type shall be performed for all characteristics included in

the standard for which the manufacturer declares the performance:

— at the beginning of the production of a new or modified access components (unless a member of the

same product range); or

— at the beginning of a new or modified method of production (where this may affect the stated

properties); or

they shall be repeated for the appropriate characteristic(s), whenever a change occurs in the access

components design, in the raw material or in the supplier of the components, or in the method of

production (subject to the definition of a family), which would affect significantly one or more of the

characteristics.

Where components are used whose characteristics have already been determined, by the component

manufacturer, on the basis of assessment methods of other product standards, these characteristics

need not be re-assessed. The specifications of these components shall be documented.

Products bearing regulatory marking in accordance with appropriate harmonized European

specifications may be presumed to have the performances declared in the DoP, although this does not

replace the responsibility on the access components manufacturer to ensure that the access

components as a whole are correctly manufactured and their component products have the declared

performance values.

6.2.2 Test samples, testing and compliance criteria

The number of samples of access components to be tested/assessed shall be in accordance with Table 1

and Annex A.

Table 1 — Number of samples to be tested and compliance criteria

Characteristic Requirement Assessment No. of samples Compliance criteria

method

Freedom of 4.2.1. 5.2.1 1 sample thermally tested 4.2

movement of

the door

Impact 4.2.2 5.2.2 1 sample thermally tested 4.2

resistance

Inner door 4.2.3 Visual 1 sample 4.2

security test

Resistance to 4.3.2 5.3 1 sample 4.3

fire

Gas tightness 4.4.1 5.4 1 sample before and after 4.4

thermally tested

Corrosion 4.4.3 and 4.6 4.6 1 sample 4.6

resistance

Dangerous 4.4.4 4.4.4 1 sample 4.4.4

substances

Thermal 4.5 4.5 1 sample 4.5

resistance

Handling 4.7.1 4.7.1 1 sample 4.7.1

Angle of 4.7.2 4.7.2 1 sample 4.7.2

opening

Closing 4.7.3 4.7.3 1 sample 4.7.3

mechanism

Space for 4.7.4 Visual 1 sample 4.7.4

additional

information

6.2.3 Test reports

The results of the determination of the product type shall be documented in test reports. All test reports

shall be retained by the manufacturer for at least 10 years after the last date of production of the access

components to which they relate.

6.2.4 Shared other party results

A manufacturer may use the results of the product type determination obtained by someone else

(e.g. by another manufacturer, as a common service to manufacturers, or by a product developer), to

justify his own declaration of performance regarding a product that is manufactured according to the

same design (e.g. dimensions) and with raw materials, constituents and manufacturing methods of the

same kind, provided that:

a) the results are known to be valid for products with the same essential characteristics relevant for

the product performance;

b) in addition to any information essential for confirming that the product has such same

performances related to specific essential characteristics, the other party who has carried out the

determination of the product type concerned or has had it carried out, has expressly accepted to

transmit to the manufacturer the results and the test report to be used for the latter’s product type

determination, as well as information regarding production facilities and the production control

process that can be taken into account for FPC;

c) the manufacturer using other party results accepts to remain responsible for the product having

the declared performances and he also:

1) ensures that the product has the same characteristics relevant for performance as the one that

has been subjected to the determination of the product type, and that there are no significant

differences with regard to production facilities and the production control process compared

to that used for the product that was subjected to the determination of the product type; and

2) keeps available a copy of the determination of the product type report that also contains the

information needed for verifying that the product is manufactured according to the same

design and with raw materials, constituents and manufacturing methods of the same kind.

6.2.5 Cascading determination of the product type results

For some construction products, there are companies (often called “system houses”) which supply or

ensure the supply of, on the basis of an agreement (which can be, for instance, a contract, license or

whatever kind of written agreement, that should also contain clear provisions with regard to

responsibility and liability of the component producer system houses, on the one hand, and the

assembler of the finished product, on the other hand), some or all of the components (e.g. insulation,

seals, support components) to an assembler who then manufactures the finished product (referred to

below as the “assembler”) in his factory.

Provided that the activities for which such a system house is legally established include

manufacturing/assembling of products as the assembled one, the system house may take the

responsibility for the determination of the product type regarding one or several essential

characteristics of an end product which is subsequently manufactured and/or assembled by other firms

in their own factory.

When doing so, the system house shall submit an “assembled product” using components manufactured

by it or by others, to the determination of the product type and then make the determination of the

product type report available to the assemblers, i.e. the actual manufacturer of the product placed on

the market.

To take into account such a situation, the concept of cascading determination of the product type might

be taken into consideration in the technical specification, provided that this concerns characteristics for

which either a notified product certification body or a notified test laboratory intervene, as presented

below.

The determination of the product type report that the system house has obtained with regard to tests

carried out by a notified body, and which is supplied to the assemblers, may be used for the regulatory

marking purposes without the assembler having to involve again a notified body to undertake the

The formulation of such an agreement can be done by licence, contract, or any other type of written consent.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...